Translate this page into:

Quaternary ZrCuCa-based thin films metallic glasses deposited by cathodic arc deposition

⁎Corresponding author. alinava@inoe.ro (Alina Vladescu (Dragomir))

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The current study’s aim is to obtain quaternary ZrCuCa based thin films using a physical vapor deposition method (PVD) - cathodic arc approach – in order to improve the surface properties of 316L stainless steel and Ti6Al4V implantable materials. The developed ZrCuCa-based layers could be potential candidates in the medical industry if they are able to combine their exceptional mechanical properties with the corrosion resistance of amorphous metallic glasses. Furthermore, addition of Mo, Mg, Si, and Sr was taken into consideration for the ZrCuCa structure and the resulted quaternary systems were analysed in detail, through electrochemical tests and bioactivity assay, which were carried out in synthetic body fluid (SBF) at human body temperature (37 °C). Surface morphology and roughness of the specimens before and after the tests were also evaluated. The results showed that regardless the substrate type, the roughness of the surface has increased for all coatings from 19 nm for 316L, and 50 nm for Ti6Al4V, to 2000 nm). The adhesion of obtained coatings was reached from 8 N to 18, the coatings on Ti6Al4V alloy was found to be from 12 N to 18 N, while on 316L steel was from 8 N to 15 N, indicating that the coatings deposited on Ti alloy have a better adhesion. The corrosion current density parameter for ZrCuCaMo and ZrCuCaMg sjowe the lowest value (316L: 21.99 µA/cm2 and 11.37 µA/cm2; Ti6Al4V: 1.62 µA/cm2 and 13.37 µA/cm2), indicating the best corrosion resistance. The mass evolution of the coatings deposited on 316L was ranged from the −0.47 mg to 1.37 mg, while for those deposited on Ti6Al4V, the values were ranged from −0.08 mg to 2.66 mg, indicating a degradation and biomineralization process, respectively. In conclusion, the electrochemical studies and bioactivity experiments demonstrated that the suggested coatings improve the substrate’s behaviour in simulated conditions, highlighting their potential as biomaterials.

Keywords

Cathodic arc

Electrochemical behaviour

Metallic glasses

Coatings

1 Introduction

Materials applicability, along with the design of a large diversity of medical devices is among the most fascinating, intriguing, and rewarding research fields within the materials science and engineering domain (Beck et al., 2019; Lee et al., 2020; Miao et al., 2023; Wang et al., 2022). The development and exploitation of ceramic materials for bone repair and reconstruction have marked a significant advancement in the evolution of medical materials over the last decades (Fernandes et al., 2017; Zhou et al., 2023; Wang et al., 2022; Sadeghzade et al., 2022). For instance, the healthcare sector has traditionally employed ceramics and glasses for diagnostic equipment, chemical wares, eyeglasses, thermometers, and also for fibre optics in endoscopy (Dorozhkin, 2010; Best et al., 2008).

The most utilized class of biomaterials in medical applications, especially in orthopaedic surgery, is the metallic ones, because they have advantages over ceramic and polymeric ones, such as increased tensile strength and fatigue resistance (Rousselle et al., 2020; Ovid’ko et al., 2018; Abd-Elaziem et al., 2022). Biomedical implants have been made from a variety of metallic materials, including stainless steel, titanium alloys, and Co-Cr alloys (Priyadarshini et al., 2019; Anne et al., 2019; Matusiewicz, 2014).

Stainless steel can be used for procedures such as orthopaedic prosthesis and for the treatment of hard tissue fractures (Rousselle et al., 2020; Bekmurzayeva et al., 2018; Zhang et al., 2022). Particularly renowned for its excellent fatigue characteristics, ductility, and work hardenability is 316L. The low blood compatibility and a continuous inability to integrate with body tissue are both present in their biological applications. When there is insufficient oxygen to maintain the passive film and the crevices form, 316L is more likely to corrode in those areas of the body (Anne et al., 2019), this being one of its main drawbacks in medical applications.

Commercially pure titanium (cp Ti) and its alloys, of which Ti-6Al-4 V, are the most known and used metallic biomaterials, due to their exceptional corrosion resistance, high strength, low density, and bioinert character, being able to form a stable thin oxide layer on their surface (Pimenov et al., 2021; Li et al., 2020; Harun et al., 2018; Aufa et al., 2022; Tardelli et al., 2020). Although Ti and its alloys present several advantages, the relative low hardening coefficient that these materials maintain canot be neglected, since common strengthening mechanisms such as work hardening may prove quite difficult to apply. Moreover, in the case of Ti6Al4V alloy, concerns regarding its long-term cytotoxicity due to the released of V and Al ions, which may enter the bloodstream, should also be considered (Anne et al., 2019; Shah et al., 2016). Vanadium is known to have toxic effects in V4+ and V5+ elemental state and as oxides, such as vanadium pentoxide (V2O5) (Montiel-Flores et al., 2021; Domingo, 1996). Considered with a lower toxic effect than V, Al has been mainly associated with some age-related neurodegenerative diseases such as Alzheimer (Bondy, 2016; Bondy, 2010).

The key drivers of this development appeared to be the social obligations to provide a higher quality of life as well as the rise in life expectancy. The interest in materials used in this class of medical implants has been marked by a notable rise in the number of publications and patents in the field, as well as an increasing number of significant international conferences (Dorozhkin, 2010).

The hard bone tissue is a sophisticated living tissue made of an organic phase, in which collagen is the main component and an inorganic phase, in which the main components, are the hydroxyapatite (HAp) crystals. Although the skeletal system is essential for the support and movement of humans as well as for protecting their critical organs, it is prone to fractures due to trauma and/or degenerative illnesses, which are frequently linked to aging. Thus, it canot be neglected that the bones of elderly individuals are more prone to fractures due to the lower bone density and strength. Therefore, since the beginning of time, and especially nowadays, when an increment of the population age worldwide is observed, has this led to a higher demand of the hard tissue treatment/healing (Best et al., 2008).

The demand for orthopaedic implants is rising due to several variables. Osteoporosis and osteoarthritis are bone-related disorders mostly brought on by the pronounced aging of the population. However, there has been an increase in recent years in various diseases linked to inactivity, a bad diet, which lead to an increased demand for implants. Additionally, the rising number of auto accidents and sports-related injuries has had a significant impact on the market. In the upcoming years, it is anticipated that the market for orthopaedic devices would expand (Garrido et al., 2021).

The fundamental difficulty in using biomaterials in medicine is finding a material to replace the damaged old bone that will last the patient's remaining years and, ideally, can be naturally replaced by growing new bone. In these cases, the lack of harmful reactions to the human body is the main criterion to classify the intervention as successful (Best et al., 2008).

The surface of the implantable materials can now be functionalized through different surface modification methods, such as thin films, which can improve the properties that include, but no limit to biocompatibility, mechanical strength, and resistance to biodegradation (Miao et al., 2023; Fernandes et al., 2017; Zhou et al., 2023; Wang et al., 2022; Sadeghzade et al., 2022; Bekmurzayeva et al., 2018; Rajan and Arockiarajan, 2021; Sawyer et al., 2020; Freund et al., 2003; Montazerian et al., 2022).

The ideal implant should be resistant to deterioration, favour/facilitate osseointegration and inhibit bacterial adhesion (Thanka Rajan et al., 2022).

On the other hand, the ideal bulk features of the implants, such as strength and elastic modulus, are preserved using the suitable surface modification treatment, adding improvements to the crucial surface properties (Thanka Rajan et al., 2022). The surface of a biomaterial significantly impacts the reaction of biological environment to the materials, which is the justification for surface modification of implants (Priyadarshini et al., 2019).

The infections are the primary cause of orthopaedic device failures, with trauma devices being more susceptible than joint replacements (Sendi and Zimmerli, 2012; Ackun-Farmmer et al., 2021; Jain et al., 2021; Filipović et al., 2020; Aggarwal et al., 2022; Hussain et al., 2022; Afewerki et al., 2020; Innes and Atwater, 2020; Intravaia et al., 2023; Yuan et al., 2021; Stewart et al., 2019). Additional issues that are linked to the implant-tissue interface, are caused by the inadequate osteointegration or stress shielding brought on by an incompatibility between the mechanical properties of the tissue and the implanted materials. To increase long-term success of implants, it is necessary to investigate new options that can satisfy biomechanical and biological criteria, as current biomaterials are reaching their limits (Fernandes et al., 2017; Zhou et al., 2023; Rajan and Arockiarajan, 2021; Sawyer et al., 2020; Freund et al., 2003; Montazerian et al., 2022; Stewart et al., 2019). The use of bioactive glass coatings to functionalize existing materials is one viable option (Rajan and Arockiarajan, 2021; Montazerian et al., 2022).

The biomaterials now in use for applications requiring load bearing are mechanically adequate, but they behave inertly when implanted. This requires a surface adjustment in order to enhance their integration with the human body environment. It is possible to increase the bioactivity of surfaces while maintaining the bulk properties using a variety of techniques. The deposition of a biomaterial that encourages the integration of the implant and host bond is one method used to transform bioinert materials into bioactive ones (Garrido et al., 2021).

Three decades ago, the field of biomaterials made the initial discovery of bulk metallic glasses. Even before scientists became interested in their use for medical purposes, they were frequently employed in industries such as sport and jewellery (Li and Zheng, 2016; Korkmaz and Kariper, 2020; Hasiak et al., 2022; Rajan and Arockiarajan, 2021). When a molten alloy is rapidly cooled, it forms metallic glasses, an amorphous structure that prevents the formation of crystalline phases and creates glassy alloys (Thanka Rajan et al., 2022; Hasiak et al., 2022).

Unlike regular glasses, bioactive glasses are made of various elements. Compared to traditional ones, their structure is considerably more disrupted. When submerged in aqueous medium, bioactive glasses exhibit unique surface reactivity-related bone bonding properties that are indicative of their bioactivity (Garrido et al., 2021; Chuang et al., 2013).

Numerous studies support the notion that bioactive glasses have drawn a lot of research attention due to their technological promise for real-world applications and their scientific importance in the biomedical field (Garrido et al., 2021; Rajan and Arockiarajan, 2021; Chuang et al., 2013; Subramanian et al., 2015; Jia, 2015).

As an alternative to HAp coatings, bioactive glasses have been suggested by a number of researchers due to their capacity to establish a stable surface that tightly binds to bone. Additionally, their dissolution-related chemicals encourage cell differentiation into bone cells (Hoppe et al., 2011).

On the other hand, the increase of the hardness and toughness characteristics represents another important advancement in coating a large variety of materials, including titanium, titanium alloys, and even stainless steels. Additionally, by changing the surface's characteristics and adding a thin layer, the material's biocompatibility and resistance to corrosion in various body fluids can increase (Eliaz, 2019).

Biomaterials such as titanium alloys and stainless steel, typically lack inherent antibacterial properties. In addition, it is widely known that metallic ions such as Ag+ and Cu2+ can operate as an effective antibacterial agent when added (Eliaz, 2019). Particularly, Zr-based metallic glasses exhibit potential antibacterial properties and significantly influence antibacterial activity (Subramanian et al., 2015; Chu et al., 2008; Chu et al., 2014). That means that due to the release of weakly bound Cu2+ or Ag+ ions, Zr-based metallic glasses with Ag and Cu are antibacterial (Etiemble et al., 2017).

Also, it is thought that the initial adhesion of bacteria to the coating surfaces is substantially lower than that of stainless-steel surfaces due to the smooth surface profile and hydrophobic effects. Release of copper ions from the thin film metallic glasses also contributes significantly to the bacteria's repulsion (Chu et al., 2014; Chu et al., 2014).

For the osteointegration, the aid comes by addition of supplementary elements to increase functionality, such as Sr and Mg, while the antibacterial activity is improved through addition of Ag. Also, in the last decades, the most popular for medicinal purposes are often Zr-, Ti-, Fe-, and Mg-based (Janne et al., 2019; Rajan and Arockiarajan, 2021; Chu et al., 2012; Bin et al., 2021; Apreutesei et al., 2015; Basova et al., 2021).

Numerous researchers have discussed the use of Ca as an alloying element for the metallic glasses in biomedical applications since this element is an essential part of the human body. Having strontium on board makes it seem more promising. Similar to calcium, strontium is an excellent bone-seeking element that can aid in protein synthesis and bone regeneration (Bin et al., 2021).

The coated specimens showed stronger corrosion potential and reduced corrosion current density when compared to crystalline materials such as stainless steel, titanium, and titanium alloys. This suggests that metallic glasses based on Zr are more corrosion resistant in different bodily fluids (Rajan et al., 2020). Thin-film coating methods use a variety of coating techniques to modify surfaces. The goal to apply this film is to increase the material's lifespan. Sputtering, pulsed laser deposition (PLD), and other physical vapour deposition (PVD) techniques are also used in this process (Priyadarshini et al., 2019; Rajan and Arockiarajan, 2021; Janarthanan et al., 2021; Rauf et al., 2018).

Among various techniques for producing thin layers, sputtering creates dense, adhesive films with the same elemental composition as the target (Subramanian et al., 2015; Kothari and Kale, 2002).

The aim of the current research is to develop thin film bioactive glasses (TFBG) from the quaternary system through cathodic arc deposition method on Ti alloys (Ti6Al4V) and stainless steel (316L) substrates. Several compositions of TFGB were taken into consideration from the quaternary system as following Zr-Cu-Ca-X, where X was replaced with Mo, Mg, Si or Sr. Thus, the influence of each element on the properties of the Zr-Cu-Ca ternary system was taken into consideration. The results on Zr-Cu-Ca ternary system can be found in the published paper REF. (Parau et al., 2023).

2 Experimental details

2.1 Samples preparation and coating deposition

For the experiments, two metallic substates widely employed in implantology, 316L stainless steel and Ti6Al4V alloy have been used. For the deposition process the method used was the cathodic arc deposition. All metallic samples were mechanically polished to achieve a roughness of 20 nm (±3 nm) for 316L and 50 nm (±6 nm) for Ti6Al4V, respectively.

The following cathodes purchased from Cathay Advanced Materials Limited (Guangdong, China) with a purity of 99.95%, were used for the deposition of the coatings: ZrCuCaMo, ZrCuCaMg, ZrCuCaSi, and ZrCuCaSr. Prior to deposition, each substrate was decontaminated by being sputter etched with Ar ions for five minutes in the deposition chamber, at a bias voltage of 950 V.

The following parameters were used for the deposition: residual pressure = 2 × 10-5 mbar; working pressure = 1 × 10-3 mbar; Ar mass flow rate = 120 sccm; substrate bias = −100 V; arc current on each cathode = 70 A, substrate temperature = 320 ⁰C.

Each process showed different deposition rates, therefore the duration of the process was adjusted in order to obtain a thin layer with a thickness of ∼ 2 µm for all types of deposited thin films. Both substrates were coated in the same deposition run, receiving the same kind of coating.

2.2 Characterization and testing methods

For the evaluation of surface morphology and elemental composition, a scanning electron microscope (SEM) (Hitachi TM3030 Plus) coupled with an energy dispersive X-ray spectrometer (Bruker) was used. The EDS tests were conducted using two replicates for each sample in three separate areas, and the results were averaged.

A surface profilometer (Dektak 150, Bruker) with a 2.5 µm stylus radius was used to measure the coatings' thickness and the surface roughness. The measurements were carried out twice for each sample in 10 randomly selected distinct areas, and the results were also averaged.

According to the Stoney approach (Freund et al., 2003; Pauleau, 2006), the residual stress level in the films was assessed by comparing the curvature radii of the Si (1 0 0) wafers before and after film deposition.

A microhardness tester was used to measure the Vickers hardness (0.05 N load), performing five indentations on each film. By using a scratch tester, the adhesion of the film on the substrate was assessed under the following conditions: indenter with a diamond tip of 0.2 mm radius; progressive load from 0 to 100 N; scratching speed of 10 mm/min; scratching distance of 10 mm (standard EN 1071–3:2005). An optical microscope was used to inspect the scratch imprints to determine the critical load. Three measurements were carried out on each type of coatings, and their average was taken into consideration.

The in vitro corrosion resistance was evaluated with a potentiostat/galvanostat by applying the potentiodynamic polarization technique in simulated body fluid (SBF) solution at 37 ± 0.5 ⁰C, (VersaStat 3, Princeton Applied Research). The counter and reference electrodes were platinum wire and KCl-saturated Ag/AgCl reference electrode, respectively. The coated substrates of different thicknesses were used as working electrode. Throughout the test, the distance between the reference and the working electrodes was kept constant.

Prior to performing the potentiodynamic measurements, the working electrode was immersed in corrosive solution for a potential-stabilizing period of 1 h, during which time the open-circuit potential (EOC) was monitored.

Then, by using electrochemical impedance spectroscopy (EIS), a sinusoidal signal with an amplitude of 10 mV RMS vs. EOC was applied over a frequency range of 0.5 ÷ 104 Hz. With a scanning rate of 0.167 mV/s, potentiodynamic curves were registered from −1 V vs. EOC to 2 V vs. SCE. VersaStudio software (version 2.60.6) was used to record the data, and ZView software (version 12136–4) was employed for the EIS fitting method.

3 Results and discussions

3.1 Composition and morphology of the coatings

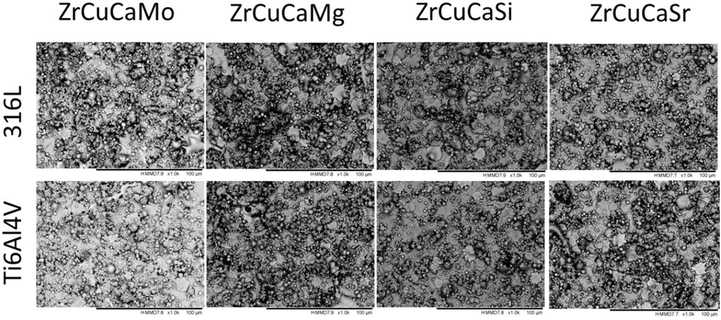

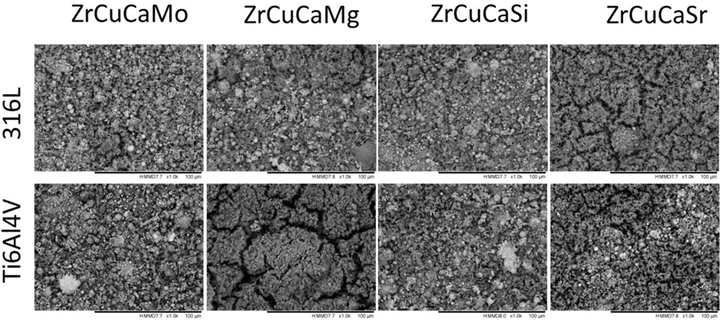

The cathodic arc deposition represents a physical vapor deposition technique involving vaporizing material from a cathode target using an electric arc. Thus, the vaporized material resulted from the cathodic arc evaporation subsequently cools and condenses to produce a thin layer on the substrate. Aside from ions, atoms, and electrons, microdroplets are also produced as a result of local heating and energetic arc events. That is why, according to the images shown in Fig. 1, that represent the SEM images of the deposited coating, it can be observed that all of the coatings' surfaces present microdroplets of different sizes. The size, the shape, and the distribution of the particles are also influenced by the deposition conditions. Also, all the coatings were found to be dense and consistent across the surface that was under investigation, which indicates that they completely cover the area.

SEM images of the coatings.

According to B. Warcholinski (Warcholinski et al., 2018) and his research conducted in 2018, increasing substate bias can reduce the amount and the size of these particles in ZrSiN coatings. Particularly, for our research, due to the type of the coatings, the substrate bias was maintained at −100 V. The limitation of biasing voltage is mainly due to the fact that light elements like Ca or Mg tend to undergo re-sputtering when the substate bias is raised too high.

Additionally, it is possible to link the quantity and size of droplets with the melting temperature of the materials produced during the deposition on the surface of cathodes.

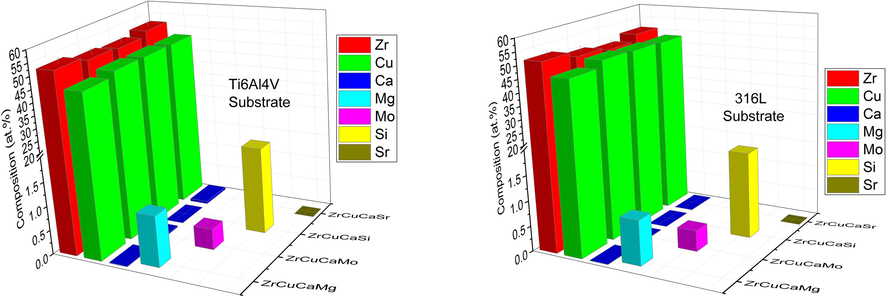

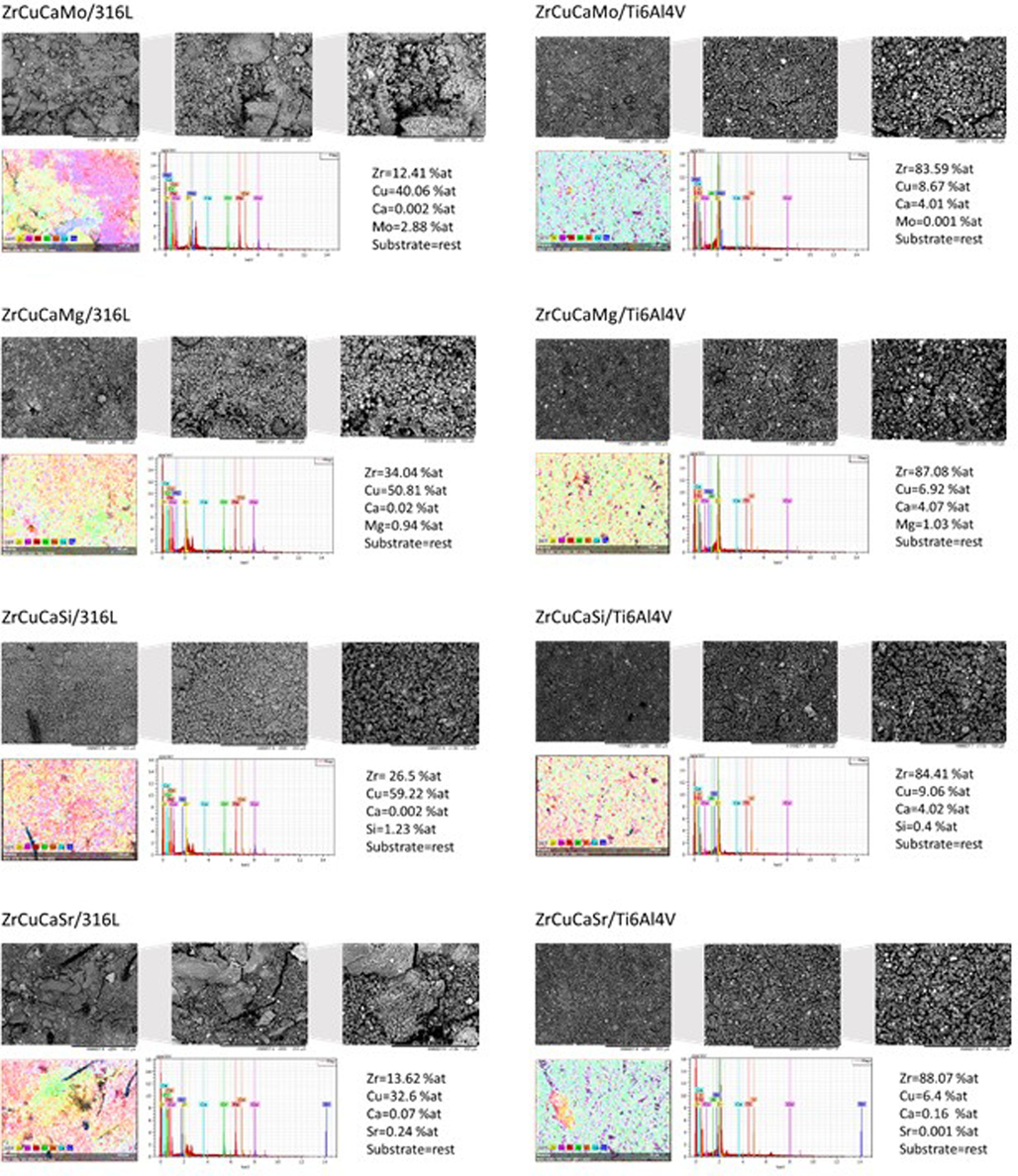

Energy dispersive spectrometry analysis, often known as EDS, was carried out on each individual sample in order to establish the elemental composition of the coatings that were deposited (Figs. 2 and 3). The chemical composition that was attained on the coatings provided conclusive evidence that the main components (Zr, Cu, Ca, Mg, Mo, Si, Sr) were present. The quantities of Zr, Cu, and Ca were not significantly different in any of the coatings, the amounts being similar.

EDS analysis of the surface's composition.

EDS map of the surface's composition.

3.2 Mechanical properties (roughness, adhesion, stress)

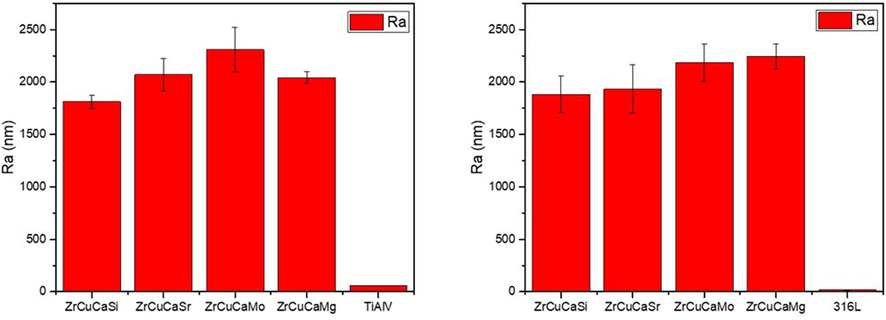

The roughness of a material is an important feature that can influence the electrochemical behaviour of the material as well as its contact with the human cells. Therefore, it is logical to expect that by controlling this value, some surface features can be strengthened as well. This hypothesis will be supported by the following data. On the other hand, changes in nanoscale surface roughness seem to alter host cellular and tissue responses (Variola et al., 2011).

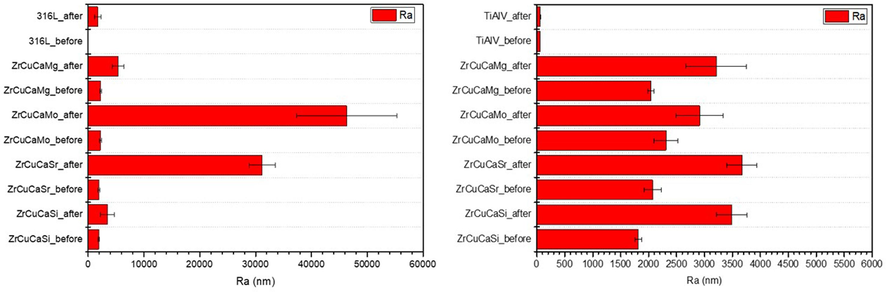

The Ra (arithmetic average) roughness metric was used to evaluate the surfaces that were under investigation for their degree of roughness (see Fig.4). On that base, it is essential to take note that the roughness of all uncoated substrates was polished to the same level (19 nm for 316L, and 50 nm for Ti6Al4V). The surface of all coatings is uniform, with no substantial variations in height to be observed anywhere.

The Ra roughness metric of the coatings.

Also, according to the obtained results, it can be noticed that compared to the substrate, all coatings presented an increase of the roughness. Based on these findings, it is reasonable to assume that the increased roughness achieved for the coatings is due to the deposition method (Janarthanan et al., 2021; Kothari and Kale, 2002; Warcholinski et al., 2018).

The highest values of the average roughness (Ra) parameter have been obtained for ZrCuCaMo deposited on Ti6Al4V substrate, and for the ZrCuCaMg coating deposited on 316L, followed by ZrCuCaMo, with a similar Ra value.

Regardless of the substrate, ZrCuCaSi presented a similar roughness, while the addition of Sr, Mo or Mg in the ZrCuCa ternary system, resulted in a significantly higher roughness.

All developed films subjected to tensile stress were obtained on Si substrate. According to the obtained results presented in Fig. 5, it can be noted that the coatings with Mg and Si are less stressed, while ZrCuCaSr exhibited the highest stress level, followed by ZrCuCaMo.

Tensile strength of the coatings deposited on Si substrate.

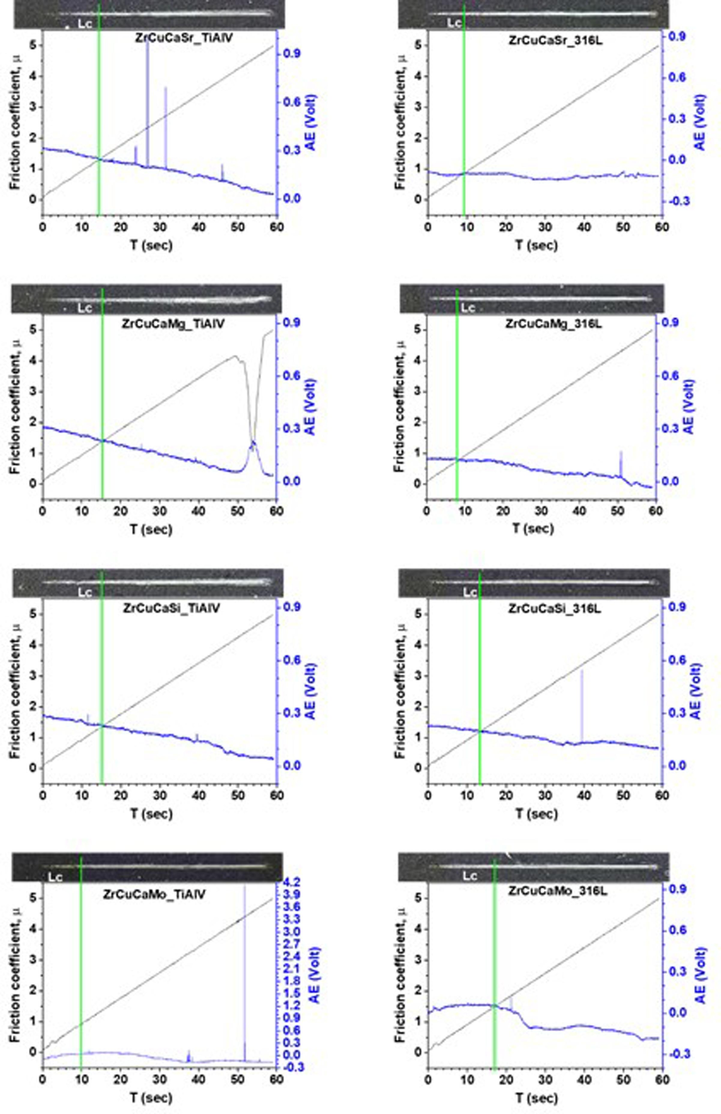

The results of the scratch adhesion test shown in Fig. 6, present the values for the critical load (Lc) evaluated using the method described in standard EN 1071–3:2005.

Results of the scratch adhesion test.

The critical loads for all coatings demonstrate an adequate adherence to both substates. In terms of substrate, it was observed that compared to 316L steel, all coatings showed improved adhesion to the Ti6Al4V alloy.

3.3 In vitro corrosion resistance in similar human environment

Electrochemical techniques are regarded as highly significant and helpful for the analysis of the reactions that take place at the coating-substrate interface. This makes possible to obtain an accurate prediction of the way the coating would behave in vivo.

The polarization resistance technique in SBF medium was used to evaluate the electrochemical behaviour of the experimental metallic glasses-based layer. This medium was chosen since the proposed coatings have potential applications in orthopedy and because SBF is similar to human plasma.

Release of alloying elements from implants (such as Al and V in Ti6Al4V) as fine metallic particles or ions into the bloodstream can cause tissue colouring, cell poisoning, discomfort, and even implant failure (Shah et al., 2016).

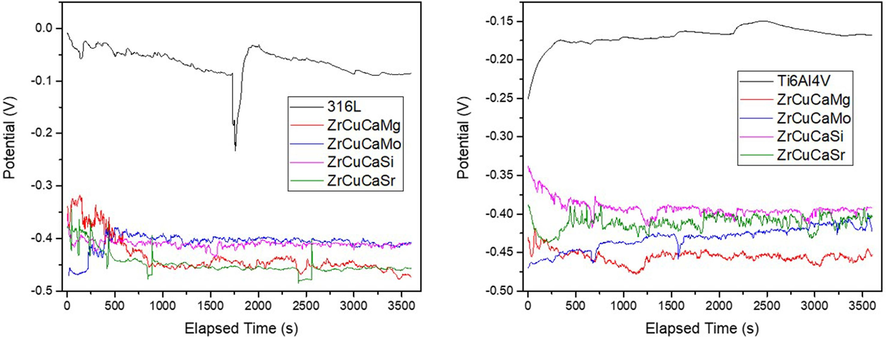

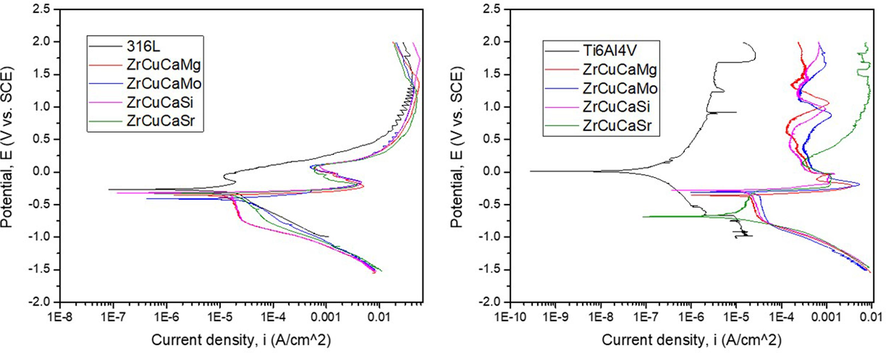

During the course of one hour in SBF solution, the open circuit potential (EOC) was registered, and Fig. 7 displays its evolution.

Open circuit potential (EOC) evolution for the investigated samples.

Also, the potentiodynamic curves measured for the uncoated and coated substrates are represented in Fig. 8. The uncoated 316L and Ti6Al4V served as reference sample.

Potentiodynamic curves of the investigated samples.

According to what was found, the EOC potential of all investigated surfaces has a propensity to move in the direction of electropositive value. Some of the coatings showed some changes in the values of open circuit potential. These variations were seen in some coatings. After monitoring the EOC for 1 h, it was observed that the coatings exhibited values extremely similar to one another, which indicated that the surfaces were stable (equilibrium state). The EOC potential of the bare substrates was found to be significantly lower than that of all coatings.

It has come to our attention that the ZrCuCaMo and ZrCuCaMg layers offered the strongest corrosion resistance, demonstrating low values of corrosion current density.

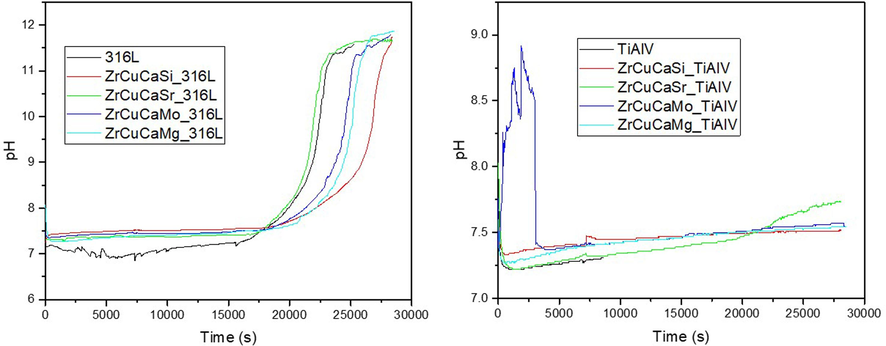

Degradation was also examined by the coatings' stability, which involved monitoring pH changes during the corrosion tests in SBF solution at a fixed temperature of 37 °C (±0.5 °C) for a duration of 8 h. In Fig. 9, the pH evolution of the coatings throughout time is presented.

Evolution of the pH during the corrosion tests in SBF at 37 °C.

With the exception of the ZrCuCaMo coating, which exhibited an irregular evolution from the very first few moments of immersion onward, indicating that the coating is quite unstable when subjected to SBF media at 37 °C, the rest of the coatings deposited on Ti6Al4V maintained a constant pH value for the entire period, with a small increment at the end.

On the contrary, for 316L steel substrate, the evolution was the opposite. The samples were immersed in SBF and it was maintained a pH that was constant for 4 h after immersion. This was followed by a considerable increase in the pH value, which indicated that the degradation process had begun.

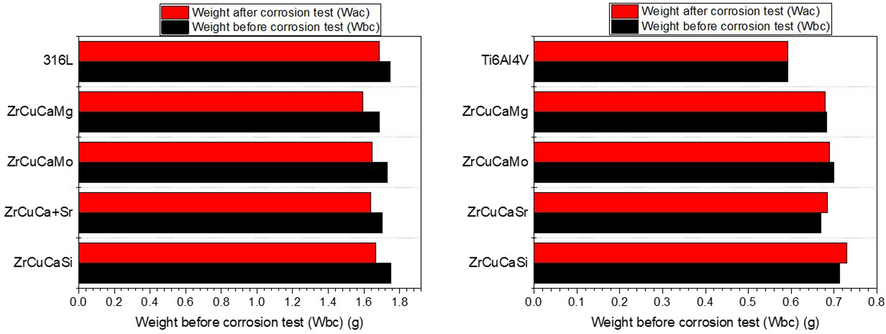

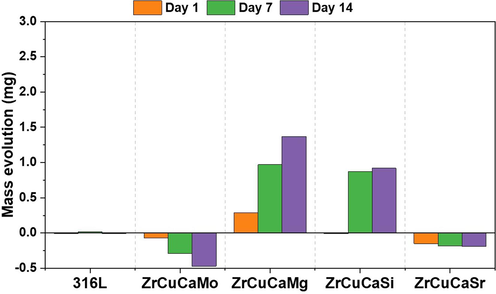

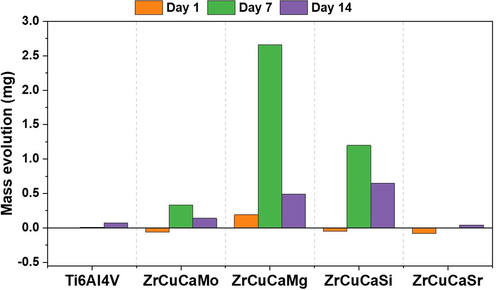

Before and after the corrosion test, the samples were weighed using an analytical balance with an accuracy of 0.01 mg in order to follow the materials' mass evolution. The mass evolution of the samples is presented in Fig. 10.

Mass evolution of the samples before and after the corrosion tests.

According to the data, it can be observed that for the coatings deposited on Ti6Al4V substrate, the samples weight remained almost constant, while the coatings deposited on 316L stainless steel presented a small decrement that can be observed after the electrochemical tests.

Also, the Ra (arithmetic average) roughness metric was used to evaluate the surfaces roughness before and after the tests and the results are shown in Fig. 11.

The Ra (arithmetic average) roughness of the coatings before and after corrosion test.

Irrespective of the substrate type, an increment of the Ra value was noted for all coatings. By comparing the Ra values, it was observed that the highest value was reached for the ZrCuCaMo deposited on 316L substrate, followed by ZrCuCaSr which has also presented a significant increase of the Ra. The rest of the coatings have registered small increases, when compared to the values before performing the electrochemical tests. On the other hand, the coatings deposited on Ti6Al4V presented similar values in all cases. For the substrate, both their Ra values remained almost the same.

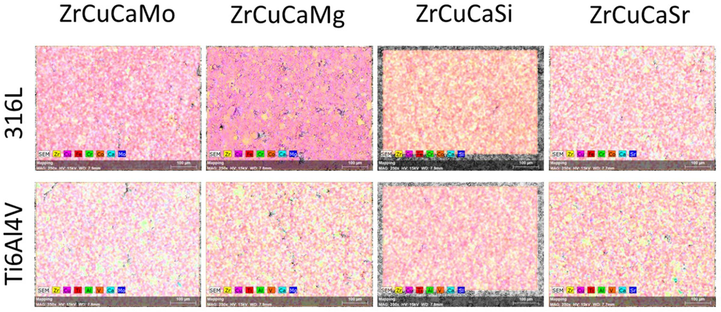

After conducting corrosion tests in SBF at 37 °C, the morphology of the coatings and their elemental composition were thoroughly examined using a scanning electron microscope (SEM) that was outfitted with an energy dispersive (EDS Quantax 70) detector. Fig. 12 illustrates the surface shape as well as the distribution of the various elements over the surface.

Morphology and elemental composition of investigated surfaces after corrosion in SBF at 37 °C.

The images obtained from the SEM demonstrate that all surfaces presented signs of alteration/deterioration/degradation, especially the coatings deposited on 316L, indicating the fact that, after the immersion, this coatings have been more affected by the SBF solution.

EDS mapping images were used to determine the elemental compositions for the coatings and the substrate. Coating elements have been found despite their decrease after 8 h of immersion in SBF at 37 °C, suggesting that they are resistant to the corrosive attack of the SBF solution even at human body temperature.

3.4 Biomineralization in SBF solution at 37 °C for 1, 7 and 14 days

It is possible to obtain an approximation of the in vitro biomineralization ability of a material by quantifying the newly generated apatite on the coatings surface. Before doing expensive tests on cell cultures or animals, it is important to carry out in vitro experiments. For example, the biomineralization ability material's can be evaluated through their immersion in simulated body fluid (SBF), which resambles the human body plasma (Oyane et al., 2003).

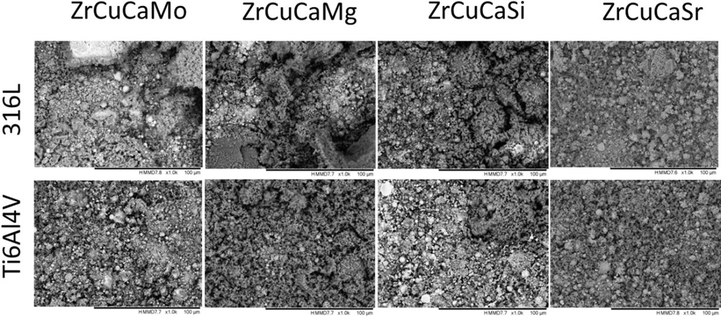

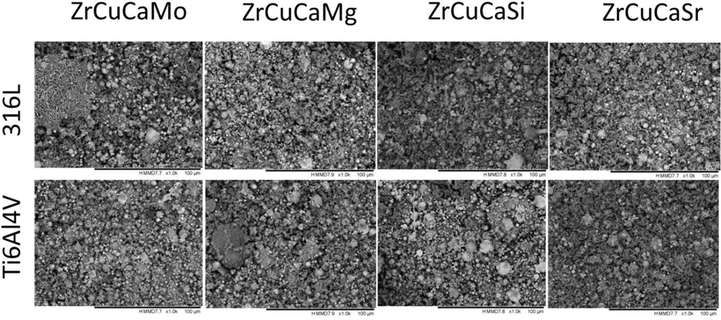

The experimental thin films metallic glasses deposited on metallic substrate, namely 316L and Ti6Al4V, were submerged in SBF media in order to determin their biomineralization capacity. Each sample was kept in an incubator, to assess the in vitro behaviour of the coatings (Memmert IF 55, Memmert GmbH, Germany) at 37 °C for 14 days while it was submerged in 50 ml of testing media in sterile containers. The media was changed every two days in order to maintain the required ionic concentration. At various time intervals, including 1, 7 and 14 days, samples were removed and analyzed by scanning electron microscopy (SEM) for surface morphology (Figs. 13–15) and mass variation (Figs. 16 and 17).

SEM images of the developed surfaces after immersion for 1 day.

SEM images of the developed surfaces after immersion for 7 days.

SEM images of the developed surfaces after immersion for 14 days.

Samples mass evolution across the defined time periods (1, 7 and 14 days) for 316L substrate.

Samples mass evolution across the defined time periods (1, 7 and 14 days) for Ti6Al4V substrate.

Each sample was cleaned with distilled water and dried for 24 h in a desiccator. Samples were then weighed with an analytical balance.

Each immersed sample was weighed five times. The mass variation was computed by using the following mathemical formula:

According to Figs. 13–15′s SEM images, after 14 days of immersion in SBF media, all coated samples are primarily covered in hemispherical precipitates with occasional fissures.

The immersion procedure in SBF might potentially be broken down into the following steps, as shown by the SEM images. Particulary, for the proposed coatings, most of them have the tendeancy to fracture. In our case, two phenomena were seen after immersion in SBF for a period of 14 days: the development of a new apatite layer, as well as some signs of disintegration. After the first day, some apatite layer can be observed in all coatings, in small amounts. One week later, this amount increased, especially for ZrCuCaMg and ZrCuCaSi, regardless the substrate. The same trend continued until day 14.

Figs. 16 and 17 illustrates the samples mass variation during the course of the specified time periods (1, 7 and 14 days).

For the coatings deposited on 316L substrate and immersed in SBF, the lost mass has increased for ZrCuCaMo and ZrCuCaSr by increasing the immersion time, indicating a sign of degradation. For ZrCuCaMg and ZrCuCaSi, the mass increased periodically over time, demonstrating a good biomineralization ability.

On the other hand, for the coatings deposited on Ti6Al4V, it can be observed that all coatings presented an increase in the mass, with the highest value reached for the ZrCuCaMg and ZrCuCaSi coatings. This indicates that the coatings deposited on this type of substrate have an accelerated biomineralization process.

Even if there is a small decrease of the coatings mass, it can be observed that according to the SEM images, the apatite layer is still formed on the tested surfaces.

4 Conclusions

Cathodic arc evaporation was used to develop thin layers of ZrCuCaX metallic glasses onto 316L stainless steel and Ti6Al4V. The X represents one of the following elements: Mo, Mg, Si, or Sr. An exhaustive investigation was carried out, and the findings and resulted interpretations are described below in detail.

According to the present study, the morphological examination of the coatings revealed the presence of microdroplets of different sizes on their surfaces. The surface obtained was fully covered, and the amount of elements were similar, irrespective of the coatings type.

When compared to the substrate, the roughness of each coatings was higher (around 2000 nm), regardless of the substrate (19 nm for 316L, and 50 nm for Ti6Al4V) they were applied on and independent of the mechanical perspective. Because of these findings, it is sufficient to support the hypothesis that the proposed deposition method is the main cause for the higher roughness achieved in the case of the coatings.

In terms of mechanical properties, it can be said that all coatings exhibited acceptable adhesion to both substates, ranged from 8 N to 18. All coatings displayed an enhanced adhesion to the Ti6Al4V alloy (12–18 N) when compared to the 316L steel standard (8–15 N).

The ZrCuCaMo and ZrCuCaMg showed the lowest value of the corrosion current density parameter (316L: 21.99 µA/cm2 and 11.37 µA/cm2; Ti6Al4V: 1.62 µA/cm2 and 13.37 µA/cm2) and therefore the best corrosion resistance among the tested materials. According to the collected data, after performing the electrochemical tests, it was noted that the weight of the coatings deposited on the Ti6Al4V substrate did not change significantly (ranged from 0.593 g to 0.713 g), compared to the ones deposited on 316L stainless steel (ranged from 1.687 g to 1.752 g), which have undergone a slight deterioration because of the electrochemical testing.

The immersion tests carried out in SBF, highlighted that, irrespective of the substrates type, all coatings showed slight signs of degradation, but also areas, which are covered with hemispherical precipitates specific to the newly formed apatite, indicating that the coatings are bioactive. The mass evolution of the coatings deposited on 316L steel was ranged from the −0.47 (degradation process) mg to 1.37 mg (biomineralization process), while for those deposited on Ti6Al4V, the values were ranged from −0.08 mg (degradation process) to 2.66 mg (biomineralization process).

Funding

We acknowledge the support of the Romanian Ministry of Education and Research, CNCS - UEFISCDI, project PN-III-P4-ID-PCE-2020–1264 (PCE95/2021), within PNCDI III.

Acknowledgement

The work was supported by the Core Program within the National Research Development and Innovation Plan 2022-2027, carried out with the support of MCID, project no. PN 23 05 (id: PN11N-03-01-2023) and through Program 1—Development of the national research-development system, Subprogram 1.2—Institutional performance-Projects to finance the excellent RDI, Contract no. 18PFE/30.12.2021.

Declaration of competing interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: [Alina Vladescu (Dragomir) has patent #A/00544/07.2022 pending to patent application.].

References

- On the current research progress of metallic materials fabricated by laser powder bed fusion process: a review. J. Mater. Res. Technol.. 2022;20:681-707.

- [CrossRef] [Google Scholar]

- Biomaterials for orthopedic diagnostics and theranostics. Curr. Opin. Biomed. Eng.. 2021;19:100308

- [CrossRef] [Google Scholar]

- Advances in dual functional antimicrobial and osteoinductive biomaterials for orthopaedic applications. Nanomedicine. 2020;24:102143

- [CrossRef] [Google Scholar]

- Drug-loaded biomaterials for orthopedic applications: a review. J. Control. Release. 2022;344:113-133.

- [CrossRef] [Google Scholar]

- Bioactive glass coatings on metallic implants for biomedical applications. Bioact. Mater.. 2019;4:261-270.

- [CrossRef] [Google Scholar]

- Zr-Cu thin film metallic glasses: an assessment of the thermal stability and phases’ transformation mechanisms. J. Alloy. Compd.. 2015;619:284-292.

- [CrossRef] [Google Scholar]

- Recent advances in Ti-6Al-4V additively manufactured by selective laser melting for biomedical implants: prospect development. J. Alloy. Compd.. 2022;896

- [CrossRef] [Google Scholar]

- The use of noble metal coatings and nanoparticles for the modification of medical implant materials. Mater. Des.. 2021;204:109672

- [CrossRef] [Google Scholar]

- Barriers and facilitators of patient access to medical devices in Europe: a systematic literature review. Health Policy (New York).. 2019;123

- [CrossRef] [Google Scholar]

- Surface modification of stainless steel for biomedical applications: revisiting a century-old material. Mater. Sci. Eng. C. 2018;93

- [CrossRef] [Google Scholar]

- Bioceramics: Past, present and for the future. J. Eur. Ceram. Soc.. 2008;28:1319-1327.

- [CrossRef] [Google Scholar]

- Mg-based bulk metallic glasses: a review of recent developments. J. Magnesium Alloys 2021

- [CrossRef] [Google Scholar]

- The neurotoxicity of environmental aluminum is still an issue. Neurotoxicology. 2010;31

- [CrossRef] [Google Scholar]

- Low levels of aluminum can lead to behavioral and morphological changes associated with Alzheimer’s disease and age-related neurodegeneration. Neurotoxicology. 2016;52

- [CrossRef] [Google Scholar]

- Characteristic studies on the Zr-based metallic glass thin film fabricated by magnetron sputtering process. Surf. Coat. Technol.. 2008;202:5564-5566.

- [CrossRef] [Google Scholar]

- Thin film metallic glasses: Unique properties and potential applications. Thin Solid Films. 2012;520:5097-5122.

- [CrossRef] [Google Scholar]

- Antimicrobial characteristics in Cu-containing Zr-based thin film metallic glass. Surf. Coat. Technol.. 2014;259:87-93.

- [CrossRef] [Google Scholar]

- Fabrication and characterizations of thin film metallic glasses: antibacterial property and durability study for medical application. Thin Solid Films. 2014;561:102-107.

- [CrossRef] [Google Scholar]

- Electrochemical characterization of Zr-based thin film metallic glass in hydrochloric aqueous solution. Thin Solid Films. 2013;529:338-341.

- [CrossRef] [Google Scholar]

- Vanadium: a review of the reproductive and developmental toxicity. Reprod. Toxicol.. 1996;10

- [CrossRef] [Google Scholar]

- Bioceramics of calcium orthophosphates. Biomaterials. 2010;31:1465-1485.

- [CrossRef] [Google Scholar]

- Innovative Zr-Cu-Ag thin film metallic glass deposed by magnetron PVD sputtering for antibacterial applications. J. Alloy. Compd.. 2017;707:155-161.

- [CrossRef] [Google Scholar]

- Multifunctional bioactive glass and glass-ceramic biomaterials with antibacterial properties for repair and regeneration of bone tissue. Acta Biomater.. 2017;59:2-11.

- [CrossRef] [Google Scholar]

- Bacterial adhesion on orthopedic implants. Adv. Colloid Interface Sci.. 2020;283:102228

- [CrossRef] [Google Scholar]

- Freund, L.B., Suresh, S., 2004. Thin film materials: stress, defect formation and surface evolution.

- Adhesion improvement and in vitro characterisation of 45S5 bioactive glass coatings obtained by atmospheric plasma spraying. Surf. Coat. Technol.. 2021;405:126560

- [CrossRef] [Google Scholar]

- A review of powdered additive manufacturing techniques for Ti-6al-4v biomedical applications. Powder Technol.. 2018;331:74-97.

- [CrossRef] [Google Scholar]

- Production, mechanical properties and biomedical characterization of zrti-based bulk metallic glasses in comparison with 316l stainless steel and ti6al4v alloy. Materials. 2022;15

- [CrossRef] [Google Scholar]

- A review of the biological response to ionic dissolution products from bioactive glasses and glass-ceramics. Biomaterials. 2011;32:2757-2774.

- [CrossRef] [Google Scholar]

- Performance analysis of biodegradable materials for orthopedic applications. Mater. Today Commun.. 2022;31:103167

- [CrossRef] [Google Scholar]

- Orthopedic implant hypersensitivity reactions: concepts and controversies. Dermatol. Clin.. 2020;38:361-369.

- [CrossRef] [Google Scholar]

- Smart orthopedic biomaterials and implants. Curr Opin Biomed Eng.. 2023;25:100439

- [CrossRef] [Google Scholar]

- Falling Orthopaedic instruments and implants- potential hazards and strategies to mitigate them. Perioper Care Oper Room Manage.. 2021;23:100169

- [CrossRef] [Google Scholar]

- Basic deposition methods of thin films**. J. Mol. Struct.. 2021;1241:130606

- [CrossRef] [Google Scholar]

- Jia, H., 2015. Improving Mechanical Properties of Bulk Metallic Glasses by Approaches of In-situ Composites and Thin Films.

- Glass formation, production and superior properties of Zr-based thin film metallic glasses (TFMGs): a status review. J. Non Cryst. Solids. 2020;527

- [CrossRef] [Google Scholar]

- Recent trends in surface engineering using cathodic arc technique. Surf. Coat. Technol.. 2002;158–159:174-179.

- [CrossRef] [Google Scholar]

- Recent advances in biomolecule-nanomaterial heterolayer-based charge storage devices for bioelectronic applications. Materials. 2020;13

- [CrossRef] [Google Scholar]

- Rational design, bio-functionalization and biological performance of hybrid additive manufactured titanium implants for orthopaedic applications: a review. J. Mech. Behav. Biomed. Mater.. 2020;105:103671

- [CrossRef] [Google Scholar]

- Recent advances in bulk metallic glasses for biomedical applications. Acta biomaterialia. 2016;36:1-20.

- [CrossRef] [Google Scholar]

- Potential release of in vivo trace metals from metallic medical implants in the human body: from ions to nanoparticles - A systematic analytical review. Acta Biomater.. 2014;10:2379-2403.

- [CrossRef] [Google Scholar]

- Tailoring micro/nano-materials with special wettability for biomedical devices. Biomed. Technol.. 2023;2:15-30.

- [CrossRef] [Google Scholar]

- Alzheimer-like cell death after vanadium pentoxide inhalation. Heliyon. 2021;7

- [CrossRef] [Google Scholar]

- Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater Sci.. 2018;94

- [CrossRef] [Google Scholar]

- Preparation and assessment of revised simulated body fluids. J. Biomed. Mater. Res.. 2003;65:188-195.

- [CrossRef] [Google Scholar]

- Comparison of 316L and Ti6Al4V biomaterial coated by ZrCu-based thin films metallic glasses: structure, morphology, wettability, protein adsorption, corrosion resistance, biomineralization. Appl. Surf. Sci.. 2023;612:155800

- [CrossRef] [Google Scholar]

- Determination and generation mechanisms of residual stresses in thin films produced by physical vapor deposition techniques. Mater. Surf. Process. Directed Energy Techniques 2006

- [CrossRef] [Google Scholar]

- Improvement of machinability of Ti and its alloys using cooling-lubrication techniques: a review and future prospect. J. Mater. Res. Technol.. 2021;11:719-753.

- [CrossRef] [Google Scholar]

- Bioactive coating as a surface modification technique for biocompatible metallic implants: a review. J. Asian Ceram. Soc.. 2019;7:397-406.

- [CrossRef] [Google Scholar]

- Thin film metallic glasses for bioimplants and surgical tools: a review. J. Alloy. Compd.. 2021;876:159939

- [CrossRef] [Google Scholar]

- Thin film metallic glasses for bioimplants and surgical tools: a review. J. Alloy. Compd.. 2021;876

- [CrossRef] [Google Scholar]

- Zirconium-based metallic glass and zirconia coatings to inhibit bone formation on titanium. Biomed. Mater.. 2020;15:065019

- [CrossRef] [Google Scholar]

- Binary Cu-Zr thin film metallic glasses with tunable nanoscale structures and properties. J. Non Cryst. Solids. 2018;498:95-102.

- [CrossRef] [Google Scholar]

- Metallic implants and CT artefacts in the CTV area: Where are we in 2020? Cancer/Radiotherapie.. 2020;24

- [CrossRef] [Google Scholar]

- Recent advances on bioactive baghdadite ceramic for bone tissue engineering applications: 20 years of research and innovation (a review) Mater Today Bio.. 2022;17

- [CrossRef] [Google Scholar]

- Improving the tribological properties and biocompatibility of Zr-based bulk metallic glass for potential biomedical applications. Materials.. 2020;13

- [CrossRef] [Google Scholar]

- Antimicrobial treatment concepts for orthopaedic device-related infection. Clin. Microbiol. Infect.. 2012;18:1176-1184.

- [CrossRef] [Google Scholar]

- Commercially pure titanium (cp-Ti) versus titanium alloy (Ti6Al4V) materials as bone anchored implants - Is one truly better than the other? Mater. Sci. Eng. C. 2016;62:960-966.

- [CrossRef] [Google Scholar]

- A review of biomimetic surface functionalization for bone-integrating orthopedic implants: mechanisms, current approaches, and future directions. Prog. Mater Sci.. 2019;106:100588

- [CrossRef] [Google Scholar]

- Biocompatibility evaluation of sputtered zirconium-based thin film metallic glass-coated steels. Int. J. Nanomed.. 2015;10:17-29.

- [CrossRef] [Google Scholar]

- Cândido dos Reis, Comparative analysis of corrosion resistance between beta titanium and Ti-6Al-4V alloys: a systematic review. J. Trace Elem. Med Biol.. 2020;62

- [CrossRef] [Google Scholar]

- A comprehensive review on biocompatible thin films for biomedical application. Ceram. Int.. 2022;48:4377-4400.

- [CrossRef] [Google Scholar]

- Nanoscale surface modifications of medically relevant metals: state-of-the art and perspectives. Nanoscale. 2011;3:335-353.

- [CrossRef] [Google Scholar]

- Recent advances in biofunctional guided bone regeneration materials for repairing defective alveolar and maxillofacial bone: a review. Japanese Dental Sci. Rev.. 2022;58:233-248.

- [CrossRef] [Google Scholar]

- Key considerations on the development of biodegradable biomaterials for clinical translation of medical devices: With cartilage repair products as an example. Bioact. Mater.. 2022;9

- [CrossRef] [Google Scholar]

- Structural and mechanical properties of Zr-Si-N coatings deposited by arc evaporation at different substrate bias voltages. J. Mater. Eng. Perform.. 2018;27:3940-3950.

- [CrossRef] [Google Scholar]

- Antibacterial surface design of biomedical titanium materials for orthopedic applications. J. Mater. Sci. Technol.. 2021;78:51-67.

- [CrossRef] [Google Scholar]

- Additive manufacturing of duplex stainless steels - A critical review. J. Manuf. Process.. 2022;73

- [CrossRef] [Google Scholar]

- Novel coatings for the continuous repair of human bone defects. Colloids Surf. B Biointerfaces. 2023;222

- [CrossRef] [Google Scholar]