Translate this page into:

A novel multifunction fracturing fluid compounding of nano-emulsion and viscous slickwater for unconventional gas and oil

⁎Corresponding authors at: Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas, Yangtze University, Caidian, Wuhan, China. wangjie@yangtzeu.edu.cn (Jie Wang), jhs_hust@sina.com (Houshun Jiang)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Visous slickwater formed by high viscous friction reducer (HVFR) has been a great success in replacing conventional slickwater in unconventional reservoir. In order to further extend the function of the slickwater to achieve the purpose of multi-effect of one recipe, a new fracturing fluid system composed of nano-emulsion and HVFR was introduced. It combines the functions of nano-emulsion and HVFR to form a new multi-functional fracturing fluid system: it can not only combine the advantages of conventional slickwater and guar gum fracturing fluid, but also avoid their disadvantages. At the same time, it has the effect of spontaneous imbibition oil displacement to enhance oil recovery, realizing the goal of combination of hydraulic fracturing and EOR. Whether the FR-900 drag reducing agent solution meets the fracturing fluid index is studied through the tests of rheological properties, drag reduction properties and sand carrying performance; CND is studied through the tests of wetting angle, demulsification rate, interfacial tension and spontaneous imbibition experiment. The synergistic effect of CND and FR-900 was analyzed by microscopic test at last. The result shown that: 1) CND can enhance the rheological properties and sand-carrying performance of FR-900 solution. After adding CND, the viscosity and viscoelasticity of FR-900 solution were improved, and the single particle sand-carrying performance and dynamic sand-carrying performance of FR-900 solution were also enhanced. The addition of CND has no effect on the friction reduction performance of FR-900. 2) the main component of CND is surfactant oil for imbibition oil displacement. The mixture of CND and FR-900 has the effect of wettability, reducing oil–water interfacial tension and fast demulsification. The experimental results of imbibition oil displacement show that 0.10 wt% CND can improve the oil recovery of FR-900 solution by 12.79%. The mixed solution of CND and FR-900 has the properties of easy breaking and low residue. 3) the field application results show that the new multifunctional fracturing fluid system has the advantages of low operation pressure, high sand-carrying performance and stimulation effects.

Keywords

Nano-emulsion

HVFR

Multifunction fracturing fluid

EOR

Field application

Nomenclature

- CND

-

Code name for nanoemulsion

- FR-900

-

Code name for drag reducer

- HVFR

-

High Viscous friction reducer

- G'

-

elastic modulus

- G''

-

viscosity models

- FR%

-

friction reduction rate of friction reducer solution

- ΔP1

-

the pressure difference generated when clean water passes through the ends of 8 mm pipe at different flow rates

- ΔP2

-

the pressure difference generated when friction reducer passes through the ends of 8 mm pipe at different flow rates

1 Introduction

Unconventional oil / gas resources are currently one of the most important energy resources in the world (EIA, 2016). Due to the low permeability of the tight reservoir, the treatment of horizontal drilling and hydraulic fracturing are often needed to obtain the industrial production capacity. Hydraulic fracturing is the main stimulation method for unconventional oil/gas reservoirs with micro-nano-darcy permeability. Linear gel, cross-linked gel and slickwater have been used for years in hydraulic fracturing unconventional reservoirs. Slickwater, with the characteristics of reducing the frictional resistance in high-speed pumping pipeline and low damage to reservoir, has been widely used in the world. Slickwater is a water-based fracturing fluid composed of friction reducer, a typical high molecular weight polypropylene or its copolymer. Friction reducer often exists in the form of oil-in-water emulsions, where polymers are distributed between the water and oil phases. When friction reducer is added to water, the emulsion quickly reverses and releases the polymer into the water, forcing it to further hydrate. Except friction reducer, slickwater also includes other types of additives, such as cleanup additive, clay stabilizers, fungicides and scale inhibitor (Liang et al., 2017; Zhao et al., 2018).

The friction reducer concentration of conventional slickwater is between 0.05 wt% and 0.20 wt%, and the viscosity of base solution is between 1 mPa·s and 7 mPa·s, which can reduce friction loss by 70–80% during the pumping process (Zhao et al., 2018). Conventional slickwater has good friction reduction and low damage, but it has bad proppant carrying performance. In horizontal wells and complex fractures, proppant cannot be effectively transported to the target location, resulting in bad conductivity of the fracture network formed after fracturing. Linear gels and crosslinked gels formed by adding crosslinking agents to the solution, the viscosity of base fluid can be increased by more than 100 times to improve the sand-carrying performance (Lei and Clark, 2007; Zhang et al., 2019). However, a moderate mixing of conventional guar gum and crosslinker in the field requires a special hydration tank to form a stable viscosity, and the friction loss in the pumping process is too large, and more solid phase residuals that damage the reservoir matrix and fractures will be generated after gel breaking. The new type of slickwater system formed by high viscous friction reducer (HVFR) has the effect of high friction reduction rate by conventional slickwater, low reservoir damage and good proppant carrying performance. The HVFR system is mainly synthesized by modified polymer Polyacrylamide. The concentration of HVFR is between 0.05 wt% and 0.80 wt%, and the viscosity of the base solution is 1 mPa·s to 60 mPa·s, different concentrations can be used as a pre-liquid or sand-carrying liquid in the actual application process (Wang et al., 2020; Wang et al., 2020b).

In summary, as a new type fracturing fluid, HVFR system combines the advantages of conventional slickwater and guar gum fracturing fluid, and overcomes their disadvantages. Zhao and Brannon et al. summarized the data of the application of viscous slickwater in unconventional reservoirs in recent years, and made statistics on the concentration, viscosity and temperature range of viscous slickwater (Zhao et al., 2018; Brannon and Bell, 2011; Van Domelen et al., 2017; Huang et al., 2021; Huang et al., 2020). However, the above studies not carried out experimental research and analysis on the mechanism of viscous slickwater to improve sand-carrying capacity. Aften, Motiee and Quintero et al. tested the viscoelasticity, static sand-carrying performance, and friction reduction performance of viscous slickwater, but did not study its dynamic sand-carrying performance (Aften, 2018; Motiee et al., 2016; Quintero et al., 2019). Ba Geri, Hu and Dahlgren et al. studied the viscoelasticity, dynamic sand carrying visualization process and friction reduction performance of viscous slickwater (Ba Geri et al., 2019; Hu et al., 2018; Hu et al., 2019; Dahlgren et al., 2018). Wang et al. comprehensively studied the performance of HVFR in the previous article, and focused on the HVFR friction reduction and sand-carrying mechanism (Wang et al., 2020; Wang et al., 2020b). In order to further expand the performance of HVFR and form a new multi-effect slickwater system, based on the above research, a multifunctional fracturing fluid system composed of nano-emulsion and HVFR was proposed in this study. The multi-functional fracturing fluid has the characteristics of friction reduction and improving flowback rate, high viscous and sand-carrying, imbibition oil displacement, and mixing on the fly. It is a novel fracturing fluid for realizing the integrated subdivision cutting volume fracturing of “fracturing, energy enhancement and oil displacement” in tight oil horizontal wells. The following will summarize and describe the synergistic effect, viscoelasticity, friction reduction characteristics, sand carrying performance, spontaneous imbibition oil displacement performance and microstructure of the multi-functional slickwater hydraulic fracturing.

2 Material and method

2.1 Material

The chemical additives selected in the experiment includes nano-emulsion CND for tight oil reservoir imbibition, the main component is anionic nano-surfactant; the high viscous friction reducer FR-900, the main component is polyacrylamide copolymer.

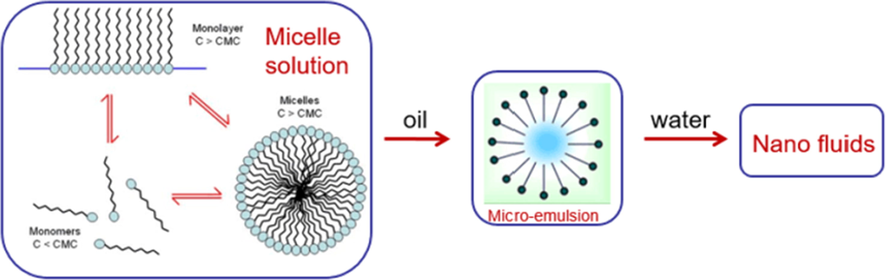

CND nano emulsion is synthesized from water phase, oil phase and surfactant by microemulsion method. It is a liquid substance, and surfactant accounts for about 20% of it. Its structure and synthetic method are shown in the Fig. 1. high viscous friction reducer FR-900 is made of polyacrylamide or polyacrylamide copolymers, both of them provided by Beijing Kemax Oilfield Chemicals Company, China.

Map for the synthetic method of nanoemulsion.

2.2 Method

2.2.1 Rheological properties test

Viscosity test: Different concentrations of single system FR-900 or mixed system FR-900 / CND solution were prepared by distilled water. The viscosity of FR-900 solution at different shear rates was tested by 35 Fann six-speed viscometer to study the effect of CND on the viscosity of FR-900 solution.

The rheological performance test includes the viscoelasticity and viscosity test of single system FR-900 or mixed system FR-900 / CND solution. Viscoelasticity is one of the main indexes of sand carrying capacity of polymer fluid. Firstly, HAKKE RS6000 rheometer was used for stress sweeping of polymer solution. Then, the stress values in the linear region near the inflection point of the stress sweep were used to conduct the frequency scanning of the solution to obtain the elastic modulus G' and the viscosity models G'' of the solution to determine the viscoelastic strength of different solutions.

2.2.2 Friction reduction test

Friction reduction is an important parameter that distinguish HVFR system from linear gel and crosslinked gel fracturing fluids. Laboratory friction reduction pipeline testing system consists of three parts: pumping system, pipeline test system and data acquisition system. Specifically include: ① Water storage tank; ② Injection pump; ③ Mass flow meter; ④ Pipes with different inner diameters; ⑤ Pressure differential sensor (0–5 MPa, ±0.02%); ⑥ Temperature control and acquisition system (0–100 °C, ±0.1 °C); ⑦ Water supply system; ⑧ Stirring system; ⑨ Data acquisition and flow control system. The pipeline test system includes the inner diameters of 6 mm, 8 mm and 10 mm, and the length is 2.5 m (Wang et al., 2020b). The equipment is shown in Fig. 2. The friction loss test was performed using 8 mm lines in this study. Friction reduction rate is calculated by the following formula (1):

Friction reduction rate pipeline test system for polymer fluid.

Where FR% is friction reduction rate of friction reducer solution; △P1 is the pressure difference generated when clean water passes through the ends of 8 mm pipe at different flow rates; △P2 is the pressure difference generated when friction reducer passes through the ends of 8 mm pipe at different flow rates.

2.2.3 Sand-carrying properties test

Static sand settling test include single-particle sand and dynamic sand carrying experiment in fracture with certain sand ratio. Single sand Settling: A certain concentration of friction reducer solution was prepared and poured into a 1000 mL measuring tube. Then, 3–4 40 / 70 mesh proppants were put into the measuring tube, and the time used for 3–4 sands to drop from 900 mL to 400 mL was recorded, and then calculate the average time. Dynamic sand carrying experiment: The 40 / 70 mesh proppant was added into the friction reducer solution at a sand ratio of 150 Kg/m3, and stirred at 800 rpm for 15 mins. Then the fracturing fluid was pumped into the crack through the pumping system to observe the suspension of proppant in the fracturing fluid.

2.2.4 Enhanced oil recovery properties test

The mechanism of surfactant enhancing oil recovery is to reduce oil–water interfacial tension, change rock surface wettability and demulsification to achieve the effect of imbibition oil displacement. Multifunctional slickwater not only has the characteristics of HVFR such as friction reduction, sand-carrying and low damage, but also has the effect of imbibition oil displacement.

In order to verify the enhanced oil recovery (EOR) characteristics of the multifunctional slickwater system, the interfacial tension value between single system / mixed system with crude oil, the demulsification rate after mixing with crude oil, the effect of changing the wettability of reservoir rock and the efficiency of imbibition oil displacement is tested respectively.

For wettability test experiments, a reservoir core in a tight oil block of Changqing Oilfield was selected to study the wetting modification effect, and the core depth was 2200 m; the experimental crude oil was tight reservoir crude oil with a viscosity of 2.7 mPa·s. The core was placed in water (2.0 wt% KCl brine), and 10 μL crude oil was dropped on the surface of the core using a micropipette to test the oil–water-core contact angle in the original state. Then the core was soaked in a 0.10 wt% CND + 0.60 wt% FR-900 slickwater solution after gel breaking for 24H for wetting modification. The “water–oil-core” contact angle was measured again after chemically treatment.

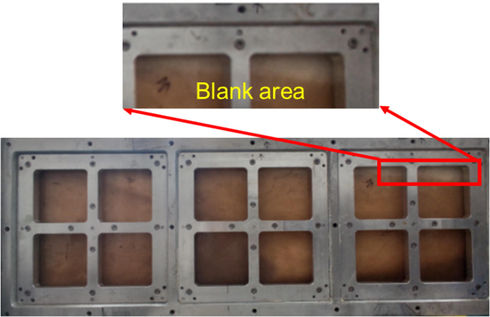

Three slickwater fracturing fluids of 0.60 wt% FR-900, 0.05 wt% CND + 0.60 wt% FR-900, 0.10 wt% CND + 0.60 wt% FR-900 are subjected to gel breaking treatment, then mix the breaker liquid and crude oil according to 7:3 and put it into a 100 mL graduated cylinder, close the lid of the graduated cylinder and shake it 200 times, then let the graduated cylinder stand still (Fig. 14), observe and record the separation time of the crude oil and the breaker liquid.

2.2.5 Nano particle size and microstructural test

The nano particle size of chemical droplets in friction reducer solution is an important index for imbibition oil displacement in micro-nano permeability reservoir. At the same time, if the nano-emulsion is mixed with HVFR, the single HVFR microstructure will be changed. The experimental data are provided for the follow-up analysis of the mechanism of the mixed system.

2.2.6 Compounded system working principle

By comparing the effects of single HVFR System and Nano emulsion / HVFR mixed liquid on rheology, friction reduction, sand-carrying performance, and imbibition oil displacement effect, and combining the results of nano particle size / microstructure test result, the mechanism of multi-function slickwater synergistic effect was analyzed. The microscopic properties test includes nano particle size and microstructure testing, the Zetasizer Nano laser nanoparticle size analyzer is used to measure fluid’s particle size, the F20 field emission transmission electron microscope was used to scan the microstructures of polymers.

3 Results and discussion

3.1 Rheological properties

3.1.1 Viscosity result

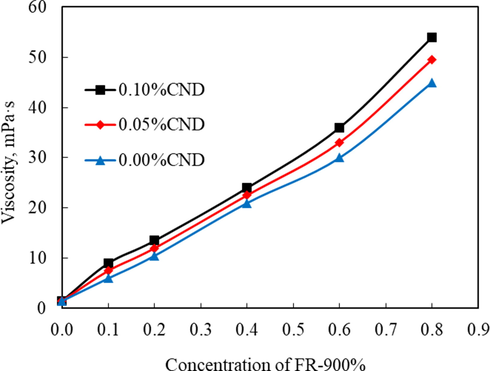

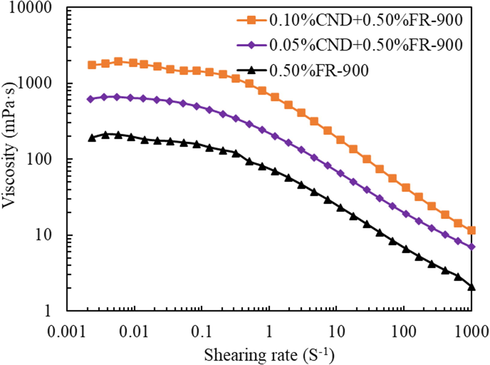

First, the solution viscosity was tested under the same shear rates at 170 S-1 using a Type 35 Fann six-speed viscometer, and the results are shown in Fig. 3. After adding 0.00 wt%, 0.05 wt% and 0.10 wt% CND, the apparent viscosity of the solution is 45 mPa·s, 50 mPa·s and 57 mPa·s when the FR-900 concentration is 0.80 wt%, indicating that CND can enhance the apparent viscosity value of FR-900 solution. The viscosity of FR-900 mixed with CND under continuous shear also confirmed that CND had the ability to enhance the apparent viscosity of FR-900 solution. Fig. 4 shows the results of viscosity changes of different types of solutions under continuous shear rate. In Fig. 4, the viscosity values of 0.5 wt% FR-900 and 0.10 wt% CND are the highest. As the shear rate increases, the viscosity of the polymer solution gradually decreases. This indicates that the solution has shear thinning properties.

Viscosity of solution after mixing FR-900 and CND.

Viscosity of FR-900 mixed with CND under continuous shear.

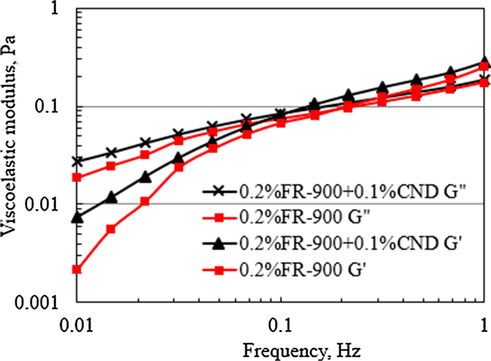

3.1.2 Viscoelastic property

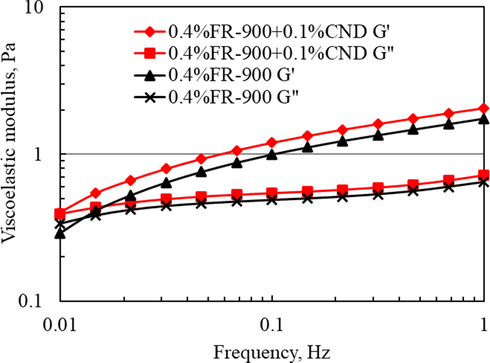

Viscoelasticity is one of the main indicators to measure the sand-carrying performance of polymer solutions. De Gennes, Yang Bo, Haiyan Zhao and others believe that the elasticity of polymer solutions is a key factor reflecting its sand-carrying performance (Zhao et al., 2018; De Gennes, 1986; De Gennes, 1990; Yang et al., 2019). Therefore, it is necessary to simultaneously test the viscosity modulus G'' and elastic modulus G' of the solution, and the intersection points of G' and G'' represent the relaxation time of the polymer network. The lower the cross point value, the stronger the suspension ability of proppant. The viscoelasticity of FR-900 friction reducer solution with different concentrations was tested by HAKKE RS6000 rheometer, and the viscoelasticity of friction reducer solution after adding 0.1 wt% CND nano-emulsion was tested (Figs. 5-7). At the same time, for the convenience of comparison, compare the corresponding viscous modulus G’’ and elastic modulus G’ values when the scanning frequency is 1 Hz, and study the effect of adding the CND nano-emulsion on the viscoelasticity of the drag reducer solution. The results are shown in Figs. 4-6.

Viscoelastic test results of 0.2 wt% FR-900 and different concentrations of CND.

Viscoelastic test results of 0.4 wt% FR-900 and different concentrations of CND.

Viscoelastic test results of 0.6 wt% FR-900 and different concentrations of CND.

The intersection of G’’ and G’ in Figs. 4-6 and the corresponding G’’ and G’ at 1 Hz were counted, and the results are shown in Table 1. As the concentration of FR-900 increases, the intersection of G’’ and G’ decreases from 0.12 Hz to 0.006 Hz, indicating that the increase in concentration corresponds to the stronger the proppant suspension capacity of the solution. After adding 0.10 wt% CND nano-emulsion to FR-900 solution, the cross point value decreased, and the corresponding G’’ and G’ values at 1 Hz increased, indicating that CND nano-emulsion is beneficial to enhance the sand-carrying performance of FR-900 solution.

CND concentration, wt%

0.00

0.10

0.00

0.10

0.00

0.10

FR-900 concentration, wt%

0.20

0.40

0.60

Cross value, Hz

0.120

0.100

0.012

0.011

0.008

0.006

1 Hz G', Pa

0.250

0.284

1.748

2.049

3.444

4.554

1 Hz G“, Pa

0.173

0.188

0.646

0.716

0.978

1.189

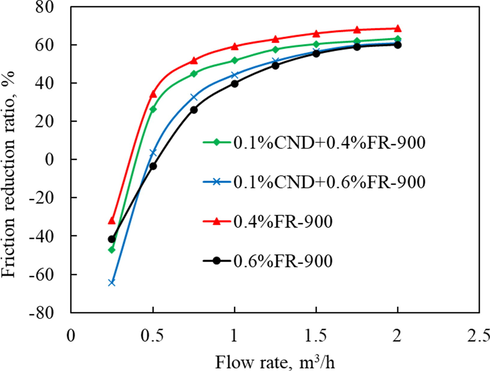

3.2 Friction reduction characteristics

The friction reduction under high-speed shearing conditions is the main feature of HVFR solution which is different from conventional slickwater solutions. This feature can help reduce the energy loss caused by frictional resistance during the fracturing process. In the actual fracturing process, the pumping flow rate reaches 10 m3/min, which is much higher than the laboratory simulation flow rate. In this study, the maximum flow rate is 2.0 m3/h due to the power limit of the equipment. Fig. 8 shows the friction reduction test results of different concentrations of FR-900 and CND. When the flow rate is 2.0 m3/h, the friction reduction rates of 0.40 wt% and 0.60 wt% FR-900 solution are 68.54% and 59.94% respectively. After adding 0.10 wt% CND, the drag reduction rates of 0.40 wt% and 0.60 wt% FR-900 solution are 63.23% and 60.73% respectively. It can be seen from the results that FR-900 has a friction reduction effect of more than 50% when flowing at a high speed, and the addition of CND has little effect on the friction reduction effect of FR-900. It can be seen from 3.1 that CND can enhance the rheological properties of FR-900 and improve the sand-carrying performance of the solution; combining the structures of 3.1 and 3.2, it can be seen that the viscosity of the solution increases after CND is mixed with FR-900, but the drag reduction performance of the solution is not affected too much, so CND has good compatibility with FR-900.

FR-900 and CND friction reduction test results.

3.3 Sand-carrying performance

The results of 3.1 and 3.2 show that CND and FR-900 have good rheological properties and friction reduction. It is necessary to study the sand-carrying capacity of the mixed solution of FR-900 and CND/FR-900. The static and dynamic sand-carrying properties of FR-900 and CND/FR-900 mixed solution were studied. In the static and dynamic sand-carrying experiments, the proppant used is 40/70 mesh quartz sand commonly used in fracturing, and the bulk density is 1.8–2.0 × 103 Kg/m3.

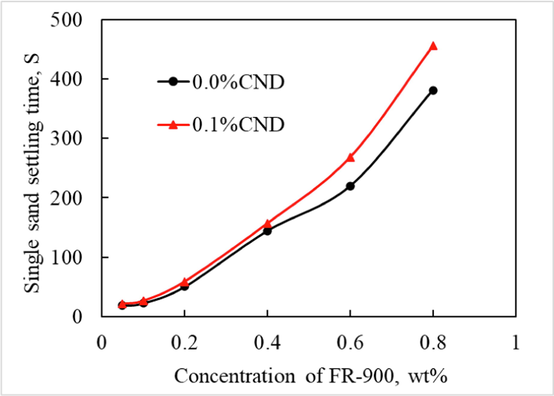

3.3.1 Single sand settling

Prepare friction reducer fluids of different concentrations and test the average time of 3–4 40/70 mesh sands fall 500 mL length, the results are shown in Fig. 9. When the concentration of FR-900 reaches 0.60 wt%, the settling time of proppant under static conditions reaches 220 s, indicating that FR-900 has good static sand carrying performance. In the actual fracturing process, the slickwater is in a high-speed flow state, so it has a stronger sand-carrying performance. After adding 0.10 wt% CND to the solution, the static sand carrying performance of the 0.60 wt% FR-900 solution increased to 269 s. Combining the viscoelasticity results after mixing CND and FR-900 solution, CND mainly enhances the sand-carrying performance of the solution by increasing the elastic modulus of the FR-900 solution.

FR-900 and CND single sand settlement time.

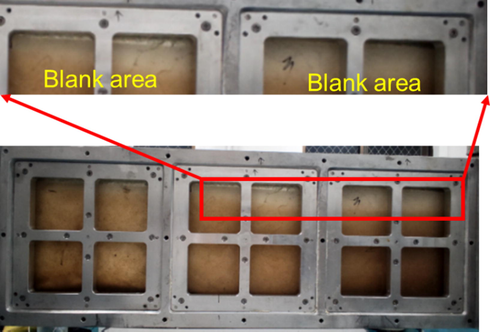

3.3.2 Dynamic carrying performance

The slickwater solution with a sand ratio of 150 Kg/m3 is delivered to the visualized fracture system through the pumping system, and simulating the dynamic sand carrying performance of the slickwater in the fracture. The solution flow rate is 1.50 m3/mins, and the result is shown in Figs. 10 and 11. The 0.6 wt% FR-900 solution exhibits good sand-carrying performance. Most proppants can be suspended in the solution, and only a small part of the solution has bad sand-carrying performance (in the red circle in Fig. 10), and then settles slowly. The slickwater mixed with 0.10 wt% CND and 0.60 wt% FR-900 further improves the sand-carrying performance of the solution, and the area with poor sand-carrying performance is reduced (Fig. 11).

0.60 wt%FR-900 dynamic sand carrying performance in fractures.

0.10 wt% CND + 0.60 wt% FR-900 dynamic sand carrying performance in fractures.

3.4 Enhanced oil recovery properties

The results of 3.1–3.3 show that CND can enhance the rheological properties and sand carrying capacity of FR-900 solution, and has little effect on the friction reduction of solution. CND has the effect of enhanced oil recovery as a surfactant for imbibition oil displacement (Liang et al., 2020a; Liang et al., 2020). Whether the mixture of CND and FR-900 will affect the imbibition oil displacement effect of CND crude oil needs further test. The wettability, demulsification, interfacial tension and imbibition oil displacement efficiency of CND and FR-900 mixed solution were studied.

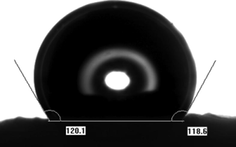

3.4.1 Contact angle

As shown in Figs. 12 and 13. The average contact angle of “water-oil-core” is 69.9° before gel breaking treatment, and the contact angle of oil drops increases to 119.4° after chemical treatment, which indicates that the core surface changes from oil-wetting to water-wetting. The mixture of CND and FR-900 still has good wettability, which is beneficial to the wettability of the fracturing fluid into the reservoir after hydraulic fracturing. In addition, the porosity of the core used in the wettability test is 4.58%, and the gas permeability is 0.214 mD.

Contact angle of oil droplets on core surface before wetting and modification, “water-oil-solid” Average contact angle = 69.9°.

Contact angle of oil droplets on core surface after wetting and modification, “water-oil-solid” Average contact angle = 119.4°.

Demulsification rate test chart of single/mixed solution.

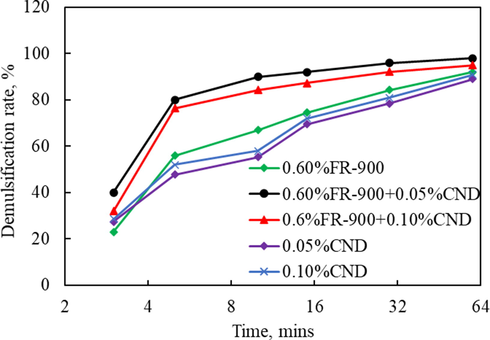

3.4.2 Demulsification rate

The result is shown in Fig. 15. The separation rate of the gel breaker with CND added from crude oil is significantly higher than that of the solution without CND. When the CND concentration is 0.00 wt%, 0.05 wt%, and 0.10 wt%, the demulsification rate corresponding to the inflection point is 56.00%, 80.02%, 76.47% respectively. The final demulsification rate was 92.00%, 98.00%, 96.12%. It shows that CND promotes the separation between crude oil and breaker liquid, and prevents crude oil and breaker liquid from forming a water-in-oil emulsion, which will increase the viscosity of crude oil and is not conducive to crude oil exploitation. For a mono-CND, the demulsification effect was lower than that of CND and FR-900, indicating that there was a synergistic demulsification effect between CND and FR-900.

Demulsification rate test results of single/mixed solution.

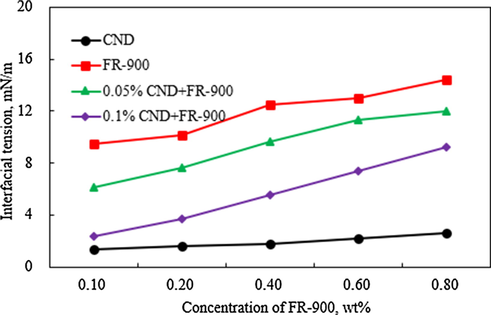

3.4.3 Interfacial tension

Studies have shown that reducing the value of oil–water interfacial tension can significantly increase oil recovery. The principle is to reduce the capillary resistance of crude oil flow by changing the value of oil–water interfacial tension (Usman, 2021; Yang et al., 2021). The HZ-800 interfacial tension meter was used to test the interfacial tension values of CND, FR-900 and the two mixtures and crude oil. The results are shown in Fig. 16. The interfacial tension between CND and crude oil is between 1.40 and 2.60 mN/m, the interfacial tension between FR-900 and crude oil is between 9.45 and 14.43 mN/m, and the interfacial tension between 0.05 wt% CND + FR-900 and crude oil is between 6.10 and 12.01 mN/m, the interfacial tension between 0.10 wt% CND + FR-900 and crude oil is between 2.40 and 9.25 mN/m. The comparison shows that CND solution and crude oil have lower interfacial tension values, and the interfacial tension value between FR-900 and crude oil is higher. After adding CND to the FR-900 solution, the interfacial tension between the slickwater and the crude oil decreased significantly, and the higher the CND concentration, the greater the decrease in interfacial tension.

Interfacial tension between solution and crude oil.

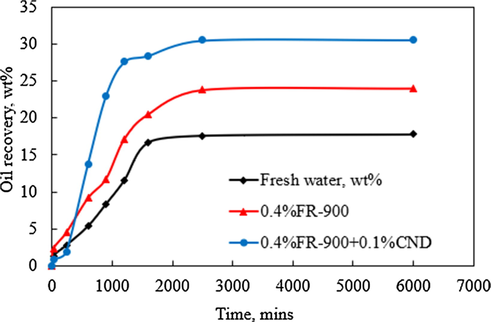

3.4.4 Spontaneous imbibition experiment

The spontaneous imbibition oil displacement experiment comprehensively reflects the effect of improving oil recovery after CND and FR-900 are mixed. The main experimental device is the Amott spontaneous imbibition bottle (Liang et al., 2020a, 2020b). Fig. 17 shows the results of the spontaneous imbibition oil displacement experiment with three different solutions. The final imbibition oil sweep efficiency in fresh water, 0.40 wt% FR-900 gel breaker liquid, 0.40 wt% FR-900 + 0.10 wt% CND gel breaker liquid were 17.79%, 24.00% and 30.58% respectively. The spontaneous imbibition oil sweep efficiency in fresh water is low, and CND + FR-900 gel breaker liquid has the highest oil imbibition displacement efficiency. This is mainly due to the combined effect of CND surfactant and FR-900 polymer. Combined with the above research results of 3.3 sand carrying performance, 3.2 friction reduction performance, 3.4.1 wetting modification and 3.4.3 reducing oil–water interface tension, it can be seen that adding CND into FR-900 can not only improve the performance of HVFR slickwater as fracturing fluid (Improve the sand-carrying performance of fracturing fluid and reduce the interfacial tension between gel breaking fluid and crude oil), but also have the effect of imbibition oil displacement to improve tight oil recovery, realizing the purpose of multi-effect of one recipe.

Imbibition oil sweep efficiency of single/mixed solution.

3.5 Performance micro interpretation

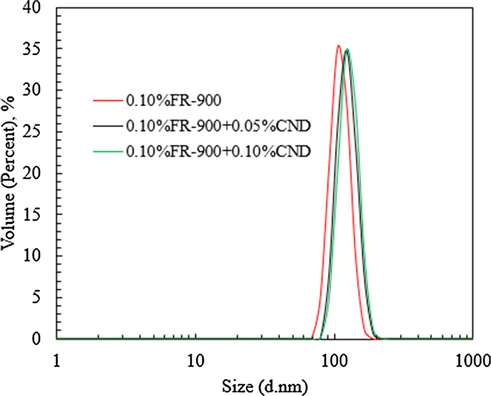

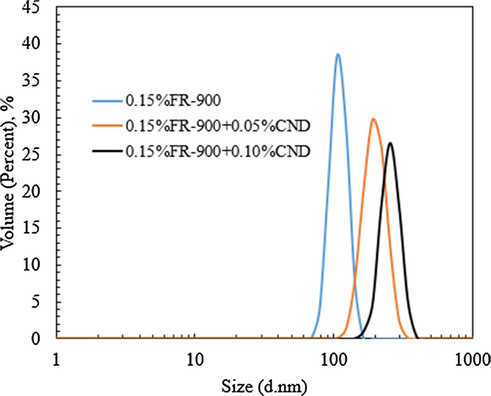

In 3.1–3.4, the rheological properties, friction reduction effect, sand-carrying performance and imbibition oil sweep efficiency function of after mixing CND and FR-900 are studied from a macro perspective. In order to further reveal the microscopic mechanism of the interaction between CND and FR-900, the following tests the nano particle size (Figs. 18-19) and TEM image (Transmission electron microscope) of the solution after mixing CND and FR-900.

Nano particle size test of solution after mixing 0.10 wt% FR-900 with different concentrations of CND.

Nano particle size test of solution after mixing 0.15 wt% FR-900 with different concentrations of CND.

Due to the high-concentration FR-900 solution is milky white, which affects the laser nanoparticle size test, two low-concentration FR-900 of 0.10 wt% and 0.15 wt% were used to mix with CND. The test results are shown in Figs. 17-18. 0.10 wt% FR-900, 0.05 wt% CND + 0.10 wt% FR-900, 0.05 wt% CND + 0.10 wt% FR-900 nano particles are 112 nm, 125 nm, 143 nm respectively; 0.15 wt% FR-900, 0.05 wt% CND + 0.15 wt% FR-900, 0.05 wt% CND + 0.15 wt% FR-900 nano particle size is 112 nm, 190 nm, 255 nm respectively, indicating that CND makes the nano-particle size of FR-900 polymer solution larger, and how CND is fused with FR-900 needs to be analyzed in combination with micro TEM images.

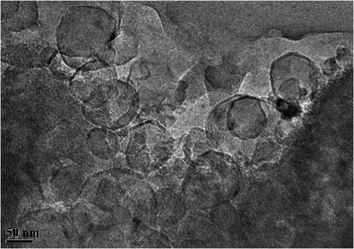

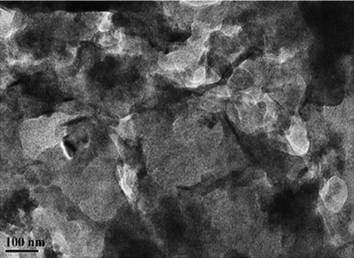

In order to further reveal the influence of the polymer microstructure on the friction reduction and sand-carrying performance of the friction reducer, the F20 field emission transmission electron microscope was used to scan the polymer microstructure after CND and FR-900 were mixed. Figs. 20 and 21 are respectively the TEM image of FR-900 polymer and the TEM image of CND and FR-900 after mixing. The microstructure of FR-900 polymer is a sheet-like structure, which belongs to the swelling and aggregation of multiple FR-900 molecules in water. After CND and FR-900 are mixed, the TEM image of the polymer shows that the overall polymer is in a fuzzy sheet shape, indicating that CND promotes FR-900 molecules further associate to form a network structure, which improves the sand-carrying performance of HVFR solution.

TEM image of 0.50 wt% FR-900 friction reducer, 50 μm.

TEM image of 0.50 wt% FR-900 + 0.05wt %CND solution, 100 μm.

Furthermore, CND and FR-900 were mixed to prepare three types of slickwater solutions, and the solution was stirred with a glass rod to observe the picking performance of the polymer solution, as shown in Figs. 22-24. The 0.60 wt% FR-900 solution picking shows that the solution has good viscoelasticity. With the increase of the concentration of CND added, the picking performance of the solution further increases, and it can basically form a whole sheet. Combining the above macro and micro research results, it can be seen that CND connects more FR-900 polymer molecules together through intermolecular association to enhance the sand-carrying performance of FR-900 solution. CND also increases the imbibition oil displacement effect of the solution, and fully realizes the purpose of one dose of multiple effects.

Hanging state of 0.60 wt% FR-900.

Hanging state of 0.05 wt% CND + 0.60 wt% FR-900.

Hanging state of 0.10 wt% CND + 0.60 wt% FR-900.

Finally, the residue content after gel breaking of the multifunctional slickwater fracturing fluid was tested to verify the low damage characteristics of the polymer solution in the reservoir. The test shows that when the gel breaker (The main component of the breaker is ammonium persulfate, the gel breaker is added together with other additives when the fracturing fluid is prepared, and the gel breaker does not work at room temperature. When the temperature is higher than 60 °C, the gel breaker oxidizes and destroys the polymer molecules and reduces the viscosity of the solution.) concentration is 50 ppm, 100 ppm and 200 ppm, the breaking time of 0.10 wt% CND + 0.60 wt% FR-900 solution is 45 mins, 35 mins and 20 mins, respectively, and the corresponding residue content is 53.5 ppm, 52.1 ppm and 47 ppm. It has the characteristics of easy gel breaking and low damage.

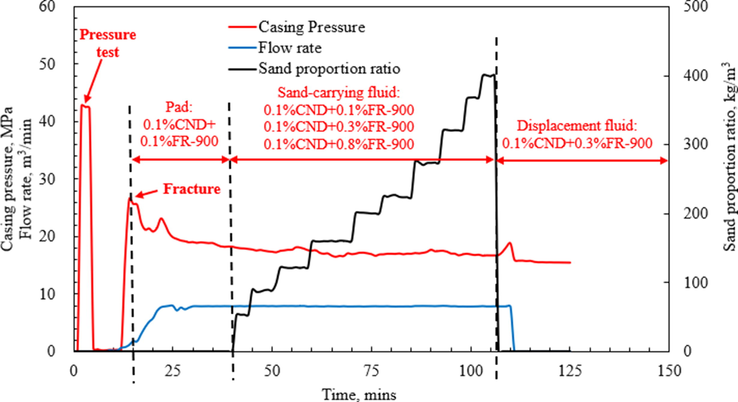

4 Field application

In order to verify the field application effect of the new multifunctional slickwater fracturing fluid system, a well X in a tight oil block in China’s Changqing Oilfield was selected for field application. The perforation section of Well X is 2208.0–2212.0 m, the proppant is 40/70 mesh quartz sand, the CND concentration is 0.10 wt%, and FR-900 includes three concentrations of 0.10 wt%, 0.30 wt% and 0.80 wt%. The fracturing operation curve of Well X is shown in Fig. 25. The maximum displacement rate is 8.0 m3/min, the maximum sand ratio reaches 400 kg/m3, the formation fracture pressure is 26.49 MPa, and the fracture extension pressure is 16.5–17.6 MPa. The fracturing process shows stable pressure and good sand-carrying performance. During the fracturing, 668.8 m3 fracturing fluid was pumped into the well, 179 m3 was drained back, the rate of drained back was 26.8%, the daily production of compact oil was 26.5 t in the trial production phase, while the daily production of conventional slickwater fracturing was only 5–6 t.

Fracture construction curve of well X.

5 Conclusions

In this paper, the performance of the new multifunctional HVFR slickwater fracturing fluid is evaluated through experimental design, experimental study, theoretical analysis and field application. The main conclusions and recommendations are as follows:

It is found that CND can enhance the rheological properties and sand-carrying performance of FR-900 solution. After CND was added, the viscosity and viscoelasticity of FR-900 solution were improved, and the single particle sand carrying capacity and dynamic sand carrying capacity of the solution were enhanced.

FR-900 combines the sand-carrying performance of linear gel and crosslinked gel, and also has the friction reduction performance of conventional slickwater. When the flow rate was 2.0 m3/h, the friction reduction rate of 0.40 wt% and 0.60 wt% FR-900 solution was 68.54% and 59.94% respectively. After adding 0.10 wt% CND, the friction reduction rate of 0.40 wt% and 0.60 wt% FR-900 solution was 63.23% and 60.73% respectively. Adding CND basically does not affect the friction reduction performance of FR-900.

The main component of CND is a surfactant for imbibition displacement. After CND is mixed with FR-900, the fracturing fluid has the effects of wetting modification, reducing oil–water interfacial tension and rapid demulsification. The results of imbibition oil displacement experiments show that 0.10 wt% CND can increase the oil recovery of FR-900 solution by 12.79%. At the same time, when the gel breaker concentration is 200 ppm, the CND + FR-900 solution can quickly break the gel within 20 mins, and the residue content is as low as 47 ppm, which has the properties of easy gel breaking and low residue.

The field test of Well X in a tight oil block in Changqing Oilfield shows that the crack expansion construction pressure of the CND + FR-900 system is 16.5–17.6 MPa, the maximum sand carrying capacity is 400 kg/m3, and the oil well output after construction is as high as 26.5 t/d, which shows that the new multifunctional fracturing fluid system has low construction pressure, high sand-carrying performance and increased production effect.

Acknowledgments

This work is financially supported by the Planned Project, Hubei Provincial Department of Science and Technology (Second Batch), (NO. 2021CFB249) & Project of Science and technology research, Education Department of Hubei Province (NO. Q20211303).

Declaration of competing interest

The authors declare no financial conflicts of interest regarding the publication of this paper.

References

- EIA, 2016. Initial production rates in tight oil formations continue to rise - today in Energy - U.S. Energy Information Administration (EIA) [WWW Document]. Available from: <https://www.eia.gov/todayinenergy/detail.php?id=24932> (Accessed 6.8.17).

- A new approach to predict field-scale performance of friction reducer based on laboratory measurements. J. Petrol. Sci. Eng. 2017 S0920410517307799

- [Google Scholar]

- Viscous slickwater as enabler for improved hydraulic fracturing design in unconventional reservoirs. Soc. Petroleum Eng. 2018

- [CrossRef] [Google Scholar]

- Crosslinking of guar and guar derivatives. SPE J.. 2007;12(3):316-321. SPE-90840-MS

- [CrossRef] [Google Scholar]

- Evaluation of permeability damage caused by drilling and fracturing fluids in tight low permeability sandstone reservoirs. J. Petrol. Sci. Eng.. 2019;175:1122-1135.

- [Google Scholar]

- A Comprehensive method to evaluate the viscous slickwater as fracturing fluids for hydraulic fracturing applications. J. Petrol. Sci. Eng.. 2020;193:107359

- [Google Scholar]

- Wang, J., Zhou, F, Bai, H, et al. 2020. A new approach to study the friction-reduction characteristics of viscous / conventional slickwater in simulated pipelines and fractures. J. Nat. Gas Sci. Eng. 83.

- Brannon, H.D., Bell, C.E., 2011. Eliminating slickwater fracturing compromises for improved shale stimulation. Soc. Petroleum Eng. doi: 10.2118/147485-MS.

- Van Domelen, M., Cutrer, W., Collins, S., et al., 2017. Applications of viscosity-building friction reducers as fracturing fluids. Soc. Petroleum Eng. doi: 10.2118/185084-MS.

- Analysis of various high viscosity friction reducers and brine ranges effectiveness on proppant transport. Soc. Petroleum Eng. 2018

- [CrossRef] [Google Scholar]

- High concentration polyacrylamide-based friction reducer used as a direct substitute for guar-based borate crosslinked fluid in fracturing operations. Soc. Petroleum Eng. 2016

- [CrossRef] [Google Scholar]

- Quintero, H., Farion, G., Gardener, D., et al., 2019. Successful application of a salt tolerant high viscous friction reducer technology: past and present. Soc. Petroleum Eng. doi: 10.2118/196211-MS.

- A critical review of using high viscosity friction reducers as fracturing fluids for hydraulic fracturing applications. Soc. Petroleum Eng. 2019

- [CrossRef] [Google Scholar]

- Hu, Y., Fisher, D., Kurian, P., et al., 2018. Proppant transport by a high viscosity friction reducer. Soc. Petroleum Eng. doi: 10.2118/189841-MS.

- Hu, Y., Popeney, C., Gilmer, C., et al., 2019, July 31. Quantification of dynamic sand settling velocity in high-viscosity friction reducers and correlation with rheology. In: Unconventional Resources Technology Conference. doi: 10.15530/urtec-2019-588.

- Case studies of high viscosity friction reducers HVFR in the STACK play. Soc. Petroleum Eng. 2018

- [CrossRef] [Google Scholar]

- Towards a scaling theory of drag reduction. Phys. Stat. Mech. Appl.. 1986;140(1–2):9-25.

- [CrossRef] [Google Scholar]

- An elastic theory of drag reduction. In: Introduction to Polymer Dynamics. Cambridge: Lezioni Lincee, Cambridge University Press; 1990. p. :34-54.

- [Google Scholar]

- Review of friction reducers used in slickwater fracturing fluids for shale gas reservoirs. J. Nat. Gas Sci. Eng.. 2019;62:302-313.

- [Google Scholar]

- Liang, X., Liang, T., Zhou, F., et al., 2020. Enhanced fossil hydrogen energy recovery through liquid nanofluid huff-n-puff in low permeability reservoirs. Int. J. Hydrogen Energy 45 (38).

- Impacts of low harm fracturing fluid on fossil hydrogen energy production in tight reservoirs. Int. J. Hydrogen Energy. 2020;45(41)

- [Google Scholar]

- Usman, A., 2021, June. Investigation of reduced interfacial tension by surfactant flooding in mixed-wet reservoirs. In: Paper presented at the SPE Trinidad and Tobago Section Energy Resources Conference, Virtual.

- Dynamic contact angle reformulates pore-scale fluid-fluid displacement at ultralow interfacial tension. SPE J.. 2021;26:1278-1289.

- [Google Scholar]

- Experimental and simulation investigations of the impact of polyacrylamide on CBM ad-/desorption. J. Petrol. Sci. Eng.. 2021;109300

- [Google Scholar]

- Fracture permeability damage and recovery behaviors with fracturing fluid treatment of coal: an experimental study. Fuel. 2020;282:118809

- [Google Scholar]