Translate this page into:

Preparation and characterization of eco-friendly composite based on geopolymer and reinforced with date palm fiber

⁎Corresponding authors. hassan.chkala@usms.ma (Hassan Chkala), n.elmansouri@usms.ma (Nour-Eddine El Mansouri)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

This study investigated the effect of incorporating different amounts of date palm fiber (DPF) on the mechanical, physical, and structural properties of geopolymer composites. These composites were formulated by utilizing mining residue as the geopolymer matrix and PDF as a reinforcing agent. The synthesis procedure involved activating the mining residue with a highly concentrated NaOH solution to form the geopolymer matrix. Subsequently, the resulting matrix was blended with different proportions of DPF, ranging from 1% to 20% (wt/wt), and underwent a 28-day curing period under ambient conditions. Mechanical properties were assessed through compression (CS) and flexural (FS, FM) tests, while water absorption (WA) and thickness swelling (TS) were employed to evaluate physical properties. Additionally, FTIR spectroscopy, X-ray diffraction (XRD), energy dispersive X-ray (EDX) and scanning electron microscopy (SEM) were used to elucidate changes in bonding nature, visualize matrix phases, analyze composition, and examine microstructure, respectively. The results demonstrated that incorporating an optimal amount of DPF fibers, of about 8% (wt/wt), yielded a geopolymer composite with outstanding mechanical properties. Both compressive and flexural strengths were twice as high compared to the geopolymer matrix, highlighting the effectiveness of DPF fiber as a reinforcing agent. However, the increase in fiber loading was associated with a decline in the physical properties of the composite, reaching an acceptable water WA value of 30% and TS value of 0.9% after 168-hours of immersion in water. Structural analysis using FTIR and XRD techniques suggested that mining residue, as an aluminosilicate raw material with a semicrystalline structure, undergoes a geopolymerisation reaction to a relatively lower extent after activation by a highly alkaline solution SEM images revealed a well-established matrix-fiber interface, providing an explanation for the achieved good mechanical and physical properties. EDX results showed an interesting composition of the geopolymer gel derived from mining residue with a significant amount of silicon and a moderate quantity of calcium and aluminum. This confirmed that the geopolymer gel formed primarily undergoes the C-A-S-H process, rather than N-A-S-H process, which is a positive indication of the geopolymer composite's mechanical properties.

Keywords

Geopolymer

Date palm fibers eco-friendly material

Reinforced composite

Structure

Mechanical

Physical properties

1 Introduction

Geopolymer is a type of cementitious material obtained from a solid aluminosilicate raw materials, like fly ash, metakaolin, clay, blast furnace slag, and silica fumes, by chemical reaction with an alkaline solution under ambient or slightly elevated temperature (Wu et al., 2019). The main components of source materials are silica (Si) and aluminium (Al), that form a three-dimensional structure network corresponding to SiO4 and AlO4 tetrahedron (Zhang et al., 2019). Among the source materials, the mine tailings, commonly referred to the mining residues and natural deposits like clay and attapulgite, are a recently studied aluminosilicate raw materials for their high aluminosilicate content (Abdulkareem et al., 2022; Allawi et al., 2022a, Allawi et al., 2022b; Xiang et al., 2022; Mabroum et al., 2020a, Mabroum et al., 2020b). They are obtained after extraction of valuable metals such as gold, copper, garnet, and iron. Their potential use in the production of geopolymer materials present a unique opportunity for mining industries, not only from the point of view of efficient waste management, but also for the possibility to convert them into valuable products. This approach allows fostering a sustainable solution that benefits the environment and industry (Xiang et al., 2022). The geopolymer materials offers numerous advantages such as high-temperature resistance, excellent mechanical properties, high-corrosion resistance, fire resistance, durability, and eco-friendliness, making them a green cementitious materials that can replace the Ordinary Portland Cement (Davidovits, 1991; Duxson et al., 2007).

The use of conventional construction materials based on Ordinary Portland Cement (OPC) is widely acknowledged to have a significant negative impact on the environment. The manufacturing of OPC not only requires a considerable quantity of natural resources and energy, but it results in emission of substantial amount of greenhouse gases. To illustrate, manufacturing a tonne of OPC demands around 1.5 tons of raw materials and emits one ton of CO2 into the atmosphere. The cement industry alone is estimated to account for approximately 7 % of all CO2 emissions worldwide (Chen et al., 2014). To address the above-mentioned drawbacks of OPC, the cement industry should then improve the sustainability of building materials. Such an attempt is motivated by the societal demand for more environmentally friendly materials (Kaddami et al., 2006; Xie et al., 2015). Renewable resources and industrial wastes are among the proposed alternatives to OPC, which are widely regarded as an option for use as building materials in order to improve the sustainability of the construction industry. Among the renewable resources, geopolymer is one of the new environmentally friendly material used in building materials to improve sustainability. This material holds great promise as a novel and environmentally friendly solution for a diverse range of applications that include: the absorption of CO2, thermal and acoustic insulation, treatment of air and wastewater, chemical catalysis, as well as the adsorption and elimination of different contaminants, including heavy metals, dyes, and drug residues, pharmaceuticals, and pesticides from aqueous solutions, and serving as a green alternative to conventional cement on masonry mortar used in heritage buildings (Ettahiri et al., 2023; Kutlusoy et al., 2023; Zhang et al., 2023; Zhang et al., 2019; Zheng et al., 2021).

Geopolymer has received considerable attention from the research community around the world due to its above-mentioned outstanding properties and also for its easy manufacturing method that does not require a lot of energy (Duxson et al., 2007). However, when used for composite materials, it has some drawbacks such as the poor ductility and fragility (Steinerova et al.,2017). To overcome these disadvantages, the geopolymer matrix has been reinforced with a variety of fibers, including carbon, steel, basalt and synthetic fibers to improve the mechanical properties of the material (Ahmed et al., 2020). It is worth nothing that the production of such fibers requires a significant amount of energy, which is considered a costly method. Moreover, the growing environmental awareness and the need to ensure the durability of building materials have led to investigate new natural fibers for reinforcing cementitious and geopolymer materials. The natural fibers, mainly from agricultural origin, are increasingly being used in the production of cement or geopolymer composites, due to their advantages such as low density, low cost, excellent specifics mechanical properties, and for their renewability and biodegradability (Korniejenko et al., 2016). Cotton, flax, and sisal fibers are some examples of natural fibers that have been suggested for improving the mechanical and physical properties of geopolymer-based composites (Alomayri and Low, 2013; Korniejenko et al., 2016).

Within this research line, many studies have been conducted to investigated the effect of adding natural fiber to the geopolymer matrix to improve its mechanical properties. For example,(Alzeer and MacKenzie, 2013a) found that a high bending strength was obtained for 10 % (wt/wt) flax fiber loading in reinforcing metakaolin-based geopolymer composite (Alzeer and MacKenzie, 2013a). In a similar study, Alomayri et al., (2013) have examined the effect of cotton fiber loading on the mechanical properties of geopolymer composites based on low calcium fly-ash as alumino-silicate material. According to their findings, both flexural strength and modulus were improved as the cotton fiber loading was increased, reaching a maximum value of about 8.3 % fiber loading (Alomayri and Low, 2013). More recently, El Bourki et al., (2023) has presented a comprehensive review paper on the application of date palm fibers as reinforcement for earth-based construction materials (El Bourki et al., 2023). They concluded that the mechanical, physical and thermal properties of earth-based materials are affected by an increase in date palm fiber loading. The dry density and thermal conductivity were decreased as fiber loading increased, whereas water absorption, compressive strength, tensile and flexural strengths were increased. The improvements in mechanical and physical properties are related to the optimal fiber loading, after which they are decreased (El Bourki et al., 2023).

To the best of our knowledge, date palm fibers (DPF) have not been previously utilized as a reinforcing agent in geopolymer composites. However, there exist numerous studies conducted on their utilization for reinforcing both thermosets and thermoplastics matrices such as epoxy, polypropylene, polyester, high density and low-density polyethylene (HDPE and LDPE) and ethylene terephthalate (Kaddami et al., 2006; Kajaste and Hurme, 2016; Saba et al., 2019). For instance, Kaddami et al., 2006examined the mechanical properties of epoxy and polyester adhesives reinforced with different fiber sizes and weight ratios. The study revealed that the addition of 17 % (wt/wt) of DPF to epoxy adhesive resulted in superior mechanical properties compared to polyester adhesive. This improvement was attributed to the stronger adhesion between epoxy adhesive and date palm fiber (Kaddami et al., 2006). In another study conducted by (Saba et al., 2019), date palm fiber was utilized as reinforcement for epoxy resin at varying levels ranging from 40 to 60 % (wt/wt). Their findings indicated that the addition of stiff and hard DPF significantly increased the tensile strength and tensile modulus of pure epoxy resin, particularly when the fiber loading was less than 50 % (Saba et al., 2019). A further increase in DPF loading beyond 50 % (wt/wt) has led to a slight decrease in tensile strength. This decline can be attributed to the failure mechanism observed in the 60 % DPF/epoxy composite, which is caused by the breakage of fibers. In summary, the enhanced mechanical properties of DPF-based polymer composites were attributed to the exceptional intrinsic mechanical properties of DPF, which include their significant strength and modulus when compared to various natural fibers, as well as their superiority over E-glass fibers and numerous aluminum alloys (Saba et al., 2019). On the other hand, the annual pruning of date palm trees (Phoenix roebelleni) in northern and central Africa generates a significant amount of lignocellulosic wastes that can be turned into suitable fibers with desirable chemical and mechanical characteristics. In addition to these properties, date palm fibers as a natural fiber, provide additional benefits such as the low cost, low density, renewability and biodegradability, which justify their use as an effective reinforcing agent in geopolymer composites.

According to the above-mentioned findings, the feasibility of using date palm fiber, a local raw material, as a reinforcing agent for the geopolymer matrix is studied. Thus, this research investigates how fiber loading affect the mechanical, physical and microstructural properties of geopolymer composites made of mining residue and DPF. Precisely, the effect of DPF loading on mechanical (compressive strength, flexural strength, flexural modulus) and physical (water absorption, and thickness swelling) properties are investigated. In addition, FTIR spectroscopy, X-ray diffraction (XRD), energy dispersive X-ray (EDX) and scanning electron microscopy (SEM) were used to elucidate changes in bonding nature, visualize matrix phases, analyze the composition and microstructure, respectively.

2 Materials and methods

2.1 Materials

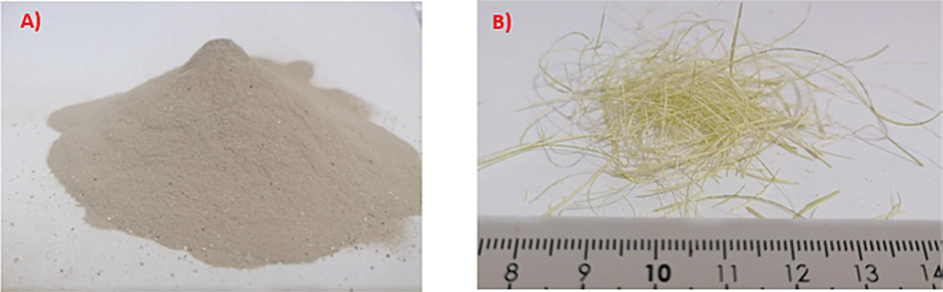

Mining residue (Mine tailings) used for formulating the geopolymer composites was collected from a former copper and cobalt mining site in the Ait Bouilli-Azilal region of Morocco (Fig. 1.A). Its chemical composition was determined using the Thermo Fiche MLAB C001 fluorescence Spectrometer, and the results are presented in Table 1. The analysis indicated a substantial presence of silicate oxide in the mining residue, along with a moderate content of calcium and aluminium oxides. This suggests that mining residue is a potential aluminosilicate raw material for use in geopolymer materials. The NaOH pellets, purchased from SDS CARLO ERBA REACTIFS company, had a chemical composition of 98 % NaOH, 1 % carbonate, with the remaining portion consisting of a mixture of chloride, phosphates, sulfate, and other components. Date palm fiber (DPF) was manually extracted from the layer of tissue surrounding the trunk of the Phoenix roebelleni date palm tree, as illustrated in Fig. 1B. The extracted date palm fibers underwent a cleaning process with water to eliminate dust and impurities, followed by air-drying at the laboratory's ambient temperature. Subsequently, the fibers were cut to an average length of 10–30 mm, and a manual grinding process was employed to reduce their diameter to 0.05–1 mm.

Photographics of A: Mining residue and B: Date palm fiber.

Chemical composition

SiO2

Al2O3

Fe2O3

CaO

MgO

K2O

MnO

TiO2

Others

Weight percentages (%)

36.2

13.14

3.63

20.20

9.53

3.04

0.68

0.48

13.10

2.2 Preparation of geopolymer composites

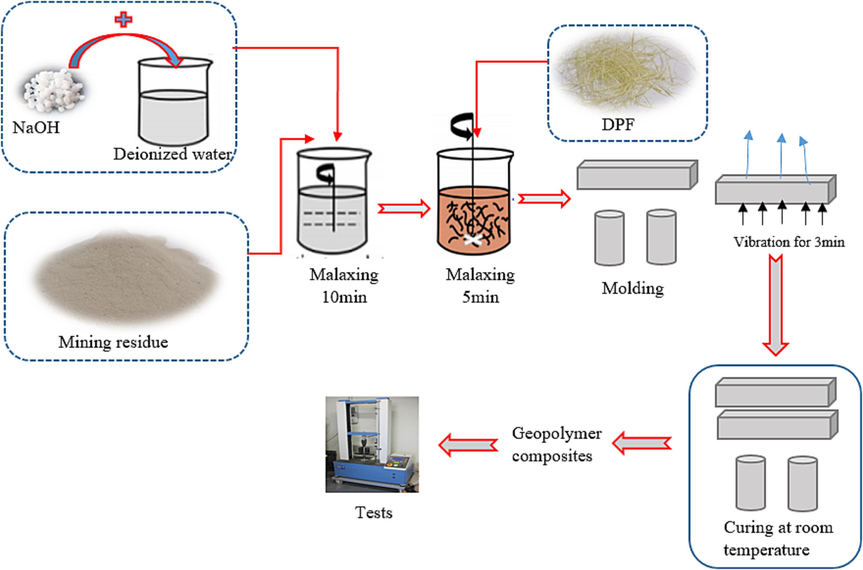

The manufacturing process of the geopolymer composites, incorporating mining residue and reinforced with date palm fiber, is illustrated in Fig. 2. Initially, a sodium hydroxide solution was prepared by dissolving NaOH pellets in deionized water, using a magnetic stirrer to achieve a highly concentrated solution with a 10 M concentration. To initiate the geopolymerisation reaction, the mining residue powder was added to the activation solution and mixed for 10 min using an electrical mixer, resulting in a uniform geopolymer paste. The ratio of the activator-to-solid ratio was 0.4.

Experimental procedure of manufacturing the geopolymer composites.

For reinforcement of the geopolymer matrix, the prepared date palm fibers with a diameter between 0.05 and 1 mm were gradually added to the geopolymer paste using a low-speed mixer until homogeneous mixtures were achieved. Additional water was added from time to time to enhance workability and ensure a good dispersion of fibers within the matrix. The resulting mixtures were poured into two types of molds, cylindrical (40 × 70 mm3) and sample prism (140 × 50 × 20 mm3), and subjected to shaking to release potential trapped air bubbles. Subsequently, the prepared specimens were covered with plastic film and allowed to cure under atmospheric conditions for 24 h before being demolded. The curing process continued under atmospheric conditions for an additional 27 days to achieve a fully cured samples, as illustrated in Fig. 3. The fiber content was varied from 0 % to 20 % (wt/wt), and this explored range was selected based on our laboratory experience and a literature review on the utilization of natural fibers as reinforcing agent for geopolymer matrices.

Appearance of specimens after demoulding.

2.3 Mechanical and physical properties

2.3.1 Compressive strength

The compressive strength (CS) was assessed by subjecting cylindrical specimens (40x70 mm3) of the geopolymer matrix and geopolymer composites reinforced with date palm fiber to compression test. Four specimens for each composition were tested using a mechanical CONTROLS testing machine operating at a speed of 3 mm/min.

2.3.2 Flexural strength and flexural modulus

The flexural strength (FS) and flexural modulus (FM) of geopolymer matrix and geopolymer composites were determined using a three-point bending tests, employing a WSM-10kN universal testing machine at a displacement rate of 1.5 mm/min. Four specimens measuring 140 × 50 × 20 mm3 from each composition were tested and the flexural strength (

) was calculated using the equation (Alomayri and Low, 2013):

The flexural modulus (

) can be obtained either graphically by measuring the slope of the linear segment of a typical stress–strain curve or determined using the equation (Alomayri and Low, 2013; Alzeer and MacKenzie, 2018):

2.3.3 Water absorption and thickness swilling

Water absorption (WA) and thickness swilling (TS) were conducted on specimens measing 40x40x20 mm3, immersed in a cold-water bath at the laboratory’s ambient temperature. The tests were carried out at various immersion durations, including 6 h, 24 h, 72 h, and 168 h. These physical properties are calculated using the following formulas (Akinyemi et al., 2019; Andiç-Çakir et al., 2014):

Structural and microstructural properties

2.3.4 FTIR spectroscopy

FTIR spectra of mining residue, geopolymer matrix, and various geopolymer composites samples embedded in KBr were acquired using a Bruker Optics Vertex 70 spectrophotometer. The analysis was performed at a resolution of 4 cm−1 and 32 co-addition scans in a frequency range of 4000–400 cm−1. The pellets were prepared with a mixture of 300 mg KBr and 5 mg of finely ground powders, using a hydraulic press. Nicolet software was employed for spectra analysis, allowing the comparison of absorbance bands corresponding to each functional group.

2.3.5 X-ray diffraction (XRD)

X-ray diffractograms of mining residue, the geopolymer matrix, and geopolymer composite samples were obtained using PHILIPS X'Pert diffractometer. The instrument is equipped with a copper anticathode Cu Kα with a wavelength 1.54A° to scan the samples from 5.00° to 70.00° 2- theta angles. The XRD analyses were performed on finely ground powders of mining residue and extractions from the fracture surface of the geopolymer matrix and geopolymer composites.

2.3.6 Scanning electron microscopy (SEM) and energy dispersive X-ray (EDX)

The microstructure of the samples was examined using a Tescan Vega Microscope device equipped with a tungsten filament electron gun. Apart from conventional secondary electron (SE) and backscattered (BSE) detectors, the device features an X-ray detector (a silicon-lithium (SiLi) diode) for non-destructive in-situ elementary chemical analysis (EDS, Energy Dispersive Spectroscopy). SEM and EDX analyses were conducted on the fracture surfaces of the geopolymer matrix and geopolymer composites.

3 Results and discussion

3.1 Mechanicals properties

3.1.1 Compressive strength

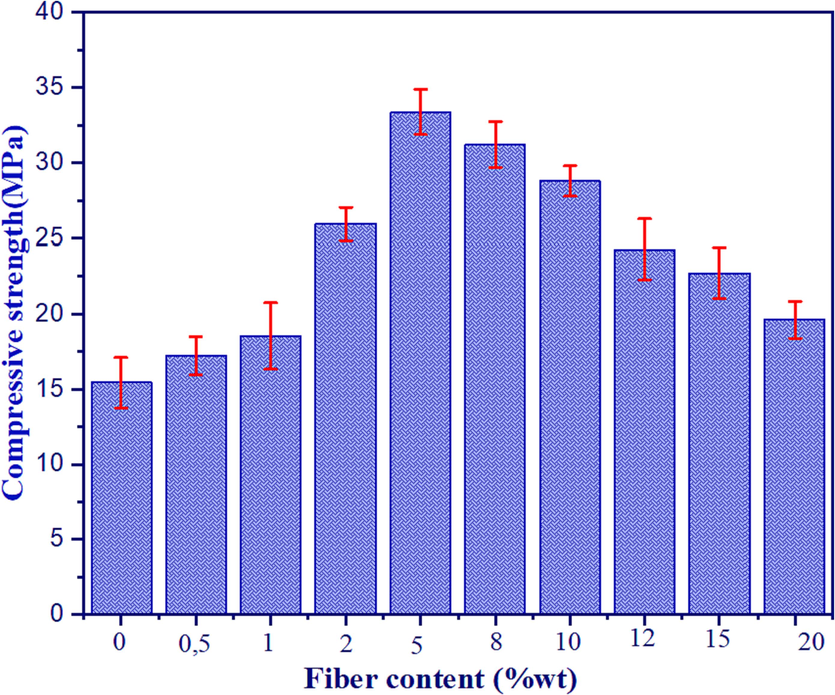

Fig. 4 illustrates the change in compressive strength (CS) as a function of fiber content for the formulated geopolymer composites with mining residue and date palm fiber (DPF). As demonstrated in this figure, the CS values exhibits a gradual increase within the range of 0–5 % (wt/wt) fiber content. Nevertheless, beyond this value, there is a noticeable and steady decrease in SC as the fiber content continues to increase. The geopolymer composite, formulated with 1 % (wt/wt) fiber content, exhibited a relatively small increment in CS of approximately 13.70 % (wt/wt) compared to geopolymer matrix. This modest gain is primarily attributed to the limited quantity of fibers incorporated into the geopolymer matrix, and is also a consequence of inadequate fiber distribution, which result in more unreinforced areas within the geopolymer matrix. Andiç-Çakir et al., (2014) have studied the effect of coir fiber content on the mechanical properties of geopolymer composites, and their findings indicated that the CS of geopolymer composites containing less than 1.5 % (wt/wt) coir fibers is similar to that of geopolymer matrix. This suggests that the geopolymer composite structure exhibits lower density in specific region, attributed to the absence of fiber (Andiç-Çakir et al., 2014).

Mean compressive strength of the geopolymer composites reinforced with date palm fibers.

More interesting are the results of CS found for the geopolymer composite formulated with 5 % (wt/wt) of fiber content, which was doubled compared to that of geopolymer matrix. This significant increase, approximately of 115 %, can be attributed to the optimal distribution of fibers within the geopolymer matrix, enhancing the overall compactness of the composite and reducing porosity and cracks. This distribution enhances the interfacial bonding force and bridging stress between the matrix and fibers, as elucidated by (Andiç-Çakir et al., 2014). In a similar study, Liu and Lv, 2022 elucidate the enhancement in CS, noting that the interface between the linen fabric and the geopolymer matrix is not subjected to shear loads. This condition allows to reduce the linen fabric separating or delamination from the geopolymer matrix under high loads (Liu and Lv, 2022). It is worth noting that the optimal value of added fibers to reinforce the geopolymer matrix, vary from a study to another, and depends on the nature of the fibers and the geopolymer matrices (Assaedi et al., 2015). For example, Assaedi et al., (2015) has found the maximum CS of 91 MPa when the flax fiber content was 4.1 % (wt/wt) for the metakaolinite-based geopolymer composites (Assaedi et al., 2015). However, the CS of geopolymer composites decreases when the fiber content exceeds 5 % (wt/wt). This decrease is mainly attributed to the elevated fiber content hindering the uniformity of the fiber–matrix interface and contributing to the formation of fiber clusters. These clusters, in consequence, compromise the adhesion between the fiber and matrix interfaces, as indicated by Liyana et al., (2013). The addition of fibers beyond the optimal quantity leads to a further increase in the porosity of the geopolymer composites, consequently causing a reduction in CS (Liyana et al., 2013).

3.1.2 Flexural strength

The flexural strength (FS) of geopolymer composites reinforced with date palm fiber versus fiber content is illustrated in Fig. 5. The increase of incorporated fibers quantity led to a notable improvement in FS of the formulated geopolymer composites, highlighting the effectiveness of date palm fiber as reinforcing agent. The results demonstrate that the FS of the geopolymer composites experienced a notable increase when the fiber content was below 8 % (wt/wt), but beyond this value, a subsequent decrease is observed. Of particular interest are the results of the formulations incorporating only 1 % and 2 % (wt/wt) of date palm fibers exhibited a 30 % and 45 % increase in FS, respectively. More interesting are the results obtained for the formulations made with 8 % and 10 % (wt/wt) of added fibers, in which the FS of the reinforced geopolymer composites was more than two times higher than that of geopolymer matrix. These results suggest that incorporating date palm fiber enhances the FS of the formulated geopolymer composites. This enhancement can be attributed to the exceptional intrinsic flexural strength of date palm fiber, effective dispersion of fibers within the geopolymer matrix, and strong adhesion between the fibers and the geopolymer matrix. Certainly, the strong adhesion and the effective dispersion play a crucial role in overcoming discontinuities in the geopolymer matrix.

Mean flexural strength of the geopolymer composites reinforced with date palm fibers.

Similar to compressive strength, the maximum flexural strength value achieved with optimal fibers amount for reinforcing the geopolymer matrix varies across studies and depends on both fibers and geopolymer matrices characteristics. For instance, Alomayri et al., (2013) reported a maximum FS of 11.7 MPa with the addition of 0.5 % (wt/wt) cotton fiber to the low calcium fly ash geopolymer composites, whereas the incorporation of 1 % (wt/wt) led to a decrease in this property (Alomayri et al., 2013). The same authors reported a maximum FS of approximately 31.7 MPa when reinforcing geopolymer composites with 8.3 % (wt/wt) woven cotton in a subsequent study (Alomayri et al., 2014b). This notable increase, form 8.2 MPa to 31.7 MPa, was almost four times higher than that of geopolymer matrix. They attribute this remarkable enhancement to the lower density of woven cotton, facilitating the formation of numerous reinforcement layers capable of resisting shear failure and supporting applied loads effectively. This, in turn, enhances stress transfer between the matrix and the woven cotton fibers, resulting in improved FS (Alomayri et al., 2013). In a more recent study, Zhang et al. (2021)found that incorporating 15 % (wt/wt) of kenaf fibers into the geopolymer matrix resulted in a maximum flexural strength of 11.8 MPa. This result is due to the good interface between the geopolymer matrix and kenaf fibers Huang et al., 2021).

It is important to highlight that incorporating more than 8 %-10 % (wt/wt) of date palm fibers into the geopolymer matrix led to a decrease in FS of the geopolymer composites. As reported for the compressive strength, this decrease is mainly due to the higher fiber content hindering the uniformity of the fiber–matrix interface and contributing to the formation of fiber clusters. These clusters compromise the adhesion between the fiber and matrix interfaces, as indicated by Liyana et al., (2013). The addition of fibers beyond the optimal amount further increases the porosity of the geopolymer composites, rendering the material less dense. This, coupled with the formation of the fiber agglomerates, results in a reduction of FS (Liyana et al., 2013).

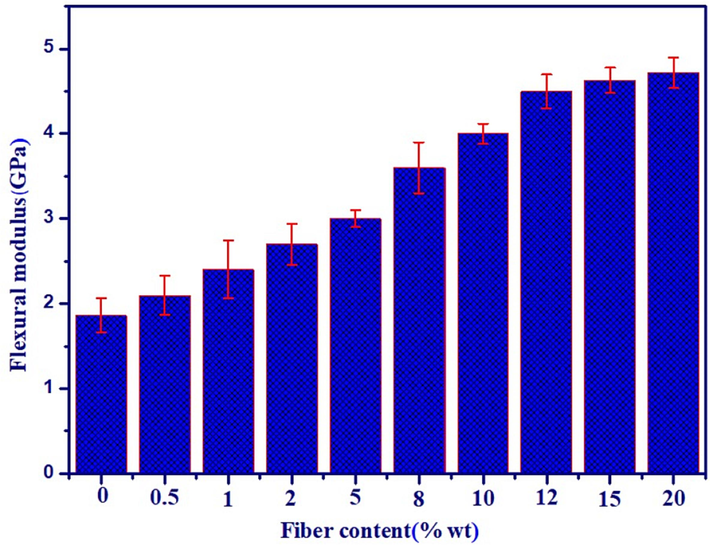

3.1.2.1 Flexural modulus

Fig. 6 illustrates the flexural modulus (FM) of the geopolymer composites reinforced with date palm fibers versus fiber content. Generally, as the loading of date palm fiber increased the FM of the reinforced geopolymer composites exhibited a corresponding increase. Achieving the optimal fiber content of 8–10 % (wt/wt), corresponding to the optimal flexural strength, results in an almost twofold enhancement in FM compared to the geopolymer matrix. For geopolymer composites with 15 %–20 % (wt/wt) fiber content, the increase reaches approximately 150 % when compared to the geopolymer matrix. These results indicate that incorporating date palm fibers enhances the stiffness of geopolymers composites. A similar trend has been observed by other authors (Alomayri et al., 2014b; Low et al., 2014). For example, Low et al., (2014) noticed an increase in FM with rising fiber content for geopolymer composites reinforced with cotton fabric. This increase is attributed to the crack bridging facilitated by the existing long continuous fibers, resulting in a higher FM compared to the geopolymer matrix. These fibers possess the capacity to sustain greater loads and can undergo multiple cracks during the loading process, thereby preventing the brittle failure of geopolymer composites (Low et al., 2014). In a similar study, Alomayri et al., 2014b) demonstrated a consistent increase in FM with an increase in cotton fiber content. For comparison, the addition of 4.5 %, 6.2 % and 8.3 % (wt/wt) of cotton fibers resulted in increasing the FM to 0.87GPa, 1.23GPa, 1.4GPa and 1.74GPa, respectively. This significant improvement in FM can be attributed to the higher intrinsic flexural modulus of the cotton fibers, influencing the flexural modulus of composite materials when reinforced with such natural fibers (Alomayri et al., 2014b). In our case, the remarkable FM achieved can be also attributed to the higher intrinsic flexural modulus of date palm fiber. These fibers act as bridges for cracks, resulting in a higher FM compared to the geopolymer matrix. Furthermore, with an increase in fiber content, the risk of brittleness diminishes, as the fibers exhibit resistance to higher loads.

Mean flexural modulus of the geopolymer composites reinforced with date palm fibers.

3.2 Physical properties

3.2.1 Water absorption

Water absorption is a critical characteristic in geopolymer composites incorporating natural fibers, given their sensitivity to water related to their hydrophilic nature. Therefore, it is essential to evaluate this property in geopolymer composites formulated with mining residue and reinforced with date palm fiber. This assessment allows for the measurement of the quantify of water absorbed under specific environmental conditions and within a defined time. The water absorption or moisture diffusion depends on various factors such: void/pore structure, humidity, temperature, fiber volume fraction, and matrix viscosity (Radzi et al., 2019).

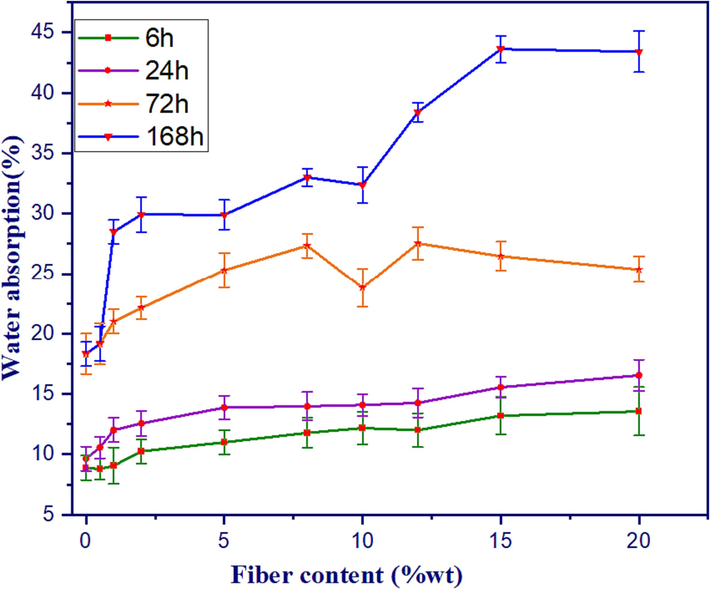

The results of water absorption (WA) of geopolymer composites immersed in a water bath for durations of 6 h, 24 h, 72 h, and 168 h are illustrated in Fig. 7. The results indicate that an increase in fiber content corresponds to a higher WA in the geopolymer composites. This is can be attributed to the significant amount of date palm fibers in the geopolymer composites, containing hydrophilic compounds like cellulose and hemicelluloses. The presence of hydroxyl groups and other oxygenated groups in cellulose and hemicelluloses emerges as a primary factor contributing to the elevated WA. Consequently, this factor enhances the overall hydrophilic nature of geopolymer composites, resulting in increased WA. Moreover, the incorporation of excessive fiber content beyond the optimal amount promotes the cracks formation, contributing to the higher WA through capillarity phenomenon. The same behaviour was reported by several researchers, where WA exhibited elevated value with higher fiber content in geopolymer composites reinforced with cotton fabric (Alomayri et al., 2014a; Low et al., 2014; Alzeer and MacKenzie, 2013). According to their findings, the higher WA is primarily attributed to the hydrophilic nature of the used cotton fabric fibers and the poor interfacial area between fibers and matrix. In a recent study, Huang et al. (2021)studied the influence of fiber content and emersion time on the WA property of geopolymer composites reinforced with rice straw Huang et al., 2021). Their results demonstrated a positive correlation between elevated WA and higher fiber content. They attributed this increase to the presence of micro-cracks in the geopolymer composites, promoting capillary water transport within the composites and facilitating water storage in the fractures, thereby gradually enhancing water absorption.

Mean water absorption of the geopolymer composites reinforced with date palm fibers. the utilized rice straw fibers.

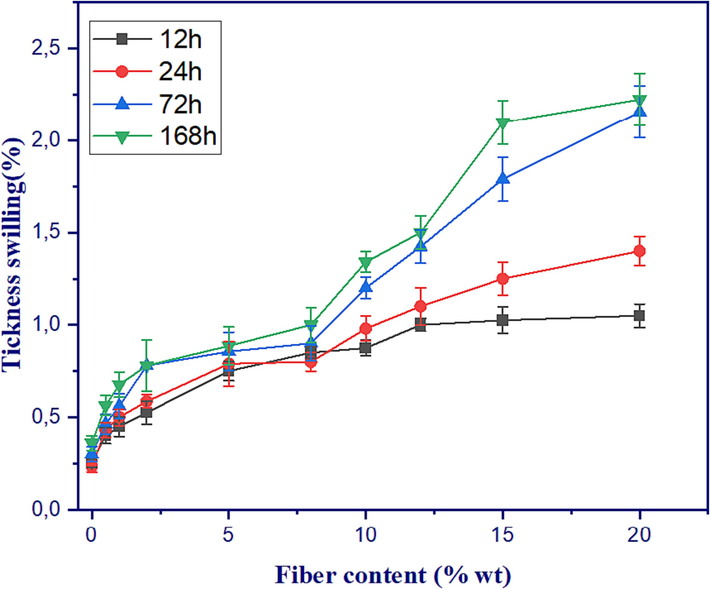

3.2.2 Thickness swelling

The thickness swelling (TS) was performed on geopolymer composites containing mining residue and reinforced with date palm fiber to evaluate changes in their dimensional stability. Fig. 8 illustrates the thickness swelling of geopolymer composites in relation to the fiber content. The results exhibit a similar trend to water absorption, indicating an increase in TS with a rise of fiber content. The TS values remained low, staying below 1 % for all formulated geopolymer composites with fiber content below the optimal fiber content of 8 %, even during prolonged immersion times. However, surpassing the optimal fiber content led to a noticeable difference in TS values for all tested immersion times. For instance, in geopolymer composite with 15 % (wt/wt) fiber content, the TS increased from 1 % to 2.2 % after immersion times of 12 h and 168 h, respectively. Alternatively, the TS exhibited greater stability after 12 h immersion time, but a significant increase occurred after 72 h of immersion when the fiber content exceeded the optimal value of 8 % (wt/wt). This increase is likely attributed to the large gaps between the fiber and the geopolymer matrix, facilitating water movement into the composites. These findings are in agreement with those reported by other researchers, suggesting that natural fibers contribute to increased TS (Alomayri et al., 2013; Gholampour et al., 2022; Huang et al., 2021). Furthermore, a poor interface between fiber and matrix and inefficient fibers dispersion within the geopolymer matrix significantly decrease the dimensional stability of the composites when the fiber content exceeds the optimal value. In a different study, Huang et al. (2021)found that TS continued to increase with prolonged immersion time, even in composites with a good interface between fiber and matrix and an efficient fibers distribution within the geopolymer matrix Huang et al., 2021). This phenomenon may be attributed to the potential presence of cracks and the higher hydrophilic nature of the utilized rice straw fibers.

Mean thickness-swilling of the geopolymer composites reinforced with date palm fibers.

3.3 Structural properties of the composite

3.3.1 X-ray diffraction

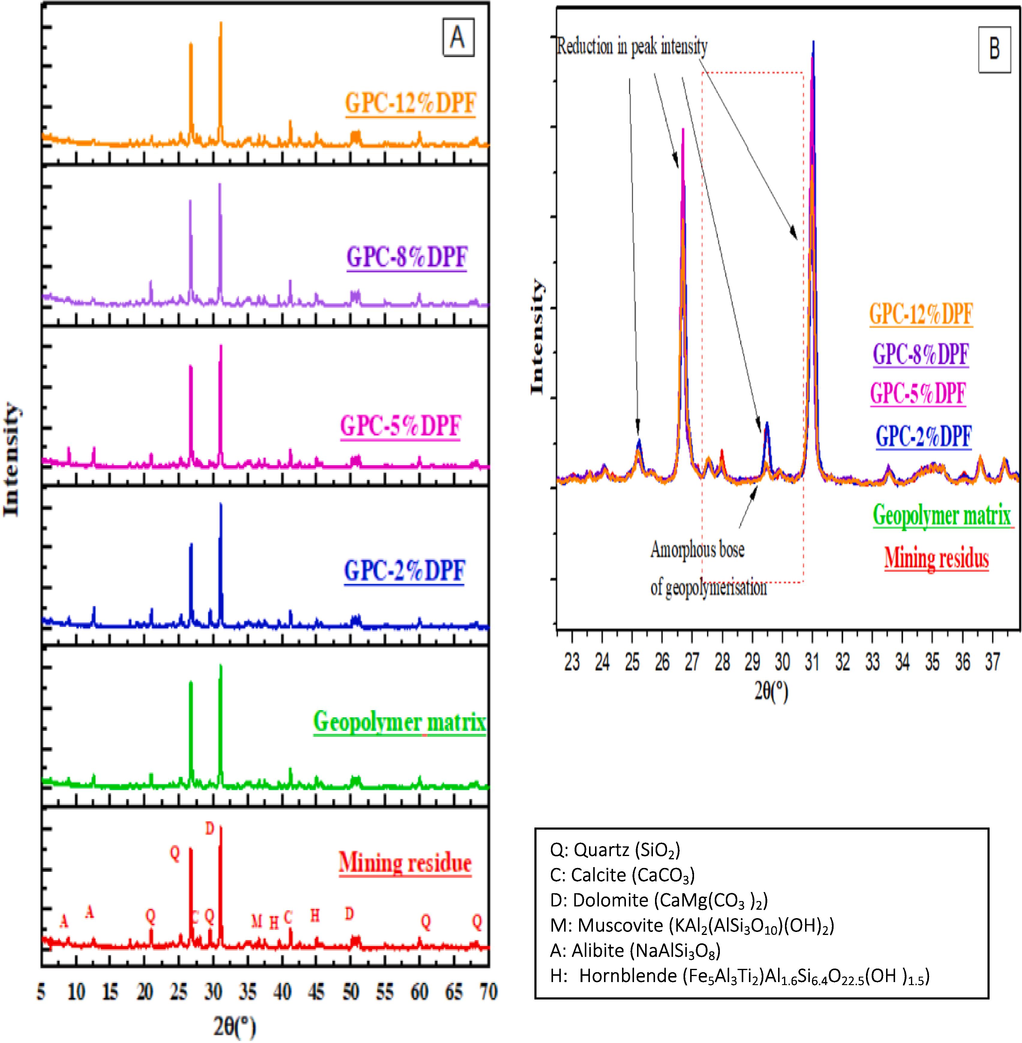

The X-ray diffraction (XRD) patterns showing the composition of mining residue, geopolymer matrix and geopolymer composites reinforced with varying date palm fiber contents of 2 %, 5 %, 8 %, and 12 % (wt/wt), are presented in Fig. 9. In this figure, it is evident that mining residue is predominantly a crystalline material, with major crystalline phases identified as quartz, calcite, dolomite, muscovite, albite and hornblende. The XRD peaks of the mining residue closely resemble to those of other raw materials used in geopolymers such as fly ash, metakaolin (Alomayri et al., 2013; Alomayri et al., 2014a; Low et al., 2014; Alomayri and Low, 2013). For example, Alomayri et al., 2014b) found that the main crystalline phases of fly ash include quartz, mullite, muscovite, dolomite, and hematite (Alomayri et al., 2014b). In another study, Ahmari and Zhang (2012) indicated that mine tailing is mainly a crystalline material with substantial amount of silica (Ahmari and Zhang, 2012).

XRD patterns of A) Mining residue, geopolymer matrix, and geopolymer composites, and B) main changes after geopolymerisation reaction.

Following the geopolymerisation reaction of mining residue using a highly concentrated alkaline solution, there is a decrease in intensity of the crystalline peaks in the 0 to 22° region. However, these crystalline peaks in XRD patterns are still present, due to the partial dissolution of the mining residue particles. Comparing the XRD pattern of the original mining residue with that of the hardened geopolymer material in Fig. 9(B), it is noticeable that the crystalline phases remain largely unchanged, except that their intensities were decreased. This can be attributed to the activation of the mining residue, as reflected in the formation of an amorphic bump characteristic in the cured geopolymer matrix, appearing in the region of 28°-30° in 2θ position. These results confirm that the crystalline phases are minimally affected by the geopolymerisation reaction, while the amorphous phases located between 0°–22° and 28–30° in 2 θ are strongly involved in the activation of the mining residue. Similar findings have been reported by several authors, suggesting that crystalline phases act as inert fillers in the geopolymer network and do not actively participate in the geopolymerisation reaction (Alomayri et al., 2014b; Alomayri and Low, 2013; Liyana et al., 2013). Additionally, a decrease in the intensity of the peaks related to the crystalline phases due to the partial dissolution of mining residue particles has been previously reported (Ahmari and Zhang, 2012; Zhang et al., 2021).

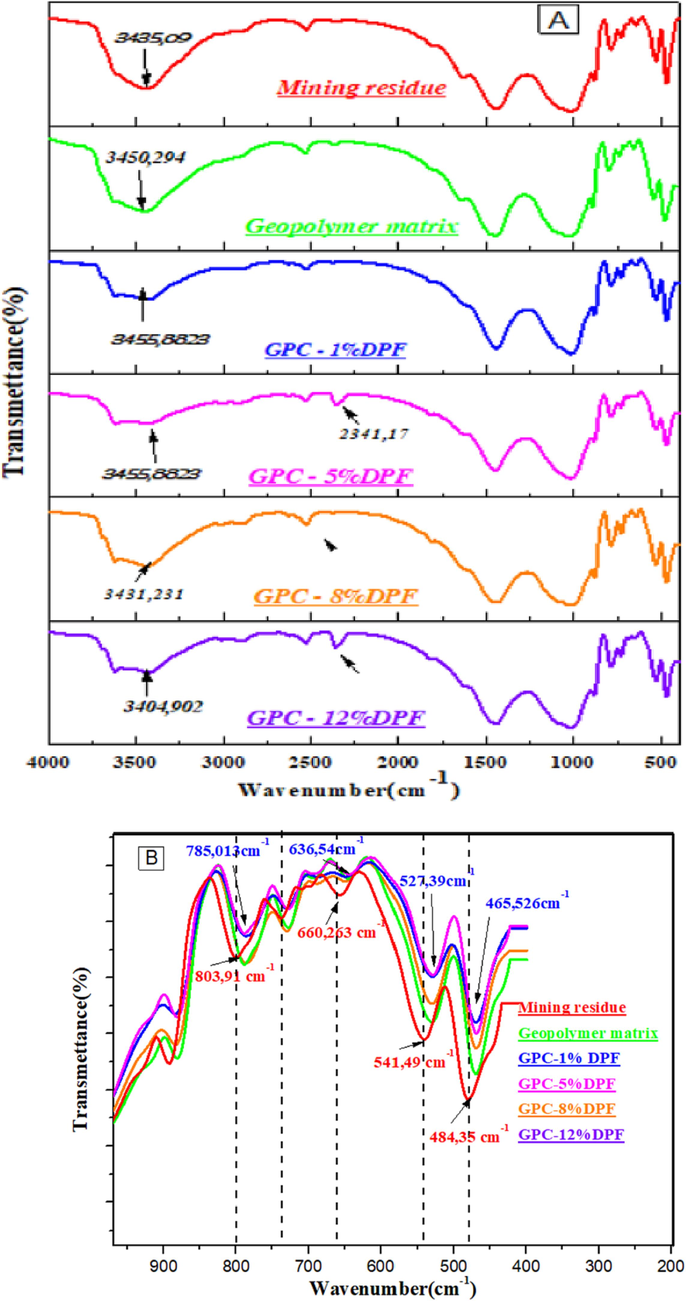

3.3.2 Infrared spectroscopy

Fig. 10 displays the FTIR spectra of mining residue, geopolymer matrix, and geopolymer composites reinforced with different percentages of date palm fibers (1 %, 5 %, 8 % and 12 %). These spectra highlight both similarities and differences among the mining residue and its geopolymer forms. The following bands and peaks are consistently observed in all spectra: The two broad bands at 3480 cm−1 and 1650 cm−1 are attributed to the stretching and bending vibrations of —OH, respectively. These bands are a result of the presence of physically absorbed free water molecules by powder and reaction products (Yan et al., 2016). The bands at 1796 cm−1, 1465 cm−1, and 875 cm−1 corresponding to the presence of calcium carbonate (Somna et al., 2011). Within the range of 930–1200 cm−1, there exist various bands that can be attributed to the Si—O—Si bonds of (Si—O)n units. This particular structure is commonly found in calcium aluminosilicate hydrate (C—A—S—H) gel (Clayden et al., 1999). The band at around 1037 cm−1 related to the asymmetric tensile vibration of Si—O—Si and Si—O—Al, which is considered as evidence of the existence of three-dimensional aluminosilicate hydrate gels (Ahmari and Zhang, 2012; Murmu and Singh, 2014). The band between 780 and 800 cm−1 is assigned to Si—OH stretch and Al—OH bond (Ettahiri et al., 2023; Hermann et al., 2022). The peaks around 520–530 cm−1 corresponding to stretch symmetrical vibration of Al—O—Si band, and 445–480 cm−1 are assigned to symmetrical stretch vibration of Si—O—Si and O—Si—O bands (Chuewangkam et al., 2022; Ismail et al., 2014; Tang et al., 2018; Wu et al., 2023).

A) FTIR spectra of mining residue, geopolymer matrix and the geopolymer composites. B) Main changes after geopolymerisation reaction.

The comparison between the spectra of mining residue and its geopolymerized forms revealed that all the absorption bands of asymmetric stretching of Si-O-Si, Si-O-Al, Si-OH, and Al-OH, which are considered as the characteristic peaks of aluminosilicate raw materials, are shifted to low wave numbers (Fig. 10B). This is due mainly to the substitution of the [AlO4]3- groups into [SiO4]4-, confirming the occurrence of the geopolymerisation reaction under highly alkaline conditions (Chuewangkam et al., 2022). On the other hand, the FTIR spectra of geopolymer composites are similar to that of geopolymer matrix, except the —OH band at 3480 cm−1 that is shifted to the long wave number and its width is decreased, and also the appearance of a small band at around 2341 cm−1 attributable to the C—O band. This suggests that mining residue are involved in geopolymerisation and aid in the formation of N-A-S-H and C-A-S-H gels.

3.3.3 Scanning electron microscopy (SEM) and EDX (Energy Dispersive X-Ray)

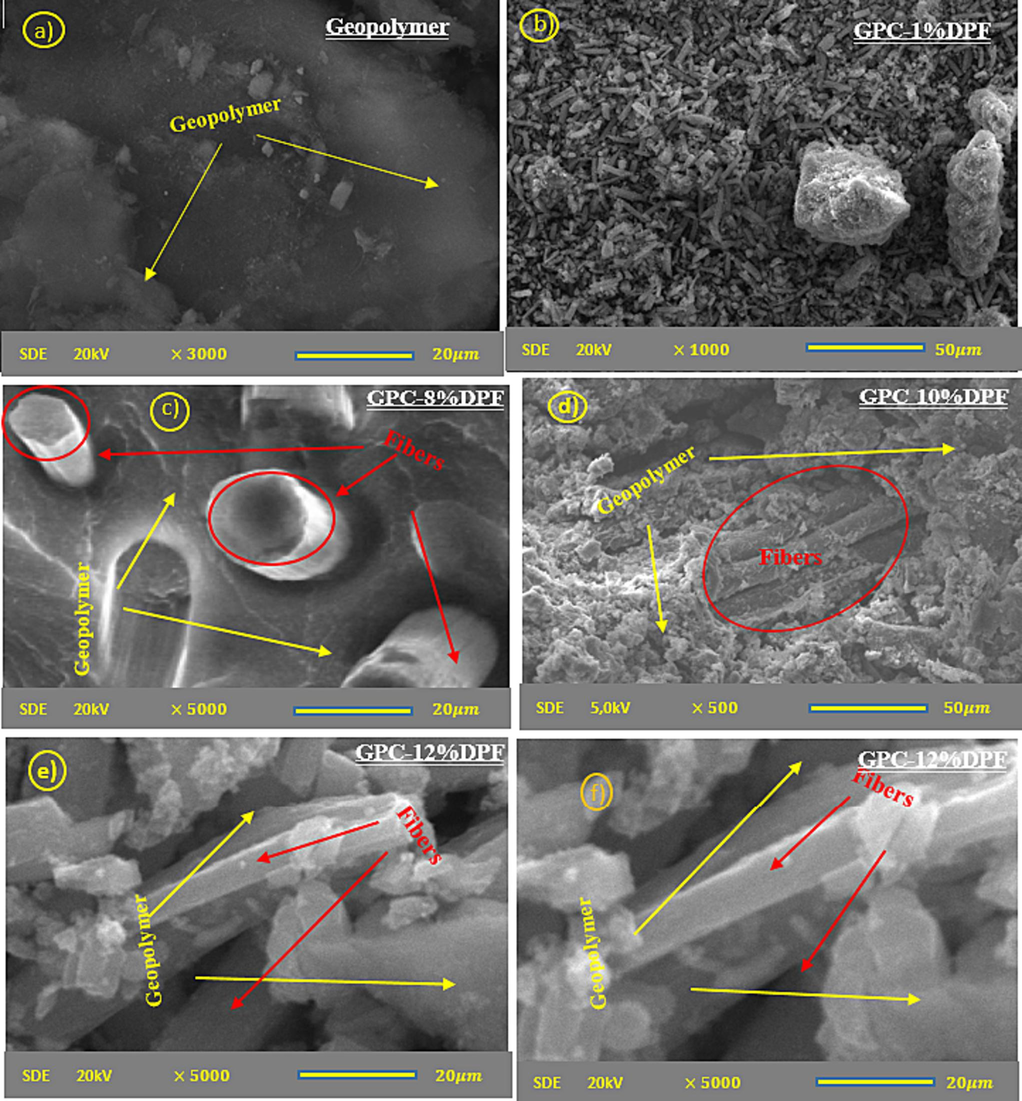

Fig. 11 shows SEM images of both geopolymer matrix and geopolymer composites reinforced with different date palm fiber contents (1 %, 8 %, 10 %, and 12 %). In Fig. 11(a and b), it is evident that the geopolymer matrix exhibits a granular appearance, loose structure and less compact matrix. The presence of voids and pores in the geopolymer matrix explain the observed low mechanical properties for geopolymer matrix. In Fig. 11(b), the SEM image illustrates the surface fracture of a geopolymer composite reinforced with a lower fiber content of about 1 wt% (wt/wt). In this image, matrix-rich regions are predominant compared to the geopolymer composite with higher fiber content (Fig. 11e and f). The presence of less compacted matrix-rich regions indicates that the matrix lacks adequate fiber reinforcement. As a result, there are insufficient fibers to resist the load from the matrix, leading to the lower mechanical properties in geopolymer composites reinforced with lower fiber content (Akinyemi et al., 2019; Asasutjarit et al., 2009; Maragkos et al., 2009). The fiber surfaces shown in Fig. 11 (e, f) are smooth with a clear texture, while the fibers illustrated in Fig. 11 (d) possess rough surface and are covered by a layer of matrix particles. This observation suggests that the geopolymer composites exhibit stronger adhesion compared to the geopolymer matrix Huang et al., 2021).

SEM images at the fracture surfaces of geopolymer matrix and geopolymer composites.

The SEM image in Fig. 11(c) illustrates the fracture surface of geopolymer composite with a fiber content of 8 % (wt/wt), exhibiting the obtained higher mechanical properties. The fibers are tightly embedded in the matrix, and no cracks or voids are observed at the fiber–matrix interface. Additionally, the pulled-out fiber is coated with geopolymer matrix, indicating strong adhesion between fiber and geopolymer matrix. Consequently, this enhances the bending strength in the longitudinal direction Huang et al., 2021). The SEM images in Fig. 11(e and f) illustrate the fracture surfaces of geopolymer composite filled with higher fiber content of about 12 % (wt/wt). It can be observed the presence of gaps between fiber and matrix, along with signs of debonding at the interface between the fiber and matrix Huang et al., 2021). Furthermore, the presence of holes left after the fibers were pulled out, local fiber-rich regions and aggregations as shown in Fig. 11 (e, f), indicate that fibers separated from the matrix inadequately absorb the load transmitted by the matrix. As a result, geopolymer composites filled with 12 % (wt/wt) fiber content exhibit reduced mechanical properties compared to that filled with the optimal fiber content of 8 % (wt/wt) (Assaedi et al., 2015; Huang et al., 2021).

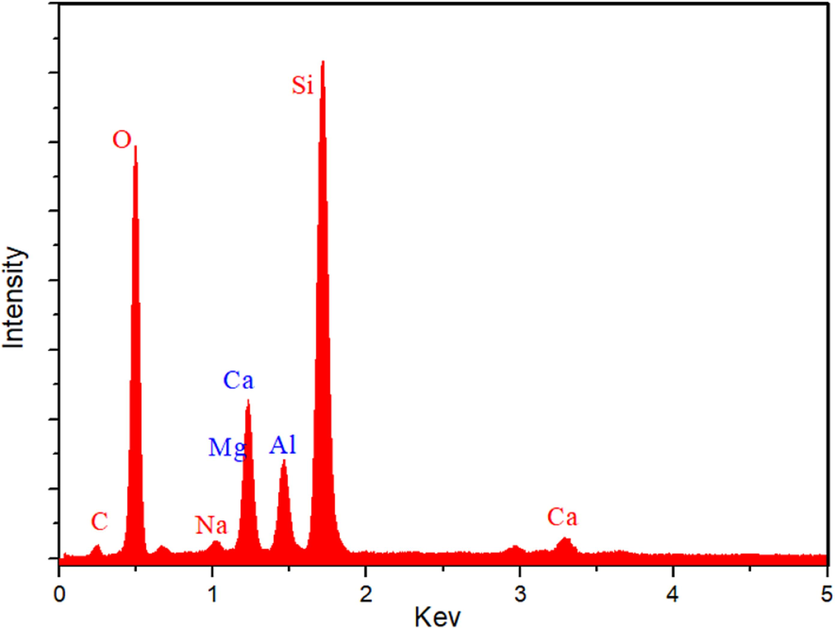

Fig. 12 illustrates the EDX spectrum for the fracture surface of the geopolymer composite with 8 % (wt/wt) fiber content, while Table 2 provides a summary of the corresponding weight and atomic mass percentages. These results align well with the results of previously presented X-ray diffraction (XRD) and X-ray fluorescence (XRF) analyses, indicating that the geopolymer composite matrix comprises inorganic materials, with silicon (Si), aluminium (Al) and calcium (Ca), as major components. In contract, sodium (Na) and magnesium (Mg) are present in minor quantities. The Si element is derived from silica (SiO2) and silicon derivatives like Muscovite and Albite, while Al element originates from the aluminum oxide (Al2O3) found in mining residue. Ca is derived from calcite and calcium carbonate, and Mg is present in the sample due to magnesium oxide (MgO) and dolomite. Na is detected in minor quantity within the binding phase of the geopolymer composite, serving as the primary element in the activator solution containing NaOH (Kourti et al., 2010; Utama et al., 2022). It is worth noting that the higher proportion of oxygen and the moderate quantity of carbon in the analyzed geopolymer composite can be attributed, to a lesser extent, to mining residue and predominantly to the organic origin of the natural fibers used in formulating the geopolymer composite.

EDX (Energy Dispersive X-Ray) of geopolymer composite at 8% (wt/wt) fiber content.

Element

Weight percentage (%)

Atomic percentage (%)

O K

43.81

59.07

Si K

23.54

16.69

Al K

10.18

6.09

Ca K

10.61

8.69

Mg K

4.49

3.78

Na K

2.61

1.33

C K

2.34

1.22

The results obtained from the EDX spectroscopy analysis reveal an interesting composition of the geopolymer gel derived from mining residue. It appears that there is a significant amount of silicon and a moderate quantity of both calcium and aluminum. Specifically, the percentages of Si, Ca, and Al are 23.54 %, 10.61 %, and 10.18 % (wt/wt) respectively, with a Si/Al molar ratio of 2.22. These findings align with previous studies, suggesting that the resulting geopolymer material conforms to the expected range of 1 to 3 (Toniolo et al., 2018). The higher concentration of Ca compared to Na confirms that the geopolymer gel formed from mining residue primarily undergoes the C-A-S-H (calcium-alumino-silicate-hydrate) process, rather than the sodium-alumino-silicate hydrate (N-A-S-H) process (Ariffin et al., 2013; Mijarsh et al., 2014). This is a positive indication of the geopolymer composite's mechanical properties. Furthermore, the data also reveals a low Ca/Si ratio of 0.32 in the formed gel, which is believed to play a crucial role in enhancing the strength of the geopolymer composite. These findings contribute to our understanding of the geopolymer gel's composition and its potential for robustness.

4 Conclusions

The objective of this study was to develop geopolymer composites using activated mining residue and date palm fiber as a reinforcing agent. To optimize their performances, we investigated the effect of fiber content on the mechanical, physical and microstructural properties of the manufactured composites. The key conclusions drawn from the results are as follows:

-

‐

The mechanical properties of the geopolymer composites (CS, FS and FM), exhibited a twofold increase compared to the geopolymer matrix when the loading of date palm fibers reached 8 % (wt/wt). The enhanced resistance to bending and breaking forces observed in this composite can be attributed to the exceptional intrinsic mechanical properties of date palm fiber, effective dispersion of fibers within the matrix, and strong adhesion between the fibers and the geopolymer matrix, highlighting the effectiveness of date palm fiber as a reinforcing agent. However; a subsequent increase in fiber content beyond 8 % (wt/wt) led to a deterioration in the mechanical properties due to the poor workability and inadequate fibers dispersion within the matrix, resulting in the formation of voids and fiber agglomerates.

-

‐

The physical properties of the reinforced geopolymer composites (WA and TS) continually increased as the loading of date palm fibers increased. After 168 h of immersion in cold water, these properties reached acceptable values of 30 % for WA and 0.9 % for TS. These increases are mainly attributed to the hydrophilic nature of date palm fiber components (hemicelluloses and celluloses) and the formation of pores as fiber content increased.

-

‐

The structural analysis of mining residue, geopolymer matrix, and geopolymer composites using FTIR and XRD techniques suggested that mining residue, as an aluminosilicate raw material with a semicrystalline structure, underwent a geopolymerisation reaction to a relatively lower extent after activation by a highly alkaline solution. The limited geopolymerisation reaction is attributed to the semicrystalline nature of mining residue, necessitating prior pretreatment by calcination to enhance its reactivity. SEM images revealed a well-established matrix-fiber interface, providing an explanation of the achieved good mechanical and physical properties. EDX results showed an interesting composition of the geopolymer gel derived from mining residue, with a significant amount of silicon and a moderate quantity of calcium and aluminum. The higher concentration of Ca compared to Na confirms that the geopolymer gel formed primarily undergoes the C-A-S-H process, rather than N-A-S-H process, which is a positive indication of the geopolymer composite's mechanical properties.

Considering the above-mentioned findings, it is evident that both investigated raw materials, namely mining residue and date palm fiber, are well-suited for the formulating geopolymer composites as construction materials. The availability of locally sourced mining residue, an aluminosilicate raw material, combined with the ease of obtaining date palm fiber through conventional manufacturing techniques, can result in a cost-effective product with a desirable mechanical property. This presents advantages for the construction industry, particularly in less developed countries or regions where there is a demand for cost-effective construction materials.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Eco-friendly synthesis of low-cost antibacterial agent (brown attapulgite-Ag nanocomposite) for environmental application. Chem. Data Collect.. 2022;37:100814

- [CrossRef] [Google Scholar]

- Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater.. 2012;29:323-331.

- [CrossRef] [Google Scholar]

- Flexural strength and failure of geopolymer concrete beams reinforced with carbon fibre-reinforced polymer bars. Constr. Build. Mater.. 2020;231:117185

- [CrossRef] [Google Scholar]

- Response of coir fibre reinforced cement composites to water repellent chemical additive and microwave accelerated curing. Cellulose. 2019;26:4987-4999.

- [CrossRef] [Google Scholar]

- Ultrasound assisted synthesis of attapulgite-PdO nanocomposite using palladium complex for hydrogen storage: kinetic studies. Inorg. Chem. Commun.. 2022;143:109787

- [CrossRef] [Google Scholar]

- Synthesis of attapulgite-MnO2 nanocomposite from manganese complex by ultrasound for hydrogen storage. J. Indian Chem. Soc.. 2022;99:100596

- [CrossRef] [Google Scholar]

- Effect of water absorption on the mechanical properties of cotton fabric-reinforced geopolymer composites. J. Asian Ceram. Soc.. 2014;2:223-230.

- [CrossRef] [Google Scholar]

- Synthesis and characterization of mechanical properties in cotton fiber-reinforced geopolymer composites. J. Asian Ceram. Soc.. 2013;1:30-34.

- [CrossRef] [Google Scholar]

- Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng.. 2013;50:1-6.

- [CrossRef] [Google Scholar]

- Mechanical properties of cotton fabric reinforced geopolymer composites at 200–1000 °C. J. Adv. Ceram.. 2014;3:184-193.

- [CrossRef] [Google Scholar]

- Synthesis and mechanical properties of novel composites of inorganic polymers (geopolymers) with unidirectional natural flax fibres (phormium tenax) Appl. Clay Sci.. 2013;75–76:148-152.

- [CrossRef] [Google Scholar]

- Synthesis and catalytic properties of new sustainable aluminosilicate heterogeneous catalysts derived from fly ash. ACS Sustain. Chem. Eng.. 2018;6:5273-5282.

- [CrossRef] [Google Scholar]

- Physical and mechanical properties of randomly oriented coir fiber–cementitious composites. Compos. Part B Eng.. 2014;61:49-54.

- [CrossRef] [Google Scholar]

- Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater.. 2013;43:80-86.

- [CrossRef] [Google Scholar]

- Materials and mechanical properties of pretreated coir-based green composites. Compos. Part B Eng.. 2009;40:633-637.

- [CrossRef] [Google Scholar]

- Characterisation of mechanical and thermal properties in flax fabric reinforced geopolymer composites. J. Adv. Ceram.. 2015;4:272-281.

- [CrossRef] [Google Scholar]

- Utilization of sweet sorghum fiber to reinforce fly ash-based geopolymer. J. Mater. Sci.. 2014;49:2548-2558.

- [CrossRef] [Google Scholar]

- Mechanical and dielectric properties of fly ash geopolymer/sugarcane bagasse ash composites. Polymers. 2022;14:1140.

- [CrossRef] [Google Scholar]

- Solid state 27Al NMR and FTIR study of lanthanum aluminosilicate glasses. J. Non-Cryst. Solids. 1999;258:11-19.

- [CrossRef] [Google Scholar]

- Geopolymers: inorganic polymeric new materials. J. Therm. Anal.. 1991;37:1633-1656.

- [CrossRef] [Google Scholar]

- The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res.. 2007;37:1590-1597.

- [CrossRef] [Google Scholar]

- A review on the use of date palm fibers to reinforce earth-based construction materials. Mater. Today Proc. 2023S2214785323032479

- [CrossRef] [Google Scholar]

- A state-of-the-art review of recent advances in porous geopolymer: applications in adsorption of inorganic and organic contaminants in water. Constr. Build. Mater.. 2023;395:132269

- [CrossRef] [Google Scholar]

- Mechanical and durability properties of natural fiber-reinforced geopolymers containing lead smelter slag and waste glass sand. Constr. Build. Mater.. 2022;352:129043

- [CrossRef] [Google Scholar]

- Enhanced performance of hydrogen peroxide modified pozzolan-based geopolymer for abatement of methylene blue from aqueous medium. Silicon. 2022;14:5191-5206.

- [CrossRef] [Google Scholar]

- Study on untreated and alkali treated rice straw reinforced geopolymer composites. Mater. Chem. Phys.. 2021;262:124304

- [CrossRef] [Google Scholar]

- Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos.. 2014;45:125-135.

- [CrossRef] [Google Scholar]

- Short palm tree fibers – Thermoset matrices composites. Compos. Part Appl. Sci. Manuf.. 2006;37:1413-1422.

- [CrossRef] [Google Scholar]

- Cement industry greenhouse gas emissions – management options and abatement cost. J. Clean. Prod.. 2016;112:4041-4052.

- [CrossRef] [Google Scholar]

- Mechanical properties of geopolymer composites reinforced with natural fibers. Procedia Eng.. 2016;151:388-393.

- [CrossRef] [Google Scholar]

- Production of geopolymers using glass produced from DC plasma treatment of air pollution control (APC) residues. J. Hazard. Mater.. 2010;176:704-709.

- [CrossRef] [Google Scholar]

- Production parameters of novel geopolymer masonry mortar in heritage buildings: application in masonry building elements. J. Build. Eng.. 2023;76:107038

- [CrossRef] [Google Scholar]

- Durability of cellulosic-fiber-reinforced geopolymers: a review. Molecules. 2022;27:796.

- [CrossRef] [Google Scholar]

- Effect of fly ash/alkaline activator ratio and sodium silicate/NaOH ratio on fly ash geopolymer coating strength. Key Eng. Mater.. 2013;594–595:146-150.

- [CrossRef] [Google Scholar]

- Elaboration of geopolymers based on clays by-products from phosphate mines for construction applications. J. Clean. Prod.. 2020;261:121317

- [CrossRef] [Google Scholar]

- Mine wastes based geopolymers: a critical review. Clean. Eng. Technol.. 2020;1:100014

- [CrossRef] [Google Scholar]

- Synthesis of ferronickel slag-based geopolymers. Miner. Eng.. 2009;22:196-203.

- [CrossRef] [Google Scholar]

- Synthesis of geopolymer from large amounts of treated palm oil fuel ash: Application of the Taguchi method in investigating the main parameters affecting compressive strength. Constr. Build. Mater.. 2014;52:473-481.

- [CrossRef] [Google Scholar]

- Hydration products, morphology and microstructure of activated slag cement. Int. J. Concr. Struct. Mater.. 2014;8:61-68.

- [CrossRef] [Google Scholar]

- Water absorption, thickness swelling and thermal properties of roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol.. 2019;8:3988-3994.

- [CrossRef] [Google Scholar]

- Date palm reinforced epoxy composites: tensile, impact and morphological properties. J. Mater. Res. Technol.. 2019;8:3959-3969.

- [CrossRef] [Google Scholar]

- NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel. 2011;90:2118-2124.

- [CrossRef] [Google Scholar]

- The brittleness and chemical stability of optimized geopolymer composites. Materials. 2017;10

- [CrossRef] [Google Scholar]

- Synthesis of highly efficient porous inorganic polymer microspheres for the adsorptive removal of Pb2+ from wastewater. J. Clean. Prod.. 2018;193:351-362.

- [CrossRef] [Google Scholar]

- Extensive reuse of soda-lime waste glass in fly ash-based geopolymers. Constr. Build. Mater.. 2018;188:1077-1084.

- [CrossRef] [Google Scholar]

- Synthesis of synthetic amorphous silica powder from palm oil mill fly ash extract by carbon dioxide impregnation. Mater. Today Proc.. 2022;63:S297-S300.

- [CrossRef] [Google Scholar]

- Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater.. 2019;224:930-949.

- [CrossRef] [Google Scholar]

- Mechanical properties and cracking behaviour of lightweight engineered geopolymer composites with fly ash cenospheres. Constr. Build. Mater.. 2023;400:132622

- [CrossRef] [Google Scholar]

- Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng.. 2015;78:153-161.

- [CrossRef] [Google Scholar]

- Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater.. 2016;112:168-182.

- [CrossRef] [Google Scholar]

- A review of the current progress and application of 3D printed concrete. Compos. Part Appl. Sci. Manuf.. 2019;125:105533

- [CrossRef] [Google Scholar]

- Effects of alkali-treated kenaf fiber on environmentally friendly geopolymer-kenaf composites: black liquid as the regenerated activator of the geopolymer. Constr. Build. Mater.. 2021;297:123787

- [CrossRef] [Google Scholar]

- Novel procedure of CO2 capture of the CaO sorbent activator on the reaction of one-part alkali-activated slag. RSC Adv.. 2021;11:12476-12483.

- [CrossRef] [Google Scholar]