Translate this page into:

Essential oil was extraction from Cinnamomum camphor peel using microwave as an aid and study of their inhibitory effect on Pseudocercospora psidii fungi

⁎Corresponding authors at: Jiaying University, Meizhou 514015, China. xiaonanzhang2021@126.com (Xiaonan Zhang)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

To apply the natural ingredients of plants in the field of food preservation, the essential oil of Cinnamomum camphor peel was isolated by salt-out pretreatment and microwave-assisted hydrodistillation. Using the single-factor mixed response surface approach, the extraction yield was optimized. A total of 14.98 mL/kg DW (dry weight: DW) was the greatest essential oil yield recorded. By using GC–MS analysis, a total of 29 compounds were found in the essential oil, with methyl eugenol (12.66 %) and safrole (10.36 %) being the two predominant compounds. However, the essential oil had a clear inhibitory effect on Pseudocercospora psidii at a concentration of 10 mg/mL. In conclusion, Cinnamomum camphora pericarp essential oil is anticipated to be a green natural pesticide that significantly inhibits pathogenic bacteria in crops.

Keywords

Cinnamomum camphora pericarp Microwave-assisted treatment

Antifungal

GC

MS

Essential oil

1 Introduction

With the increasing demand for natural and healthy foods such as fruits and vegetables, crop infection caused by pathogens has become a major obstacle to food safety (Yesuf, 2013). For example, Pseudocercospora psidii is an asexual fungus that causes premature leaf loss in fruit trees and death in guava, banana, and Citrus fruit (Librelon et al., 2022; Yesuf, 2013). The content of infected fruit juice is reduced, which makes the fruit unfit for consumption or processing. (Akoutou Mvondo et al., 2020; Alakonya et al., 2018; Seshadri et al., 2020). They also exist in a free state and are stable during heating, freezing and processing. Therefore, finding an effective antimicrobial method has become a hot issue in the food industry.

Essential oil (EO), a natural antifungal agent, was extracted from plants. To improve the flavor and quality of food, EOs are frequently used as food additives (Anžlovar et al., 2014; Muhammad et al., 2020). Most EOs are considered safe by the Food and Drug Administration. A literature survey of the ecological and biological properties of EOs and preliminary tests of antimicrobial activity by Martina B et al. demonstrated that EOs have potential antifungal effects on various organisms that can endanger plants or human health (Bottoni et al., 2021). Many studies have shown that the application of plant compounds can reduce disease severity in many crops, and EOs are an effective way to control early blight in tomato plants (Tomazoni et al., 2017). Cinnamomum camphora seeds are plants of the Lauraceae family and are also known as Cinnamomum camphora trees. These plants are native to tropical Asia, Malaysia, and Taiwan and are cultivated at altitudes of 1000 to 1800 metermetres. In the 17th century, it was introduced into Europe, where it was widely cultivated (Guo et al., 2016). Jiang H et al. reported that camphora, eucalyptol, linalool, and triene are the main components of Cinnamomum leaves, branches, and seed EOs (Jiang et al., 2016). It has been reported that EO from Cinnamomum camphora seeds can inhibit the growth of microorganisms (bacteria and fungi) on the surface of bananas and has the potential to become a natural antimicrobial (Lv et al., 2021).

The extraction of plant EOs is one of the key steps in the study of their biological activities. Ionic solution pretreatment has been widely used in the field of plant extraction, such as for Foeniculi fructus (Shi et al., 2021) and Polygonum cuspidatum (Yang et al., 2014). An ionic solution prepared with sodium chloride helps to destroy the cell wall and improve the permeability of the cell wall so that the EO penetrates more fully from the cell and increases the yield during the extraction process; this process is called “salting out” (Shi et al., 2021; Tran et al., 2019). The heat generated by microwave radiation can cause the outflow of essential oil by destroying cell glands, and microwave extraction can penetrate the plant matrix and generate heat in plants, leading to cell rupture and enhanced mass transfer (Liu et al., 2018). H2O is instantly heated by microwave irradiation so that the pressure inside the cell increases suddenly, causing the cell wall to rupture quickly. The essential oil and water present in the plant material are then evaporated from the broken cells by azeotropic distillation, improving the yield. Using fresh plant material or dried material, this method is thought to be a green methodology for the preparation of essential oils, making the entire process more affordable, straightforward, and quick . Therefore, we speculated that salting out pretreatment of raw material with sodium chloride solution combined with microwave-assisted hydrodistillation would result in a satisfactory extraction rate of EO.

Cinnamomum camphora seed kernels have attracted much attention in the last decade due to their high level of medium-chain oil (48.24–62.60 %, wet basis) and protein (17.15–26.33 %, wet basis). Essential amino acids and high quality exhibit superior functional properties, including foaming capacity and emulsifying activity, in Cinnamomum camphora seed kernels (Yan et al., 2020); thus, these seeds may have great application prospects in the food industry, as Cinnamomum camphora seed pericarp will be wasted during this process. To make better use of resources, it is important to isolate the pericarp and kernel. Thus, in this paper, we investigated the antimicrobial activity of Cinnamomum camphora pericarp essential oil (CPEO) and explored the development of new Cinnamomum resources from a new perspective.

2 Materials and methods

2.1 Materials and instruments

Fresh Cinnamomum camphora seeds were collected from Meizhou, Guangdong Province. Pseudocercospora psidii was obtained from Northeast Agricultural University Food Science College. Anhydrous sodium sulfate and sodium chloride (purity 99 %) were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). N-hexane (Analysis Pure, purity ≥ 99 %) was purchased from Guangfu Technology Co., Ltd. (Tianjin, China). Potato dextrose agar (PDA) was purchased from Bo Microbiology Technology Co., Ltd. (Shanghai, China). Luria–Bertani broth (500 g) was purchased from Haibo Biotechnology Co., Ltd. (Qingdao, China). Rifampicin (purity > 99.5 %) was purchased from Shanghai Yuanye Co., Ltd. (Shanghai, China), and ampicillin trihydrate (purity > 98 %) was purchased from Shanghai Yuanye Co., Ltd. (Shanghai, China).

The equipment used in this study included a microwave oven (independently developed and modified by the laboratory of Jiaying University). An electrothermal incubator (HPX-9272MBE, Shanghai) was used. A high-pressure steam quenched the bacteria (GR60DP, Shanghai). A constant-temperature water bath (BWS-12, Shanghai) was used. A laboratory pure water purification system (Master Touch-S30UVF, Shanghai) was used. An intelligent digital magnetic stirrer (SP-16, Hangzhou) and a vortex shaker (VM-500S, Zhejiang) were used.

2.2 Essential oil extraction process

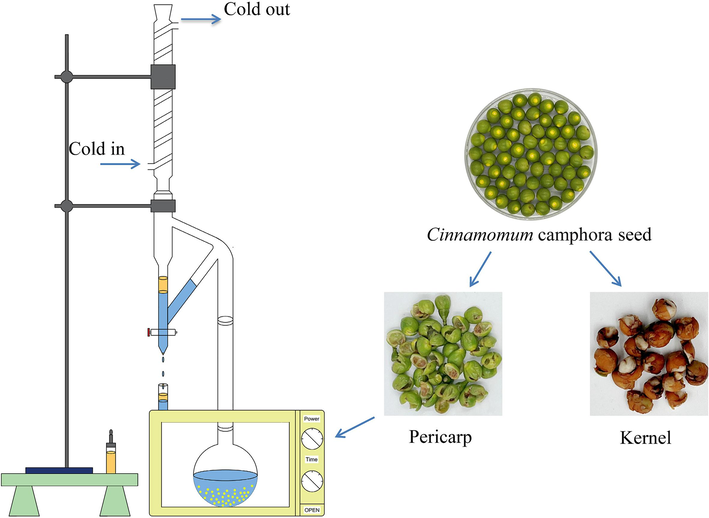

We used the following methods to pretreat Cinnamomum camphora seeds: fresh Cinnamomum camphora seeds were cleaned, and the pericarp and kernel were carefully separated. The moisture content of the pericarp was subsequently calculated via the drying method. When the experiment began, the pericarp was ground and filtered through a 20-mesh sieve using a pulverizer. One hundred grams of raw material was weighed, sodium chloride at a concentration ranging from 1 to 7 % was added, and the mixture was soaked for 5–200 min. Cinnamomum camphora pericarp essential oil (CPEO) extraction was carried out at a liquid-material ratio ranging from 1 to 6 and a microwave power ranging from 120 to 700 W. The extraction process of CPEO is shown in Fig. 1. (Drawn by Adobe Illustrator, version number: 2021 25.2.3.259). Origin (pro-2021) software was used to construct the single factor experiment results. A microwave extraction device was independently developed by Jiaying College, and the obtained CPEO solution was dried with anhydrous sodium sulfate, sealed, and stored at 4 °C in the dark.

Extraction of essential oil from Cinnamomum camphora seed pericarp (separation of the pericarp and kernel from the Cinnamomum camphora seed).

2.3 Response surface optimization

Based on the single-factor experiment, the three factors that had the most influence on the yield of CPEO (Y) were the liquid–solid ratio (X1), microwave power (X2), and pretreatment time (X3). The above three factors were optimized and evaluated by using the Box-Behnken design (13.0.1.0). The optimal extraction conditions were determined, and verification experiments were conducted. The levels of each factor are shown in Table 1. X1, Material–liquid ratio. X2, Microwave power. X3, pretreatment time.

Level

X1 (mL/g)

X2 (W)

X3 (min)

−1

3

385

100

0

4

540

150

1

5

700

200

2.4 Identification of compounds in the essential oil

CPEO compounds were detected by a gas chromatograph-mass spectrometer (Agilent Technologies 7890A-5975C MSD, USA, California). First, the CPEO was dried with anhydrous sodium sulfate and diluted with a 10-fold volume of n-hexane, and the chromatographic column used was an HP-5 ms column (30 × 0.25 mm; Agilent Technologies, Palo Alto, USA). One microliter of the sample was injected at a temperature of 250 °C, heated to 230 °C at a rate of 3 °C/min, held for 10 min, and analyzed by a combined flame ionization detector (GC-FID). The carrier gas was N2, and the flow rate was 1 mL/min.

2.5 Antifungal activity

A CPEO solution with Tween 80 (0.1 %) was used as the experimental sample, and a culture medium with Tween 80 was used as the negative control (for which the CPEO concentration was 0 mg/mL). For Pseudocercospora psidii, 125 μL of CPEO was spread on a petri dish containing potato dextrose agar (PDA) medium, and sterile filter paper (6 mm) was placed in the petri dish containing 10 μL of fungus containing 1 × 105 CFU/mL.

3 Results and discussion

3.1 Essential oil extraction

3.1.1 Influence of different parameters on the yield of CPEO

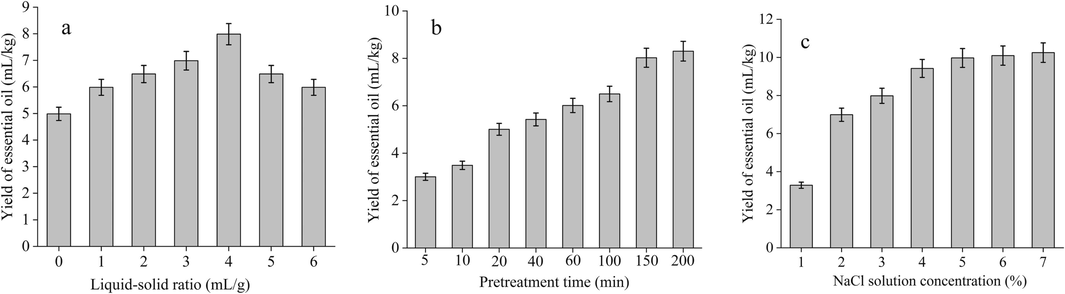

The effect of the liquid–solid ratio on the yield of CPEO under a certain range of microwave times and powers is shown in Fig. 2a. With an increase in the liquid-to-material ratio, the yield of CPEO also increased. When the liquid-to-material ratio was 4, the yield of CPEO was the highest. The increase in the yield of CPEO may be because during the extraction process, the greater the ratio of liquid to material is, the greater the diffusion of CPEO in water and the increase in the yield of CPEO. However, when the liquid-material ratio continues to increase, it may lead to the hydrolysis and dissolution of some compounds in water, resulting in a decrease in the yield of CPEO (Cui et al., 2018).

Effects of different factors on the yield of CPEO.

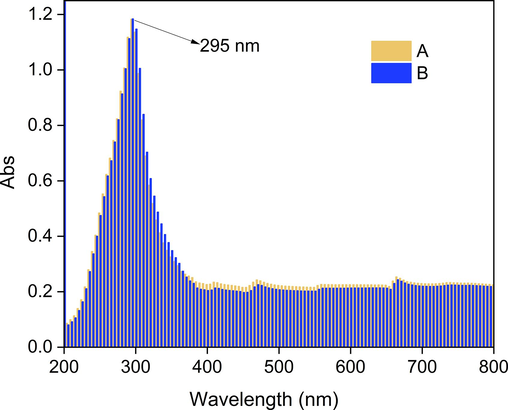

Fig. 2b shows the effect of different pretreatment durations (5–200 min) on the yield of CPEO. First, the extraction rate of CPEO increased with prolonged pretreatment time. When the pretreatment time reached 150 min, the yield of CPEO reached 8.45 mL/kg DW (dry weight: DW). These results may be caused by the long-term immersion of salting out helping to increase the osmotic pressure of the cell wall inside the pericarp, which causes the cells to swell and subsequently become brittle, thereby destroying the cell wall, enhancing mass transfer and increasing the rate of CPEO outflow from the raw material. After 150 min of pretreatment, the CPEO yield increased gradually and became nearly flat, which indicated that an appropriate pretreatment time was conducive to the ability of the salting out solution to penetrate plant tissue and soften the cell wall (Solanki et al., 2020), and the salting out effect was fully achieved after 150 min. As shown in Fig. 2c, with the gradual increase in the amount of salting out solution, the yield of CPEO also increased significantly. When the addition of salting out solution reached 5 %, the yield of CPEO increased slowly, reaching a yield of approximately 10 mL/kg DW (dry weight: DW), after which the yield continued to balance. We employed spectrophotometer to scan the aqueous solution of essential oil in the extraction procedure. Sample A is normal, and B has been treated with a salting out solution.

They all have a distinct absorption peak at 295 nm (As is shown Fig. 3). However, the absorbance of A is slightly higher than B during full-wavelength scanning, this indicates that the absorption peak of the sample after salting-out treatment is smaller; salting out solution can reduce the loss of CPEO and reduce the solubility of some nonpolar components of CPEO in water. Refer Peng et al.: full-wavelength scanning of extracted samples was performed by spectrophotometer, and the sample yield increased significantly after treatment with LiCl solution, which is similar to the conclusion of this study (Peng et al., 2022). The reason for this result may be that the osmotic pressure inside and outside the cell reaches equilibrium, hindering the separation of CPEO from the material. During the extraction process, a mixture of CPEO and water formed an emulsion. When salting out of solution is added, the loss of CPEO can be avoided, and the solubility of some nonpolar components of CPEO in water can be reduced. Moreover, it can increase the density of water and serve as a polarizing electrolyte, facilitating the separation of CPEO from water.

Microwave-assisted extraction of the absorption value of aqueous solution in the extraction process of samples before (A) and after (B) NaCl treatment.

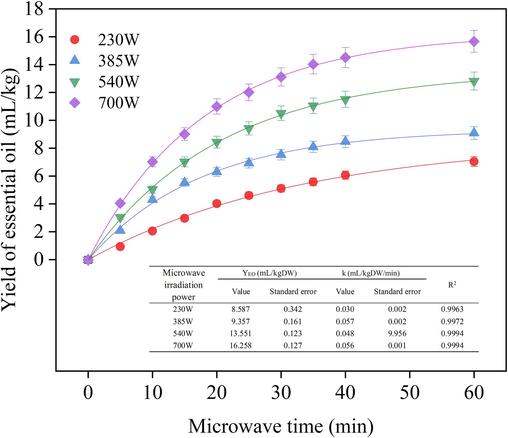

3.1.2 Extracted kinetic analysis

As shown in Fig. 4, the highest yield of CPEO was 4.26 mL/kg DW when the microwave power was 120 W and the microwave time was 60 min. From 40 to 60 min, the yield of CPEO exhibited the fastest increase, which may be due to the slow increase in the temperature of the extraction system at low microwave power; subsequently, the material absorbs more microwave energy, and the temperature increases within 40–60 min, so the yield of CPEO increases. When the microwave power was 230–385 W, the yield of CPEO increased rapidly from 0 to 20 min and then increased slowly, with the highest yields of 7.06 mL/kg DW and 9.09 mL/kg DW, respectively.

Effects of microwave power and extraction time on the CPEO yield.

This may be due to the increase in microwave power and the rapid increase in temperature, which accelerate the destruction of plant cells so that additional CPEO is generated by water vapor, and the increase in yield of CPEO increases rapidly within 20 min. A high microwave power leads to a rapid temperature change, and prolonged heat can lead to the decomposition of volatile compounds in EO (Liu et al., 2022); thus, the yield of CPEO increases slowly after 20 min. In the initial stage of extraction, the yield of CPEO increases rapidly, but after a certain time, the yield slows down and tends to be constant. The reason for this phenomenon is that the amount of oil in the material decreases, while the boiling point increases (Liu et al., 2022). When the microwave power was 700 W, the yield of CPEO increased the fastest during 0–10 min, an increase of 70.4 %. The increase rate between 10 and 20 min was the second highest, 39.7 %. The reason for the gradual decrease in the increase rate may be that the CPEO rich in the raw material gradually flows out with longer extraction time, and the CPEO rich in the raw material also decreases.

The yield of CPEO was low at lower power, possibly because the heat generated at low power was insufficient to completely destroy the glands and oil containers, resulting in an incomplete outflow of CPEO (Chen et al., 2016). As the microwave power increases, the yield increases, and the yield of CPEO is proportional to the microwave time and microwave power. With increasing microwave power, microwave radiation and electromagnetic energy increase faster in a short time, penetrating the plant matrix and generating heat in the raw material, leading to cell rupture and mass transfer enhancement so that CPEO will flow out of the raw material and improve yield. When the microwave power was continuously increased within the same unit time, the CPEO production also increased significantly. Therefore, the results obtained from the extraction kinetics study are consistent with those obtained from univariate experiments.

3.1.3 Response surface optimization

3.1.3.1 Response surface test and model analysis

Multiple linear regression and quadratic multinomial fitting were performed on the data through Design-Expert 10 software. The results of the ANOVA are shown in Table 2. X1, Material–liquid ratio. X2, Microwave power. X3, Pretreatment time. YCPEO, yield of Cinnamomum camphora pericarp essential oil (mL/kg DW). CV%, coefficient of variation %. *, P < 0.05. **, P < 0.01; ***, P < 0.001.

Run

BBD experiments

ANOVA

X1 (mL/g)

X2 (W)

X3 (min)

YCPEO (mL/kgDW)

Source of variation

Sum ofsquares

Degree of freedom

Mean square

F value

P value

1

5

700

150

14.88

Model

16.14

9

1.79

170.56

< 0.0001***

2

4

700

100

15.32

X1

0.14

1

0.41

39.41

0.0004***

3

4

385

200

12.55

X2

8.93

1

8.93

849.51

< 0.0001***

4

5

540

100

15.21

X3

0.54

1

0.54

50.98

0.0002***

5

3

700

150

15.72

X12

0.11

1

0.11

10.68

0.0137*

6

4

540

150

15.61

X22

0.24

1

0.24

22.39

0.0021**

7

4

540

150

15.58

X32

0.22

1

0.22

21.03

0.0025**

8

3

540

200

15.08

X1X2

0.31

1

0.31

29.11

0.0010**

9

4

700

200

15.29

X1X3

4.23

1

4.23

402.36

< 0.0001***

10

4

540

150

15.70

X2X3

0.75

1

0.75

71.37

< 0.0001***

11

5

540

200

14.19

Residual

0.07

7

0.01

12

3

385

150

13.43

Lack of fit

0.05

3

0.02

0.1062

13

3

540

100

15.13

Pure error

0.02

4

0.01

14

4

540

150

15.56

Corrected

16.21

16

15

4

385

100

13.52

Credibility analysis of the regression equations

16

4

540

150

15.52

Index mark

Standard deviation

Mean

CV%

Press

R2

Adjust R2

Adequacy precision

17

5

385

150

13.26

Y

0.10

14.80

0.69

2.60

0.9955

0.9896

40.12

The P value of the regression model was less than 0.01, indicating that the model was extremely statistically significant. The misfit term P = 0.1062 indicated that the model fitting degree was good, the unknown factors had little interference on the model fitting results, and the model error was small. R2 = 0.9955, which indicated a high degree of fit of the equation. The effect of each factor on the yield of CPEO was in the order of X2 > X3 > X1. The primary term X2 and the secondary terms X22 and X32 had significant effects on the extraction yield of CPEO (P < 0.01). The primary terms X1 and X3, the quadratic term X12, and the interaction terms X1X2, X1X3, and X2X3 had significant effects on the yield of CPEO (P < 0.05). The regression equation was obtained as follows:

Y = 15.59–0.23X1 + 1.06X2 − 0.26X3 − 0.17X1X2 − 0.24X1X3 + 0.23X2X3 − 0.27X12 − 1.00X22 − 0.42X32.

where Y is the yield of CPEO (mL/kg DW) and X1, X2, and X3 are the liquid–solid ratio, microwave power, and pretreatment time, respectively. A term with a positive coefficient has a great effect on the CPEO yield, while a term with a negative coefficient has the opposite effect.

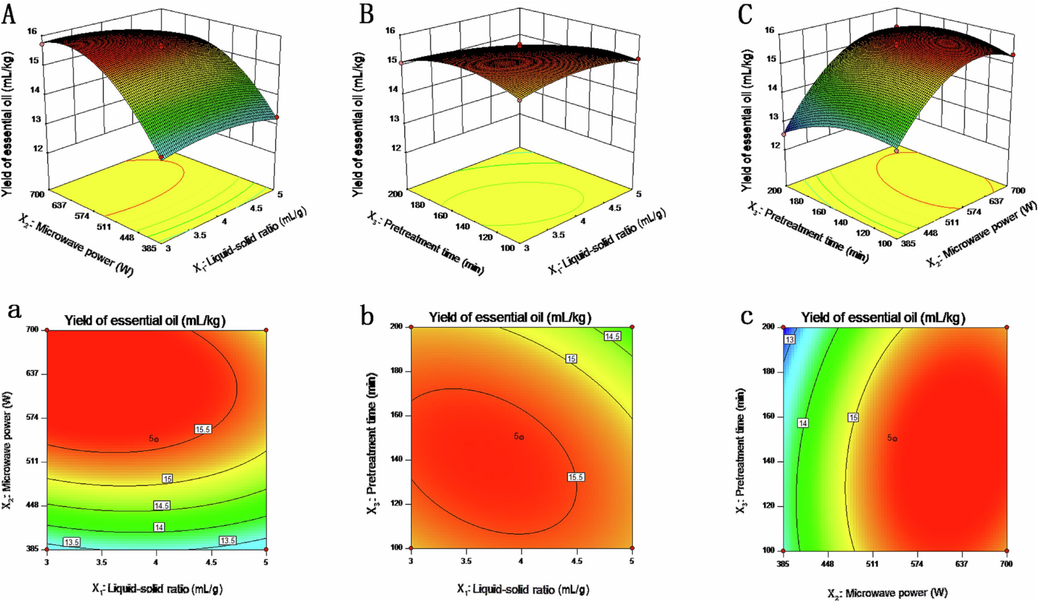

3.1.3.2 Interaction response surface and contour analysis

Taking the yield of CPEO (Y) as the response value, the response surface map and contour map of the interaction between the liquid–solid ratio (X1), microwave power (X2), and pretreatment time (X3) were prepared by Design-Expert 10, and the results are shown in Fig. 5. The influence and interaction of various factors on the extraction rate of CPEO could be reflected by the steep change in the response surface and the shape and sparsity of the contour lines. The steeper the response surface and the denser the contour lines are, the more significant the impact on the total output. According to the response surface plot in Fig. 5A, the curve of the liquid–solid ratio versus microwave power was steep, indicating that the yield of CPEO was strongly affected by the interactions between them. According to the response surface diagram in Fig. 5B, the curve of the liquid–solid ratio was flat, and the pretreatment time curve was steep, indicating that the interaction between them had a certain effect on the yield of CPEO. In addition, the contour shape of the liquid–solid ratio and pretreatment time in Fig. 5b was oval, indicating that they were significantly related. According to the response surface plot in Fig. 5C, the curve between the microwave power and pretreatment time was steep, indicating that the yield of CPEO was strongly affected by the interactions between them. The contour plot of the microwave power versus pretreatment time is oval in Fig. 5c, indicating that there was a significant interaction between them.

Optimization of essential oil yield by the response surface method. Interactions between the water ratio and the material-liquid ratio and microwave power (A), between the material-liquid ratio and pretreatment time (B), and between the microwave power and pretreatment time (C).

3.1.3.3 Response surface model verification

According to the regression fitting equation, the optimal extraction process parameters for CPEO were as follows: the liquid–solid ratio was 3.05, the pretreatment time was 111.21 min, and the yield was 14.98 mL/kg DW. To verify the reliability of the process parameters, combined with the convenience of practical operation, the process parameters were adjusted to a liquid–solid ratio of 3, the pretreatment time was 111 min, and three parallel experiments were carried out under the conditions of a fixed microwave time of 20 min and catalyst addition amount of 7 %. The extraction rate of CPEO was 15.25 mL/kg DW. The relative error with respect to the theoretical value of 14.98 mL/kg DW predicted by this model is less than 2 %, indicating that the optimal process parameters obtained from the regression fitting equation are highly reliable. The yield and quality of essential oil have increased as a result of the application of cutting-edge technologies such as microwave aided hydrodistillation, ultrasonic Assisted hydrodistillation, Soxhlet extraction, and supercritical fluid extraction. Supercritical fluid extraction is a useful technique for avoiding organic solvent residues, but it will also result in the loss of polar components in essential oils and contaminated samples from non-volatile materials like fatty acids (Fernandes et al., 2019). It has been reported that hydrodistillation is a common technique for extracting essential oils using conventional techniques (Khan et al., 2023). In addition to its lengthy heating period and high energy intensity, hydrodistillation reduces yield by producing an excessive amount of pure sol when the constituents of essential oils form hydrosol (Hu et al., 2021). The ultrasonic assisted hydrodistillation method can effectively damage plant cells through ultrasonic cavitation and accelerate the heating speed, however, it has certain drawbacks, including low efficiency and the loss of heat-sensitive components during the distillation process (Modi et al., 2019). According to (López-Hortas et al., 2020), the cable extraction approach efficiently reduces raw material waste and yields more polar compounds; however, the extraction period is excessively long, resulting in higher energy consumption. In comparison to the aforementioned techniques, microwave aided water distillation's synergistic impact on heat and mass transfer during essential oil separation significantly increases the heating rate and encourages the essential oils to spill quickly (Desai and Parikh, 2015). Under microwave conditions, in situ water and essential oil components of plant cells can be heated quickly through dipole action (Liu et al., 2011). The steam produced by in situ water can severely damage plant cell walls and encourage the spill of essential oil components (Peng et al., 2021). To sum up, compared with water distillation, Soxhlet extraction, and ultrasonic-assisted extraction, microwave-assisted hydrodistillation can effectively shorten the extraction time and save solvent, and the yield of CPEO is greater than that reported for Cinnamomum camphora leaves, lemongrass, grapefruit peel, etc.

3.1.4 The actual content of essential oil yield

The methodology for determining essential oil content in the Pharmacopoeia of the People's Republic of China (2020), published by China Medical Science and Technology Press, is utilized in this work to determine the essential oil of Cinnamomum camphor peel. The processed raw materials are put into a hard round-bottom 1000 mL flask and connected to the essential oil extractor of the reflux condensing tube. All parts are connected with glass grinding, and the scale of essential oil is 0.1 mL; Make sure the joint is tight to prevent the escape of volatile component. After repeatedly mixing 400 mL of deionized water with 100 g of material, connect the reflux condensing tube of the essential oil extractor. The upper end of the self-condensing tube is filled with water to fill the scale part of the essential oil extractor, then put in the electric heating sleeve bring it to boil. After the amount of oil in the tester stops increasing, stop the heating process and check the amount of essential oil. Under the identical factor level conditions, the yield of essential oil obtained by the microwave aided hydrodistillation method was 7.52 mL/kg, while the yield of essential oil extracted by the pharmacopoeia method was 6.64 mL/kg. When comparing the two processes, the approach used in this study produced a slightly higher yield of essential oil extraction than the method found in the Chinese pharmacopoeia. Furthermore, using GC–MS identification on the first two outcomes, we were able to determine the essential oil chemical structures listed below.

3.2 GC–MS

We conducted GC–MS on the extracted CPEO (Table 3), and the results showed that the CPEO contained 29 compounds, of which the most abundant component was methyl eugenol (12.66 %), the second most abundant component was safrole (10.36 %), followed by linalool (9.70 %), eucalyptol (7.09 %) and α-phellandrene (6.22 %). The proportion of ingredients listed accounted for 46.03 % of the total CPEO. The findings of Gao et al.'s study show that under varying power circumstances of 230 W, 385 W, 540 W, and 700 W, the total compound concentration of Melaleuca bracteata essential oil compounds varies (Gao et al., 2023). Since the equivalent total content of the discovered chemicals is 92.8 %, 98.91 %, 99.02 %, 99.48 %, and 98.16 %, we can only hypothesize that varying the power in this study will have a negligible impact on the essential oil. Second, research by Xinyu Yang revealed that the range of magnesium chloride's influence on the yield of essential oil was 0–1.07 mmol/gDW (Yang et al., 2022). The equivalent yield of essential oils is between 17 and 21 mL/kgDW. We hypothesize that while varying addition amounts influence the overall quality of the essential oil production, they will also have an impact on the chemicals that are present in essential oils. Additionally, as the solid-to-liquid ratio rises, an excess of solvent may dissolve a tiny amount of additional essential oil compounds at a high temperature. This will cause the extracted essential oils to have varied chemical compositions due to variations in the solid-to-liquid ratio. In conclusion, the chemical structure of essential oils will be slightly impacted by variations in microwave power (W), NaCl (%), and the solid–liquid ratio. RI = Retention index; ND = not detected.

NO.

Compounds

RI

CAS number

Relative area (%)

Similarity (%)

MAH

HD

1

α-Pinene

939

000080-56-8

1.87

2.61

94

2

Camphene

993

000079-92-5

1.09

1.03

90

3

α-Phellandrene

1003

000099-83-2

7.22

8.77

92

4

Eucalyptol

1015

000470-82-6

9.09

8.23

94

5

1,3,6-Octatriene, 3,7-dimethyl-, (Z)-

1039

003338-55-4

1.67

ND

97

6

γ-Terpinene

1064

000099-85-4

1.49

3.32

94

7

Linalool

1080

000078-70-6

8.91

7.65

97

8

Cyclohexene, 1-methyl-4-(1-methylethylidene)-

1097

000586-62-9

ND

1.53

95

9

(+)-2-Bornanone

1144

000464-49-3

4.08

3.32

97

10

α-Terpineol

1190

000098-55-5

3.97

3.07

91

11

Terpinen-4-ol

1206

000562-74-3

1.76

4.65

94

12

Citronellol

1232

000106-22-9

ND

0.16

95

13

2,6-Octadien-1-ol, 3,7-dimethyl-, (E)-

1258

000106-24-1

1.41

0.06

94

14

Safrole

1286

000094-59-7

12.13

10.51

95

15

1,2,4-Metheno-1H-indene, Octahydro-1,7a-dimethyl-5-(1-methylethyl)-,

1362

022469-52-9

0.52

0.63

94

16

α-Copaene

1378

003856-25-5

2.29

2.28

99

17

Methyleugenol

1402

000093-15-2

13.66

17.44

97

18

Tricyclo[2.2.1.0(2,6)]heptane, 1,7-dimethyl-7-(4-methyl-3-pentenyl)-, (-)-

1427

000512-61-8

4.24

2.15

89

19

Humulene

1456

006753-98-6

2.97

5.42

92

20

Benzene, 1,2-dimethoxy-4-(1-propenyl)-

1462

000093-16-3

3.71

1.23

95

21

γ-Elemene

1465

029873-99-2

1.49

2.23

91

22

3-Cyclohexene-1-methanol, α, α,4-trimethyl-, Propanoate

1468

000080-27-3

2.33

ND

91

23

γ-Muurolene

1481

030021-74-0

2.68

4.3

87

24

Naphthalene, Decahydro-4a-methyl-1-methylene-7-(1-methylethenyl)-,

1489

017066-67-0

1.37

1.98

99

25

Naphthalene, 1,2,4a,5,8,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)-,

1519

000523-47-7

0.71

1.62

95

26

1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl-, (E)-

1565

040716-66-3

1.3

ND

91

27

(+)-Spathulenol

1582

006750-60-3

0.47

0.01

99

28

Caryophyllene oxide

1589

001139-30-6

0.26

ND

93

29

Tetradecanal

1614

000124-25-4

0.41

0.53

99

Total (%)

93.10

94.73

Extraction time (min)

40

300

3.3 Antifungal activity

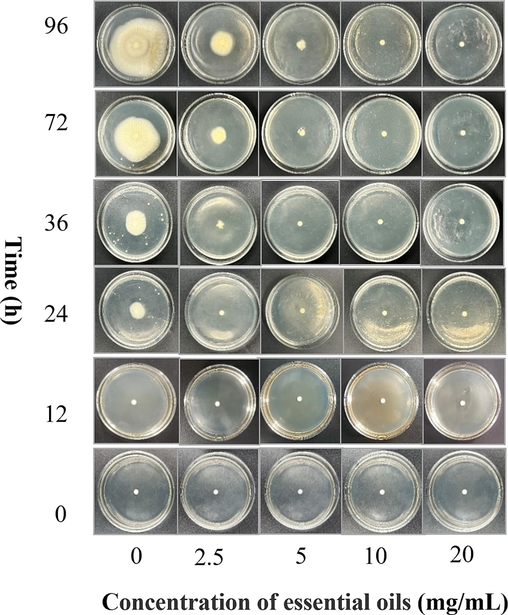

The extent of fungal inhibition of CPEO was determined by the agar method (Hu et al., 2019). Pseudocercospora psidii is a clonal fungus with a long growth cycle, so the total duration of the fungal inhibition test was 96 h. In this study, culture medium supplemented with Tween 80 was used as a negative control. The experiments were carried out by using different concentrations of CPEO solution. As shown in Fig. 6, with prolonged growth, the growth area of the fungi also increased accordingly. However, as the concentration of the CPEO solution continued to increase, the growth ability of the fungi decreased. Therefore, there was an inverse relationship between the growth of fungi and the concentration of CPEO. When the concentration of the CPEO solution was greater than 5 mg/mL, the antifungal activity was significant.

Antifungal effects of CPEO at different concentrations.

The Pseudocercospora psidii strain grows slowly for up to 24 h. As the culture time increased, the growth area of the fungus gradually increased (Zhang et al., 2022). After 96 h of culture, fungal growth was obvious in the medium supplemented with 2.5 mg/mL CPEO, and in the negative control, fungal growth had spread from the center of the medium to the periphery, during which large white hyphae could be observed (see Fig. 6). When the concentration of CPEO was 5 mg/mL, there was a small number of fungi in the 96-h culture medium, indicating that the 5 mg/mL CPEO solution was slightly active. However, when the concentration of the CPEO solution reached 10 mg/mL, the culture medium after 96 h had no fungus, so a concentration of 10 mg/mL CPEO had a significant effect on inhibiting the fungus.

4 Conclusion

In this work, microwave-assisted hydrodistillation was used to isolate essential oil from Cinnamomum camphora pericarp. The Cinnamomum camphora pericarp had previously been processed with salting out solution. A single-factor combined response surface approach was used to optimize the extraction yield, and GC–MS was used to identify the CPEO compounds. Various typical crop microbes were tested for resistance using CPEO solutions. According to the findings, the pretreatment time was 111.21 min, the greatest CPEO yield was 14.98 mL/kg DW, the ideal liquid-to-material ratio for the extraction process was 3.05, and the error in the verification experiment's result was less than 2 %. The CPEO included 29 different chemicals, among which methyleugenol (12.66 %), safrole (10.36 %), linalool (9.70 %), eucalyptol (7.09 %), and phellandrene (6.22 %) were the major compounds in the EO according to GC/MS analysis. Moreover, 10 mg/mL CPEO had a considerable impact on Pseudocercospora psidii inhibition. As a result, CPEO produced using the aforementioned methods has the potential to act as a natural insecticide, and these findings offer theoretical justification for the effective use of plant resources.

Acknowledgements

This work was supported by the Guangdong Province Key Construction Discipline Promotion Project (2022ZDJS087) and Meizhou Science and Technology Fund (2021B0204007, 2021B0201001). Research projects at Jiaying College (2023KJY05, 2022KJY09). Jiaying College Talent Research Initiation Project (2022RC39), Innovation and Entrepreneurship Training Program (202210582010).

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Effects of complex cocoa-based agroforests on citrus tree decline. Crop Prot.. 2020;130:105051

- [CrossRef] [Google Scholar]

- Progress in understanding Pseudocercospora banana pathogens and the development of resistant Musa germplasm. Plant Pathol.. 2018;67:759-770.

- [CrossRef] [Google Scholar]

- Essential oil of common thyme as a natural antimicrobial food additive. Food Technol. Biotechnol.. 2014;52:263-268.

- [Google Scholar]

- Sub-tissue localization of phytochemicals in Cinnamomum camphora (L.) J. Presl. Growing in Northern Italy. Plants. 2021;10:1008

- [CrossRef] [Google Scholar]

- Study of two-stage microwave extraction of essential oil and pectin from pomelo peels. LWT. 2016;66:538-545.

- [CrossRef] [Google Scholar]

- Essential oils from Carex meyeriana Kunth: optimization of hydrodistillation extraction by response surface methodology and evaluation of its antioxidant and antimicrobial activities. Ind. Crop. Prod.. 2018;124:669-676.

- [CrossRef] [Google Scholar]

- Extraction of essential oil from leaves of lemongrass using microwave radiation: optimization, comparative, kinetic, and biological studies. ACS Sustain. Chem. Eng.. 2015;3:421-431.

- [CrossRef] [Google Scholar]

- Yield and quality of chia oil extracted via different methods. J. Food Eng.. 2019;262:200-208.

- [CrossRef] [Google Scholar]

- Gao, H., Zhao, R., Fan, C., Yang, Y., Wang, Z., Gu, H., Yang, L., Tian, H., Zhang, Q., Zhang, X., 2023. An efficient approach to obtain essential oil, oleanoic acid, 3-O-acetyloleanolic acid and betulinic acid from fresh leaves of Melaleuca bracteata F. Muell. “Revolution Gold” using microwave and gravity-assisted solvent-free distillation followed by extra. Ind. Crops Prod. 203, 117178. doi: 10.1016/j.indcrop.2023.117178.

- The chemical composition of essential oils from Cinnamomum camphora and their insecticidal activity against the stored product pests. Int. J. Mol. Sci.. 2016;17:1836

- [CrossRef] [Google Scholar]

- Comparison of antifungal activity of essential oils from different plants against three fungi. Food Chem. Toxicol.. 2019;134:110821

- [CrossRef] [Google Scholar]

- A comparison of extraction yield, quality and thermal properties from Sapindus mukorossi seed oil between microwave assisted extraction and Soxhlet extraction. Ind. Crop. Prod.. 2021;161:113185

- [CrossRef] [Google Scholar]

- GC×GC-TOFMS analysis of essential oils composition from leaves, twigs and seeds of Cinnamomum camphora L. presl and their insecticidal and repellent activities. Molecules. 2016;21:423

- [CrossRef] [Google Scholar]

- Khan, S., Sahar, A., Tariq, T., Sameen, A., Tariq, F., 2023. Chapter 1 - Essential oils in plants: Plant physiology, the chemical composition of the oil, and natural variation of the oils (chemotaxonomy and environmental effects, etc.). In: Nayik, G.A., Ansari, M.J.B.T.-E.O. (Eds.), Academic Press, pp. 1–36. doi: 10.1016/B978-0-323-91740-7.00016-5.

- Librelon, S.S., Pereira, F.A.C., de Pádua, P.F., Pereira, N.B.M., Gomes, L. de B.W., Pereira, R., Pereira, L.F., Pozza, E.A., de Souza, E.A., 2022. Pseudocercospora griseola, the causal agent of common bean angular leaf spot: strain characterization and sensitivity to fungicides. Plant Pathol. 71, 1431–1439. doi: 10.1111/ppa.13556.

- Optimization of microwave-assisted extraction of essential oil from lavender using response surface methodology. J. Oleo Sci.. 2018;67:1327-1337.

- [CrossRef] [Google Scholar]

- Cinnamomum camphora fruit peel as a source of essential oil extracted using the solvent-free microwave-assisted method compared with conventional hydrodistillation. LWT. 2022;153:112549

- [CrossRef] [Google Scholar]

- Application of ionic liquids based microwave-assisted simultaneous extraction of carnosic acid, rosmarinic acid and essential oil from Rosmarinus officinalis. J. Chromatogr. A. 2011;1218:8480-8489.

- [CrossRef] [Google Scholar]

- Microwave hydrodiffusion and gravity versus conventional distillation for Acacia dealbata flowers. Recovery of bioactive extracts for cosmetic purposes. J. Clean. Prod.. 2020;274:123143

- [CrossRef] [Google Scholar]

- Study on the composition and physiological activity of the essential oils and extracts of Cinnamomum camphora fruit. Chem. Biodivers.. 2021;18:e2100201

- [CrossRef] [Google Scholar]

- Sonohydrodistillation: innovative approach for isolation of essential oil from the bark of cinnamon. Ind. Crop. Prod.. 2019;142:111838

- [CrossRef] [Google Scholar]

- Antioxidant activity and quality attributes of white chocolate incorporated with Cinnamomum burmannii Blume essential oil. J. Food Sci. Technol.. 2020;57:1731-1739.

- [CrossRef] [Google Scholar]

- Essential oil extraction from fresh needles of Pinus pumila (Pall.) Regel using a solvent-free microwave-assisted methodology and an evaluation of acetylcholinesterase inhibition activity in vitro compared to that of its main components. Ind. Crop. Prod.. 2021;167:113549

- [CrossRef] [Google Scholar]

- Separation of essential oil from fresh leaves of Phellodendron amurense rupr. By solvent-free microwave-assisted distillation with the addition of lithium salts. J. Clean. Prod.. 2022;372:133772

- [CrossRef] [Google Scholar]

- Essential oils of Cinnamomum loureirii and Evolvulus alsinoides protect guava fruits from spoilage bacteria, fungi and insect (Pseudococcus longispinus) Ind. Crop. Prod.. 2020;154:112629

- [CrossRef] [Google Scholar]

- Study on the mechanism of ionic liquids improving the extraction efficiency of essential oil based on experimental optimization and density functional theory: the fennel (Foeniculi fructus) essential oil case. Molecules. 2021;26:3169

- [CrossRef] [Google Scholar]

- Improved hydrodistillation process using amphiphilic compounds for extraction of essential oil from java citronella grass. Chem. Pap.. 2020;74:145-156.

- [CrossRef] [Google Scholar]

- In vitro and in vivo activity of essential oils extracted from Eucalyptus staigeriana, Eucalyptus globulus and Cinnamomum camphora against Alternaria solani Sorauer causing early blight in tomato. Sci. Hortic. (Amsterdam). 2017;223:72-77.

- [CrossRef] [Google Scholar]

- Tran, T.H., Ke Ha, L., Nguyen, D.C., Dao, T.P., Thi Hong Nhan, L., Nguyen, D.H., Nguyen, T.D., N. Vo, D.-V., Tran, Q.T., Bach, L.G., 2019. The study on extraction process and analysis of components in essential oils of black pepper (Piper nigrum L.) seeds harvested in Gia Lai Province, Vietnam. Processes 7, 56. doi: 10.3390/pr7020056.

- Influence of phenolic compounds on physicochemical and functional properties of protein isolate from Cinnamomum camphora seed kernel. Food Hydrocoll.. 2020;102:105612

- [CrossRef] [Google Scholar]

- Optimization of ionic liquid based microwave assisted extraction of five anthraquinones from Polygonum cuspidatum by response surface method. Zhongyaocai. 2014;37:871-875.

- [Google Scholar]

- An improved approach of salting-out solvent-free microwave mediated rotary distillation for essential oil preparation from fresh leaves of magnolia (Oyama sieboldii) Food Chem. X. 2022;16:100524

- [CrossRef] [Google Scholar]

- Pseudocercospora leaf and fruit spot disease of citrus: achievements and challenges in the citrus industry: a review. Agric. Sci.. 2013;4:324-328.

- [CrossRef] [Google Scholar]

- Anti-microbial activity of citronella (Cymbopogon citratus) essential oil separation by ultrasound assisted ohmic heating hydrodistillation. Ind. Crop Prod.. 2022;176:114299

- [CrossRef] [Google Scholar]