Translate this page into:

Graded regulation technology for enhanced oil recovery and water shutoff in pore-cavity-fracture carbonate reservoirs

⁎Corresponding authors at: Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University, Caidian, Wuhan, China. wangjie@yangtzeu.edu.cn (Jie Wang), jhs_hust@sina.com (Houshun Jiang)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Clarified the types of chemical agents for graded regulation of pore-vug-fracture carbonate reservoirs. Plugging effect and oil–water selectivity of gel and nanospheres. Wetting modifiers improve the efficiency of injection water to wash the oil are investigated. Comprehensively discussed the synergistic mechanism of profile control and water shutoff and improving the efficiency of oil washing with injected water.

Abstract

Although a single type of chemical agent (eg, gels, microspheres, surfactants, etc.) has achieved some effects in enhanced oil recovery of carbonate reservoirs, for pore-cavity-fracture carbonate reservoirs, the use of a single type of chemical agent does not perform well. The main objective of this study is to study the effect of different types of chemical agents in enhanced oil recovery of complex carbonate reservoirs. In order to determine the screening principle of chemical agents, the types of water channeling in the North Troyes reservoir were analyzed. For complex fractures, step by step plugging, multi-agent and multi-slug comprehensive intervention is carried out to ensure the plugging of high-permeability channels and inhibit the seepage of large channels. It can plug channeling fracture channel, adjust secondary dominant channel and reduce matrix flow resistance, so as to expand macroscopic swept volume and improve microscopic water flooding efficiency. The results show that it is difficult to comprehensively control water channeling in pore-cave-fracture carbonate reservoir, and the reservoir heterogeneity in the test area can be improved by mixing different types of control and flooding agents and carrying out deep profile control. The plugging rate of gel is 97.18 %, and the oil–water selection ratio is 0.45 in fractured core; the expansion rate of nano - microspheres is more than 3 times; the wetting modifier can improve the imbibition oil displacement efficiency by 14.76%, and the test result shown that nano - microspheres and wetting modifier have good synergistic oil displacement effect. The field application result shown that daily oil production of oil well in the test area increased by 5.0 m3/d and the daily water rate decreased by 19.0% compared with that before the control flooding. The findings of this study can help for better understanding of enhanced oil recovery in pore-cave-fracture carbonate reservoir.

Keywords

Pore-cavity-fracture

Carbonate reservoir

Stabilizing oil and water shutoff

Graded regulation

Filed application

Nomenclature

- NPM

-

Nano-Polymer Microspheres

- Ppm

-

Concentration unit, mg/L

- CA

-

Contact angle

1 Introduction

As an important part of oil and gas resources in the world, carbonate reservoirs are widely distributed in the world (Alhuraishawy et al., 2018; Dong et al., 2018). However, the oil recovery of carbonate reservoirs was heavily influenced by the abundant of natural fractures and edge/bottom water (Dong et al., 2019; Dong et al., 2019; Dong et al., 2020). Deep profile control and water shutoff treatment has been successfully and widely applied in sandstone reservoirs, but there are relatively few successful cases in carbonate reservoirs. Sharma et al. believed that the reasons for the low recovery of carbonate reservoirs included the factors of low water flooding sweep efficiency caused by reservoir wettability, abundant of vuggy fractures and reservoir heterogeneity (Sharma and Mohanty, 2013), and higher salinity would shorten the validity period of gel plugging agents. The chemical systems commonly used for profile control and water shutoff treatment in carbonate reservoirs include gel (Alhuraishawy et al., 2019; Wang et al., 2019), polymer microsphere (Zhao et al., 2019) and foam system (Bourbiaux et al., 2017).

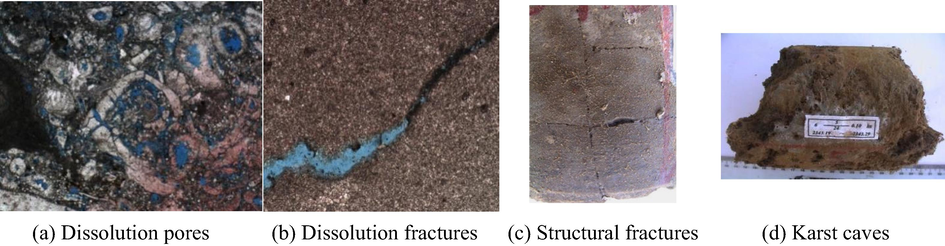

The North Troyes oilfield in Kazakhstan is a typical fractured carbonate reservoir. Due to the water injection not timely and the complexity of the reservoir, the level of formation pressure is low, the water injection channeling is fast, the oil well production declines quickly, and the contradiction between restoring the formation pressure and water cut rising is serious. Fig. 1 shows the different types of pore, fracture and cave in the KT-1 reservoir, including Fig. 1(a) dissolution pores, Fig. 1(b) dissolution fractures, Fig. 1(c) structural fractures, and Fig. 1(d) karst caves. The main reservoir KT-I in North Troyes oilfield has experienced complex sedimentation-diagenesis, with strong heterogeneity and various reservoir space types, including pores, karst caves and fractures. Fractures and caves account for 16%, which seriously affects the water flooding recovery.

Different types of pore fractures in KT-1 reservoir core of North Troyes oilfield.

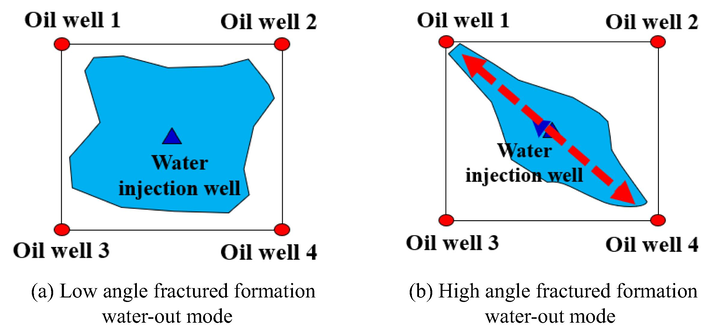

Taking well group 545 as an example, the watered-out mode of oil wells are analyzed by tracer technology, including low angle fractured formation watered-out mode in Fig. 2(a) and high angle fractured formation water-out mode in Fig. 2(b). The low angle fractured formation mainly produce multi-direction watered-out mode, while directional flooding is the main water-out pattern of high-angle fractures. The accurate adjustment and plugging of directional flooding can be realized by calculating the volume of high-angle fracture. For low angle fractures, plugging depth must be large, otherwise it is easy to produce fluid channeling leading to short effective period, so plugging agent injection must have a suitable volume to achieve large volume filling of fracture formation.

Water-out mode of the main producing zone in North Troyes oilfield.

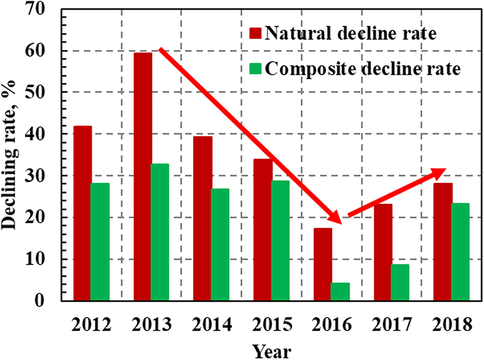

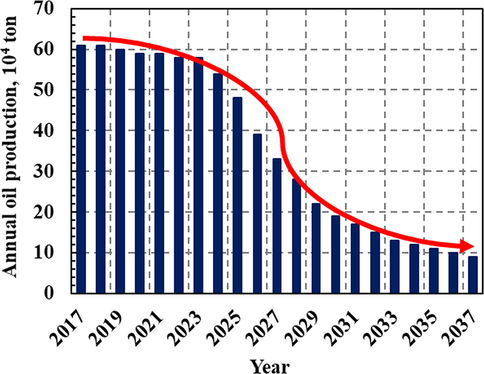

Fig. 3 shows the histogram of oil production natural decline and comprehensive decline in the North Troyes oil field over the years. Before 2012, the oilfield did not implement large-scale water-injection to increase formation pressure and enhanced oil recovery. Since 2013, the production decline has slowed down and then recovered. Fig. 4 shows the result map of oilfield prediction and development. According to the current water injection mode, oilfield production will be reduced from 610,000 tons in 2017 to 90,000 tons in 2037. Therefore, it is urgent for oilfield development to actively explore effective stabilizing oil and water shutoff comprehensive treatment technology.

Histogram of oil production natural decline and comprehensive decline in North Troyes oilfield over the years.

Effect diagram of prediction oil production.

Liu, Davletbaev, Li et al summed up a series of experience of measures for different types of water outlet mode (Liu et al., 2019; Davletbaev et al., 2010; Li et al., 2012): for single fractured reservoir, organic–inorganic compound crosslinked plugging agent can be used to plug the high permeability channel. Among them, gel plugging agent can realize the selective plugging of oil–water seepage channel. For the combination of pore and fractured reservoir, the soluble silicate plugging agent and low-medium density solidified particle plugging agent are generally selected for water shut-off and profile control. For the complex fracture-cave-type reservoirs, solidifiable particle plugging agents with different densities are generally selected (Long et al., 2009). Das et al. thought that many factors lead to the fractured-vuggy carbonate reservoirs can’t obtain good blocking effect, such as the water plugging time, the poor adaptability of plugging agent, the strong heterogeneity/high salinity/high temperature/ultra-deep of the reservoir and plugging agent couldn’t reach to suitable position in the formation (Das and Salgaonkar, December 2012). Zhanazhol oilfield is a fractured carbonate reservoir with a similar reservoir type to North Troyes reservoir. Che, Wang et al. have carried out several rounds of fracture water plugging in Zhanazhol oilfield, but the water plugging effect was not good due to the complex reservoir type. It is difficult to realize profile control and water shutoff treatment, and the four different companies failed to achieve the ideal operation effect (Che et al., 2018; Wang et al., 2013; Zheng et al., 2019). Dordzie, Dejam and Olayiwola used nanoparticles with low salinity water and surfactant for enhanced oil recovery in sandstone and carbonate reservoirs (Dordzie and Dejam, 2021; Olayiwola and Dejam, 2021; Olayiwola and Dejam, 2019). They found that the alternating injection of NPs along with the LSW and surfactant is not only the best effective and efficient recovery mechanism but also economical for oil recovery in carbonate reservoirs.

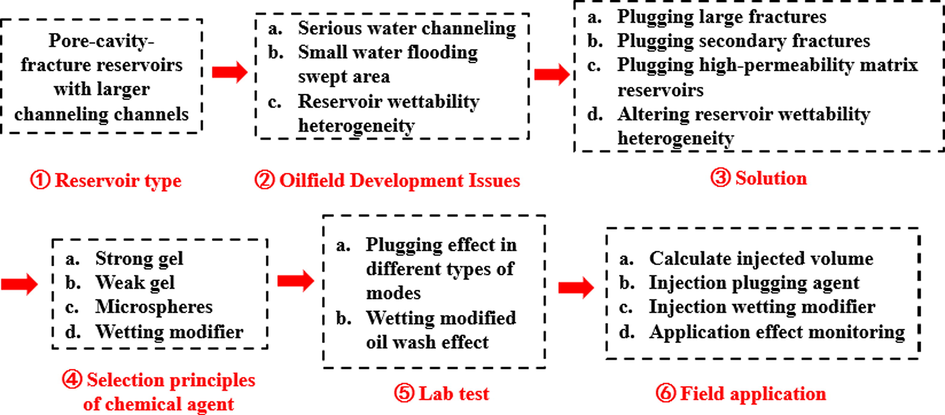

By investigating and summarizing the articles related to profile control and water plugging in carbonate reservoirs, it can be seen that the use of profile control, water plugging or nanoparticles with surfactant to improve the oil washing efficiency of injected water, can achieve good enhanced oil recovery effects in different standpoints, these results have been confirmed in the work of Liu, Das, Dordzie, Dejam and Olayiwola, and their research has strong reference significance for the stabilizing oil and water control in North Troyes. The North Troyes oilfield is the weakly volatile oil reservoir, the low-angle fractures are relatively developed, and the tracer shows that the water flooding speed is up to 540 m/d, which leads to the rapid water flooding of the oil well after water injection It is not a simple pore-fracture type. Besides, the reservoir characteristics also includes wettability heterogeneity, therefore, a single method of profile control and water plugging cannot achieve effective good effect. In this article, combined with the existing methods of profile control and water plugging, the North Troyes Oilfield will be used multiple methods to achieve the purpose of stabilizing oil and controlling water. Fig. 5 lists the problems and solutions roadmap for the North Troyes oil field.

Lists the problems and solutions roadmap for the North Troyes oil field.

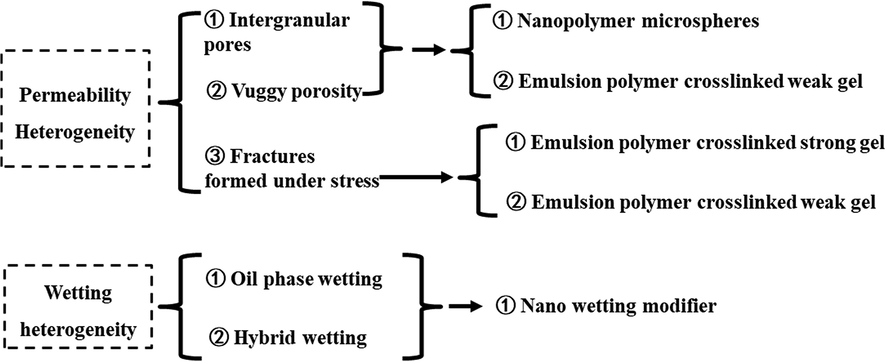

The X well group is selected as pilot pattern and the solution as shown in Fig. 6. For intergranular pores and dissolved pores, the emulsion polymer weak gel or nano polymer microspheres are used to realize the grading plugging of large, medium and small pore throats; for the fractured formed under stress, the combination of high concentration emulsion polymer strong gel and medium concentration emulsion polymer flexible weak gel is used for plugging. For the problem of wettability heterogeneity, nano-wetting modifier is used to modify oil-wetting and mixed-wetting reservoir surface into water-wetting, which improve water flooding efficiency. The following is based on the experimental conditions of reservoir temperature 54 °C and reservoir core of the fractured carbonate reservoir in North Troyes, and the physical models of fractured and porous media carbonate reservoirs are made, in order to comprehensively evaluate the adaptability of different chemicals.

Comprehensive treatment and enhanced oil recovery measures of water channeling in pore-cave-fracture carbonate reservoir.

Different from the conventional single method to enhance oil recovery, for the North Troyes pore-cavity-fracture carbonate reservoirs, the use of different chemical agents for graded regulation profile control and water plugging is the innovation of this article. Due to the high salinity of carbonate reservoirs, different types of chemical agents cannot achieve long-term effectiveness. At the same time, for low-permeability tight carbonate reservoirs, the gel injectability is poor, and the gel need replaced by other types of chemical agents. In this article, first, the characteristics of carbonate rock reservoirs in North Troyes are analyzed, and the existing methods for profile control and water shutoff of carbonate rock are synthesized, and different chemical agents are selected for different types of water channeling modes; and then the effects of different types of chemical agents were evaluated, and the usage amount of the on-site operation is calculated; finally, through the field application effect evaluation, it was shown that the graded regulation method achieved the purpose of stabilizing oil and water control in the North Troyes Oilfield.

2 Methodology

2.1 Experimental material and procedure

2.1.1 Experimental material

The graded regulatory chemical system in North Troyes oilfield includes “HR9806 emulsion polymer + organic chromium crosslinker”, nano-polymer microsphere (NPM) and nano-wetting modifier CND.

HR9806 emulsion polymer is composed of white oil, emulsifier and polymer monomer. The main component is modified polyacrylamide, and the solid content is 30 %. The crosslinker is organic chromium, which is produced by Jiangsu Hengfeng Chemical Co., Ltd. When the concentration of HR9806 reaches 0.8 wt%, it can be used as a strong gel, and when the concentration of HR9806 is low, it can be used as a flexible weak gel. Nano polymer microspheres (NPM) were provided by Gansu Zhongke Polymer Petroleum Technology Co., Ltd., China, and the main components were dispersants and polyacrylamide polymer microspheres monomers. Nano wetting modifier CND is provided by Beijing Comex Oilfield Chemical Technology Co., LTD., China. CND nano emulsion is synthesized from water phase, oil phase and surfactant by microemulsion method. It is a liquid substance, and surfactant accounts for about 20% of it.

Mineral salts used in simulated formation water include sodium chloride, potassium chloride, magnesium chloride and calcium chloride, which are produced by China Pharmaceutical Preparation Co., Ltd.; core and crude oil are taken from KT-1 reservoir in North Troyes oilfield; calcium carbonate powder is produced by China Pharmaceutical Co., Ltd. The reservoir temperature was 54.0 ℃, and the salinity of formation water reached 8.23 × 104 mg/L. The divalent cations were mainly Ca2+ and Mg2+ ions.

2.1.2 Experimental procedure

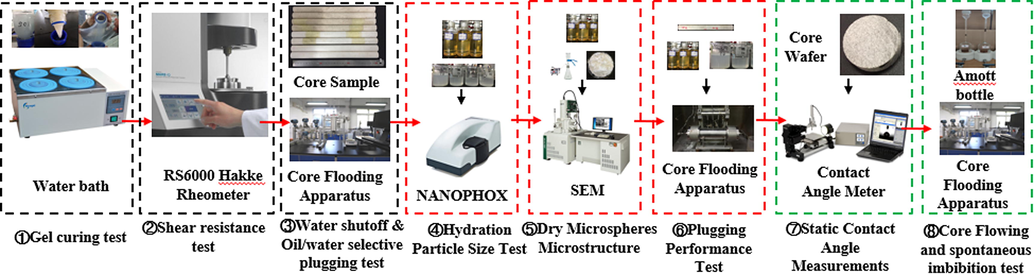

In order to determine the adaptability of graded regulatory chemicals in KT-1 reservoir, according to the field application requirements, (1) The gelling performance, shear resistance and oil–water selective plugging performance of HR9806 emulsion polymer crosslinking system in different salinity brines and different sizes of fractured carbonate rocks were tested; (2) Hydration expansion performance of polymer nanoparticles and selective plugging performance in microcracks; (3) Wetting modification effect of nano-wetting modifier and core displacement experiment. Fig. 7 is experimental flow chart.

Experimental flow chart.

3 Adaptability test of profile control in reservoir

3.1 HR9806 emulsion polymer adaptability test

North Troyes oilfield is a fractured carbonate reservoir. Affected by carbonate rocks, the salinity of formation water is high, reaching 82290 ppm, and the divalent cations are mainly Ca2+ and Mg2+ ions. When the emulsion polymer is used in the field, it must have good resistance to salinity. The migration of polymer solution in the formation is diluted by formation water, and there are differences in salinity in different regions. The gelling performance of the system under six salinity levels are tested respectively. The gel strength level and mineral composition of brine refer to Appendix 1 and Appendix 2.

Table 1 shows the gelling performance of emulsion polymers and organic chromium crosslinkers at six salinities. HR9806 solution has good gelling properties in simulated North Troyes injection water No.① and diluted saturated brine No.⑥, but the gelling time of HR9806 is greatly shortened by water type No.⑥. In the simulated formation water and diluted formation water No.②∼⑤, the gelling performance of HR9806 aqueous solution isn’t well. Therefore, it is recommended to prepare HR9806 aqueous solution by using simulated North Troyes injection water No.①. At the same time, before HR9806 solution is injected, a certain amount of No.① water should be injected in advance to scour the formation around the injection well in advance, so as to reduce the influence of mineral salts in the formation water on the gelling performance of HR9806 solution.

Recipe

0.5 wt% HR9806 + 0.15 wt% Organic chrome cross linker

Water type

①Simulated injection water of North Troyes, Salinity = 1685 ppm

②Salinity = 36000 ppm

③Salinity = 57000 ppm

④Salinity = 70000 ppm

⑤Salinity = 82290 ppm (Simulated formation water)

⑥Salinity = 90750 ppm (Diluted saturated salt water)

Gelling time, hours

6.0

3.0

2.0

8.0

48.0

3.0

Gel strength

Level 4, High strength gel

Level 3, Flexible weak gel

Level 2,

Dehydration problemLevel 2, Severe dehydration problem

Level 4, High strength gel

Level 4, High strength gel

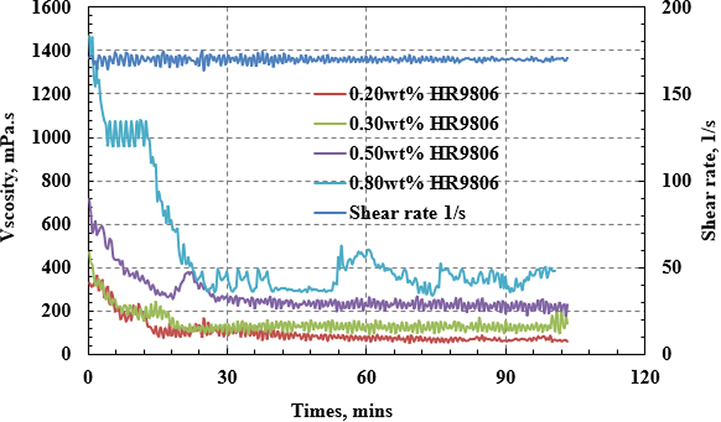

Fig. 8 shows the shear resistance of gels formed by HR9806 with different concentrations at a fixed rate of 170 1/s under the condition of 0.15 wt% crosslinker. According to Fig. 8, the viscosity of the gel system formed by stabilized 0.20 wt%, 0.30 wt%, 0.50 wt% HR9806 and 0.80 wt% HR9806 was 66.53 mPa.s, 129.42 mPa.s, 227.70 mPa.s and 355.77 mPa.s, indicating that HR9806 had good shear resistance and still had high viscosity under high shear rate. The higher the concentration of emulsion polymer HR9806 was, the stronger the shear resistance of the gel system formed was.

Shear resistance of 0.15 wt% crosslinker with different HR9806.

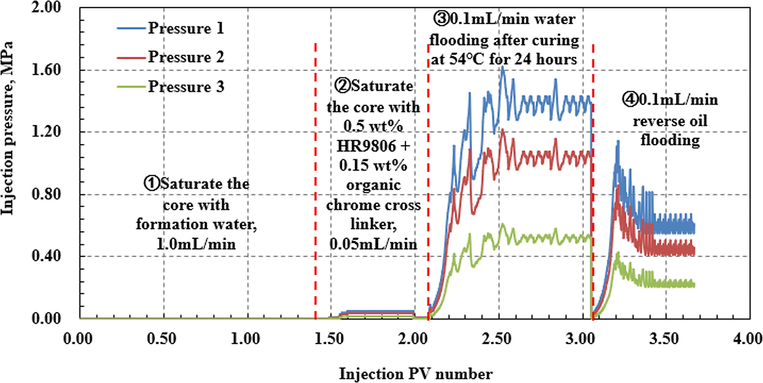

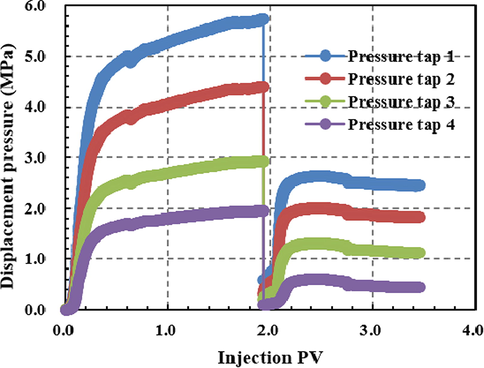

In order to further study the plugging performance and oil–water selective plugging effect of HR9806 emulsion polymer crosslinking system for large fractures, cores with fracture equivalent width of 0.5680 mm were selected for experiments. According to the calculation of experimental results in Fig. 9, the liquid measured permeability of fractured core before plugging is 780 mD, the forward water flooding permeability after plugging is 22.02 mD, and the reverse oil flooding permeability after plugging is 49.37 mD. Equation (1) is introduced to calculate the chemical additives’ oil/water selectivity ratio:

Pressure curves of 0.50 wt% HR9806 + 0.15 wt% crosslinker plugging and oil–water selectivity experiment.

3.2 NPM adaptability test

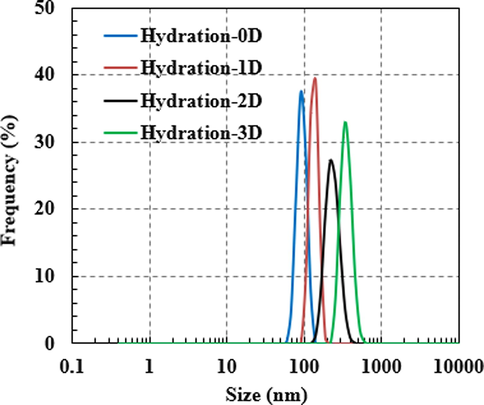

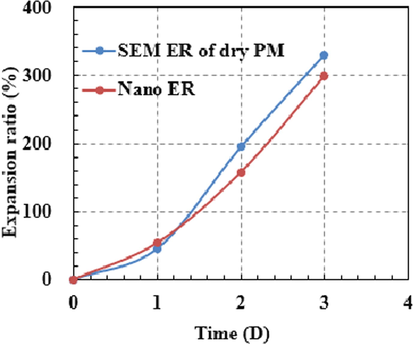

A laser nano-particle analyzer was used to test the particle size of the polymer microsphere solution after swelling, as shown in Fig. 10. The particle sizes of microsphere solution measured at 0–3 days were 125.8 nm, 193.5 nm, 324.3 nm and 502.4 nm, respectively. The 1–3 days expanding ratios were 53.82 %, 157.79 % and 299.36 %, respectively. The swelling ratios of microspheres calculated by SEM and laser nano-particle size analyzer was plotted in the same curve (Fig. 11). There was little difference between the two methods. The swelling ratio of microspheres in solution was close to that of dried microspheres after hydration, indicating that the particle size of microspheres after hydration and swelling was not affected, and the microspheres had good stability in solution and in drying state.

Particle size test results of microspheres hydration on different days.

Calculation results of swelling ratio of microspheres.

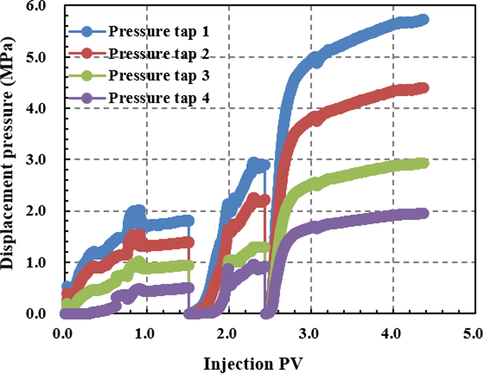

The plugging effect of NPM solution in reservoir was simulated by core flow experiment. The injection velocity at each stage of core flow is the same as 0.3 mL/min, so as to facilitate the comparison between different stages. The experimental curve is shown in Fig. 12. According to Fig. 12, the injection pressure of NPM solution is slightly higher than that of simulated formation water, which is mainly due to the resistance of dispersed microspheres in the solution to increase the injection pressure of the solution. Although the injection pressure of NPM is higher than that of simulated formation water, it still has good injection property. NPM has good injection property is the first step to realize its deep plugging effect. After injecting 1PV 0.3 wt% NPM solution, close the experimental equipment and open the oven at 54 °C for 3 days to simulate the shut-in after the completion of field operation. The results of subsequent water flooding experiments show that NPM forms a certain plugging effect in the core. The subsequent water flooding pressure is higher than the injection pressure of simulated formation water and NPM solution before plugging, and the four pressure measuring points form a uniform pressure drop. It shows that NPM is evenly distributed at the entrance end of the core and the deep part. In reality, the deep plugging effect is not plugged.

Plugging curve of 1.7mD matrix core.

NPM water plugging without oil plugging is the key to achieve the decline of water production and oil production is not affected. After the follow-up water flooding, the core injection end and the outlet end are replaced by the simulation reservoir oil production process, and the crude oil is injected reversely at the speed of 0.3 mL/min. The experimental curve is shown in Fig. 13. After plugging 1.7 mD core, the injection pressure of forward injection formation water is 5.95 MPa, and the injection pressure of reverse injection oil is 2.46 MPa. The calculation shows that the oil/water selectivity coefficient Kwa/Koa of NPM is 0.21 in the core of 1.07 mD matrix, which has good water and oil plugging properties.

Calculation results of swelling ratio of microspheres.

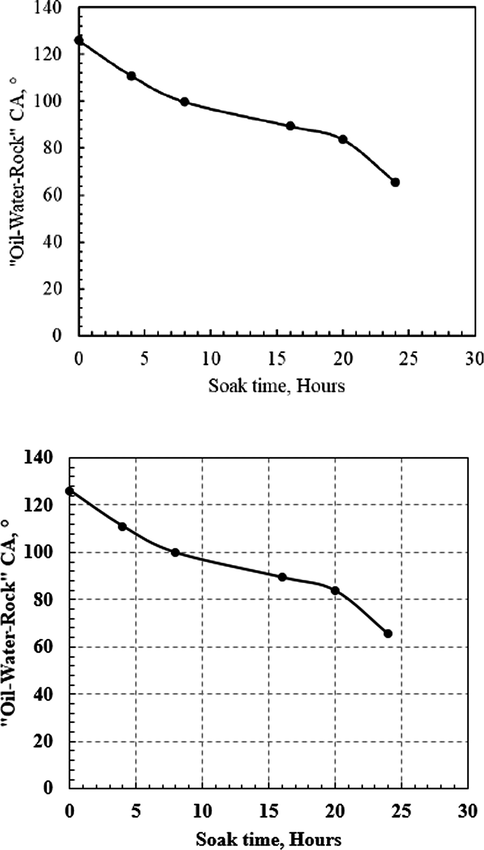

3.3 CND nano inherited regulator adaptability test

In the experiment, KT-1 reservoir core was selected to study the wetting modification effect. The core was put into crude oil, and 10 μL of water was dropped on the surface of the core using a micro-liquid shifter. The contact angle of “oil–water-core” in the original state was tested, and then the core was soaked in 0.15 wt% CND solution for different times for wetting modification. The chemically treated core was put into crude oil again, and the contact angle of oil–water-core was measured again, as shown in Fig. 14. Under the initial state, the average contact angle of oil–water-core on the core surface is equal to 126.0°. After chemical treatment, the contact angle of water drops decreases to 65.4°, indicating that the core surface changes from oil moisture to water moisture.

Oil–water-core contact angle after 0.15 wt% CND treatment.

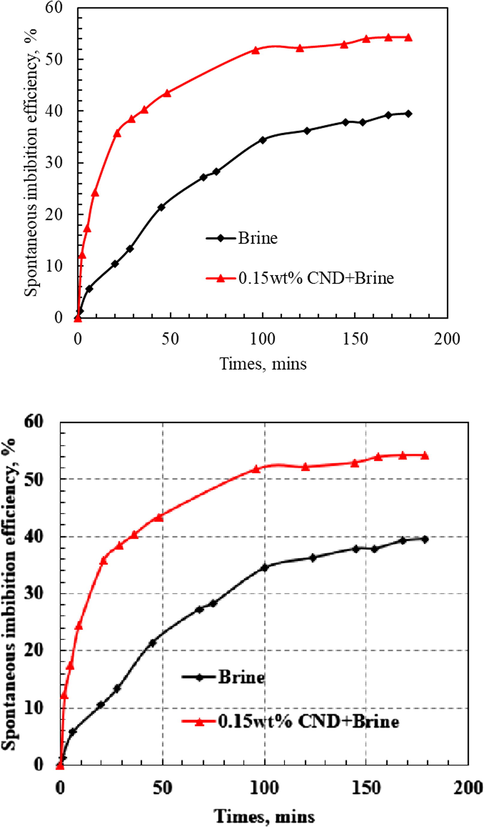

The spontaneous imbibition displacement experiment reflects the ability of nano-wetting modifier CND to displacing crude oil in low permeability reservoirs under capillary force. Fig. 15 shows the experimental results of 0.15 wt% CND spontaneous imbibition oil displacement efficiency. Before CND treatment, the spontaneous imbibition oil displacement of cores in clear water and 0.15 wt% CND were 39.51% and 54.26%, respectively. CND can improve the imbibition oil displacement efficiency by 14.76%, with significantly effective.

0.15 wt% CND spontaneous imbibition displacement efficiency.

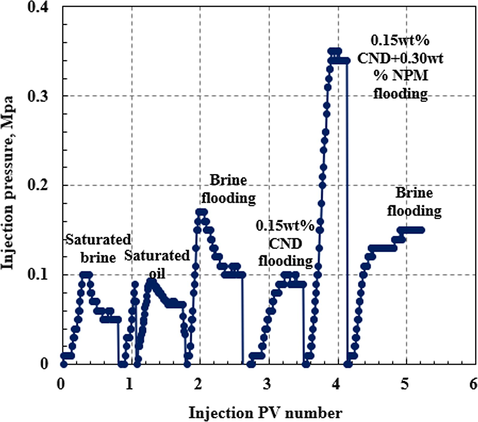

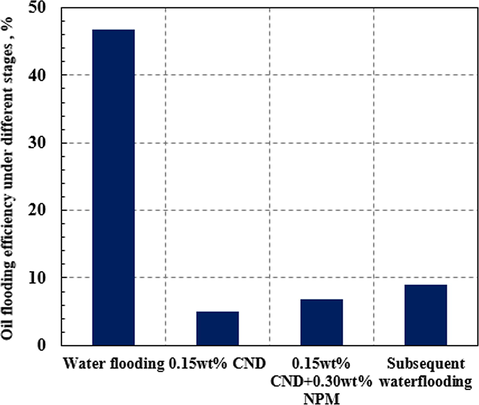

After the core is saturated with crude oil, NPM and CND are combined to conduct the flooding experiment. Fig. 16 shows the displacement pressure difference at both ends of the core at different stages. The required pressure of saturated brine is higher than that of saturated crude oil, indicating that the core belongs to oil phase wetting. Fig. 17 shows the experimental results of 0.15 wt% CND spontaneous imbibition oil displacement efficiency. The core permeability of water flooding, 0.15 wt% CND, 0.15 wt% CND + 0.30 wt% NPM and subsequent water flooding are 46.7%, 5.0%, 6.8% and 8.9%, respectively. CND and CND + NPM have the effect of further improving oil recovery, and the combination of CND and NPM has better effect on improving oil recovery. This is mainly due to the hydration and expansion of NPM in the core, plugging the macroporous throat, and improving the sweep efficiency of CND and subsequent water flooding.

Displacement pressure difference at both ends of core at different stages.

0.15 wt% CND spontaneous imbibition displacement efficiency.

Through 3.1 to 3.3, the adaptability of the three types of chemical agents with graded regulation in KT-1 reservoir of North Troyes oilfield is evaluated, showing good plugging and profile control effect. The X well group is selected for field application below.

4 Field application

4.1 Field operation procedure

For different scale fractures, step by step plugging, multi-agent and multi-slug comprehensive intervention is carried out to ensure the plugging of high-permeability channels and inhibit the seepage of large channels. It can plug channeling fracture channel, adjust secondary dominant channel and reduce matrix flow resistance, so as to expand macroscopic swept volume and improve microscopic water flooding efficiency. Firstly, channeling fracture channels in carbonate reservoirs are plugged by injecting high concentration of HR9806 emulsion polymer crosslinking system and medium concentration of HR9806 emulsion polymer crosslinking system. Then, the nano-polymer microspheres were injected to adjust the secondary dominant channeling channel. Finally, the nano-wetting modifier was injected to modify the wettability of low permeability reservoirs, reduce the flow resistance of injected water and peel the oil film on the surface of rock, and improve the subsequent water flooding recovery. In the field operation process, the formation pressure deficit of oil wells corresponding to different injection wells is quite different, so the injection volume and injection rate of chemical agents in different wells are quite different. X well group contains 6 water injection wells, different chemical injection quantity is shown in Table 2.

Type of chemical agent

X1 Well

X2 Well

X3 Well

X4 Well

X5 Well

X6 Well

0.8 wt% HR9806 + 0.15 wt% Crosslinker, m3

350

250

300

250

500

200

0.5 wt% HR9806 + 0.15 wt% Crosslinker, m3

14,000

7500

9000

5500

8000

7500

0.30 wt% NPM, m3

12,000

10,000

18,000

9000

18,000

15,000

0.15 wt% CND, m3

12,000

10,000

18,000

12,000

12,000

15,000

4.2 Stage effect evaluation

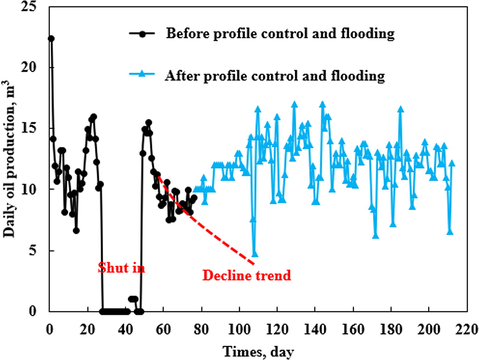

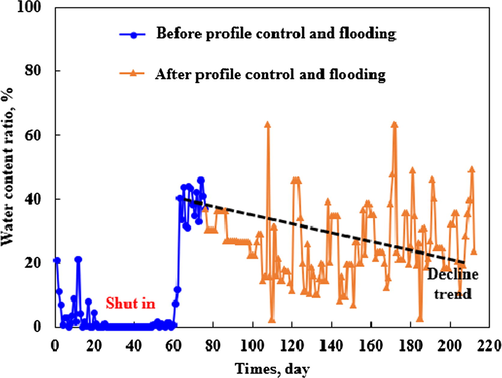

The effect before and after profile control and flooding in well X1 is shown in Figs. 18 and 19. Fig. 18 shows the oil production curve of X1 well before and after profile control and flooding. According to the curve, the oil production of X1 well decreased from initial 23 m3/d to 10 m3/d before profile control and flooding. After stage shut-in, the daily oil production decreased from 15 m3/d to 8.5 m3/d, and continued to decline. Within 140 days of comprehensive profile control and flooding, the oil production of well X1 was gradually stable and slightly increased to 13.5 m3/d, and the daily oil production was 5.0 m3/d higher than that before profile control and flooding. Fig. 19 shows the variation curve of water content of well X1 before and after profile control and flooding. According to the curve, the daily water production rate of well X1 before profile control and flooding was above 44.0 %. Within 140 days of comprehensive profile control and flooding, the daily water production rate of oil wells gradually decreased, stabilized at about 25.0 %, and the daily water production rate decreased by 19.0 %. It shows that the effect of stabilizing oil and controlling water is remarkable.

Oil production curve of Well X1 before and after profile control and flooding.

Water production rate curve of well X1 before and after profile control and flooding.

5 Summary and conclusions

In this paper, reservoir temperature of 54 °C and reservoir core of fractured carbonate reservoir in North Troyes, Kazakhstan is used as the experimental conditions, and the fractured and porous media carbonate physical models are made to comprehensively evaluate the adaptability of different profile control and flooding system in the graded regulation of the carbonate reservoir in North Troyes, and they are successfully applied to the X group of North Troyes oilfield. The main conclusions are as follows:

It is difficult to comprehensively control water channeling in pore-cave-fracture carbonate reservoirs. After mixing different types of profile control agents and conducting deep profile control, the reservoir heterogeneity in the test area is improved. At the same time, the daily oil production of oil wells in the test area is 5.0 m3/d higher than that before profile control, and the daily water production rate decreases by 19.0 %. The pilot test of deep profile control for stabilizing oil and controlling water in carbonate reservoirs has achieved preliminary results.

The recommended use of different types of chemical agents in X well group of North Troyes oilfield is as follows: The high strength gel formed by “0.80 wt% HR9806 + 0.15 wt% crosslinker” and the flexible weak gel formed by “0.50 wt% HR9806 + 0.15 wt% crosslinker” are used to block the fractured pores formed under stress. “0.30 wt% NPM + 0.15 wt% CND” was used for plugging and flooding of interparticle pores, dissolved pores and wettability heterogeneity. This paper only shows the optimized concentration of different types of chemicals, in different types of reservoirs need to be combined with the actual conditions of reservoir optimization.

Through the adaptability test of graded regulation chemicals in KT-1 reservoir and the pilot test study of X well group, continuous optimization, tracking and adjustment are carried out to explore the deep profile control system and technology suitable for carbonate reservoirs, so as to provide the basis for stabilizing oil and controlling water similar reservoirs.

Due to the high salinity of carbonate reservoirs, different types of chemical agents cannot achieve long-term effectiveness. At the same time, for low-permeability tight carbonate reservoirs, the gel injectability is poor, and the gel need replaced by other types of chemical agents.

Acknowledgments

This work is financially supported by the Cooperative Innovation Center of Unconventional Oil and Gas (Ministry of Education & Hubei Province), Yangtze University, (NO. UOG2022-01), Key Laboratory of Drilling and Production Engineering for Oil and Gas, Hubei Province, (NO. YQZC202202), Planned Project, Hubei Provincial Department of Science and Technology (Second Batch), (NO. 2021CFB249) & Project of Science and technology research, Education Department of Hubei Province (NO. Q20211303).

Credit author statement

All data in the article comes from the author, without plagiarism and copyright issues.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Experimental study of combining low salinity water flooding and preformed particle gel to enhance oil recovery for fractured carbonate reservoirs. Fuel. 2018;214:342-350.

- [Google Scholar]

- Preformed partial gel injection chased by low-salinity waterflooding in fractured carbonate cores. SPE Res. Eval. Eng.. 2019;22(1):110-121.

- [Google Scholar]

- Computed-tomography-scan monitoring of foam-based chemical-enhanced-oil-recovery processes in fractured carbonate cores. SPE J.. 2017;22(3):912-923.

- [Google Scholar]

- Che. M, Wang. Y, Peng. J. (2018). propped fracturing in deep naturally-fractured tight carbonate reservoirs. In: SPE Russian Petroleum Technology Conference, Moscow, Russia.

- Das. P, Salgaonkar. L. (2012). Laboratory evaluation of organically crosslinked polymer for water shutoff in high-temperature well applications. In: SPE Kuwait International Petroleum Conference and Exhibition, Kuwait City, Kuwait.

- Fracture-based strategies for carbonate reservoir development. In: SPE Russian Oil and Gas Conference and Exhibition. 2010.

- [Google Scholar]

- Dong. R, Wheeler. M, Ma. K, et al. (2020). A 3D acid transport model for acid fracturing treatments with viscous fingering. In: Paper presented at the SPE Annual Technical Conference and Exhibition, Virtual. SPE-201465-MS.

- Low-IFT foaming system for enhanced oil recovery in highly heterogeneous/fractured oil-wet carbonate reservoirs. SPE J.. 2018;23(6):2243-2259.

- [Google Scholar]

- Ultralow-interfacial-tension foam-injection strategy in high-temperature ultrahigh-salinity fractured oil-wet carbonate reservoirs. SPE J.. 2019;24(6):2822-2840.

- [Google Scholar]

- Prediction of mechanical stability of acidizing-induced wormholes through coupled Hydro-ChemoMechanical simulation. In: Paper presented at the 53rd U.S. Rock Mechanics/Geomechanics Symposium, New York, New York, USA. 2019. ARMA-2019-0011

- [Google Scholar]

- Enhanced oil recovery from fractured carbonate reservoirs using nanoparticles with low salinity water and surfactant: a review on experimental and simulation studies. Adv. Colloid Interface Sci.. 2021;293:102449

- [Google Scholar]

- Research and application of profile control technology in carbonate reservoir. J. Southwest Petrol. Univ. (Science & Technology Edition). 2012;34(5):5.

- [Google Scholar]

- Liu. Z, Yan. Y, Song. Z, et al. (2019). Stress distribution in ordovician carbonate rocks of the Tuofutai region in the Tahe Oilfield. In: The 53rd U.S. Rock Mechanics/Geomechanics Symposium, New York City, New York.

- Laboratory study of water shutoff in the fracture-cavity carbonate reservoir. Petrol. Explorat. Devel.. 2009;36(1):108-112.

- [Google Scholar]

- Olayiwola. S, Dejam. (2019). A comprehensive review on interaction of nanoparticles with low salinity water and surfactant for enhanced oil recovery in sandstone and carbonate reservoirs. Fuel, 241 1045–1057.

- Comprehensive experimental study on the effect of silica nanoparticles on the oil recovery during alternating injection with low salinity water and surfactant into carbonate reservoirs. J. Mol. Liquids. 2021;325:115178

- [Google Scholar]

- Wettability alteration in high-temperature and high-salinity carbonate reservoirs. SPE J.. 2013;18(04):646-655.

- [Google Scholar]

- Effect of multiple factors on preformed particle gel placement, dehydration, and plugging performance in partially open fractures. Fuel. 2019;251:73-81.

- [Google Scholar]

- Wang. Z, Zheng. J, Luo. M. (2013). A successful subsalt exploration example in the precaspian Basin. In: International Petroleum Technology Conference, Beijing, China.

- A comprehensive investigation of polymer microspheres (PMs) migration in porous media: EOR implication. Fuel. 2019;235:249-258.

- [Google Scholar]

- Controlling factors of remaining oil distribution after water flooding and enhanced oil recovery methods for fracture-cavity carbonate reservoirs in Tahe Oilfield. Petrol. Explorat. Devel.. 2019;46(04):746-754.

- [Google Scholar]

Appendix 1

(see Table 1.1).

① Simulated injection water of North Troyes, Salinity = 1685 ppm

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

191

88

13

307

Negion, ppm

339

262

12

473

② Salinity = 36,000 ppm

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

1081

253

7852

6684

Negion, ppm

1919

747

7148

10,316

③ Salinity = 57,000 ppm

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

1802

505

10,470

11,795

Negion, ppm

3198

1495

9530

18,205

④ Salinity = 70,000 ppm

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

2523

758

13,087

13,761

Negion, ppm

4477

2242

11,913

21,239

⑤ Salinity = 82,290 ppm (Simulated formation water)

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

3002

1000

15,705

15,726

Negion, ppm

5328

2960

14,295

24,274

⑥ Salinity = 90,750 ppm (Diluted saturated salt water)

Mineral species

Calcium chloride

Magnesium chloride

Potassium chloride

Sodium chloride

Kation, ppm

90

126

0

35,385

Negion, ppm

160

374

0

54,615

Appendix 2

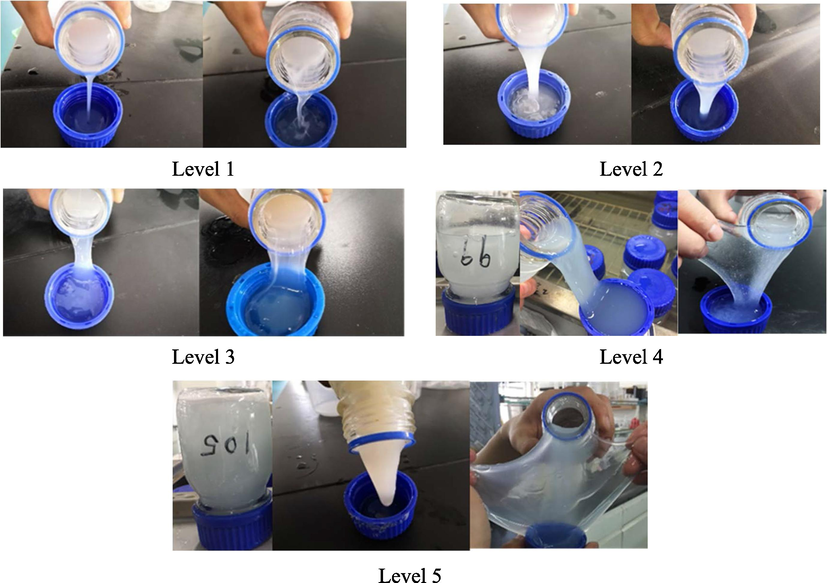

The common visual code method for judging the strength of polymer gel is suitable for strong gel, and the criterion of gel strength of weak gel should be reclassified to judge the strength of weak gel. On the basis of the phenomena observed in the repeated experiments, it can be divided into five strength levels: Level (solution), level 2 (solution has a certain viscosity, but without forming gel system), Level 3 (part of the solution in gel state, the rest to solution state), Level 4 (mesh gel solution fully formed, but weak gel, unable to form the phenomenon of wall hung), Level 5 (solution completely mesh gel state formation, high gel strength, can form the hanging wall).

(see Fig. 21).

Division and description of five levels of weak gel strength.