Translate this page into:

Gasification char residues management: Assessing the characteristics for adsorption application

⁎Corresponding author. anisatikah@unimap.edu.my (Anis Atikah Ahmad)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Due to the world-wide energy crisis and economic issues, biomass has become a resource of global interest as an alternative to activated carbon (AC) produced using non-renewable feedstock (i.e. coal-based). The production of AC from biomass has been determined to be sustainable owing to the abundance of biomass resources on Earth. Biomass gasification has significantly gained market interest and was predicted to reach a value of USD 126 billion by 2023. A critical concern for the existing commercial gasification plants is the handling of char residues, which represent approximately 10% of the initial feedstock mass and are presently treated as waste. The conversion of these chars into AC that can be used for adsorption applications is a possible alternative. This review article focuses on evaluating the characteristic of the gasification char (GC) that is used for adsorption processes. The current AC production method was briefly reviewed. In addition, recent studies on adsorption using GC were explored and summarised.

Keywords

Activated carbon

Gasification char residues

Adsorption

Solid waste

1 Introduction

Biomass gasification has gained significant attention recently, particularly in developing countries. The IMARC Group estimated that the gasification market reached USD 78 billion in 2017 and anticipated an increasing trend up to USD 126 billion by 2023 (IMARC Group, 2017). Gasification is a thermochemical process where carbonaceous materials are converted into gaseous products at temperatures from 600 to 1000 °C, in the presence of a gasification agent, such as air, oxygen, steam, or a combination of these (Ahmad et al., 2016). The main product of gasification is synthetic gas (usually a mixture of H2, CH4, CO, and CO2), and its composition usually depend on the initial feedstock properties and operational conditions (Ahmad et al., 2016; Al-zareer et al., 2016; Galindo Al et al., 2014), whereby the by-products include char, tar, and water vapor. The gasification char (GC) is the irregularly shaped particles which comprised of unreacted carbon with several amounts of siliceous ash. It has well-developed pore properties and potentially become an excellent adsorbent or/and precursor for activated carbon (AC) production. The flow rates of biomass feedstock and gasification agent, equivalence ratio, reactor temperature, and pressure are among the important operating parameters that critically affect the process.

One of the challenges in biomass gasification industry is the solid waste disposal mostly in the form of char, which represents approximately 5–10% of the initial feedstock (De Gisi et al., 2016). Presently, char is treated as waste, which is considered to be an actual loss for plant owners (Benedetti et al., 2017) and no special disposal method has been employed. The growth of gasification industry will create a substantial increase in solid waste management problem. Hence, it is beneficial to seek an alternative application for GC. From the previous finding, GC has shown a reliable performance as an adsorbent in water and wastewater treatment application. However, the research on the GC application in adsorption is quite limited. Several reported literatures regarding its application in adsorption includes malachite green (MG) (Ahmad et al., 2021; Ahmad et al., 2020; Ahmad et al., 2020), rhodamine B (RhB) (Maneerung et al., 2016); methylene blue (MB) (Ahmad et al., 2023; Pessôa, 2019) & amaranth (AM) (Ravenni et al., 2020); congo red (CR) and crystal violet (CV) (Jung et al., 2019); sulphate (Runtti et al., 2016), phosphate & nitrate (Kilpimaa et al., 2015; Kilpimaa et al., 2014), nickel, iron and copper (Runtti et al., 2014); atenolol (ATN) (Ahmad et al., 2020), acetaminophen (ACE) and caffeine (Galhetas et al., 2014; Galhetas et al., 2014), diclofenac (DCF) (Back et al., 2020), toluene (Bhandari et al., 2014) and chromium (III) removal (Godinho et al., 2017; Dias, 2018).

2 Gasification char (GC)

Char is the unreacted carbonaceous solid residue obtained after the gasification process. The physical and chemical properties of char are significant to determine its potential applications. The sorption performance and pore characteristics of adsorbents depend on their physical and chemical properties.

2.1 GC physicochemical properties

The specific Brunauer–Emmett–Teller surface area (SBET), total pore volume (TPV), and average pore diameter (APD) of char are among the most important factors that influence its adsorption performance. The SBET of char is the ratio of the total pore surface area to the total char particle mass (You, 2017). The pore size determines the accessibility of the active sites and mass transfer limitation. According to the International Union of Pure and Applied Chemistry, micropores, mesopores, and macropores are pores featuring diameters of < 2, 2–50, and > 50 nm, respectively (Maneerung et al., 2016; Pessôa, 2019). Particles presenting different pore sizes can be expected to exhibit different behaviours during adsorption, as the pressure increases. The sorption behaviour in micropores is almost entirely dominated by the interactions between the fluid molecules and pore walls. By contrast, the sorption behaviour in mesopores depends not only on the fluid-wall attractions, but also on the attractive interactions between fluid molecules, which leads to multilayer adsorption and capillary condensation (Thommes, 2010).

The properties of GC are influenced by the gasificiation operating paremeter such as temperature and biomass equivalence ratio (ER). For instance, increasing the gasification temperature can promote the release of volatiles which subsequently increase the char porosity. However, too high temperatures may cause the break-down of pore walls and the consequent sintering of the material with consequent porosity reduction (Benedetti et al., 2017). Zhai et al. (Zhai, 2017) characterised sawdust char obtained at high gasification temperature in steam atmosphere using a fixed bed reactor and discovered that the carbon conversion rate increased as the reaction temperature, time, and steam flow rate increased. The SBET of sawdust ash increased from 948.84 and 987.61 m2/g when the temperature reached 800 and 1000 °C, respectively. Similar observation was found by Pelaez-samaniego et al. (Pelaez-samaniego et al., 2020) who gasified wood in 0.4 × 0.102 m (length × internal diameter) reverse downdraft gasifier. The upsurge trend of char SBET from 379 to 517 m2/g was reported with increasing temperature from 725 to 838 °C. This was due to the release of volatiles and tar at high temperatures (Tian et al., 2020). Besides, a remarkable improvement of pore structure was observed by Zhang et al. (Zhang et al., 2020) with the SBET and TPV prominently increased from 186 to 552 m2/g and 0.252 to 0.665 cm3/g, respectively, due to the increase of gasification rate in Boudouard reaction at high temperature. Higher gasification temperature could accelerate the carbon burn-off, leading to the broadening of the existing pores and thus enlarging the surface area or pore volume (Zhang et al., 2018; Zhang et al., 2018). However, at very high temperature (>1200 °C), the excessive consumption of the residual carbon matrix in the char could lead to the collapse of the developed porous structure; the blockage of some pores (due to enrichment of the inherent inorganic elements); and the fusion and sintering of the pores (Zhai, 2017). In general, increasing operating temperature can extremely increase the gasification reaction rate, but at very high temperature, the char surface area and pore volume may not be linearly improved.

Another important parameter in gasification is ER, which is defined as the ratio of the biomass mass flow rate to the air mass flow rate divided by the same ratio at the stoichiometry of the reaction considered (Palies, 2020). The increase in the relative biomass/air ratio resulted in producing more aromatic and stable char, and the increase in carbonisation reaction extent. Qian et al. (Qian, 2013) investigated the effects of biomass (switchgrass, sorghum straw and red cedar) and ER (0.20, 0.25 and 0.28) on the physiochemical properties of GC, and determined that as the ER increased, the ash content and SBET of most char increased, while the moisture and fixed carbon contents of the char decreased. Furthermore, using Fourier transform infrared spectra results, they concluded that the surface functional groups of char were found to differ between biomass types, but remained similar with the change in ER. Meanwhile, Liu et al. (Liu, 2018) reported that the volatile and fixed carbon of the chars decrease with ER rising, leading to the increase in the ash content. This was due to the increase in the ratio of oxygen and fuel with ER rising, resulting in more consumption of fixed carbon in the gas–solid reactions.

Char production was reported to increases from 0.15 kg/kg to 0.18 kg/kg when increasing ER from 1.6 to 4.6 (Hernández et al., 2016). Higher ER values also lead to a decrease in the bulk density of the produced char, which indicates the fuel conversion through the release of volatile matter and the conversion of a fraction of the remaining char via heterogeneous reactions (partial oxidation, steam reforming, and Boudouard reaction). Hernández et al. (Hernández et al., 2016) also reported that the carbon content of the char increases from 40% to 55% wt. when increasing the ER, which confirms the progressive carbonisation of the char. However, they found that all the obtained chars have low SBET (<70 m2/g), which is not suitable for adsorption application without further activation. In another study, GC from straw gasification was reported to have high SBET of 1027 m2/g (Hansen et al., 2015).

Maneerung et al. (Maneerung et al., 2016) reported that the char has high surface area after steam activation at 900 ⁰C, proving that activated GC generally have a higher SBET. They prepared AC from woody biomass gasification for dye adsorption and discovered that the SBET had a significant increment from 172 to 776 m2/g, which gave it high dye adsorption capability.

In their study on the rate of biomass gasification, Lundberg et al. (Lundberg et al., 2016) found that the SBET of the GC varied from 469 to 1581 m2/g, depending on different boundary conditions. Similarly, Dias et al. (Dias, 2017) compared the characteristics of chars from the gasification and pyrolysis of rice waste streams as potential adsorbent materials. They discovered that GC had SBET ranging from 26.9 to 62.9 m2/g, while pyrolysis chars lacked a porous matrix due to their high volatile matter content. The authors suggested that GC had favorable properties for adsorption and could be further developed for this purpose, whereas the pyrolysis chars required additional activation.

The choice of feedstock source can significantly affect the final properties of GC. Wood-based GC tend to have a higher SBET and TPV compared to other feedstocks (Oni et al., 2019). This can be attributed to the reduction of relatively large cell structures in wood to smaller pores during gasification, resulting in an overall increase in SBET (Weber and Quicker, 2018) and consequently, PV. The increase in SBET and TPV may also be related to the loss of micro-molecule organic compounds and volatilization of gases or water during gasification, leading to the creation of voids within the GC matrix (Ippolito, 2020). On the other hand, GC produced from manures/biosolids typically exhibit lower SBET, which is likely due to deformation, structural cracking, or micropore blockage during gasification, along with less distinct porous structures in the feedstock (Ahmad, 2014).

In a nutshell, the GC properties vary among the samples depending on the combination of gasification technology, temperature, gasification agent, ER and initial feedstock (Benedetti et al., 2017). Table 1 summarises the physical characteristics of GCs reported in the literature. ER = Equivalance ratio, a = Total micropore volume.

Feedstock

Type of gasifier

Gasification agent

Temperature (°C)

SBET (m2/g)

TPV

(10-3 cm3/g)Reference

Switchgrass

Fluidised bed

Air (ER = 0.28)

700–800

21

11.88a

(Qian, 2013)

Sorghum

Air (ER = 0.28)

5.6

2.14a

Red cedar

Air (ER = 0.25)

61

31.33a

Wheat straw pellet

Circulating fluidised bed

Steam

750

75

40

(Hansen et al., 2015)

Pine wood

Two stage

1000–1200

1027

580

Sieved pine wood

426

520

Dealcoholised marc of grape

Entrained flow

Air

1200

60

N/A

(Hernández et al., 2016)

Steam

1200

35

Activated mesquite wood chips

Downdraft fixed-bed

N/A

N/A

776

657

(Maneerung et al., 2016)

Soft wood chips

Bubbling fluidised bed

Steam

850

489

N/A

(Lundberg et al., 2016)

Soft wood pellets

1581

Sawdust

Fixed bed

Steam-air

800–1000

945–988

N/A

(Zhai, 2017)

Rice husk and polyethylene mixture

Bubbling fluidised bed

Steam-air

850

27–63

N/A

(Dias, 2017)

Wood chips

Downdraft

Air

∼650

352

240

(Benedetti et al., 2017)

Pellets

Rising co-current

Air

∼700

128

180

Wood chips

Downdraft

Air

∼650

78

80

Wood chips

Downdraft

Air

∼800

281

130

Wood chips

Dual-stage

Air

∼900

587

300

Wood chips

Dual-stage

Air

∼850

272

150

Pine wood

N/A

N/A

600–900

N/A

N/A

(Marks et al., 2016)

Switchgrass

Downdraft

N/A

N/A

64

90

(Bhandari et al., 2014)

Switchgrass

Fluidised bed

N/A

N/A

2

20

Pine wood

Updraft

Air

1000

183

90

(Huggins et al., 2015)

Poplar wood

Fluidised bed

Steam

750

573.8

219

(Ducousso et al., 2015)

Woodchip

Downdraft

Air

725–838

517

288.8

(Pelaez-samaniego et al., 2020)

Coal

N/A

CO2

800–950

346.74

262.7

(Liu, 2021)

Miscanthus

N/A

Steam

1000

981.75

566.5

(Tian et al., 2020)

Glyricidia sepium woodchip

Downdraft

Air

N/A

39.52

28.0

(Ahmad et al., 2020)

Woodchip

Downdraft

Air

N/A

257.96

87.5

(Ahmad et al., 2020)

Hevea brasiliensis root

Downdraft

Air

N/A

135.22

80.0

(Ahmad et al., 2021)

Numerous papers have been published on the characterisation of GCs. From the available data, the chars featuring high SBET and TPV values were gasified at high temperature and steam was used as gasification agent. The SBET and TPV values of GCs ranged from 2 to 1581 m2/g and 0.002 to 0.657 cm3/g, respectively, and these values were comparable with those of AC, which exhibited SBET and TPV values ranging from 500 to 2000 m2/g and 0.20 to 0.60 cm3/g, respectively (Marsh and Rodríguez-Reinoso, 2006). Therefore, these chars are suitable to be developed as low-cost adsorbents, as they are more affordable and their production require lower energy amounts than AC (since the production of GCs does not involve a carbonisation step). Moreover, the feedstocks for the production of GCs are abundant and are mainly obtained from biowastes.

Despite exhibiting good physical properties, GC cannot be used as sole indicator of good pollutants removal (Abdelhadi et al., 2017). Seredych et al. (Seredych et al., 2009) studied the removal of dibenzothiophene (DBT) and 4,6-dimethyldibenzothiophene (4,6-DMDBT) from effluents using different types of carbon and reported that, although the adsorption of DBT and 4,6-DMDBT was mainly due to the presence of small micropores in the structure of GC, the acidic groups located in the larger pores of the char additionally attracted the DBT and 4,6-DMDBT molecules via specific interactions. In addition, they suggested that the specific carbons that were required for the removal of DBT and 4,6-DMDBT should present high volumes of pores smaller than 10 Å coupled with certain numbers of strong acidic groups in the slightly larger pores, which would enhance the specific adsorption/surface reactions and at the same time would not block or limit the accessibility of the small pores. These findings demonstrated that the physical properties of chars are not the only factors that could affect the adsorption process. Therefore, it is important to study the chemical properties of GCs.

The chemical characteristics of GC that are relevant to adsorption applications include the carbon and ash contents, functional groups, aromaticity, and pH. Table 2 summarises the total carbon, ash, and elemental composition of several types of GCs. Char presenting high carbon content (50–90%) is suitable to be transformed into AC, which could be used for adsorption (Danish and Ahmad, 2018).

Feedstock

Technology

Gasification agent

Temperature (°C)

Carbon (%)

Fixed carbon (%)

Volatile matter (%)

Moisture (%)

Ash

(%)Reference

Switchgrass

Fluidised bed

Air (ER = 0.20, 0.25, 0.28)

700–800

43.19

15.01

70.36

9.7

4.62

(Qian, 2013)

Sorghum

40.68

17.46

68.1

9.39

5.05

Red cedar

47.51

15.62

71.79

8.5

4.09

Sorghum

Downdraft

Air (ER = 0.20)

850

67.9

66.8

12.2

0.8

20.2

(Qian et al., 2015)

Red cedar

66.4

71.7

22.8

1.0

4.5

Pine wood

N/A

N/A

600–900

79.34

N/A

8.0

N/A

10.79

(Marks et al., 2016)

Poplar wood

Fluidised bed

Steam

750

77.4

N/A

N/A

6.2

3.6

(Ducousso et al., 2015)

Glyricidia sepium woodchip based

Downdraft

Air

N/A

59.87

67.23

13.51

9.65

9.63

(Ahmad et al., 2020)

Woodchip

Downdraft

Air

N/A

58.74

75.88

10.79

8.16

5.17

(Ahmad et al., 2020)

Hevea brasiliensis root

Downdraft

Air

N/A

75.12

77.95

10.44

6.51

5.11

(Ahmad et al., 2021)

Corn stover

Fluidised bed

Steam

850

42.0

41.4

8.4

3.2

47.1

(Cheah et al., 2014)

Oak

76.9

N/A

N/A

0.3

N/A

Spruce wood chips

Downdraft

Air

800

87.6

N/A

N/A

N/A

N/A

(Ravenni et al., 2020)

Municipal solid wast

Downdraft

Steam + Air

N/A

48.3

23.6

26.0

N/A

50.4

(Jung et al., 2019)

Oil sludge

Furnace

Steam

900

5.61

0.13

12.49

1.05

86.33

(Zhiwei, 2021)

Woodchip

Dual stage

Air

850

91.4

N/A

N/A

N/A

4.2

(Benedetti et al., 2019)

Penicillin mycelial dreg and

Thermogravimetric analyzer

Steam

1000

59.64

N/A

N/A

N/A

29.47

(Yuan, 2021)

Pinus patula woodchip

Downdraft

Air

N/A

75.98

89.51

7.23

2.88

3.26

(Pelaez-samaniego et al., 2020)

Pine sawdust

Fixed-bed

CO2

N/A

84.83

79.80

19.68

2.01

0.56

(Zhang et al., 2020)

Data on functional groups provide information on the possible interactions between adsorbents and adsorbates. Carboxylic acids, anhydrides, lactones, lactols, and phenols, are acidic, carbonyl and ether groups are neutral, while quinone, chromene, pyrone, and nitrogen groups are basic (Zhai, 2017; Pelaez-samaniego et al., 2020). For AC (Tian et al., 2020; Zhang et al., 2020) and chars (Langley and Fairbrother, 2007), greater amounts of oxygen-containing surface functional groups (especially carboxyl) result in enhanced sorption capacities for metal ions in controlled aqueous media (Uchimiya et al., 2011).

Ogata et al. (Ogata et al., 2011) reported that the sorption capacity of wheat bran for heavy metals depended on the components of the sorbent (pectin and carboxyl groups). Zhong et al. (Zhong et al., 2018) modified commercial AC using nitric acid oxidation and heat treatment at different temperatures to produce different amounts of oxygen-containing surface functional groups. They determined that the oxygen-containing surface functional groups, especially carboxylic groups, controlled the adsorption of MB and methyl orange by AC. Meanwhile, Ducousso et al. (Ducousso et al., 2015) reported that phenol, ether, and quinone were determined to be the dominant oxygen-containing groups on the surface of wood chip gasification biochar. Stavropoulos (Stavropoulos et al., 2008) reported that the phenol adsorption capacity of AC could be enhanced by increasing the content of functional groups on its surface.

Generally the number of functional groups on the surface of GC is small owing to the significant loss of functional groups, such as hydroxyl, carboxyl, and carbonyl at high gasification temperature (Wiedner et al., 2013). Moreover, the number of functional groups also depends on the feedstock used for producing the char. A higher O/C ratio for a char material could indicate the presence of more functional groups (such as hydroxyl, carboxyl, and carbonyl), which could contribute to a higher cation exchange capacity value (Hansen et al., 2015; Lundberg et al., 2016), owing to the higher negative charge on the surface of the char (Xu et al., 2011). Scholars predicted that electrostatic interactions could occur between the negatively charged char surface and positively charged pollutants (Şolpan et al.).

A high degree of carbonisation removes the acidic functional groups of the feedstock, therefore causing the char surface to become basic (Shen et al., 2016). Depending on the feedstock used to produce char, the pH of GC is generally alkaline (7 < pH < 12) (Ippolito, 2020; Ahmad, 2014). The basicity of char is attributed to the presence of small amounts of oxygen-containing groups on its surface. These groups are responsible for the electrostatic interactions between the positively charged char and negatively charge pollutants. In addition, the presence of alkali and alkaline metals such as K and Ca also lead to the alkaline pH (Saffe et al., 2020).

The degree of aromaticity of GC is generally higher (Abdulrazzaq et al., 2014) at high temperature (Huggins et al., 2015; Ducousso et al., 2015). This indicates that GC presents high chemical stability, therefore making it suitable for soil amendment and adsorption applications.

In conclusion, the characteristics of char such as its porous structure, high SBET, large number of surface functional groups, and mineral content make it suitable as adsorbent for removing pollutants from the environment (Marsh and Rodríguez-Reinoso, 2006; Abdelhadi et al., 2017). The oxygen-rich functional groups, including C⚌O, C—O, and aromatic groups on the surface of GC could act as strong active sites and promote its adsorption capability (Xue, 2012).

3 Adsorption

Adsorption is a mass transfer process whereby elements gather at the interface of two different phases, such as gas–solid and liquid–solid (De Gisi et al., 2016; Xue, 2012). The adsorbed substance is called adsorbate, while the substance used to adsorb the adsorbate is called adsorbent. Adsorption can be either a chemical (chemisorption) (Aljeboree et al., 2017) or/and physical (physisorption) process (Toumi, 2018). Generally, for physisorption, the attractive forces between the adsorbate molecules and adsorbent are Van der Waals forces, which are weak in nature and result in reversible adsorption. On the other hand, if the attraction forces are due to chemical bonding, the adsorption process is called chemisorption. Chemisorption is characterized by the formation of strong chemical associations between the molecules or ions of adsorbate and the adsorbent surface, which are generally due to the exchange of electrons between them and thus, chemisorption is generally irreversible. In general, the adsorption process involves both chemical and physical adsorption.

Adsorption has been determined to be superior to other pollutants removal techniques owing to its flexibility and simplicity of design, high efficiency, insensitivity to toxic pollutants, and ease of operation compared to other removal techniques such as membrane separation, ion exchange, coagulation/flocculation, chemical oxidation, electrochemical, photochemical and biodegradation. Table 3 summarizes the advantages and disadvantages of various pollutant removal methods.

Technology

Advantages

Disadvantages

Adsorption

High efficiency, offer excellent quality of the treated effluent, simple operation (simple equipment, adaptable to many treatment process)

Ineffective to certain pollutants, issues on the disposal of adsorbent residues (elimination of the adsorbent requires incineration, regeneration or replacement of the material).

Membrane separation

Small space requirement, simple, rapid and efficient even at high concentrations

Investment costs are often too high for small and medium industries, high energy requirements, high maintenance and operation costs.

Ion exchange

Rapid and efficient process

Ineffective for certain target pollutants (disperse dyes, drugs, etc.), performance sensitive to pH of effluent, require regular inspection and unloading and loading of new exchange resins, which are disruptive to operations and mean ongoing operational costs

Coagulation/ Flocculation

Rapid and efficient for insoluble contaminants

(pigments, etc.) removalHigh sludge production and disposal issues, requires accurate chemical dosing (this may be an unsuitable wastewater treatment method if the inlet water quality fluctuates often

Advanced oxidation process

High efficiency, rapid

Sludge production, economically unfeasible, high chemical reagents and electricity consumption, formation of by-products

Electrochemical process

High efficiency (more effective and rapid organic matter separation than in traditional coagulation), does not require the addition of chemical reagents

High initial cost of the equipment, high electricity consumption

Photochemical process

No sludge production, rapid

The formation of by-products and power consumption

In adsorption, the removal efficiency depends on the pore characteristics and the surface functional groups of the adsorbent. This information can be examined from the physical and chemical properties of the adsorbent.

4 Activated carbon

Activated carbon is the generic term used to describe a family of carbonaceous adsorbents exhibiting highly amorphous and extensively developed internal pore structure. Activated carbon has been demonstrated to be an effective adsorbent for a wide variety of pollutants from aqueous or gaseous media. Moreover, AC is widely used owing to its exceptionally high surface area (500–1500 m2/g), well-developed internal microporosity (pore size distribution of < 1–100 nm), and wide spectrum of surface functional groups (carboxyl, carbonyl, hydroxyl, and amine) (Zhai, 2017; Danish and Ahmad, 2018). All these characteristics confer AC the extraordinary capacity to adsorb a great diversity of molecules (Ahmad et al., 2020).

Activated carbon can be prepared by physical and chemical activation. Physical activation consists of two steps. The first step involves carbonisation, whereby the precursor material is pyrolyzed in an inert atmosphere at medium–high temperature (300–800 °C) (Danish and Ahmad, 2018; Rivera-Utrilla et al., 2011). The product resulted after carbonisation is called char. The second step is the activation of char at high temperature (700–1000 °C) in the presence of activating agents, such as CO2 or steam. Since the reactivity of CO2 at high temperature is lower than that of steam, the activation process using CO2 can be easier to control, and therefore, CO2 is more commonly used as activating agent. Additionally, CO2 activation favours microporosity formation, while steam activation favours microporosity widening. Therefore, AC prepared using steam exhibits lower micropore volume, but larger meso- and macropore volumes than AC prepared using CO2 (Pallarés et al., 2018).

For chemical activation, the carbon sample is impregnated with various activation agent (e.g. KOH, ZnCl2, FeCl3, H3PO4, and H2SO4) (Shafeeyan et al., 2010; Sánchez-Polo and Rivera-Utrilla, 2002; Klasson et al., 2009), and subsequently, this mixture is pyrolyzed in a conventional furnace (Ribas, 2014) or microwave oven (Rodrigues et al., 2011). The resulting AC product often possesses a large surface area per unit of volume and multi-channel pores that aid the adsorption process (Ogungbenro et al., 2018). Activation agents facilitate the carbonaceous materials decomposition and enhance the carbon yield (Duan et al., 2017). KOH is widely applied and preferred as compared to other activators due to its major role in the improvement of specific surface area as well as porosity (produces wide and narrow micropores) (Singh et al., 2019). Liu et al. (Liu et al., 2012) reported that the AC prepared by KOH showed improvement in O-containing functional groups. Meanwhile, Shu et al. (Shu et al., 2013) found that the use of ZnCl2 required low energy consumption, but its volatility and toxicity posed a negative environmental impact. H3PO4 treatment offers low operating cost, but the AC specific surface area is somehow smaller than KOH activation (Rajapaksha, 2016).

AC can also be produced through physicochemical activation which combined physical and chemical activation process. It is conducted when chemical activator is not completely diffused which results in pore clogging. This process involves the sample impregnation with chemical agent followed by heating step with the existence of oxidizing gas at 200–900 °C (Chowdhury et al., 2011). The combination of physical and chemical activation promotes the improvement of the pores textural and chemical characteristics compared to single activation method (physical or chemical activation).

However, at industrial scale, physical activation is preferred, to avoid the use of chemicals, which can reduce both the costs of the process and associated pollution. In addition, it could be concluded that physical activation is more adequate than chemical activation for preparing AC intended for applications that require accurate control of pore size distribution (Prauchner and Rodríguez-Reinoso, 2012). Table 4 summarises the activation agents that have been studied for the synthesis of AC. TPV = Total pore volume, APD = Average pore diameter.

Feedstock

Activation agent

Application

SBET (m2/g)

TPV (cm3/g)

APD (nm)

Reference

Coffee grounds

H3PO4

Methylene blue and Nylosan Red removal

925.00

0.718

>3

(Reffas, 2010)

Celery residues

H2SO4

Congo red removal

24.93

0.041

N/A

(Mohebali et al., 2019)

Banana peels

KOH

Methylene blue and Co2+ removal

1396.60

0.750

N/A

(Yu et al., 2018)

Corn starch

KOH

Pyraclostrobin removal

160.60

0.095

2.37

(Suo, 2019)

Pistachio wood wastes

NH4NO3

Hg2+ removal

1448.00

0.901

2.48

(Sajjadi, 2018)

Alga (Ulva lactuca)

KOH

Cu2+, Cr3+, Cd2+, and Pb2+ removal

193.90

0.108

1.113

(Ibrahim et al., 2016)

Plum stones

H3PO4

Cd2+ and Pb2+, Ni2+, and chlorophenols removal

829.00

0.418

1.008

(Pap et al., 2017)

Glebionis coronaria L.

KOH

Cd2+ and Co2+ removal

174.30

N/A

N/A

(Tounsadi, 2016)

Apricot stones

H3PO4

Congo red removal

88.05

0.2641

17.632

(Abbas and Trari, 2015)

Date pits

FeCl3

Methylene blue removal

780.06

0.573

N/A

(Theydan and Ahmed, 2012)

Waste tea

H3PO4

Methylene blue and phenol removal

1398.00

1.177

N/A

(Gokce and Aktas, 2014)

Tomato stems

FeCl2

Congo red removal

971.00

0.576

2.782

(Fu et al., 2017)

Rice straw

KOH

Acetaminophen and ibuprofen removal

1330.50

0.522

N/A

(Nam et al., 2018)

Tara gum

FeCl3

Antipyrine removal

1680.00

0.990

N/A

(Bedia et al., 2018)

Caesalpinia ferrea seed pod wastes

ZnCl2

Captopril removal

1480.00

0.572

N/A

(Kasperiski, 2018)

Date palm tree fronds

CO2

N/A

1094.00

0.438

1.609

(Shoaib and Al-swaidan, 2015)

Rubber-seed shells

Steam

N/A

948.00

0.988

3.650

(Sun and Jiang, 2010)

Coffee grounds

KOH-steam

Phenol and methylene blue removal

1865.00

0.960

N/A

(Laksaci et al., 2017)

Crofton weed

CO2

N/A

1036.00

0.710

2.750

(Zhao-qiang et al., 2014)

Fish waste

Steam

N/A

N/A

N/A

N/A

(Fadhil et al., 2017)

Pinewood soot

Steam

Phenol and chlorine removal

470.00

1.300

N/A

(Trubetskaya et al., 2019)

Tyre carbon black

Steam

470.00

0.600

N/A

Beechwood soot

Steam

260.00

0.500

N/A

Wheat straw soot

Steam

400.00

N/A

N/A

Macadamia nut shells

Steam

N/A

844.00

0.4852

2.301

(Aworn et al., 2008)

CO2

487.00

0.2522

2.070

Corncob

Steam

675.00

0.3590

2.128

CO2

836.00

0.4258

2.042

Bagasse bottom ash

Steam

595.00

O.3953

2.679

CO2

546.00

0.3059

2.434

Sawdust fly ash

Steam

613.00

0.4926

3.216

CO2

816.00

0.5469

2.682

Rice husk fly ash

Steam

74.00

0.0532

2.894

CO2

39.00

0.0296

3.014

Previous studies mostly mentioned KOH, ZnCl2, FeCl3, H3PO4, and H2SO4 as activation agents for chemical activation to improve the textural properties and sorption capability of AC. However, it is worth highlighting that chemical activators such as NH4NO3 and FeCl2 are comparable with conventional activators. Meanwhile, steam and CO2 are commonly used for physical activation.

Presently, most of the CAC is synthesised from non-renewable precursors such as coke, pitch, and coal-based feedstock (Rashidi and Yusup, 2017). The major concerns when utilising these materials are related to their sustainability and high cost owing to the intensive regeneration and reactivation processes they have to undergo, which could also result in the degradation of their adsorption properties and subsequently affect the economic feasibility of the operation (Gupta et al., 2011). Another important AC precursor is coconut shell charcoal, which possess excellent properties as AC. However, the excessive demand of AC led to its mounting prices (Schaeffer, Jun. 2011), hence, other renewable, low-cost adsorbents that could be used on large-scale are needed. An adsorbent is considered “low-cost” if it requires little processing and is abundant in nature, or waste material from another industry, which has lost its economic value (Yagub et al., 2014).

5 Recent studies on adsorption applications

Khasri et al. (Khasri et al., 2018) studied the removal of MB using Pentace species sawdust AC (PSAC). They reported that the optimum activation conditions for PSAC were reached when the radiation power, radiation time, and impregnation ratio were 418 W, 6.4 min, and 0.5, respectively, which resulted in the 27% PSAC yield and 94% MB removal. They also reported that the SBET, TPV, and APD of PSAC were 914.15 m2/g, 0.52 cm3/g, and 3.19 nm, respectively.

The adsorption of acridine orange (AO) was studied using zinc oxide-almond shell AC powder (Zbair et al., 2018). Similar to the findings reported by Khasri et al. (Khasri et al., 2018), the adsorption of AO followed the pseudo second order kinetic model. The maximum removal of AO (99.43%) was achieved at neutral solution pH, when the concentration, temperature, and stirring time were 80 ppm, 40 °C, and 25 min, respectively. Zbair et al (Zbair et al., 2018) concluded that the electrostatic interactions, π-π interactions, and hydrogen bonding between AO and Zn2+/AC were the main possible phenomena involved in the adsorption mechanism.

Bouaziz et al. (Bouaziz et al., 2017) examined the potential of almond gum as low-cost adsorbent for the removal of MG from aqueous solutions. They studied the effects of the adsorbent dose, pH, contact time, particle size, initial dye concentration, temperature, and agitation on dye removal, and reported that the kinetic behaviour was similar with those observed by Khasri et al. (Khasri et al., 2018) and Zbair et al. (Zbair et al., 2018). Based on the thermodynamic changes in enthalpy, entropy, and free energy, Bouaziz et al. (Bouaziz et al., 2017) concluded that the adsorption of MG on the surface of almond gum was endothermic and occurred spontaneously.

The ability of pomelo peels to remove MB from aqueous solution was enhance by pre-treating them with ultrasounds at 30, 60, and 90% amplitude (Low and Tan, 2018). It was determined that the pre-treated pomelo peels required shorter time to reach their higher saturation limit of the adsorption capacity than the non-treated ones. The Dubinin–Radushkevich model fitted the adsorption isotherm data very well compared to the Langmuir, Freundlich, and Temkin models.

Ahmed & Hameed (Ahmed and Hameed, 2018) prepared pyrolyzed barley straws char for the adsorption of salicylic acid. They investigated the effects of the initial salicylic acid concentration (50–250 ppm), contact time (0–24 h), initial pH (3–11), and temperature (25–45 °C) on the adsorption performance of char, and reported that the equilibrium data fitted well to the Langmuir isotherm, the maximum salicylic acid uptake of 210.6 mg/g being reached at 45 °C. Moreover, they concluded that the adsorption of salicylic acid by char was spontaneous, endothermic, and occurred through chemisorption.

Wheat straw ash was used to synthesise NaY zeolite for the adsorption of tetracycline using the sol–gel method (Ali et al., 2018). The characteristics and effectiveness of NaY as adsorbent for tetracycline were evaluated, and it was determined that the SBET and TPV of the prepared NaY were 657.4 m2/g and 0.34 cm3/g, respectively. The Langmuir equation was successfully applied to analyse the isotherm data, and revealed the maximum equilibrium uptake of 230.7 mg/g at 50 °C.

Ogata et al. (Ogata et al., 2018) prepared wheat bran (WB) for the adsorption of Mo. They used virgin WB, calcined WB (at 200 to 1000 °C), and HCl treated WB (at HCl concentrations from 0.01 to 6.0 mol/L) and reported that the SBET of the calcined WB was larger than that of virgin WB. However, the amount of Mo adsorbed on the virgin WB was greater than that adsorbed on the WB treated using different concentrations of HCl. They concluded that the Mo adsorption mechanism was related to the three-dimensional protein structure of WB.

Table 5 summarises the findings of recent adsorption studies. SBET = specific Brunauer–Emmett–Teller surface area, TPV = total pore volume, APD = average pore diameter, PZC = point of zero charge, PSO = pseudo second order, PFO = pseudo first order, and HSDM = Homogeneous solid diffusion model, MB = methylene blue, AO = acridine orange, MG = malachite green, CR = congo red, OII = orange II, IR = impregnation ratio, qm = maximum monolayer adsorption capability, qs = Dubinin-Radushkevich constant related to adsorption capacity.

Feedstock

Physical properties

Activation conditions

Application

Adsorption capacity (mg/g)

Kinetics

Isotherm

Reference

Medical waste

SBET: 1379 m2/g

TPV: 0.778 cm3/g

APD: 2.25 nmPyrolyzed in an N2 atmosphere at 600 °C, KOH activation IR: 1,

calcined at 800 °CMB and reactive yellow (RY) removal

922.2 (MB)

343.4 (RY)PSO

Langmuir

(Ullah, 2022)

Peanut shell

SBET: 179.3 m2/g

TPV: 0.08 cm3/g

APD: 1.7 nmCarbonization & CO2 activation flow rate: 100 mL/min, heating rate: 5 °C/min

Naphthenic acids removal

884

Elovich

Langmuir

(Campos et al., 2022)

Pinecone, white popinac, and sugarcane bagasse biochar

N/A

Pyrolyzed in an N2 atmosphere at 550 °C for 4 hr and mixed with FeSO4‧7 H2O, and MnSO4 ‧ H2O at

Cu2+ removal

32.7–43.1

PSO

Langmuir

(Huang et al., 2023)

Butiacapitate residue

SBET: 914.15 m2/g

TPV: 0.52 cm3/g

APD: 3.19 nmTreatment with ZnCl2 IR: 1 and heating at 105 °C (48 h)

Paracetamol and ketoprofenon removal

134.52

N/A

Monolayer & double layer process model

(Yanan, 2022)

Pentace sawdust

SBET: 914.15 m2/g

TPV: 0.52 cm3/g

APD: 3.19 nmPower: 418 W

Time: 6.4 min

KOH IR: 0.5MB removal

357.14

PSO

Redlich Peterson

(Khasri et al., 2018)

Zinc oxide-almond shell

SBET: 1391.0 m2/g

TPV: 1.26 cm3/g

APD: 3.21 nmTemperature: 300 °C (2 h) then 800 °C (3 h) at 10 °C/min.

KOH IR: 5AO removal

909.1

PSO

Langmuir

(Zbair et al., 2018)

Almond gum

N/A

No activation

MG removal

196.07

PSO

Freundlich

(Bouaziz et al., 2017)

Pomelo peel (ultrasound pre-treated)

N/A

No activation

MB removal

113.14 (qs)

1883.88 (qm)N/A

Dubinin–Radushkevich

(Low and Tan, 2018)

Barley straw

SBET: 435.52 m2/g

TPV: 0.241 cm3/g

APD: 2.216 nmNo activation

Salicylic acid removal

210.56

PSO

Langmuir

(Ahmed and Hameed, 2018)

Wheat straw ash

SBET: 657.44 m2/g

TPV: 0.341 cm3/gNo activation

Tetracycline removal

230.69

PSO

Langmuir

(Ali et al., 2018)

Wheat bran

SBET: 0–260.9 m2/g

No activation

Mo removal

84.0

PSO

Langmuir

(Ogata et al., 2018)

Carbonised cellulose

N/A

No activation

Diclofenac sodium removal

27.3

PSO

Langmuir

(Feng et al., 2018)

Cashew nuts

SBET: 1871 m2/g

TPV: 1.254 cm3/gTreatment with ZnCl2 IR: 1.5 and carbonisation at 400 °C (2 h)

MB removal

456

N/A

Langmuir

(Spagnoli et al., 2017)

Pyrolyzed crab shells

SBET: 81.57 m2/g

TPV: 0.0861 cm3/g

APD: 4.22 nmNo activation

(only carbonisation by pyrolysis)MG and CR removal

12 502 (MG)

20 317 (CR)PSO (MG)

PFO and PSO (CR)Langmuir

(Dai, 2018)

Prunus dulcis leaves

SBET: 426.346 m2/g

TPV: 0.282 cm3/g

APD: 2.644 nmTreatment with NaOH IR: 5 and heating at 50 °C (4 h)

Acid green 25 removal

50.79

PSO

Langmuir

(Jain and Gogate, 2018)

Acacia mearnsii waste

SBET: 4.867 m2/g

Steam explosion (remove tannins)

Acetone + H2SO4 (acetosolv treatment)Crystal violet removal

280

HSDM

Freundlich

(Pereira et al., 2018)

Yerba mate

SBET: 20.74 m2/g

PZC = 4.7No activation

OII and MB removal

47 (OII)

52 (MB)PSO

Sips

(Albadarin et al., 2018)

Inula viscosa leaves

N/A

N/A

Zn2+ removal

N/A

PSO

Langmuir

(Rouibah, Jan. 2023)

Olive waste residue

PZC = 6.6

Treatment with KOH (0.2 M)

MB removal

504.9

N/A

Langmuir

(Ferkous, 2022)

Cotton fiber waste

N/A

Treatment with ZnCl2 IR: 1 and pyrolyzing at 500 °C (1 h)

CI Reactive Red removal

970.34

PSO

N/A

(Behloul, 2022)

Recent adsorption studies indicated the increasing trend in the utilisation of low-cost materials from agricultural residues as well as new applications of char for adsorbing polluting pharmaceutical compounds. However, the agricultural residue from biomass gasification plants (which is GC), has not been well explored yet.

6 Previous studies on liquid adsorption applications using GC residues

Contrarily to other materials used for adsorption studies, the use of gasification residues is scarcely found in the literature. The literature regarding its application in adsorption is somewhat limited to ion and dye removal. Only few researchers reported the emerging contaminant adsorption utilizing GC as adsorbent or precursor for AC.

6.1 Ion removal

The activated char from pine and spruce gasification have been used for removing nitrate and phosphate ions (Kilpimaa et al., 2015; Kilpimaa et al., 2014). Both physical and chemical activation was conducted using char from a downdraft gasifier. Physical activation by CO2 at high temperature was found to be the most effective process. The maximum monolayer adsorption capability (qm) of activated char for phosphate and nitrate removal was 80 and 20.5 mg/g, respectively. Similar type of char (pine & spruce) was used by Runtti et al. (Runtti et al., 2014) who studied the adsorption of iron, copper and nickel ions. They gasified the wood chips at a rate of 50 kg h − 1 in a 150 kW downdraft gasifier, operating at 1000 ⁰C. They found that the removal of metal ions by GC with and without chemical activation was 2–5 times greater than commercial AC. The highest maximum experimental sorption capacities (qm,exp) for iron, copper and nickel by GC were 20.5, 23.1 and 18.2 mg/g, respectively. They concluded that the GC (with and without chemical activation) could be utilized in wastewater treatment due to their high adsorption efficiency. In another study, Runtti et al. (Runtti et al., 2016) chemically activated GC using ZnCl2, BaCl2, CaCl2, FeCl2 and FeCl3, for sulphate removal. They revealed that the removal of sulphate ions using FeCl3 was notably higher (qm, exp = 19.55 mg/g) compared to the unmodified GC residue and commercially available AC (q m, exp = 7.59 mg/g). The sorption data exhibited PSO kinetics, while the isotherm analysis indicated that the sorption data can be represented by the bi-Langmuir isotherm model.

Godinho et al. (Godinho et al., 2017) analysed the efficiency of chars obtained from the gasification and co-pyrolysis of rice wastes as adsorbents of Cr3+ ion from aqueous solutions, and concluded that GC was very efficient to remove Cr3+ ion from aqueous solutions, without requiring further activation. A similar study was conducted by Dias et al. (Dias, 2018), who determined that rice waste chars obtained from steam-oxygen gasification presented higher Cr3+ ion removal efficiencies and uptake capacities than CAC. Although the prepared chars in this study were very effective for removing Cr3+ from aqueous solutions (by both precipitation and adsorption), the char (80% rice husk w/w + 20% w/w polyethylene, with the solid/liquid ratio of 5 mg/L) only presented better results than CAC for the removal of Cr3+ from industrial wastewater when precipitation occurred.

6.2 Dye removal

Another application of GC in adsorption was discussed by Jung et al., (Jung et al., 2019), who studied the removal of CR and CV dye using the GC from municipal solid waste. They reported that adsorption performances were higher for municipal solid gasification waste at lower steam rate (37 kg/h) and higher air supply rate (214 Nm3/h, ER = 0.36), which were 49.7 mg/g and 356 mg/g for CR and CV adsorption respectively, suggesting that higher air supply rate with lower steam rate were effective gasification process conditions.

Meanwhile, Maneerung et al. (Maneerung et al., 2016) investigated the removal of RhB using AC from the gasification of mesquite wood chips in a downdraft fixed-bed gasifier, and reported that the prepared AC exhibited high RhB adsorption capability. This was due to its high SBET (776.5 m2/g) and the abundance of carboxyl and hydroxyl groups on its surface. The study also revealed that the equilibrium data ideally fitted to the Langmuir isotherm, the maximum monolayer adsorption capability of AC being 189.8 mg/g, and concluded that, the utilisation of GC as a precursor of AC lowered the AC production cost, offered a cost effective and environmentally friendly method of recycling char, and lessened the environmental problems related to its disposal.

The removal of MG dye was also reported using GC from gasified Hevea brasiliensis root (Ahmad et al., 2021), gasified Glyricidia sepium (Ahmad et al., 2020) and gasified wood chip (Ahmad et al., 2020) in batch and fixed bed column adsorption. All the GCs were physicochemically activated via microwave irradiation technique with the aid of KOH and CO2 as the activation agent. The adsorption capacity and production cost of gasified Hevea brasiliensis root, gasified Glyricidia sepium and gasified wood chip were 259.49 mg/g and 0.23 USD/ kg; 230.47 mg/g and 0.54 USD/ kg; and 226.06 mg/g and 0.23 USD/ kg, respectively.

Another application of GC in cationic dye removal was reported by Pessôa et al. (Pessôa, 2019) and Ravenni et al. (Ravenni et al., 2020) using GC derived from açaí berry (Euterpe oleracea Mart) residues and woodchips, respectively. Pessôa et al. (Pessôa, 2019) discovered that the NaOH-activated GC improved the SBET from 1.94 to 491.90 m2/g which led to the increase of MB adsorption capacity from 33.73 to 93.23 mg/g. The performance of activated GC was also tested in raw textile wastewater, which exhibited a reduction of 84.62% in the effluent Biochemical Oxygen Demand (BOD). Meanwhile, Ravenni et al. (Ravenni et al., 2020) reported slightly lower MB adsorption capacity (25.1 mg/g) than Pessôa et al. (Pessôa, 2019), probably due to no GC activation prior to the adsorption as well as different type of GC feedstock was used. Ravenni et al. (Ravenni et al., 2020) also concluded that the performance of GC for cationic dye-MB (25.1 mg/g) and anionic dye-AM (25.3 mg/g) adsorption were comparable with commercially available AC (25.4 and 23.5 mg/g for MB and AM, respectively).

6.3 Emerging contaminant removal

Galhetas et al. (Galhetas et al., 2014) used K2CO3 to activate pine gasification residue for the adsorption of ACE. In another study, Galhetas et. al (Galhetas et al., 2014) also used the gasification residue of pine and coal for ACE and caffeine adsorption from aqueous solutions. They reported that activated pine produced porous materials that aided the ACE and caffeine adsorption processes, which were ruled by the micropore size distribution of the carbons. They concluded that the surface chemistry seemed to be the determinant factor that controlled the affinity of caffeine towards carbons.

Another use of GC for emerging contaminant removal was reported by Ahmad et al. (Ahmad et al., 2020). In this study, the Glyricidia sepium woodchip (GGSWAC) was activated via microwave irradiation techniques with the aid of KOH and CO2 as the chemical and physical agents for ATN adsorption. The BET surface area increased from 39.52 to 483.07 m2/g after the activation step. It was found that the ATN adsorption fitted well to n-BET model indicating a multilayer adsorption with the saturation capacity of 121, 143 and 163 mg/g at 30, 45 and 60 °C, respectively. Meanwhile, the kinetic study showed that the ATN adsorption followed Avrami model equation with R2 = 0.99. In addition, the adsorption of ATN onto GGSWAC was endothermic (ΔHS° = 234.17 kJ/mol) in the first layer of adsorption and exothermic in the subsequent layer (ΔHL° =-165.62 kJ/mol). The ATN adsorption was controlled by both diffusion and chemisorption. In continuous operation, the Thomas and Yoon–Nelson models successfully predicted the ATN adsorption with R2 of 0.9822 and 0.9817, respectively. Table 6 summarises the literature findings on the adsorption applications of GC residue. SBET = specific Brunauer–Emmett–Teller surface area, RhB = rhodamine B, GC = gasification char, PC = pyrolysis char, AC = activated carbon, CAC = commercial activated carbon, RH = rice husk, RS = rice straw, PE = polyethylene, ID = internal diameter, L = length, L/S = liquid/solid ratio, S/L = solid/liquid ratio, AM amanth dye, CR = congo red dye, CV = crystal violet dye, ATN = atenolol, ACE = acetaminophen, DCF = diclofenac, MB = methylene blue dye, MG = malachite green dye. Summary: Publications on adsorption using GC residue are rather scarce. Based on the limited literature consulted, the adsorption performance of GC residue was demonstrated to be comparable with that of CAC. The sorption process can be further enhanced by various activation processes that could improve the porosity and surface area of char.

Feedstock

Technology

SBET (m2/g)

Application

Activation

Adsorption capacity (mg/g)

Remarks

Reference

Agent

T (°C)

SBET (m2/g)

Hevea brasiliensis root

Downdraft

135.22

MG

KOH-CO2

N/A

477.74

259.49

Monolayer and multilayer adsorption involved

(Ahmad et al., 2021)

Glyricidia sepium

Downdraft

39.52

MG

KOH-CO2

N/A

633.30

230.47

Glyricidia sepium possessed excellent characteristics for BG4 and ATN removals due to high SBET

(Ahmad et al., 2020)

Downdraft

39.52

ATN

KOH-CO2

N/A

483.07

163

(Ahmad et al., 2020)

Woodchip

Downdraft

257.96

MG

KOH-CO2

N/A

351.93

226.06

The optimum activation conditions (radiation power = 616 W, impregnation ratio = 1.06, time = 1 m) resulted in 99.01% MG dye removal

(Ahmad et al., 2020)

Mesquite wood

Downdraft fixed-bed gasifier

776.46

RhB

CO2

700

485.20

189.83

prepared AC exhibited high dye adsorption capability

(Maneerung et al., 2016)

800

736.65

900

N/A

Steam

700

538.98

800

736.94

900

776.46

N2

700

177.74

800

280.02

900

286.90

Açaí berry seeds

Downdraft

1.94

MB

NaOH

491.90

93.23

Maximum adsorption capacity increased 173% in comparison to non-activated açaí biochar.

(Pessôa, 2019)

Woodchip

Downdraft

598

MB

AM–

–

–

25.1

25.3GC showed a comparable removal efficiency with CAC

(Ravenni et al., 2020)

Municipal Solid waste

Downdraft

(low steam rate)11.4

CR

–

–

–

49.7

Higher air supply rate with lower steam rate were effective gasification process conditions for CR and CV adsorption

(Jung et al., 2019)

CV

356

Downdraft

(high steam rate)2.73

CR

–

–

–

35.7

CV

235

Pine and spruce

150 kW air-blown downdraft gasifier

(T = 1000 °C)52.4

SO42-

ZnCl2

BaCl2

CaCl2

FeCl3

FeCl2

500

500

500

500

500

52.4

19.5FeCl3-modified carbon residue is a potential sorbent for SO42- ion removal which removed SO42- ions better than CAC in the concentration range of 50 to 1000 mg/L

(Runtti et al., 2016)

Pine and spruce

150 kW air-blown downdraft gasifier

(T = 1000 °C)52.4

PO43- and NO3–

CO2

CO

N2

ZnCl2

HCl

H2SO4

KOH

HNO3

600–800

600–800

600–800

N/A

N/A

N/A

N/A

N/A152–590

126–135

145–160

285

194

157

117

25920.5

(PO43-)

80

(NO3–)The sorption capacity can be improved by chemical activation

(Kilpimaa et al., 2015; Kilpimaa et al., 2014)

Pine and spruce

150 kW downdraft gasifier

(T = 1000 °C)14.4

Ni2+, Fe2+, and Cu2+

ZnCl2

N/A

259

18.2 (Ni2+)

20.5 (Fe2+)

23.1 (Cu2+)The amounts of pollutants removed by carbon residue with and without activation were higher than those removed by CAC.

(Runtti et al., 2014)

Pine

Fluidised bed reactor (gasification agent = air, T = 850 °C)

101

Acetaminophen and caffeine

K2CO3

700

800570

1509434.8 (ACE)

476.2 (Caffeine)The increase in temperature resulted in an increase in the sorption capacity

(Galhetas et al., 2014; Galhetas et al., 2014)

Spruce woodchip

Floating-fixed-bed

308.15

DCF

–

–

35.09

-

(Back et al., 2020)

RH (GC)

RH + PE (PC)Steam gasification and co-pyrolysis

N/A

Cr3+

N/A

N/A

21.1 (GC)

1.44 (PC)GC is better adsorbent than PC.

100% removal

GC presented the highest uptake capacity(Godinho et al., 2017)

50% w/w RH + 50% w/w RS

80% RH w/w + 20% w/w PEBubbling fluidised bed

reactor using steam–air as gasification agent25

<5Cr3+

N/A

N/A

N/A

8.51

6.2Sorption capacity of GC significantly higher than CAC.

The high mineral content of chars played an important role(Dias, 2018)

7 Adsorption mechanisms

The adsorption process involves intermolecular transfer of adsorbate onto the solid surface of the adsorbent. The physical adsorption is carried out mainly through hydrogen bonding, electrostatic interaction and π–π interaction (Sophia and Lima, 2018). Hydrogen bonding (H-bonding) involves the interaction between a hydrogen atom and an electronegative atom (usually N, F, or O). The former is called the H-bond donor, the latter the H-bond acceptor. Previous study showed that the MG adsorption by gasified Hevea brasiliensis root (GHBRAC) was assisted by H-bonding between the carboxyl groups or hydroxyl groups (H-bond donors) of the GHBRAC and H-bond acceptor in MG; as well as H-bonding between hydroxyl group in MG and carbonyl group (H-bond acceptor) of the GHBRAC (Ahmad et al., 2021). Besides, H-bond was also found to aid the adsorption of CV and CR onto gasified municipal solid waste based on the shifts in OH peak wavenumber observed from Fourier transform infrared (FTIR) spectroscopy (Jung et al., 2019).

Electrostatic interaction comprises the attractive or repulsive interactions between charged molecules. The opposite charges such as cations (positive) and anions (negative) will be attracted to each other while the same charges will repel. The electrostatic attraction or repulsion between particles due to their charge can be measured by zeta potential. The electrostatic interaction is commonly influenced by solution pH and ion strength. The influence of pH can be clarified in terms of point of zero charge (pHPZC) value. For cationic adsorbate, at pH < pHPZC, the adsorbent surface becomes predominantly positively charged and tend to repel the cationic adsorbate since the number of the negatively charged groups at the surface of the adsorbent decreased, while the positively charged groups increased. Hence the adsorption of the adsorbate molecules to the surface of the adsorbent will commonly declines as pH below pHPZC. In contrast, the adsorbent surface becomes deprotonated at pH > pHPZC due to availability of large number of negatively charged ions, thus adsorbate cations approach strongly towards the negatively charged sites on the adsorbent surface through electrostatic attraction and result in maximum removal (Banerjee et al., 2016). Electrostatic interaction was reported to aid the adsorption of MB onto açaí gasification waste (Pessôa, 2019). This was shown by the increase in MB adsorption at pH greater than pHPZC since there is an increase in electron receptor-donor interaction forces between sorbent and sorbate. Other studies that report this type of interaction includes RhB removal by gasified mesquite wood chips (Maneerung et al., 2016), tetracycline removal by biochars derived from alfalfa and Bermuda grass (Jang and Kan, 2019), ACE and MB adsorption by activated biochar derived from municipal solid wastes (Sumalinog et al., 2018) and cephalexin adsorption by pomegranate peel (Rashtbari et al., 2020).

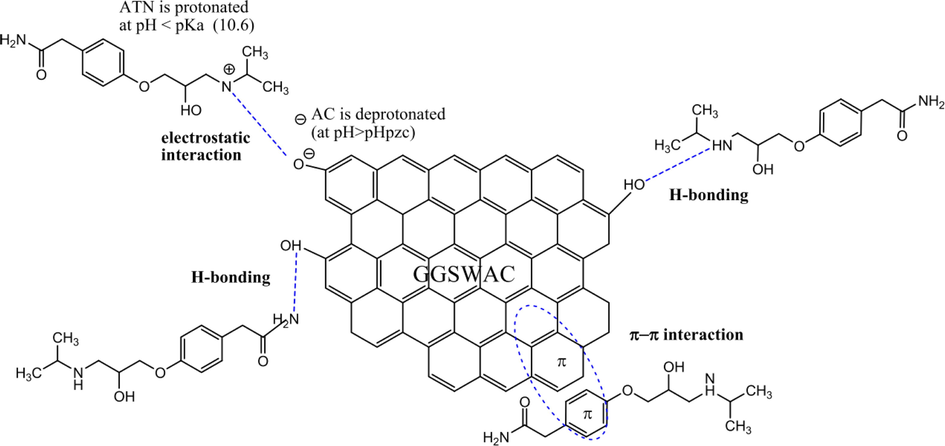

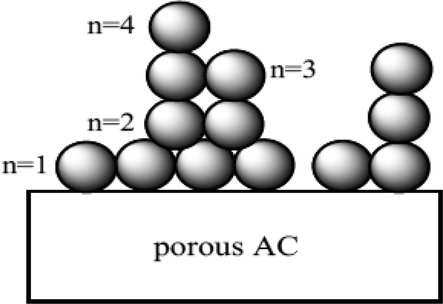

π-π interaction (also known as π-π electron donor–acceptor interaction) involves the interaction between the π electrons in a carbonaceous adsorbent and the π-electron in the aromatic ring of an adsorbate (Tran et al., 2017). π- π interaction generally exists in an aromatic supramolecular system (Gong, 2019). High aromaticity and hydrophilicity of the adsorbent will promote the formation of π-π interactions, in the presence of π electrons in the adsorbate and reactive oxygen groups in the adsorbent (Jung et al., 2019). The adsorbent and adsorbate will bound together by electron transfer between the electron donor and acceptor (Cheng, 2021). This adsorption mechanism plays a leading role in the adsorption process of many carbonaceous materials on various pollutants such as cationic dye (MG, MB) (Ahmad et al., 2020; Ahmad et al., 2020; Pessôa, 2019), anionic dye (amaranth) (Ravenni et al., 2020), reactive dye (remazol brilliant violet 5r) (Khasri et al., 2021), ATN (Ahmad et al., 2020), 2,4-dinitrophenol (Azari et al., 2021), tetracycline (Li, 2022), sulfamethoxazole and Bisphenol A (Ahsan, 2018). Fig. 1 shows the mechanism of ATN adsorption onto gasified Glyricidia sepium which involved H-bonding, electrostatic interaction and π-π interaction.

Mechanism of ATN adsorption onto gasified Glyricidia sepium (Ahmad et al., 2020).

The chemical adsorption involves a chemical bond (covalent or ionic bond) resulting from the substantial sharing or transfer of electrons between the adsorbent and adsorbate. It requires high energy for regeneration and may not be fully reversible. As the adsorbate molecules are adsorbed on the surface of the adsorbent through valence bonds, they form a monolayer adsorption. The chemisorption energy between the adsorbate molecules and adsorbents can vary significantly depending on the bond strength (Kwon et al., 2011). The adsorption mechanisms of various pollutants onto different feedstock of GC are summarized in Table 7.

Category

Feedstock

Pollutant

Mechanism

Reference

Ions

Pine and spruce woodchip

SO42-

physical pore filling,

electrostatic interactions(Runtti et al., 2016)

Pine and spruce woodchip

NO3–

physical pore filling, electrostatic interactions

(Kilpimaa et al., 2015)

Pine and spruce woodchip

Fe2+, Cu2+ and Ni2+

electrostatic attraction, ion-exchange, adsorption–precipitation, hydrogen bonding, and chemical inter- action

(Runtti et al., 2014)

Gasified rice waste

Cr3+

ion exchange, physical pore filling, precipitation, electrostatic interactions

(Godinho et al., 2017; Dias, 2018)

Dyes

Glyricidia sepium

MG

H-bond, π-π interaction, electrostatic interaction

(Ahmad et al., 2020)

Woodchip

MG

H-bond, π-π interaction, electrostatic interaction

(Ahmad et al., 2020)

Mesquite wood chips

RhB

H-bond, electrostatic interaction

(Maneerung et al., 2016)

Municipal solid waste

CR & CV

H-bond, π-π interaction, hydrophobic interactions, electrostatic interaction

(Jung et al., 2019)

Hevea brasiliensis root

MG

H-bond, π-π interaction, electrostatic interaction

(Ahmad et al., 2021)

Emerging contaminant

Glyricidia sepium

ATN

H-bond, π-π interaction, electrostatic interaction, London dispersion force

(Ahmad et al., 2020)

Spruce woodchip

DCF

hydrophobic and π-electron-donor–acceptor & π-cation interactions, pore-size effects, electrostatic interaction & H-bond

(Back et al., 2020)

8 Factor affecting adsorption

8.1 Effect of initial concentration and contact time

The adsorption performance of the solid adsorbent generally increases with the initial concentration of the adsorbate. This is due to the increase in driving force for transporting the adsorbate molecules from aqueous phase to the adsorbent surface (Ahmad et al., 2016; Kallel et al., 2016). The number of collisions between the adsorbate molecules and the adsorbent functional groups also rises as the initial concentration increases, which resulted in the escalation of the adsorption capacity (Hadi et al., 2015).

Maneerung et al. (Maneerung et al., 2016) observed that the amount of RhB adsorbed on activated-GC derived from woody biomass increased with the initial concentration. At 25 °C, the equilibrium adsorption capacity of activated-GC significantly increased from 132 to 232 mg/g when the initial RhB concentration was increased from 13 to 28 mg/L. The increase in adsorption capacity was due to a higher concentration gradient or stronger driving force between the liquid and GC solid phases at a higher initial RhB concentration. This in turn led to an increase in adsorption capacity. In general, the initial concentration plays a crucial role in overcoming mass transfer resistance of adsorbate molecules between liquid and solid phases during adsorption (Ab Aziz et al., 2023; Kwon et al., 2011).

In the studies of ATN adsorption by GGSWAC, Ahmad et al. (Ahmad et al., 2020) observed a similar trend where the adsorption uptake of ATN molecules on the adsorbent increased from 25.65 to 120.94 mg/g as the initial concentration of ATN increased from 50 to 300 mg/L. This was due to the greater mass transfer driving force at higher initial concentrations which helped to overcome the mass transfer resistance of ATN between the liquid and solid phases. The higher initial concentrations resulted in more ions competing for available sites on the surface of the adsorbent, as reported by Azari et al. (Azari et al., 2021), thus leading to a higher ATN adsorption capacity. These findings were consistent with the adsorption studies conducted by To et al. (To et al., 2017) and Fu et al. (Fu et al., 2020). Additionally, in the study on iron, copper, and nickel removal, Runtti et al. (Runtti et al., 2014) observed that the adsorbent reached its saturation point at higher initial metal concentrations and could no longer accommodate further sorption due to the absence of available sites.

Meanwhile, contact time can be defined as the agitation time needed for the adsorbent–adsorbate system to achieve steady state. The adsorption process can be described by few steps; (1) film diffusion (mass transfer from the liquid phase to the adsorbent surface across the liquid film), (2) intraparticle diffusion (diffusion within the pores of adsorbent) and (3) surface reaction (adsorption on the surface of adsorbent) (Tan and Hameed, 2017; Choudhary et al., 2020). The equilibrium time commonly varies according to adsorbent pore structure and particle size, type of the adsorbate, adsorbate concentration, solution temperature and pH. Hadi et al. (Hadi et al., 2015) reported that the equilibrium time for the mesoporous adsorbent is much lesser than the microporous adsorbent. Additionally, the tinier particle size of adsorbent requires shorter equilibrium time compared to adsorbent with larger particle size (Bohli et al., 2013).

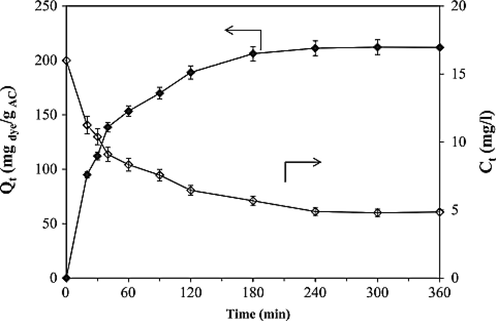

The adsorption experiment to determine the adequate adsorption time of RhB by activated GC was conducted by Maneerung et al. (Maneerung et al., 2016) at room temperature using 5 mg of activated GC and 100 mL of 20 mg/L RhB solution (pH 7). The amount of adsorbed RhB (Qt) increased rapidly with the contact time up to 180 min, after which it slowly increased until it reached equilibrium at maximum adsorption capability at ∼ 240 min of contact time. This is because the initial adsorption rate was rapid due to the high number of vacant sites of the activated GC for adsorption, and then it slowly increased due to the saturation of active sites for adsorption. The maximum adsorption capacity at equilibrium of the activated GC prepared was approximately 215.7 mg/g as shown in Fig. 2.

Effect of contact time (Maneerung et al., 2016).

Similarly, Runtti et al. (Runtti et al., 2016) reported that the initial stage of the sorption experiment had a higher rate of sulphate ion removal due to the greater number of available adsorption sites. The optimal sulphate removal efficiency (97.6%) and sorption capacity (10.3 mg/g) were achieved in approximately one minute, after which there was a slight decrease in the removal. efficiency.

8.2 Effect of temperature

Temperature is another important parameter that may affect adsorption by affecting solubility and molecular interactions with solid particles. The solution temperature can either improve or reduce the adsorption performance depending on the nature of the adsorbate-adsorbent interaction, whether exothermic or endothermic process (Chen, 2022). In ACE adsorption using GC from pine wood, the increase in adsorption capacity due to temperature was observed by Galhetas et al. (Galhetas et al., 2014), which is consistent with previously reported data (Ahmad et al., 2020; Ahmad et al., 2021; Ahmad et al., 2020; Ahmad et al., 2020), demonstrating a temperature dependence that is a characteristic of an endothermic process. The authors also explained that the relationship between the dimension of ACE species present in solution and the micropore size network of the GC samples can account for this phenomenon. At lower temperatures, the critical dimension of ACE monomers is close to the opening of the pores corresponding to the maximum of the micropore size distribution of the lab-made sample. However, with an increase in temperature from 20 to 40 °C, the vibration energy of the molecules increases, leading to an activation of adsorption. This favours the accessibility of the species to the microporosity with widths near to the critical dimensions of the molecule, resulting in an increase in monolayer adsorption capacity.

On the contrary, Maneerung et al. (Maneerung et al., 2016) found that the adsorption capacity of RhB slightly decreased as the temperature increased. For example, when the initial concentration was kept constant at 22 mg/L, the amount of RhB adsorbed on the GC decreased from 210.2 to 196.4 mg/g as the temperature increased from 25 to 60 °C. This observation indicates that the adsorption of RhB onto the GC is an exothermic process.

The study of temperature is vital in evaluating the thermodynamic parameters such as the change of Gibbs free energy (ΔG°), enthalpy (ΔH°) and entropy (ΔS°), which can provide the information related to the adsorption nature (Moralı et al., 2018). An accurate estimation of these parameters relies on the appropriate determination of the equilibrium constant, KC. The thermodynamic parameters can be estimated using KC values obtained from adsorption-isotherm constants or the partition coefficient (Ribas, 2014; Rodrigues et al., 2011). However, several factors need to be considered thoroughly to obtain a reliable value of these thermodynamic parameters; (1) The KC value must be unitless. (2) The van't Hoff linear regression coefficient (R2) must be high. (3) The adsorbate concentration used in the adsorption equilibrium study are low or high (Nguyen et al., 2017). Since the KC values can be estimated from several methods, significant variation in the thermodynamic parameters can be found. Hence, the most reliable approach should be studied so that the determined thermodynamics parameters are relevant.

Rangabhashiyam et al. (Rangabhashiyam et al., 2018) used the distribution constant, Kd to estimate the thermodynamic properties of MG adsorption onto Carica papaya wood (CPW). The authors estimated Kd value from the intersection of ln(qe/Ce) versus Ce plot. The results showed a declining trend in the value of Gibbs free energy with increasing temperature, suggesting that adsorption of MG was preferred at higher temperature. The results of the enthalpy change revealed that the MG adsorption process was endothermic, and the positive values of the entropy change indicated the increase randomness in the system.

The estimation of KC values from Langmuir isotherm, KL for MG, MB, and RhB adsorption were employed by Geçgel et al. (Geçgel et al., 2016), who used AC obtained from waste Elaeagnus stone. They reported the negative values of Gibbs free energy, which revealed the spontaneity of the process; the positive values of entropy change indicating the increase in the randomness in the system; and the positive values of enthalpy which reconfirm that the adsorption of MG was endothermic. Similar approach has been performed by Qu et al. (Qu et al., 2019), who evaluated the MG adsorption using apricot-AC, coconut-AC, peach-AC and coal-AC. The thermodynamic results obtained by Qu et al. (Qu et al., 2019) were in good agreement with Geçgel et al. (Geçgel et al., 2016). In contrast, Sayğili & Güzel (Sayğili and Güzel, 2015) calculated the thermodynamic properties of CR and MG adsorption using distribution coefficient with Kd = Qm KL with unit of L/g, which was different from those of KL (L/mg). The results for thermodynamic properties were in good agreement with other researchers with high value of R2.

8.3 Effect of pH

A pH of the solution is another important factor that affect the adsorption capacity. The pH value can influence the ionization degree of the adsorbate and metal ion speciation in a solution. A solution‘s pH affects the degree of the adsorption. H+ and OH– ions are commonly adsorbed, thus affecting the adsorption process by dissociating the functional groups on the active sites of the adsorbent surface, resulting in a shift in the kinetics of reaction and in the properties of equilibrium (Rathi and Kumar, 2021).

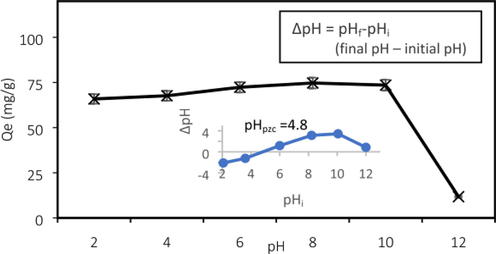

The influence of pH can also be clarified in terms of point of zero charge (pHPZC) value. At pH < pHPZC, the adsorbent surface becomes mainly positively charged which tends to attract the anionic adsorbate owing to the increase in the number of the positively charged groups at the surface of the adsorbent, leading to the increase in adsorption of the adsorbate molecules to the surface of the adsorbent. In contrast, the adsorbent surface becomes deprotonated at pH > pHPZC due to the availability of large number of negatively charged ions on the surface of adsorbent, resulting in the electrostatic repulsion between the negatively charged adsorbent surface and the anionic adsorbate. For instance, Ahmad et al. (Ahmad et al., 2020) reported that, at pH value lower than pHPZC (pH < 4.8), the GC surface were positively charged while at pH value greater than pHPZC (pH > 4.8), the surfaces became negatively charged. Therefore, when the pH is above pHPZC (pH > 4.8), the GC surface possessed the net negative charge and promoted the electrostatic attraction with positively charged ATN solution. Hence the adsorption uptake increased from 67.65 to 74.71 mg/g at pH 4 and pH 8 as depicted in Fig. 3. However, at pH above the pKa value, ATN molecules were deprotonated and became neutral, thus causing a declining trend in ATN uptake at pH 10 to 12. Similar trend was reported by Haro et al. (Haro et al., 2017), To et al. (To et al., 2017), Fu et al. (Fu et al., 2020) and Chang (Chang et al., 2019).

Effect of pH (Ahmad et al., 2020).

Sharma et al. (Sharma, 2019) found that the maximum MG adsorption by AC derived from Pinus roxburghii cone occurred at pH 6 with pHPZC value of 8.4. At pH 6 (below the pHPZC), the surface of AC was positively charged, while the MG molecules was either neutral or slightly negatively charged, thus demonstrating the greatest interactions between AC and MG molecules, leading to high adsorption performance.

Meanwhile, the effect of pH was described using chemical equation by Maneerung et al. (Maneerung et al., 2016), who studied the RhB removal using activated GC. Under the basic condition, the hydroxyl (—OH) groups and carboxyl (—COOH) groups on the surface of GC were deprotonated and became more negatively charged, which led to the increase in the electrostatic interaction between the negatively charged GC and the positively charged RhB molecule. In contrast, under the acidic condition, the hydroxyl groups and carboxyl functional groups of the GC as well as the carboxyl functional groups of RhB molecules were protonated and became more positively charged. Hence the adsorption capability declined owing to the strong electrostatic repulsion between the positively charged RhB molecules and the positively charged GC.

Under basic condition: —COOH + OH– → —COO– + H2O —OH + OH– → —O- + H2O

Under acidic condition: —COOH + H+ → —COOH2+ —OH + H+ → —OH2+

Under neutral condition, Maneerung et al. (Maneerung et al., 2016) added that RhB molecules were mostly adsorbed on the surface of GC via hydrogen bonding between carboxylic (—COOH) groups of RhB molecules and both hydroxyl (—OH) groups and carboxylic (—COOH) groups present on the surface of GC. They finally concluded that the basic condition was more favorable for the adsorption of cationic dye-RhB by the prepared GC.