Translate this page into:

Emerging electrocatalysts for green ammonia production: Recent progress and future outlook

⁎Corresponding author. shahidiqbal@hzu.edu.cn (Shahid Iqbal),

⁎⁎Corresponding author at: Nanomaterials Research Center, Department of Chemistry, College of Science, Mathematics, and Technology, Wenzhou-Kean University, Wenzhou 325060, Zhejiang Province, China. abahadur@wku.edu.cn (Ali Bahadur)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

In the Haber-Bosch process (HBp), which uses elevated pressure and temperature to produce more concentration of nitrogen and hydrogen gases, 90% of the 175 million metric tons of NH3 generated worldwide in 2016 were manufactured in this process. According to the road plan for sustainable ammonia production sustainably, using water as a reducing agent is the most effective way to fix nitrogen in close-quarters ambiance. A complete explanation of theoretical and practical work on electrocatalytic nitrogen reduction is provided in this article, with special attention paid to the low selectivity of nitrogen reduction to ammonia in comparison to protons to hydrogen. Since they are essential for accurately achieving high nitrogen production and Faradaic efficiency (FE), their information outlines electrocatalysts, electrolyte selection criteria, and managed experiment design. Under diverse conditions, the evolution of theory and experiment is examined. Finally, feedback is given on this field’s present issues and prospects.

Keywords

Nitrogen reduction

Electrochemical reaction

Electrocatalyst

Nitrogen production rate

Faradaic efficiency

1 Introduction

Ammonia production has contributed to population growth and has been employed as fertilizer throughout the past century. Nitrogen sustains around 27% of the world's population and is provided via ammonia fertilizers. In 1908, a German scientist named Fitz Haber developed a device to fulfill the demand using recycled hydrogen and nitrogen under high pressure and temperature. This technique, known as the HBp, was carried out commercially by Carl Bosch in 1911. In 1918, Fritz Haber's efforts in producing NH3 earned him the Nobel Prize in Chemistry. This incredible approach showed a novel ammonia production method combining nitrogen and hydrogen. The following reaction: N2 + 3H2 → 2NH3 occurs when H2 and N2 are mixed at high pressures of 20 to 40 MPa and temperatures of 400 to 600 °C using an iron-based catalyst. Low temperatures are necessary for this exothermic reaction to produce ammonia (ΔHo298K= −44.91 KJ/mol, ΔGo298K= −16.3 KJ/mol, Keq = 749.9). The nitrogen-nitrogen bond is exceptionally strong. According to equilibrium calculations, 99% of NH3 decomposes into nitrogen and hydrogen at pressures of 0.1 MPa and temperatures above 400 °C. Higher temperatures are required to overcome this bond strength barrier, and NH3 decomposes into nitrogen and hydrogen. Therefore, the HBp, which produces ammonia, operates at a high pressure of 20–40 MPa. A single reaction synthesizes approximately 15% of ammonia, and the remaining nitrogen and hydrogen can be recycled back into the reaction chamber, producing an approximate 97% yield of ammonia (Qing et al., 2020; Foster et al., 2018). This procedure is used to produce fertilizer on a massive scale, and about 80% (136 megatons in 2011) of ammonia production is utilized for this purpose, according to the survey (Kandemir et al., 2013). In the field of agriculture, the HBp has brought a revolution. Nitrogen in gaseous form (N2) is present in the environment at 78% by volume. It is not helpful in gaseous form for plants. Soil having nitrogen benefits agricultural productivity, but nitrogen depletes each crop very quickly (Wang et al., 2018). The Haber-Bosch method, which produces NH3 as fertilizer, is frequently used to increase agricultural productivity·NH3 is only of the world's most widely formed industrial compounds, and 89.9% of it is produced using the Haber-Bosch method. The productivity of NH3 increased from 117 million metric tons in 1996 to 175.0 million metric tons in 2016 (Qing et al., 2020; Zhang et al., 2016).

According to a 2016 survey, about 88% of ammonia consumption in the USA was for fertilizer. The fertilizer forms of ammonia were urea, ammonium phosphates, anhydrous ammonia, ammonium nitrate, and other nitrogen compounds for direct use. Ammonia residue makes several chemical compounds, plastics, resins, industrial refrigerants, explosives, and synthetic fibers (Wang et al., 2018; Chen et al., 2023; Xu et al., 2024). The consumption of ammonia drastically changes the landscape of our planet. Since 1950, the amount of N2 consumed has quadrupled. According to estimates, the HBp for NH3 provides around 40% of the world's nutritional protein source. Synthetic ammonia is terrible for the environment because it requires a lot of energy and fossil fuels (Wang et al., 2024). Another disadvantage is that capturing N2 requires low temperatures, whereas hydrogen produced from fossil fuels undergoes highly endothermic reactions (Gui et al., 2024). Low-temperature procedures are typically necessary to obtain nitrogen feedstock from the environment. This is because synthesizing H2 from fossil fuels comprising coal, natural gas, petroleum, and oil involves highly endothermic reactions. Natural gas accounts for almost 70% of the hydrogen in ammonia synthesis (Zhen et al., 2024). Desulfurization, steam reforming, and water–gas shift reactions are all components of the multi-stage natural gas hydrogen production process (Qing et al., 2020; Ercolino et al., 2015).

Steam reforming:

Water-gas shift reaction:

Steam reforming is an energy-intensive process due to its endothermic nature. When factoring in the cost of natural gas, it becomes evident that around 75% of the overall ammonia production expenses are attributed to the production of H2 (Chen et al., 2022). The remaining 25% of the cost pertains to the separation and synthesis of ammonia, which necessitates 485 kJ/mol per mole of energy. The production of industrial ammonia consequences in the release of approximately 300 million metric tons of carbon dioxide (CO2), contributing to roughly 3–5% of the worldwide natural gas consumption and over 1% of yearly energy production (Chen et al., 2022; Shipman and Symes, 2017; Licht et al., 2014). If the current pace of consumption holds, fossil fuels may run out in the next 100 years. Releasing greenhouse gases like CO2 into the atmosphere quickly alters the climate. About 400 ppm of CO2 is present in the air, more than double the industrial standard (280 ppm) (Blasing et al., 2016). Extreme weather, arctic permafrost melting, and widespread coral bleaching are all believed to be effects of man-made climate change (Wallace et al., 2014; Schuur et al., 2015; Hughes et al., 2017). Authors and international organizations have recently advocated for ammonia as a carbon-free energy carrier for renewable sources. Ammonia is documented as a viable and environmentally friendly fuel with global potential for future utilization (Valera-Medina et al., 2021; Khan et al., 2024; Mahmood et al., 2024). Ammonia's consumption in heavy transportation, energy production, and distributed energy storage are all growing rapidly. Ammonia can replace a sizeable amount of the liquid fuel now used if it is produced on a big scale (MacFarlane et al., 2020; Wang et al., 2019; Mahmood et al., 2024). This chemical is vital to the fertilizer industry, producing 150 million tons globally annually.

In addition, ammonia is considered a viable option for transporting chemical energy owing to its high hydrogen gravimetric density (17.8 wt%) (Iqbal and Iqbal, 2013). Although it is currently challenging to transport and store hydrogen, it is an excellent fuel for zero-emission vehicles since, in a fuel cell, it reacts with oxygen to produce just water (Eberle et al., 2012). Since hydrogen has a boiling point of −253 °C at atmospheric pressure, it can only be stored under either high pressure or low temperature (Irfan et al., 2021). On the other hand, ammonia has a vapor pressure of 0.86 MPa at 20 °C and a boiling point of −33 °C at atmospheric pressure, allowing it to liquefy in benign conditions. Also, a solid infrastructure is in place for transporting and storing large volumes of liquid ammonia. Ammonia can be converted into hydrogen at the application site through thermal decomposition or electrolysis (Ju et al., 2017; Little et al., 2015). The performance of solid oxide fuel cells is comparable to that of hydrogen gas because they permit the direct use of ammonia as fuel (Molouk et al., 2015). Ammonia is also fuel for power plants and internal combustion engines (Xiao et al., 2016; Mahmood et al., 2024). This review focuses on the techno-economic analysis that researchers have done for the technological challenges and advances in the fixation of the electrochemical conversion of N2 to NH3 (Irfan et al., 2020; Mahmood et al., 2024; Yan et al., 2024). Contemporary research focuses on developing new, highly engaged catalysts for ammonia synthesis by employing ruthenium, cobalt, nickel, promoted iron, and metal nitrides to discover their industrial application. Moreover, the efficiency of the HBp can be enhanced by optimizing the conversion rate through the utilization of lower temperatures and pressures.

Over the past decade, several attempts have been made to design catalysts that can fix nitrogen reduction under favorable reaction conditions to produce ammonia and other beneficial nitrogen-containing compounds. These processes include low-temperature thermal catalysis, non-thermal plasma catalyst supports, enzymatic catalysis, photocatalysis, and electrochemical catalysis (Shi et al., 2020; Shen et al., 2023; Liu et al., 2023). Innovative catalysts for ammonia synthesis, which employ oxynitride hydrides, nitrides, amides, hydrides, and oxide supports, are promising substitutes for traditional Ru, Fe, Ni, and Co-based catalysts. There has been substantial research dedicated to exploring the connection between catalyst morphology and carriers, indicating that, while these new catalysts hold great potential, there is room for further improvements in activity. The presence of anionic oxygen and nitrogen vacancies in promoters or co-catalysts dramatically increases the stability and activity of catalysts used in ammonia synthesis. Developing catalysts that are resistant to oxygenate is crucial for enhancing the overall efficiency of HBp, particularly in the context of small-scale green ammonia production. This advancement also simplifies the gas treatment procedures involved. These innovative catalysts must undergo a rigorous stability study for industrial applications under varied operating settings with various contaminants in the precursor gases. Novel catalysts must carefully consider the cost to compete with less expensive fused iron catalysts. The advantages of increased catalytic activity cannot be lost due to the more expensive catalyst if the aim is to replace the current fused iron catalysts (Humphreys et al., 2021).

Although ammonia production is exothermic and can attain more significant thermodynamic conversion at reduced temperatures, the present catalysts need higher temperatures to generate reasonable rates (He et al., 2019; Pan et al., 2018; Liu et al., 2018). In designing future catalysts, it should be considered that they operate at a low temperature to optimize conversion in the reactor loop. Nitride-supported nickel-based and hydride-supported nickel-based catalysts have been demonstrated to offer low-temperature activity using a chemical cycle process. Therefore, the possible solution for low-temperature ammonia synthesis is nickel-based catalysts with specifically designed support materials. The activity of the Ru-supported CaFH catalyst at this low temperature is due to weak ionic bonding in solid solution, which again presents an important area for investigation. This catalyst has effectively produced ammonia at the extremely low temperature of 50 °C (Humphreys et al., 2021). Oxygenates in the feed gas stream contaminate the catalysts for ammonia production and significantly decrease their activity. As a result, ammonia synthesis plants typically use various purifying techniques. The capital and operating costs of these purification methods significantly increase in large-scale ammonia synthesis plants, which restricts the production of small-scale green ammonia and makes these technologies unfeasible. Therefore, oxygen and anion vacancies in the catalyst may contribute to developing ammonia-production catalysts resistant to oxygenation (Humphreys et al., 2021). These purification procedures raise the capital and operational expenses of large-scale ammonia synthesis facilities, limiting the availability of green ammonia synthesis on a smaller scale and making these technologies expensive. Oxygen and anion vacancies in the catalyst could open the way for oxygenate-tolerant ammonia synthesis catalysts.

Scientists have invented contemporary techniques to reduce the energy needed for ammonia manufacturing and carbon dioxide emissions. Lowering the operating temperature and pressure of an ammonia plant may lead to a substantial reduction in both construction and running expenses. A heterogeneous catalyst based on ruthenium (Ru) is essential. The KBR Advanced Ammonia Process (KAAP), which produces ammonia at 10 MPa, uses Ru-based catalysts (Brown et al., 2014). It is also reported that ternary intermetallic compounds such as transition metal-LiH composites (Wang et al., 2017), La-Co-Si (Gong et al., 2018), Ru/Ba-Ca(NH2)2 Ru/C12A7:e-, (Gong et al., 2018), and Ru/Pr2O3 (Sato et al., 2017) exhibit exceptional catalytic efficiency for ammonia production from nitrogen and hydrogen at 400 °C and 1 MPa pressure. Ru-based catalysts are rarely used in commercial processes due to excessive cost and poor stability (Foster et al., 2018). As mentioned, two significant limitations are the high energy requirements for producing hydrogen from natural gas and the CO2 emissions from ammonia synthesis. The electrolysis of water using electricity generated by wind or solar sources to produce hydrogen is promising (Energy, 2018). Unexpectedly, the cost of producing renewable energy is falling dramatically, and substantial advancements have been made in the research of electrocatalysts for processes that include the production of oxygen and hydrogen (Qing et al., 2020; Jin et al., 2018; Zou and Zhang, 2015). As a result, it is possible and profitable to produce ammonia using renewable energy. Renewable electricity is intermittent, which is the main issue in combining renewable hydrogen production with a Haber-Bosch reactor because the Haber-Bosch reaction is continuous and requires a constant hydrogen supply. Therefore, the installation cost of renewable ammonia plants will significantly enhance if more energy or H2 storage infrastructure is built to fill hydrogen's supply and demand gap. The main benefit of electrochemical nitrogen reduction technology is the ability to connect sporadic renewable electricity generation with ammonia production directly.

To achieve this, the researchers concentrate on creating transition metal-nitrogen complexes that allow nitrogen to be reduced to ammonia under benign reaction circumstances (Nishibayashi, 2015; Zhao et al., 2022). Another strategy to achieve environmentally friendly ammonia synthesis is the employment of semiconductors with sunlight to generate photocatalytic reactions (Brown et al., 2016; Zhao et al., 2017). The ideal scenario involves photo-generating valence band holes from water and N2 as precursors, oxidizing water, and reducing N2 to ammonia with conduction band electrons (Hirakawa et al., 2017). The major barriers to effective photocatalytic ammonia production are high-energy reaction intermediates and poor N2 binding to the catalyst surface (Li et al., 2017). Manufacturing nitric oxide OR ammonia from nitrogen is possible using the plasma formed by ionizing gases (Patil et al., 2015). H2 and N2 molecules first dissociate on the catalyst's surface in the HBp, then recombine as free radicals in the plasma (Hessel et al., 2013). It has been demonstrated that, at atmospheric pressure, the generation of ammonia from nitrogen and hydrogen is enhanced by plasma and catalysts (Qing et al., 2020; Iwamoto et al., 2017). In recent years, the effective synthesis of ammonia using electrocatalysts from the N2 reduction reaction has recently attracted much attention. This method could replace the Haber-Bosch method, which has problems with noteworthy energy utilization and high carbon dioxide production. Consequently, the number of studies focused on the electro-catalytic reduction of nitrates has dramatically expanded (Wang et al., 2021). Nitrogen is recycled by the electrochemical process of converting nitrate into ammonia, which is more valuable than nitrogen (Wang et al., 2020). However, this method is still not mature, and needs to comprehend the mechanisms of materials for heterogeneous electrocatalytic reduction of nitrates and efficiently compare performance of various electrocatalysts (Wang et al., 2021; Wu et al., 2024). Extensive research has been conducted on electrocatalysts, including transition metals (such as bi-transition metals, mono-transition metals, and transition metal composites) and non-metals, due to their crucial role in nitrate reduction. These materials exhibit excellent electrochemical performance and economic efficiency.

Due to the interest in fuel cells and electrolyzers, extensive research is being done on electrocatalyst materials for the evolution and oxidation of hydrogen and oxygen. However, even though experimental trials were described in 1960, the electrochemical generation of ammonia has just become the subject of significant study. At the electrode surface of an electrochemical cell, N2 is reduced to form ammonia. The following summary of the electrode procedure: Protons are supplied to create ammonia, and electrons from an external circuit lower the N2 molecules that must stick to the electrode's surface. Electrochemical cells offer numerous potential benefits for ammonia production. Ammonia can be synthesized electrochemically under gentle circumstances. Due to its utilization of electricity instead of heat to initiate the N2 molecules, it exhibits significantly higher efficiency than the Haber-Bosch technique. An extensive investigation has been conducted to better understand the electrochemical production of ammonia across a broad temperature range, from room temperature to 800 °C (Zhen et al., 2024). Second, manufacturing ammonia using renewable electricity is possible with the electrochemical synthesis of ammonia (Foster et al., 2018). Large-scale operations (usually 1000–1500 tons/day) have been required for ammonia manufacturing to achieve economies of scale. The electrochemical synthesis method enables ammonia production on a small scale and in specific locations, utilizing renewable energy from wind or solar sources. Water can be used as a source of H2 in the electrochemical production of ammonia. Natural gas reserves are usually considered for the location of modern ammonia plants to help synthesize H2. Since water is the most prevalent liquid on Earth, there is no such restriction when using it as the H2 source for the electrochemical generation of ammonia. In this case, the catalytic reduction of nitrogen and oxidation of water in the electrochemical cell enables the generation of ammonia without the requirement for fossil energy as an H2 source. Furthermore, advancements in membrane electrode assembly methods for water electrolyzers and fuel cells can potentially improve the electrochemical production of ammonia (Qing et al., 2020; Wang et al., 2019; Greenlee et al., 2018; Rouwenhorst et al., 2020; Liu et al., 2021; Zhang et al., 2021).

The effectiveness of the electrochemical synthesis process is contingent upon the efficiency of the water electrolysis step, hydrogen pressurization stage, and ammonia synthesis step. Each of these steps' efficiencies is a function of several other factors, such as pressure, temperature, recycle rate, ammonia separation, and others. In addition to liquid electrolytes like ionic liquids, aqueous acidic and alkaline electrolytes, and more practical molten alkali metal hydroxides or chloride salts, the electrochemical synthesis of ammonia has also been done using solid electrolytes like PEM8, AEM, and high-temperature proton and oxygen conductive solids oxide membranes (Gao et al., 2017; Ni et al., 2023). Because electrolysis in acidic electrolytes releases ammonium ions into the solvent and changes the solution's acidity, this approach is used for electrocatalyst screening (Suryanto et al., 2018). Nitrogen's poor solubility makes electrolysis in solutions even more difficult. Therefore, a suitable gas diffusion electrode design is crucial for productivity (Soloveichik, 2019). Numerous electrocatalysts, such as supported and unsupported noble metals, metal oxides, and metal nitrides, have been used for electrochemical NH3 production, depending on the pH and physical state of the electrolyte (solid, polymer, or liquid). Studies have also been done on catalysts devoid of transition metals, such as black phosphorus and carbon, doped with nitrogen and BN. Building effective and specific catalysts for nitrogen reduction reaction (NRR) is sought since NRR will produce more ammonia (Wang et al., 2019; Soloveichik, 2019).

New reaction systems and electrodes were invented due to the rising interest of scientists and researchers in the electrochemical reduction of nitrogen, and they have made substantial progress toward achieving a higher ammonia production rate in the past several years. Consequently, a wide range of readers should be interested in thoroughly examining this subject. Considerable research efforts have been directed toward exploring electrode materials for electrocatalytic nitrogen reduction reactions (ENRR). This research has encompassed a wide array of materials, including supported and unsupported noble metals, nitrides, phosphides, metal carbides, metal oxides, as well as non-metallic materials. The primary objective of these investigations is to boost electrochemical proficiency, a critical factor in the context of ENRR. The role of electrocatalysts is of paramount importance as they significantly influence the performance and catalytic processes involved in the electrochemical production of ammonia (NH3). Nevertheless, to make a logical choice for a novel system that can efficiently carry out the electrocatalytic reduction of N2, it is crucial to fully understand the underlying mechanisms of the electrode materials, which are currently not fully developed. Numerous evaluations have emphasized the progress made in electrolytes for ENRR, but evaluating different most recent electrocatalyst materials has been neglected. Hence, an immediate assessment of the latest advancements in this domain is vital.

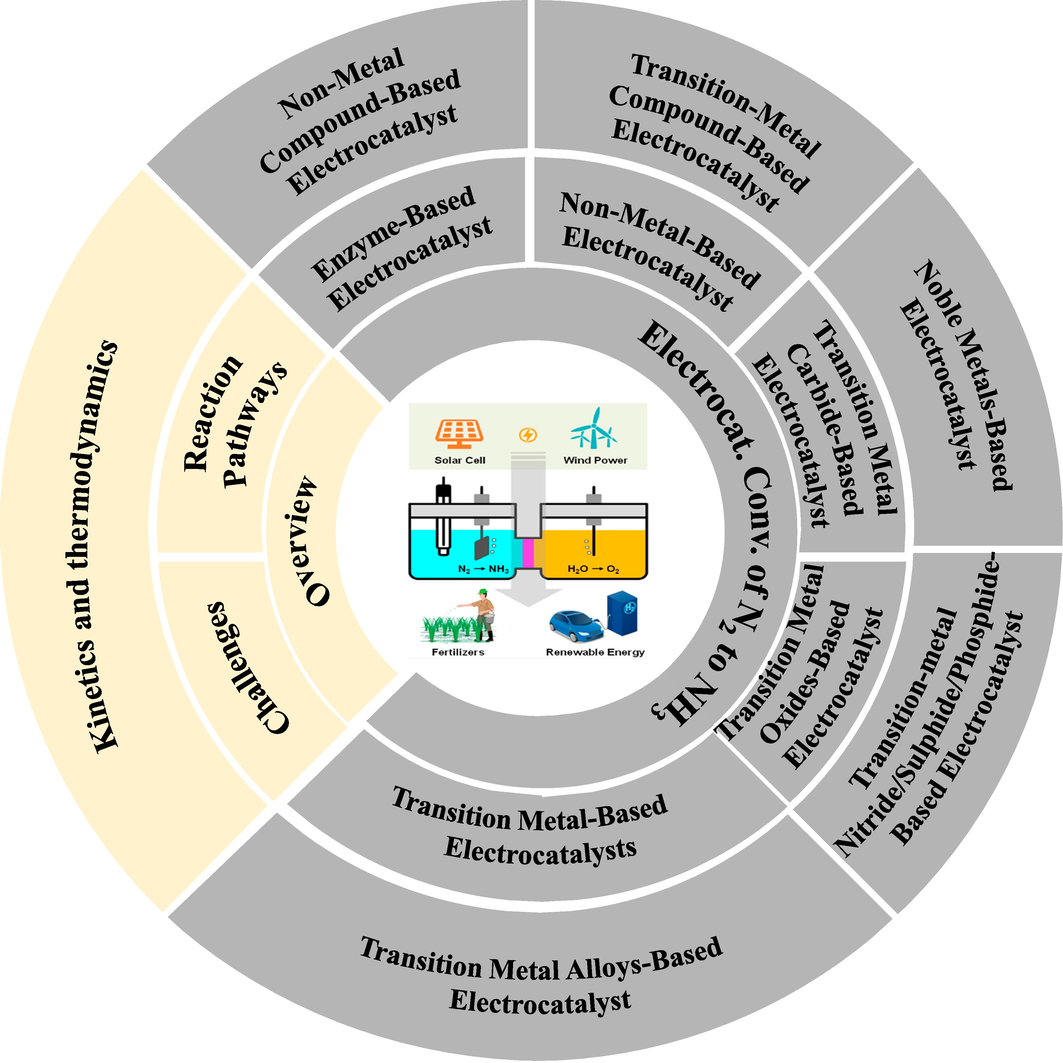

In this review, we examine the latest advancements in electrocatalyts used for ENRR, focusing on the production of ammonia (NH3) (Fig. 1). This review aims to offer insights into the latest advancements in this field while also providing essential foundational information. This review follows the following structure: In Section 2, the reaction pathway for the electrolytic reduction of nitrogen is briefly examined. This section delves into the electrolytic production of ammonia, covering topics related to reaction kinetics and thermodynamics. A discussion of the challenges of nitrogen reduction in selectivity and solutions to improve selectivity is suggested. Section 3 discusses the relationship between electrocatalyst performance and structure from a theoretical and experimental pint of view. It provides an overview of current developments in electrocatalysts NRR. Section 3 also provides an overview of non-metal compound-based electrocatalyst and their performance in NRR. Finally, the state of the field is summarized in Section 4, which also extends plans on existing concerns and future developments.

A Schematic diagram illustrating the recent advancements in electrocatalysts employed for the ENRR with a specific focus on ammonia (NH3) production is presented below.

2 Fundamental aspects of catalytic nitrogen reduction

2.1 Reaction pathways

Nitrogen is obtained from atmospheric N2 molecules in the electrochemical process for ammonia production in an aqueous electrolyte. Water electrolysis produces protons, which are subsequently transported to the surface of the electrocatalyst employing a voltage (Van der Ham et al., 2014). This technique usually uses a three-electrode setup consisting of two chambers divided by a membrane, especially for proton exchange. The cathode supports the reduction process known as NRR, which depends on the electrolyte's pH. At the same time, the anode promotes the oxidation process known as the oxygen evolution reaction (OER). The production of ammonia takes place through the generation of protons at the counter electrode under acidic conditions. These protons are subsequently transported across a proton exchange membrane to the cathode. Thus, Eqs. (4) and (5) explain the anodic and cathodic reactions, respectively.

Anodic reaction:

Cathodic reaction:

Under conditions that are either basic or alkaline, nitrogen molecules undergo direct combination with water and electrons at the cathode, resulting in the production of ammonia. This process is distinct from what occurs under acidic conditions (Hou et al., 2020). The working electrode generates hydroxyl (OH–) ions sent to the cathode via an anion exchange membrane. As depicted in the equations (6) to (8), these ions undergo oxidation at the cathode to yield oxygen (O2).

Anodic reaction:

Cathodic reaction:

The overall reaction:

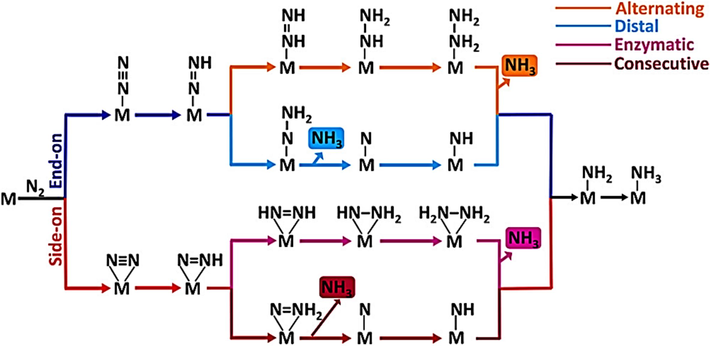

The process underlying the electrochemical conversion of N2 to NH3 is not completely understood owing to its complex character. Examining the reaction mechanisms associated with the ammonia synthesis process is essential, but comprehending the pathways is important for attaining electrochemical ammonia production. The formation process involves associative and dissociation mechanisms (Xu et al., 2020; Ma et al., 2021; He et al., 2024). The nitrogen reduction process's reaction pathways depend on the arrangements in which N2 molecules are adsorbed. During the nitrogen reduction reaction, alternating and distal channels allow for the end-on adsorption of nitrogen, as seen in Fig. 2.

The diagram illustrates the process of N2 reduction to NH3 using different pathways. Used by permission (Ma et al., 2019). Copyright 2019, American Chemical Society.

The electron acceptor–donor mechanism involving the vacant d-orbitals of transition metals and nitrogen's empty π* orbitals plays a crucial role in activating nitrogen molecules for the NRR (Zhang et al., 2021; Paul et al., 2023). Transition metals have vacant or partially filled d-orbitals that can participate in bonding interactions with other molecules. These d-orbitals can accept electrons from or donate electrons to reactant molecules, making them highly versatile catalysts. N2 molecules have a strong triple bond (N≡N), which makes them chemically inert under standard conditions. The π* (antibonding) orbitals of N2 are typically empty and play a key role in its activation. When N2 approaches the surface of a transition metal catalyst, it gets adsorbed onto the metal surface. This adsorption is the first step in the activation process. The N2 molecule aligns itself such that its π* orbitals are close to the metal’s d-orbitals. The transition metal can donate electrons from its d-orbitals into the empty π* orbitals of N2. This electron donation weakens the triple bond in N2, making it more reactive. Additionally, this procedure may include back-donation, in which electrons from the occupied π-bonding orbitals of N2 may be moved to the unoccupied d-orbitals of the metal. This creates a synergistic effect that further diminishes the strength of the N≡N bond. An electron transfer occurs, resulting in the creation of an activated N2 complex on the surface of the catalyst. This complex is characterized by a partially broken N≡N bond, making it more susceptible to subsequent chemical reactions. Once N2 is activated, it can undergo further reduction steps, adding additional electrons and protons to the system. These steps eventually lead to the formation of ammonia (NH3). The specific pathway can vary depending on the catalyst and reaction conditions, but the initial activation through electron transfer is a common and critical step.

Enzymatic and sequential pathways are involved in the nitrogen reduction reaction, which leads to side-on nitrogen adsorption (Ma et al., 2019). The HBp employs a dissociative pathway to reduce nitrogen into ammonia. Before undergoing hydrogenation, the triple bonds within the adsorbed N2 molecule are broken, leading to the presence of N atoms on the surface of the catalyst. These N atoms are then subjected to hydrogenation, resulting in the production of ammonia (Wang et al., 2019). This dissociative pathway prevents the electrochemical reduction of nitrogen to ammonia under normal circumstances since it requires a large amount of energy. The adsorbed nitrogen molecules with two nitrogen centers are protonated in an associative alternating pathway awaiting the final bond between N-N is dissociated. The process of N2 reduction to NH3 using different pathways are shown in Fig. 2 (Shipman and Symes, 2017). The initial ammoflow nia molecule is primarily formed by the dissociation of the last N-N bond, while the remaining ammonia molecules are generated through sequential proton addition. The first ammonia molecule is produced through consecutive hydrogenation reactions within the associative distal pathway, specifically targeting the N atoms farthest from the catalyst. Following this, the second ammonia molecule is created by gradually introducing protons onto the catalyst's surface, where they interact with the captured nitrogen atom. From a thermodynamic perspective, the electrochemical reduction of N2 to yield NH3 is notably favored through distal and alternate pathways involving associative mechanisms under ambient circumstances (Yang et al., 2020; Paul et al., 2023). First, ammonia molecules are formed by dissociating the last N-N bond, and the progressive addition of protons produces second and subsequent ammonia molecules. The first ammonia is produced in the associative distal pathway by a sequence of subsequent hydrogenation events directed at the N atoms farthest from the catalyst. Following this, the second ammonia molecule is produced by gradually introducing protons onto the catalyst's surface, where they interact with the trapped nitrogen atom. This process contributes to the overall synthesis of ammonia.

2.2 Reaction kinetics and thermodynamics

Nitrogen gas is frequently utilized to establish an inert atmosphere and serve as a carrier gas in reactive environments due to the remarkable stability of the nitrogen molecule. Despite a strong triple bond between nitrogen-nitrogen with a prominent dissociation energy of 941.0 kJ mol−1, this feature alone does not explain the inertness of nitrogen. Surprisingly, compounds such as carbon monoxide (CO, 1070.0 kJ mol−1) and acetylene (HCCH, 963.0 kJ mol−1) exhibit much greater reactivity with even higher triple bond dissociation energies than nitrogen. Several factors contribute to nitrogen's inertness. To begin with, the nitrogen molecule has a lower proton affinity than methane and no stable dipole (493.8 kJ mol−1). Its negative electron affinity is −1.9 eV, its ionization potential is 15.83 eV, and a notable energy gap of 10.82 eV between its lowest unoccupied and highest occupied molecular orbitals. When combined, these properties obstruct electron transfer reactions, which makes it difficult to activate nitrogen atoms even in extremely acidic settings, where quick protonation is not always possible (Van der Ham et al., 2014; Jia and Quadrelli, 2014). The process of hydrogenation of nitrogen to produce ammonia does not happen spontaneously (with a standard enthalpy change of formation of −92.22 kJ mol−1 and a standard Gibbs free energy change of formation of −16.48 kJ mol−1), but it is thermodynamically favored. The formation enthalpies of diazene (N2H2, ΔHf° = 212.90 kJ/mol for (Z)-diazene) and hydrazine (N2H4, ΔHf° = 95.34 kJ mol−1) exhibit very high values. Due to the extremely high energy of the predicted intermediates, producing ammonia via a homogenous (non-catalytic) method is currently impossible (Jia and Quadrelli, 2014).

Moreover, these intermediates are part of the reaction pathway but can divert the process from the desired ammonia production, reducing overall yield. Understanding and controlling the formation of these intermediates is crucial for optimizing the NRR. Ammonia conversion efficiency can be improved by: (i) Design heterogeneous catalysts that favor the formation of NH3 over other intermediates. Transition metals such as Fe and Mo have shown promise in selectively reducing N2 to NH3. By tuning the electronic properties of these catalysts, one can enhance selectivity (Adalder et al., 2023); (ii) Adding promoters such as alkali metals (e.g., K, Na) can improve the electron density at the active sites, promoting the selective reduction of N2 to NH3. Surface functionalization with specific groups can create an environment that stabilizes the desired intermediates leading to NH3, thereby suppressing the formation of N2H₄ (Wang et al., 2020); (iii) Fine-tuning the applied potential during electrochemical NRR can help in controlling the energy landscape of the reaction pathway, promoting NH3 production and suppressing other intermediates (Paul et al., 2023); (iv) Using in-situ techniques like in-situ X-ray absorption spectroscopy (XAS) and in-situ infrared spectroscopy (IR) to monitor the formation of intermediates can provide insights into the reaction mechanism. This allows real-time adjustments to reaction conditions to favor NH3 formation (Zaera, 2021), and (v). Using density functional theory (DFT) calculations to predict the most favorable reaction pathways and design catalysts that selectively reduce N2 to NH3 (Yao et al., 2020). Computational studies can help identify the binding energies of intermediates and guide experimental efforts. By implementing these strategies, we can enhance the efficiency of ammonia conversion in the NRR, suppress the formation of unwanted intermediates like hydrazine, and improve the overall yield of NH3 (He et al., 2022). These approaches provide a deeper understanding of the reaction mechanisms and pave the way for designing more effective catalysts and reaction systems for ammonia synthesis.

Heterogeneously catalyzed ammonia synthesis involves the formation of chemisorbed intermediate complexes, which offer an alternate pathway for the reaction with much-reduced energy barriers that can be surmounted by thermal energy. Six protons and six electrons must be transferred to convert nitrogen into ammonia through a multi-step electrochemical process similar to the catalytic reduction of nitrogen. It is important to note that under acidic and alkaline circumstances, the equilibrium potentials of the half-reactions leading to nitrogen reduction and hydrogen evolution are different (Deng et al., 2018; Cui et al., 2018). The electrode's suitable negative potential should accelerate the N2 reduction process at both atmospheric pressure and room temperature. The equilibrium potentials for reactions (9)–(12), which produce hydrogen, are like those for processes which reduce N2. Conversely, in a solitary half-reaction, the H2 evolution mechanism necessitates only two electrons to produce one hydrogen. In contrast, the E° for the 6-electron reduction of nitrogen to ammonia is determined by averaging the values across multiple individual steps.

Reactions (13)–(15) offer the thermodynamic parameters (E° values) for further two-electron reductions from N2 to NH3. Unless explicitly mentioned otherwise, these E° values are determined through calculations based on empirically derived ΔGf° (298K). It's crucial to remember that other values have been published in study articles and investigations since the source and that the origin of some E° figures may not be clear. When possible, references to ΔGf° (298.0K) values mitigate potential misinterpretation. In most cases, the ΔGf° (298.0K) values utilized in calculating E°, unless specified otherwise, have been sourced from the National Bureau of Standardization database (Wagman et al., 1982).

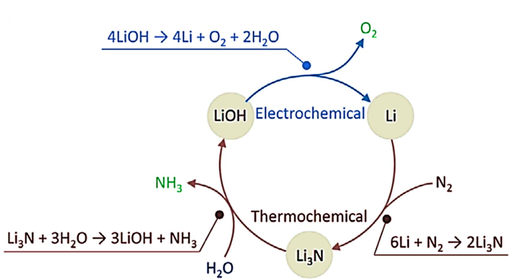

To overcome the difficulty of activating the inert molecule, the hybrid electrochemical loop (HETL) approach combines the electrochemical step with the thermochemical step to convert N2 to NH3 and CO2 to C (Singh and Rohr, 2017; Luc et al., 2018). Lithium (Li) is the sole metal capable of reacting with nitrogen gas (N2) under normal room circumstances. This unique property positions Li as a promising option for selectively activating N2. McEnaney et al. have just published a study on a lithium-mediated high-entropy transition metal nitride method for the synthesis of ammonia. The procedure commenced by employing an electrochemical technique to generate lithium metal from lithium hydroxide (LiOH) within an electrochemical cell utilizing molten salt at a reaction temperature ranging from 600 to 700 K (McEnaney et al., 2017). The cycle was completed when the resultant metallic Li interacted with N2 to create lithium nitride (Li3N), which was then exposed to water to create NH3. (Fig. 3) (Siddiqui and Dincer, 2018; Jiao and Xu, 2019).

Schematic diagram of ammonia synthesis via electrochemical and thermochemical looping method.

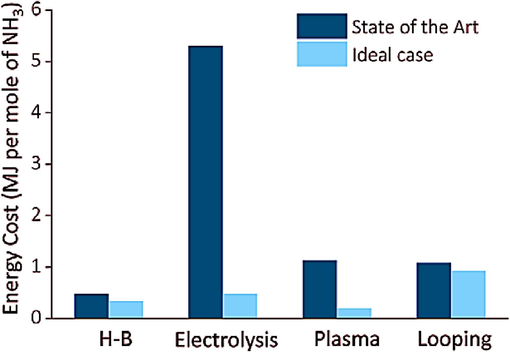

Given that quantifiable yields were obtained at all thermochemical stages, the NH3 process had a FE of 88.5%, much greater than that of the SOA-N2 electrolysis process (FE, 10%). Furthermore, the LiOH electrolysis approach demonstrated an impressive current density surpassing 500 mA cm−2. This value exceeds the current density achieved through the state-of-the-art SOA-N2 electrolysis method by two orders of magnitude. Nevertheless, the conversion of Li+ to metallic Li through electrical reduction necessitates a cell potential exceeding −3.1V. Consequently, the overall energy expenditure for ammonia production using the HETL method amounts to 1.08 MJ mol−1 NH3. Li-mediated looping costs 0.93 MJ mol−1 NH3 under ideal conditions, suggesting limited potential for enhancement (Jiao and Xu, 2019). Fig. 4 illustrates a comparative analysis of the energy expenditure associated with several techniques of ammonia production.

A comparison of the energy cost for the NH3 synthesis through the Haber–Bosch process (H-B), Electrolysis, Plasma, and Looping methods (McEnaney et al., 2017; Mehta et al., 2018).

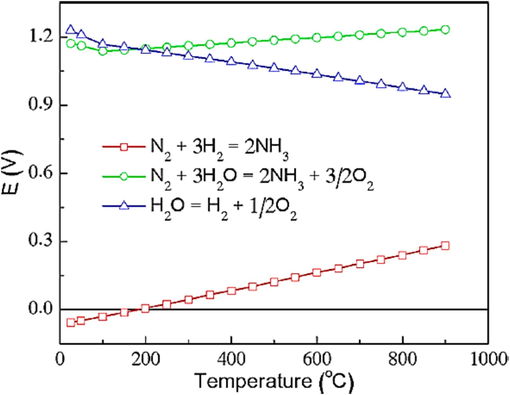

The thermodynamic method has also established an energetic relationship known as the “scale relationship” among the mediates in catalytic interactions encompassing multiple intermediate steps (Koper, 2013). When examining oxygen evolution and reduction reactions, it becomes evident that the adsorption energies of the intermediates OH and UN consistently exhibit a 3.2 ± 0.2 eV variance. This discrepancy exceeds the 2.46 eV difference typically observed in an ideal catalyst. This energy difference can be attributed to the fact that both intermediates share an identical coordination on the catalyst surfaces. Therefore, oxygen evolution and reduction reactions need a minimum overvoltage of 0.25 to 0.35 V (Koper, 2013; Man et al., 2011). The binding energies of NH2 and N2H are interdependent in the N2 reduction reaction, leading to an unfavorable energy scaling between these reaction intermediates. This unfavorable scaling leads to a minimum overvoltage of 0.4 V (Van der Ham et al., 2014). It is necessary to overcome scale relationships to create better electrocatalysts. One potential avenue involves discovering reaction pathways that do not necessitate the participation of one of the intermediates. Alternatively, an alternative approach is to design catalysts capable of binding the two intermediates in distinct and unique ways (Brown et al., 2014; Koper, 2013). The performing temperature of the electrochemical cell significantly influences the thermodynamics of N2 reduction. Illustrated in Fig. 5 are the thermodynamic voltages essential for electrolysis of ammonia production and water splitting, spanning a temperature range from 25 to 900 °C. In this temperature range, negative values signify that synthesizing ammonia from N2 and H2 (illustrated by red squares) occurs spontaneously based on thermodynamic principles, particularly at a pressure of 0.1 MPa. Conversely, the two half-reactions essential to produce ammonia from N2 and H2O (depicted by green circles) are non-spontaneous, necessitating an external energy source to drive them. For instance, at a temperature of 25 °C, a minimum voltage of 1.17 V is involved to facilitate these reactions. At temperatures below approximately 175 °C, a somewhat lower minimum voltage is necessary for water splitting, as indicated by the blue triangles (Qing et al., 2020).

The graph illustrates the thermodynamic electrolysis energies for various processes, including water splitting (indicated by blue triangles), ammonia construction from N2 and H2O (denoted by red squares), and the reactions involving N2 and H2O (represented by green circles) (Qing et al., 2020). Copyright 2020 American Chemical Society.

2.3 Challenges for electrocatalytic nitrogen reduction to ammonia

Significant advancements have recently been yielded in the electrochemical production of ammonia in aqueous solutions under standard conditions. Nevertheless, the inadequate rates of ammonia generation and the low Faraday efficiency significantly restrict its practical utility (Kibsgaard et al., 2019; Suryanto et al., 2019). The leading constraints of the catalytic electrochemical performance are: (i) Due to the little overpotential, the FE is impeded by a major side reaction known as hydrogen evolution reaction (HER) (Montoya et al., 2015). (ii) In the process of N2 conversion, the N2 molecule experiences chemical adsorption onto the active site of the catalyst. Subsequently, the catalyst provides electrons to initiate the activation process (Kuang et al., 2020). With the elevated dissociation energy (941 kJ/mol) and a little proton attraction of N2 molecules owning to triple bonds, it is hard for nitrogen molecules to adsorb on the catalyst’s active site and activate, resulting in low electrochemical performance of the catalyst for ammonia production (Chen et al., 2023). (iii) The constrained solubility and suboptimal mass transport of nitrogen in aqueous electrolytes significantly impact the electrocatalytic efficiency of the catalyst. To attain a heightened rate of ammonia synthesis, improving nitrogen transfer can be achieved by enhancing nitrogen's solubility in the electrolyte and increasing the catalyst's surface area. (iv) The primary parameter for evaluating the electrocatalyst's performance in ammonia production is the measurement of the quantity of ammonia generated. Various techniques are employed for including ion-selective electrode detection, ammonia detection, ion chromatography, isotope detection and spectrophotometry (Cui et al., 2018). (v) The amplification process from lab-scale H-type cells to industrial-scale flow cells significantly impacts catalyst requirements. Industrial-scale NRR processes demand catalysts with enhanced durability, scalability, and efficiency, capable of operating under continuous flow conditions. Developing such catalysts requires a comprehensive understanding of material properties, reaction mechanisms, and reactor design. Addressing these challenges through innovative research and development is crucial for advancing sustainable and efficient nitrogen reduction technologies at an industrial level.

Spectrophotometry primarily relies on using Nessler’s reagent and the indophenol blue techniques. These approaches are widely favored for ammonia detection owing to their cost-effectiveness and remarkable sensitivity. The indophenol blue method stands out because it provides low detection limits (10 × 10−6 mol L−1), excellent color representation, and outstanding reproducibility. On the other hand, the Nessler reagent method offers advantages in minimizing reagent consumption and efficiently utilizing time. However, its color reagent, mercury, does not effectively safeguard the environment. Nevertheless, the presence of metal ions in the solution can result in imprecise results. A control experiment has been proposed to remove any potential sources of interference (Tang and Qiao, 2019). The ion-selective electrode method is a rapid and straightforward technique capable of detecting a broad spectrum of concentrations, ranging from 0.01 to 17,000 ppm. Maintaining precise control over the temperature and stirring velocity is crucial throughout the experimental procedure. Conversely, ion chromatography is renowned for its exceptional accuracy, reproducibility, and strikingly low 3 × 10−7 mol L−1 detection limit. The electrolytes that include Na+ and Li+ are not appropriate for this function because of their short retention times, and organic electrolytes are also not useful (Cui et al., 2018). Furthermore, experiments with the 15N2 isotope are also necessary to determine the ammonia's source, namely the nitrogen-containing catalyst responsible for the nitrogen reduction reaction. Using at least two different detection techniques to accurately identify the quantity of goods is advisable since this will provide more compelling results (Hao et al., 2019).

3 Electrocatalytic conversion of nitrogen into ammonia

In response to the persistent need for high-efficiency electrochemical energy conversion and storage devices, many catalysts have been extensively investigated to evaluate their suitability as economical and effective electrode materials for various electrochemical reactions. Catalytic performance is profoundly affected by factors like crystallinity, shape, particle size, and the abundance of surface-active sites, widely recognized as pivotal considerations in this sphere. The discovery of new electrocatalysts via a mix of theoretical understanding and experimental innovation has been crucial to the progress in the electrochemical reduction of N2 to NH3 (Ghorai et al., 2021). These electrocatalysts have played a vital role in enabling these substantial achievements. Most of the experimental research has been on developing catalysts composed of noble metals, transition metals, and non-metals to address the kinetic limitations of the nitrogen reduction reaction and enhance selectivity under normal circumstances. Recently, various attempts have been made to obtain varying ammonia production rates and FE values, ranging from less than one percent to several tens of percent, employing an electrocatalyst under normal conditions (Table 1). This section examines the correlation between the performance and structure of electrocatalysts, considering both theoretical and experimental perspectives. This article comprehensively summarises the latest electrocatalyst advancements used for nitrogen reduction processes. The ammonia formation from NO3– and NO2– can be given by the reactions (16)–(18):

Electrocatalyst

Ammonia production rate (mol·s−1 cm−2/µg mg–1cat. h−1/Sμg/h cm−2)

Faradaic Efficiency (FE)

Electrolyte

Ref.

TiO2/Ti

9.16 × 10−11

2.50 %

0.1 M Na2SO4

(Zhang et al., 2018)

MoS2/CC

8.08 × 10−11

1.17 %

0.1 M Na2SO4

(Zhang et al., 2018)

MoO3 nanosheet

4.80 × 10−10

1.9 %

0.1 M HCl

(Han et al., 2018a)

Mo nanofilm

3.09 × 10−11

0.72 %

0.01 M H2SO4

(Yang et al., 2017)

Ru/C

3.43 × 10−12

0.28 %

0.1 M HCl

(Kordali et al., 2000)

PEBCD/C

2.58 × 10−11

2.85 %

0.5 M Li2SO4

(Chen et al., 2017)

Fe2O3-CNT

3.58 × 10−12

0.15 %

KHCO3

(Chen et al., 2017)

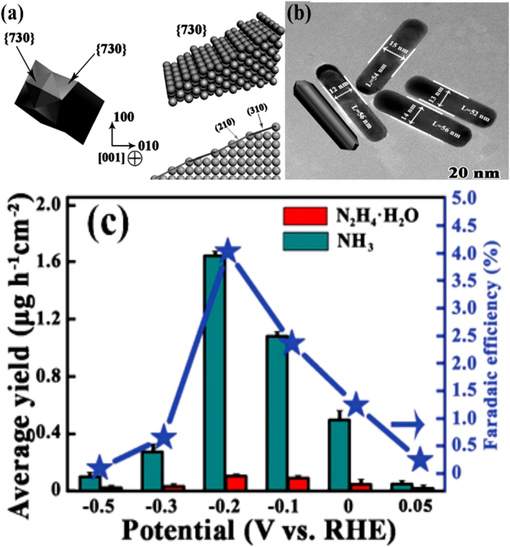

Au nanorod

2.69 × 10−12

4 %

0.1 M KOH

(Bao et al., 2017)

CP2TiCl2

9.50 × 10−10

0.23 %

H2O

(Jeong et al., 2017)

MnO/TM

1.11 × 10–10

8.02 %

0.1 M Na2SO4

(Wang et al., 2019)

Mo nanofilm

3.09 × 10–11

0.72 %

0.01 M H2SO4

(Yang et al., 2017)

Mo2N

4.60 × 10−10

4.5 %

0.1 M HCl

(Ren et al., 2018)

VN/TM

8.40 × 10–11

2.25 %

0.1 M HCl

(Suryanto et al., 2018)

Ag nanosheet

4.62 × 10−11

4.8 %

0.1 M HCl

(Huang et al., 2018)

γ-Fe2O3

0.212

1.9 %

0.1 M KOH

(Kong et al., 2017)

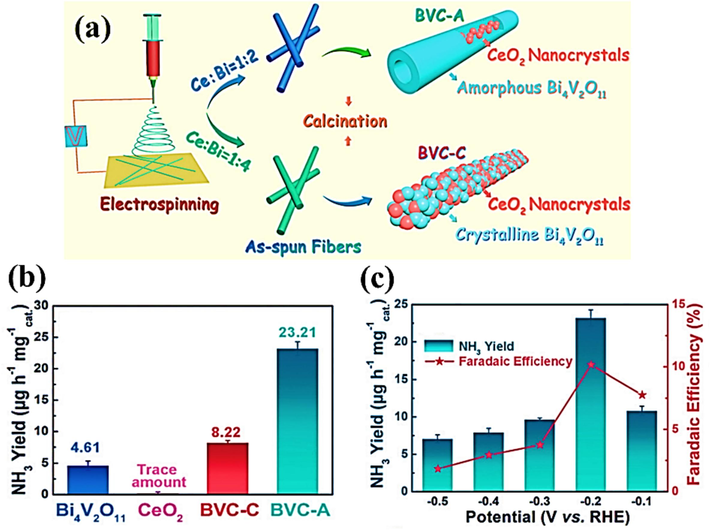

Bi4V2O11/CeO2

23.21

10.16 %

0.1 M HCl

(Lv et al., 2018)

N-doped porous carbon

23.8

1.4 %

0.05 M H2SO4

(Liu et al., 2018)

Au nanorods

1.648

3.88 %

0.1 M KOH

(Bao et al., 2017)

B4C

26.57

15.95 %

0.1 M HCl

(Qiu et al., 2018)

Nb2O5 nanofiber

43.6

9.26 %

0.1 M HCl

(Han et al., 2018b)

Hollow Cr2O3 microspheres

25.3

6.78 %

0.1 M Na2SO4

(Zhang et al., 2018)

TiO2-rGO

15.13

3.3 %

0.1 M Na2SO4

(Zhang et al., 2018)

Fe2O3 nanorods

15.9

0.94 %

0.1 M Na2SO4

(Xiang et al., 2018)

Defect-rich MoS2 nanoflower

29.28

8.34 %

0.1 M Na2SO4

(Li et al., 2018)

Cr2O3/CPE

28.13

8.56 %

0.1 M HCl

(Du et al., 2018)

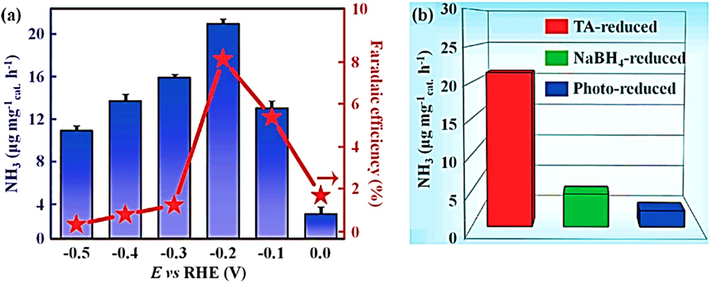

TA-reduced Au/TiO2

21.40

8.11 %

0.1 M HCl

(Shi et al., 2017)

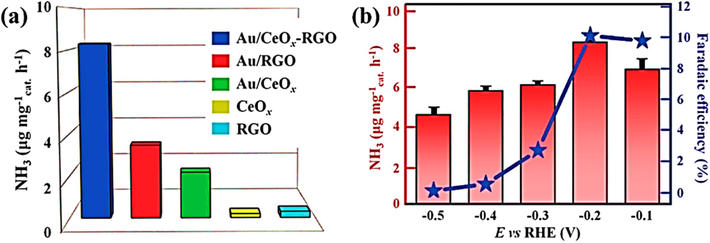

α-Au/CeOx-RGO

8.31

10.1 %

0.1 M HCl

(Li et al., 2017)

Au flowers

25.57

6.05 %

0.1 M HCl

(Wang et al., 2018)

β-FeOOH nanorods

23.32

6.7 %

0.5 M LiClO4

(Zhu et al., 2018)

AuHNCs

3.90

30.2 %

0.5 M LiClO4

(Nazemi et al., 2018)

Ag-Au@ZIF

0.61

18 %

THF-based

(Lee et al., 2018)

Ru/Ti

7.34

−

0.5 M H2SO4

(Kugler et al., 2015)

MoN

0.06

1.15 %

0.1 M HCl

(Zhang et al., 2018)

Fe3O4/Ti

0.012

2.6 %

0.1 M Na2SO4

(Liu et al., 2018)

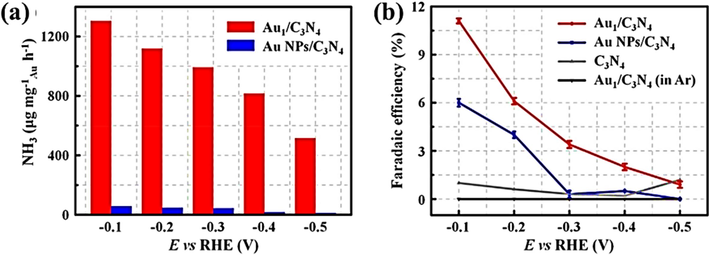

3.1 Transition metal-based electrocatalysts

Transition metals are the predominant nanoparticles, exhibiting either crystalline or amorphous structures, characterized by their extremely small dimensions, large surface area, and numerous active edge sites. Transition metals are predominantly utilized in catalysis due to the relative simplicity of synthetic methods involved in their production, resulting in the majority of nanomaterials employed in this field. Both theoretical and practical investigations have demonstrated that the utilization of transition metal catalysts enhances the performance of nitrogen reduction reactions. It is important to emphasize that the performance of these transition metal catalysts is significantly elevated in both alkaline and acidic environments (Geng et al., 2018; Liu et al., 2018; Han et al., 2019). Sclafani et al. used an iron cathode and a stainless-steel anode to study the electrochemical synthesis of ammonia in a 6 M aqueous KOH solution. The experiment continued until an equilibrium state was achieved, as confirmed by the absence of ammonia in the liquid, indicating a stable rate of NH3 formation. Remarkably, they attained an impressive ammonia generation rate of 5.3 × 10−14 mol s−1 cm−2 at a voltage of −1.06 V, with a Faraday efficiency of approximately 1%. The cathode voltage, relative to the saturated calomel electrode (SCE), ranged from −0.92 to −1.21 V. The rate of ammonia synthesis experienced a decline when the cathodic potential intersected with the hydrogen evolution region, attributable to the competition between the two processes. In a subsequent experiment by Grayer et al., a Faraday efficiency of up to 5.4% was discovered (Grayer and Halmann, 1984). Most of the ammonia, according to the scientists, was created by the electrolyte's elimination of N2-containing contaminants.

In their experiment, Geng et al. utilized Ru SAs/N-C, which refers to single Ru atoms scattered on nitrogen-doped carbon, demonstrating excellent Faraday efficiency for N2 electroreduction (Geng et al., 2018). Tao et al. (2019) used a monatomic Ru catalyst and nitrogen-doped porous carbon to achieve outcomes comparable to Geng et al. (2018). The first instance of catalysts with a single Fe site was presented by Lü et al. (2019). The hydrothermal technique was used to create frameworks composed of bimetallic Fe/Zn zeolite. After carbonization and etching processes, the framework was converted into individual iron sites connected to nitrogen-doped carbon frameworks. These specific iron sites are denoted as ISAS-Fe/NC. The distribution of Fe, N, and C elements was mapped using EDX spectroscopy to analyze their composition. The results illustrated a uniform dispersion of iron (Fe) and nitrogen (N) elements within the framework. The atomic arrangement of the Fe sites was elucidated via XANES. During the NRR testing, a notably high Faraday efficiency of 18.6 ± 0.8% was achieved, employing a 0.1 M phosphorus-saline buffer solution (PBS). This solution is pondered as a more ecologically sustainable choice compared to acidic or alkaline alternatives. The rate of ammonia production was 62.9 g per hour per square centimeter. Single-atom catalysts provide the highest recorded Faraday efficiency and ammonia-generating rate for Fe, while also demonstrating good selectivity for NRR.

In their study, Cai et al. (Cai et al., 2022) examined the electrocatalytic performance of noble metal catalysts for the reduction of N2 in aqueous solutions under normal circumstances. The study employed commercially available catalysts, including nanoparticles of noble metals (Pt, Pd, Rh, Au) that were uniformly dispersed on carbon support. The particle sizes varied between 1.5 and 7 nm. The assessments were conducted in an H-type cell utilizing 0.1 M HCl as the electrolyte. The obtained outcomes were then compared to a lithium-mediated approach in nonaqueous electrolytes. Surprisingly, the noble metal catalysts showed little to no ammonia production despite their known catalytic properties. This discrepancy was attributed to the presence of nitrogen-containing contaminants in the catalysts. To obtain reliable results, the study demonstrated the importance of removing these contaminants by consecutive cyclic voltammetry (CV) scans. In contrast, the lithium-mediated system produced significant ammonia, highlighting its effectiveness for nitrogen reduction.

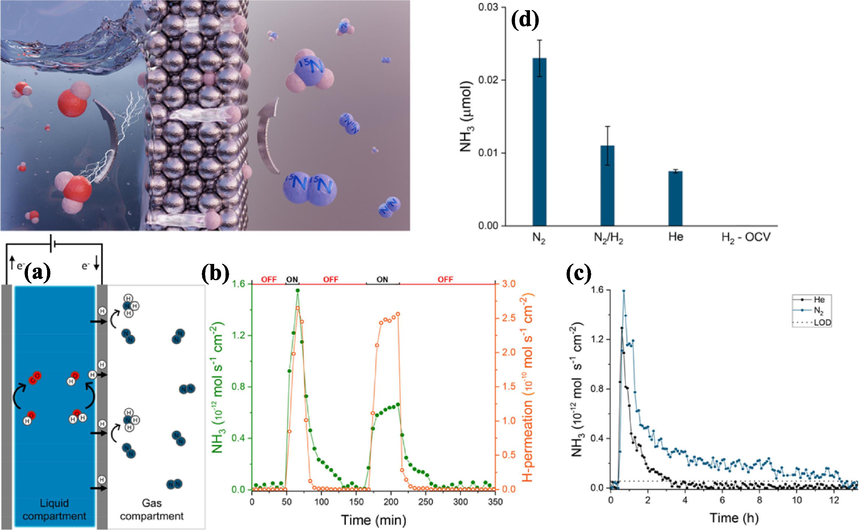

In a groundbreaking approach to electrochemical ammonia synthesis, Davide et el. (Ripepi et al., 2021) have introduced an innovative catalyst design that separates the activation of hydrogen and nitrogen, facilitating the production of ammonia at ambient conditions (Fig. 6). This unconventional electrochemical setup utilizes a dense metallic hydrogen-permeable electrode, primarily composed of nickel. This electrode is a pivotal component in this system, allowing for the independent activation of hydrogen and nitrogen. In the proposed system, a two-compartment setup is created, with the hydrogen activation occurring on one side (in contact with the electrolyte) and the nitrogen activation on the opposite side (in contact with gaseous nitrogen). The electrolyte facilitates the electrochemical water oxidation and reduction reactions, driving the production of atomic hydrogen within the electrode lattice. This atomic hydrogen is then allowed to permeate through the nickel electrode, ensuring its controlled access to the nitrogen activation sites while blocking the ingress of unwanted species like oxygen and water. The process of adsorbed N2 interacting with diffusing atomic hydrogen produces ammonia. The critical insight is that atomic hydrogen effectively circumvents the need for available active sites on the catalyst surface for hydrogen and nitrogen dissociation, overcoming a major challenge in ammonia synthesis. Additionally, this setup offers the advantage of directly producing ammonia in the gas phase, making product separation easier and preventing ammonia from diffusing back to the anode surface. In addition, the researchers discovered that active N2 on the nickel surface obstructs the process of activating gaseous hydrogen. This emphasizes the advantages of utilizing permeating atomic hydrogen for nitrogen hydrogenation.

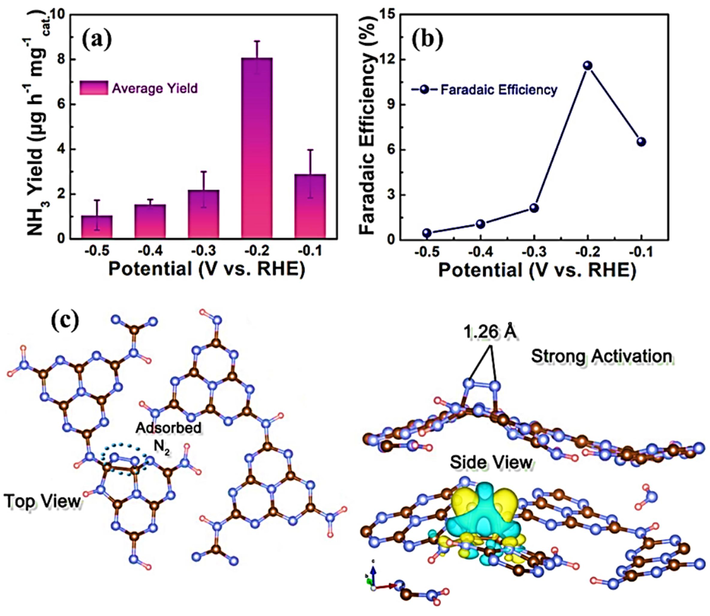

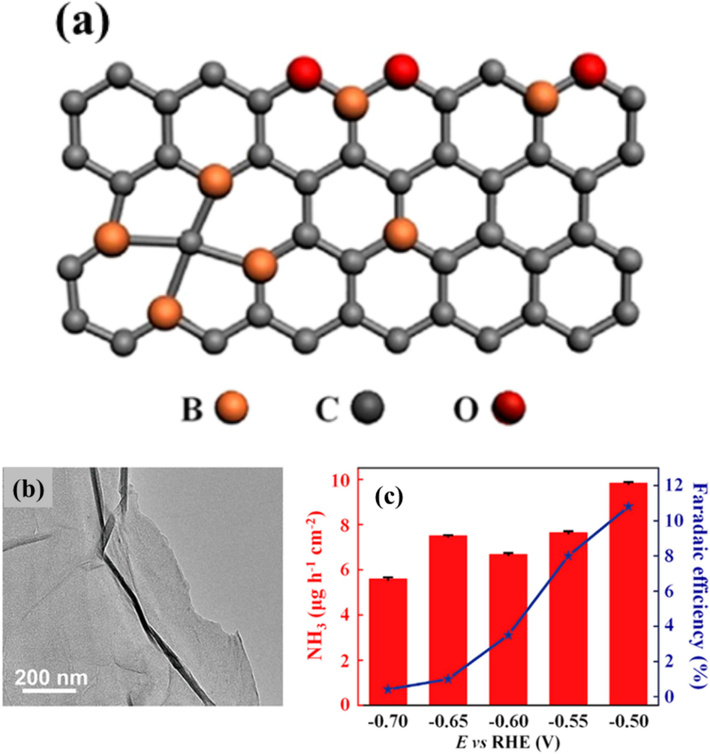

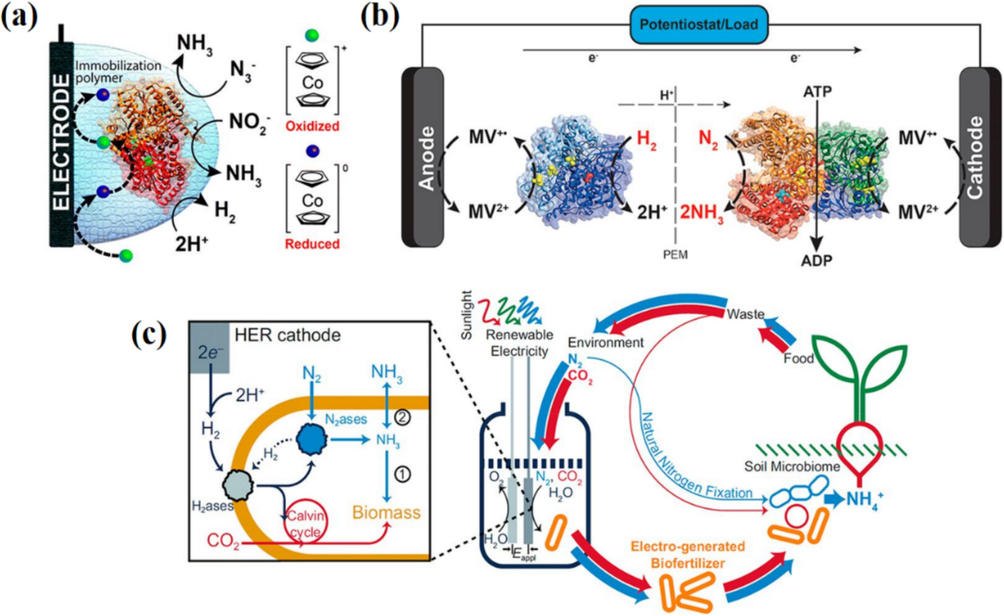

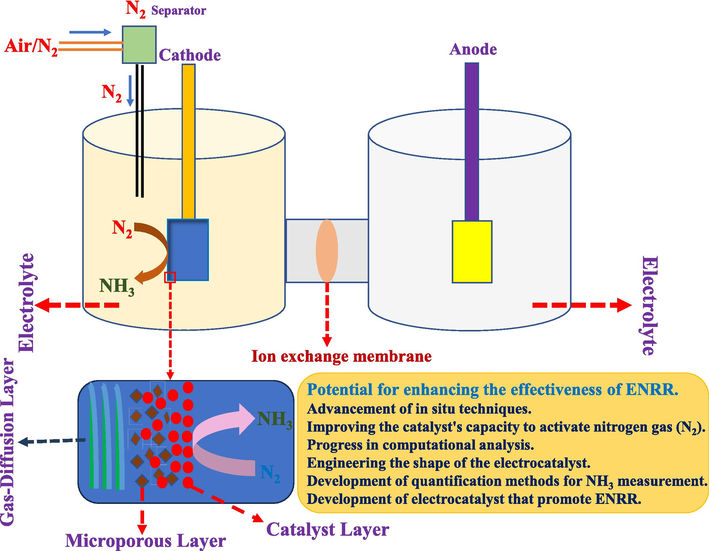

The diagram provides a conceptual representation of the proposed setup for direct ammonia production through electrochemically generated and permeating atomic hydrogen. Within this configuration, a slender and compact metallic cathode is employed to facilitate the passage of atomic hydrogen. This system comprises two distinct active interfaces: one interacts with the electrolyte to enable hydrogen electrochemical activation (situated on the liquid compartment side), while the other interfaces with the gas compartment to initiate dinitrogen activation and hydrogenation processes. The direct interaction of adsorbed nitrogen with the atomic hydrogen that seeps through it produces ammonia within the gas compartment. Using a 0.0125 mm thick Ni-electrode, the rate of ammonia synthesis (solid green symbols) and the electrochemical penetration of hydrogen (open orange symbols) are tracked over time in the accompanying graph (b). When switching from open circuit circumstances (OFF) to cathodic charging, data is gathered (ON). The release of atomic hydrogen from the gas compartment and the interaction of hydrogen with nitrogen to generate NH3 are the two processes that lead to hydrogen gas (H2). The long-term rate of ammonia generation in N2 (blue) and He atmospheres is investigated in panel (c) (black). An increased rate of synthesis and an extended duration of ammonia (NH3) production up to nine hours are seen in the nitrogen gas (N2) environment. The point at which detection becomes feasible is known as the limit of detection (LOD) threshold, and the black dotted line shows it. Lastly, after 12 h of electrochemical hydrogen permeation under normal circumstances, panel (d) compares the amount of ammonia generated in the nitrogen (N2), helium (He), and combination of nitrogen and hydrogen (N2:H2, 96:4%) atmospheres. Compared to He, the quantity of NH3 is around three times more when N2 is present. Notably, ammonia did not show up when pure H2 was utilized in the absence of electrochemical hydrogen permeation. The figures' error bars show the standard deviation computed from three or more measurements using recently taken samples (Ripepi et al., 2021). Copyright 2021 American Chemical Society.

The Co−Mo−CNF catalyst, featuring molybdenum and cobalt within a carbon nanofiber matrix, has been meticulously designed to amplify NRR selectivity towards NH3. Cobalt, known for its exceptional water dissociation capabilities, augments the local proton supply around molybdenum, a critical site for NRR hydrogenation. This groundbreaking catalyst demonstrates remarkable ammonia (NH3) production, attaining a 72.72 μg h−1 mg−1 rate and an exceptional Faraday efficiency of 34.5% at a voltage of −0.5 V vs. RHE (Chung et al., 2022). An innovative approach emerges by creating hybrid Cu2O-CeO2-C nanorods on a copper mesh scaffold, achieved using a metal–organic framework template technique. This breakthrough converts a copper-loaded cerium-based metal–organic framework (Ce-MOF) into heterojunctions consisting of copper oxide (Cu2O) and cerium oxide (CeO2), which contain interfacial structures of copper-oxygen-cerium (Cu-[O-X]-Ce). These structures are embedded inside a carbon matrix. Theoretical analysis emphasizes the reduced establishment energy of oxygen vacancies within Cu-[O-X]-Ce complexes, in contrast to standalone Cu2O or CeO2 phases, indicating their advantageous characteristics. The existence of oxygen-deficient Cu-[O-X]-Ce structures promotes the creation of Cu(I) species abundant in electrons at their interfaces, significantly enhancing the electrocatalytic N2 conversion. This pioneering catalyst showcases an impressive NH3 generation rate of 6.37 × 10−3 µg per second per square centimeter and a commendable FE of 18.21% at −0.3 V compared to the reversible H2 electrode. The significance of charge distribution manipulation in Cu-based electrocatalysts for enhancing nitrogen reduction activity is emphasized by this study (Jing et al., 2022).

The performance of a novel electrocatalyst designed for nitrogen reduction, comprising a vanadium single-atom dimer (V-O-V) on N-doped carbon (O-V2-NC), is exceptionally remarkable. The oxygen-spanned metal atom dimer acts as the electron-deficient active center for N2 reduction in this catalyst, which has a vanadium dimer coordinated with N2 and bridged by oxygen. Theoretical simulations unveil a dynamic structural transformation process during the reaction, with the V-O-V core undergoing protonation, resulting in a temporary disintegration into V-O and V species. However, it subsequently reassembles into its original configuration upon the complete release of all nitrogen species. The O-V2-NC structure exhibits outstanding electrochemical NRR performance, characterized by a notable Faraday efficiency of 77% and a yield of 9.97 µg mgcat.−1 h−1 at 0 V (versus the reversible hydrogen electrode, RHE). Additionally, it demonstrates substantial ammonia production, generating 26 µg mgcat.−1 h−1 with a 4.6% Faraday efficiency at −0.4 V (versus RHE) (Wang et al., 2023). The research centers on creating Ag-doped Cu nanosheets supported on carbon paper, denoted as Ag-Cu-NS/CP, as highly effective electrocatalysts designed for NRR. The presence of Ag causes the creation of Cu sites that lack electrons in the Ag-Cu-NS/CP system. The altered copper sites effectively inhibit the HER and enhance the adsorption of N2 in neutral conditions, resulting in a substantial improvement in NRR activity. When operated at −0.4 V relative to the reversible H2 electrode, the Ag-Cu-NS/CP catalyst demonstrates an impressive Faraday efficiency of 20.9% and an NH3 generation rate of 61.5 µg mgcat.−1 h−1 within a 0.1 M Na2SO4 electrolyte. This research introduces a straightforward yet highly effective method for producing potent and selective electrocatalysts tailored for NRR (Qu et al., 2022).

The researchers Xue et al. have presented a single-atom catalyst (SAC) called Mo@C9N4, which consists of a single Mo atom attached to the C9N4 substrate. This catalyst demonstrates remarkable efficiency in the conversion of N2 into NH3. The Mo@C9N4 structure has proven to be highly effective in catalyzing the activation and reduction of gaseous N2 to NH3 on its surface, as revealed through density functional theory (DFT) simulations. The NRR predominantly occurs at the Mo center, following a favored distal pathway with a limiting potential of 0.40 V, which is advantageous. Significantly, the Mo@C9N4 catalyst demonstrates remarkable structural durability and a notable preference for NRR (Xue et al., 2021). Interlayer strain compression within bismuth (Bi) nanocrystals has emerged as a pivotal aspect for enhancing the selectivity and activity in NH3 electrosynthesis via NO3– reduction. The lattice compression leads to shorter Bi-Bi bonds, which in turn broadens the 6p electron bandwidth, resulting in improved electron delocalization. This has been confirmed through extensive spectroscopic studies and theoretical calculations. As a result, it increases the chemical attractions of nitrogen compounds in between, making it easier to activate NO3– and lowering the energy needed for better performance. Furthermore, it reduces the release of *NO2, inhibiting nitrite production. The Bi electrocatalyst, when subjected to strain-compressive conditions, demonstrates an outstanding FE of 90.6% and a substantial NH3 production rate of 46.5 g gcat.−1 h−1, even at current densities as elevated as 300 mA cm−2, which can be easily implemented on an industrial scale. This innovation shows significant potential for the effective and specific synthesis of NH3 (Zhang et al., 2022).

A highly dispersed amorphous Cu catalyst demonstrated exceptional working in nitrate-reduction to ammonia, achieving an impressive ammonia yield rate of 1.42 mol gcat.−1h−1 and an extraordinary FE of 95.7%. This exceeds the capabilities of Cu catalysts that have undergone crystallization. The effectiveness of amorphous Cu can be ascribed to its higher quantity of catalytic sites, enhanced strength of NO3– adsorption with flat adsorption topologies, and greater facilitation of the potential deciding step of *NO protonation to *NHO. Significantly, the shapeless Cu catalyst has strong electrochemical durability at −0.3 V, while crystalline competitors show reduced effectiveness at more negative potentials (Shen et al., 2023). The electrocatalytic capability for ammonia production experiences a substantial boost thanks to a distinctive Ni foam catalyst crafted using an active H2 bubble template-supported electrodeposition method. The distinctive structure of the catalyst's foam enhances its efficiency. This process achieves an outstanding Faraday efficiency of over 95% for ammonia synthesis while operating within a low potential range of −0.1 to −0.3 V versus RHE. The only by-product of nitrate reduction is hydrogen. Remarkably, electrolysis only converts nitrate to ammonia without producing other nitrogen-containing compounds, such as NO, N2O, or N−2, demonstrating a 100% selectivity (Liu and Wang, 2022).

3.2 Transition metal alloys-based electrocatalyst

There has been a growing interest in the use of renewable electrical energy for the ambient electrochemical reduction of N2 to NH3. Because it uses less energy and has a greater energy conversion efficiency than current techniques, this environmentally friendly electrochemical N2 reduction process has a lot of promise as an ammonia manufacturing alternative (Lv et al., 2018; Cui et al., 2017). To facilitate electrochemical nitrogen reduction, there is an ongoing demand for active metallic catalysts that exhibit both exceptional activity and selectivity in ammonia production. The alloying of numerous transition metals produces synergistic effects that make it possible to create bimetallic nanostructures with much higher electrocatalytic activity than monometallic ones. Moreover, the incorporation of transition metals into alloys might reduce the utilization of precious metals. Transition metal alloys are advantageous in numerous applications due to their exceptional catalytic activity and cost-effectiveness. Xiang et al. (2018) produced a Pd0.2Cu0.8/RGO bimetallic catalyst by combining tannic acids, Cu, Pd, and graphene oxide precursors reduced using NaBH4. The Pd0.2Cu0.8/RGO catalyst exhibited an exceptional NH3 production rate of 2.80 g mgcat.−1 h−1. The Faraday efficiency is exceptionally high, reaching 4.6% when measured at 0.0 V compared to the RHE. A Faraday efficiency of 0.6% was observed in a nitrogen-saturated solution of 0.1 M aqueous KOH. Wang et al. synthesized Pd-Ru alloy catalysts featuring tripod and nanorod architectures. The tripod made of a RuPd alloy demonstrated a FE of 1.85% and a rate of ammonia generation of 37.23 g mgcat.−1 h−1 (1.94 × 10−10 mol s−1 cm−2) (Wang et al., 2019; Wang et al., 2019). Compared to Pd-Ru nano dendrites or pure Pd nanoparticles, a higher yield of ammonia was observed over the RuPd alloy tripod with higher structural stability. The formation of Pd-Ru nanorods was detailed to produce NH3 at an impressive rate of 34.2 g mgcat.−1 h−1 (equivalent to 5.62 × 10−11 mol s−1 cm−2) with an FE of 2.4%, based on the electrochemically working surface area. Given the NH3 generation per unit area, the nano-rod assembly structure may still be chosen even though tripod structures produce more NH3 per milligram of the catalyst.

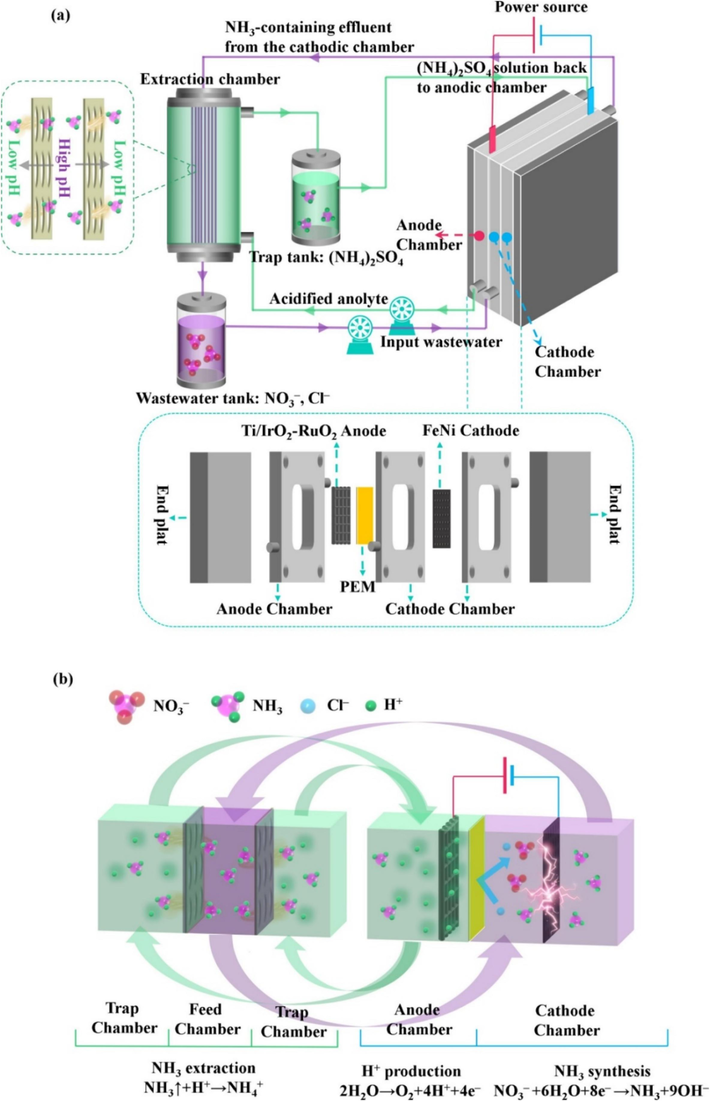

Shi et al. introduced an innovative electrochemical flow-through cell to significantly advance sustainable wastewater treatment and ammonia fertilizer synthesis (Fig. 7). This system incorporates a porous working FeNi alloy cathode and a membrane extraction unit of hollow polypropylene fibers. It allows for the simultaneous electrochemical reduction of nitrate (NO3–) to ammonia and the in-situ generation of acid/base to facilitate NH3 extraction in the form of ammonium sulfate salts ((NH4)2SO4). The study's findings were impressive: The system demonstrated exceptional performance over 14 h, removing 150 mM NO3– from synthetic wastewater with a cathodic current density of 30 mA/cm2. It also obtained a 98 percent ammonia selectivity, 93 percent Faraday efficiency, and 97 percent total ammonia nitrogen (TAN) recovery. Of significant note, the NH3 recovery flux reached 2050 g-(NH4)2SO4/m2/d, and the specific energy consumption was measured at 11 kWh/kg-(NH4)2SO4, surpassing the performance of many existing processes. This research highlights the central role of direct electron transfer in electrochemical NO3– reduction to NH3. The analysis of interfacial reactions underscores the reactivity and specificity of the NiFe2O4 (3 1 1)-Ni site on the thermally working FeNi alloy surface, rendering it highly efficient for electrochemical NO3– reduction to NH3, surpassing the competitive processes of N2 or H2 generation (Shi et al., 2023).

The schematic diagram illustrates the flow-through electrolysis cell that was employed, along with its operational principles (Shi et al., 2023). Copyright 2023, Elsevier.

3.3 Transition metal oxides-based electrocatalyst

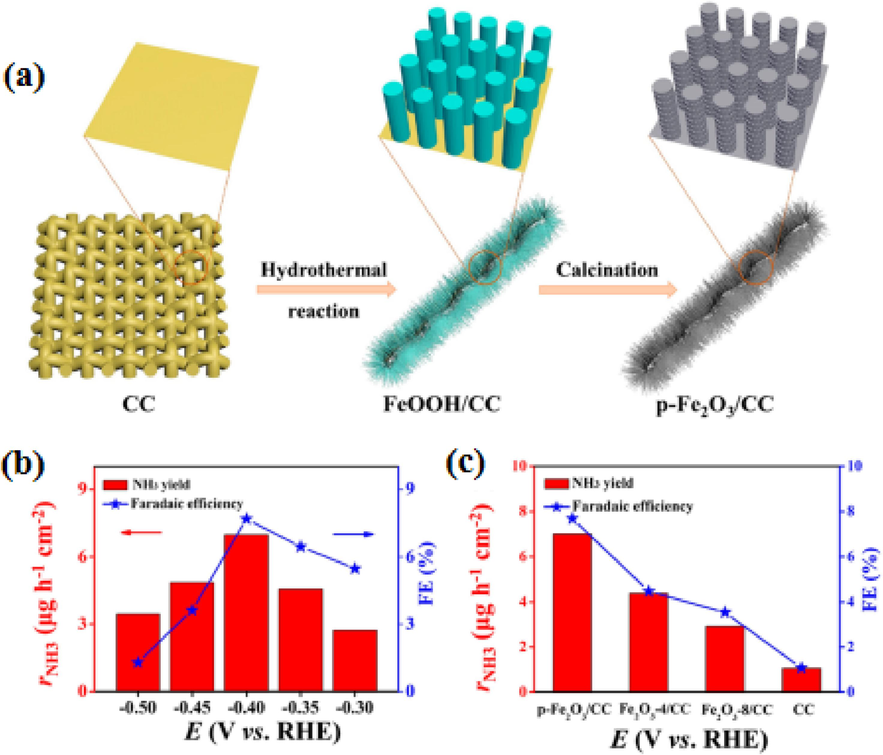

There is a growing attention in the electrochemical synthesis of ammonia due to its energy-efficient nature and utilization of water as a hydrogen source. However, developing cost-effective materials and high performance for catalyzing N2 reduction reactions has been a bottleneck in enabling scalable ammonia production. While precious-metal-based electrocatalysts have shown promise in electrochemical ammonia synthesis, their high cost and low FE fall short of meeting industrial demands. To address this, the prospect of designing a transition metal oxide-based array architecture for ammonia electrosynthesis appears promising. The goal is to boost the production rate of NH3 and enrich FE. Transition metal oxide-based array architecture may offer a viable solution to overcome the limitations associated with current electrocatalysts in ammonia synthesis, making it more aligned with industrial requirements. Wang and colleagues devised a method for creating porous Fe2O3 nanorods on carbon cloth (p-Fe2O3/CC) through a combination of hydrothermal processes and high-temperature calcination, as illustrated in Fig. 8a. The resulting porous structure of p-Fe2O3/CC presented an abundance of active sites and open channels, facilitating nitrogen adsorption and its conversion into ammonia. Remarkably, the p-Fe2O3/CC catalyst demonstrated remarkable stability in the electrochemical conversion of N2 to ammonia, achieving a peak NH3 production rate of 13.56 g mgcat.−1 h−1 and a Faraday efficiency of 7.69% in a 0.1 M Na2SO4 solution at −0.4V vs. RHE. Notably, the ammonia production rate and Faraday efficiency declined when operating at a lower potential. This effect was assigned to the adsorption of H2 on the surface of the p-Fe2O3/CC catalyst, which blocked active sites, as illustrated in Fig. 8b (Wang et al., 2019).

The study investigates the electrochemical nitrogen reduction using the p-Fe2O3/CC catalyst. The text contains a visual representation of the catalyst preparation process and data regarding the NH3 generation rate and Faradaic efficiency observed with the p-Fe2O3/CC catalyst under various potentials. Furthermore, it compares the NH3 generation rate and Faradaic efficiency between the p-Fe2O3/CC catalyst and the Fe2O3-4/CC, Fe2O3-8/CC, and CC catalysts. This content has been shared with permission (Wang et al., 2019). Copyright 2019, American Chemical Society (ACS).

Additionally, the influence of the duration of hydrothermal synthesis on the efficiency of the p-Fe2O3/CC catalyst was also examined. The study revealed that the p-Fe2O3/CC catalyst, synthesized hydrothermally for 6 h, had the maximum NH3 generation rate and FE. The exceptional performance of the p-Fe2O3/CC catalyst can be attributed to its notably higher double-layer capacitance (Cdl) value, measuring 46 mF cm−2. In contrast, the Cdl values for Fe2O3-8/CC and Fe2O3-4/CC stand at 21 mF cm−2 and 28 mF cm−2, correspondingly. This variance in Cdl values indicates the electrochemically working surface area (ECSA) for the catalyst, providing a multitude of active sites essential for the nitrogen reaction, as demonstrated in Fig. 8c. Additionally, the influence of the duration of hydrothermal synthesis on the efficiency of the p-Fe2O3/CC catalyst was also examined.

The study revealed that the p-Fe2O3/CC catalyst, synthesized hydrothermally for 6 h, had the maximum NH3 generation rate and FE The exceptional performance of the p-Fe2O3/CC catalyst can be attributed to its significantly higher double-layer capacitance (Cdl) value, which stands at 46 mF cm-2, a marked contrast to the values of 21 mF cm−2 for Fe2O3-8/CC and 28 mF cm−2 for Fe2O3-4/CC. This Cdl value indicates the electrochemically working surface area (ECSA), providing numerous active sites crucial for the nitrogen reaction, as illustrated in Fig. 7c. Hu et al. used a similar procedure in another investigation to create a Fe/Fe3O4 catalyst: they first oxidized the Fe foil and then reduced it electrochemically. This catalyst was subsequently utilized for the electrochemical conversion of N2 to NH3 under standard atmospheric conditions. Notably, the nitrogen reduction reaction demonstrated a substantial improvement in working the Fe/Fe3O4 catalyst compared to pure Fe foil. The FE of the Fe/Fe3O4 catalyst surpassed that of Fe foil by a remarkable 120-fold. This catalyst reached its peak ammonia production rate at 0.19 µg cm−2 h−1, accompanied by a FE of 8.29%, in a 0.1 M phosphate buffer solution at −0.3V versus RHE. Furthermore, the influence of oxidation temperature was investigated, revealing that the catalyst's performance can be accredited to the varying ratios of Fe to Fe3O4. In summary, the Fe/Fe3O4 catalyst displayed superior performance in the nitrogen reduction reaction when compared to Fe, Fe2O3, and Fe3O4 nanoparticles, emphasizing the efficiency of the Fe/Fe-oxide composite as a highly effective electrocatalyst (Hu et al., 2018). Liu et al. utilized the hydrothermal synthesis and prepared efficient Fe3O4 nanorods on Ti mesh (Fe3O4/Ti) electrocatalyst for electrocatalytic reduction from nitrogen to ammonia with long-term electrochemical stability. The Fe3O4/Ti electrocatalyst realized an NH3 generation rate of 5.6 × 10−11 mol s−1 cm−2 and FE of 2.6% in 0.1 M Na2SO4 at −0.4 V vs RHE. It showed a negligible loss in the electrochemical performance after its stability test 6 times (Liu et al., 2018).

Zhang and their team developed a TiO2 nanosheet array on a Ti plate (TiO2/Ti) through hydrothermal synthesis. They harnessed it as an exceptionally well-organized electrocatalyst for the electrochemical generation of ammonia from N2 in typical environmental conditions. The TiO2/Ti electrocatalyst achieved an impressive peak ammonia production rate, reaching 9.16 × 10−11 mol·s−1 cm−2 within a 0.1 M Na2SO4 solution at a potential of −0.7 V versus RHE. It is worth noting that while the TiO2/Ti electrocatalyst exhibited a peak FE of 3.34% for NH3 generation at −0.6V, this efficiency slightly decreased to 2.50% at −0.7V due to competing H2 evolution processes. Considering the rate of NH3 generation, the potential of −0.7V was identified as the most favorable, surpassing that of most electrocatalysts documented for the N2 reduction reaction under normal conditions (as indicated in Table 1). The exceptional performance of the TiO2/Ti electrocatalyst in NH3 synthesis can be ascribed to the creation of O2 vacancies, which significantly enhance the adsorption and activation of nitrogen during the electrochemical tests. The TiO2/Ti electrocatalyst demonstrated exceptional electrochemical durability in NH3 synthesis. After the 10-cycling test, the NH3 production rate and FE remained at 90.2% and 88.8% of their initial values, respectively. The electrode's decay effect during extended electrolysis had a minor impact on the losses (Zhang et al., 2018).

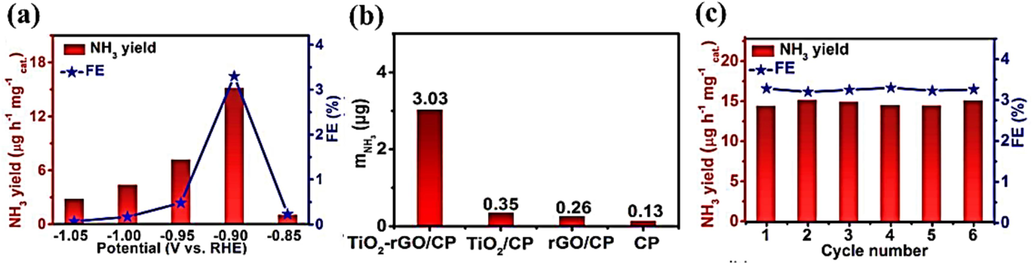

In a study by Zhang and colleagues, TiO2-rGO was synthesized using a hydrothermal technique and then applied to carbon paper (CP) to produce the TiO2-rGO/CP electrocatalyst. This electrocatalyst demonstrates remarkable selectivity in the electrochemical reduction of N2 to NH3. Specifically, the TiO2-rGO/CP electrocatalyst exposed a peak ammonia production rate of 15.13 µg mgcat.−1 h−1 and a high FE of 3.3% in a 0.1 M Na2SO4 solution at a potential of −0.90 V vs RHE. To assess the performance of various electrocatalysts during 2-hour electrolysis at −0.9V, a comparison was made involving different materials, namely CP, TiO2/CP, rGO/CP, and TiO2-rGO/CP, as depicted in Fig. 9(a) and 9(b). When CP was employed as an electrocatalyst in the nitrogen reduction procedure, it yielded significantly lower performance. However, the TiO2-rGO/CP electrocatalyst outperformed both the TiO2/CP and rGO/CP electrocatalysts due to the well-distributed TiO2 nanoparticles on rGO, providing an optimal contact of nitrogen-rich working sites for efficient adsorption and reduction into ammonia. In addition, TiO2-rGO/electrochemical CP's stability was thoroughly assessed using six consecutive recycling experiments at a potential of −0.9V (Fig. 9(c)). Because there were no changes in the NH3 production rate or FE throughout the testing, the findings showed the TiO2-rGO/CP electrocatalyst's exceptional electrochemical stability (Zhang et al., 2018).

Here are the results from electrochemical nitrogen reduction using the TiO2-rGO catalyst: (a) The NH3 production rate and Faradaic efficiency of the TiO2-rGO/CP catalyst at various potentials in a 0.1 M Na2SO4 solution. (b) The amount of NH3 generated after two hours of electrolysis at −0.90 V under ambient conditions. (c) The NH3 production rate and Faradaic efficiency during six recycling tests at a potential of −0.90 V. The figures and data are presented with permission from the source (Zhang et al., 2018). Copyright 2018, Royal Society of Chemistry (RSC).