Translate this page into:

Recent developments of membranes and electrocatalysts for the hydrogen production by anion exchange membrane water electrolysers: A review

⁎Corresponding authors. kishore.chand@edu.unige.it (Kishore Chand), paladino@unige.it (Ombretta Paladino)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Abstract

Hydrogen production using anion exchange membrane water electrolysis (AEMWE) offers hope to the energy crisis faced by humanity. AEM electrolysis can be coupled with intermittent and renewable energy sources as well as with the use of low-cost electrocatalysts and other low-cost stack components. In AEM water electrolysis, one of the biggest advantages is the use of low-cost transition metal catalysts instead of traditional noble metal electrocatalysts. AEMWE is still in its infancy despite irregular research on catalysts and membranes. In order to generate commercially viable hydrogen, AEM water electrolysis technology must be further developed, including energy efficiency, membrane stability, stack feasibility, robustness, ion conductivity, and cost reduction.

An overview of studies that have been conducted on electrocatalysts, membranes, and ionomers used in the AEMWE is here reported, with the aim that AEMWE research may be made more practical by this review report, by bridging technological gaps and providing practical research recommendations, leading to the production of scalable hydrogen.

Keywords

Hydrogen generation

AEM water electrolysis

Oxygen evaluation reaction

Hydrogen evolution reaction

Membrane electrode assembly

Ion conductivity

- AEM

-

Anion exchange membrane

- PEM

-

Proton exchange membrane

- AEMWE

-

Anion exchange membrane water electrolysis

- PEMWE

-

Proton exchange membrane water electrolysis

- PGMs

-

Platinum group metals

- AELs

-

Alkaline electrolyzers

- MEA

-

Membrane electrode assembly

- DI

-

Deionized water

- QA

-

Quaternary ammonium

- KOH

-

Potassium hydroxide

- NaOH

-

Sodium hydroxide

- Pt

-

Platinum

- Ir

-

Iridium

- OER

-

Oxygen evolution reaction

- HER

-

Hydrogen evolution reaction

- GDL

-

Gas diffusion layer

- ACL

-

Anode catalyst layer

- CCL

-

Cathode catalyst layer

- NC

-

Nitrogen–carbon

- RG-AEM

-

Radiation grafted anion exchange membrane

- AEMFC

-

Anion Exchange Membrane Fuel Cell

- NMR

-

Nuclear magnetic resonance

- EPTMAC

-

(2,3-Epoxypropyl)trimethylammonium chloride

- PES-X-IL

-

QA-Functionalized Poly(ether sulfone)

- QCS

-

Quaternized chitosan

- PVA

-

Poly (vinyl alcohol)

- RH

-

Relative humidity

- IEC

-

Ion exchange capacity

- GO

-

Graphene oxide

- DMAOP

-

Dimethyloctadecyl[3(trimethoxisilyl)propyl] ammonium chloride

- PBI

-

Polybenzimidazole

- PAEK

-

Poly (arylene ether ketone)

- QGO

-

1,4 diazabicyclo[2,2,2] Octane functionalized graphene oxides

- QPSF

-

Quaternized poly-sulfone

- CQPSU

-

Cross linked quaternized polysulfone

- QASEBs

-

Quaternary ammonium poly(styrene-ethylene/butylene-styrene)

- TQAPEK

-

Triple quaternary ammonium-functionalized poly(ether-ketone)s

- SAXS

-

Small angle X-ray scattering

- WU

-

Water Uptake

- ETFE

-

Ethylene tetrafluoroethylene

- PTP

-

Quaternized poly[(terphenyl piperidinium)–co-(oxindole terphenylylene)

- PEEK

-

Polyetheretherketone

- PAES-x-IMPPO

-

Imidazolium functionalized poly arylene ether sulfone, Poly(2,6 dimethyl-1,4 phenylene)

- DABDA

-

4-(Dimethylamine)butyraldehyde diethyl acetal

- [VBI]Br

-

1- Vinyl-3-butylimidazolium bromide

- PPESK

-

Poly (Phthalazinon ether sulfone ketone)

- PFSA

-

Per fluorinated Sulfonic Acid

- S-PESO2NH-GCL-OH

-

Short side chain perfluorosulfonamide Glycidoxypropyltrimethylammonium chloride- hydroxide inomer

- QAPPT

-

Quaternary ammonia poly(Nmethyl-piperidine-co-p-terphenyl)

- λ

-

Absorbed water molecules

- m-TPN

-

m-terphenylene

- PAP-TP

-

Poly(aryl piperidinium)-poly(p-terphenyl N,N-dimethylpiperidinium)

- LDPE

-

Low density polyethyelene

- HDPE

-

High density polyethylene

- BTMA

-

Benzyltrimethylammonium

- HMT-PMBI

-

Hexamethyl-p-terphenyl-poly-(benzimidazolium) solid polymer electrolyte

- QPPO/QGO

-

Quaternized polyphenylene oxide/Quaternized graphene oxide

- PBI

-

Polybenzimidazol

- ZIF

-

Zeolitic imidazolate framework

- AWE

-

Alkaline water electrolysis

- NF

-

Nickel foam

- LDH

-

Layered double hydroxide

- CV

-

Cyclic voltammetry

- LSV

-

Linear sweep voltammetry

- Q-POLY

-

Poly(benzimidazole imide)

- Vs%)

-

Volume swelling ratio

- SR

-

Swealing ratio

- CM-DQxQy-2

-

1-(N’- N’ – dimethylamino)-2-(N,N,N-trimethylammonium) dodencane (X= spacer between the 1st and 2nd charges was X-methylene and Y= number of alkyl group outside the second charge)

- CM-TQxQyQ-2

-

1-(N’,N’-dimethylamino)-6-2-(N,N,N-trimethylammonium) dodencane

- CMPSF

-

Chloromethylated polysulfone

- MOF

-

Metal organic framework

- ORRs

-

Oxygen reduction reactions

- NCNT

-

Nitrogen-doped carbon nanotubes

- NiCo-LDH

-

NiCo layered double hydroxide

- TMO

-

Transition metal oxide

- MMO

-

Mixed metal oxide

- DFT

-

Density functional theory

Abbreviations

1 Introduction

The development of de-fossilization and renewable energy infrastructure is accelerating as people become more conscious of the negative effects of climate change. In the twenty-first century, hydrogen is arguably the most important energy carrier, referred to as the “ultimate energy carrier” (Li and Baek 2021). Steam reforming of partial oxidation of methane, natural gas, and coal gasification make up the majority of commercially available hydrogen. These methods emit contaminants into the atmosphere in addition to producing greenhouse gases (Shiva Kumar and Himabindu 2019). In order to realize the ambitious target of reducing and ultimately eliminating CO2 emissions within this timeframe, different scenarios for hydrogen production have been considered.

The production of hydrogen from water includes water splitting and electrolysis. Chemical conversion of biomass, thermal processes, photocatalytic water splitting are all ways to split water. With a series of successive chemical reactions, oxygen and hydrogen are produced when water is broken down. The thermal conversion occurs between 800 and 2000 °C (E. Funk 2001). Solar or nuclear power plants can convert water into hydrogen and oxygen to generate energy (Xiao et al., 2012). Thermal methods are advantageous due to the fact that they can be used to avoid the problems associated with the stages of component separation, but they are economically advantageous only coupled to plants where high surplus of thermal energy is available.

Hydrogen and oxygen can be made from water using water electrolysis at low temperatures (Steinfeld 2005, Wei et al., 2007, Senftle et al., 2010, Millet and Grigoriev 2013). Water electrolysis is the principal method for manufacturing huge volumes of hydrogen, which is the only carrier and storage medium for renewable electricity. Depending on the electrolyte used, electrolysis can be differentiated: proton exchange membrane water electrolysis (PEMWE) and Alkaline electrolysis (AEL) are the two major techniques in use for water electrolysis to produce hydrogen (Zeng and Zhang 2010, Marini et al., 2012, Manabe et al., 2013, Rashid et al., 2015).

To make hydrogen economically and environmentally competitive with fossil fuels, scientists are researching new efficient and cost-effective methods to produce it via water electrolysis. Hydrogen produced through traditional water electrolysis is inefficient, energy-intensive, has high overpotential, and can corrode easily. Polyelectrolyte membrane electrolyzed water provides several advantages over standard porous membrane electrolyzed water, including a longer electrolytic cell life, higher efficiency, lower hydrogen generation costs, and lower maintenance costs (Schmidt et al., 2017, Hadikhani et al., 2021). A water electrolyzer based on PEMWE has recently been investigated, and it performs exceptionally well in ultrapure/ distilled water due to its high efficiency up to 75 % (Ayers et al., 2010, Ul Hassan et al., 2020, Al Munsur et al., 2021). Unfortunately, a PEM-based water electrolysis device is expensive, due to the employment of expensive noble metal catalysts (IrO2 and Pt) and defluorination membranes(Abbasi et al., 2019, Henkensmeier et al., 2020, Lindquist et al., 2020, Oh et al., 2021). PEM electrolyzers can function properly and are robust, but it has proven a difficult task to deploy them at the required industrial scale due to a paucity of platinum group metals (PGMs) used as electrocatalysts. Contrary to this, conventional AELs do not offer the flexibility to accommodate multi-megawatt installations at low cost (Carmo et al., 2013, Paoli et al., 2015). An alternative solution is a water electrolyzer based on anion-exchange membranes, which can use inexpensive PGM-free electrocatalysts (such as nickel, iron, or cobalt), in order to reduce cost of an electrolyzer and to efficiently produce pressurized hydrogen (Li et al., 2021).

Anion exchange membranes (AEMs) still perform poorly, which limits the progress of AEMWE. In order to prevent oxygen and hydrogen products from mixing while enabling transport of OH−, the AEM is used between the cathode and anode as a solid-state electrolyte (Zhang et al., 2018). Due to the lower mobility of OH− ions than protons, AEM has a lower ionic conductivity than PEM (Park et al., 2018, Yan et al., 2020). Additionally, most AEMWEs degrade tremendously under alkaline conditions, reducing their performance over time (Mustain et al., 2020). The development of highly conductive and alkali stabilized AEMs is therefore imperative.

As public interest in MEA has grown, a number of studies have explored how commercial AEMs can be used to create high-performance AEMWEs, especially within MEA components. In the past few years, several commercial AEMs have been developed and commercialized. These include Fumapem® (Fumatech Co., Germany), A201® (Tokuyama Co., Japan), Sustainion® (Dioxide Materials Co., USA), Aemion TM (Ionomr Innovation Co., Canada), and Orion TM1TM (Orion Polymer, USA). As part of the early development of the A201® and for the discontinued product, at 1.9 Vcell the low performance was observed for AEMWE (350–550 mAcm−2)(Pavel et al., 2014, Cho et al., 2017, Vincent et al., 2017). As a result of incorporating Fumapem® membranes in AEMWE, Park et al. (Park et al., 2019)achieved 1500 mA cm−2 performance at 1.9 Vcell when analyzing method of fabrication, MEA parameters, operating conditions. A201® and Fumapem®, however, are known to have poor durability when used as AEM. Liu et al.(Liu et al., 2017) published a report on the performance and durability of Sustainion® membranes developed by Dioxide Materials Co.; by using FASe50® (Fumatech, Germany), they doubled the AEMWE performance. At 180 h, FASe50® showed a significant change in voltage, but it continued to perform at 1950 h. AEMWE with AemionTM membrane was proposed by Fortin et al. (Fortin et al., 2020) and demonstrated 2000 mAcm−2 performance at 1.82 Vcell and 60 °C. In addition, the degradation rate at 50 °C was 3.21 mV h−1. Most AEMs have been checked with AEMWE except Orion TM1TM.

Electrolyzers that use anion exchange membranes have shown increasing interest that combine the advantages of AEL and PEM (Wang et al., 2019). Vincent et al. (Vincent et al., 2017, Vincent and Bessarabov 2018) investigated different AEMs by adding different supporting electrolytes. (KHCO3, K2CO3 and KOH). Using Tokuyama A201 membranes, Ni/(CeO2-La2O3)/C and CuCoOx as cathode and anode catalysts, respectively, the best performance was achieved in 1 % K2CO3 electrolyte at 500 mAcm−2 and 1.95 V at 60 °C. While using NH3/H2-treated and subsequently anodized Fe-NiMo as the anode catalyst, Chen et al. (Chen and Hu 2020) demonstrated the ability to obtain 1.0 A cm−2 at 1.57 V and 80 °C in an AEM electrolyzer. According to Fabry et al. (Fabbri et al., 2017) the flame sprayed Ba0.5Sr0.5Co0.8Fe0.2O3 δ anode catalyst increased the cell performance when deionized water was substituted for commercial IrO2. Li et al (Li et al., 2020) reported high current density at 85 °C (2.7 A cm−2 at 1.8 V) when an electrode binder was used with quaternized polystyrene electrode and platinum as cathode catalyst, but the durability of these cells remains a challenge. it is important to have both flexibility and hydrophilicity of the side chains when creating AEMs with good alkaline stability and high ionic conductivity. A flexible linkage of a -(CH2)6- group is designed in the side chain to increase the density of local ionic groups. In addition, there is a long flexible spacer in the side chain (hexyleneoxy groups) linking the first QA group to the backbone, which would weaken the electron-withdrawing effect of QA groups. Furthermore, the ether-containing spacer can be made electronegative, which enhances cationic mobility and ionic interaction, ultimately facilitating the fabrication of microphase segregation morphology in AEMs (Gong et al., 2017).

2 Hydrogen production techniques

Since hydrogen has only one proton and one electron, it is considered a low-polluting and highly efficient fuel (Merle et al., 2011). Normally, hydrogen doesn't occur in nature. Methanol, gasoline, and propane are some of the fuels which contain it. Hydrogen is therefore produced by a number of processes. A variety of carbon-free methods such as reverse electro-electrodialysis, photo-assisted electrolysis, photo-thermal, electro-thermal, and thermochemical water splitting are being explored as potential sources of diverse energy(Dincer and Balta 2011, Dincer and Zamfirescu 2012, Acar et al., 2015, Tufa et al., 2016, Wang et al., 2017).

One of the technologies that is gaining popularity is water electrolysis to produce hydrogen, due to its high purity and a range of niche applications, including the production of power-to-gas. Alkaline electrolysis and PEM electrolysis are the two conventional types of electrolysis. Hydrogen can be produced by electrolysis using sources of renewable energy like solar (Manabe et al., 2013). Solid polymer electrolytes like Nafion (often PEM) are used in PEM electrolysis (Carmo et al., 2013). PEM electrolysers can operate at a current density of 2000 mA cm−2 at an operating voltage of 2.1 V at 90 °C. In addition, platinum group metals are limited as electrocatalysts due to the acidic nature of the atmosphere (Millet et al., 2011). Compared to platinum group metal electrolysis, AEL uses less expensive catalysts and separators, such as diaphragms. Due to its high corrosion potential, the 30 % KOH electrolyte in contact with the ambient air leads to a formation of K2CO3 that reduces the efficacy of the alkaline electrolyser (Zeng and Zhang 2010). For electrolysis to become cheaper and more efficient, non-PGM catalysts and low-cost membrane systems are required. Electrolysis using AEMs based on polymer materials and non-platinum catalysts have recently been introduced (Vincent and Bessarabov 2018). The electrolysis technique called AEM could be considered as a combination between PEMWE and alkaline electrolysis. The anode and cathode of an AEM water electrolysis system usually contain non-noble metal electrocatalysts. Ionic conductivity is provided by 1 % dilute K2CO3. At 1.9 V, the maximum current density is 500 mAcm−2. An AEM electrolyser's performance is mainly determined by the AEM. In an electrochemical reaction, the AEMs serve as barriers for gases and electrons produced by the electrochemical reactions as well as carriers of hydroxyl ions(Manabe et al., 2013, Vincent and Bessarabov 2018).

2.1 Typical/Conventional electrolysis

2.1.1 Alkaline electrolysis

As with alkaline electrolysis mainly non noble metal are used but specially nickel-based oxide anodes and cobalt-based oxide cathodes are the most frequently used anodes and cathodes, respectively, and liquid electrolytes are usually 30 to 40 % KOH (Ganley 2009). Alkalinity is provided by the electrolyte circulated across the electrodes. Cathode and anode chambers are separated by porous diaphragms, though they do not conduct hydrogen and oxygen (Zeng and Zhang 2010). Among the many materials used for diaphragms are polyphenylene, polysulfide polypropylene, asbestos, and potassium titanate (Wendt and Hofmann 1989, Kjartansdóttir et al., 2013). Cell voltage is between 1.85 and 2.2 V and efficiency is around 60–80 % in an alkaline electrolysis cell operating at a current density of 400 mAcm−2. In addition to being relatively safe due to the low temperatures, an advantage of alkaline electrolysis is that a noble metal catalyst is not required to produce hydrogen (Ferrero et al., 2013, Vincent and Bessarabov 2018).

2.1.2 Proton exchange membrane electrolysis

PEM electrolysis typically uses Pt black and IrO2 as a cathode and anode catalysts, respectively (Millet et al., 2010). In place of a liquid electrolyte, a solid acidic membrane (Nafion, DuPont) is used (as the hydrogen is produced by the reaction, the ions travel from the anode to the cathode and are separated out as hydrogen and oxygen). At 90 °C, PEM electrolyzers are capable of operating at 2.1 V and a current density of 2000 mAcm−2. In PEM electrolysis, hydrogen and oxygen are produced more rapidly than in alkaline electrolysis due to the acidic nature of the electrolyte and the metal surface of the electrodes. PEM electrolysis is safe because it does not use a caustic electrolyte. In PEM electrolysis, high pressures are used for the cathode, but atmospheric pressure is permitted for the anode (Rossmeisl et al., 2007).

2.1.3 Anion exchange membrane water electrolysis

The technology is still being developed. Research about AEMWE has generated a lot of interest among universities and research organizations, especially because of its low cost and possible high performance. The AEM electrolysis research community has published few articles compared to that of the other traditional electrolysis technologies. Further research is needed on the following aspects of AEM electrolysis, specifically: stability of membranes and catalysts, power efficiency, reduced cell costs, and ease of use (Leng et al., 2012, Pavel et al., 2014). Contribute to the development of a hydrogen economy, significant improvements still need to be made to AEM-based electrolyzers. Various parameters, including electrolysis performance of AEM, membranes, electrocatalysts, ionomers, and the MEA in general, should be thoroughly reviewed.

3 Polymeric anion exchange membranes

For electrochemical systems, polymeric AEMs have been developed since the past few years. In alkaline water electrolysis, a conventional diaphragm can be replaced with an AEM and, in addition to being adopted for electrolysis, these membranes are also useful for fuel cells. Electrolysis has not been accomplished at industrial scale with AEMs yet (Piana et al., 2008, Piana et al., 2010, Faraj et al., 2011, Varcoe et al., 2014), even if there are several potential benefits in using AEMs.

-

The platinum group metal (PGM) is replaced by a transition metal catalyst in this process [Economical Friendly].

-

Electrolytes can be substituted and instead of concentrated KOH, DI water or a small amount of alkaline solution is adopted.

-

In AEM electrolysis, a membrane containing quaternary ammonium ion exchange groups is less expensive than a membrane based on Nafion.

-

CO2 and AEMs interact very little despite the fact that metal ions are absent from AEMs.

In this technology, there is no corrosive liquid electrolyte, which reduces weight and size, prevents leakage, provides volumetric stability, and facilitates handling. For hydrogen production, AEM technology is highly reliable and low-cost (Pavel et al., 2014).

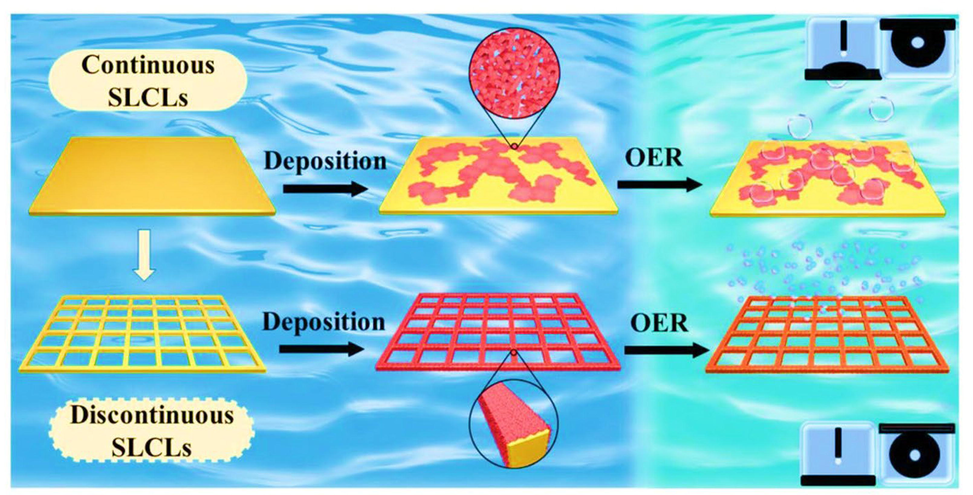

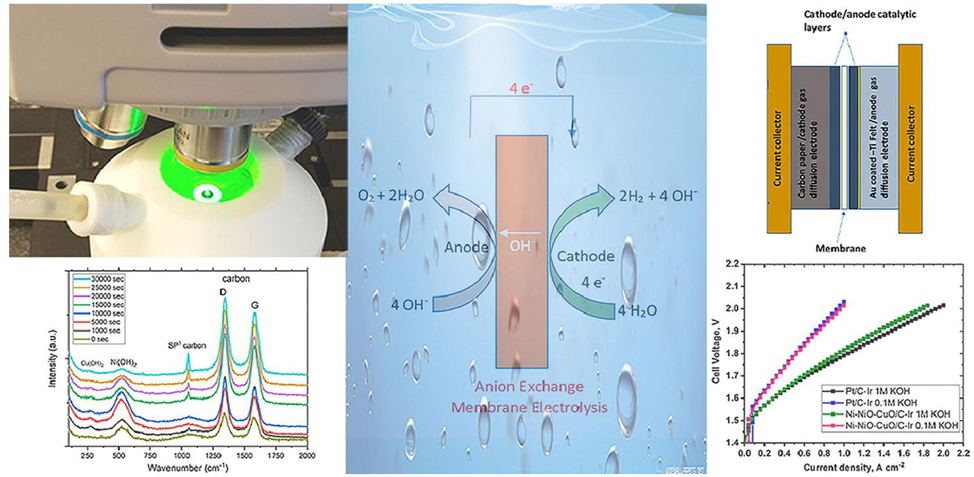

3.1 Basic principle of polymeric AEM electrolysis

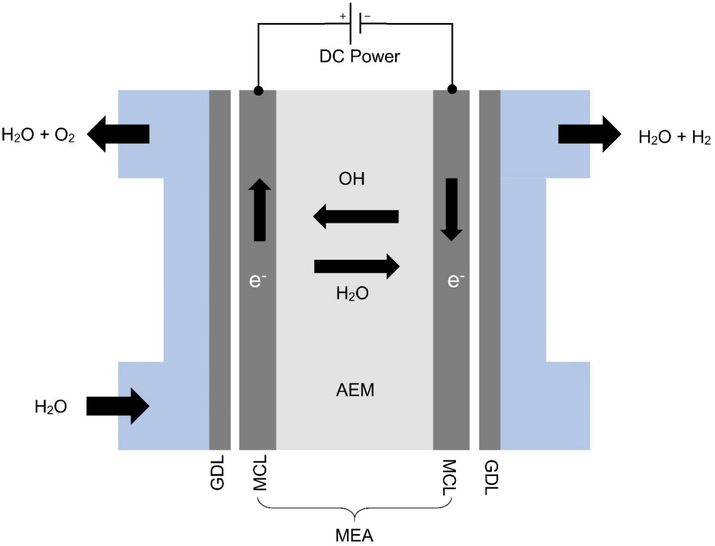

As an alternative to water electrolysis, the AEM method combines the merits of alkaline and PEM electrolysis into a single cell. AEM and its components are shown in Fig. 1. In order to provide DC current to the cathode and anode, power is supplied from a separate external source. The reaction is composed of two half-cell reactions, namely, the HER and OER. Water is passed through the anode and two electrons are added to produce hydrogen and hydroxyl ions. Thus, the hydroxyl ions diffuse to the anode portion of the AEM through positive attraction, whereas electrons move through the external circuit to the anode portion. In the anode chamber, the hydroxyl ions are recombined with oxygen and water through the loss of electrons. By forming bubbles on the anode's surface, oxygen is released. During both half-cell reactions, the electrode surfaces must be actively catalyzed in order to generate and release the corresponding gases. Half-cell reactions are presented in Eqs. (1)–(3) (Rossmeisl et al., 2007):

Schematic diagram of an AEMWE. ACL: anode catalyst layer, MEA: membrane electrode assembly, GDL: gas diffusion layer and CCL: cathode catalyst layer, Elsevier 2018 granted a copyright license to reproduce the Figure (Vincent and Bessarabov 2018).

It takes 1.23 V of theoretical thermodynamic cell voltage to split water into hydrogen and oxygen at 25 °C. For efficient hydrogen production, however, the cell voltage must be higher than 1.23 V. Electrolyte and electrolyzer components must have additional voltage in order to overcome the ohmic and kinetic resistances. PEM electrolysis is typically performed at 1.75 V and alkaline electrolysis at 1.85–2.05 V, respectively, at 70–90 °C (Vincent and Bessarabov 2018).

4 Overview of the membranes, ionomers in the AEMWEs

Electrolysis makes up 4 % of global energy storage and transportation. Different electrode materials and diaphragm separators are being tested in the cathodic/anodic compartments to improve overall system efficiency. The Membranes and ionomers developed for AEMWE could also be used in reverse systems as AEMFC electrolytic membrane assembly, coupling options, and storage media all continue to improve in order to improve efficiencies.

The external circuit that supplies DC power is made up of the electrolysis reactor, cathode, and anode. AEMs separate the internal and external circuits in alkaline electrolytes. In the external circuit, OH is transferred from the anode side to the external circuit, where it combines with water at the anode side. As a result of this reaction, OH and oxygen are produced. Hydrogen gas is created by splitting the hydrogen network bond on the cathode side, which produces hydrogen ions when combined with electron transfer (Leng et al., 2012). The Gibbs free energy is greater than the theoretical potential when half-reactions occur. Due to ohmic resistance and electrolyte kinetics, the minimum applied potential is normally higher than 1.85 V, which is due to the minimum applied potential exceeding the theoretical potential (Dincer and Acar 2015).

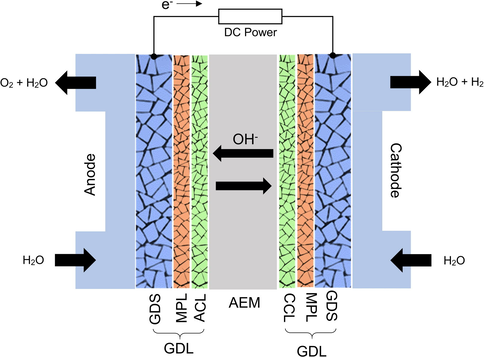

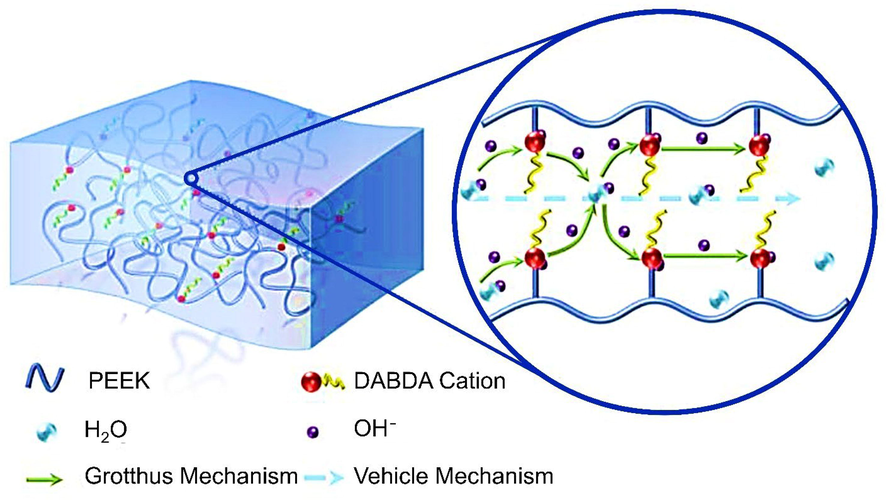

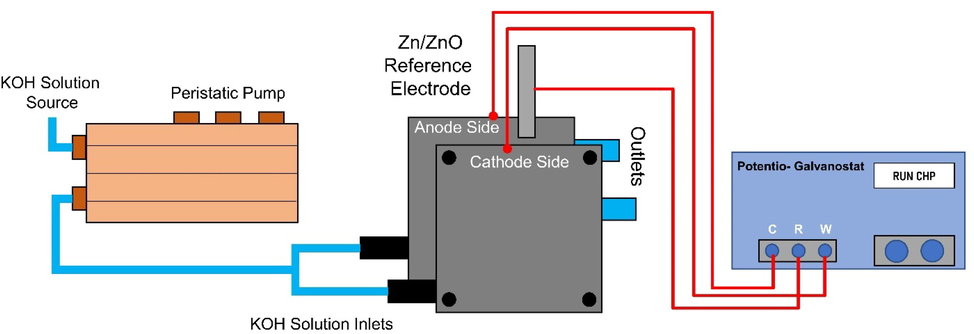

The studies about AEMs are also carried out for the development of reverse systems, producing energy from hydrogen, as anion exchange membrane fuel cells (AEMWE). Recent AEMFC studies have concentrated on the mechanisms of oxidation of hydrogen and reduction of oxygen in alkaline media, as well as the development of new materials, including anion exchange membranes, ionomers, and electrocatalysts (Roche et al., 2007, Xu et al., 2007, Yanagi and Fukuta 2008, Li et al., 2009, Liang et al., 2009, Zhu et al., 2009, Kostowskyj et al., 2010, Yang et al., 2014). The schematic diagram of AEMWE is shown in the Fig. 2.

Diagram of an AEMWE, figure modified and reproduced with the copyright permission from Elsevier 2018(Truong et al., 2018).

AEM materials with polymer backbones have previously been explored by the researchers, including (phenylene)s (Hibbs et al., 2009), poly(olefin)s (Noonan et al., 2012), poly (ether imide) s (Wang et al., 2009), poly(sulfone)s (Gu et al., 2009, Wang et al., 2009, Pan et al., 2010, Yan and Hickner 2010, Mohanty et al., 2014), poly (phenylene oxide) s (Li et al., 2012, Li et al., 2013), poly (arylene ether) s (Wang et al., 2010, Gu et al., 2011) and poly (styrene) s (Luo et al., 2010, Zeng et al., 2010). AEM membrane candidates have also included quaternary ammonium (QA) functionalized polymer electrolyte membranes. The researchers also investigated polymers with tethered QA such as poly (aryl ether sulfones) (Rao et al., 2013, Jasti and Shahi 2014, Wang et al., 2015), poly (aryl ether ketones) (Xu et al., 2012, Chen and Hickner 2013, Jasti and Shahi 2014, Wu et al., 2014), radiation grafted poly(vinylidene fluorides) (Danks et al., 2003), poly(styrene)s (Ran et al., 2012, Ran et al., 2013), poly(olefins) (Ran et al., 2012, Nasef 2014) and poly(phenylene oxides) (Schauer et al., 2015). Due to the lower mobility of the hydroxyl ions within these alkaline exchange membranes, their conductivity is lower than acidic exchange membranes. Researchers have explored the following two strategies to address this issue: (1) researching the physics of organic cations with hydroxide conductivity, such as guanidinium (Zhang et al., 2010, Kim et al., 2011), phosphonium (Noonan et al., 2012), imidazolium(Yan et al., 2014); and (2) Besides controlling polymer architectures to produce phase-separated morphologies, block copolymers are also used (Price et al., 2013, Rao et al., 2013), the preparation of combs (Li et al., 2013), crosslinking, and adding spacer chain pendants, these methods have all led to the development of AEMs that provide sufficient hydroxide conductivity (higher than 10-2 S cm−1).

Furthermore, AEMs are not chemically stable when exposed to alkaline environments, one of the major challenges they face in practical applications is their implementation in alkaline environments. It is possible for QA cations to degrade under certain conditions (at 60 °C and higher pH) in the following ways. The reactions include (i) nitrogen ylide formation (Chempath et al., 2008), (ii) Hofmann reaction elimination of β-hydrogen (E2) (Cope and Trumbull), (iii) direct nucleophilic substitution of a carbon atom (SN2) (Chempath et al., 2010), and direct nucleophilic substitution of arylene(SAr) (Choe et al., 2014). As a result of these degradation pathways, IEC and hydroxide conductivity are rapidly affected. AEMs functionalized with imidazolium are among the most exciting non-QA AEMs for increasing alkaline stability. Although imidazolium cations have five-membered heterocyclic rings and π--conjugated structures, they should still be stable in alkaline conditions. The π--conjugated structure helps to delocalize positive charges by preventing nucleophilic attack by OH−groups using SN2 or Hofmann elimination of positive charges (Li et al., 2011, Ye and Elabd 2011). In the previous literature, there are numerous varying results and contradictory conclusions about imidazolium cations. The goal of Kim et al. was to improve the stability(cation) of the membrane using the commercial polymer parmax 1200 as a starting material. When immersed in 1.0 M KOH at 60 °C for seven days, parmax exhibited greater stability than quaternary ammonium functionalized polymers. A conjugate imidazole-ringed alkaline parmax polymer (Hossain et al., 2015) that is relatively resistant to the nucleophilic attacks of hydroxyl ions so that its limitations would not be experienced. AEMs functionalized with 1,2 dimethylimidazolium at 80 °C in 1 M KOH were prepared by Sun et al. and compared to 1-methyl-3-(4-vinylbenzyl) imidazolium chloride at same condition (1 M KOH & 80 °C). In comparison with the unsubstituted C2 imidazolium in alkaline environment, 1,2 dimethylimidazolium shows significant advantages (Yang et al., 2015). Zhang et al. found a 6.8 % mass and a 23.3 % conductivity for the imidazolium cation attached to polysulfone after 24 h in 3 M NaOH under 60 °C (Zhang et al., 2011). Also, Guo et al. reported that poly (styrene-co-butyl methacrylate)s containing imidazolium functionalized polymers were stable under 60 °C in 6 M NaOH for 120 h(Guo et al., 2010). Furthermore, a study was done by Lin and co-authors, investigating the alkaline stability of imidazolium cations that are substituted with methyl on a poly(phenylene oxide) backbone. Even after 9 days of ageing in the aqueous 2 M KOH solution, the IEC remained unchanged even after immersion at 25 °C. As the temperature was raised to 60 °C, IEC dropped suddenly to 40 % and 50 % for 7 and 9 days, respectively (Lin et al., 2013).

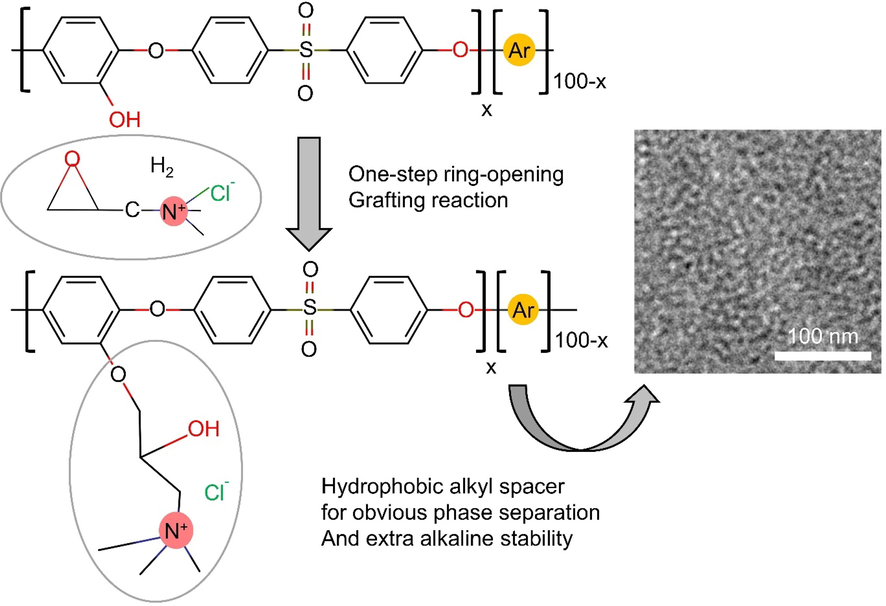

As compared to the conventional method EPTMAC is more straightforward, according to Xiu Qin Wang et al. who synthesized AEMs bearing pendent QA groups based on poly (ether sulfone) s by nucleophilic substitution polycondensation, functionalization and demethylation under mild conditions. The highest ionic conductivity measured at 80 °C was 46.8 mS cm−1, as reported by Xiu Qin wang et al. According to the 1H NMR analysis of the PES-80-IL membrane after immersion in a 2 M aqueous KOH, the membrane loses nearly 50 % of its QA groups as shown in the Fig. 3(Wang et al., 2017).

Synthesis process of membrane (PES-80-IL). The Image was reproduced with the copyright permission of Elsevier 2017(Wang et al., 2017).

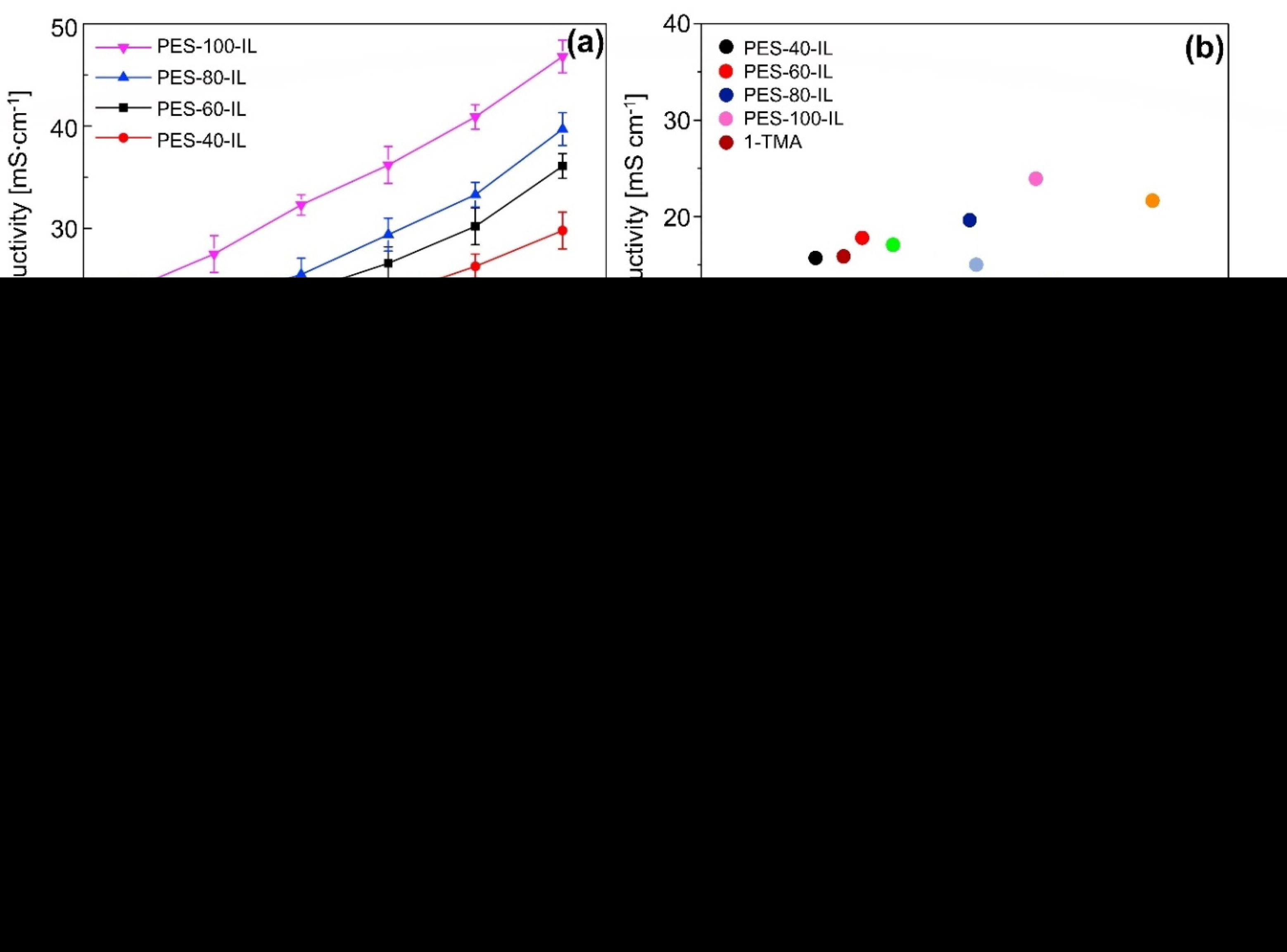

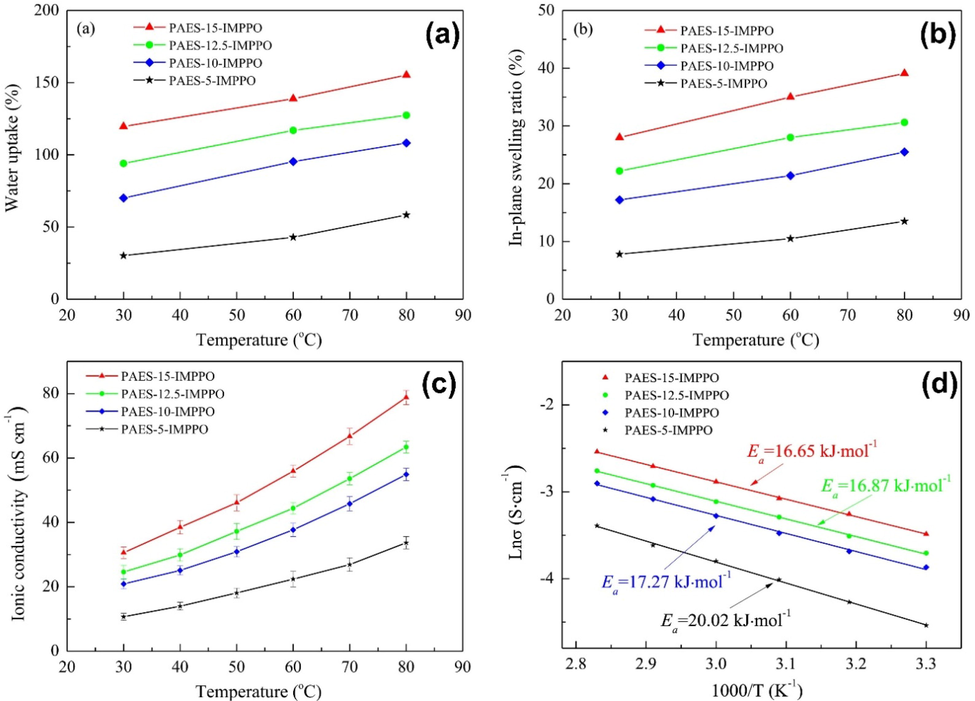

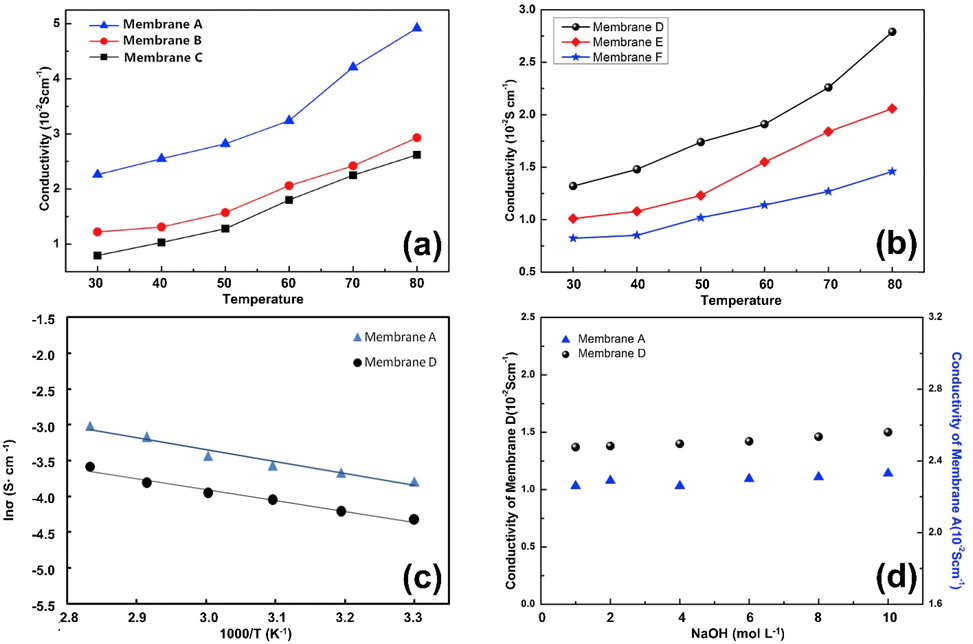

An important aspect of AEMs is their ionic conductivity. For a hydroxide conductivity measure to be useful, it must be>10 mS cm−1(Li et al., 2012). Membranes' conductivity to hydroxide can be observed in Fig. 4 (a). The temperature distribution is nearly linear between 30 and 80°. The hydroxide conductivity increased as the temperature increased due to the higher mobility of the flexible pendent QA group. In contrast to membranes with lower ion conductivity, such as the PES-x-IL membrane (x = 40, 60, 80), membranes with higher IEC have a higher conductivity. Due to its distinct microphase separated morphology and the presence of well-developed ion-conductive channels, the PES-100-IL membrane may also be highly conductive.

Hydroxide conductivity of AEMs varies with temperature (a), IEC conductivity of various AEMs at 30 °C (b), PES-x-IL membrane Arrhenius plots (X = 40, 60, 80, and 100) (c), PEC-80-IL conductivity and (d) IEC is assessed at 60 °C in a 2 M KOH solution, figures were reproduced with the copyright permission Elsevier 2017 (Wang et al., 2017).

Comparing the conductivity of AEMs at 30 °C to PES-x-IL membranes can be seen in Fig. 4 (b). Despite its higher conductivity, the PES-x-IL membrane performs better at 30 °C than other PES-based AEMs, with values ranging from 4.5 to 24 mS cm−1 (Hu et al., 2012, Li et al., 2012, Di Vona et al., 2014, Song et al., 2016), and even better than the Tokuyama AHA membrane. A key component to fabricating efficient ion conductive channels appears to be the formation of hydrophobic and hydrophilic phase separations in the membranes. The ionic conductivity of AEMs with sidechains is acceptable and makes them good candidates for fuel cell testing. But there is still room to improve ionic conductivity. The Arrhenius law relating hydroxide conductivity to temperature is shown in the logarithmic graph of Fig. 4(c). The activation energy (Ea 10.85 to 12.10 kJmol−1) of PES-x-IL membranes is generally like that of reported AEMs (10 to 23 kJmol−1) (Liu et al., 2016). From these experiments, it appears that PES-x-IL membranes exhibit similar ion conductivity in aqueous hydroxide solutions. The lower activation energy indicates fewer energy requirements for ionic conduction.

The activation energy of PES-100-IL is lower than that of PES-40-IL. Increasing the number of QA groups in the membrane reduces the activation energy. Higher IEC may result from the fact that more ionic groups can conduct ions, and therefore, higher IEC lowers activation energy. For testing the stability of the PES-x-IL membrane, the PES-80-IL membrane was treated. The 1H NMR was used to examine the post-alkaline structure changes in the PES-80-IL membrane after being incubated at 60 °C in a 2 M aqueous KOH solution for 600 h. The degradation rate was computed based on the decrease in the integral ratio of QA band peaks (H12) to the aromatic proton peaks (H2). The ratio of H12/H2 is 1.15 in the alkaline stability test, which is about 56 % of the original value. Additionally, an abrupt decrease in the signal between 4.0 and 4.8 ppm was caused by nucleophilic substitution of QA groups: Hofmann elimination of hydrogen b by attack of hydroxide ions. Testing was performed to determine if the membranes had alkaline stability by observing the IEC and hydroxide conductivity during the test. This can be seen in Fig. 4(d). Within 600 h, the PES-80-IL membrane conductivity reaches 26.6 mS cm−1, which is 70 % of its initial value (38.6 mS cm−1). In addition, the IEC for the PES-80-IL membrane decreases from 1.56 meq g−1 to 0.92 meq g−1, which is approximately 58 % of the initial value. Conductivity has a higher retention rate than IEC. Conductivity is explained by the fact that there may be basic tertiary amines, essentially degradation products left behind in copolymers.

As described in Shujan chao et al., (Zhao et al., 2021) one-pot ethylene glycol-assisted solvothermal method was used to prepare three-dimensional hierarchical flowers like layered hydroxide and QCS/PVA matrix blended together for improved mechanical strength (Fig. 5). The maximum hydrogen ion conductivity of the synthesized membrane is 25.7 mScm−1, which is higher than the conductivity of pristine membrane. Furthermore, the membranes showed ionic conductivity of up to 92 % in 2 M KOH for 100 h. Due to the decreased methanol permeability and increased conductivity, the pristine membrane produced a peak power density of only 40mW cm−2 in comparison with the composite membrane containing 6 % LDHs.

An integration of 3D-LDH into QCS/PVA blend matrix and the fabrication of flower-like 3D-LDH. Images reproduced with permission from Elsevier 2021 (Zhao et al., 2021).

The radiation grafted anion exchange membrane (RG-AEM) developed by Wang et al. (Wang et al., 2019) has excellent performance characteristics when fully hydrated. An AEMFC peak power density of 850 mW cm−2 was achieved using a PtRu/C, H2/air and Pt/C (CO2 free) H2 anode and Ag/C cathode oxide electrocatalyst in this membrane, 100 % relative humidity environment at 80 °C with OH anion conductivity of 200 mS cm−1. he RG-AEM shows less than 7 % degradation at 80 °C after 500 h when it is hydrated to 1/4 RH with 100 % N2 (CO2-free) atmospheres as mentioned in Fig. 6.

LDPE15-AEM at 80 °C with different cathode electrocatalysts for H2/O2 AEMFCs. The Image reproduced with the copyright permission by RSC advances 2019 (Wang et al., 2019).

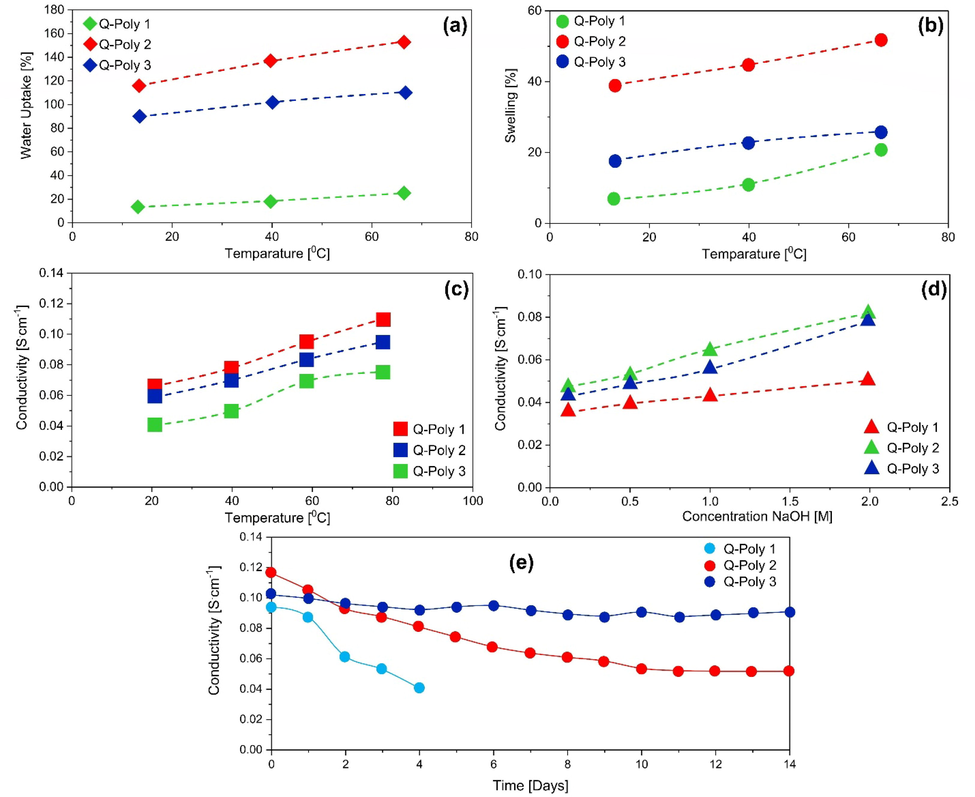

The membranes Q-POLY (1–3) were prepared by Koorosh Firouz Tadayani (Firouz Tadavani et al., 2019) as shown in Fig. 7 for the purpose of anion exchange as shown in Fig. 7 different cations were present, with varying degrees of basicity. They found that the membranes they synthesized were highly anion conductive, with conductivity between 83 and 117 mScm−1 at 80 °C. In addition to changing the OH− conductivity, the crosslinking was also altered to alter mechanical properties and chemical stability. Among its physical properties, Q-poly-3 exhibits a power density of 89 mWcm−2, an OH− conductivity close to or equal to 10 mScm−1, a fuel crossover>10 % of Nafion, and a tensile strain of 40.39 % and a tensile strength of 51.25 Mpa. The porous nature of the membrane along with its good mechanical properties leads to a high-water absorption value of 91 % at room temperature but due to cross linking it exhibits an 18 % swelling ratio. A synthesis procedure is given in Fig. 8 or the Q-Poly-3 monomer. The membrane's ionic conductivity remained within 7 % of that of its monomer after 14 days of storage in alkaline solution.

Anion conductivity of membranes synthesized with various cations exhibits long-term chemical stability and simple monomer synthesis procedure (a-d). Elsevier 2019 provided permission to reproduce images (Firouz Tadavani et al., 2019).

WU and SR for Q-poly (1, 2 & 3) at various temperatures (a & b), conductivity of hydroxide at different temperatures and NaOH concentrations (c and d), and conductivity of hydroxide over 14 days at 80 °C and 2 M NaOH (e). The Elsevier 2019 has given permission to reproduce the figures (Firouz Tadavani et al., 2019).

Fig. 8(a & b) reports the results of water uptake and swelling ratio measurements at 30, 50, and 70 °C for all membranes. According to these results, water uptake of Q-poly-2 (115 % at 30 °C) increased with increasing IEC value compared with Q-Poly-1 (14 % at 30 °C) and Q-Poly-3 (91 % at 30 °C). Furthermore, membrane performance improves with increasing temperature, indicating that membranes are capable of working effectively under cell conditions (70 °C). Q-Poly-3 displayed a higher water uptake than Q-Poly 1, due to its higher porosity while Q-Poly-1 and Q-Poly-3 had similar IEC values. Increasing WU reduces mechanical properties and improves SR. Although both Q-Poly-3 and Q-Poly-2 membranes exhibited high WU, both membranes had a high level of mechanical strength. A titration was used to determine the IEC for all membranes in Fig. 8 (c and d), with Q-Poly-2, IEC increased in comparison to Q-Poly-1 because imidazole was added. The IEC values of Q-poly-3 were nearly identical to those of Q-poly-1.

In comparison to Q-Poly-1, Q-Poly-3 has shown higher anion conductivity, which can be attributed to its porous morphology that facilitates the transfer of ions through hydrophilic channels. In comparison with Q-Poly-2, the imidazole ratio was reduced by adding vinyl benzene segments. Under various conditions, the prepared membranes were measured for hydroxide conductivity. Temperature and concentration of NaOH affect hydroxide conductivity as shown in Fig. 8(c and d). Q-Poly 2 exhibited the highest hydroxide conductivity in 2 M NaOH solution at 80 °C (117 mScm−1). Fig. 8 (d) demonstrates how NaOH concentration affects hydroxide conductivity at room temperature, and as NaOH concentration was increased, hydroxide conductivity increased. Despite the importance of high anion conductivity in the preparation of membranes, maintaining ion conductivity for an extended period of time is a more important issue. The literature indicates that many membranes exhibit high ion conductivity. Although hydroxide conductivity was reduced by 50 % over time (200–500 h) (Lin et al., 2013, Dai et al., 2016, Feng et al., 2017, Lu et al., 2017). At 80 °C and 2 M NaOH solution, the membrane conductivity was measured for 14 days with the membranes synthesized in this work (see Fig. 8 (e)). After 4 days, Q-Poly-1 degradation was high. Additionally, although Q-Poly-2 initially had the best ion conductivity, its ionic conductivity gradually declined (about 75 %) over time. During its stability study, Q-Poly-3′s ion conductivity dropped by less than 7 %. According to the relationship between crosslinking and chemical stability (Lin et al., 2013, Firouz Tadavani et al., 2019), Q-Poly 3 is more stable because of its higher crosslinking.

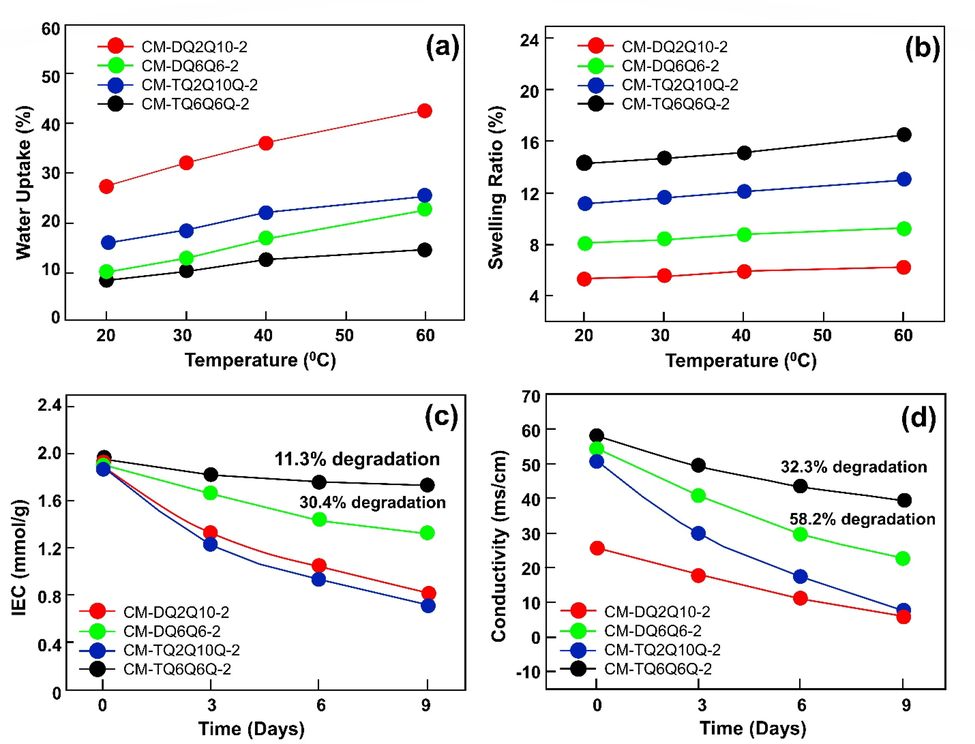

AEM with four structures based on side chain type polysulfone was synthesized and studied by Chao wang et al (Wang et al., 2021) as shown in Fig. 9. Rather than using hazardous chemicals like chloromethyl ether, they selected chromethylate polysulfone. The Menshutkin reaction was used to synthesize cations and four side chains with different numbers. They claimed that it was possible to achieve high IEC values with four grafted side chains having two or three cations in the lower grafting degree thus alleviating the OH– attack on the benzyl in the main chain. According to them, the synthesized AEM (CM-TQ6Q6Q-1, 1.38 mmol. g−1), 13.7 mScm−1 OH−conductivity, 8.9 % swelling ratio and 2.48 Ω cm2 resistance is measured. Furthermore, 96 % of the original IEC reversion was observed. With an alkaline concentration time of ∼ 1.8, the CM-RQ6Q6Q−1 AEM showed high performance (90.0 % efficiency and 8.47 kEh.kg−1 energy consumption) while retaining 96.4 % of its original IEC, which is comparable to typical commercial AEM (Neosepta AHA). In addition, CMTQ6Q6Q-2 was found to exhibit higher alkaline stability and OH– conductivity than any other form of AEM with the same IEC (1.9 mmol. g−1). The results were compared with those from the commercially available form of Anion exchange membrane (Neosepta). The obtained outcomes indicate that, the synthesized CMTQ6Q6Q-1 exhibits five times greater NaOH enrichment than Neopsepta. AHA, as shown in Fig. 9 (a-d).

WU (a), SR (b), temperature testing and IEC retention (c), and OH− conductivity (d) of CM-DQxQy-2 and CM-TQxQyQ-2(Immersion of CM-DQxQy-2 and CM-TQxQyQ-2 in 2.0 M NaOH solution for varying amounts of time at room temperature). The image reproduced with the copy right permission of Elsevier 2021 (Wang et al., 2021).

As we move forward in research, the main challenge is to improve alkaline stability. Tests showing hydride stability revealed that the majority of cationic groups adhered to the polymer chains, such as ruthenocene (Zha et al., 2012), phosphonium (Gu et al., 2009), sulfonium (Zhang et al., 2012)or trimethyl ammonium, (Zhang et al., 2010) guanidinium cations, are rapidly degraded in alkaline environments at elevated temperatures (Marino and Kreuer 2015). Moreover, most polymers are derived from polyether sulfones or ketones, and polymers can degrade under alkaline conditions (Arges and Ramani 2013). In addition to the polymer membrane, there are also polybenzimidazoles (Henkensmeier et al., 2011, Thomas et al., 2011, Lee et al., 2013, Henkensmeier et al., 2014, Wright et al., 2016) that help keep the polymer backbone stable. Hydroxide ion attack on imidazolium moiety C2 causes degradation (Henkensmeier et al., 2011).

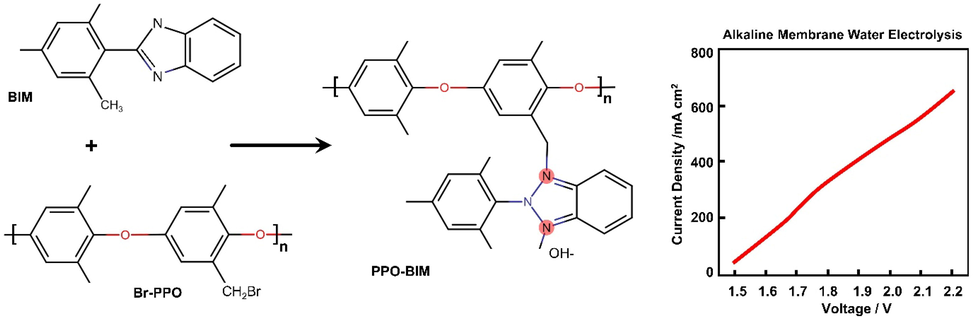

According to Angela Marinkas et al., (Marinkas et al., 2018) (2,6- dimethyl-1,4 phenylene oxide) brominated backbones of polystyrene and methylated N atoms of the 2-mesitylbenzimidazole groups under the operating conditions 0.5 M KOH and 50 °C, are alkaline stable but are unstable at 80 °C for 1 M KOH. Under these conditions severe weight loss was observed. IEC values for the prepared materials are 1.6 to 2.9 mmol OH− g−1. A self-supporting membrane could only be reliably formed with materials that had an IEC value of 1.9 (PPO24-BIM). As IEC grows from 1.6 to 3 mmol OH− g−1, there is a decrease in crystallinity, which decreased from 14 to 3 %. Self-supporting membranes can be formed using materials that have IEC values of 1.6 and 2.2, but not reproducibly. At room temperature PPO24-BIM had conductivity of 8 mS cm−1, had a thermal stability above 200 °C, and had mechanical properties comparable to those of the commercially available membranes (FAA3-30). During water electrolysis 300 mAcm−2 were obtained at 1.8 V as shown in Fig. 10. Consequently, there is a need for further research on the stability of polymer backbones without ether groups.

Chemical synthesis of imidazole containing polymer membranes (PPO-BIM), reproduced with the copyright permission of Elsevier 2018(Marinkas et al., 2018).

Siarung Changkhamchom et al,. (Changkhamchom et al., 2021) created a new type of membrane and they used it for a glucose fuel cell. The DMAOP and GO were combined with quaternized polybenzimidazole (3-PBI), which was quaternized with 3-bromopropyl trimethylammonium bromid, by using a composite AEM containing 0.5 %(V/V) Q-Go/Q-PBI, They states that highest hydroxide conductivity was highest at 27 °C, the ion exchange capacity was highest at 1.79 ± 0.03 mmol g−1, the water uptake was best at 66.61 ± 0.57 %, and glucose permeability was highest 1.79 ± 0.83 × 10–8 cm−2.s−1. The experimental data also showed that this synthesized AEM has higher hydroxide conductivity and glucose permeability was lesser than that of commercially available membranes (FAB-PK-130-Fumasep®).

AEM application has been consistently pursued with different types of polymers, including poly (arylene ether sulfone), poly (phenylene oxide), poly (fluorenyl ether ketone sulfone), and poly (vinyl alcohol) (Pan et al., 2018, Zakaria and Kamarudin 2020). Various researchers states that the engineered plastic PBI containing the benzimidazole group is very chemically and thermally stable. For the improvement of anion stability, different researchers have used different processes, such as the methylation reaction (Henkensmeier et al., 2011), the quaternization reaction (Hou et al., 2011), and the alkaline doping procedure (Hou et al., 2008). Each technique has its own advantages and disadvantages, but the quaternization technique has also been shown to improve membrane durability and ionic conductivity. There are several advantages to Q-PBI (Shin et al., 2020) including the high hydroxide conductivity and chemical stability. However, some quaternized pendent groups within the leading polymer chain are unstable in alkaline aqueous solutions, creating an issue in AEMFC when utilizing potent. A well-known quaternization method for PBI includes a pendant quaternary ammonium moiety and an imidazolium side group (Xia et al., 2012, Jheng et al., 2014, Shin et al., 2020).

AEM can be improved by using different kinds of materials, such as multiwall carbon nanotubes (Hosseini et al., 2013), Chitosan nanoparticles (Liao et al., 2015) or graphene oxide (Zhang et al., 2018). Graphene oxide, however, caught the eye of researchers due to its large surface area (Wang et al., 2020), good barrier properties, and excellent mechanical strength (Ye et al., 2011).

Among the greatest challenges facing polymer scientists, electrochemists, and membrane scientists is the development of AEMs with highest mechanical properties and higher hydroxide ion conductivity. In order to commercialize a membrane, it needs to meet several requirements, including scalability, the use of cost-effective/economical materials and methods; by controlling morphology and selecting the appropriate cationic ion-exchange groups, the mechanical properties of the polymer can be improved. The polymer backbone of the membranes is tethered to the fixed cationic sites. The phosphonium and quaternary ammonium salts of polysulfone produced via chloromethylation and quaternization followed by reaction with an amine. With potassium hydroxide, the form salt can easily be alkalinized to produce an AEM that conducts hydroxyl ions (Arges et al., 2010).

Various kind of cations have been explored for Anion exchange membranes, including imidazolium(Lin et al., 2013), QA (Tuan and Kim 2016), phosphonium(Noonan et al., 2012), pyridinium (Kim et al., 2017), sulfonium (Zhang et al., 2012), and guanidinium (Arges and Ramani 2013). Though QA is commonly used because of its cost competitiveness, high anion conductivity and ease of preparation (Qiu et al., 2012), toxic trimethylamine and low alkali thermochemical stability are serious disadvantages (Ran et al., 2012). A large proportion of recent attention has been paid to imidazolium, since it is easily modified, synthetically convenient, and has comparable ionic conductivities (Wang et al., 2018). Due to its ability to stabilize through charge delocalization, imidazolium can also replace ammonium cations. For long-term applications, however, its stability in strong alkaline environments must be improved. According to several studies the ring opening mechanism led to the decomposition of imidazolium cations via the hydroxide attack at C2 position. Several researchers have used the C2 substitution in order to improve its alkaline stability (Wang et al., 2013, Hugar et al., 2015). Additionally, it has been reported that the addition of N3 alkyl substituents can improve its chemical stability (Gu et al., 2014, Yang et al., 2016). In general, N3-alkyl substituents should have four/five carbon atoms because imidazolium-based AEM had alkaline stability that was about the same (and in some cases even worse) than N3-methyl substituted counterparts if N3 substituents had longer alkyl chains (over six carbon) (Yang et al., 2015, Yang et al., 2016).

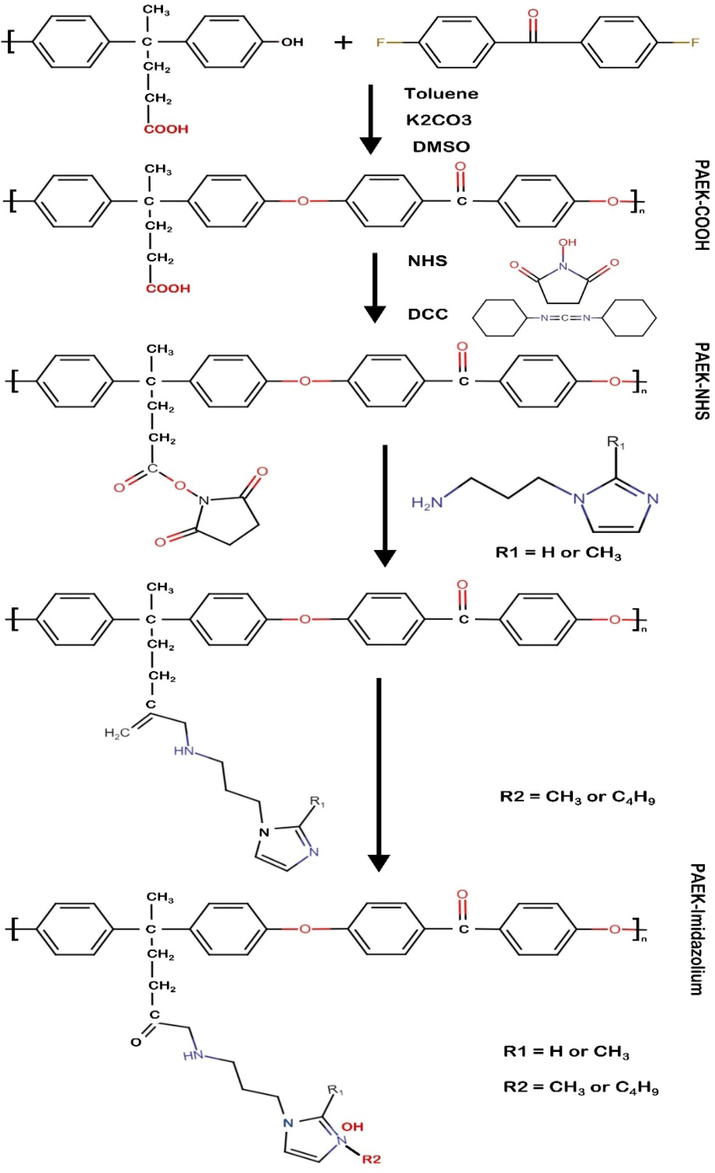

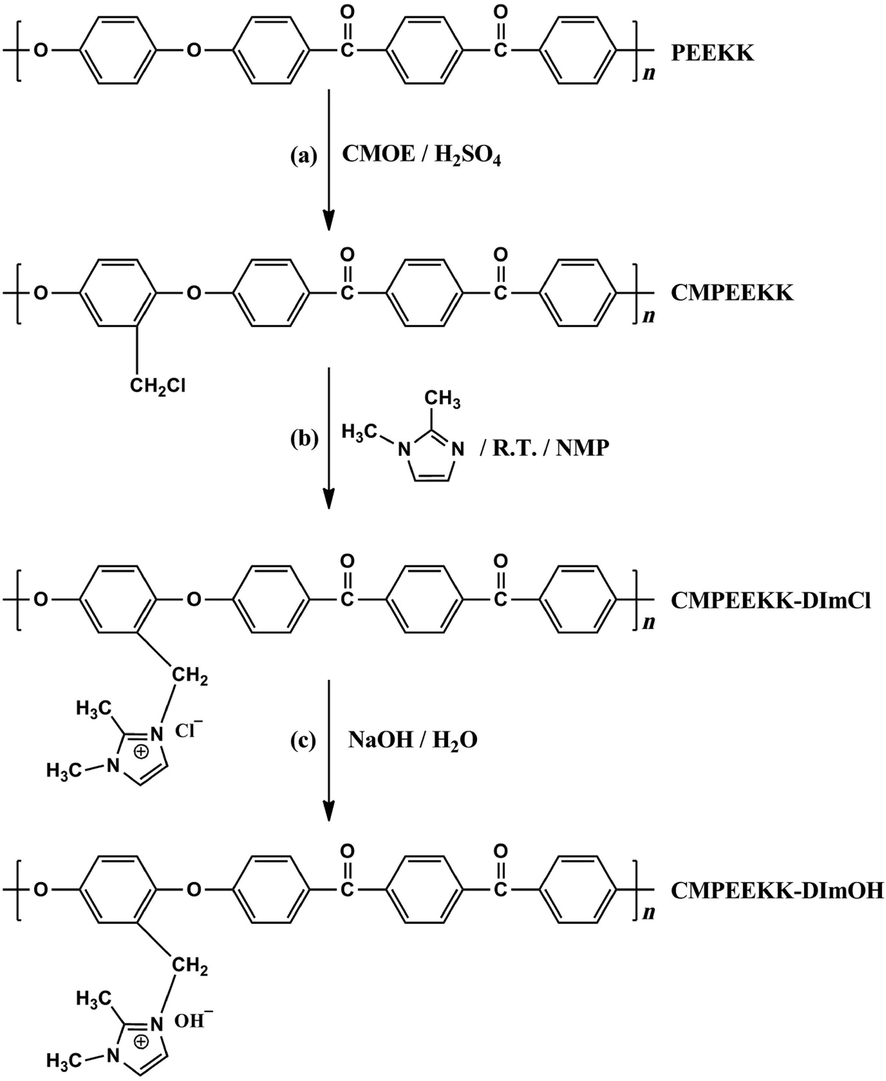

A number of properties of poly(arylene ether) ketone-based anion electrolyte membranes were investigated by substituting the imidazolium functional group at the C2 and N3 positions by Duong diem tham et al, as shown in Fig. 11(Tham and Kim 2019). These membranes were tested in a zero-gap cell to test their electrolysis performance with alkaline water. They found that all membranes outperformed the commercially available membrane (Fumasep FAA-3) in terms of ionic conductivity and electrochemical efficiency. A PAEK-APMBI membrane and a C2 methyl membrane had high voltages and ionic conductivities of 2.63 V and 0.0154 S cm−1, respectively, at 60 °C in KOH solution (10 %) while Furmasep FAA-3 membranes showed voltages and ionic conductivities of 2.63 V and 0.01 S cm−1, respectively. IEC was retained by 96 % in PAEK-APMBI membrane in an alkaline environment for a long period of time, whereas IEC was reduced by 38 % in Fuimasep FAA-3 membrane after long-term treatment in alkaline environment.

Schematic representation of PAEK-Imidazolium membranes. Reproduced with the copyright permission of Elsevier 2019 (Tham and Kim 2019).

Researchers believe that the PAEK-APMBI membrane is an attractive candidate for electrolyzing anion exchange membranes and Baolong Wang et al (Wang et al., 2016) conducted experiments with QA, C2 substituted, and imidazolium to compare the differences in poly (arylene ether ketone) functionalized with benzyltrimethylammonium, benzylmethylimidazolium, and benzyldimethylimidazolium. It was found that benzyltrimethylammonium (7 %) degraded in 1 M NaOH at 60 °C, while benzyldimethylimidazolium and benzylmethylimidazolium had 46 % and 55 % degradation, respectively. Benzyltrimethylammonium > benzyldimethylimidazolium > benzylmethylimidazolium is the order of stability. In comparison with the other two functionalized polymers immersed in 1 M NaOH and 60 °C, benzyltrimethylammonium showed better stability in the alkaline environment at elevated temperatures.

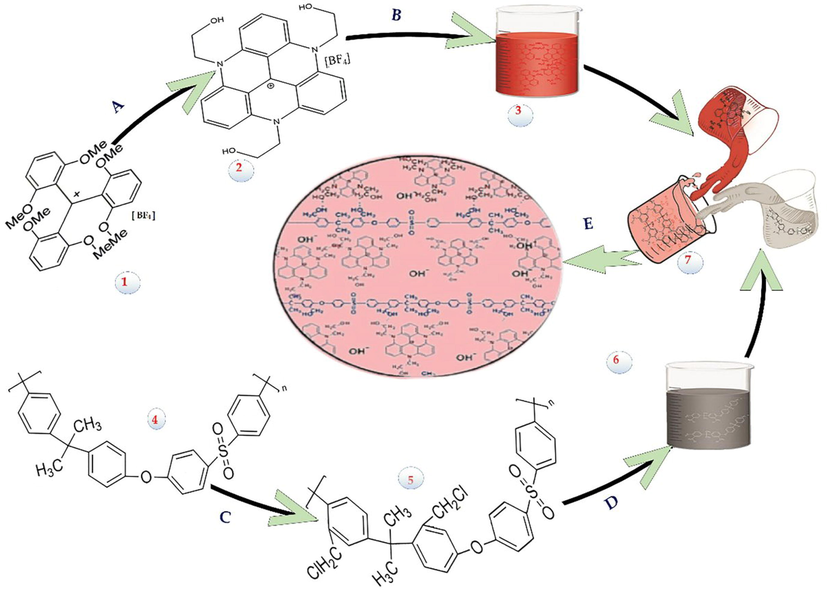

The structure of poly (arylene-ether) ketone with an aminopropyl moiety at the pendant site (PAEK-APMP) was investigated by 1H NMR in a paper published by Lee et al. In the present work, a series of membranes were synthesized, including PAEK-APMP 50, 75, 100 and 150; among which PAEK-APMP 75 and PAEK-APMP 100 under low water uptake (less than55 %) exhibited good hydroxide ion conductivity (>0.011 Scm−1) at 60 °C. In addition to comparing synthetic membranes with commercial ones, they found that hybrid PAEK membranes grafted with quaternary ammonium groups exhibited excellent chemical, mechanical, and hydrolytic stability. The hybrid PAEK-APMP 75 and 100 membranes also performed better on an electrolytic test than PAEK-QA and FAA-3(Fumasep) membranes (Lee et al., 2018).

Due to the hydration of cationic domain structures, water uptake closely correlates with membrane mechanical properties and ionic conductivity. Fig. 12 (a) shows the membrane's water uptake in relationship to temperature. Due to the ease with which hydration of ionic cluster occurs in PAEK-APMP membranes, water uptake is increased with increasing APMP contents. It was not possible to measure Fumasep FAA-3 membrane's water uptake beyond 60 °C due to membrane decomposition in water above that point. PEAK-QA had a lower water uptake despite a higher IEC value than PAEK-APMP75. In PAEK membranes, APMP groups form strong hydrogen bonds with water. As a result, water uptake increases, leading to higher ionic conductivity. The anion conductivities of a PAEKAPMP, a PAEK-QA, and a Fumasep FAA-3 membrane are shown in Fig. 12 (b). IECs of FAA-3 membranes were higher than PAEK membranes, resulting in higher anion conductivity. In spite of this, FAA-3 exhibited poor hydrolytic stability, preventing measurement of anion conductivity above 60 °C. At 30 °C and 80 °C, the anion conductivity varied from 0.0001 to 0.0054 Scm−1 and 0.0034–0 0184 Scm−1 depending on the amount of APMP substituted in the PAEK-APMP membranes.

The water uptake and anion conductivity as a function of temperature of the PAEK-APMP, Fumasep FAA-3, and PAEK-QA membranes (a and b), respectively, tensile stress vs strain behavior of PAEK-APMPs and Fumasep FAA-3 (c), Variation in the IEC of Fumasep FAA-3, PAEK-QA, and PAEK-APMP membranes in a solution of 10 % NaOH at 60 °C (d), and the polarization curves of PAEK-APMP-75 and PAEK-APMP-100 along with Fumasep, FAA-3, PAEK-QA, and zirfon membranes were measured at 60 °C in an electrolysis system composed of 10 wt% KOH solution for all membranes (e), Images were reproduced with permission from Elsevier(2018) under the copyright (Lee et al., 2018).

Fig. 12 (c) illustrates the tensile behavior of PAEK-APMP membranes after they have been injected with APMP at different doses. APMP is replaced more often, which decreases its tensile strength while increasing its elongation at break. In association with water, the APMP induces a plasticizing effect on the membrane. PaeK-APMP150, which has the highest concentration of APMP, had the best tensile strength of 17.2 MPa and elongation of 73.8 %. However, Fumasep FAA-3 membranes exhibited a much lower elongation than PAEK membranes despite having a higher tensile strength. Fig. 12 d depicts the IEC changes measured during four weeks in NaOH solution in 10 wt% at 60 °C for PAEK-APMP, Fumasep FAA-3 and PAEK-QA membranes. Due to its frequent operation at lower temperatures, Fumasep FAA-3 was also tested at 50 °C in addition to 60 °C. Fumasep FAA-3 and PAEK-QA membranes show rapid decreases in IEC as a result of the Hofmann elimination reaction (Mohanty and Bae 2014). While Fumasep FAA-3 had a higher initial IEC value, its degradation rate was also similar to PAEK-QA. The degradation rate of PAEK-APMP membranes was substantially lower than other types of membranes regardless of the initial IEC value. In alkaline conditions, APMP suffers from less susceptibility to Hofmann elimination reaction compared to QA PAEKAPMP. This ensures that membranes containing QA can retain ion transport capability under alkaline conditions for a longer period. An electrolyzer constructed with different membranes is illustrated in Fig. 12 (e). PAEK-APMP-75 and PAEK-APMP-100 membranes have lower potentials and maintain higher performance than Zirfon separators (used in AWE). When the current density in PAEK-APMP membranes was low, they performed in a similar way to PAEK-QA membranes. However, when the current density was above 150 mAcm−2 regardless of IEC, they performed significantly better. This may be due to the chemical stability of QA ion conductivity. In their early stages of development, FAA-3 membranes showed performance that was similar to that of APMP100, however, they were quite hydrolytically unstable due to weak mechanical and thermal properties. The PAEK membranes synthesized in this study performed well and were durable, without any abnormalities before or after use (Lee et al., 2018).

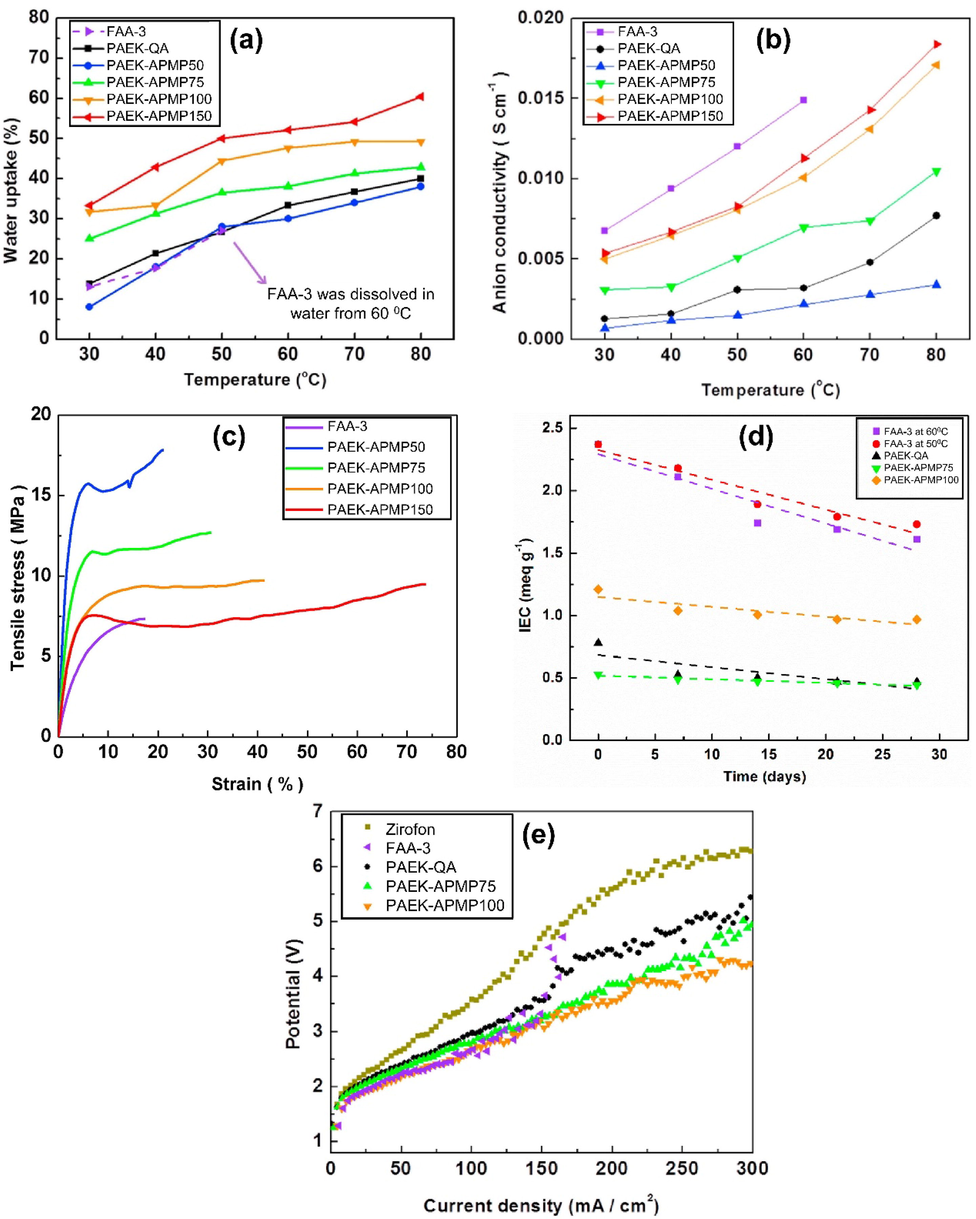

An electrochemically oriented AEM was fabricated by using a convenient approach by Thomas et al. AEMs containing polysulfone hydroxide anion and negative charge carriers, triazatriangulenium carbonation (4,8,12-triethano-4,8,12-triazatriangulenium tetrafluoroborate), pKR + values>20 were used. It can be seen from the different results that the polysulfone matrix contains a large carbocation network for 4,8,12-trizatriangulenium, that it’s ionization capacity is good (2.44 ± 0.72 mew/g) and that it can transport hydroxide anions smoothly with an Ea value of 6.56 kJmol−1. The high stability of the triazatriangulenium cation is responsible for 88 % of the initial membrane conductivity in a 3 M KOH at 60 °C for 35 days, in addition to the high ion conductivity of 23. 5 mS cm−1 at 90 °C., shown in Fig. 13 below (Thomas et al., 2021).

AEM fabricated by using TATA+ –OH. The steps involved; (1) Initial materials used for the fabrication of AEM; tris(2,6- dimethoxyphenyl)-methylium tetrafluoroborate), (2) Addition of (4,8,12 tri-ethano-4,8,12-triazatriangulenium-TATA+ –OH), (3) TATA+ –OH dispersion in NMP, (4) PSF, (5) CMPSF, (6) NMP and CMPSF Dispersion, (7) Further, CMPSF and TATA+–OH solutions are mixed and sonicated on different reaction conditions: (A) Addition of N2/Ethanolamine at 190 °C; (B) TATA+–OH stirred; (C) addition of (CH3)3SiCl, Paraformaldehyde and SnCL4/N2 for 72 h; (D) CMPSF was stirred; (E) The final step in the process is to determine the electrochemical synthesis pathway for the TATA+ –OH carbocation AEM using evaporating solvents and drying settled casted membranes. Images were redrawn by with the copyright permission from Elsevier 2021(Thomas et al., 2021).

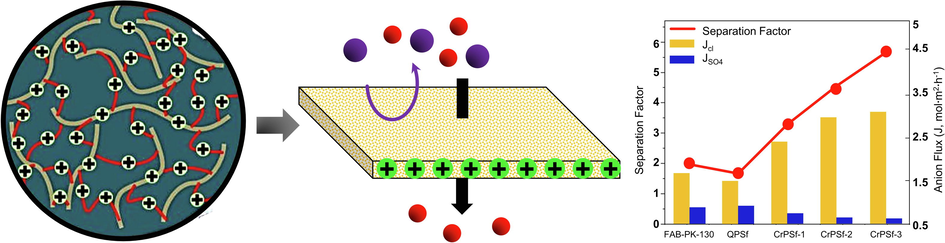

Utilizing crosslinking and methylation of polysulfone, Priya Goel et al (Goel et al., 2021) synthesized a series of monovalent anion selective membranes from 1.5 dizabicyclooctane functionalized graphene oxide (QGO). QGO cross-linked on membranes provide additional functional sites, as well as a dense polymer matrix. They studied the effects QGO on different properties such as electrochemical and physicochemical properties and using a CrPSf-3 membrane (nano cross-linker at 3 wt%), the researchers determined that it had good mechanical and thermal stability and the best ion exchange capacity with water uptake of 31.20 %, a swelling ratio of 9.90 %, a counter-ions transport coefficient of 0.95, and a chloride ion conductivity of 72 mScm−1. With 0.05 mol. L-1 of mixed salt solution (NaCl + Na2SO4), electrodialysis was studied to investigate the membrane permselectivity of Cl− and SO42−. Compared to commercial FAB-PK-130 (2.01) and QPSF (1.7) membranes, the separation factor (SF) of the CrPSf-3 membranes was 5.7 for Cl- / SO2-4. As a consequence, CrPSf-3 membranes displayed a much higher Cl− flux rate than commercial membranes (1.6 molm−2h−1) and pristine QPSf (1.45 molm-2h−1) as shown in Fig. 14.

Multi-cationic cross-linked monovalent selective AEM based on QGO for electrodialysis. Figure reproduced with copyright permission of Elsevier's (2021) permission (Goel et al., 2021).

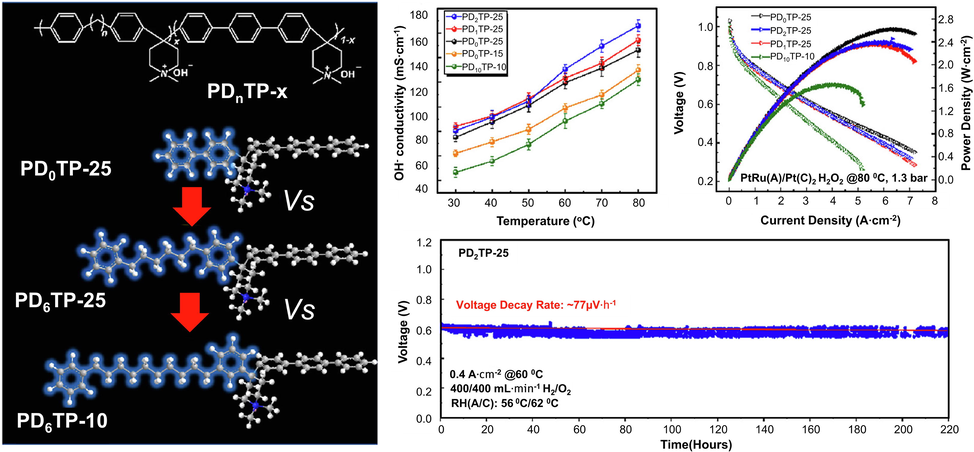

Chuan Hu et al. examined the ploy (aryl-co-aryl piperidinium)-x (PDnTP-x) with alkyl spacers in five alkyl positions (n = 0, 1, 2, 6, and 10) to explain their conclusions. A short alkyl chain is more dimensionally stable and gas-tight (H2 permeability 10 Barrer) than a long chain, whereas long alkyl chains displayed better dimensional stability as mentioned in Fig. 15. PDnTP-x membranes were found to be excellent alkaline and oxidative stabilizers (200 h in Fenton's reagents) on all of the polyaromatic AEMFCs, cells of the long chain type had a greater power output of 1.7 Wcm−2. There is a continuous operation time of 220 h for PDnTP-x AEMFCs of the short chain type using a current density of 0.4 A cm−2 and a voltage decay rate of 77 µ V h−1 (Hu et al., 2022).

Performance and durability of membrane(ploy (aryl-co-aryl piperidinium)-x) based fuel cells based on different test conditions and cathode catalysts and AEMs-water uptake, platinum-cathode, 1.3 bar-backpressure (both sides), and current density of 0.4 A cm−2 at 60 °C. Figure reproduced with copyright permission of Elsevier's (2022) permission (Hu et al., 2022).

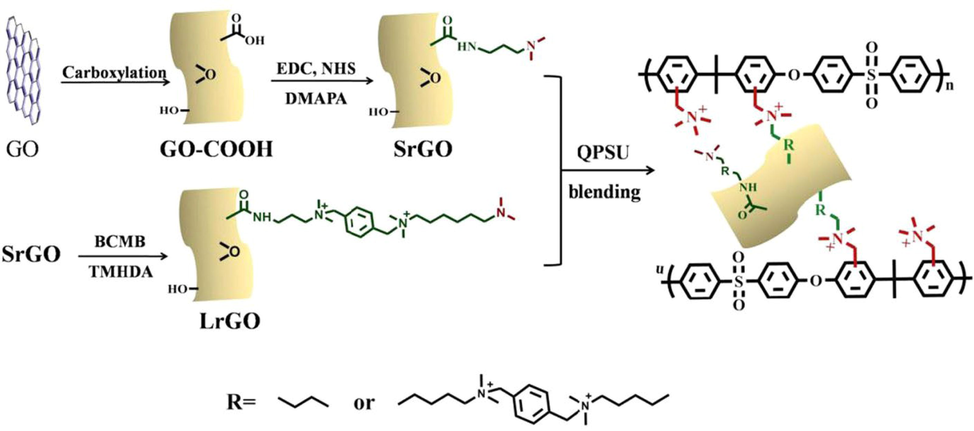

As depicted in Fig. 16, Yang Bai et al. formed nanostructure (CQPSU-X-rGO) supported on quaternized polysulfone (QPSU) and functionalized with small molecules of varied chain lengths after crosslinking by reduced graphene oxide. A control was prepared with QPSU-n cross-linked to organic small molecules. Comparisons of quaternary ammonium groups generated by elastic long chain cross linked membranes and elastic short chain cross linked membranes indicate that membranes with elastic long chain cross linked agents demonstrate superior conductivity. The CQPSU-XLrGO and CQPSU-X-SrGO demonstrated superior chemical stability and conductivity to cross linked AEMs (CQPSU-2 %-LrGO, at 80 °C σOH = 139.7 mS/cm). AEMs prepared by cross-linking functionalized rGO have therefore been shown to possess improved properties as cross-linkers and fillers (Bai et al., 2019).

The chemical synthesis of functionalized rGO and their crosslinked QPSU-based AEMs. Copyright permission was obtained from Elsevier 2019 for the redrawn figure (Bai et al., 2019).

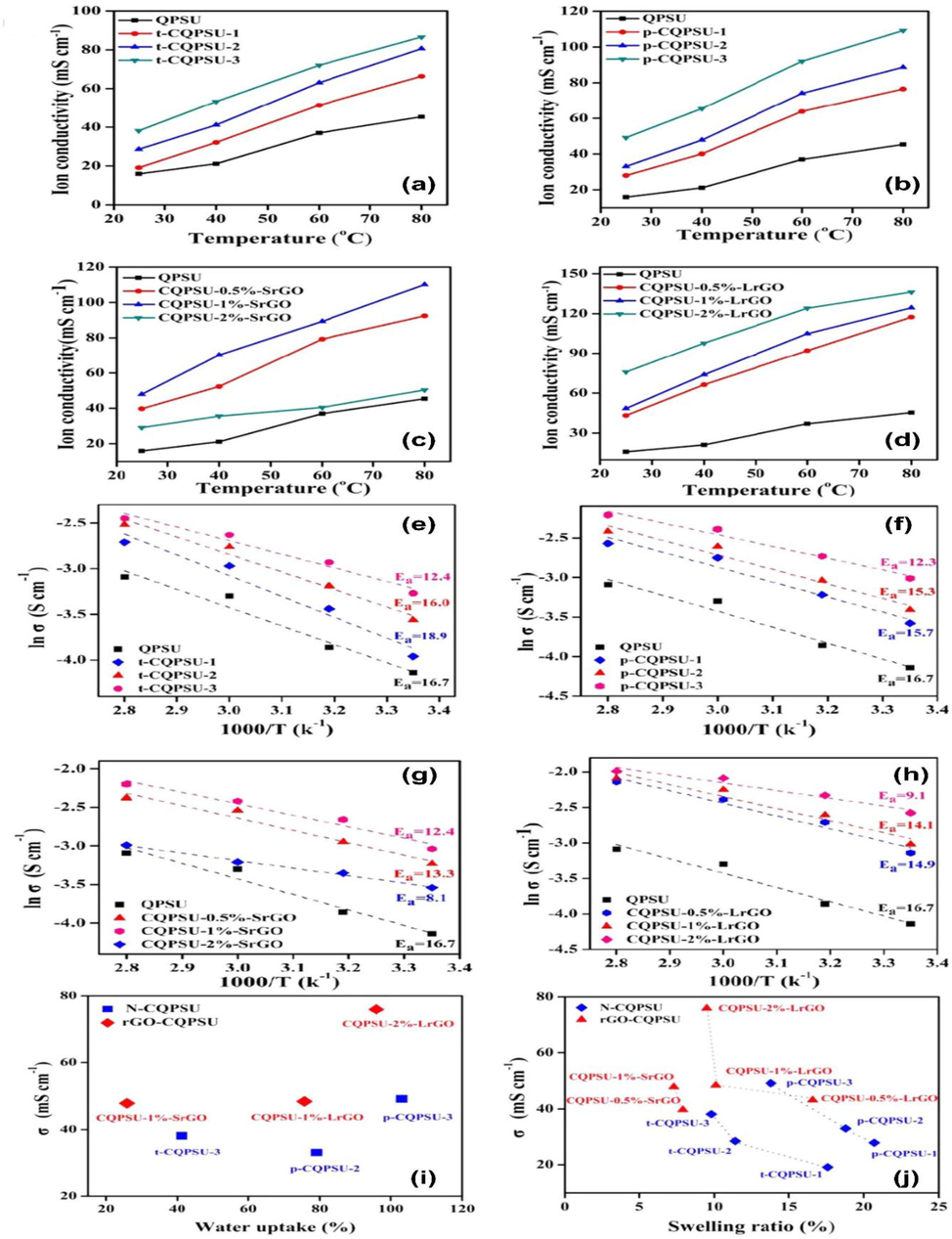

PTMHDA (Fig. 17 b) and LrGO (Fig. 17 d) prepared by long-chain cross-linkers demonstrated higher hydroxide conductivities than TMHDA (Fig. 17 a) and SrGO (Fig. 17 c) prepared by short-chain cross-linkers (Bai et al., 2019). PTMHDA and LrGO have been shown to be capable of generating more quaternary ammonium groups, which enhance WU. Furthermore, modified rGOs cross-linked composite AEMs show greater hydroxide conductivity than small molecules-cross-linked polymers. As a result of this, functionalized rGO in AEMs can disperse ionic clusters with greater uniformity, improving ion conductivity as compared to small molecules-cross-linkers. CQPSU-2 %-SrGO membrane's ion conductivity was further reduced when the SrGO content was increased to 2 %. Inorganic fillers introduced in excess can lead to a decrease of hydroxide conductivity due to the obstruction of ion transport pathways. Despite the higher doping, the CQPSU-2 %-LrGO membrane had the highest conductivity of 139.67 mS cm−1 at 80 °C.

(a-d) Hydroxide conductivity of different AEMs, (e-h) Arrhenius curves of different AEMs, (i) Water uptake and OH− conductivity, and (j) swelling ratio and hydroxide conductivity of different AEMs at room temperature. Figure reproduced with the copyright permission from Elsevier 2019 (Bai et al., 2019).

The authors also found that the long-chain molecule cross-linker proposed for AEMs which utilized functionalized rGO as a cross-linker can effectively solve the compatibility problem between the filler molecules and the polymer matrix, and further enhance overall performance, including ion conductivity in cross-linked AEMs (Bai et al., 2019). Based on the temperature-dependent ion conductivity plots in Fig. 17(e-h), one can calculate the apparent activation energy (Ea) of OH− conduction for different AEM samples (Bai et al., 2019). Ea values of modified rGO-cross-linked composite AEMs (8.1–14.9 kJ mol−1) were somewhat lower than those of cross-linked polymer membranes (12.3–18.9 kJ mol−1). QPSU-2 %-LrGO and QPSU-2 %-SrGO had the highest Ea values, with 9.1 kJ mol−1 and 8.2 kJ mol−1, respectively. Based on the fact that the rGO-crosslinked composite membranes had comparable ion conductivity to other membrane samples, the nonionic nature of rGO should contribute to lowering Ea for ion conduction in AEMs[1 9 3]. In Fig. 17(i, j), the hydroxide conductivity was plotted as a function of WU and SR to better understand the ion conductivity of different cross-linked AEMs In comparison to the cross-linked polymer films with similar WU, the modified rGO cross-linked composite films exhibit significantly higher OH-conductivity (Fig. 17 i). CQPSU-2 %-LrGO membrane has an OH− conductivity of 75.9 mS cm−1 with a controlled WU of 95.5 %. p-CQPSU-3 had a OH− conductivity of 49.2 mS cm−1 even when its WU reached 103.1 %. AEMs with rGO cross-linked are more uniform in their nanophase separation structures as a result of increased ion transmission through the lamellar structure of rGO. According to Fig. 17 (j), membrane samples prepared by short-chain cross-linker of THMDA exhibited a lower swelling ratio than those prepared with long-chain cross-linker of PTHMDA. Long-chain cross-linkers provide flexibility to the membranes, preventing the inner structure from being tightly packed. Compared to cross-linked polymer membranes with similar SR, the rGO-cross-linked composite membrane had higher OH− conductivity. Due to the incorporation of rGO, the membranes remained dimensionally stable due to decreased movement of the polymer chain(Bai et al., 2019).

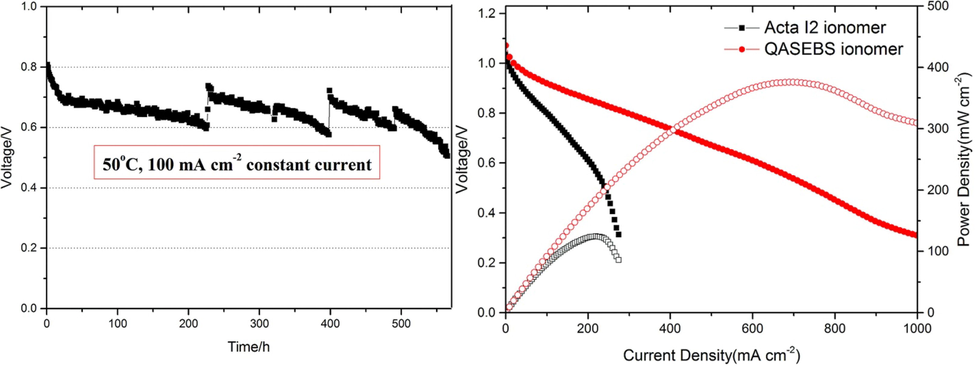

Recently, it has been reported that pendent quaternary ammonium ionomers made of polysulfone (PSf) can dissolve only in solvents having high boiling points, like dimethylformamide (DMF) and dimethylacetamide (DMAc), which are difficult to remove from solution when finely dispersed catalysts are present (Lu et al., 2008, Park et al., 2008, Pan et al., 2010). An ionomer of quaternary phosphonium functionalized PSf with a low boiling point, superior hydroxide conductivity and superior alkaline stability has been created by Yang et al,.(Yang et al., 2015) A H2/O2 AEMFC outperformed the MEA without ionomers by 3.5 times at 50 °C, as measured by its peak power density of 138 mWcm−2 at 50 °C. In their study, Sun et al. synthesized quaternary ammonium-based ionomers with a wide range of ion exchange capacities using SEBS as the backbone, a thermoplastic elastomer with good thermal, mechanical and chemical stability. With a back pressure of 2 atm and a temperature of 50 °C, an AEMFC(H2/O2) achieved a peak output of 210 mWcm−2, this is significantly higher than a MEA with PSf-based ionomers (50 mW cm−2) (Sun et al., 2012). However, despite the ion conductivity and solubility of these ionomers being acceptable, their MEA performance did not align with state-of-the-art PEMFCs. The public domain also contains only a limited number of publications discussing AEMFC performance, particularly durability (Varcoe et al., 2006, Wang et al., 2017). The Xueqiang Gao et al. study synthesized novel ionomers containing a triblock copolymer that is highly conductive and durable. In this study, the authors showed that poly(styrene-ethylene/butylene-styrene-SEMS) can be grafted with a functional group, and that the OH– conductivity of the ionomer at 75 °C is 30 mScm−1. In H2/O2 AEMFCs, this ionomer also demonstrated excellent durability with a degradation rate of 0.22 mVh−1 over 500 h at a constant current density of 100 mA cm−2. The performance of the MEA with QASEBs ionomer was also compared to that of the commercially available Acta I2 ionomer. A MEA ionomer with QASEBs reaches 375 mWcm−2 at 50 °C, which is three times more powerful than an Acta I2 ionomer (124 mW cm−2). shown in Fig. 18 (Gao et al., 2017).

Portrays the efficacy of various electrode systems utilizing QASEBS and Acta I2 ionomers and the durability of MEA using QASEBS ionomer. The Figure reproduced with the copyright permission of RSC advance 2017 (Gao et al., 2017).

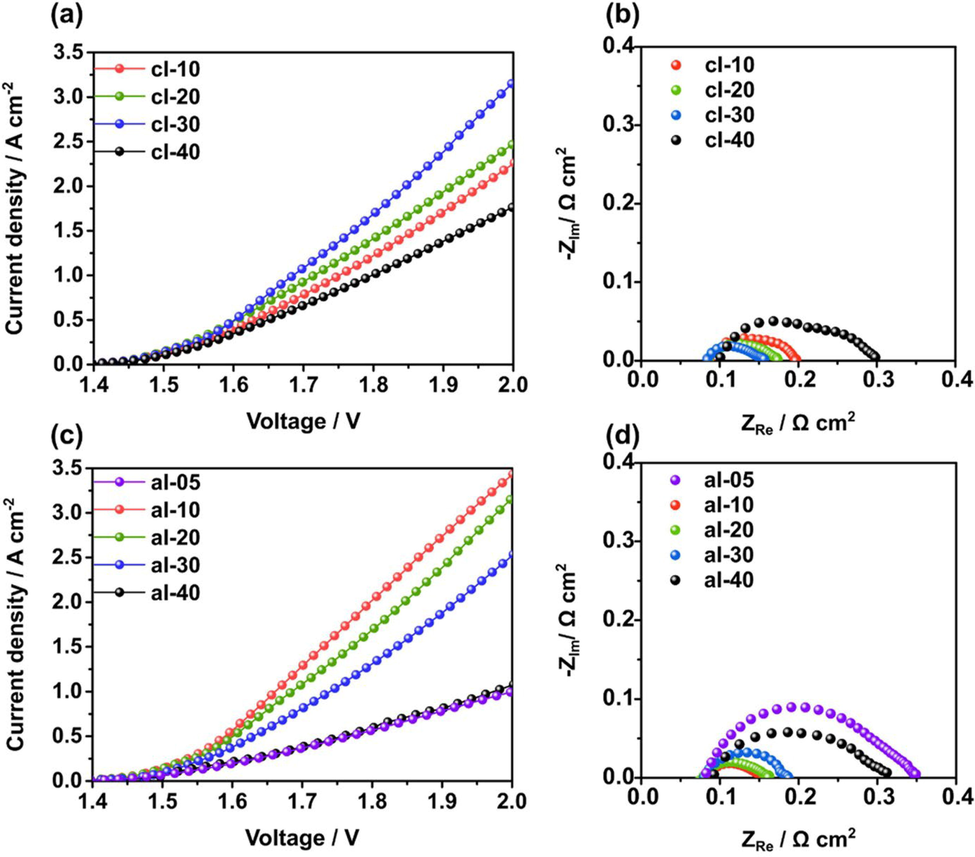

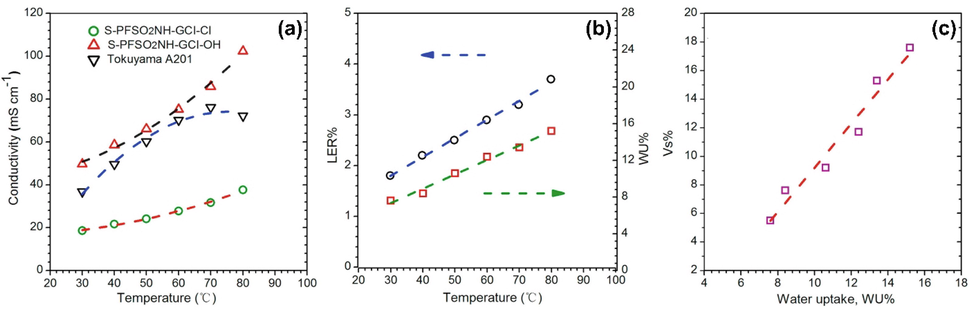

Sun Young Kang et al. reported high stability and ionic conductivity of their AEMWE system by using TM1TM membrane combines with a polyphenylene backbone and quaternary ammonium groups as the functional group(Meek et al., 2019). AEMWE performs better due to the hydrophobicity and geometry of the membrane. In their study, they found the Orion TM1TM membrane to be thermally stable and more temperature resistant than the FAA-3 membrane. The Fig. 19 below illustrates the AEMWEs’ polarization curves (cl-10, 20, 30, & 40) and the ionomer content of anode was constant (20 %). At 1.9 Vcell, the current density of cl-10, 20, 30, and 40 were 1.72, 1.92, 2.40, and 1.38 A cm−2, respectively. Here, 10–40 indicates the cathode ionomer content ranges from 10 to 40 wt%. After increasing the content of ions from 10 to 30 wt%, performance gradually increased till 30 %, then decreased at 40 %. The results are shown in Fig. 19(b).

The polarization curves and Nyquist plot for AEMWEs (cl-10, 20, 30 & 40)along with varying ionomer contents (10-40 wt%) at 1.9 Vcell are shown as symbols in (a & b), At 20%, the anode ionomer content remained constant. The polarization curves and Nyquist plots of the AEMWE's (al-05, 10.20,30, and 40) were calculated at 1.9 Vcell using 5, 10, 20, 30, and 40 wt% as anode ionomer contents. During the experiment, ionomer of cathode concentration was remained same at 30% by weight. This reproduction is permitted with Elsevier's(2022) consent (Kang et al., 2022).

Fig. 19 (c) illustrates the performance of AEMWEs that contained 5 %(al-5), 10 % (al-10), 20 % (al-20), 30 % (al-30), and 40 % (al-40) ionomers. Cathode ionomer (30 %) was fixed. From al-05 to al-10, the performance of AEMWEs increased, while from al-10 to al-40, it decreased. There is a ionomer in a certain amount that facilitates ion movement in the catalyst layer, which assists electrochemical reactions, However, excessive ionomer blocks the catalyst's active sites. Despite its very small ionomer content, al-05 exhibits high activation and mass transport resistance, as shown in Fig. 19(d). A second characteristic of al-05 is that it has dense structures with small secondary pores, increasing the resistance to reactant and product transport. The result of the experiment is that as the percentage of the ionomer increased from 5 to 10 %, activation and mass transport resistance have decreased, and cell performance has improved, this indicates that 10 wt% is sufficient for efficient ionic connections. Moreover, they noted that the cell performance was reduced when the ionomer content was > 10 wt%, possibly due to the larger secondary pores caused by the large ionomer content, and they recommended that the optimal cathode and anode ionomer content should be 30 % and 10 wt% in regard to the catalyst loading. Furthermore, they found that the optimum catalyst loading was 0.4mgptcm−2 and 2.0 mgIro2 cm−2.

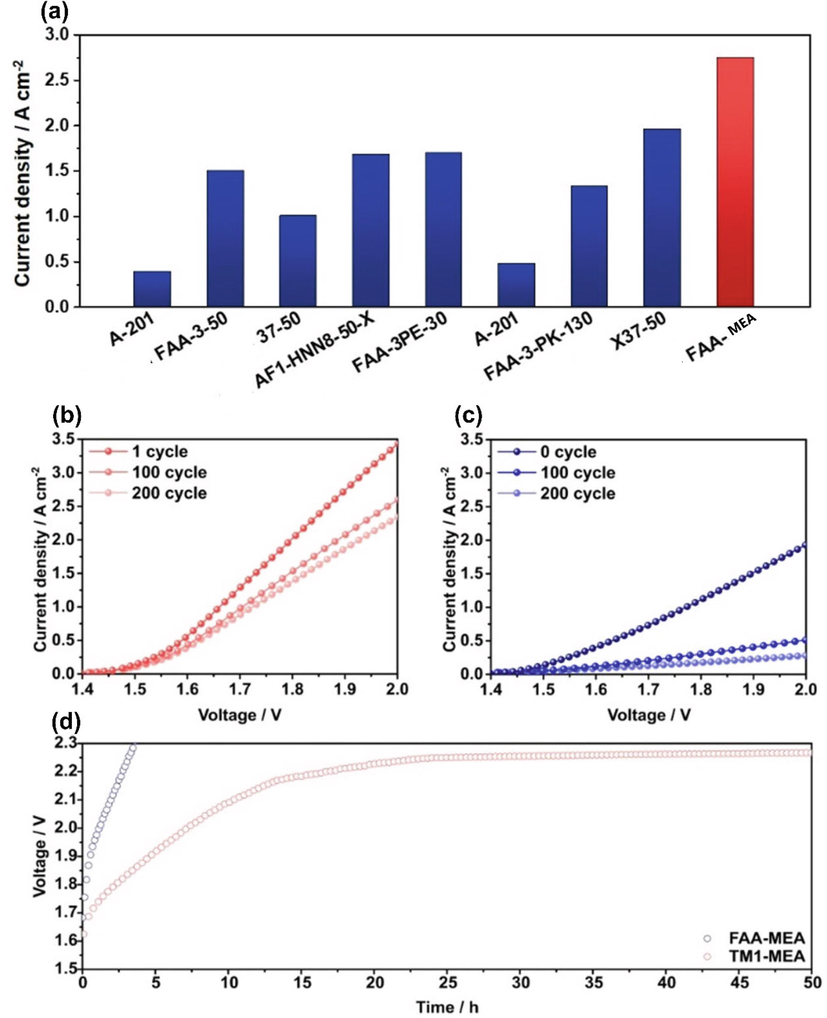

Optimized TM1-MEA's current density is 2.75 A cm−2, allowing it to operate a 1.9 Vcell. Due to its high stability of 55 mVh−1 and its superior structure, the orion-TM1TM membrane offers superior performance. According to Fig. 20(a), current density at 1.9Vcell is approximately calculated from a graph based on the values reported in the literature for AEMWE(Pavel et al., 2014, Liu et al., 2017, Vincent et al., 2017, Cossar et al., 2019, Park et al., 2019, Fortin et al., 2020, Jang et al., 2020, Thangavel et al., 2020). Compared to the literature, they claimed and demonstrated to have achieved the best results, as seen in Fig. 20 (a). Fig. 20 (b and c) shows the results of evaluating cycling stability using TM1-MEA and FAA-MEA under optimum conditions. Following 200 cycles, the TM1-MEA was significantly more stable than the FAA-MEA, resulting in a reduction in the current density by 32 % and an 85 % reduction in the FAA-MEA. Both showed rapid decreases in current density during the first hundred cycles. According to Fig. 20 (d), TM1-MEA displayed a gradual increase in voltage until about 20 h and then exhibited a constant voltage profile for 50 h, whereas FAA-MEA mounted sharply in 3.4 h to 2.3 Vcell. In comparison with previous studies on commercially available ionomeric anion exchange membranes for AEMWEs, their work provided the highest performance. Consequently, ionomeric AEM for AEMWE can be considered as Orion TM1TM membrane. Overall, it was found that the TM1-MEA performed better than the FAA-MEA in every feeding condition, whether it was pure water or diluted alkaline solution.

(a) A comparison between the results of AEMWEs presents in the previous studies (as mentioned on x-axis) (Pavel et al., 2014, Liu et al., 2017, Vincent et al., 2017, Cossar et al., 2019, Park et al., 2019, Fortin et al., 2020, Jang et al., 2020, Thangavel et al., 2020) and the ones developed FAA-MEA (70 °C). (b) Polarization curves of FAA-MEA and (c) TM1-MEA after 100 and 200 cycles. Under optimized conditions at 500 mA cm−2 stability tests were performed on two types of AEMWE such as TM1-MEA and FAA-MEA (d). The Figure was reproduced with the permission of Elsevier 2022(Kang et al., 2022).

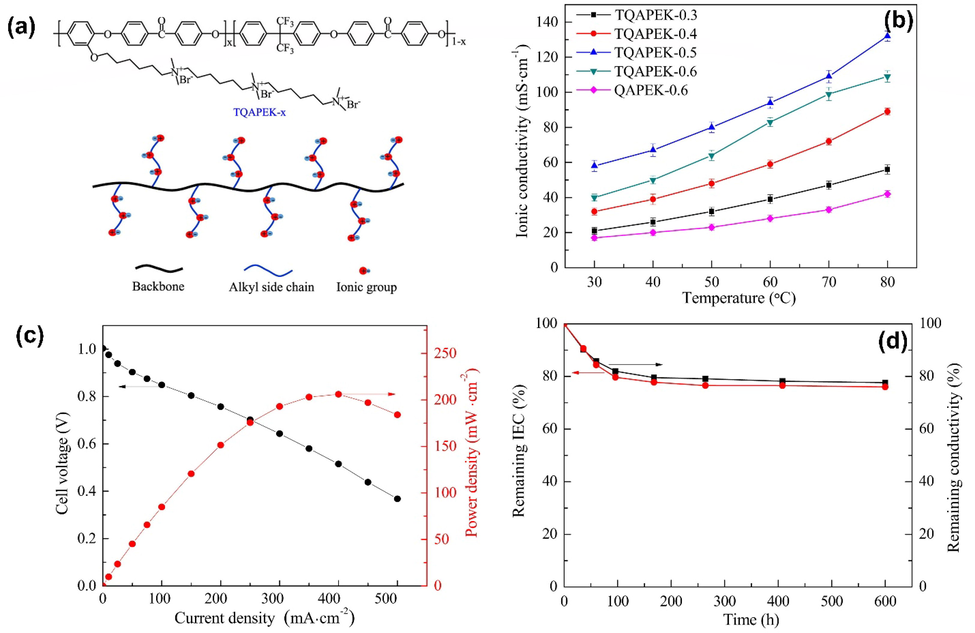

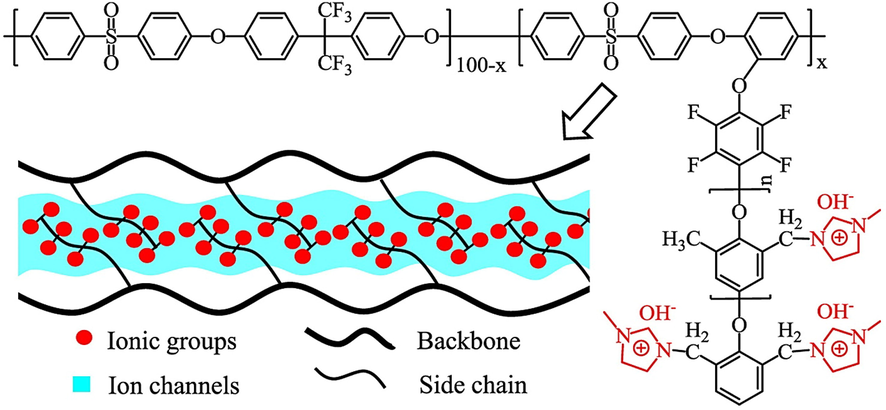

There has been much interest in backbones and cationic head groups. AEMs are largely made up of aromatic polymers because of their high thermal stability, solubility, and chemical resistance (Zarrin et al., 2012, Lee et al., 2015, Mohanty et al., 2015). In addition to aromatic polymers, exploration of several newly discovered structures has been conducted, including poly (biphenyl alkylenes) (Lee et al., 2015), poly(terphenylenes) (Lee et al., 2017), N-spirocyclic quaternary ammonium ionenes (Pham et al., 2017) and perfluoroalkyl copolymers/ quaternized aromatic (Mahmoud et al., 2017). There have also been reports of cationic head-groups such as quaternary ammonium groups (QA) (Zhu et al., 2016, Mahmoud et al., 2017, Zhu et al., 2017), imidazolium ions (Gong et al., 2017, Guo et al., 2017, Lin et al., 2017), guanidinium ions (Xue et al., 2017), phosphonium ions (Noonan et al., 2012), and aliphatic heterocyclic QA head groups (Hahn et al., 2013, Dang and Jannasch 2016). Due to their availability and reasonable stability, the QAs are among the most popular cationic groups (Mahmoud et al., 2017). Ling Li et al. (Li et al., 2018) used demethylation, polycondensation, and the Williamson reaction to prepare the synthesized poly(ether ketone) bearing multi cation side chains via Poly(ether ketone)s. It has been confirmed by TEM and SAXS that multication side chains promote phase segregated morphologies between hydrophilic and hydrophobic phases. At 80 °C, the TQAPEK-0.5 membrane has the highest IEC of 1.94 meq g−1 as well as the highest hydroxide conductivity of 132.8 mS cm−1. AEM possesses a high alkaline stability due to hexyleneoxy groups connecting the side chain to the backbone. It took TQAPEK-0.5 only 22.4 % longer to decrease its conductivity at 60 °C in a solution of 2 M KOH after 600 h. Moreover, a single cell utilizing TQAPEK-0.5 membrane can generate a peak power density of 206 mW cm−2 when the current density is 400 mA cm−2. Additionally, the as-prepared AEMs exhibit good thermal and mechanical properties, promising their use in FC as shown in Fig. 21.

Nucleophilic polycondensation produces poly(ether ketone)s containing multication side chains(a), temperature dependence of ion conductivity (b), curve of polarization(c), alkaline resistance (d) of TQAPEK-0.5 in a H2/O2 single cell at 60 °C, The figure was reproduced with the permission of Elsevier 2018(Li et al., 2018).

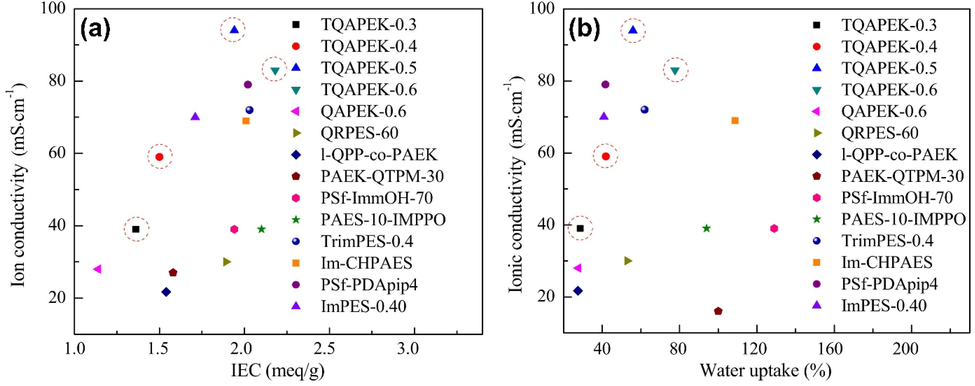

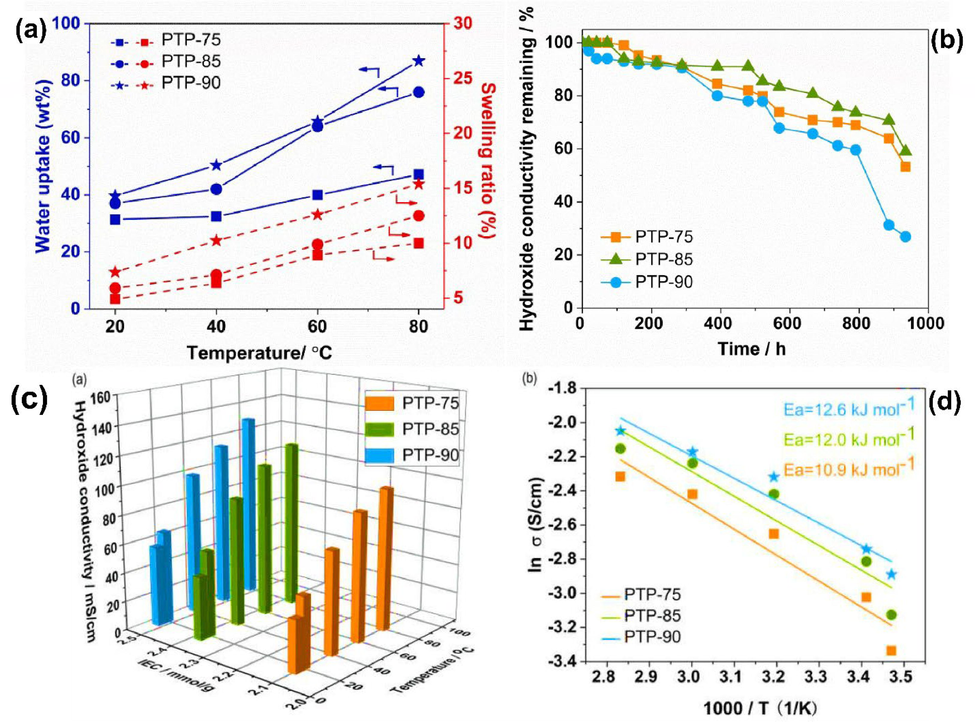

As depicted in Fig. 22, TQAPEK-x has a better conductivity than other membranes reported for WU and IEC. As shown in the graphs, all membranes of TQAPEK-x appear at the top left, indicating that membranes in Li Liang et al's work have higher transport of OH– efficiencies at lower WU and IEC. Additionally, membranes with multications on the side chains may be an effective material to increase ionic conductivity by efficiently using water due to the structure-induced segregation of microphases (Li et al., 2018).

Study of AEMs' conductivity at 60 °C in relation to (a) IEC and (b) water uptake from previous studies (Yang et al., 2014, Shen et al., 2015, Dong et al., 2016, Guo et al., 2016, Lin et al., 2016, Dong et al., 2017, Guo et al., 2017, Lu et al., 2017, Strasser et al., 2017) and TQAPEK-x. Image was reproduced with the copyright permission Elsevier 2018(Li et al., 2018).

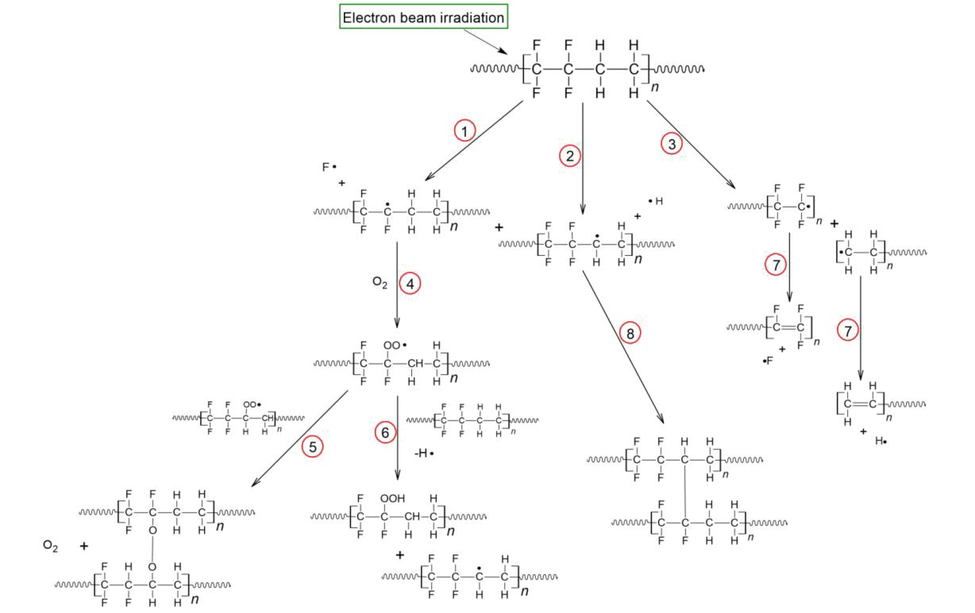

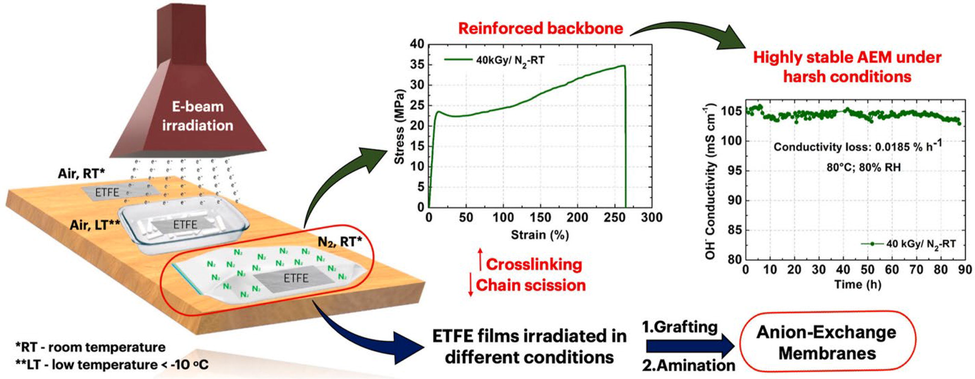

According to the literature, AEM base polymers based on ETFE are promising. Polyethylene and polytetrafluoroethylene units alternate in the structure of ETFE, giving it properties that describe in terms of their physicochemical properties, both types of polymers (hydrocarbons and fluorocarbons) have excellent chemical and thermal stability (Nasef et al., 2003, Nasef and Hegazy 2004, Kizewski et al., 2013, Douglin et al., 2021). ETFE's C—C, C—H, and C-F bonds in its backbone may detach during irradiation. As a result, macroradicals are formed (reactions (1)–(3) in Fig. 23). Three competitive reactions occur between these radicals, affecting the structure of the backbone, affecting its mechanical properties, and thereby changing the material's properties (Kizewski et al., 2013). During irradiation with air (reaction 4, Fig. 23), the bonds are split into macroradicals which react with atmospheric oxygen, resulting in peroxide. Upon reaction with peroxyl radicals, alkylperoxides can be formed (as shown in reaction-5 of Fig. 23) and/or hydrogen can be abstracted, resulting in hydroperoxides (as shown in reaction-6 of Fig. 20). Additionally, they can undergo more complex changes or undergo other complex reactions that may lead to oxidative degradation (Arakawa et al., 1982), causing the chain to cleave (Dawes et al., 2007). Afterwards, unsaturated structures are produced by C—C scission followed by dehydrofluorination (reaction-7 in Fig. 23), another reaction indicating degradation. Finally, following dehydrofluorination, two adjacent radicals react to form crosslinks (reaction-8 in Fig. 23) (Nasef et al., 2003). Crosslinking and degradation caused by scission processes can result in a conflict between chemical and mechanical reinforcement (Chapiro 1964). For ion exchange membranes, ETFE films are commonly used as the basis polymer, particularly for PEMFC applications(Gürsel et al., 2007, Ben youcef et al., 2009, Ben youcef et al., 2010, Lappan et al., 2010, Nasef 2014, Nasef et al., 2016, Sproll et al., 2016). Recent studies have also reported the performance of AEMs in single fuel cell tests (Fang et al., 2012, Mamlouk et al., 2012, Wang et al., 2017, Gonçalves Biancolli et al., 2018, Omasta et al., 2018).

Reactions (1), 2 and 3: C–F, C—H, C—C bond cleaveges, respectively, and formation of macroradicals upon irradiation. Reaction 4: formation of peroxyl radicals after contact with O2. Reaction 5: peroxyl radicals reacting to form peroxides. Reaction 6: abstraction of hydrogen and formation of hydroperoxides. Reactions 7: By C—C scission followed by dehydrofluorination, an unsaturated structure is formed, Reaction 8: After dehydrofluorination, the radicals react to form crosslinking structures (reactions (1) and (2)). Figure reproduced with the copyright permission of Elsevier 2022 (Biancolli et al., 2022).