Translate this page into:

Sustainable management of alkaline battery waste in developing countries by waste reduction and metal recovery development: A cost-benefit study based on waste flow analysis to select the optimum scenario

⁎Corresponding authors. a.esrafili@iums.ac.ir (Ali Esrafili), gholamim@iums.ac.ir (Mitra Gholami)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University. Production and hosting by Elsevier.

Abstract

Alkaline batteries are one of the most used types of household batteries. The annual consumption of billions of alkaline batteries produces battery wastes that are not recycled in most countries. In this study, alkaline battery waste management status was investigated by defining an economic model based on cost-benefit analysis. Scenarios for improving the current situation by combining battery waste reduction methods and developing battery waste recycling units were compared using this financial model. The results showed that 24 tons of solid wastes from three sizes of alkaline batteries were landfilled annually, which caused 4.52 tons of zinc to leak into the environment. The cost-benefit of zinc recovery from the alkaline batteries was estimated by 73.1 USD/kg. Based on this, the study estimates that the linear management of alkaline battery waste results in an annual financial potential loss of 198,832 USD. 30% reduction in battery wastes by replacement of rechargeable batteries and the development of battery waste processing units to 50% of the current potential will reduce the annual release of zinc to the environment by 0.9 tons and the annual net income will be equivalent to 131,229 USD. Changing the management of alkaline battery wastes from a linear economy to a material recovery cycle will have a positive financial balance in addition to reducing environmental damage.

Keywords

Life cycle cost

Solid waste management

Battery waste

1 Introduction

The use of household electrical and electronic equipment such as remote controls, toys, watches, mobile phones, laptops, and the like has caused the use of batteries to increase. Batteries are divided into two general groups, including non-rechargeable disposable primary and rechargeable batteries (Ebin et al. 2019). Non-rechargeable batteries, of which alkaline batteries are one type, have a higher ratio in household use (Kalmykova et al. 2017, Terazono et al. 2015). These batteries have three different sizes, known as AA, AAA, and AAAA. In the past, these types of batteries, in addition to zinc and manganese, contain other metals such as mercury, which caused household battery waste to be classified as hazardous waste, but today, Hg-free alkaline batteries are produced (Briffaerts et al. 2009). However, the ratio of alkaline batteries in battery consumption is estimated at 60%, and estimates of the increase in the consumption of this type of battery up to 9 billion units per year cause a serious concern about the environmental consequences of battery wastes (da Silveira Leite et al. 2019, Ebin et al. 2016).

Although the use of alkaline and non-rechargeable batteries has spread all over the world, the control of its environmental consequences is not serious, especially in developing countries. For example, it was reported that every citizen of the United States consumption 10 alkaline batteries every year, in Canada, more than 671 million non-rechargeable batteries were sold in one year, and in the United Kingdom, the weight of alkaline battery waste in one year reached about 12 tons (Fisher et al. 2006, Malavika 2004). However, the low proportion of non-rechargeable batteries and alkaline batteries in the municipal solid waste has caused the importance of battery waste management to be neglected. This situation is more common in developing countries that have a low source suppression rate (Esmaeilizadeh et al. 2020, Helen et al. 2013).

One of the problems caused by alkaline batteries is their very short life time due to non-rechargeability, which results in a large amount of battery waste (da Silveira Leite et al. 2019). Battery waste is known as a hazardous waste due to the presence of heavy metals such as mercury and lead (Vellingiri et al. 2018), so their landfill with municipal solid waste is considered a threat to water resources and the environment. The entry of heavy metals such as lead, mercury, and zinc from battery waste and other types of solid waste containing these pollutants into the food chain and causing health complications for humans has been proven (Sadeghi Poor Sheijany et al. 2020, Torkashvand et al. 2021b). However, in many countries there is still no proper program for battery waste management. But a promising point in battery waste management is the ability to metals recovery from this type of waste.

Although the recycling of battery waste with the aim of metals recovery is a potential to improve the current situation, there are problems in this purpose in developing countries. Many developing countries such as Brazil and Iran do not have a plan to recycle this type of battery and alkaline battery wastes are landfilled (Alavi et al. 2015, da Silveira Leite et al. 2019). But metals such as zinc and manganese have caused these wastes to be a suitable case for recycling as a secondary source of metals (Anholeti et al. 2022, Deep et al. 2016). Numerous studies were done to zinc recovery from this type of waste, which can be considered as a waste reduction method (De Souza &Tenório 2004, Lannoo et al. 2019). There are various methods of metal recovery from solid waste, the most widely used method for alkaline batteries is acid leaching, which has an easy operating (Ahmadipour et al. 2011, de Souza et al. 2001).

Although the recovery of metals such as zinc from alkaline battery waste can have a good income and is a solution for alkaline battery waste management, but choosing this option must be done based on detailed analysis. The widely used techniques in choosing cost-effective methods in solid waste management include life cycle cost and material flow analysis (Islam & Huda 2019, Torkashvand et al. 2021a). This study was conducted with the aim of investigating the current status of alkaline battery wastes management in Iran and economic evaluation of alternative options. The main aim of this study was to create a decision support tool, which was done by defining four scenarios to alkaline battery wastes reduction and economic evaluation of each scenario based on waste flow analysis.

2 Method

2.1 Study area and quantitative data

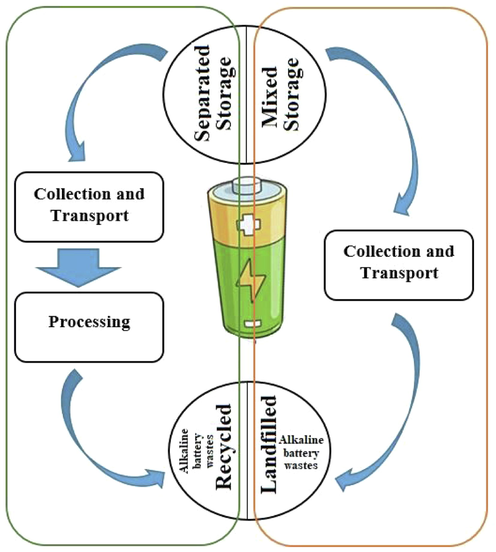

This study was conducted on the consumption of alkaline batteries (AA, AAA, AAAA) in Iran and their waste management. The physical scope of the study included the entire Iranian market. The life cycle border of the study included the battery waste production to its landfill (Fig. 1). Alkaline battery waste quantity data was calculated by monitoring their consumption market in Iran using information registered in government trade institutions. Alkaline battery waste routes were identified by evaluating the general solid waste routes in Iran and interviewing the waste management organization based on tested methods (Torkashvand et al. 2021a). The ratio of each of the identified routes of battery waste quantity was estimated by interviews with formal and informal waste management staffs and physical analysis recorded in waste management organizations. Due to the proper efficiency of the material flow analysis technique in determining the quantity of solid waste and its economic estimation (Cochran & Townsend 2010, Makarichi et al. 2018, Turner et al. 2016), waste flow analyzes were performed in each of the identified routes. The alkaline battery waste flow analysis border according to the model of Fig. 1 started from the waste storage and included the further steps of waste management including collection, transportation, processing, and landfill. Economic data for alkaline battery waste management steps at the study border were taken from recycling industries, government agencies, and interviews with informal workers in 2022 (Torkashvand et al. 2021a). Due to the fact that the structural components of the three batteries is different, the weight ratio of zinc in each of the types of batteries studied was measured and the subsequent financial analyzes were calculated based on the weight ratio of the batteries and proportional to the share of each in the annual battery consumption in Iran.

The economic border of the study.

2.2 Economic model

The cost-benefit of battery waste management in this study was based on the zinc recovery income from alkaline battery recycling and waste management costs include the collection to the landfill (Cucchiella et al. 2014). The financial model was defined based on the experiences of using life cycle cost studies in municipal solid waste management and was calculated separately for each of the identified routes (McDougall et al. 2008, Trifa et al. 2022). The final financial model listed below is based on the formulas proposed by Torkashvand et al. 2020 was defined in five sections and calculated for each of the routes as well as in presumed scenarios to improve the current situation (Torkashvand et al. 2021a).

Where Tsc is total storage cost, Bn is number of batteries, Bd is density of batteries, Oc is operating cost, Mc is maintenance cost, and Py is years of project.

Where Tctc is total collection and transport cost, Bw is weight of batteries, Mw is weight of collected municipal solid waste, Tvc is total vehicle cost, and Lc is labor cost.

Where Tlc is total landfill cost, Lic is total landfill investment cost, and Loc is landfill operating cost.

Where Trc is total recycling cost, Mc is material cost, and Ec is energy cost, and Eqc is equipment cost.

Where Tc is total cost, and Zp is Zinc price.

2.3 Scenarios

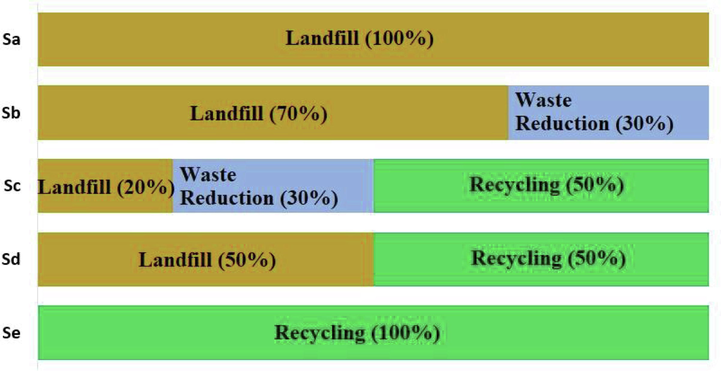

In this study, in addition to evaluating the current status of alkaline battery wastes management, four scenarios were assumed to evaluate the economic consequences of changes in alkaline battery wastes management. Five scenarios that included current conditions and four assumed scenarios were evaluated based on the financial model defined above. The scenarios were defined with variables including the change in the ratio of recycling to landfill, as well as the replacement of a proportion of alkaline batteries with rechargeable batteries as a solution to waste reduction. As shown in Fig. 2, the first scenario (Sa) included the current situation where all the battery wastes were landfilled. The second scenario (Sb) consisted of replacing 30% of non-rechargeable batteries with rechargeable batteries and landfilling the remaining 70%. In the third scenario (Sc), in addition to replacing 30% of alkaline batteries with rechargeable batteries, recycling of 50% of non-rechargeable batteries was assumed, and the landfill volume in this scenario was 20%. In the fourth scenario (Sd) without changing the type of batteries, it was assumed that 50% of the current volume of the landfilled batteries would be reduced by recycling. And in the fifth scenario (Se), it was assumed that in a long-term program with the development of the battery recycling industry, all the alkaline battery wastes will be recycled. An important point in scenarios is the service life of rechargeable batteries. Based on this, the scenarios will include two categories, which include improving the situation in the short term and achieving sustainable management in the long term. In the second category, all non-rechargeable and rechargeable batteries will be recycled, which is assumed to be the best case in Sd. While in the first category, a portion of both types of batteries will be landfilled, which is assumed in the Sb and Sc scenarios.

Current status (Sa) and assumed scenarios (Sb-Se).

3 Results and discussion

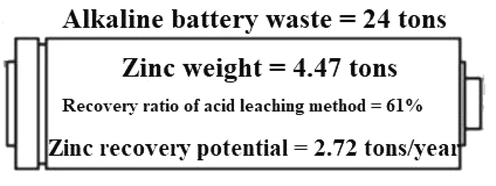

As shown in Table 1, two million of the types of alkaline batteries were sold in the studied area every year, and the same amount of alkaline battery wastes were produced. The results showed that the types of alkaline batteries had a different share of consumption. AA batteries had the highest ratio among the studied batteries and constituted 60% of the total consumption per year. According to the average weight of the studied batteries, the waste weight of AA, AAA, and AAAA batteries was estimated to be 15.6, 6.6, and 1.8 tons/year, respectively. Therefore, 24 tons of alkaline battery wastes were produced. Also, according to the weight ratio of the anode in the alkaline batteries, the weight of the metal anode of battery waste was estimated to be 6.4 tons/year, include share of AA, AAA, and AAAA batteries by 4.2, 1.8, and 0.41 tons/year, respectively. The analysis of anode in the alkaline batteries showed that the weight ratio of zinc in them was equal to 70%. Therefore, the zinc recovery potential in the alkaline battery wastes was estimated as 4.47 tons/year, and the share of AA, AAA, and AAAA batteries respectively 2.9, 1.2, and 0.33 tons/year. The results of zinc recovery by acid leaching method showed that, 61% of zinc in alkaline battery wastes could be recovered (Fig. 3).

Battery type

Annual consumption (million)

Average weight (grams)

Waste weight (tons)

Zinc weight (tons)

AA

1.2

13

15.6

2.9

AAA

0.6

11

6.6

1.2

AAAA

0.2

9

1.8

0.33

Zinc recovery potential from alkaline battery wastes management.

According to the country's population, the per capita alkaline battery wastes was 0.27 g/year which was very low compared to the per capita production of 640 g of municipal solid waste per day (Torkashvand et al. 2021a). But this was more than the 11.8 tons of alkaline batteries consumed in the United Kingdom in 2003 (Fisher et al. 2006). But that was less than the 671 million non-rechargeable batteries sold in Canada in 2007. The per capita consumption of alkaline batteries was 0.02 per year, which is much lower than the per capita consumption of 10 alkaline batteries per year in the United States (Malavika 2004). Therefore, the studied battery wastes constitute a very small share of the total municipal solid waste. The low amount of alkaline battery wastes compared to other components of municipal solid waste has caused its proper management to be neglected and this type of waste is landfilled in a short cycle. These conditions are also seen in the case of some other types of municipal solid waste. For example, the low weight ratio and small size of cigarette butts as one of the important urban litter, one of the reasons for neglecting its proper management (Torkashvand et al. 2020).

Another reason for landfilling alkaline battery wastes is the lack of source separation for this type of waste. The results showed that the alkaline battery wastes were not separated as a recyclable waste by citizens, and all batteries were disposed of mixed with other components of municipal solid waste. Different studies showed that the ratio of source separation in developing countries is low (Helen et al. 2013, Hemmati et al. 2019). In Iran, the participation of citizens in the source separation of solid waste has been stated in different studies as less than 30% (Esmaeilizadeh et al. 2020, Nasrabadi et al. 2008). However, the activity of informal waste management in developing countries has created an opportunity to separate some types of waste and recycle them (Diaz &Otoma 2014, Yousafzai et al. 2020). For example, the impact of waste pickers' activity in plastic waste recycling in one of the cities of Iran was reported by 38% (Torkashvand et al. 2021a). The result of the interview with the waste pickers showed that informal recycling routes did not tend to separate the alkaline battery wastes. Therefore, all the alkaline battery wastes entered the landfill. These conditions, which were observed in Sa, caused 24 tons of alkaline battery wastes ewer landfilled. Therefore, every year 6.46 tons of metal anodes containing 4.47 tons of zinc were removed from the recycling rout. Also, the results showed that there was no specialized recycling center for the alkaline battery wastes. Despite the presence of significant amounts of metal in the alkaline battery wastes and the economic value of their recovery (Shin et al. 2007, Vellingiri et al. 2018), the reluctance to separate this type of waste even by waste pickers indicated the lack of metal recovery industries and other recycling methods related to alkaline battery wastes.

A serious concern about the current status of alkaline battery waste management is environmental pollution. Although the Basel convention has classified only batteries containing cadmium, lead, and mercury as hazardous waste (Kuchhal & Sharma 2019), alkaline battery waste containing zinc and manganese can cause these metals to leak into the environment. Zinc has health effects including kidney damage and cancer, and can have environmental consequences, including liver-related diseases in animals and effects on their growth process (Kuchhal & Sharma 2019). Therefore, in the current status of alkaline battery waste management, which is detailed in Sa, every year 4.47 tons of zinc landfilled, which has a serious potential in soil and water pollution and the possibility of its transfer to citizens by food chain. Landfilling wastes with the potential to release zinc will increase the concentration of this metal in the landfill leachate and will increase its management costs and the resulting health and ecological risk. In some researches in Iran, zinc had the highest concentration in landfill leachate among heavy metals, but its main origin was related to the geological structure of the region (Sadeghi Poor Sheijany et al. 2020). However, the impact of solid waste composition on the concentration of metals in landfill leachate was emphasized by researchers. For example, the landfilling cigarette butts with municipal solid waste leads to increase of metals such as lead, cadmium, and zinc in landfill leachate (Torkashvand et al. 2021b).

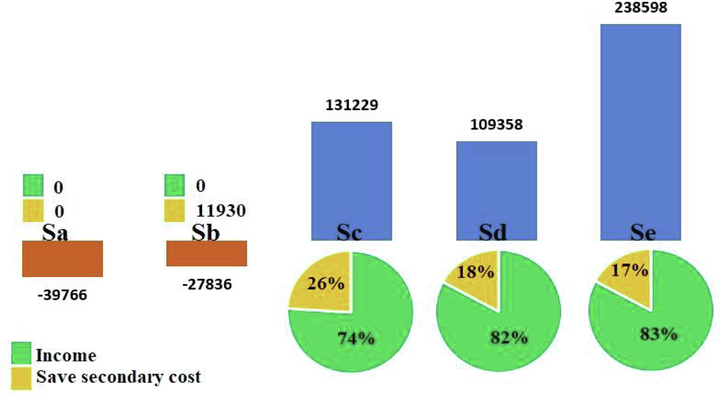

Regardless of waste management costs including storage to landfill, the financial balance of the alkaline battery waste processing steps was positive. Calculation of battery waste management costs with the aim of zinc recovery based on Eqs. (1)–(5) showed, the cost of alkaline battery waste processing and the price of recovered zinc were 57.7 USD and 130.8 USD per kilogram, respectively. Therefore, the financial balance of zinc recovery from the alkaline battery waste was calculated 73.1 USD per kilogram. As shown in Table 2, in Sa due to the lack of source separation and recycling industry, about 4.5 tons of zinc were landfilled annually. Meanwhile, this value was 3.16 tons, 0.9 tons, 2.2 tons, and 0 in the second to fifth scenarios, respectively. Therefore, Sa due to non-recovery was the worst environmental scenario as well as cost-benefit. But as shown in Fig. 4, the best economic conditions were observed in Se, which included the ideal conditions in recycling the all alkaline battery wastes. In this scenario, the annual cost-benefit balance of alkaline battery waste management was 238,598 USD. As shown in Fig. 4, the scenarios that have a positive cost-benefit balance are marked with a blue column, while the scenarios that have a negative cost-benefit balance are marked with a brown column. Therefore, in addition to the positive impact on environmental protection and reducing the emission of pollution from solid waste, the third to fifth scenarios were also economically attractive. In Sc and Sd, the cost-benefit balance of alkaline battery waste management was estimated 131,229 USD and 109,358 USD respectively. Also, after Se, which included the ideal conditions to achieve long-term goals, Sc had the best environmental protection conditions by applying the best combination of alkaline battery consumption management with the aim of waste reduction and alkaline battery waste recycling to achieve short-term goals. Therefore, Sc can be considered as a short-term goal and Se can be considered as a long-term goal of changing program in the battery waste management in Iran.

scenarios

Landfilled battery waste (tons)

Reduced battery waste (tons)

Recycled battery waste (tons)

Recovered zinc (tons)

Sa

24

0

0

0

Sb

16.8

7.2

0

0

Sc

4.8

7.2

12

1.36

Sd

12

0

12

1.36

Se

0

0

24

2.72

Cost-benefit status of different scenarios (USD).

Waste reduction policies will have a great impact on reducing the subsequent costs of waste management and the volume of landfilled waste per day (Guo et al. 2021). The change in consumption pattern assumed in this study by replacing alkaline batteries with rechargeable types in Sb and Sc can reduce the volume of landfilled battery waste without the need to develop recycling units. This method was presented as a successful example in other studies. For example, the reduction of landfilled waste by applying the waste reduction method in an Indonesian city was estimated by 25% after 1–3 years and 50% after 8–15 years (Sudibyo et al. 2017). In this study, by changing the consumption pattern and replacing 30% of alkaline batteries with rechargeable batteries, it was estimated that landfilling of zinc will be reduced by 1.36 tons, which can be effective in reducing the concentration of this metal in leachate and pollution of soil and water resources. Therefore, combining recycling methods and waste reduction methods can be effective as complementary tools in improving the status of solid waste management, including the alkaline battery wastes (Guo et al. 2021). This condition was also observed in Sc, which led to a reduction of 3.61 tons of zinc landfilling.

A change in the management of the alkaline battery wastes by development of recycling and waste reduction can have positive economic consequences. In the current situation, although the costs of the alkaline battery wastes management included a very low ratio of the total solid waste management costs, but the lack of zinc recovery from this type of waste had a lost equivalent to 198,832 USD per year. This loss was calculated based on the net income of zinc recovery by 73.1 USD per kilogram. Changing the management of other components of municipal waste has had a similar effect on cost-benefit. For example, Torkashvand et al. 2021, by evaluating the cost benefit of different plastic waste management scenarios in Iran, showed that in the best scenario, the financial balance of plastic waste management increased by 89% (Torkashvand et al. 2021a). Also, reducing pollutant emissions through increasing zinc recovery and reducing landfilling of the alkaline battery wastes is effective in reducing environmental costs. In a study in Sri Lanka, the costs of the emission of gas pollutants in the waste management program were calculated, which showed that 55% of the life cycle cost of municipal waste management in this country is related to environmental costs, and the share of capital and operating costs were 3% and 41% respectively (Menikpura et al. 2012). Therefore, in addition to the lost income in Sa, which includes the current method of alkaline battery waste management, the subsequent environmental costs, which include the control of metal in water and soil sources, as well as the control of diseases related to pollutant leakage from alkaline battery waste must be considered. this results are shows importance of replacing the current situation with one of the second to fifth scenarios.

The strengths and limitations in this study can be consider in future similar research. Investigating the direct costs of battery waste management and the financial potential of recovering heavy metals from it was one of the strengths of this study. Also, defining different scenarios based on local conditions to improve the current status in the short term and achieve sustainable management of these hazardous wastes in the long term and comparing their subsequent financial results can be considered another strength of this study. However, an important limitation of this study was the lack of investigation of indirect environmental consequences caused by the leakage of heavy metals from landfilled batteries into water sources. Also, the indirect economic consequences of the current status of battery waste management in developing countries, such as the treatment costs of polluted water, can be considered in future studies. Identifying the increase in the concentration of heavy metals in the leachate affected by the presence of batteries in the landfilled wastes and the potential increase in pollution in the affected water in accordance with water standards for different uses can be considered in future studies.

4 Conclusion

Waste management of alkaline batteries in Iran was studied. The results showed that in the current situation, two million batteries are sold per year in Iran, which are landfilled after consumption in a short cycle. 24 tons of battery waste were landfilled annually in Iran due to the lack of source separation, the lack of battery recycling units, and the neglect of proper management of these wastes due to their insignificant ratio in the municipal solid waste. These conditions have led to the potential threat of annual leakage of 4.5 tons of zinc from landfilled alkaline battery waste into the environment. Comparison of assumed scenarios to replace the current situation with methods based on alkaline battery waste reduction and zinc recovery program showed that all assumed scenarios had a better financial balance than the current situation. Se was the best scenario that has the highest income, while after that Sc had a better situation than other scenarios, but in terms of secondary cost savings, Sc was the best scenario. Improving management of alkaline battery wastes is possible by changing the consumption pattern and replacing alkaline batteries with rechargeable types or developing waste recycling units for alkaline batteries or a combination of two methods. Changing the management method of alkaline battery wastes in the best scenario will lead to an annual income equivalent to 198,832 USD.

Acknowledgment

The authors gratefully acknowledge the financial support given by the Iran University of Medical Sciences, Tehran, Iran (Grant Number: 1400-3-2-22314; Ethics Code: IR.IUMS.REC.1400.1255).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Synergistic effect of D2EHPA and Cyanex 272 on separation of zinc and manganese by solvent extraction. Sep. Sci. Technol.. 2011;46:2305-2312.

- [Google Scholar]

- Waste electrical and electronic equipment (WEEE) estimation: A case study of Ahvaz City, Iran. J. Air Waste Manag. Assoc.. 2015;65:298-305.

- [Google Scholar]

- Zn/ZnO heterostructures photocatalyst obtained by sustainable processes from alkaline batteries waste: Synthesis, characterization and application. Mater. Chem. Phys.. 2022;284:126058

- [Google Scholar]

- Waste battery treatment options: comparing their environmental performance. Waste Manag.. 2009;29:2321-2331.

- [Google Scholar]

- Estimating construction and demolition debris generation using a materials flow analysis approach. Waste Manag.. 2010;30:2247-2254.

- [Google Scholar]

- Implementation of a real option in a sustainable supply chain: an empirical study of alkaline battery recycling. Int. J. Syst. Sci.. 2014;45:1268-1282.

- [Google Scholar]

- Hydrometallurgical recovery of Zn (II) and Mn (II) from alkaline batteries waste employing aqueous two-phase system. Sep. Purif. Technol.. 2019;210:327-334.

- [Google Scholar]

- Characterization of used alkaline batteries powder and analysis of zinc recovery by acid leaching. J. Power Sources. 2001;103:120-126.

- [Google Scholar]

- Simultaneous recovery of zinc and manganese dioxide from household alkaline batteries through hydrometallurgical processing. J. Power Sources. 2004;136:191-196.

- [Google Scholar]

- A facile chemical route for recovery of high quality zinc oxide nanoparticles from spent alkaline batteries. Waste Manag.. 2016;51:190-195.

- [Google Scholar]

- Cost–benefit analysis of waste reduction in developing countries: a simulation. J. Mater. Cycles Waste Manage.. 2014;16:108-114.

- [Google Scholar]

- Production of zinc and manganese oxide particles by pyrolysis of alkaline and Zn–C battery waste. Waste Manag.. 2016;51:157-167.

- [Google Scholar]

- Recovery of industrial valuable metals from household battery waste. Waste Manag. Res.. 2019;37:168-175.

- [Google Scholar]

- Key informants’ perspectives on the challenges of municipal solid waste management in Iran: a mixed method study. J. Mater. Cycles Waste Manage.. 2020;22:1284-1298.

- [Google Scholar]

- Battery waste management life cycle assessment. Environmental Resources Management ERM Ltd.; 2006.

- Solid waste management in China: Policy and driving factors in 2004–2019. Resour. Conserv. Recycl.. 2021;173:105727

- [Google Scholar]

- Waste source separation planning by cost-benefit analysis in Tehran-Iran. J. Environ. Earth Sci.. 2013;3:113-125.

- [Google Scholar]

- Effects of source separation education on solid waste reduction in developing countries (a case study: Ardabil, Iran) The Journal of Solid Waste Technology and Management. 2019;45:267-272.

- [Google Scholar]

- Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. Journal of Environmental Management. 2019;244:344-361.

- [Google Scholar]

- Portable battery lifespans and new estimation method for battery collection rate based on a lifespan modeling approach. Resour. Conserv. Recycl.. 2017;120:65-74.

- [Google Scholar]

- An environmentally friendly closed loop process to recycle raw materials from spent alkaline batteries. J. Clean. Prod.. 2019;236:117612

- [Google Scholar]

- Material flow analysis as a support tool for multi-criteria analysis in solid waste management decision-making. Resour. Conserv. Recycl.. 2018;139:351-365.

- [Google Scholar]

- Environmental effects associated with battery disposal. Frost and Sullivan. 2004;28

- [Google Scholar]

- Integrated solid waste management: a life cycle inventory. John Wiley & Sons; 2008.

- Sustainability assessment of municipal solid waste management in Sri Lanka: problems and prospects. J. Mater. Cycles Waste Manage.. 2012;14:181-192.

- [Google Scholar]

- Evaluating citizen attitudes and participation in solid waste management in Tehran, Iran. J. Environ. Health. 2008;71:30-33.

- [Google Scholar]

- Evaluation of heavy metal contamination and ecological risk of soil adjacent to Saravan municipal solid waste disposal site, Rasht, Iran. Environ. Monit. Assess.. 2020;192:757.

- [Google Scholar]

- Development of metal recovery process from alkaline manganese batteries in sulfuric acid solutions. Materials Transactions. 2007;48:244-248.

- [Google Scholar]

- Municipal solid waste management in Indonesia-A study about selection of proper solid waste reduction method in DI Yogyakarta Province. Energy Procedia. 2017;143:494-499.

- [Google Scholar]

- Battery collection in municipal waste management in Japan: challenges for hazardous substance control and safety. Waste Manag.. 2015;39:246-257.

- [Google Scholar]

- Littered cigarette butt as a well-known hazardous waste: a comprehensive systematic review. Journal of Hazardous Materials. 2020;383:121242

- [Google Scholar]

- Analysis of cost–benefit in life-cycle of plastic solid waste: combining waste flow analysis and life cycle cost as a decision support tool to the selection of optimum scenario. Environ. Dev. Sustain.. 2021;23:13242-13260.

- [Google Scholar]

- Effect of cigarette butt on concentration of heavy metals in landfill leachate: health and ecological risk assessment. J. Environ. Health Sci. Eng.. 2021;19:483-490.

- [Google Scholar]

- Trifa, S., Loukil, T.M., Louati, A. 2022. Review of Solid Waste Collection Cost and Route Optimization in Developing Countries, In: 2022 14th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA). IEEE, pp. 1-9.

- Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. Journal of cleaner production. 2016;129:234-248.

- [Google Scholar]

- The utilization of zinc recovered from alkaline battery waste as metal precursor in the synthesis of metal-organic framework. J. Clean. Prod.. 2018;199:995-1006.

- [Google Scholar]

- Sustainability of waste picker sustainopreneurs in Pakistan’s informal solid waste management system for cleaner production. J. Clean. Prod.. 2020;267:121913

- [Google Scholar]