Translate this page into:

Biofuels from microalgae biomass: A review of conversion processes and procedures

⁎Corresponding authors. samuel.ebhodaghe@eng.uniben.edu (Samuel Ogbeide Ebhodaghe), ojeaga.imanah@uniben.edu (Ojeaga Evans Imanah),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Abstract

Key areas for improvement in microalgae conversion include the nature of catalysts been utilized. Bio-based catalysts should be preferred due to high cost of synthetic catalysts. Methodical limitations such as high equipment cost for process scale-up can prevent research from advancing as it could. Promising microalgae conversion processes which could be progressed are the use of bio-based solvents and supercritical fluids for biodiesel production, hydrothermal liquefaction for biogas production, microwave-induced pyrolysis for syngas production, and ultrasound/microwave enhanced extraction for bio-oil production. For future developments, the use of the promising conversion techniques would probably gain the interest of more researchers than at present, considering the merits of same. In other words, more research is expected to evolve in coming years.

Abstract

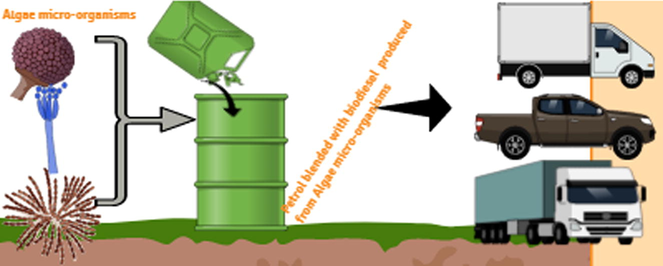

Achieving the EU 2030 vision of a 15% minimum amount of biofuels utilized in the road transportation require more research on biofuel production from biomass feedstock. To this end, this review study examines the use of green, deep eutectic solvents and direct transesterification approaches for biomass conversion to biofuels. Next, biogas production from anaerobic co-digestion of microalgae biomass is presented. Lastly, the effect of operating conditions, as well as advantages and limitations of several biomass conversion techniques are outlined. Of note, this study presents promising microalgae conversion processes which could be progressed are the use of bio-based solvents and supercritical fluids for biodiesel production, hydrothermal liquefaction for biogas production, microwave-induced pyrolysis for syngas production, and ultrasound/microwave enhanced extraction for bio-oil production. These are based on the possibility of high yield and process economics. We have also enumerated knowledge gaps needed to propel future studies.

Keywords

Biofuel

Microalgae

Lipid

Syngas

Anaerobic co-digestion

Pyrolysis

Transesterification

1 Introduction

Fossil fuels are cheap energy sources which have continued to meet world’s growing energy needs. With an exhaustible reserve, fossil fuel prices will undoubtedly rise when demands gradually begins to exceed supply (Georgianna and Mayfield, 2012). This now suggests the need for more development of sustainable energy sources. This is important because of the obviously increasing scarcity of conventional fuels associated with the expanding and unimpeded population growth as well as industrialization (Ambat, 2018; Ambat et al., 2019).

Considering the benefit of not using much arable land space, biofuels can be produced from organisms such as algae since they demonstrate a higher yield estimate when compared to most crops. For example, cultivating algae on a 30-million-hectare plot can yield a conservative biofuel estimate of 40,000 L per hectares per year. Research has shown that this can potentially substitute the 1,200 billion liters of petroleum used by the United States, for example (Georgianna and Mayfield, 2012). Comparing this algae biofuel estimate with the United States soya (29-million-hectare) and corn ethanol production (64-billion-liters from 14-million-hectares), the use of algae is preferable (Doe, 2010; Akhihiero et al., 2019; Akhihiero and Ebhodaghe, 2020).

Especially, the merits of bioenergy production, nutrients recovery, carbon sequestration, high photosynthetic efficiency, ability to accommodate high lipids/carbohydrates content, as well as being cultivation tolerant (Goswami et al., 2019) indicate the environmental and energy benefits of microalgae (Independence, 2007; DOE, 2016; Pradhan et al., 2017; Ahmed, 2017; Roostaei et al., 2018). These are reasons for the current rapid advances in the field. Thus, several notable studies have presented their findings on a number of conversion processes and procedures.

To illustrate, research on biofuel production from microalgae is investigating the cost benefit analysis of several novel production processes. For instance, Pandey et al. (2020) proposed a two-step novel integrated process to develop a sustainable and economically viable biofuel production from algal. This was combined with high-strength FCWW treatment simultaneously. Table 1 shows a list of abbreviations and their meanings. This integration was based on an earlier report that removing total nutrient load by only biological treatment of high-strength FCWW was less effective and time consuming (Rivas et al., 2010). So, this study showed that integrating the two-step novel processes of coagulation and microalgae cultivation is more effective for developing biofuels from algae, and it’s also a simultaneous treatment of the FCWW. This is because of several reasons. One, comparing the microalgae grown in pre-treated FCWW with Chlorella pyrenoidosa grown in BG-11 media, the former showed 230–270 mg/L/day biomass productivity and 58.84–77.41/mg/day lipid productivity. These respective productivities were 2.95 to 3.52-fold and 3.63 to 4.77-fold higher than that of C. pyrenoidosa grown in BG-11 media. Two, the potential suitability of C. pyrenoidosa as a biodiesel feedstock was demonstrated by the presence of C16:0, C18:0, C18:1, and C18:2 in its’ lipid profile. This observation was made on its’ growth profile in the multi-objective optimized pre-treated FCWW. Three, cost benefit analysis of the investigated FCWW-based algae indicates the potential of achieving commercial reality of the algal oil cost which is competitive to crude oil. This shows the possibility of resolving environmental problems associated with FCWW disposal, because of the mixotrophic cultivation of C. pyrenoidosa NCIM 2738 on the pretreated FCWW. This is also because of the conversion of the organics into lipid. Taken together, the study estimates the sum of $9.59million/year as the total profit generated by the integrated two-step process model, and $79.03 per barrel as estimated algal oil production cost. Taking a different approach in developing a sustainable and economically viable biofuel production from algal, Garg and Jain (2020) developed the models of low temperature transesterification of algal oil for biodiesel yield depending on process variables with the use of response surface methodology (RSM) and artificial neural networks (ANN). That is, the effect of process variables such as: methanol to oil percentage (v/v), catalyst concentration, and reaction time on biodiesel production through algal oil transesterification at low temperature. Error percentage was lower for the ANN than for RSM, which shows that the ANN provides reliability of the regression model in predicting possible conversion to any of the conditions provided in the study. Also, the Box-Behnken experimental design reveals a 20–60% methanol to oil percentage (v/v), 0–2 wt% catalyst concentration and 60–180 min reaction time at 50 °C constant temperature. Moreover, a quadratic regression model with R2 value of 0.99 and 0.96 were obtained for the ANN and RSM, respectively. Thus, examining a comparative view of RSM and ANN models show the good predictability of the latter for process optimization of biodiesel production. Building on the work of Pandey et al, a similar research by Phukan et al. (2020) has investigated the combination of remote sensing data and experimental appraisal for cost effective and sustainable microalgae biofuel production. This work was focused on leveraging microalga feedstock for biofuel production and wasteland reclamation.

FCWW

Fresh Cheese Whey Wastewater

NCIM

National Collection of Industrial Microogranism

ANN

Artificial Neutral Network

RSM

Response Surface Methodology

FFA

Free Fatty Acid

FAME

Fatty Acid Methyl Ester

MCHA

N-methylcyclohexylamine

WLEP

Wet Lipid Extraction Procedure

GCMS

Gas Chromatography Mass Spectrophotometer

LCA

Life Cycle Assessment

SCW

Subcritical Water

WGSR

Water-Gas Shift Reaction

DES

Deep Eutectic Solvents

SCM

Supercritical Methanol

MW

Microwave

SCT

Supercritical Transesterification

SCMT

Supercritical Methanol Transesterification

FAEE

Fatty Acid Ethyl Ester

GA

Generic Algorithm

OLR

Organic Loading Rate

FOS-D/TAC

Fossil Diesel/ Total Annual Cost

CCD

Central Composite Design

COD

Chemical Oxygen Demand

HRAP

High Rate Algal Ponds

UASB

Anaerobic sludge blanket

TWAS

Thickened Waste Activated Sludge

WAS

Waste Activated Sludge

GAMS

General Algebraic Modelling System

SR

Stoichiometric Ratio

SFR

Steam Flowrate

HHV

Higher Heating Values

WGSR

Waste Gas Stream Reactioin

HTG

Hydrothermal Gasification

CLC

Chemical Looping Combustion

PAH

Polyaromatic Hydrodcarbons

VOC

Volatile Organic Hydrocarbon

NOX

Oxides of Nitrogen

HTL

Hydrothermal Liquefaction

UHTL

Ultrasonic-assisted Hydrothermal Liquefaction

HIP

Hexane and Isopropanol

EMCR

Extracted Marine Chlorella sp. Residue

CS

Camellia shell

Nevertheless, previous review studies have advanced the field of biofuels production from microalgae biomass, through several extended and evaluative studies. For example, Kröger and Müller-Langer (2012) reviewed the important properties of algal, biofuel production processes (transesterification and hydro-processing) and its’ associated economic and environmental challenges. Alternatively, Mubarak et al. (2015) reviewed the different methods of extracting lipids from microalgae biomass for biodiesel production. The work presented that the use of ultrasonication, microwave-assisted techniques in solvent extraction increases microalgae lipid yield. This detailed review specifically considered the use of microalgae for biodiesel production. Next, Qari et al. (2017) reiterated the importance of microalgae as a renewable energy source and the associated challenges. Futhermore, Osman et al. (2021) reviews advances in biomass conversion to biofuels and their environmental impact by life cycle assessment. Also, Zanuso et al. (2021) discusses the advantages and limitations of hydrolytic lignocellulolsic biomass enzymes immobilization, and the hydrolysis of different lignocellulosic biomasses, while Srivastava et al. (2021) considers bio-wastes and the use of microbial systems for their breakdown. A further review on recent studies involving biodiesel production from microalgae biomass is presented in Table 4, while Table 5 lists several methods of biodiesel production from microalgae with their advantages and limitations

Moving forward, Raheem et al. (2018) recently reviewed the use of different conversion processes – pyrolysis, gasification, hydrothermal liquefaction, fermentation and transesterification, in syngas and biodiesel production. Yet, this review was limited to few microalgae conversion processes. Nevertheless, current reviews have focused on recent advances on catalytic upgrading of alga-derived oil (Zhou and Hu, 2020), and a comprehensive overview of biofuel derivation from raceway pond and photo-bioreactors (Susaimanickam et al., 2020). In addition, Peng et al. (2020) has reviewed the processes of algae cultivation, harvesting, drying and extraction in biofuel production. None of these current reviews have critically addressed a broader range of microalgae conversion processes to specific biofuel products. This is presently not found in the literature. This is important because it would enhance more research on biofuel production from improved scope of production possibilities.

By extension, Kumar et al. (2015) presented the potential application of algal biomass for biofuel and bio-based products production. While this paper describes a variety of processes and pathways of bio-valorizing algal biomass as well as brief discussion of lipid extraction techniques from algal biomass, an in-depth understanding on why these techniques are applied and suitable conditions of application in biofuel production weren’t presented.

To this end, different processes for converting microalgae oil to biodiesel, syngas, bio-methane, bio-hydrogen, and bio-oil have been analytically presented in this review. The aim of this review is to present a critical and systematic understanding of recent developments in biofuel production from microalgae biomass, and offer future directions for more research. With the presented recommendations for more research, the field is expected to evolve more in the coming future. This review presents the challenges associated with the use of most microalgae conversion processes and their subsequent adoption into research practice. Moreover, technical and methodical limitations associated with these processes will be highlighted. Additionally, the use of solvent extraction as the most reported lipid extraction process is first highlighted. Then, a systematic review on its’ of the extraction process, as well as areas of research dispute have been equally presented. A list of abbreviations is presented in Table 1.

1.1 Lipid extraction processes

The use of microalgae for biofuel production is promising due to their high lipid content (Jung et al., 2018). This is because, several factors such as specie type, initial lipid content and amount of biomass treated per unit time do influence the choice of an extraction method (Ranjan et al., 2010). Some of the lipid extraction techniques frequently presented in the literature include: Bligh and Dryer, microwave oven, supercritical fluid extraction, pressurized fluid extraction, ultrasound, sonication and soxhlet extraction. Table 2 shows the advantages and limitations of lipid extraction methods. Ease of extraction No set-up cost Toxic and non-ecofriendly Economical Saves energy Reduces time and solvents Significantly reduces energy consumption Requires dry biomass, though wet biomass can sometimes be used Easy recyclability Greener approach Energy efficient Low technical viability Non-feasibility of solvent synthesis Environmentally friendly Reduces extraction time Low solvents usage Enhances lipid yield Use of volatile or non-polar solvent isn’t efficient Non-standard scale-up Prohibitive capital and operational cost Environmentally friendly Low extraction time Low solvent usage Deeper penetration Difficulty in scale-up Very high operational costs. Low extraction time Fit for wet algae feedstock High extraction efficiency Easy scale-up High energy demands High cost of set-up Derived from bio-based feedstock Eco-friendly and efficient Cost effective Limited feedstock supply Not yet feasible on a large scale High FFA recovery Low toxicity Absence of separation step High equipment and operational cost High extraction efficiency High catalyst cost and energy requirements Energy efficient Non-toxic Enables wet biomass extraction Poor surfactants selection and recovery Low energy consumption High lipid recovery Enables wet biomass extraction State of microalga determine process efficiency Difficulty in enzyme selection

Methods

Advantages

Limitations

References

Conventional

(Sati et al., 2019; Tanzi et al., 2013; Wahlen et al., 2011)

Simultaneous extraction and transesterification

(Im et al., 2014; Shomal et al., 2019; Cicci et al., 2018)

Use of switchable solvents

(Samori et al., 2013; Du et al., 2013; Martinez-Guerra et al., 2014)

Microwave irradiation

(Teo and Idris, 2014; de Moura et al., 2018; Adam et al., 2012)

Ultrasound

(Araujo et al., 2013; Meullemiestre et al., 2016; Lee and Han, 2015)

Hydrodynamic cavitation

(Setyawan et al., 2018; Wu et al., 2019; Mahmood et al., 2017)

Bio-based solvents

(Breil et al., 2016; Silve et al., 2018; Salana et al., 2014)

Supercritical fluids

(Santana et al., 2012; Cheng et al., 2011; Seo et al., 2015)

Oxidation

(Hua et al., 2016; Lai et al., 2017; Seo et al., 2016)

Surfactants

(Montalbo-Lomboy et al., 2014; Zuorro et al., 2016; Sierra et al., 2017)

Enzymatic catalysis

(Zheng et al., 2012; Hu et al., 2017; Ramaluckan et al., 2014)

1.1.1 Solvent extraction

Phukan et al. (2011) investigated the use of thirteen different solvents for extracting lipids from chlorella sp. This was because this specie produces more amount of oil than most other algal species. Excess amount of lipids were extracted (>10%) with the use of chloroform, ethanol and hexane solvents in an optimum time of 3 h. This may be due to the possible formation of volatile degradation products. Also, the binary mixture of 1:1 chloroform: ethanol showed better efficiency with a lipid production quantity of 11.76%, while the best single solvent – chloroform, produced 10.78%. The high efficiency of the binary mixture can be attributed to the fact that the use of solvents greater than binary combination will be impractical for upscaling and even increase the biodiesel production costs. For the chloroform, it produced > 75% fatty acid methyl esters (FAME), which was 58% and 25% greater than those of hexane and ethanol, respectively. This is due to chloroform’s polarity and solubility properties (Veeranan et al., 2017). Taken together, these findings indicate that of the different examined solvents, ethanol, chloroform, and hexane are generally more efficient in lipid extraction. Moreover, there is need for more research to examine the cost and economic analyses of the solvent extraction processes. This is important because the efficiency of the extraction process is better presented when production yields and its’ economics are assessed. Although Ramaluckan et al has initially suggested that the use of solvents greater than binary combination could increase the biodiesel production costs, Naghdi et al. (2016) examined the use of chloroform, methanol and hexane solvents mixture in extracting Ulva fasciata algal oil. The study demonstrated that a mixture of chloroform: methanol: hexane with 1:1:2 vol ratio produced a maximum oil yield of 9.85%. Also, the acid and saponification values of the algal oil were 13.73 mg KOH/g and 194.7mgKOH/g respectively, while the saturated fatty acid content was 75.43% in the produced algal oil. The presence of 12- hydroxyl-9-octadecenoic acid essential for biodiesel production was indicated. Despite the obvious suitability of U. fasciata for biodiesel production, this process is not cost effective.

Building on the work of Ramaluckan et al, a more recent study (Patil et al., 2018) has investigated the appropriation of the residual biomass for bioethanol production. The study evaluated the efficiency of scalable pretreatments in enhancing lipid recovery from algal slurry. This evaluated method of lipid recovery from wet C. muelleri algal biomass when pretreated with ultraviolet light and hexane: ethanol solvent mixture circumvents the need for drying of algal biomass. Pretreatments can compensate for lipid reduction by making the intracellular lipids more readily available to be recovered, which was actually realized through the utilization of the co-solvent mixture at room temperature. This process may contribute towards the development of a more economical microalgae oil production route. This is because the residual biomass was analyzed and found to contain carbohydrates for the fermentation process of bioethanol production. In the same way, using hexane and ethanol on UV-C and thermally pretreated algae slurries led to more than doubling of the total extractable lipids and transesterifiable lipids.

The possible non-economic nature of this process has motivated more recent studies. In particular, Yang et al. (2017) analyzed supercritical carbon-dioxide extraction of lipids from algal biomass using azeotropic co-solvents of hexane and ethanol. This study indicates that the use of supercritical carbon-dioxide extraction assisted with azeotropic co-solvents is an effective technique for extracting total lipids/bio-oils from algae. This is because of several reasons. First, 20–32 % of the valuable eicosapentanoic acid was extracted from the algae. Second, the utilized method provides the advantages of: increased total lipid yield and selectivity, improved lipid purity, and reduced extraction time with preserved thermo-labile compounds. Third, the heating value for neutral algal lipid of 40.36 MJ/kg obtained was close to that of petroleum-derived crude. In the same way, a maximum total algal lipid yield of 31.37% was obtained at reaction conditions of 340 bar pressure, 12: 1 co-solvent (hexane + ethanol- 1:1) to algae/solid ratio, 80 °C and 60 min reaction temperature and time respectively, under CO2 flowrate controlled condition. The choice to use a high co-solvent amount was influenced by its’ ability to increase the total lipid yield. So, these reaction conditions significantly affect lipid yield, recovery of long chain fatty acids and the economics of the extraction process. Future work should consider explaining how the process can be improved to enhance the heating value of the lipid. Effect of processing factors on several lipid extraction methods are shown in Table 3. Enhances similarities of biodiesel properties to standards Economically feasible, with elimination of excess alcohol usage Low quality of biodiesel due to presence of 0-C-C bonds Uses ‘green’ solvents, which are environmentally friendly Cheaper than use of lipids extraction and biodiesel synthesis Increases FAME yield Reduces reaction time Low biodiesel yield Higher biodiesel yield than conventional transesterification process Reduces biodiesel production costs Time-saving Occurrence of side-reactions, which reduces yield

Lipid extraction methods

Biomass pre-treatment

Solvent used

Amount of solvent

References

Conventional method

(a) Bligh and Dyer method

Treatment with HCl and heating for 1hr at 80 °C for 1hr

Chloroform/water/Methanol

1.50 mL methanol, 1 mL chloroform, 1 mL water

(Jensen (2008))

(b) Froch method

Biomass were soaked with 10% NaOH at a ratio of solid to liquid of 10% and boiled at 100 ◦C for 15 min

Chloroform: methanol

2:1

(Cheirsilp and Kitcha, 2015)

Simultaneous extraction and transterficiation

–

Methanol/H2SO4

0.1–0.8 g of methanol/0.1–0.4 mL H2SO4

(Im et al., 2013)

Switchable solvents

–

N,N-dimethylcyclohexylamine (DMCHA)

2–50 mg/L

(Samorì et al., 2013)

Oxidation surfactants

[a] N-lauroyl sarcosine

Methanol: chloroform

1:1

(Yellapu et al., 2016)

[b] four different surfactants

Ethyl acetate

50 mL

(Feng et al., 2021)

Microwave Irradiation

–

Methanol : Chloroform and Hexane: water

2:1

1:1(Krishnan et al., 2019)

Ultrasound

Defragmentation of lignocellulosics, organic matter solubliisation and enhanced hydrolysis.

–

–

(Onumaegbu et al., 2018)

Hydrodynamic cavitation

Lyophilized N. Salina biomass

Hexane: methanol and Chloroform: methanol

7:3

2:1(Ilgyu and Jong-In, 2015)

Bio-based Solvents

Lyophilisation, mortar and pestle.

Ethyl acetate, ethyl lactate, cyclopentyl methyl ether, 2-methyltetra hydrofuran

1:1:1:1

(Wan, 2013)

Technique

Strain

Operating conditions

Lipid yield

References

Enzymatic transesterification

Micractinium sp

38 °C, 1:3.1 methanol to oil molar ratio, water content of 2.5%, relative to the oil weight

18.7 ± 1.2%

(Huang et al., 2015)

Catalytic transesterification

Chlorella vulgaris

30 °C reaction temperature, 160u/g enzyme content, 3:1 alcohol to oil molar ratio, 0.2 quality ratio of water to oil, >5times reuse of lipase GH2 catalyst.

>90%

(Shirazi et al., 2017)

In-situ or direct supercritical methanol transesterification

Spirulina platensis

260 °C temperature of detector and injector, 130gr/L internal standard concentration of 10 µl methyl heptadecanoate solution

16 wt%

(Chauhan et al., 2019)

In-situ or direct supercritical methanol transesterification

Chlorella sp. FC2 IITG

Supercritical methanol conditions of: 255 °C, 1200-1400psi for 25mins

52 wt%

(Wahidin et al., 2018)

Microwave-assisted transesterification

Nannochloropsis sp

1:4 wet algae to methanol ratio (wt/vol), and methanol: ionic liquid ratio of 1:0.5 at 14mins microwave exposure

40.9% biochar yield

(Han et al., 2020)

Method

Advantages

Limitations

References

Supercritical methanol transesterification

(Wahidin et al., 2018; Cercado et al., 2018)

Microwave-assisted transesterification

(Han et al., 2020; Singh et al., 2017)

Ultrasound-assisted transesterification

(Saengsawang et al., 2020; Ahmad et al., 2020)

In contrast, Sathish and Sims (2012) argues that N-methylcyclohexylamine (MCHA) and 1-butyl-3-methylimidazolium hexafluorophosphate (C4-min)(PF6) are feasible extracting and separating solvents respectively, which are suitable for algal oil extraction. This was presented when the study recovered extracted algal oil through a simple phase separation method using the solvents. This simple phase separation method doesn’t require drying algal slurries before extraction. This is because, the adopted low-energy consumption method extracted wet algal slurries directly while solvent was recycled. Using (C4-min)(PF6) to separate algal oil from the crude extraction liquid recovered 77% of the algal lipid, while the use of MCHA recovered 85% at 200 rpm. This may be because amphiphilic amine solvents are water miscible, as (C4-min)(PF6) is effective for dissolving polar substances such as amines, due to its’ characteristic property as an ionic liquid. While Yang et al investigates the elimination of the drying process through the use of (C4-min)(PF6) and MCHA agents, Shwetharani and Balakrishna (2016) had earlier taken a different approach. They developed a different method of lipid extraction that similarly doesn’t require drying, but additionally removes chlorophyll two contamination prior to lipids collection. The developed wet lipid extraction procedure (WLEP) provides an approach to algal biomass processing with material and energy cost reduction associated with biofuel production. This is illustrated through the extraction of 79% transesterifiable lipids contained in the wet biomass of 84% moisture using acid and base hydrolysis. Also, the procedure removed chlorophyll two contaminants/organic solvent demand of the algal lipid extract through precipitation. Similarly, the procedure generated side streams which can be feedstock for microbial conversion to additional bio-products. Ponnusamy et al. (2014) takes a different approach from Sathish et al. They demonstrated the use of photo-catalysis as a route for bio-oil extraction from wet Nannochloropsis oculata algal biomass. The use of solar energy and nanoparticle catalysts reduced cost and energy requirements by omitting the dewatering and drying stages of the algal oil production. The use of GCMS analysis indicated the presence of FAME, an indicator of its’ biodiesel potential. In addition, the titanium oxide properties of photo-activity, low cost and toxicity, good chemical and thermal stability, suggest that titanium dioxide nanoparticles are efficient photo-catalysts for rupturing the rigid micro-algal cell membrane in an aqueous environment using sunlight.

The use of solvents in lipids extraction is obviously an energy-intensive process due to the frequent need for solvent recovery. Because of this, research is now exploring other similar lesser-demanding alternatives. For instance, Jian et al. (2015) has analyzed the life cycle energy requirements and greenhouse gas emission of algal biodiesel. They found that biodiesel production using subcritical water (SCW) extraction poses a potential alternative to traditional solvent extraction. This is because the SCW extraction process is an energy efficient one that uses wet algae feedstock, while decreasing energy demand about 5 times lower than the traditional solvent extraction. This is because no considerable energy is spent on drying since dry algae feedstock is not required. Besides, there is reduction in energy required for solvent recovery as water is the utilized process solvent. Consequently, the water available after harvesting algae can be potentially used as a solvent to extract neutral lipids at selective subcritical conditions of water. Illustratively, this study reveals that about 53 wt% of extracted dry algae (32 wt%) are neutral lipids. Also found was that 0.6 kg of CO2 is sequestrated for every 1 kg of biodiesel produced.

Furthermore, Hu et al. (2020) later improved on the life cycle assessment (LCA) of Ponnusamy et al by assessing the effects of nitrogen deficiency on algae cultivation and oil extraction on life cycle fossil energy ratio of biodiesel. The algal oil conversion rate and energy content of algae have the greatest effects on the LCA results of the biodiesel production, followed by utilization ratio of algal residue, energy demand for algae drying, capacity of water mixing, and algae productivity. Changing esterification efficiency and heat value of algae have the greatest effects on the life cycle fossil energy ratio of algal biodiesel. This is because when esterification efficiency and heat value of algal decreased by 40%, the life cycle fossil energy ratio of algal biodiesel changed by 40% and 36.17%, respectively. Other parameters (such as utilization ratio of algal residue, algal cultivation water recycling rate, energy demand for algal drying, capacity of mixing and algal productivity) were of negligible effects because 40% reduction of these properties only resulted in algal biodiesel life cycle fossil energy ratio changes between 10% and 15%.

Presently, research is investigating the conversion of algal lipid extraction residue to bio-crude oil. To illustrate, Zhang et al. (2019) recently gasified algal lipid extraction residues-derived crude oil in supercritical water (SCW). It is believed that the residue from lipid extraction of algal can be used as feedstock to produce high-yield and value-added biofuels via liquefaction. This is because of several reasons. One, the study reports that the bio-crude oil yield (65.4 wt%-78.5 wt%) was higher than that obtained from rubber wood sawdust (48.8 wt%-59.9 wt%) and bamboo sawdust (47.9 wt%-63.7 wt%), when compared. This is because of enhanced biomass degradation at higher temperatures (Akhihiero et al., 2020). This is confirmed by other studies (Shakya et al., 2015). Two, the main bio-crude oil components obtained from algal lipid extraction by-products were hydrocarbons, aromatics, ketones, and alcohols. In addition, nitrogenated compounds were obtained. These major bio-crude oil components have been previously confirmed by earlier studies (Guo et al., 2015; Sinag et al., 2004). when compared with NaOH (2.13 wt%) and Ru/C catalysts, the use of K2CO3 showed maximum total combustible gas yield (8.15 wt%) when used with algal lipid extraction residue-derived bio-crude oil feedstock via SCW gasification at 500 °C for 60mins and 10 wt% biomass concentration. The suitability of K2CO3 may be because the reaction between CO2 and KOH produced a higher CO2 than NaOH yield, in the water–gas shift reaction (WGSR). This is traceable to the promoted breakage of C-C bonds and WGSR. By extension, the use of K2CO3 catalyst produced the highest methane yield (0.69 mmol/g). To enhance economics of the process, current research is also examining the use of some novel methods for a sustainable biomass production. Building on the work of Hu et al, Lu et al. (2016) investigated the effect of wet cell disruption based on mild pressure and heat shock treatment. Also, the study optimized cell growth and lipid productivity at enhanced CO2 concentrations and at varying photoperiod conditions. The study shows that the novel method of mild pressure with heat shock extraction process is cost effective for microalgae lipid extraction. This is because of several reasons. One, the method was used to disrupt the cell walls of C.vulgaris which significantly maximized lipid recovery, while minimizing energy consumption, as 27.7% elevated energy output was recorded. Two, oleic acid (C18:1) with 51.62% is the main component in both processes of conventional and suggested lipid extraction with respective energy outputs of 417.7 and 533.6MJton-1. The latter demonstrated a 26.7% increase in biodiesel yield. Three, respective biomass and lipid productivities of 94% and 54.8% were induced by 8% elevated CO2. This was as the novel method (of mild pressure with heat shock extraction) facilitated a 21% lipid recovery, while 12.5% additional total lipid recovery was obtained using mild pressure with heat shock. Also, 1.96% and 0.58% of poly- and mono-unsaturated fatty acids were respectively recovered using the extraction procedure.

1.1.2 The use of deep eutectic solvents

Cheng et al. (2015) investigated the influence of aqueous deep eutectic solvents (DES) on lipid extraction from Chlorella sp. using a mixture of ethyl acetate and ethanol solvents to enhance the lipid recovery. Effect of the three aqueous DES (i.e. aqueous choline – chloride (a Ch-O) - ethylene glycol (a Ch-EG), and aqueous urea-acetamide aU-A)) on the pretreatment of chlorella sp. biomass were evaluated by measuring lipid content, lipid recovery efficiency and carbohydrate content. That is, the aqueous DES pretreatment significantly enhanced the lipid recovery (P < 0.05), which actually was a function of DES. Also, treatment of the algae with the DES- a Ch-O, a Ch-EG, and aU-A reduced the total carbohydrate content recovery in algal biomass at 24.21%, 20.14% and 27.89% respectively. This is because of a resulting cytoplasm reduction from the microalgae cells (Pan et al., 2017). Thus, lipid recovery was improved after aqueous DES pretreatment, which is due to the fact that aqueous DES can improve the efficiency of lipid extraction from chlorella sp. biomass using a mixture of ethyl acetate and ethanol. This is because of their ability to disrupt cell wall.

In the same way, Piligaev et al. (2018) investigated the improvement of extraction yield through cell disruption using acid DES. The effects of solvent amount, DES and biomass mass ratio, extraction time and temperature on FAME were studied, while comparing one-step and two-step processes of biodiesel production from microalgae biomass. It was found that the use of one-step with DES extracts FAME feasible for microalgae-based biodiesel production. This is because of several reasons. Firstly, the total FAME content extracted using one-step method with DES treatment was improved by 30% when compared with the two-step method, and also 70% increase was observed in comparison to when DES pretreatment was absent. Similarly, the two-step method also improved the FAME content when compared with absence of DES pretreatment. Next, the otherwise increase of DES resulted to a corresponding increase in destruction of cells and FAME, with the use of one-step method. Since microalgae cell destruction is a function of the DES strength, FAME recovery can be enhanced with same. So, this explains why 1:3 mol/mol of chlorine-acetic acid was more effective in the study than other DES ratios in recovering FAME from both chlorella sp. and chclorococcum sp. biomass.

2 Microalgae conversion processes to biofuels

2.1 Biodiesel

2.1.1 Transesterification

Currently, research is investigating the use of bio wastes-derived catalysts for a more sustained biodiesel production. As a result, Karpagam et al. (2020) recently provided more understanding on the activity of waste egg shell-derived Nano-CaO catalyst on the transesterification and its’ optimization by varied Nano-CaO catalyst dosage, time, and temperature with five-level central composite design based full factorial response surface model. 93.44% maximum fatty acid methyl ester (FAME) yield was obtained at optimal conditions of 2.06% (wt/wt) catalyst at 180mins and 60 °C temperature and 200 rpm constant string speed. Moreover, catalyst reusability and stability was up to 6 cycles, which confirms to an average of 85.22% biodiesel yield. This is important because catalyst recycling prevents the challenges of solvent usage, energy consumption and operational restraints. This is why the use of a heterogeneous catalysts is preferred to homogeneous catalysts. Taken together, these findings show that the Nano-CaO catalyst derived from waste egg shell is sustainable and cost-effective for biodiesel production. Correspondingly, a recent study (Nguyen et al., 2020) synthesized and characterized bio-nanoparticles from waste seashells as catalysts for the direct transesterification of Coelastrella sp. M−60 for FAME conversion. The investigated bio-nano CaCO3 and bio-nano CaO yielded maximum FAME proportions of 20.6 ± 1.7 and 20.3 ± 1.1%, respectively. Comparing these yields with the conventional acid catalysis indicate that the former (bio-nanoparticle mediated transesterification) produced an average of 1.29 and 1.02 respective fold FAME increase than the latter (18.8 ± 1.1%). This is because, basic sites present in the bio-nanoparticle catalysts (due to the corner-shared oxygen vacancies) are the active sites responsible for FAME conversion, which were both easily accessible and highly populated. This is why the bio-nanoparticle mediated transesterification is preferable to conventional acid catalysis. In summary, bio-waste derived catalysts provides a greener and frugal means of biodiesel production. Other current findings such as those of Das et al. (2020), Wadood et al. (2020) and Cheirsilp and Louhasakul (2013) confirm the suitability of the use of bio-wastes for improved biodiesel production.

2.1.1.1 Single-step methods

Patil et al. (2012) studied the role of direct transesterification of microbial lipid into biodiesel. This was to reduce both the raw material and processing costs of biodiesel production. This transesterification process gave a biodiesel yield (FAME > 70% in one hour) comparable to the conventional 3-step method, though the former eliminated cell drying and lipid extraction steps. This is why direct transesterification process could contribute immensely to industrializing oil production from microbes and industrial wastes. For this reason, Rathnam et al. (2020) investigated the direct conversion of algal biomass into biodiesel using supercritical methanol (SCM) and microwave-assisted (MW) transesterification methods. The MW approach improved extraction of algal- with a 60% higher conversion efficiency, reduced extractive-transesterification time (4-5mins) and increased 80.13% yield based on total lipid content. The non-catalytic SCM produced pure solvents and catalyst residues, and reduced energy consumption in separation and purification stages. This reduction in energy consumption is due to the simplified purification step. This is because, the study indicated that the GCMS-revealed FAME percent purity could have influenced the efficient separation and purification of the product in supercritical reaction. Also, the sample weight loss occurring through thermal degradation (from 10%, 50%, and 90% to the initial weight) were observed at temperature values of 195 °C, 362 °C, and 430 °C respective to the increasing degradation of the weight losses. Overall, these findings demonstrate the reason why the single-step methods are regarded means of reducing chemical and energy consumption in biodiesel production process. However, the study indicated that SCM processed methyl ester has higher thermal stability compared to the MW transesterified product.

2.1.1.1.1 Supercritical transesterification (SCT)

The use of catalysts in microalgae conversion to biodiesel is an old conventional method that can result to soap formation when free fatty acid content is > 0.5%, and reduced biodiesel yield when water is present in the feedstock. This is why SCT involving catalysts absence is presently considered. Besides the fact that the absence of catalysts may result in slow reaction processes, its’ usage may incur added costs to the process (Wahidin et al., 2018). Consequently, Chauhan et al evaluated the feedstock quality for direct conversion of Chlorella sp. FC2 IITG microalga into biodiesel using supercritical methanol transesterification (SCMT). 96.9% maximum FAME yield was obtained at optimum values of 52% (wt/wt) lipid content, 5.75 mL/g water content and 115 mL/g methanol loading. This reduced alcohol loading as well as high water content per gram of biomass demonstrates the economic feasibility associated with the use of SCMT. Also, comparing the physicochemical properties of produced biodiesel with ASTM D-6751 and EN14214 standards show identical properties of viscosity (4.554 mm2/s), cetane number (60.236), and flash point (159.236 °C). This similarity indicate that the produced biodiesel could be a potential alternative to conventional fuel. So, the use of SCMT can produce biodiesel of good quality. Reporting the alternative use of ethanol and ethyl esters, Reddy et al. (2014) produced fatty acid ethyl esters (FAEE) from Schizochitrium limacinum microalga with the use of supercritical ethanol and ethyl acetate. The rate constants (1.7 * 10-4 to 10.2 * 10-4 for ethanol, and 0.405 * 10-4 to 3.18 * 10-4 for ethyl ethyl acetate) and activation energies (67.1 and 78.5KJ/mol for ethanol and ethyl acetate systems, respectively) examined by respective pseudo first order kinetics and Arrhenius equation reveal that the reaction is faster with ethanol, while the use of ethyl acetate decreases the glycerol oversupply. Furthermore, Knothe (2005) studied the effects of process parameters in dry algae single-step conversion to ethanol (in wt/vol) ratio of 1:6–1:15, reaction temperature of 245–270 °C, and 2-30mins reaction time on the FAEE yield at supercritical ethanol conditions. The study indicates that this “green” conversion process has the potential to provide an energy-efficient and economical route for the production of renewable biodiesel. This is because, the calorific value of FAEE’s was 43 ± 1.8 MJ/kg, which is comparable to that of regular diesel fuel. This calorific value is higher than that of FAME produced from the same biomass. Moreover, significant energy savings were possible by eliminating the algae drying step through the simultaneous extraction and conversion of wet algae to crude biodiesel. Additionally, the thermogravimetric analysis of the FAEE samples in oxygen and nitrogen atmosphere revealed the high oxidative stability of FAEE. Similarly, Nan et al. (2014) examined process optimization in biodiesel production from Chlorella protothecoides by non-catalytic transesterification. The investigated interaction parameters – temperature and molar ratio, molar ratio and water content, residence time and water content – have the same effect on the transesterification of triglycerides with methanol and ethanol. This is because, water favors FAME yield by causing hydrolysis and esterification reactions. This is partly because the addition of water reduces the molar ratio of alcohol to oil needed to achieve a high yield. Thus, adding water to the process realizes a high biodiesel yield at reduced alcohol-to-oil molar ratio. This is important because it reduces the cost of anhydrous alcohol and water removal from feedstock. Also, the behaviors of the FAEE yield under the effects of these interaction parameters are similar to those of FAME yield.

More recently, the conversion of microalgae oil to FAME using SCM transesterification by sequential hybrid optimization using RSM, ANN and genetic algorithm (GA) has been maximized (Srivastava et al., 2018). The purpose of the study was to optimize the non-catalytic transesterification of microalgae oil to biodiesel under supercritical methanol conductions. An optimization condition generated by GA for the SCM transesterification with temperature of 285.2 °C, 26.5mins and MeOH: oil molar ratio all gave 99.16% conversion efficiency. Since the SCM transesterification yield was about 99–100% conversion efficient, the process is considered a zero waste generation process for biodiesel production. Anyway, research on modifying the supercritical transesterification reaction has been reported by Aghilinategh et al. (2020). They conducted a one-pot production of biodiesel from Chlorella vulgaris in SCM in the presence of TiO2 and SrTiO3 nano-catalysts with the presence of co-solvents. The modification process indicates that preparation of catalysts using photochemical method prevents the catalysts from leaching even at harsh reaction conditions. This is because the use of n-hexane co-solvent produced highest yields of biodiesel and other products, due to the material property of very low dielectric constant. This is due to its’ ability to improve the rate of mass transfer occurring from better biomass dissolution.

2.1.1.1.2 Microwave-assisted transesterification

The use of MW technology significantly reduces reaction time, increases biodiesel yield and makes catalyst recovery processes easy. Accordingly, Bhuana et al. (2020) studied biodiesel production through in situ transesterification of Chlorella sp. This was by examining the effects of acid catalyst concentration, microwave power and retention time. This study showed that a high biodiesel yield of sufficient quality is possible through the optimization process by Box-Behnken Design. This is because, 63.6% biodiesel yield was obtained at 370 W microwave power, 0.2 M catalyst concentration and 82.7mins transesterification time.

Moving forward, Lawan et al. (2020) recently illustrated the role of microwave reactor system in efficient and sustainable waste lard biodiesel production. Building on the work of Bhuana et al, Teo and Idris (2014) described the use of MW for enhanced extractive-tansesterification of algal lipids from dry chlorella sp. The extractive-transesterification of dry algal biomass using MW irradiation can substitute for the simultaneous extraction and transesterification two-step reaction. This is because, the MW contributes to higher algal lipid and fatty acid ethyl ester (FAEE) yields. This is demonstrated from the FAEE conversion of the algal lipids, which were 96.2%, 94.3% and 78.1% for MW, MW with hexane and the conventional Bligh and Dyer (BD) methods respectively. These FAEE conversions were obtained from the respective maximum lipid yields of 20.1%, 20.1%, and 13.9%. Also, hexane solvent reduced the reaction condition severities, though comparable lipid and FAEE yields were produced. This is because, hexane and ethanol co-solvent can enhance the extractive ability for FFA and eventually improve the transesterification reaction yields. Similarly, Rathnam et al. (2020) investigated the effect of microwave irradiation on the simultaneous extraction and transesterification of dry algal biomass to diesel. This study was aimed at optimizing the microwave transesterification using RSM. The in-situ transesterification process proved to be fast and easy in biodiesel production from the dry biomass. Methanol assists the reaction to complete faster because it is a strong microwave absorption material whose OH– group radical dominates the microwave spectrum and results in localized superheating.

2.2 Bio-methane

2.2.1 Anaerobic digestion

Herrmann et al. (2016) investigated the co-fermentation of Arthrospira platensis using carbon-rich co-substrates at a carbon to nitrogen ratio of 25 to enhance biomass conversion. Co-digestion of microalgae and seaweed can be effectively applied to integrated costal bio-methane. Actually, the use of microalgae assists in indirect biogas upgrading. This is because of several reasons. First, the mono-digestion of A. platensis was stable at a low organic loading rate (OLR) of 1 g VSL-ld-1 (volatile solids). This was indicated by a low FOS/TAC ratio of < 0.27, as the ratio being below 0.3 indicate stable process operation (Drosg, 2013). Second, co-digestion with carbon-rich co-substrates (such as beet silage, barley straw, and brown seaweed) increased process stability. This is because, there is a more balanced nutrient supply, and reduced formation of inhibitory ammonia when the carbon-rich co-substrates degrade. This is due to a lower portion of nitrogen-rich biomass in the feedstock mix. For example, adding barley straw to A. platensis to balance the C: N ratio ensured increased performance of the continuous anaerobic digestion process in process stability. However, co-digestion with L. digitata resulted in the largest increase in process stability. This was up to an organic loading of 4.0 g VSL-1d-1. Table 6 shows recent studies on biogas production from anaerobic digestion of microalgae biomass.

Technique

Strain

Operating conditions

Biogas yield

References

Microwave co-treatment

Enteromorpha

20:1 slurry liquid: solid ratio, 6mins pretreatment time, and microwave pretreatment power of 600 W

53.60 mL/Gts

(Zaidi et al., 2019)

Hydrothermal liquefaction

Tetraselmis chlorella

∼37 °C, 200 rpm of digester stirring

327.2 mL/gVSin for Tet., and 263.4 mL/Gvs FOR Chlr.

(Fernandez et al., 2017)

Ultrasound co-pretreatment

Microcystis sp

Ultrasound treatment for 30mins, 20 g zero-valent iron/g of algal total solid

30.39, 37.11, 38.06, 42.52, 49.27, 48.93 and 60.84 CH4/Kg accumulative biomethane production in reactors 1–7, respectively.

(Li et al., 2020)

Recently, Sanchez-Bayo et al. (2020) evaluated the WLEP of lipids from Isochrysis galbana to study solvents with different polarities. The research suggested that anaerobic digestion can enhance the economic feasibility of microalgae bio-refineries. This is because, biogas production was evenly evaluated through the anaerobic digestion process of the residual biomass. Presently, research is considering the use of mono-substrates for continuous bio-methane production. For example, Klassen et al. (2020) recently confirmed the application of low-N cultivation/fermentation strategy on a robust natural microalgae isolate. Research has shown that this low-N biomass of Chlamydomonas sp. can be applied as a mono-substrate for a continuous highly efficient methane generation. This is because, the natural wastewater-derived microalga isolate tolerates high temperature and light conditions while coping with microbial contaminants. This is a demonstration of its’ potential in future biotechnological applications. Also, the use of this microalga resulted in 87% energy conversion efficiency from biomass to bio-methane. Additionally, biogas and bio-methane productivity of 765 ± 20 and 478 ± 15mLNg-1VSd-1 respectively, characterized the continuous long-term anaerobic digestion. This is same as its’ volumetric methane productivity of 1912 mLNL-1.

2.2.1.1 Co-digestion

Sittijunda and Reungsang (2018) optimize concentrations of algal biomass crude glycerol and inoculum from co-digestion of the algal biomass with crude glycerol using RSM and CCD design. From the study, 2.31 mL-CH4/g-VS added maximum methane yield was obtained at conditions of 20.02 g-VS/L crude glycerol, 9.76 g-VS/L inoculum concentration and 5.50 g-VS/L algal biomass concentration. This maximum methane yield was 57.75 times higher than the 0.04 mL–CH4/g-VS added obtained under reduced conditions. Under optimum conditions, maximum methane and energy production of 58.88 mL-CH4/L and 92.47 J/g-VS were respectively obtained, while 14.59% difference between observed and predicted methane production are reported. Additionally, the study identifies Methanosarcina sp., Methanoregula sp., Methanospirillum sp., and Methanoculleus sp. as the main methane producers present in the fermentation broth. Summarily, the RSM optimized process improved bio-methane production. Improving upon the work of Sittijunda et al, Vassalle et al. (2020) evaluates a up flow anaerobic sludge blanket (UASB) reactor and the use of high rate algal ponds (HRAP) for sewage treatment efficiency and biogas production, at demonstration scale. While 50% COD was removed in the UASB co-dig, the entire process removed a total 65% COD after the HRAP and 61 % N-NH4. This observation has been previously reported (Villa-Navarro et al., 2018). However, 57% average COD was removed for the UASB cont. The observed lower average COD reduction in the UASB co-dig may be due to microalgae biomass recirculation in the co-digested reactor, leading to a transport of stabilized organic matter from the solid to the liquid phase. On biogas production, an average 304.42NL/Kg VS (that is, 149.81 NL/Kg COD) for UASB cont, and 331.12 NL/Kg VS (that is, 165.63 NL/Kg COD) for UASB co-dig were reported. These values indicate a 10% UASB co-dig increase after co-digesting sewage with microalgae biomass. For organic content, a 9% increase is associated with the use of UASB co-dig than the UASB cont.

Furthermore, Lu et al. (2019) optimized bio-methane production from anaerobic co-digestion of microalgae and septic tank sludge. The study analyzed the effects of the total organic concentration and microalgae proportion in optimized bio-methane production. The total volatile solids concentration of 16–20 g/L and 26–47% proportion of microalgae biomass indicates the possibility of observed peak methane production and > 300 mL/gVSfed as observed from the surface response plot. Similarly, the methane production depends on several factors as the experimental design showed 1.04F-test, 0.96 correlation coefficient and 5.14% coefficients of variance. These findings indicate that the organic concentrations and microalgae proportions affect methane production. By extension, Zamalloa et al. (2012) valorised by anaerobic digestion, the Scenedesmus obliquus and Phaeodactylum tricornutum microalgae under mesophilic and thermophilic conditions. The microalgae biomass was up-concentrated to the 1.9–2.8gVSL-1d-1 range at a low hydraulic retention time. An overall conversion efficiency of 50% was achieved when P. tricornutum was digested at a volumetric organic loading rate of 1.9gVSL-1d-1 at a hydraulic retention time of 2.2 days at either thermophilic or mesophilic conditions. Moreover, the 1.5 times higher biomass potential of P. tricornutum than S. obliquus indicates that the suitability of the former for anaerobic digestion depends on its’ species. This has been confirmed by an earlier report (Mussgnug et al., 2010). These findings suggest that hydrolysis of the microalgae cells limits the anaerobic processing of intensively grown S. obliquus and P. tricornutum biomass. However, hydrolysis of certain microalgae (such as D. salina) might be slower in mesophilic fermentation (at 33 °C) than at thermophilic fermentation (at 54 °C). This is because, the biomass strain can grow up to temperatures of 35 °C (Hodaifa et al., 2010). In the same way, Garoma and Nguyen (2016) investigated the feasibility of producing bio-methane from the anaerobic co-digestion of Scenedesmus quadricauda and thickened waste activated sludge (TWAS). The microalgae produced almost same amount of methane as the wastewater sludge, TWAS. This is because, the methane produced ranged from 234 − 318 mL/g of chemical oxygen demand digested and 329 – 530 mL/g of volatile solids digested at 35 °C. Though the net methane produced was varied for different S. quadricauda/TWAS proportions, results indicate that there were no significant differences in methane prediction rate amidst the various proportions. This is because, 89% of paired t-tests performed on the rate of produced methane resulted in p-values > 0.05. These findings show that anaerobic co-digestion could be able to enhance renewable energy generation, even with minimal capital costs.

Current research is examining the effects of low temperature thermal pretreatments in solubility and co-digestion of waste activated sludge and microalgae mixtures. Specifically, Avila et al. (2020) assessed the effectiveness of 37 °C and 60 °C low temperature thermal pretreatments of 50:1, 25:1 and 10:1 (v/v) waste activated sludge (WAS) and microalgae ratios in solubility of biomasses and in methane yield of the co-digested mixtures. The use of anaerobic microorganisms in the low temperature thermal pretreatment during degradation produced a high methane yield for the WAS and flocculated microalgae mixture of diallyl dimethyl ammonium chloride flocculant. This is because of several reasons. First, pretreating the non-flocculated co-digestate mixture at 60 °C revealed the effect of time intensiveness on the mixture’s solubility during the first 24 h, with lower later variations. Then, solubility of the WAS and microalgae mixture increases with temperature. This is because, higher solubility of the co-digestates was observed at 60 °C pretreatment when compared with 37 °C. Effect of the diallyl dimethyl ammonium chloride flocculant addition was revealed in the co-digestate mixture solubility which was higher in comparison to mixture without the flocculant. Besides temperature effect on the solubility of the co-digestates, ratio of the co-digestates also influences their solubility. This is because, microalgae volume in the mixture was reported to increase with solubility. More research is needed to identify other parameters to determine the effect of the pretreatment in the co-digestion. This is because, non-enhancement of the co-digestate anaerobic digestibility after the pretreatment indicate that solubility of the mixture unlike temperature pretreatment cannot promote further methane production.

2.3 Syngas

2.3.1 Gasification

The effect of process parameters (such as pressure, temperature, microalgae concentration and co-reactant addition) on the supercritical water gasification of microalgae biomass for hydrogen syngas production has been intensely reported of recent. To illustrate, Freitas and Guirardello (2013) evaluated the effects of these parameters for hydrogen and syngas production using thermodynamic analysis. Investigating the effect of initial temperature under hydrogen formation demonstrated an increase of produced syngas with initial temperature. The use of Gibb’s energy minimization and entropy maximization methods is considered reliable for thermodynamic predictions in the supercritical water gasification reactive systems of the microalgae biomass. This is because, the use of GAMS® 23.2.1 software resolved initially proposed problems since the computational time was inferior to 1 s for all analyzed cases. Moving forward, Azadi et al. (2014) simulated the production of algae-derived hydrogen and syngas using a dual fluidized bed gasifier. The lower heating value of the produced syngas increased from 17 to 24 MJ/Kg dry feed when the oil content increased from 0 to 40 wt%. The ratio of H2 : CO in the algae-derived syngas increased when the water–gas-shift reaction was favored by the operating conditions in the forward direction. In brief, algae oil content can possibly influence the lower heating value of syngas. Table 7 identifies recent studies on syngas production from microalga, while Table 8, presents methods of syngas production from microalgae with their advantages and limitations. Drying at 105 °C for 24hrs. Watts power of 0, 750, 1500, 2250, 3000 and 3750 Time (seconds) of 0, 30, 60, 90 and 120 700 °C pyrolysis temperature Dried at 105 °C for 24hrs 600 °C, 28 MPa, 200 g/h flowrate 851 °C, 16.4 wt% catalyst loading, and 28.80mins reaction time 400–600 °C 800 °C High energy efficiency Efficient syngas production Difficulty in equipment sizing and design Challenge in system profits determination Enhances syngas yields even at low temperature Minimizes CO2 production Produces low PAHs amounts Non-feasibility of large scale production Maintains high chemical energy as in microalgae feedstock This is a waste-reducing process Inadequate recovery rate Catalysts are often stable for some time, even after several usage Scaling-up of process

Technique

Strain

Operating conditions

Gas yields

References

Chemical-looping gasification

Chlorella vulgaris

Microwave pretreatments at:

1.16 Nm3/Kg

(Hu et al., 2017)

Microwave-induced pyrolysis

Porphyra

73.3 vol%

(Hong et al., 2017)

Hydrothermal gasification

Leachate

H2, CH4 and CO2 yields of 69.36 ± 4.5, 10.6 ± 2.8, 17.5 ± 4.7 respectively.

(Damergi et al., 2019)

Catalytic gasification

Chlorella vulgaris

48.95 mol%

(Raheem et al., 2018)

Microwave-induced pyrolysis

Chlorella vulgaris

15-25 wt%, 65-85gH2 per kg feedstock

(Parvez et al., 2020)

Microwave-induced pyrolysis

Scenedesmus almeriensis

94 vol%

(Beneroso et al., 2013)

Method

Advantages

Limitations

References

Chemical-looping gasification

(Nurdiawati et al., 2019; Liu et al., 2018)

Microwave-induced pyrolysis

(Hong et al., 2017; Beneroso et al., 2013)

Hydrothermal gasification

(Brown et al., 2010; Onwudili et al., 2013)

Catalytic gasification

(Samiee-Zafarghandi et al., 2019; Raheem et al., 2019)

More recently, Li (2018) studied the effect of reaction temperature, stoichiometric ratio (SR) and steam flowrate (SFR) on H2/CO ratio in produced syngas. The work evaluated the efficiency of three different Chinese algae for gasification process while utilizing air and steam gasification agents. From the study, 44.8 g/kg maximum hydrogen yield was obtained at 950 °C and 2.4 kg/h SFR. Moreover, low H2/CO content was achieved at higher temperature, while a higher H2/CO content was gotten at higher SFR. The former occurred because gasification temperature increases with CO production, while increase in hydrogen concentration was recorded at a much reduced rate (Pala et al., 2017). These findings show that lower heating value of the syngas increased with SFR and gasification temperature. Also, these parameters determine H2/CO content in syngas. Currently, there is a more targeted interest at pilot-scaling of system gasifiers. For example, Soares et al. (2020) evaluates the effects of air–fuel equivalence ratio on syngas composition, higher heating value and production rates. That is, an experimental investigation of wastewater microalgae in a pilot scale downdraft biomass gasifier. This was through the gasification of wastewater microalgae with the use of air as the gasifying agent. The H2/CO ratio observed in the syngas was 0.61, which is quite close to the 0.60 recommended for synthetic fuel production (that is, Fischer-Tropsch gasoline and diesel) (Ciferno and Marano, 2002). This is important because the H2/CO ratio of 0.61can reduce the process complexity, as the characteristics of the syngas are already synonymous with ideal H2/CO ratio (Ferreira et al., 2019). This is important as cost which could have been associated with installation of additional equipment is averted. Moreover, the cold gas efficiency is 87% with 6.2 MJ/Nm3 higher heating value and 2.8Nm3/kg dry biomass production rate. The syngas HHV indicates best performance of microalgae gasification at an air–fuel equivalence ratio of 0.23. So, the syngas composition is 11.9% H2, 19.5% CO, 8.5 %CXHY and 9.8% CO2.

2.3.1.1 Direct gasification

Raheem et al. (2015) characterized the process behavior, and optimized syngas production using microalga gasification. This was conducted using a horizontal tubular reactor under different conditions of process temperature, heating rate and microalga biomass loading. Beside temperature, microalgae biomass loading was most influential in enhancing hydrogen yield. That is, optimum hydrogen output was achieved at a loading of 1.44 g. However, an allowable range of 0.6–2.5 g would still increase hydrogen yield as reported in the study. This increased range may be due to increase in mass of reactive species per unit volume required to shift the equilibrium of the WGSR to the right (CO + H2O ↔ H2 + CO2). Overall these findings indicate that direct gasification of microalgae biomass in air can enhance commercial-scale production of syngas. Building on the work of Raheem et al, Adnan and Hossain (2018) gasified microalgae biomass while integrating converted tar molecules produced during the gasification stage. The controlled use of oxygen as a gasifying agent in the combustion zone aids complete conversion of tar to syngas. This occurred when a minimum effect of pressure was observed after maximum gasification system efficiency. This is because, higher pressure demands higher oxygen energy ratios for the maximum cold gas efficiency to be reached, which is similar to complete carbon conversion. Moreover, the gasification system efficiency (GSE) improved through the injection of oxygen in the combustion zone. This is because, gasifying N. oculata at conditions of 1 bar, O2 ER ratio of 0.13 with no steam results in the highest GSE of 0.60 with 0.44 hydrogen concentration. It is clear from these findings that the use of oxygen in the combustion zone improves the gasification performance and system efficiency.

2.3.1.2 Co-gasification

Arun et al. (2020) produce hydrogen-rich gas from sewage sludge and wastewater-derived microalgae using a battery waste-derived catalyst. The study indicates that the process of HTG is feasible for optimum hydrogen gas production. This is because, the experiment show that 38.27 wt% maximum hydrogen yield was obtained at 4 wt% catalyst loading and temperature of 440 °C for 2:1 waste ratio. Also, the RSM optimization result indicate that 40 wt% hydrogen gas yield was obtained at the optimum process conditions of 2.3 wt% catalyst load, 426.36 °C, temperature and time of 70.22mins. However, the use of catalyst can lead to its’ poisoning, sintering and even deactivation during the HTG process. For this reason, Sztancs et al. (2020) investigated the improvement of biogas production through the process of co-Hydrothermal gasification (co-HTG) of wet Chlorella vulgaris biomass and hydro-char (HC). The co-gasification process promotes hydrogen and methane formation as well as selectivity in HTG. This is because, high yields of hydrogen (19.49 mol/kg), methane (2.98 mol/kg) and 82.31% carbon conversion ratio, all demonstrate that the use of wet and waste biomass feedstock are essential for effective hydrothermal upgrading. So, the use of HC is preferable to catalysts. This is because, the study reports a 41.6% raise up to 29.97 mol/kg in the total gas yield when concentration of the co-gasifying agent was increased from 0.2 to 2 wt%. Taken together, these findings indicate that co-HTG of Chlorella vulgaris and HC blends enhance the total gas yield, carbon conversion efficiency and boosts methane and hydrogen selectivity.

2.3.1.3 Chemical looping combustion (CLC)

Recently, the need to enhance microalgae biomass conversion efficiency has motivated more research on other gasification techniques besides the direct method. Therefore, Hu et al. (2018) studied the effect of oxygen carrier content and temperature on chemical looping gasification of Chlorella vulgaris in a fixed bed reactor. Oxidizing the oxygen carrier at 800 °C produced 100% Fe3+. This is probably because with temperature increase from 600 °C to 1000 °C, at 100 °C intervals, the highest gas product yields occurred at the range of 700 °C to 800 °C, representing a 11.64% increase from the initial value. However, further temperature increase resulted in a decrease because the promotion of high temperature is stronger than the prevention of inactivation occurring because of sintering. That is, higher temperature would weaken the oxygen carrier reduction. Also, this continuous temperature increase caused a gradual Fe3+ increase which was less, when below 800 °C. Furthermore, Fe2O3 reduced into more Fe3O4 and FeO with temperature increase from 700 °C to 800 °C. This is because, the small particles present in the crystal disappeared and were replaced by the larger crystal particles. This is evident from the elemental composition analysis of oxygen carrier under different temperature. In brief, these findings show that a high conversion efficiency of biomass and bio-products yield can be achieved at 800 °C.

Improving on this work, Adnan and Hossain (2019) applied the integrated processes of drying and gasification (using CO2 absorber and chemical-looping combustion, respectively) on wet Spirulina biomass to produce hydrogen-rich syngas. This process considered in-situ energy supply using a thermodynamic approach. Gasifying high moisture content of the microalgae using the integrated process produced syngas with high concentration of hydrogen. Also, gasifying the microalgae with 45 wt% moisture content under process conditions of 2.00 S/C ratio and 0.00 02 ER ratio as well as char to CLC of 1.0, provides the highest hydrogen concentration of 0.72. Similarly, adjusting char flow to the CLC can provide positive effect on the syngas composition. This is specifically notable for high moisture gasification containing Spirulina biomass. Furthermore, the highest cold gas efficiency of 1.15 and 0.62 GSE were obtained when Spirulina-containing 45 wt% moisture content was gasified at process conditions earlier described.

2.3.2 Pyrolysis

Rahman (2018) converted the water hyacinth biomass to bio-oil, bio-char and syngas through the thermochemical conversion process of pyrolysis. The effect of temperature, heating rate, carrier gas flowrate and particle size on product distribution were investigated for the conversion process. Research has earlier indicated that the formation of high amounts of syngas is due to the presence of an enormous amount of volatile matter (of 65.60 wt%), not moisture content (Choudhury et al., 2014; Harman-Ware et al., 2013). Though a high CO2 evolution was initially observed at 300 °C, a general decrease from 110 to 29 mL per minute was noted with temperature increase from 300 to 600 °C. A thorough explanation of CO2 conversion to CO which led to reduction of the former has been previously reported (Santos and Capareda, 2016). Also observed was the increase of the decomposition reaction kinetics with reactor temperature. This led to the shifting of peak flowrate value towards shorter time. Taken together, components of the syngas (CO, CH4, and H2) increased with temperature, except for CO2.

2.3.2.1 Microwave-enhanced pyrolysis

The general use of microalgae ubiquitously for syngas production may not yield desirable outcome seeing they differ. Therefore, the need to determine microalgae suitability using the microwave-enhanced pyrolysis method has prompted several research directions. For example, Cho et al. (2016) conducted the microwave-enhanced pyrolysis of porphyra, chlorella, and spirulina, using pyrolysis of model algae to represent main algae constituents. These constituents include powdered oil, α-cellulose and ovalbumin, which were useful in the model algae preparation. Comprising 73.3 vol% of syngas, porphyra was most reactive of the three algae having 87.1 wt% gaseous fraction. Similarly, the presence of high carbohydrate content favored the formation of syngas with 23.4–61.8% increase in comparison to spirulina, and 22.8–59.6% increase in comparison to chlorella. These occurred because the high carbohydrate content in porphyra resulted in PAHs and small gas molecule formation at high temperatures. These findings demonstrate that the suitability of macro-algae porphyra seaweed for syngas production of 85.6–87.1 wt% capacity. However, this research can be improved to large-scale commercial gasification process with further steam reforming of C1-C3 hydrocarbons. Confirming the earlier study of Rahman (2018), syngas increased gradually from 400 to 550 °C. However, the CO constituent surged when the pyrolytic temperature increased to 700 °C.

Building on the research findings of Hong et al, Cho et al (Cho et al., 2015) investigated the role of CO2 as a reaction medium in thermochemical production of syngas from red seaweed. Having identified red seaweed as suitable for syngas production, this study enhanced the generation of syngas using the reaction medium. A pyrolytic oil reduction of about 70% at 620 °C was observed when the ratio of CO to H2 was improved by 400% at same 620 °C in the presence of CO2. Besides this improvement (2.0 at 750 °C), CO2 can also enhance syngas production in the thermal cracking of volatile organic carbons during thermal degradation of biomass (Cho et al., 2015). This is because the specified gas phase reaction between VOCs and CO2 would probably affect the composition of pyrolytic oils (Liang et al., 2015). Therefore, the use of CO2 reaction medium in improving syngas generation is demonstrated.

2.4 Bio-oil and Bio-char

Taking a closer examination of the previously reported work of Rahman (2018), the water hyacinth-produced bio-char pyrolytic product is suitable for renewable solid fuel production. The water hyacinth possessed high carbon content and calorific value. That is, the contents of carbon (33.33 wt%), nitrogen (0.7 wt%), and sulfur (0.4%) indicate the tendency of the pyrolysis process to yield less NOX and SOX amounts while enhancing bio-char production. Also, the 20 MJ/Kg calorific value of the water hyacinth is similar to the reports for potato peels (20.3 MJ/Kg) (Abnisa et al., 2013), empty fruit bunches (21.34 MJ/Kg) (Bilgen and Kaygusu, 2008), and even coals (Torri et al., 2011). So, the high carbon content and the physicochemical property of 13.59 MJ/Kg heating value indicate the suitability of producing bio-char pyrolytic product. Though this study has demonstrated the relation between biomass carbon content and bio-char production with reduced NOX and SOX amounts, it is possible to produce carbon-negative biofuels and chemicals. For this reason, Grierson et al. (2009) investigated the potential conversion of Chlamydomonas reinhardti biomass into nitrogen-rich bio-char, bio-oil and biodiesel. This was a preliminary investigation conducted after bio-hydrogen production. At a temperature of 350 °C, the biomass was converted into bio-oil with elemental composition of 54% carbon, 33% oxygen, 6.7% hydrogen, 0.53% sulfur and 5.4% nitrogen. Though research has previously reported a higher bio-oil yield from lignocellulosic biomass (Torri et al., 2010), the use of C. reinhardtii algae reveals a higher nitrogen content than most lignocellulosic biomass (such as corn stover 0.7%, poplar 0.5%, sweet sorghum 1%, switchgrass 0.3%) (xxxx). Having a higher nitrogen content in bio-char is desirable because of the abatement of greenhouse gases, which enhances the possibility of converting carbon–neutral energy into carbon-negative bio-energy (Kruse and Hankamer, 2010; Amin et al., 2019). Anyway, pyrolysis can reduce this high nitrogen content in bio-oil when protein is extracted from biomass residue such as that of marine chlorella sp. (Sarkar et al., 2014).

2.4.1 Pyrolysis

Earlier research has already provided basis for further research on work of Ma et al. (2019) on biorefinery integration with biofuels production. Miao et al. (2004) explored the potential of harvested and lipid extracted microalgae pyrolytic feedstock. Pyrolytic algae oil is a renewable feedstock for sustainable biorefinery development. Since process conditions and nature of feedstock determines biogas and bio-oil composition, higher temperature and long decomposition time enhanced biogas yield with lipid bound algae. On the other hand, bio-gas production increased with hydrogen yield while decreasing CO2. This was observed at reduced decomposition time and temperature. Also, previous findings have shown that the feedstock possesses good fuel properties of straight-chain alkanes in microalgae bio-oils which are similar to those in diesel fuel (Aboulkas et al., 2017). The bio-oil obtained from the fast pyrolysis of microalgae also has low oxygen content with quite high heating value of 29 MJ/kg, 1.16 kg/m3 density and 0.10 Pas viscosity. These properties make bio-oils suitable to conventional fuel oil. However, Norouzi et al. (2016) disagrees with this. They developed processes for bio-oil and biochar production from algae waste and found that the bio-oil produced from algae waste cannot be used as bio-fuel, but the bio-char which exhibits good solid fuel properties. This is because, the high water and oxygen contents, as well as presence of unsaturated and phenolic compounds renders the pyrolized bio-oil unsuitable as fuel. Nevertheless, this presents the need for upgrading or pretreatment of bio-oil to enhance their suitability as bio-fuel (Sarkar et al., 2014). Additionally, the carbon content and HHV of bio-char ensues its’ suitability as a renewable solid fuel. Alternatively, it can be used as a carbon source for carbon materials production, while its’ high nutrient contents of Ca, K, Mg, N and P, makes it fit as a soil additive.

2.4.1.1 Catalytic and Non-Catalytic pyrolysis