Translate this page into:

The effect of nanoparticles on the rheological behavior of base engine oil SN500 HVI and providing a predictive new correlation of nanofluid viscosity

⁎Corresponding author. ameri@iaush.ac.ir (Elham Ameri)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

New engine lubricating oils based on nanotechnology have emerged with significant capabilities. In this study, the viscosity of SN 500 HVI/ lubricating nanofluid was recorded for analysis in solid volume fractions (SVF) of 0-1.5% with different shear rates (range of 650 to 13,250 ) at temperatures in the range of 5–60 °C. The nanoparticles were modified with oleic acid. Nanoparticle functional groups were identified by Fourier transform infrared spectroscopy (FT-IR), morphology was examined by field emission scanning electron microscopes (FESEM), before and after modification. The prepared nanofluid was stable for up to 20 days at room temperature and no sediment was observed at rest. The non-Newtonian behavior for this nanofluid was proved in experiments of all samples with different SVFs. The rheological data of the new nano-lubricant stated that with the increase of nanoparticles in the base oil, the viscosity increases and the increase of temperature has a negative effect. Based on the recorded SN 500 HVI/ nanofluid viscosity data (with changes in effective factors: temperature, shear rate and SVF), a surface response modeling was performed and a relation for viscosity prediction was presented with .

Keywords

Base engine oil

Nanoparticles

Nano-lubricants

Viscosity

Experimental correlation

1 Introduction

The main and most important task of engine oil is lubrication, reducing friction and improving engine efficiency (Guo et al., 2020). Friction and wear are the cause of mechanical failure (about 80%) (Ren et al., 2020). Forming a layer of oil with a suitable thickness reduces the wear of different engine parts to a minimum (Cui et al., 2020). Nano scale additives to oil have recently been considered as one of the most promising solutions to improve the tribological properties of oils due to their anti-wear and anti-friction properties (Ali et al., 2019). For example, spherical nanoparticles act as very small bearings when placed between two surfaces, reducing friction, wear and temperature (Wu et al., 2021). The use of various mineral nanoparticles has been reported as lubricant additives such as Ag, Ni, Pd and Au, etc. (Yang et al., 2020). However, limited research has focused on the tribological properties of nanoparticles in lubrication (Gu, 2018).

Research shows that the optimum concentration of most nano-additives in base oils is between 0.2% and 2% (Hatami et al., 2020). Tribological enhancement is generally defined in three types of mechanisms including chemical reaction (Song et al., 2019), physical deposition (Asadi et al., 2018), and self-repair (Mahara and Singh, 2020). In other words the nanoparticles disperse in lubricating oils to form nano-lubricants (Sharma et al., 2018). Nano-lubricants easily reach the desired area, so lubrication with them is effective (Liu et al., 2017). The nanoparticles in the oil cover the lubricated area and prevent wear (Xie et al., 2016). New lubricants synthesized with nanotechnology prevent direct wear of engine components (Peng et al., 2009). So, nanoparticle-containing lubricants prevent destructive friction between surfaces, and if the surface of objects is not polished, the nanoparticles polish the surfaces over time by placing them on the surface (Xie et al., 2021). Therefore, researchers are looking to engineer and optimize nanoparticles that provide high-pressure tolerance, extreme friction, and abrasion resistance in lubrication (Desai et al., 2021).

The demand for new lubricants is increasing day by day (Kanojia et al., 2021). Consumers have found that using new nanofluid-based lubricants that can withstand high pressures at different temperatures is cost-effective because it reduces wear and increases engine life and keeps the engine running longer and does not need to be repaired (Mohan Rastogi et al., 2020). Another important purpose of using nanofluid oils is to reduce vibration due to component friction, which in turn reduces engine noise (Shahnazar et al., 2016).

Therefore, nanoparticles in lubricating oils is a new approach to achieve this goal. At the nano-scale, materials have distinct properties, the most important unique feature of nanoparticles that can be used in the lubrication industry is their very high surface area (Hatami et al., 2020). The properties of materials such as reactivity or mechanical behavior depend on the surface atoms. Therefore, the presence of nanomaterials in the oil affects the surface properties (Wang et al., 2020). Peng et al. (2010) investigated the effect of nanoparticle size as an additive on the tribological performance of paraffin oil and their findings showed that surface-modified nanoparticles with oleic acid increased the tribological performance of the lubricant. In a similar study, Li and Zhu (2003) used oleic acid to modify the surface. Their results showed that the reaction mechanism between nanoparticles and oleic acid is esterification. However, much research is needed to investigate and introduce nanoparticle-based lubricating oils that have special abilities to increase the stability and durability of engine mechanical components.

In this study, the viscosity of SN 500 HVI/ lubricating nanofluid in different conditions of temperature, concentration and shear rate was investigated. This lubricant containing nanoparticles was studied at different temperatures. The effect of the concentration of nanoparticles in the base oil on the viscosity was recorded at different shear rate. nanoparticles have unique properties in terms of heat transfer. nanoparticles have been used in various studies as a major flame retardant component (Meng et al., 2018); In addition, this material is environmentally friendly (Chen et al., 2015; Kavusi and Toghraie, 2017).

However, so far no comprehensive research has been done on this substance as an additive to the base oil. The nanoparticles have been considered as one of the nanoscale additives that researchers have not used in their studies to investigate its effect on lubricating base oil, while extensive studies have been performed on other nanoparticles such as , these studies are further reported in three subjects: investigation of viscosity (Mahfouz, 2020) and rheological behavior (Hasan et al., 2019), heat transfer and, performance of diesel engines (Asadi et al., 2018). In a study, Asadi et al. (2018) used this substance as an additive to oil to study nanofluid heat transfer parameters. Ruhani et al. (2019b, 2019a) studied the effect of volume fraction and temperature on the viscosity of hybrid nanofluids (50%–50%)/water and silica–ethylene glycol/Water. Their results showed that the convection heat transfer coefficient is affected by viscosity. Also, Increasing the thermal conductivity of fluids is conceivable by increasing the volume fraction of nanoparticles (He et al., 2020; Rostami et al., 2020; Soltani et al., 2020). In general, with increasing temperature, the viscosity of nanofluid decreases and with increasing the volume fraction of nanoparticles, the viscosity increases (Boroomandpour et al., 2020; Hasan et al., 2019; Toghraie et al., 2019).

The SN 500 HVI engine oil has been less studied as one of the engine lubricants. Therefore, in the present study, lubricating nanofluid was prepared by mixing nanoparticles in SN 500 HVI lubricating oil and the positive effect of the presence of nanoparticles was investigated.

2 Experimental

2.1 Material

The SN 500 HVI oil was purchased from Sepahan Oil Company. The SN 500 HVI oil is a base oil that is obtained from solvent refining and de-waxing processes and is sold as Grade I base oils. This base oil was selected for the addition of nanoparticles and tribological study due to the production volume and having desirable chemical and physical properties. The physical and chemical properties of the base oil are given in Table 1. The

nano-particle (particle size

), oleic acid (Technical grade, 90%) and, n-heptane 99% were purchased from Sigma-Aldrich.

Base oil

Viscosity at 40 °C (

)

Viscosity at 100 °C (

)

Viscosity index (VI)

Pour point (°C)

Flash point (°C)

SN 500 HVI

85–102

10.5–11.2

90

−6

245

2.2 Nanoparticle surface modification

The oleic acid modification enables nanomaterials to exhibit higher anti-wear properties that can be used as a new lubricant and tribological material for the vehicle (Gu, 2018). Chen and Zhu (2017) examined the tribological properties of different molar ratios of oleic acid to and found that when the molar ratio of oleic acid to copper sulfide was 2:1, lubricating oil additives could improve the anti-wear properties of the base oil by up to 50%.

Nanoparticle surface modification was performed with oleic acid. The method of surface modification experiments followed based on the results of previous studies (Chen and Zhu, 2017; Kang et al., 2008). First, of nanoparticles were mixed with of n-heptane at °C and stirring speed of for ; then of oleic acid was added slowly and stirred for . Second, the mixture was subjected to ultra-sonication at a frequency of and a power of for at °C ( run and rest); n-heptane evaporated and oleic acid was fixed on the surface of the nanoparticles. Third, the nanoparticle mixture in oleic acid was centrifuged at 4000 rpm for 1 h. The supernatant was removed and the residue mass was washed with n-heptane 3 times at room temperature. Finally, the modified nanoparticles were dried at °C for .

2.3 Nanofluid preparation

The nanofluid was prepared by mixing different amounts of nanoparticles in the base oil.

To prepare nanofluid with different concentrations, the mass of nanoparticles was calculated based on Eq. (1) (Hemmat Esfe et al., 2017):

2.4 Characterization

The morphology of the nanoparticles, before and after surface modification, were studied using FE-SEM (TE-SCAN, Czech). The functional groups of the nanoparticles were identified with FT-IR spectra in the , using a C88731 spectrophotometer (Perkin Elmer Co., Germany). The effect of oil containing nanoparticles to prevent wear was investigated using a pin-on-disc test (TSN-WTC-02, TSN Co., Iran) according to standard ASTM G99. Nanofluid rheological properties were recorded using a rheometer (MCR Rheometers 301, BROOKFIELD, USA), following the standard ASTM G77-05. The turbidity of the base oil and the oil containing the nanoparticles were investigated with a turbidity meter (TUB-430, GONDO Co., Taiwan).

3 Results

3.1 Characterization of nanoparticles

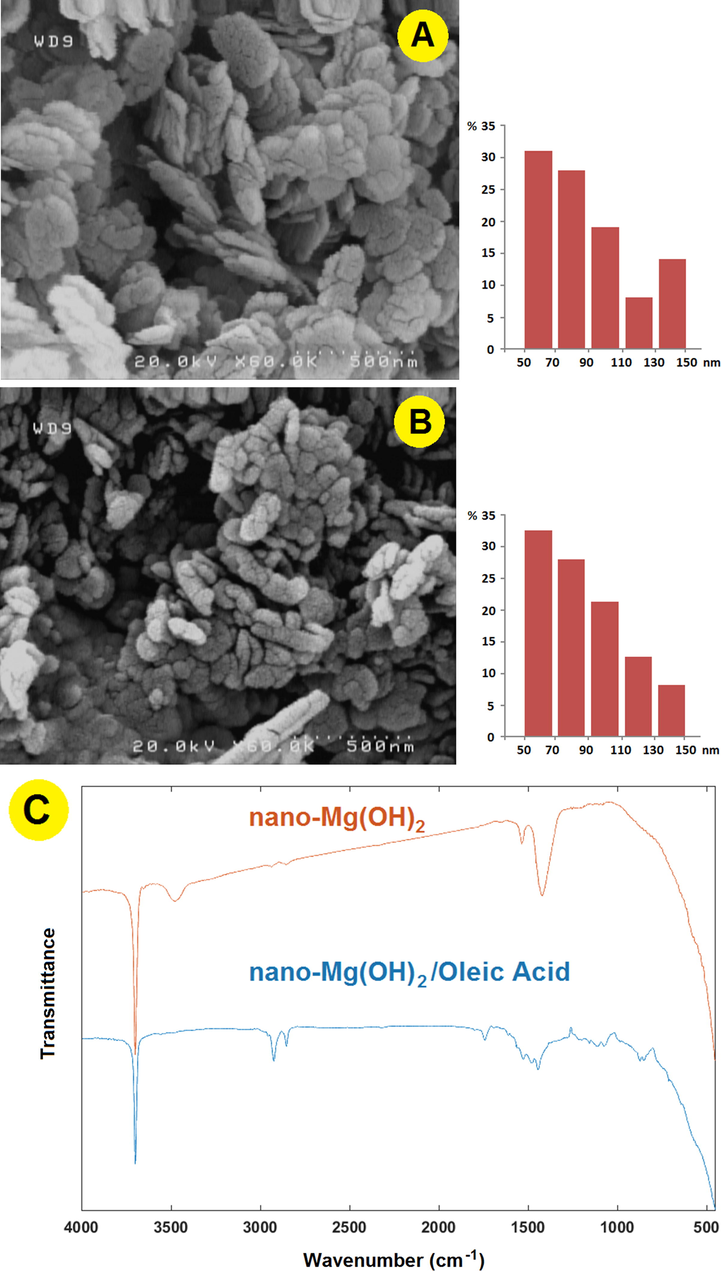

The FE-SEM of

nanoparticles was shown in Fig. 1a. The average size of

nanoparticles was found at about 100 nm (in the range of 50–150 nm) using Image J software. Based on the results in Fig. 1b, the particle size did not change after surface modification.

FE-SEM images of

nanoparticles (a) before and (b) after modified with oleic acid. (c) FTIR spectra of

nanoparticles and modified

nanoparticles with oleic acid.

Fig. 1c shows the functional groups of nanoparticles before and after surface modification. The sharp and intense peaks at 3697 and 3476 are attributed to the stretching of —OH (Dong et al., 2010; Yan et al., 2009). The peaks at 1406 and 1635 are assigned to the —OH and Mg—OH bond bending vibration, respectively (Kailasa and Wu, 2012). The small peaks at 2925 and 2853 correspond to the asymmetric stretching vibrations of aliphatic groups (—CH2—)n. In the nano- /Oleic acid, the band at 1745 is related to stretching vibration of C⚌O in a carboxylic acid (Zahir et al., 2019). The tender band of surface adsorbed hydroxyl groups reveals the presence of oleic acid molecules on the surface of magnesium hydroxide by substituting hydroxyl groups (Yan et al., 2009).

3.2 Nanofluid stability

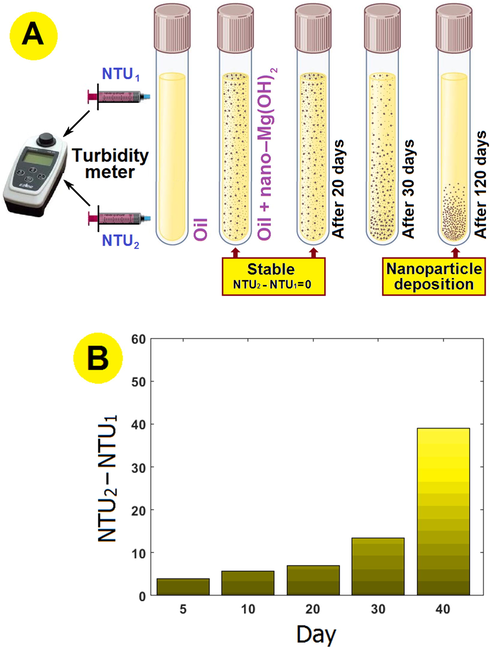

Nanofluid stability means that the distribution of nanoparticles in the oil is uniform and homogeneous. An innovative method was used to evaluate the stability of nanofluid. In this method, a glass tube with a diameter of

and a length of

was used. Measuring turbidity in fluids is a method of assessing physical quality; The stability of a nanofluid is directly related to the stability of turbidity (Linke and Drusch, 2016). According to Fig. 2a, the nanofluid with SVF of 1.5% was introduced into the tube at temperature of 30 °C (an oven was used to keep the temperature constant), and in the stationary state, the turbidity of the nanofluid was measured at both the top and bottom of the tube (Zawawi et al., 2017). The difference between the two measured turbidity means that the nanofluid is not stable. If the difference between the two measured turbidity is close to zero, it means that the nanofluid is stable. This method is more accurate than the “direct visualization” method (Hemmat Esfe and Mosaferi, 2020) and can be analyzed quantitatively. Also, this method is much simpler than the “measurement of density changes” method. The turbidity of nanofluid samples was measured for 120 consecutive days. The results showed that all samples were stable at all temperatures after 25 days. Fig. 2b compares the stability of the samples after 30 days.

Schematic of nanofluid stability test by turbidity measurement method (a), Quantitative examination of turbidity changes at the top and bottom of tubes containing SN 500 HVI/

nanofluids for 50 consecutive days (b).

3.3 Nanofluid behavior

To study the behaviors of nanofluid, the fluid interactions were investigated by shear stress. Newtonian fluid behavior is observed when the relationship between shear stress and shear rate is linear. Therefore, in the diagram of shear stress vs. shear rate, the curve has a constant slope, and viscosity is not dependent on shear rate changes (Gundarneeya and Vakharia, 2021). If the viscosity of a fluid is not constant and depends on changes in shear rate, this fluid will be non-Newtonian. The rheological behavior of a non-Newtonian fluid is not in accordance with Newton's law (Kanojia et al., 2021). To identify and study the non-Newtonian behavior of a fluid, experimental data can be fitted into an experimental relation (Singh et al., 2021). The Ostwald–de Waele power law is used in an algebraic relation to fit experimental data and study fluid behavior (Hemmat Esfe et al., 2017) his relationship is given in Eq. (2) (Hemmat Esfe et al., 2017):

A relation for calculating the superficial viscosity is extracted using the power law. This relationship is expressed in Eq. (3) (Sepyani et al., 2017):

In Eqs. (2) and (3):

,

and

are shear stress, shear rate and, dynamic viscosity, respectively; n is the power law index. Also, the constants m and n are calculated by plotting the shear stress curve versus the shear rate.

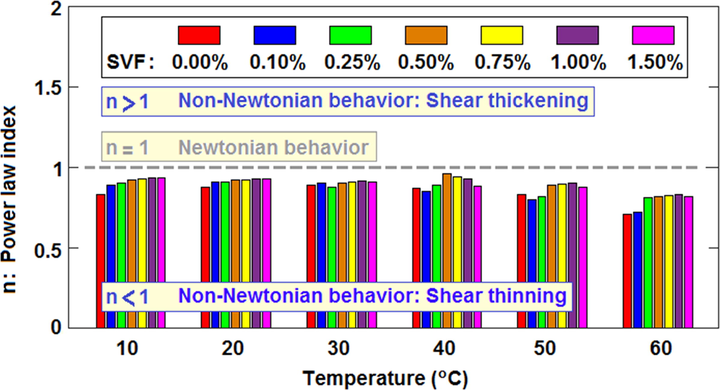

indicates the quasi-plastic behavior of the fluid, in Newtonian fluids

and, when

, fluid has dilatant behavior. For nanofluids that were prepared in this study with different SVFs, a power-law index was plotted against a temperature range of 10–60 °C as shown in Fig. 3. As shown in Fig. 3, the “n” parameter is smaller than one, so the nanofluids produced here behave as non-Newtonians of the pseudo-plastic type, to be more precise: “shear-thinning” type. The effect of temperature on nanofluid behavior showed that the non-Newtonian properties of the nanofluid increased with increasing temperature. The nanofluid flow containing

nanoparticles between the components of a mechanical system is a layered motion (Layers over each other).

Power-law index of SN 500 HVI/

nanofluids at 10–60 °C.

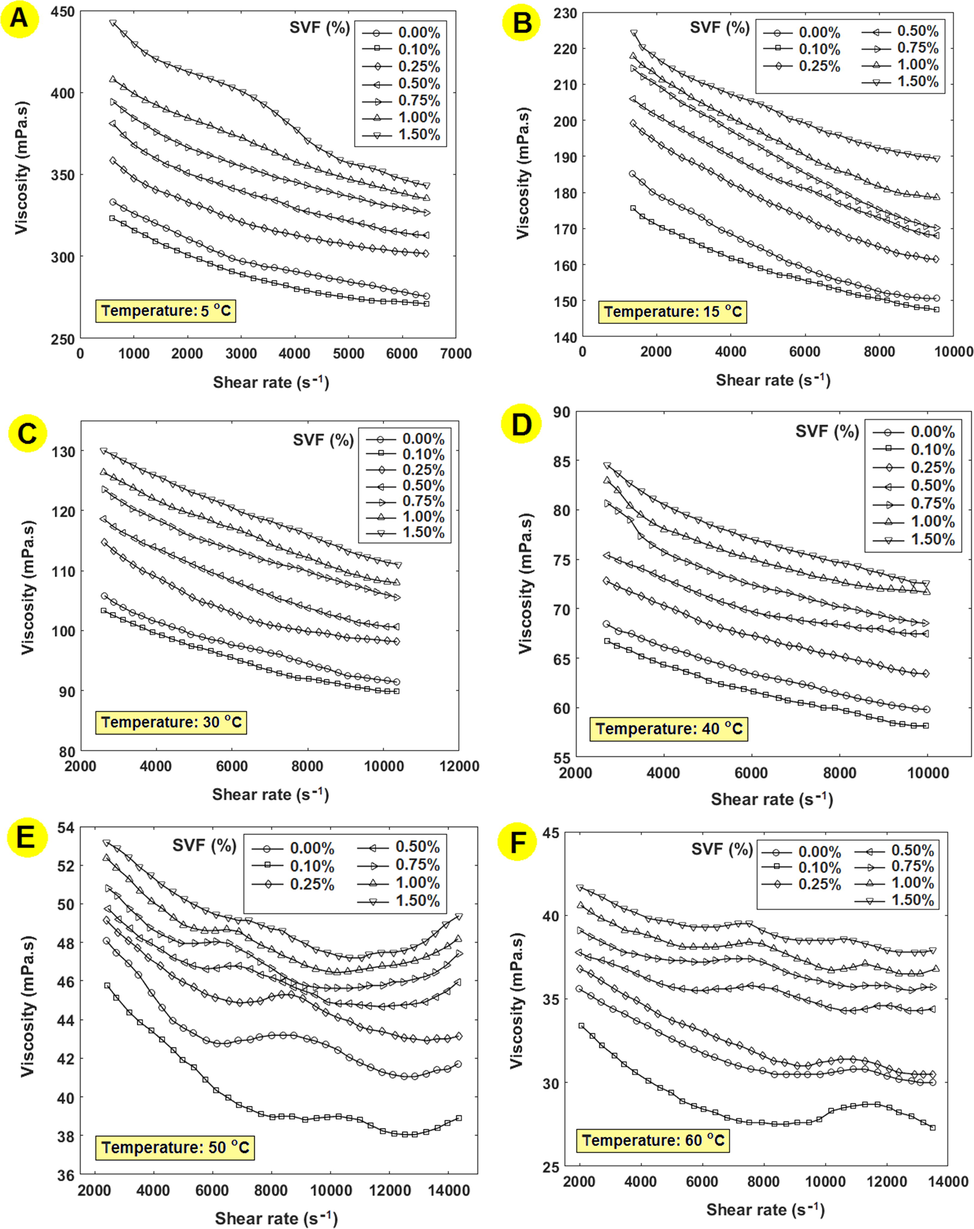

Viscosity is affected by changes in both temperature and SVF. Fig. 4a-f shows the viscosity changes of the nanofluid with changes in the shear rate for different temperatures. In nanofluid rheological tests with the lowest SVFs, the recorded viscosity was lower than that of the base oil viscosity. This result showed the same result for all temperatures. Therefore, nanoparticles act like ball bearings, causing fluid layers to move more smoothly (easier slipping) over each other. In addition. This evidence suggests that the viscosity of the nanofluid is strongly influenced by the shear rate; In other words, the behavior of the nanofluid is non-Newtonian. Also, comparison of recorded viscosity changes with increasing temperature at different SVFs showed that the viscosity changes did not follow a specific pattern.

The viscosity SN 500 HVI/

nanofluids with changes in the shear rate at 5 °C (a),15 °C (b), 30 °C (c), 40 °C (d), 50 °C (e) and 60 °C (f).

3.4 Study of nanofluid viscosity at different temperatures and SVFs

The performance of lubricating oils depends on their chemical and physical nature. The nanofluids prepared by adding nanoparticles have improved properties and provide effective lubrication. In addition, the nanoparticles in the base oil reduce the destructive effects of friction and wear on mechanical parts. Therefore, lubricating oils increase the service life of the mechanical parts by minimizing wear between surfaces. The viscosity of the oils in the hydrodynamic films produced in the lubrication changes in response to temperature changes. The flow of fluid is layered on top of each other, the quantity of viscosity is defined as the force of friction between adjacent layers of fluid on top of each other that slide and flow in relation to each other. Increasing the temperature weakens the intermolecular forces in the nanoparticles and base fluid molecules, which reduces the viscosity of the nanofluid. Increasing the temperature increases the mobility of the molecules. The bonds and gravitational forces weaken due to the increase in temperature. Therefore, with increasing temperature, the mobility of nanoparticle molecules and base oil molecules increases and the intermolecular forces weaken, which reduces the viscosity of the nanofluid. The viscosity of each fluid changes for a variety of reasons, including the addition of different materials or changes in temperature, so oils that are essentially low in viscosity or whose viscosity decreases with changes in chemical and physical conditions require less force to flow. Because the amount of flow resistance force (friction force between fluid layers) is low.

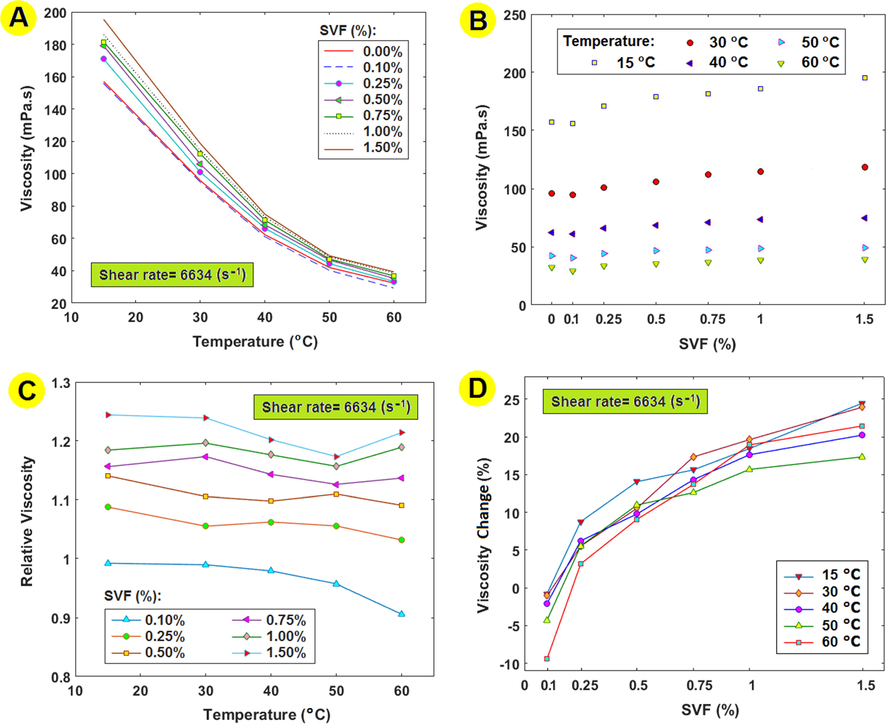

The curve of changes in nanofluid viscosity vs. temperature (15–60 °C) was plotted (at a constant shear rate) in Fig. 5a. The increasing temperature reduced the viscosity of the nanofluid. As the temperature increased, the mobility of the molecules increased, and thus, as the molecules moved away from each other, resulting in a decrease in intermolecular gravity, the viscosity of the oil stream decreased. Fig. 5b shows the changes in nanofluid viscosity against SVFs at a range of temperatures of 15–60 °C and a constant shear rate of 6634

.

The viscosity of SN 500 HVI/

nanofluids with changes in temperature (a), the viscosity of SN 500 HVI/

nanofluids with changes in SVFs (b), the relative viscosity of SN 500 HVI/

nanofluids with changes in temperature (c) and, the viscosity change of SN 500 HVI/

nanofluids with changes in SVFs (d) at a constant shear rate.

Increasing the SVF increases the number of nanoparticles in a constant volume of the base oil. As the nanoparticles approach each other, the gravitational forces of the van der waals between all nanofluid molecules increase, causing the nanoclusters to grow. Increasing the nanoclusters increases the viscosity. The lubrication is on the verge of a performance mutation, with the advent of nanotechnology and the properties of new nanomaterials. New nanoparticle lubricants reduce friction between engine components, reduce heat generation, protect parts from wear, eliminate wear waste, and save fuel for engines. Fig. 5c shows the changes in relative viscosity against different temperatures at the constant shear rate (6634 ) for different SVFs. Relative viscosity decreased in all nanofluid samples (different SVFs) due to temperature increase. Fig. 5d shows the changes of the nano-lubricant viscosity vs. SVFs changes, at different temperatures and constant shear rate (6634 ). At low SVF values, the distance between the nanoparticles suspended in the base oil is large compared to the conditions where the SVF is high, so the nanofluid viscosity is low because the nanofluid layers slide easily together. The highest decrease in viscosity was observed at SVF of 0.1% and temperature of 60 °C. As the concentration of in the nanofluid increases, the collisions between the oil molecules and the nanoparticles increase. Increased collisions, cause an increase in the slip resistance of the nanofluid layers; therefore, the viscosity of the nanofluid increases. At SVF of 1.5%, the effect of increasing the temperature from 30 to 60 °C was shown a positive effect on increasing the viscosity (Viscosity enhancement at 60 °C more than viscosity enhancement at 50 °C and 40 °C). Also, the maximum increase in viscosity was observed at SVF of 1.5% at temperature of 15 °C.

4 Proposed correlation

The Design-Expert software was used to provide a relationship to predict viscosity (Mahfouz, 2020). The experiments were designed based on central composite design (CCD) in the standard response surface method (RSM). Table 2 shows the ranges as well as the coded and un-coded levels of the variables considered in this study. The software suggested an experiments pattern with 20 runs, Table 3 shows runs and the result of each batch process.

Independent variable

Symbol

Levels

-

−1

0

+1

+

SVF (%)

0

0.3

0.75

1.2

1.5

Temperature (°C)

5

16

32.5

49

60

Shear rate

650

3204

6950

10,696

13,250

Response

Viscosity

Run

Actual level of factors

Responses

Viscosity

Actual

Predicted

Residual

1

0.75

32.5

650

95.45

97.46

−2.01

2

0.75

32.5

6950

75.12

75.87

−0.7493

3

0.75

32.5

6950

75.86

75.87

−0.0093

4

0.75

32.5

6950

75.21

75.87

−0.6593

5

1.5

32.5

6950

75.24

77.05

−1.81

6

0.75

32.5

13,250

86.32

83.81

2.51

7

1.2

16

10,696

191.51

195.66

−4.15

8

0.3

49

3204

41.82

38.02

3.8

9

0.75

32.5

6950

76.46

75.87

0.5907

10

0.75

32.5

6950

76.51

75.87

0.6407

11

0.3

49

10,696

35.85

34.46

1.39

12

0

32.5

6950

62.42

60.11

2.31

13

0.3

16

10,696

166.44

171.82

−5.38

14

0.75

5

6950

311.77

302.87

8.9

15

0.75

60

6950

32.64

41.04

−8.4

16

1.2

16

3204

206.59

208.34

−1.75

17

0.75

32.5

6950

75.97

75.87

0.1007

18

1.2

49

3204

39.34

34.32

5.02

19

1.2

49

10,696

35.38

31.76

3.62

20

0.3

16

3204

181.52

185.5

−3.98

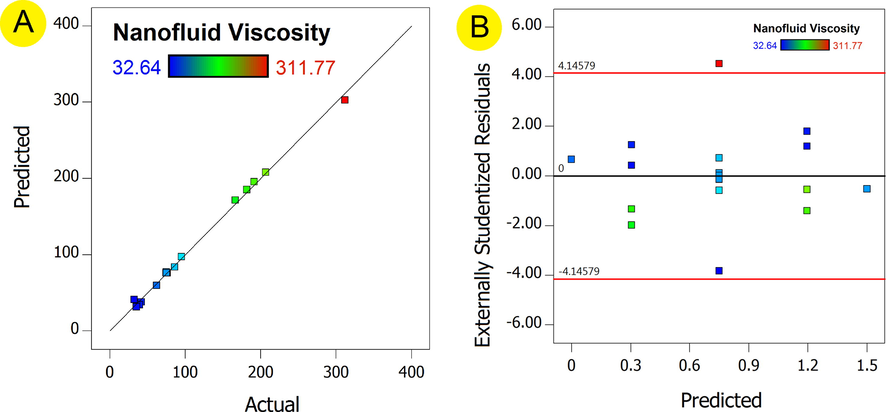

According to experimental results and its predicted (Table 3), the quadratic model was selected for response, that this model proposed by the software. This model was expressed by Eq. (4):

A positive sign against each term of the Eq. (4) indicates a synergistic effect and the negative sign indicates a synergistic effect on the response surface

. The

values for model equations were 0.997, the adjusted

and predicted

were 0.995 and 0.978, respectively with difference less than 0.2. The analysis of variance (ANOVA) helps to check the accuracy and validity of the proposed model. According to Table 4, based on ANOVA, the models for

was highly significant with F-value 386.70; p-value

0.0001. Therefore, these models are acceptable for the predicted results and optimization of the factors affecting the nanofluid viscosity. The actual responses versus predicted responses in Fig. 6a shown approximately a linear relationship with partial variation. According to Fig. 6b, the externally studentized residuals versus the predicted response has been distributed above and below the x-axis with unusual structure and no obvious pattern. The maximum and minimum differences between the data obtained from calculations and the data obtained from experiments is

, which indicates that the predicted data are reliable and the relationship presented to predict the behavior of the nanofluid lubricant prepared in This research is appropriate.

Sum of Squares

Degree of freedom

Mean Square

F-value

p-value

Model

1.010E + 05

9

11218.03

386.70

< 0.0001

346.10

1

346.10

11.93

0.0062

82757.01

1

82757.01

2852.73

< 0.0001

225.10

1

225.10

7.76

0.0193

352.32

1

352.32

12.14

0.0059

0.5050

1

0.5050

0.0174

0.8976

51.16

1

51.16

1.76

0.2137

95.73

1

95.73

3.30

0.0993

16631.25

1

16631.25

573.30

< 0.0001

392.72

1

392.72

13.54

0.0043

Residual

290.10

10

29.01

Cor Total

1.013E + 05

19

Comparison of experimental and predicted responses (a), Diagnostics and model graphs for viscosity: residuals versus predicted (b).

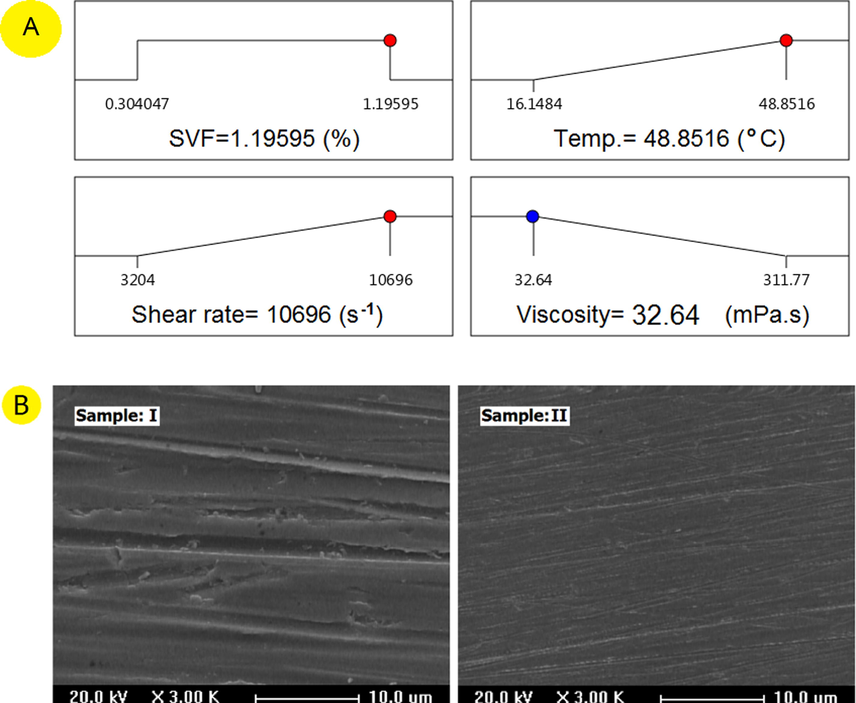

5 Study of surface wear morphology

Based on experimental results and the viscosity prediction model, the SVF was optimized to reduce the viscosity at the highest temperature and shear rate. Fig. 7a shows the ramp of this optimization. Based on the popularity of this optimization (Desirability = 1), the effect of 1.2% SVF on surface wear was studied using FE-SEM imaging of the disk surface and comparison with wear in the control sample (lubrication with oil without nanoparticles). In the pin-on-disc test, the operating conditions were as follows: power: 1200 W, speed: 300 rpm, temperature: 28 °C, time: 10 min, disk diameter: 5

, disk thickness: 6

, disk weight: 40

, pin diameter: 5

, pin length: 5

, pin head curvature: 10° and, 10 drops of lubricant fluid; according to ASTM G 99 standard. The obvious changes in the wear of the pin on the disc are shown in Fig. 7b for two samples of lubricating oil (I: pure base oil, II: oil containing

nanoparticles). Due to direct friction at the joint boundary between the pin and the steel disc, dense scratches and deep furrows were observed in the sample in which the pure base oil was used as lubricating oil. When nano-particles are added, the

can be transferred to the surface, filling fine grooves and smoothing the surface (forming a protective film during the rubbing process) (Roy et al., 2019). It can be inferred that the presence of nanoparticles can prevent the direct contact of friction surfaces (He et al., 2021).

Desirability ramp for the numerical optimization of affecting factors on the process response (a). FE-SEM photographs of wear tracks (b).

6 Conclusion

In this study, the tribological properties were investigated with and without oleic-acid modified nanorods as lubricant additives in SN 500 HVI oil. Experiments were performed at different temperatures, SVFs and shear rates. The results proved that this new nanofluid has a non-Newtonian behavior. The addition of modified nanoparticles to the base oil was so stable that no sediment was observed after 20 days at rest. The optimum SVF in additive nanoparticles to base oil is much lower than 2%. Because the results showed that by increasing the SVFs in the base oil, strong intermolecular attraction is created, nano-clusters grow and consequently nanofluid viscosity increases. Increasing the temperature increases the mobility of the molecules and as a result weakens the intermolecular forces of the nanoparticles and the base oil molecules, which leads to a decrease in the viscosity of the nanofluid. As the nanofluid (SN 500 HVI/ nanoparticle) temperature increased, the non-Newtonian behavior intensified. The mentioned interactions are of positive importance for the use of nanoparticles in the field of tribology and the design and operation of high-performance -based nano-lubricants.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Advances in carbon nanomaterials as lubricants modifiers. J. Mol. Liq.. 2019;279:251-266.

- [CrossRef] [Google Scholar]

- An experimental and theoretical investigation on heat transfer capability of Mg (OH)2/MWCNT-engine oil hybrid nano-lubricant adopted as a coolant and lubricant fluid. Appl. Therm. Eng.. 2018;129:577-586.

- [CrossRef] [Google Scholar]

- A comprehensive experimental investigation of thermal conductivity of a ternary hybrid nano fl uid containing MWCNTs- titania-zinc oxide / water- ethylene glycol (80: 20) as well as binary and mono nano fl uids. Synth. Met.. 2020;268:116501

- [CrossRef] [Google Scholar]

- Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int.. 2017;43:4246-4251.

- [CrossRef] [Google Scholar]

- A novel preparation of nano-sized hexagonal Mg(OH)2. Procedia Eng.. 2015;102:388-394.

- [CrossRef] [Google Scholar]

- Role of nanoparticle materials as water-based lubricant additives for ceramics. Tribol. Int.. 2020;142:105978

- [CrossRef] [Google Scholar]

- Analysis of thermo-physical properties of SAE20W40 engine oil by the addition of SiO2 nanoparticles. Mater. Today Proc.. 2021;2–7

- [CrossRef] [Google Scholar]

- Dong, H., Du, Z., Zhao, Y., Zhou, D., 2010. Preparation of surface modi fi ed nano-Mg (OH) 2 via precipitation method. Powder Technol. 198, 325–329. https://doi.org/10.1016/j.powtec.2009.11.014

- Modifying the lubricating and tribological properties via introducing the oleic acid in CuS nanomaterials for vehicle. Opt. Laser Technol.. 2018;108:1-6.

- [CrossRef] [Google Scholar]

- Performance analysis of journal bearing operating on nanolubricants with TiO2, CuO and Al2O3 nanoparticles as lubricant additives. Mater. Today Proc.. 2021;45:5624-5630.

- [CrossRef] [Google Scholar]

- Interactions of Cu nanoparticles with conventional lubricant additives on tribological performance and some physicochemical properties of an ester base oil. Tribol. Int.. 2020;141:105941

- [CrossRef] [Google Scholar]

- An experimental study on the rheological behavior of hybrid Tungsten oxide (WO 3) -MWCNTs / engine oil Newtonian nano fl uids. J. Mol. Struct.. 2019;1197:497-507.

- [CrossRef] [Google Scholar]

- Recent developments of nanoparticles additives to the consumables liquids in internal combustion engines: Part II: Nano-lubricants. J. Mol. Liq.. 2020;319:114156

- [CrossRef] [Google Scholar]

- Improved lubrication performance of MoS2-Al2O3 nanofluid through interfacial tribochemistry. Colloids Surfaces A Physicochem. Eng. Asp.. 2021;618:126428

- [CrossRef] [Google Scholar]

- Using of Artificial Neural Networks (ANNs) to predict the thermal conductivity of Zinc Oxide – Silver (50 % – 50 %)/ Water hybrid Newtonian nanofluid. Int. Commun. Heat Mass Transf.. 2020;116:104645

- [CrossRef] [Google Scholar]

- Rheological characteristics of MgO/oil nanolubricants: Experimental study and neural network modeling. Int. Commun. Heat Mass Transf.. 2017;86:245-252.

- [CrossRef] [Google Scholar]

- Effect of MgO nanoparticles suspension on rheological behavior and a new correlation. J. Mol. Liq.. 2020;309:112632

- [CrossRef] [Google Scholar]

- Kailasa, S.K., Wu, H., 2012. With oleic acid as hydrophobic affinity probes for the analysis of hydrophobic. https://doi.org/10.1039/c2an35788g

- Synthesis and tribological property study of oleic acid-modified copper sulfide nanoparticles. Wear. 2008;265:150-154.

- [CrossRef] [Google Scholar]

- SiO2 nanoparticles effect to the Mahua oil for friction and wear characterization. Mater. Today Proc.. 2021;2–5

- [CrossRef] [Google Scholar]

- A comprehensive study of the performance of a heat pipe by using of various nanofluids. Adv. Powder Technol.. 2017;28:3074-3084.

- [CrossRef] [Google Scholar]

- Surface-modification of SiO 2 nanoparticles with oleic acid. Appl. Surf. Sci.. 2003;211:315-320.

- [CrossRef] [Google Scholar]

- Turbidity in oil-in-water-emulsions — Key factors and visual perception. FRIN. 2016;89:202-210.

- [CrossRef] [Google Scholar]

- Exploring the effect of nanoparticle size on the tribological properties of SiO2 / polyalkylene glycol nanofluid under different lubrication conditions. Tribol. Int.. 2017;109:467-472.

- [CrossRef] [Google Scholar]

- Tribological analysis of the neem oil during the addition of SiO2 nanoparticles at different loads. Mater. Today Proc.. 2020;28:1412-1415.

- [CrossRef] [Google Scholar]

- Viscosity prediction and optimization of ZnO-coconut oil nanofluids using numerical simulation. Mater. Today Proc.. 2020;42:1437-1441.

- [CrossRef] [Google Scholar]

- Preparation of amino-functionalized Fe3O4@mSiO2core-shell magnetic nanoparticles and their application for aqueous Fe3+removal. J. Hazard. Mater.. 2018;341:198-206.

- [CrossRef] [Google Scholar]

- Effect of SiO2 nanoparticles on the tribological characteristics of jatropha oil. Mater. Today Proc.. 2020;2–5

- [CrossRef] [Google Scholar]

- Size effects of SiO nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol.. 2010;62:111-120.

- [CrossRef] [Google Scholar]

- Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol. Int.. 2009;42:911-917.

- [CrossRef] [Google Scholar]

- Ren, B., Gao, L., BotaoXie, Li, M., Zhang, S., Zu, guoqing, Ran, X., 2020. Tribological properties and anti-wear mechanism of ZnO@graphene core-shell nanoparticles as lubricant additives. Tribol. Int. 144, 106114. https://doi.org/10.1016/j.triboint.2019.106114

- Measurement of the thermal conductivity of MWCNT - CuO / water hybrid nanofluid using artificial neural networks (ANNs) J. Therm. Anal. Calorim. 2020

- [CrossRef] [Google Scholar]

- Investigating the micropitting and wear performance of copper oxide and tungsten carbide nanofluids under boundary lubrication. Wear. 2019;428–429:55-63.

- [CrossRef] [Google Scholar]

- Statistical investigation for developing a new model for rheological behavior of Silica – ethylene glycol / Water hybrid Newtonian nanofluid using experimental data. Physica A. 2019;525:616-627.

- [CrossRef] [Google Scholar]

- Statistical investigation for developing a new model for rheological behavior of ZnO – Ag (50 %– 50 %)/ Water hybrid Newtonian nanofluid using experimental data. Physica A. 2019;525:741-751.

- [CrossRef] [Google Scholar]

- An experimental evaluation of the effect of ZnO nanoparticles on the rheological behavior of engine oil. J. Mol. Liq.. 2017;236:198-204.

- [CrossRef] [Google Scholar]

- Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy. 2016;41:3153-3170.

- [CrossRef] [Google Scholar]

- Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol. Int.. 2018;119:99-111.

- [CrossRef] [Google Scholar]

- Singh, Y., Badhotiya, G.K., Gwalwanshi, M., Negi, P., Bist, A., 2021. Magnesium oxide (MgO) as an additive to the neem oil for efficient lubrication. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2020.12.1181

- Experimental measurements of thermal conductivity of engine oil-based hybrid and mono nano fl uids with tungsten oxide (WO 3) and MWCNTs inclusions. Powder Technol.. 2020;371:37-44.

- [CrossRef] [Google Scholar]

- Song, W., Yan, J., Ji, H., 2019. Applied Surface Science Fabrication of GNS / MoS 2 composite with different morphology and its tribological performance as a lubricant additive 469, 226–235. https://doi.org/10.1016/j.apsusc.2018.10.266

- Designing an Artificial Neural Network (ANN) to predict the viscosity of Silver / Ethylene glycol nanofluid at different temperatures and volume fraction of nanoparticles. Physica A. 2019;534:122142

- [CrossRef] [Google Scholar]

- Novel additive of PTFE@SiO2 core-shell nanoparticles with superior water lubricating properties. Mater. Des.. 2020;195:109069

- [CrossRef] [Google Scholar]

- Investigation on the robust adsorption mechanism of alkyl-functional boric acid nanoparticles as high performance green lubricant additives. Tribol. Int.. 2021;157:106909

- [CrossRef] [Google Scholar]

- Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol. Int.. 2016;93:63-70.

- [CrossRef] [Google Scholar]

- Tribological properties of carbon nanotube/SiO2combinations as water-based lubricant additives for magnesium alloy. J. Mater. Res. Technol.. 2021;12:138-149.

- [CrossRef] [Google Scholar]

- Hydrophobic magnesium hydroxide nanoparticles via oleic acid and poly (methyl methacrylate) -grafting surface modification. Powder Technol.. 2009;193:125-129.

- [CrossRef] [Google Scholar]

- A review of heating/cooling processes using nanomaterials suspended in refrigerants and lubricants. Int. J. Heat Mass Transf.. 2020;153:119611

- [CrossRef] [Google Scholar]

- Zahir, H., Rahman, M.M., Irshad, K., 2019. Shape-Stabilized Phase Change Materials for Solar Energy Storage: MgO and Mg (OH) 2 Mixed with Polyethylene Glycol 1–21.

- Propriétés thermo-physiques du nanolubrifiant composite Al2O3-SiO2/PAG pour les systèmes frigorifiques. Int. J. Refrig.. 2017;80:1-10.

- [CrossRef] [Google Scholar]