Translate this page into:

Development of EVA and LLDPE polymer-based carvone and spearmint essential oil release systems for citrus postharvest diseases applications

⁎Corresponding author. mapossabenjox@gmail.com (Antonio B. Mapossa)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Carvone and spearmint essential oil vapours are suitable candidates for the control of citrus postharvest pathogens due to their strong antifungal activity. However, the high volatility of essential oils remains a hurdle that needs to be overcome before it can be applied as an alternative fungicide. This work investigates the antifungal activity of 20 and 30 wt-% spearmint essential oil or carvone, incorporated into ethylene–vinyl acetate (EVA) and linear low-density polyethylene (LLDPE) strands postharvest pathogens affecting kumquats. Following the melt-extrusion process, an average yield of 16–29 % and 15–28 % of the total carvone and spearmint essential oil, respectively, was determined in the polymer strands. Morphological studies using scanning electron microscopy (SEM) revealed the presence of microporous structures in the internal structure of the strands. The membrane-like skin that covers the polymer strand was also confirmed by SEM. Variations in the release rates were observed between carvone and spearmint essential oils, which was attributed to the difference in the vapour pressure of the neat essential oils. Furthermore, in this study, the results demonstrated that the diffusion exponent ‘n’ of the Korsmeyer–Peppas, Weibull and Log-logistic models exceeded 1.0. In most cases, the Super Case II mechanism was observed. In the case of the Mapossa model, as k2 was ˃> 1, it implies that the outer skin-like membrane covering the polymer strand fully controlled the carvone release. The application of the essential oil-loaded polymer strands resulted in a significant reduction in deterioration, caused by citrus postharvest pathogens, of kumquats kept at room temperature for 21 days. This study indicates that the incorporation of spearmint essential oil or carvone into LLDPE or EVA polymer strands promoted the preservation of kumquat over a 21-day period.

Keywords

Spearmint essential oil

Carvone

Release rate

Antifungal activity

Kumquats

polymer

1 Introduction

The most prevalent and problematic citrus postharvest pathogens in South Africa are Penicillium digitatum, Penicillium italicum and Geotrichum citri-aurantii (Plaza et al., 2004; Bazioli et al., 2019). Due to the continuous source of fungal inoculum in citrus groves and packhouses, these problematic diseases have become the primary focus of citrus postharvest disease management. Various control strategies (physical and chemical treatments) have been implemented to prevent the occurrence of these pathogens, as well as to minimise their impact on citrus fruit. The use of synthetic fungicides is considered to be the most effective and cheapest method for the control of postharvest diseases (Eckert & Ogawa, 1988, Bazioli et al., 2019; Manssouri et al., 2016). However, restrictions on the application of fungicides have been implemented due to environmental and health concerns (Beresford, 2010). The use of postharvest synthetic fungicides is particularly prohibited on fruits such as kumquats (Citrus japonica Thunb), because they are eaten with the peel (Rodov et al., 1992). Thus, alternative and more consumer- and environmentally friendly control methods have been extensively explored.

Numerous studies undertaken have proven that the preventative and curative effects of essential oils can be exploited as an ideal fungicide for citrus postharvest treatment (Plaza et al., 2004; Combrinck et al., 2011; Jhalegar et al., 2015; Regnier et al., 2014; Bakhtiarizade & Souri, 2019). Studies have confirmed the improved effectiveness of vapour application of essential oils as compared to the liquid phase application (Tyagi & Malik, 2011, Manssouri et al., 2016). One major advantage of vapour phase application of essential oils is the ability to use low concentrations of the essential oils, which are less likely to affect the organoleptic properties of the fruit and have less pronounced phytotoxic effects on the rind (Antunes & Cavaco, 2010; Lopez-Reyes et al., 2010). The use of spearmint essential oils and R-carvone to combat fungal diseases has proven to be feasible, however the volatile nature of the essential oil can negatively affect the shelf stability and acceptability of the product (Sokovic & van Griensven, 2006; Regnier et al., 2010). In vivo analysis of spearmint essential oil, with carvone as the major component of the essential oil, against major citrus postharvest pathogens indicated the strong antifungal activity the essential oil (Du Plooy et al., 2009). However, the exploration of natural products for the control of biological spoilage and thus the extension of the storage life of perishable food is incomplete if methods to enhance the stability of these natural products are not investigated concurrently.

The incorporation of additives into packing material to improve the quality and safety of food can be defined as active packaging (Sharma et al., 2021). Active packaging using essential oils results in the reduction or delay in the growth rate of microorganisms (Fasihnia et al., 2017). This type of packaging is used for the protection of bioactive compounds against environmental conditions as well as for controlled release purposes (Mozafari, 2006; Ezhilarasi et al., 2013). Over the last decade both synthetic and biobased polymers have been investigated for their potential use as control release agents in packing material (Huang et al., 2019; Salgado et al., 2021). There are several notable advantages to using biodegradable polymers in packaging, nevertheless challenges relating to the high production and processing costs, poor mechanical and barrier properties have to be addressed before these polymers can be effectively applied (Ibrahim et al., 2021; Rosseto et al., 2019). In addition, Peighamardoust et al. (2016) emphasised the need for more comprehensive studies on the application of encapsulated products, especially those composed of common-use-food contact polymers. Polyethene (PE) remains one of the most widely used material in packaging because of the excellent processability, chemical inertness, harmlessness when in contact with food, good thermal properties, and low cost. Studies have shown that the addition of clay nanocomposites (<10 %) into polymers results in the enhancement of the mechanical and barrier properties, thermal stability and the permeability and compatibility of the active compounds within the polymer (Ugel et al., 2011; Peighambardoust et al., 2016). These improvements hold much potential for the packaging industry. A study by Fasihia et al. (2017) revealed that the addition of organoclays resulted in the enhanced antimicrobial activity of polyethylene nanocomposite films. Similarly, an improvement in the antimicrobial and inhibitory effects of chitosan films was observed when nanoclay was incorporated into the chitosan films (Mohammadzadeh-Vazifeh et al.,2020). Numerous other studies have been conducted on the use of nanofillers and carriers of active compounds for food packing applications. However, there are limited reports and in vivo studies on the antimicrobial properties of polyolefin-based/clay nanocomposite incorporated with essential oils for postharvest application.

The incorporation of antimycotic agents such as imazalil into a low-density polyethylene (LDPE) film assisted in the inhibition of surface mould growth (Weng & Hotchkiss, 1992). Complete inhibition of Penicillium spp. and Aspergillus toxicarruis on cheese grown in an open system was achieved, using 1000 mg/kg of imazalil in such films. Similarly, several essential oils were incorporated in polypropylene (PP) and ethylene vinyl alcohol (EVOH) copolymer films, and the inhibitory property of the released oils was tested against a variety of microorganisms, including Penicillium spp. (Lopez et al., 2007). The antifungal activity of the essential oils released from the films was effectively maintained for more than two months. Wattananawinrat et al. (2014) studied the development of LDPE/EVA films incorporated separately, with clove leaf-, cinnamon bark- and sweet basil essential oils. The antimicrobial properties of the clove leaf and sweet basil essential oils against Escherichia coli and Staphylococcus aureus were evident in the films that contained the essential oil. A 99 % inhibition in the growth of both E. coli and S. aureus was observed at a concentration of 2.08 % clove leaf oil and 0.73 % cinnamon bark oil, incorporated in LDPE/EVA films. Results from the study indicated that the volatilisation rate of the essential oils varies with respect to the essential oil used. From these studies, the incorporation of essential oils and active terpenes into thermoplastics such as EVA and LDPE/EVA films would be a viable solution for pathogen control in food and agricultural packaging.

In view of the practical implications of the different techniques proposed for the application of essential oils in active packaging, this work aimed to evaluate the impact of spearmint essential oil or carvone incorporated into organoclay infused EVA or LLDPE polymer strands against postharvest pathogens. The ultimate goal of this work is design and develop commercially viable protective devices for the postharvest treatment of fruit. The objective of this study was to develop antimicrobial polymer strands containing carvone or spearmint essential oil as the active material, using melt-extrusion. Specifically, the study focused on characterizing the morphological structure of the extruded strands in order to demonstrate their slow-release potential and antifungal activity. Lastly, the release kinetics of the selected essential oils from polymer strands were investigated. This work reports on the structure and active release performance of the prepared polymer strands which contain spearmint essential oil or carvone.

2 Materials and methods

2.1 Materials

Poly(ethylene-co-vinyl acetate) (EVA) (grade Elvax 760A ex DuPont) pellets were pulverised by Dreamweaver. The VA content was 9 %, the density 0.930 g cm − 3 and the melt flow index (MFI) 2.0 g/10 min (190 °C/2.16 kg). Linear low-density polyethylene (LLDPE) (Sasol HR411) was obtained from Sasol. The density was 0.939 g.cm−3 and MFI was 3.5 g/10 min (190 °C/2.16 kg). Carvone was obtained from Sigma-Aldrich (CAS No.6485–40-1) (98 % purity). Spearmint essential oil was obtained from Holistic Emporium, the major constituents of the essential oil are carvone (62.0 wt-%), limonene (24.6 wt-%), and 1,8-cineole (4.6 wt-%) as described by Phala et al., 2022. All chemicals were used as received.

Dellite 43B organo-modified clay was supplied by Laviosa Chimica Mineraria S.p.A. The approximate medium particle size was 8 μm. This organoclay, intercalated with dimethyl benzyl hydrogenated tallow ammonium, was used to modify the rheological consistency of the liquid essential oils.

2.2 Thermo-oxidative stability

The thermal stability of carvone and spearmint essential oil with a 62 wt-% carvone content (Holistic Emporium) was evaluated to ensure that both the terpene and the essential oil are stable under the extrusion temperatures, which ranged from 10 to 200 °C. The active ingredients (6.00 g) were placed in open beakers and exposed to high heat in an EcoTherm-Labcon convection oven at 180 °C and 200 °C for 30 min to simulate polymer extrusion conditions. The samples were removed from the oven, left to cool and then analysed to establish whether the chemical composition had changed. Evaluation was achieved using a Perkin Elmer Fourier Transform infra-red (FTIR) spectrometer (Spectrum two) (FTIR). A small amount of each liquid sample was placed directly onto the diamond ATR cell and analysed over the range of 400 – 4000 cm−1. Spectra were obtained at a resolution of 4 cm−1 with four scans per sample. Spectra were compared to the original carvone and spearmint essential oil.

2.3 Extrusion compounding

The carvone- or spearmint essential oil-impregnated EVA and LLDPE strands were prepared with the assistance of a TX28P 28 mm diameter co-rotating twin-screw extruder (CFAM Technologies [Pty] ltd, Potchefstroom, South Africa) with a L/D ratio (length of the screw to its outside diameter) of 18, according to the method described by Mapossa et al., 2019 and Sitoe et al., 2020. The screw design of this machine comprised intermeshing kneader blocks that also impart a forward transport action. A mass amounting to 20 (80.0 g) and 30 (120 g) wt-% of the carvone or spearmint essential oil in the final product mixture, was weighed in a beaker. In a separate container, approximately 300 and 260 g of either of the two polymers was weighed and 43B Dellite® organoclay was added to a total of 5 wt-% (20.0 g). The organoclay (5 wt%) was used to modify the consistency of the liquid spearmint essential oil and carvone in order to assist feeding of the mixture via the hopper into the compounding extruder. The polymer and clay powders were mixed together with the spearmint essential oil and carvone in a plastic container to obtain a semi-dry consistency that could be fed into the compounding extruder. Upon addition of the active ingredients, the final ratios of the mixtures were:

-

75 wt-% EVA or LLDPE: 20 wt-% spearmint or carvone: 5 wt-% clay Dellite 43B

-

65 wt-% EVA or LLDPE: 30 wt-% spearmint or carvone: 5 wt-% clay Dellite 43B

The temperature profiles, from hopper to die, were set at 140/160/160/160 °C and 140/160/170/170 °C for EVA and LLDPE compositions respectively. The screw speed was varied from 105 to 150 rpm. The extruded polymer strands were then quenched by cooling in an ice-bath, to ensure that a microstructure is generated. The strand diameters produced for the different formulations ranged from 2.0 to 3.0 mm. The diameters of the polymers strand were measured with a Mitutoyo Digital Calliper. The reported strand diameters represent averages of five separate measurements. The strands were stored in a freezer at −20 °C for further analysis.

2.3.1 Extrusion efficiency

The extrusion efficiency (EE), which is the amount of carvone or spearmint oil that were successfully entrapped in the polymers, was established using extraction and thermogravimetric analysis. The polymer strands were cut to three sizes (50-, 70- and 100-mm lengths); which weighed between 0.89 and 0.22 g. They were placed in 50 mL centrifuge tubes, followed by the addition of 40.0 mL of dichloromethane (AR grade, Merck). The polymer strands were left to shake for five days. All the samples were then centrifuged using a Rotofix centrifuge (Labotec, South Africa) at 9000 rpm for 5 min. The dichloromethane was decanted, and the remaining polymer was left to dry overnight, then weighed. The carvone or spearmint essential oil-free polymer strands described above, were stored for further use in morphological studies. The EE was calculated using Equation (1).

where: Mt is the total mass of the carvone, or spearmint essential oil loaded in the polymers and Mi is the initial amount of the carvone or spearmint oil added.

Thermogravimetric analysis was also applied for the determination of EE of the polymer strands. A 10 mg portion of each of the samples was weighed into a ceramic sampling pan. Thermal decomposition of the samples was achieved using a Perkin Elmer TGA 4000 with nitrogen as a purge gas (for an inert atmosphere). The temperatures ranged from 30 to 650 °C, with a heating rate of 20 °C/min. Neat carvone, spearmint essential oil, LLDPE and EVA were analysed under the same conditions.

2.3.2 Morphology

Carvone or spearmint essential oil-free polymer strands were submerged in liquid nitrogen for about 10 min and then fractured. The fracture surface was rendered conductive by coating with carbon using an Emitech K950X coater prior to analysis. The samples were viewed using a Zeiss Ultra 55 Field Emission Scanning Electron Microscope at acceleration voltages of 1 and 5 kV.

2.4 Release rate studies

Time-dependant release studies were conducted as follows: (a) Oven ageing tests were done to track the mass loss of the active components from the polymer strands over time. The strands were suspended in a convection oven 25 °C and in the cold room 4 °C. The mass of the strands was recorded every second day. The experimental data was predicted by different models. (b) Volatiles emitted from the polymer strands were sampled from the same sampling bottle using Tenax TA® tubes (Tube type: Tenax® TA, 1/4-inch OD × 3 1/2-inch size). An air-tight specially modified 100 mL Schott sampling bottle was utilised for sampling of spearmint oil and carvone volatiles. The strands were placed in a sealed Schott bottle and equilibrated for 10 min. Exactly 25.0 mL of the vapour was extracted and adsorbed onto a Tenax TA® tube, The samples were desorbed from the Tenax TA® tubes using a thermal desorption unit (TDU; Unity, Markes International) as described by Augustyn et al. 2010. The qualitative analysis of the volatile components released was achieved using an Agilent gas chromatograph (Model 6890 N) coupled to a Model 5975B mass selective detector according to the parameters listed in the Appendix.

2.5 Antifungal activity of the impregnated polymer strands

2.5.1 In-vitro antifungal activity

Fungal cultures of P. digitatum (green mold) and G. citri-aurantii (sour rot) isolated from infected fruit were verified and supplied by Citrus Research International (CRI)(Nelspruit, South African). The cultures were subcultured onto Potato Dextose Agar (PDA) (Biolab, Wadeville, South Africa) and incubated for 8 days at 25 °C (Phala et al.,2022). The volatile exposure assay as described by Regnier et al. (2010) was used to evaluate the efficacy of the encapsulated carvone or spearmint essential oil. Exactly 10 µL spore suspension of either P. digitatum (green mould) and G. citri-aurantii (sour rot) were inoculated onto pre-set Potato dextrose agar (PDA) (Biolab, Wadeville, South Africa). The concentration of the prepared inoculum was adjusted to 1 × 106 for green mould and 1 × 108 spores/mL sour rot, equivalent to an optical density (OD) of 0.14. The polymer stands were cut into small fragments such that the mass of either carvone or spearmint essential oil present within each section was equivalent to 10, 50 and 100 mg. Each of the polymer strands fragments were placed onto the Petri-dish lids and the inoculated agar was inverted so that the Petri-dish was upside-down. The dishes were sealed with Parafilm™ (American Natural, Chicago) to prevent the vapours from escaping. The plates were incubated for seven days at 25 °C. Thereafter, plates that showed no growth were re-inoculated with a fresh spore suspension. This was repeated until the terpene/essential oil displayed no further inhibition towards the fungi. The percentage inhibition was subsequently calculated.

2.5.2 In vivo efficacy

Export quality kumquats were obtained from Levubu (Mpumalanga, South Africa). The first batch of fruit was used for in vivo evaluation of EVA strands containing carvone and spearmint essential oil, while the second batch of fruit was used to evaluate the efficacy of LLDPE strands containing carvone and spearmint essential oil. The fruit were subjected to the normal packhouse treatment procedure, namely a chlorinated wash in a hot bath at 40 °C. The fruit were divided into five groups comprising ten boxes each, according to their respective treatments. Approximately 15 g of each of the polymer strands were weighed and tied onto the inside of the box; such that they were not touching the fruit (Fig. 1). The weight loss and decay were measured, and the results expressed as the average of 10 boxes per treatment group.

Photograph of kumquats exposed to the essential oil polymer strands. The strands were impregnated with 20 wt-% of either carvone or spearmint essential oil and 5 wt-% of organoclay Dellite® 43B.

2.5.3 Sensory evaluation

Sensory evaluation of the kumquats was done to verify the presence of off-odour and off-flavour in the fruit. The sensory panel consisted of 20 untrained judges (males and females), who were 21 – 60 years old. For each treatment group the samples were removed from storage one hour before evaluation for them to equilibrate under room temperature conditions. The coded fruit samples were presented to the panel in random order with a two-minute interval between servings, when water was provided as a palate cleanser. The evaluation form consisted of five descriptors, which were quantified using a nine-point Hedonic scale (Appendix?). The approach is modelled after the method described by Stone & Sidel (2004). Appearance, texture and flavour were evaluated using this method and the average values were included for assessing the consumer acceptability. The panellists were also asked to assess the aroma-type that they perceived while tasting.

3 Results and discussion

3.1 Thermal-oxidative stability

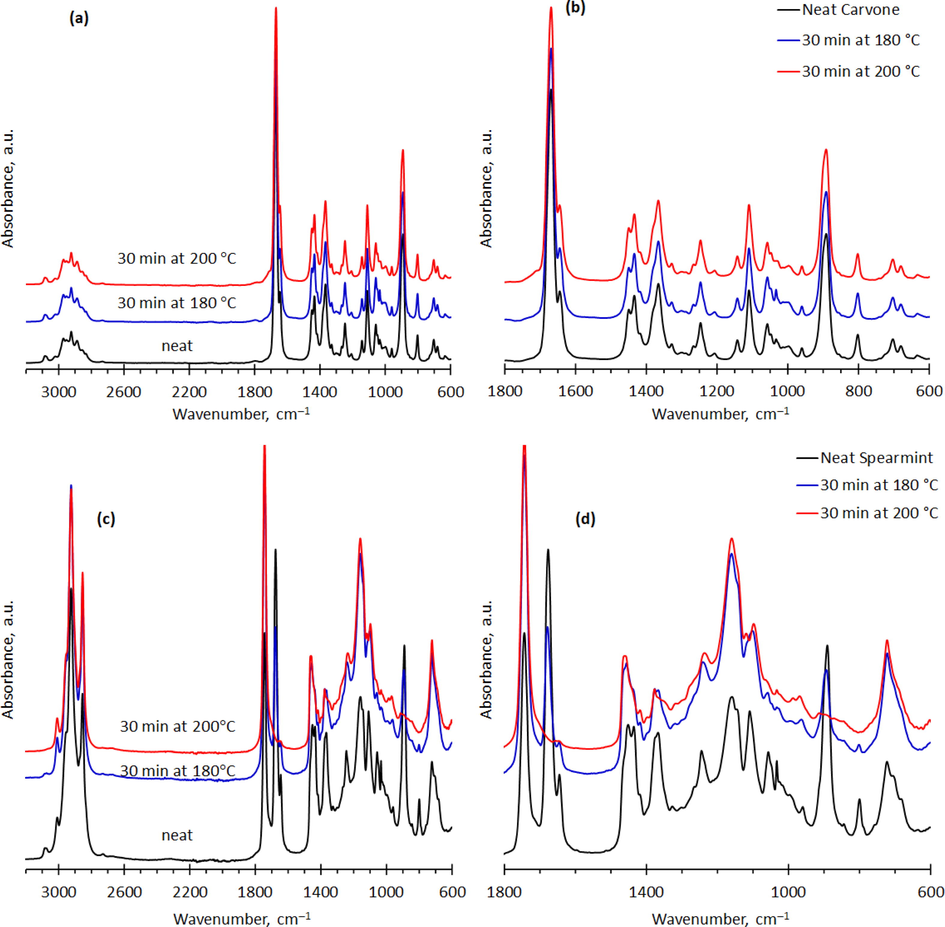

During extrusion of the polymer strands, carvone and spearmint essential oil are subjected to typical polymer processing temperatures, which are > 180 °C. Thus, it was deemed necessary to determine whether the active ingredient could withstand short-time exposure (30 min) to such high temperatures (Mapossa et al., 2020). Establishing the thermal stability of the active components is important to ensure that no thermal degradation occurs. The obtained FTIR spectra (Fig. 2) demonstrates the thermal-oxidative stability of carvone and spearmint oil. It is evident from the spectra that carvone remains stable within the studied temperature range. However, spearmint essential oil, which is a mixture of compounds, is not as thermally stable as its major component (carvone). The thermal degradation of constituents of spearmint essential oil at 200 °C is evident from the disappearance of the bands at 1675 and 887 cm−1 in the spectra (Fig. 2c and 2d). However, when the essential oil was subjected to 180 °C, no major changes in the functional groups were observed. The short heat exposure revealed that carvone and spearmint essential oil can withstand the extrusion temperature, provided they remain at 180 °C or lower. Therefore, for the polymer compounding extrusion process, maximum temperatures of 160 and 170 °C were used for EVA and LLDPE, respectively. This reduction in temperature was utilised without compromising the structural and mechanical integrity of the produced strands.

Fourier Transform infrared spectroscopy (FTIR) spectra of (a) carvone and (c) spearmint essential oil. (b) Expanded views of the band absorption region of carvone; and (d) the carbonyl absorption region of spearmint essential oil. The FTIR spectra shows the neat active ingredients before and after thermal–oxidative stability testing by exposure to air, at either 180 ∘C for 30 min or 200 ∘C for 30 min.

3.2 Active ingredient content of the extruded strands

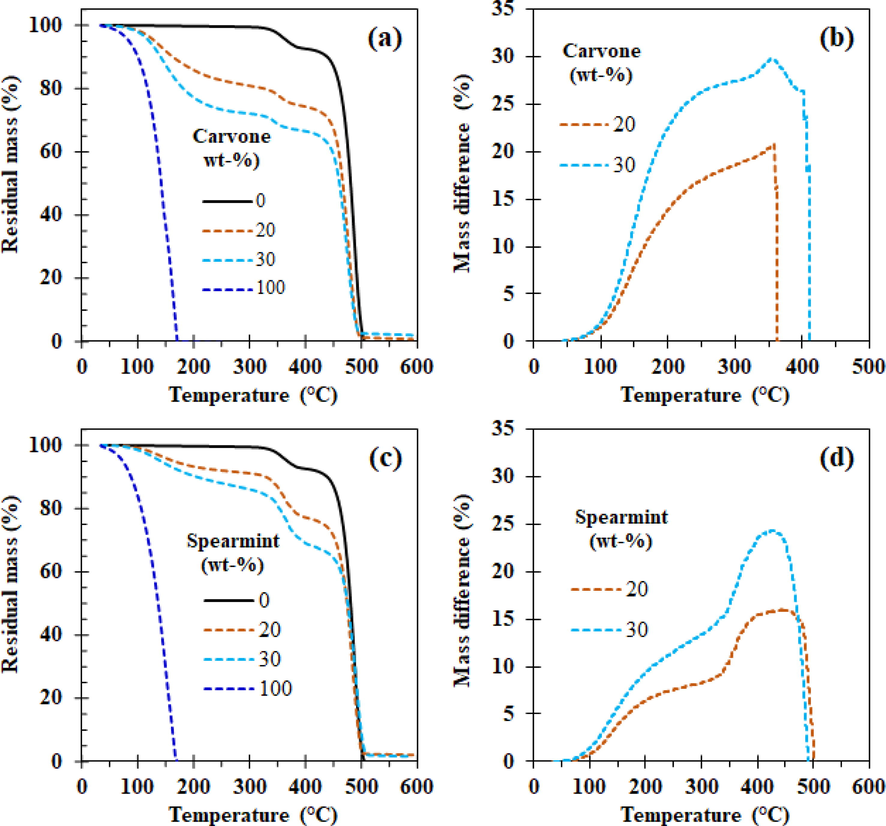

Fig. 3 (a and c) indicate typical TGA graphs obtained for neat carvone, neat spearmint essential oil, neat EVA and the polymers strands filled with the active ingredients. The volatile active ingredients incorporated in the polymer strands can be observed in the first mass loss on the TGA plots. The evaporative mass loss of neat carvone commenced at 64 °C and was accomplished by 180 °C, while mass loss of neat spearmint essential oil started at 53 °C and was completed by 172 °C. Complete volatilisation of carvone and spearmint essential oil incorporated in the polymer strands was observed at temperatures above 300 °C. Fig. 3 (b and d) shows the difference between the EVA strands containing 20 and 30 % of the active ingredient. The plot demonstrates a clear maximum for both the formulation (20 and 30 % carvone), and this was correlated with the amount of the carvone oil in the polymer nanocomposite. Two events of degradation for neat EVA polymer were observed, where these are related to the (i) the loss of vinyl acetate units via a de-acylation process resulting in the formation of double bonds, and (ii) to the degradation of resulting partially unsaturated polyethylene polymer material (Sitoe et al., 2020). This behavior was not observed for neat LLDPE polymer, which demonstrated one event of degradation.

Thermogravimetric plots of: (a) neat carvone, neat EVA and EVA strands initially containing 20 or 30 wt-% of carvone and 5 wt% Dellite 43B clay, (b) a plot of the mass difference between neat EVA and EVA strands containing 20 or 30 wt-% carvone, (c) neat spearmint essential oil, neat EVA and EVA strands initially containing 20 or 30 wt-% of spearmint essential oil and 5 wt% Dellite 43B clay, (d) Plot of the difference in mass loss between the neat EVA and EVA strands containing 20 or 30 wt-% spearmint essential oil.

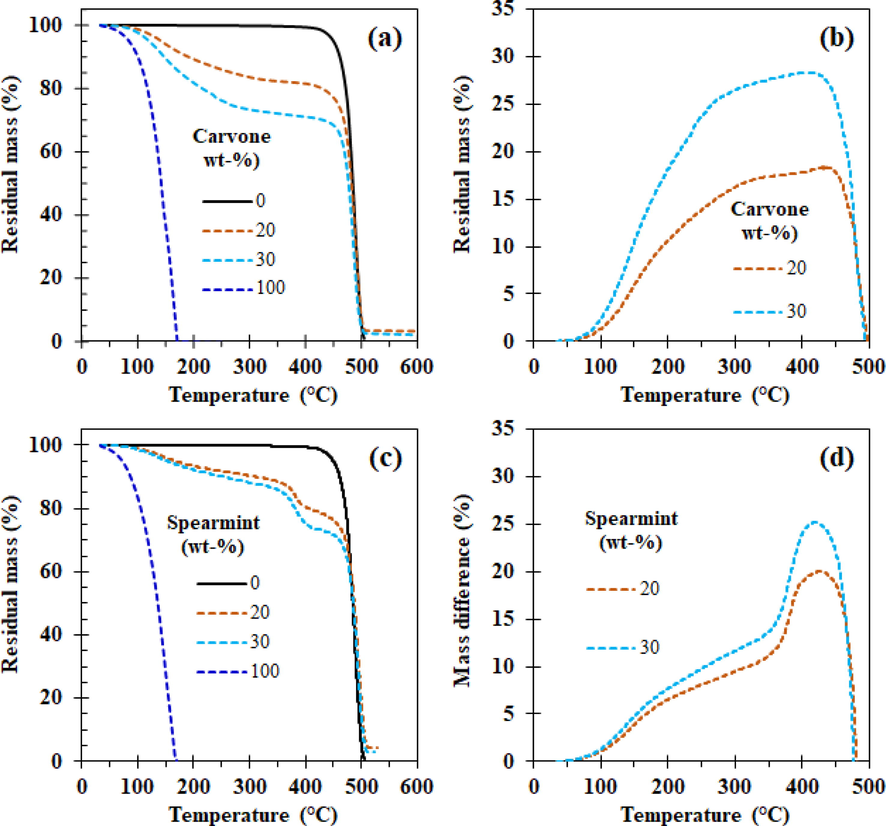

Comparable to Fig. 3, Fig. 4 (a and c) represents TGA graphs obtained for neat carvone, neat spearmint essential oil, neat LLDPE and the LLDPE polymers strands filled with the active ingredients. Fig. 4 (b and d) represents mass difference between the LLDPE strands containing 20 and 30 %. Unlike the EVA polymer, neat LLDPE demonstrated one event of degradation. Similar to the EVA polymer, the use of LLDPE polymer resulted in the increase of complete volatilisation temperature of carvone and spearmint essential oil at temperatures (<300 °C). In summary, it is evident from the TGA results that the incorporation of carvone and spearmint essential oil into the polymers (EVA and LDPE) results in a reduction in the volatilisation rate of the active ingredient.

Thermogravimetric plots of: (a) neat carvone, neat LLDPE strands and LLDPE strands initially containing 20 or 30 wt-% of carvone and 5 wt% Dellite 43B clay, (b) a plot of the mass difference between neat LLDPE and LLDPE strands containing 20 or 30 wt-% carvone, (c) neat spearmint essential oil, neat LLDPE and LLDPE strands initially containing 20 or 30 wt-% of spearmint essential oil and 5 wt% Dellite 43B clay, (d) Plot of the difference in mass loss between the neat LLDPE and LLDPE strands containing 20 or 30 wt-% spearmint essential oil.

Table 1 lists the diameter and composition of the carvone and spearmint essential oil-incorporated polymer strands. The diameters of both the EVA and LLDPE strands were found to range between 1.99 and 3.03 and 2.58 – 2.65 mm, respectively. The compounding efficiency, in terms of the amount of active ingredient included in the polymers, was found to be lower than what was added to the polymer formulations (20 and 30 wt-% active compounds). The results obtained using solvent extraction were comparable to those obtained using TGA, indicating a consistent distribution of the active ingredient throughout the polymer strands. The volatility of both carvone and spearmint essential oil is evident in the reduced mass of the active ingredient present following the compounding process. However, it was certain that no degradation had taken place, since the stability analysis indicated stability at 180 °C. Spearmint essential oil had a slightly lower loading capacity for all the polymer formulations, when comparing it to carvone. It was deduced that the reduction occurred due to a loss of the lower boiling point compounds present in the oil as a result of the high temperatures. Nevertheless, >80 % of the total added active ingredient was incorporated into the polymer strands, regardless of the temperatures. This can be considered an acceptable value considering the volatile nature of the active material and the temperatures used in the process. Similar results were reported by Llana-Ruiz-Cabello et al. (2018), who found an 80 % average of the oregano essential oil present in their polymer films following the melt-extrusion process. They also attributed their loss to the volatility of the essential oil components. Other researchers reported similar losses, explained by the volatilisation behaviour of the active components during the extrusion process (Altiok et al., 2010; Ramos et al., 2012).

Active content (wt-%)

Polymer

Compound

Nominal

Solvent extraction

TGA

Diameter (mm)

EVA

carvone

20

18.2 ± 0.6

20.7

3.0 ± 0.3

EVA

carvone

30

28.9 ± 0.2

29.7

2.5 ± 0.2

LLDPE

carvone

20

16.1 ± 0.7

18.4

2.6 ± 0.3

LLDPE

carvone

30

24.1 ± 0.3

28.3

2.7 ± 0.5

EVA

spearmint

20

17.6 ± 0.6

16

2.8 ± 0.2

EVA

spearmint

30

27.7 ± 0.6

24.4

2.0 ± 0.1

LLDPE

spearmint

20

15.0 ± 0.2

20

2.6 ± 0.2

LLDPE

spearmint

30

22.9 ± 0.2

25.2

2.6 ± 0.1

3.3 Morphology

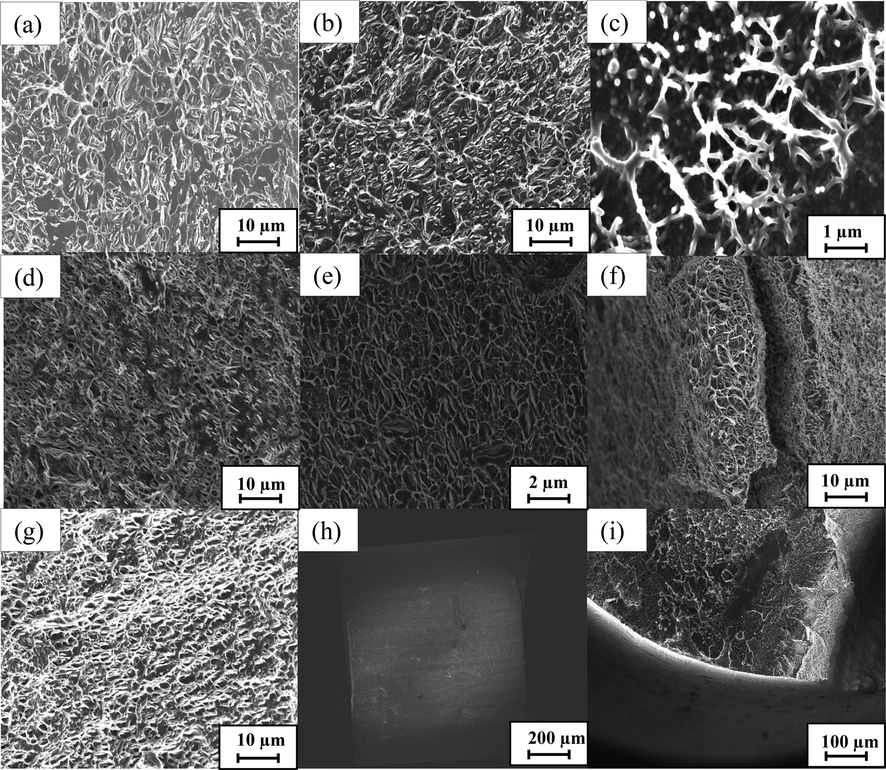

Scanning electron microscopy imaging was used to examine the morphology of the prepared polymer strands containing 20 wt-% and 30 wt-% active ingredients. As illustrated in Fig. 5 a – g, a large number of pores were present in the surface morphology of all the polymers, which might facilitate the permeability of the active material within the polymer. The presence of these pores verify that the formation of a homogenous polymer and active ingredient-rich mixture can be generated through the phase separation phenomenon of spinodal decomposition (Cabral & Higgins, 2018). According to Mapossa et al. (2019), the internal structure of the polymer serves as a reservoir and a protective environment for the active ingredient trapped inside. Furthermore, the outer dense skin layer probably provides a diffusion barrier that controls the release of the active ingredient at sufficient levels over extended periods. There were observed differences between the microporous nature of the two polymer strands. The images indicate a more interwoven structure with well-defined pores sizes obtained for the LLDPE strands, as compared to the interwoven voids of various sizes randomly dispersed within the EVA polymer strands. It is evident that the type of active material and the amount added affect the final microporous structure and only slightly affect the microporosity within the strands.

Scanning electron microscopy micrographs showing the effect of carvone or spearmint on the structure of the internal microporous region of extruded EVA and LLDPE strands. The SEM represents: (a) 20 wt-% carvone into the EVA, (b) 20 wt-% spearmint into the EVA, (c) 30 wt-% carvone into the EVA, (d) 20 wt-% carvone into the LLDPE, (e) 20 wt-% spearmint into the LLDPE, (f) 30 wt-% carvone into the LLDPE, (g) 30 wt-% spearmint into the LLDPE, (h) outer surface of EVA polymer strand appearance, and (i) cross-section showing the outer skin covering of the LLDPE polymer strand.

3.4 Release rate studies

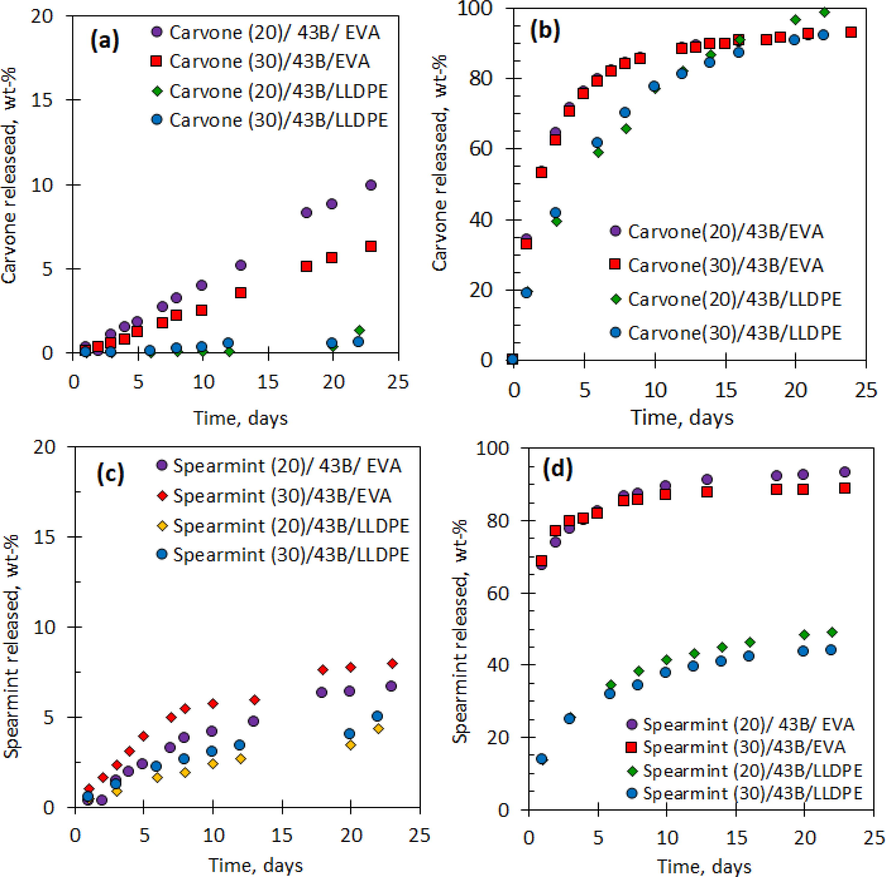

The release studies of carvone and spearmint oil from the polymer strands were conducted isothermally at 4 and 25 °C, which represent the temperatures used for most citrus fruit during storage and transportation, respectively. Plots of the release of carvone and spearmint essential oil from the EVA or LLDPE matrices versus time at 4 and 25 °C, respectively, are depicted in Fig. 6. The results confirm that the release rate is dependent on temperature. Differences in the release rates were observed between carvone and spearmint essential oil and were influenced by the type of polymer used. The use of LLDPE resulted in a slightly lower release rate for both the active materials. However, leakage of the oil from the strands was observed at a higher concentration of the active material.

Mass loss of carvone or spearmint oil from polymers strands at 4 °C and 25 °C over a period of 21 days, where (a) represents the different carvone concentrations incorporated into EVA and LLDPE strands and incubated at 4 °C; (b) represents the different carvone concentrations incorporated into EVA and LLDPE strands and incubated at 25 °C; (c) represents the different spearmint essential oil concentrations incorporated into EVA and LLDPE strands and incubated at 4 °C; and (d) depicts the different spearmint essential oil concentrations incorporated into EVA and LLDPE strands and incubated at 25 °C; and Dellite 43B clay.

Following a 21-day incubation at 25 °C, almost all of the carvone had been released from the EVA and LLDPE (Fig. 6). There were no substantial differences between the release patterns of carvone and spearmint essential oil when incorporated into EVA strands. However, spearmint essential oil was released slower when incorporated in LLDPE strands as compared to carvone. This slowed release for spearmint essential oil incorporated into the LLDPE matrix may be attributed to interaction of the different oil components within the polymer, since the release of the active material is dependent on polarity. This relates to the chemical interactions between the volatiles and the inner core of the polymer (Malhotra et al., 2015). Electrostatic interactions between the essential oil and the polymer chains are said to affect the release rate of the active components (Avila-Sosa et al., 2012). The slower release of the spearmint essential oil components may be attributed to the variations in the volatility of the components within the essential oil, and thus leading to the strong interactions of some of these components with the polymer matrix. According to Efrati et al. (2014), polymers with high crystallinity have a greater ability to retain essential oils for longer periods. The crystallinity of EVA is lower than that of LLDPE, resulting in the more rapid permeation of the spearmint essential oil components through the EVA structure.

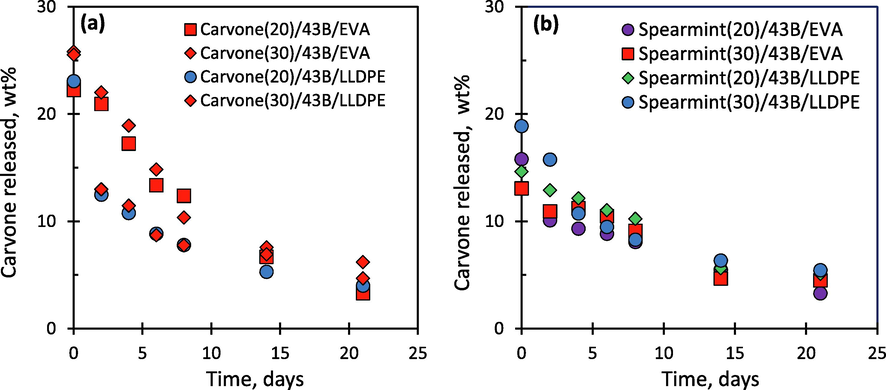

The carvone emitted from the polymer strands was determined by sampling using Tenax TA® over a 21-day period. Results from the analysis are expressed as the percentage of carvone released from the strand as determined by GC–MS coupled to a thermal desorption unit. For both neat carvone and spearmint essential oil, a large percentage of carvone was released on the first two days, with a lower percentage of carvone released by the LLDPE strands than by the EVA strands. A sharp decline in the amount of carvone released from the strands then occurred over the next eight days (Fig. 7 a and b). After ten days, the release of carvone from both the EVA and LLDPE strands remained relatively constant. Carvone is released from the spearmint oil-incorporated strands at a slower and more consistent rate, as compared to the carvone/polymer strands. Similar to the mass loss results, a greater percentage of carvone was released over the five days. However, unlike the mass loss data, there was only a slight difference in the carvone content released from the EVA and LLDPE strands. Thus, both the EVA and LLDPE strands are suitable vehicles for the slow release of terpenes.

Percentage volatiles emitted from EVA and LLDPE strands containing carvone or spearmint oil, incubated at 25 °C for 21 days. The samples were collected using Tenax TA® tubes and analysed using a thermal desorption GC–MS where a) represents carvone-incorporated polymer strands, and b) spearmint essential oil-incorporated polymer strands; All polymer strands contained 5 wt-% of 43B clay.

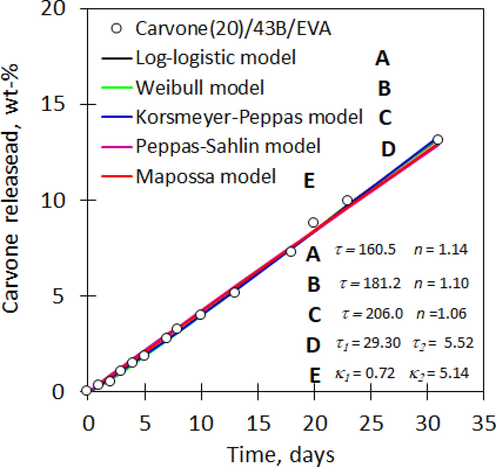

3.5 Modeling release of active components from polymer strands

The profiles of the release rate of carvone from an EVA strand fitted by different models, namely Korsmeyer-Peppas (Korsmeyer et al., 1983) (Equation (2), the Peppas-Sahlin model (Sitoe et al., 2020) (Equation (3)), Log-logistic (Focke et al., 2017) (Equation (4)), Weibull (Cunha et al., 1998) (Equation (5)), and Mapossa (Mapossa et al., 2019) (Equation (6)) models, are presented in Fig. 8. These models yielded correlation coefficients “r’’ from 0.9989 to 0.9993.

Representative release rate fits using different Korsmeyer-Peppas, Mapossa, Weibull, Peppas-Sahlin and Log-logistic models. The sample contained 20 wt-% carvone and 5 wt-% of clay.

where τ is a time constant, t is the release time and n is the diffusional exponent for active ingredient release. Values of n ≤ 0.50 represent the Fickian diffusion mechanism, values in the range 0.50 < n < 1.0 reflect anomalous diffusion, values n = 1.0 correspond to the non-Fickian diffusion mechanism and finally when n > 1.0 it was considered to follow the Super Case II mechanism.

This release kinetics model is a consequence of the indication that it is possible to calculate the approximate two contribution mechanisms (diffusional and relaxational) in an anomalous active release process. The symbols τ1 and τ2 represent the Fickian diffusion constants.

Here, exponent n provides a parametric interpolation between the predictions of the logistic equation (n → 0) and second order kinetics (n).

where the Fickian diffusion mechanism is represented by values of n ≤ 0.75. Where Fickian diffusion and Case II transport mechanisms are represented by values in the range of 0.75 < n < 1, Weibull’s model reduces to classical first-order kinetics when n = 1.

where X represents the the amount of active component remaining to the elapsed time (t); the characteristic time τ and the shape parameter β both depend on geometric features and the physical properties of the polymer and active ingredient.

In this study, the results demonstrated that the diffusion exponent ‘n’ of the Korsmeyer–Peppas, Weibull and Log-logistic models exceeded 1.0. In most cases, the Super Case II mechanism was observed. In the case of the Mapossa model, as k2 was ˃> 1, it implies that the outer skin-like membrane covering the polymer strand fully controlled the carvone release. In this case the carvone is be released slowly and at a constant rate from the microporous strand. More plots of the other samples are presented in the Supplementary Material.

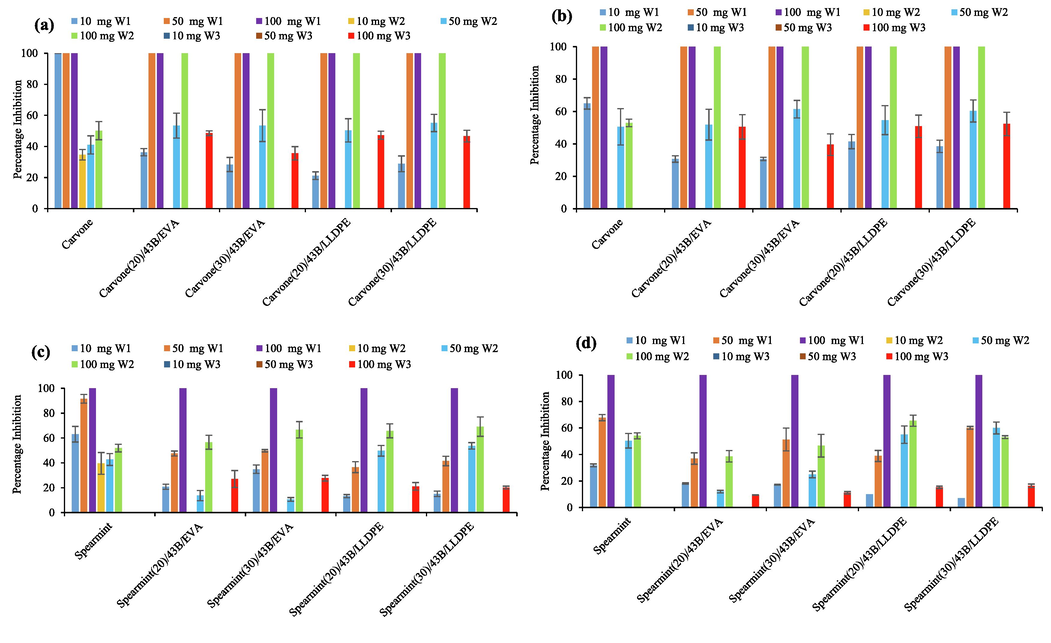

3.6 Antifungal activity

Polymer films containing different concentration of carvone or spearmint essential oil were tested against the target pathogens using a volatile exposure assay. The active ingredient transferred to the headspace made contact with the pathogens and induced pathogen inhibition in a concentration-dependent manner. Fig. 9 illustrates the efficacy of the vapours released from carvone/spearmint essential oil polymer strands over a 21-day period. On a weekly basis, fresh inoculum was subjected to the active ingredient incorporated into polymer strands attached to the Petri-dish lids, provided the percentage fungal inhibition was higher than 50 %. Evidently, 100 mg of both carvone and spearmint essential oil, present in both EVA and LLDPE polymers, resulted in the complete inhibition of both green mould and sour rot for two weeks (Fig. 9). By the third week, exposure of the new inoculum to the carvone and spearmint oil vapours resulted in only a slight inhibition of pathogen growth, implying that the carvone in the headspace was largely depleted. The antifungal activity of the neat carvone and spearmint oil not incorporated into strands, resulted in complete pathogen inhibition for one week, upon introduction of fresh inoculum on the second week of analysis, pathogenic inhibition decreased to<60 %, indicating more rapid evaporation of the “free” carvone.

Antifungal activity of carvone/spearmint essential oil incorporated in EVA and LLDPE polymer strands as determined using the volatile exposure assay over a 21-day period, where (a) represents the percentage inhibition of carvone:EVA/LLDPE strands against green mould; (b) is the percentage inhibition of carvone:EVA/LLDPE strands against sour rot; (c) is the percentage inhibition of spearmint oil:EVA/LLDPE strands against green mould; (d) is the percentage inhibition of spearmint oil:EVA/LLDPE strands against sour rot; W1-W3 represents the number of weeks that the experiment was conducted (W1 = week 1; W2 = week 2; W3 = week 3); All polymer strands contained 5 wt-% of 43B clay.

The polymer material used to immobilise the active substance plays a pivotal role in the efficacy of the active substance, because it regulates the release of the active material. Similar to the release studies, there was a continuous release of the active material over the three-week period, resulting in the inhibition of the pathogens for the entire three-week period. To be effective, the release time of the active substance from the polymers must be longer than the cellular generation time, thus resulting in the inhibition or growth retardation of the pathogens. Furthermore, the concentration of the released active material needs to be high enough to ensure a sufficient concentration of the active material in the headspace, as can be seen from Fig. 8. However, in vitro analysis does not provide a good reflection of the effects of the polymer material on the release of the active material, since it is tested in a closed system. The active material is more concentrated in the Petri-dish as opposed to the open environment of a citrus packhouse and storage facility.

3.7 Efficacy of impregnated polymers (EVA & LLDPE) against postharvest pathogens affecting kumquats under packhouse conditions

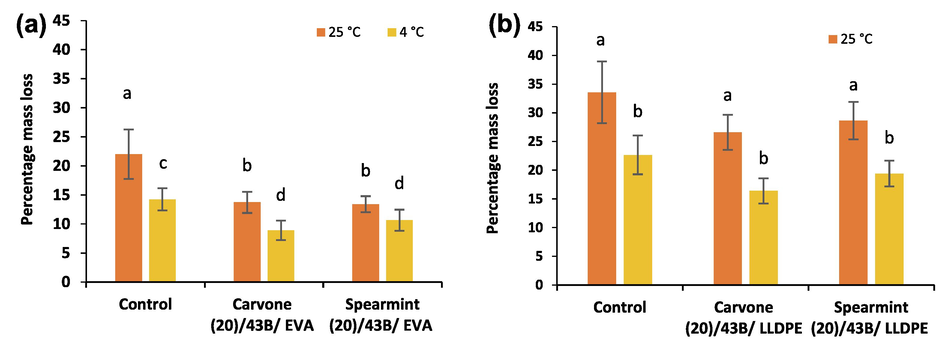

The essential oil-polymer release studies confirmed the slow-release potential of EVA and LLDPE polymers. Treatment of the fruit with spearmint essential oil or carvone vapours released from the EVA resulted in a significant reduction (p < 0.05) in mass loss. The vapour treated fruits retained about 30 % more mass as compared to the control, at 25 and 4 °C storage conditions (Fig. 10a). A difference was observed in the mass loss of the fruit treated with the LLDPE spearmint essential oil- or carvone-incorporated strands and their controls, however the difference was not significant (p > 0.05) (Fig. 10b). The perishability of citrus fruits is generally proportional to their respiration rate, which can be influenced by the transpiration rate of the fruit that, in turn, is affected by rind injuries and fruit maturity (Strano et al., 2016). Therefore, we can assume that the variation observed was due to the difference in fruit maturity, since the EVA-treated fruit were harvested a month earlier than the LLDPE-treated fruit.

Mass loss for kumquats following exposure to vapour released from active polymer strands impregnated with carvone or spearmint oil (20 wt-%). (a) ethylene–vinyl acetate (EVA, 75 wt-%) and (b) linear low-density polyethylene (LLDPE, 75 wt-%); All polymer strands contained 5 wt-% of 43B clay. Error bars represent standard error of mean values (N = 10 boxes of fruit). For each treatment group, the different letters above the columns represent data that are significantly different, as determined by a T-test (significance was distinguished if p < 0.05).

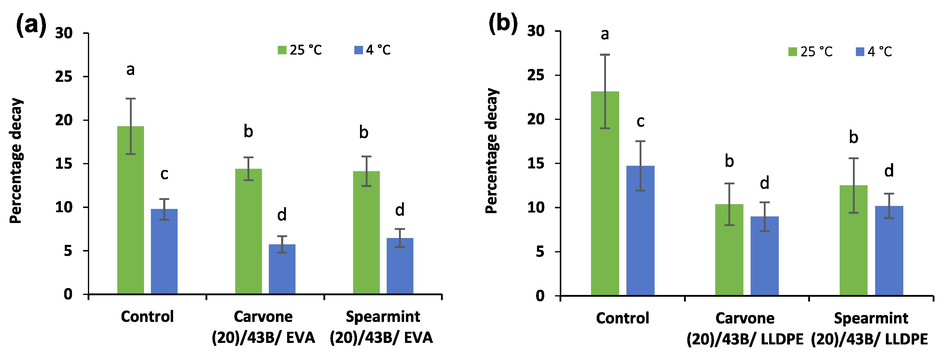

A significant reduction (p < 0.05) in the disease occurrence caused by citrus postharvest pathogens of the treated fruit in comparison to the control was observed (Fig. 11). Similar to the trend obtained from mass loss results, a reduction of about 40 % in disease development was observed on fruit treated with essential oil or carvone vapours impregnated into EVA, at both the storage temperature conditions. Exposure of the fruit to spearmint essential or carvone vapours incorporated in LLDPE strands resulted in a decreased decay occurrence of approximately 50 and 36 % at 25 and 4 °C storage conditions, respectively. Mass loss can be linked to vitamin degradation, fruit browning and enzyme activity, resulting in an increased rate in the growth of microorganisms, which increases the susceptibility of the fruit to fungal decay (Mohammadi et al., 2016). This theory explains the direct relationship between mass loss results and fruit decay. Spearmint essential oil or carvone fumigation was effective in decreasing postharvest rot of kumquats, but the efficacy varied under the two experimental conditions (25 °C and 4 °C). Cold storage ensured that the fruit quality was preserved, with only about 40 and 36 % of decay observed for fruit treated with essential oils released from EVA or LLDPE wall material, respectively. A higher concentration of spearmint essential oil or carvone vapours was released from the EVA strands as compared to the LLDPE strand as observed in the release studies (Figs. 6 and 7). Therefore, early saturation of the fruit environment was provided by fumigation when using the EVA strands, as compared to the slower and more consistent release from the LLDPE strands, resulting in the observed efficacy variation. It therefore seems that the antifungal effect of the fumigants is largely dependent on the rate of release of the active compound and the concentration of the fumigant in the fruit atmosphere. Although in vitro vapour exposure assays provide an indication of the efficacy of spearmint oil and carvone towards a specific pathogen, it does not give the optimum concentration required to ensure complete pathogen inhibition in vivo, due to the high vapour-to-air concentration present in the Petri-dish. The essential oil concentration required to inhibit microbial growth is higher in foods as compared to cultured media. This has been attributed to the interaction between the phenolic compounds and the food matrix (Tzortzakis & Economakis, 2007). To ensure a long protection period from infection due to the application of vapours, the decay of these fruit could be prevented or, at least, delayed until reaching the consumer in formulations with EVA as a wall material.

Percentage decay occurrence of kumquats exposed to vapour released from active polymer strands impregnated with carvone or spearmint essential oil (20 wt-%). (a) ethylene–vinyl acetate (EVA, 75 wt-%) and (b) linear low-density polyethylene (LLDPE, 75 wt-%); All polymer strands contained 5 wt-% of 43B clay. Error bars represent standard error of mean values (N = 10 boxes of fruit). For each treatment group, the different letters above the columns represent data that are significantly different as determined by a T-test (significance was distinguished if p < 0.05); and 43B = Dellite 43B clay.

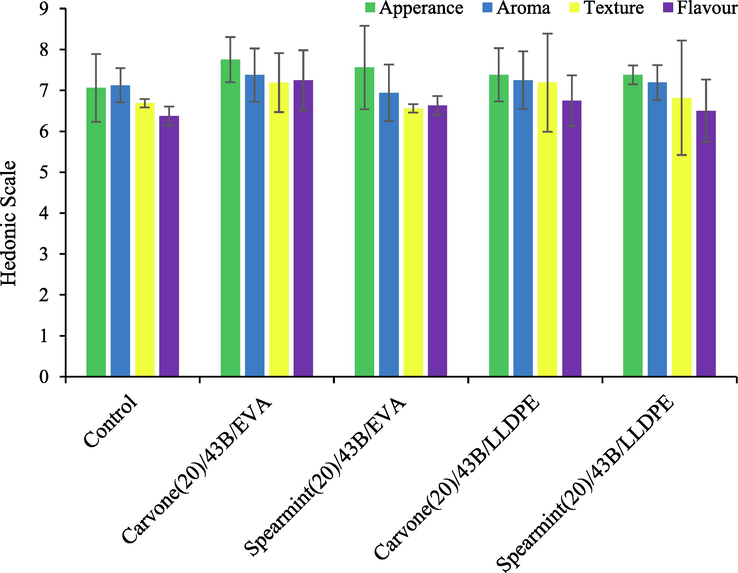

3.8 Sensory evaluation

Results of the sensory analysis for Kumquat fruit treated with spearmint oil, carvone vapours and the control are provided in Fig. 12. The averages of all the evaluated parameters for both the control and the treated fruit fell between “like slightly” (6) and “like very much” (8) on the hedonic scale. There was no variable distinction observed in the appearance, aroma, texture and flavour of the control fruit and the treated fruit (p > 0.05). However, the control fruit had a lower acceptability score as compared to the treated fruit. The higher score given to the treated fruit may be due to the lower weight loss of the fruit, resulting in the retention of sugars and acids within the fruit. When asked about the specific aroma of the fruit, a large majority of the panellist could only detect the citrus aroma. Two out of the twenty panellists recognised a minty aroma in the fruits treated with spearmint oil.

Sensory evaluation using the hedonic scale, for kumquat treated with various treatments under room temperature (25 °C).

Consumer perceptions of the quality of any product is largely based on the sensorial properties including appearance, colour, aroma and flavour (Costell et al., 2010). Extended exposure of fruit to essential oil vapours may results in phytotoxic effects, which may affect the quality of the fruit (Arroyo et al., 2007). The use of controlled-release material namely EVA and LLDPE, assisted in minimizing the odour effect of the applied volatiles. A sensory evaluation conducted by Aguilar-Gonzalez and colleagues (2017), on the response of tomatoes inoculated with Aspergillus niger and exposed to mustard seed oil in the vapour phase, revealed an off-flavour in the treated tomatoes. Consequently, the effect of the essential oil on the organoleptic properties of fresh produce seems to be dependent on the type of fruit treated, the concentration of the vapour and the overall exposure time. Therefore, in this study, the fruit used and the vapour concentration are compatible, since there was little to no observed alteration to the sensorial properties of the kumquats.

4 Conclusions

In this study, the significant amount of carvone and spearmint essential oil were successfully incorporated into either the EVA or LLDPE polymers by melt-extrusion at two different loading levels (20 and 30 wt%), without any degradation of the active volatile components. Thermogravimetric analysis revealed suppression of carvone or spearmint essential oil volatility when incorporated into the LLDPE and EVA strands. The melt-extrusion process resulted in the formation of microporous polymer strands, with scaffolds serving as storage for the active ingredients. In addition, this process also yielded a membrane-like skin covering the polymer strands that controls the release rate of the active compounds from the microporous polymer strands. Exposure of green mould and sour rot to the polymer strands resulted in growth inhibition of the pathogens, suggesting that the applications of these polymers could improve the quality of citrus by the action of volatile compounds on the surface growth of the pathogens. Furthermore, in vivo analysis demonstrated the successful use of carvone, or spearmint essential oil vapours incorporated in EVA or LLDPE polymer strands for the control of postharvest fungi that infect kumquats under packhouse conditions.

Acknowledgments

The authors would like to thank National Research Foundation (NRF) (grant number: 111201) and the Postharvest Innovation Fund (PHI), a public-private partnership between the Department of Science and Innovation (DSI) and the Fresh Produce Exporters’ Forum (FPEF) of South Africa, for funding this project, and sincere gratitude to Institute of Applied Materials, Department of Chemical Engineering, University of Pretoria, for compounding of polymer-active ingredient strands.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Response of Aspergillus niger inoculated on tomatoes exposed to vapor phase mustard essential oil for short or long periods and sensory evaluation of treated tomatoes. J. Food Qual.. 2017;1–7

- [CrossRef] [Google Scholar]

- Physical, antibacterial and antioxidant properties of chitosan films incorporated with thyme oil for potential wound healing applications. J. Mater. Sci. - Mater. Med.. 2010;21:2227-2236.

- [CrossRef] [Google Scholar]

- The use of essential oils for postharvest decay control. A Review. Flavour Fragr. J.. 2010;25:351-366.

- [CrossRef] [Google Scholar]

- Antifungal activity of strawberry fruit volatile compounds against Colletotrichum acutatum. J. Agric. Food Chem.. 2007;55:5701-5707.

- [CrossRef] [Google Scholar]

- Secondary metabolites as protection against mango gall fly 423 infestation. Flavour Fragr. J.. 2010;25:223-229.

- [CrossRef] [Google Scholar]

- Antifungal activity by vapor contact of essential oils added to amaranth, chitosan, or starch edible films. Int. J. of Food Microbiol.. 2012;153:66-72.

- [CrossRef] [Google Scholar]

- Beneficial effects of rosemary, thyme and tarragon essential oils on postharvest decay of Valencia oranges. Chem. Biol. Technol. Agric.. 2019;6:9.

- [CrossRef] [Google Scholar]

- Biological control of citrus postharvest phytopathogens. Toxins (Basel). 2019;11(8):460. 10.3390%2Ftoxins11080460

- [Google Scholar]

- Towards reduced reliance on fungicides for disease control in New Zealand’s crop-based industries. N. Z. Plant Prot.. 2010;63:138-144.

- [Google Scholar]

- Spinodal nanostructures in polymer blends: on the validity of the Cahn-Hilliard length scale prediction. Prog. Polym. Sci... 2018;81:1-21.

- [CrossRef] [Google Scholar]

- In vitro activity of eighteen essential oils and some major components against common postharvest fungal pathogens of fruit. Ind. Crop Prod.. 2011;33(2):344-349.

- [CrossRef] [Google Scholar]

- Costell, E., Carbonell, I., Tárrega, A. & Bayarri, S., 2010. Sensory quality control of fresh produce. Editor(s): David Kilcast, In: Woodhead Publishing Series in Food Science, Technology and Nutrition, Sensory Analysis for Food and Beverage Quality Control, Woodhead Publishing, pp 276-292.https://doi.org/10.1533/9781845699512.3.276.

- Optimal experimental design for estimating the kinetic parameters of processes described by the Weibull probability distribution function. J. Food Eng.. 1998;37:175-191.

- [Google Scholar]

- Essential oil-amended coatings as alternatives to synthetic fungicides in citrus postharvest management. Postharvest Biol. Technol... 2009;53:117-122.

- [CrossRef] [Google Scholar]

- The chemical control of postharvest diseases: Deciduous fruits, berries, vegetables and root/tuber crops. Ann. Rev. Phytopathol.. 1988;26:433-469.

- [CrossRef] [Google Scholar]

- The effect of polyethylene crystallinity and polarity on thermal stability and controlled release of essential oils in antimicrobial films. J. Appl. Polym. Sci.. 2014;131(11):40309.

- [CrossRef] [Google Scholar]

- Nanoencapsulation techniques for food bioactive components: A review. Food Bioproc. Tech... 2013;6(3):628-647.

- [CrossRef] [Google Scholar]

- Nanocomposite films containing organoclay nanoparticles as an antimicrobial (active) packaging for potential food application. J. Food. Process. Preserve.. 2017;42(2):e13488.

- [Google Scholar]

- Kinetic interpretation of log-logistic dose-time response curves. Sci. Rep.. 2017;7(1):1-11.

- [Google Scholar]

- Poly (Ethylene–Co–Vinyl Acetate)/Clay Nanocomposites: Effect of Clay Nature and Compatibilising Agents on Morphological Thermal and Mechanical Properties. 2011.

- [Google Scholar]

- Polymeric Antimicrobial Food Packaging and Its Applications. Polymers. 2019;11(3):560.

- [CrossRef] [Google Scholar]

- Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings. 2021;11:1423.

- [CrossRef] [Google Scholar]

- In vitro and in vivo activity of essential oils against major postharvest pathogens of Kinnow (Citrus nobilis × C. deliciosa) mandarin. J. Food Sci. Technol.. 2015;52:2229-2237.

- [CrossRef] [Google Scholar]

- Mechanisms of solute release from porous hydrophilic polymers. Int. J. Pharm.. 1983;15:25-35.

- [Google Scholar]

- Characterisation and antimicrobial activity of active polypropylene films containing oregano essential oil and Allium extract to be used in packaging for meat products. Food Addit. Contam. Part A Chem. Anal. Control Risk Assess.. 2018;35(4):783-792.

- [CrossRef] [Google Scholar]

- Efficacy of plant essential oils on post-harvest control of rot caused by fungi on four cultivars of apples in vivo. Flavour Fragr. J.. 2010;25:171-177.

- [CrossRef] [Google Scholar]

- Antimicrobial food packaging: potential and pitfalls. Front. Microbiol.. 2015;6:611. 10.3389%2Ffmicb.2015.00611

- [Google Scholar]

- Antifungal activity of essential oil from the fruits of Ammodaucus leucotrichus Coss. & Dur., in liquid and vapour phase against postharvest phytopathogenic fungi in apples. J. App Pharm Sci.. 2016;6(5):131-136.

- [CrossRef] [Google Scholar]

- Microporous polyolefin strands as controlled-release devices for mosquito repellents. Chem. Eng. J.. 2019;360:435-444.

- [CrossRef] [Google Scholar]

- Mosquito repellent thermal stability, permeability and air volatility. Pest Manag. Sci.. 2020;76(3):1112-1120.

- [Google Scholar]

- Postharvest treatment of nanochitosan-based coating loaded with Zataria multiflora essential oil improves antioxidant activity and extends shelf-life of cucumber. Innov. Food Sci. Emerg. Technol... 2016;33:580-588.

- [CrossRef] [Google Scholar]

- Investigation of the antimicrobial properties of nanoclay and chitosan based nanocomposite on the microbial characteristics of Gouda cheese. 2020.

- [Google Scholar]

- Bioactive entrapment and targeting using nanocarrier technologies: An introduction. In: Mozafari M.R., ed. Nanocarrier Technologies: Frontiers of Nanotherapy. Netherlands: Springer; 2006. p. :1-16.

- [CrossRef] [Google Scholar]

- Application of organoclay nanoparticle in low-density polyethylene films for packaging of UF cheese. Packag. Technol. Sci.. 2016;29(7):355-363.

- [CrossRef] [Google Scholar]

- Inhibition of kumquat postharvest fungi through vapor contact with spearmint essential oil and carvone. ACS Agric. Sci. Technol.. 2022;2(2):330-333.

- [CrossRef] [Google Scholar]

- Evaluation of the potential of commercial post-harvest application of essential oils to control citrus decay. J. Hortic. Science and Biotechnology. 2004;79(6):935-940.

- [CrossRef] [Google Scholar]

- Characterization and antimicrobial activity studies of polypropylene films with carvacrol and thymol for active packaging. J. Food Eng.. 2012;109:513-519.

- [Google Scholar]

- Evaluation of Lippia scaberrima essential oil and some pure terpenoid constituents as postharvest mycobiocides for avocado fruit. Postharvest Biol. Tech.. 2010;57(3):176-182.

- [CrossRef] [Google Scholar]

- Application of essential oils as multi-target fungicides for the control of Geotrichum citri-aurantii and other postharvest pathogens of citrus. Ind. Crop Prod.. 2014;61:151-159.

- [CrossRef] [Google Scholar]

- Ultraviolet illumination induces scoparone production in kumquat and orange fruit and improves decay resistance. J. Am. Soc. Hortic Sci... 1992;117:788-792.

- [Google Scholar]

- Rosseto, M., Rigueto, C. V. , Krein, D. D. , Balbé, N. P. , Massuda, L. A. , & Dettmer, A. (2019). Biodegradable Polymers: Opportunities and Challenges. In A. Sand, & E. Zaki (Eds.), Organic Polymers. IntechOpen. https://doi.org/10.5772/intechopen.88146.

- Recent developments in smart food packaging focused on biobased and biodegradable polymers. Frontiers in Sustainable Food Systems.. 2021;5

- [CrossRef] [Google Scholar]

- Development, characterization and modeling of mosquito repellent release from microporous devices. SPE Polymers. 2020;1(2):90-100.

- [Google Scholar]

- Antimicrobial activity of essential oils and their components against the three major pathogens of the cultivated button mushroom Agaricus bisporus. Eur. J. Plant Pathol.. 2006;116:211-224.

- [CrossRef] [Google Scholar]

- Advance in citrus postharvest management: Diseases, cold storage and quality evaluation. Citrus Pathology, InTech. 2016;139–159

- [CrossRef] [Google Scholar]

- Antimicrobial potential and chemical composition of Eucalyptus globulus oil in liquid and vapour phase against food spoilage microorganisms. Food Chem.. 2011;126(1):228-235.

- [CrossRef] [Google Scholar]

- Antifungal activity of lemongrass (Cympopogon citratus L.) essential oil against key postharvest pathogens. Innov. Food Sci. Emerg. Technol... 2007;8(2):253-258.

- [CrossRef] [Google Scholar]

- Morphological and thermal properties of LDPE/EVA blended films and development of antimicrobial activity in food packaging film. Energy Procedia. 2014;56:1-9.

- [CrossRef] [Google Scholar]

- Inhibition of surface molds on cheese by polyethylene film containing the antimycotic imazalil. J. Food Prot.. 1992;5(55):367-369.

- [CrossRef] [Google Scholar]

Appendix A

Supplementary material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.arabjc.2022.104458.

Appendix A

Supplementary material

The following are the Supplementary data to this article:Supplementary Data 1

Supplementary Data 1