Translate this page into:

Rheological, physio-chemical and organoleptic characteristics of ice cream enriched with Doum syrup and pomegranate peel

⁎Corresponding author at: Department of Analytical Chemistry, Faculty of Applied Science, Umm Al-Qura University, Makkah, Saudi Arabia. amhameed@uqu.edu.sa (Ahmed M. Hameed), aasayqal@uqu.edu.sa (Ahmed M. Hameed),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Doum fruit and pomegranate peels are riches healthy nutrients such as fiber, minerals and antioxidant potentially protect from diet related diseases. This research was conducted to study the influence of ice cream enriched with pomegranate peels powder (PPP) and Doum fruit syrup (DFS) alone or in a combination at different ratios on its physicochemical, rheological, microbiological, and organoleptic properties. Ice cream enriched with PPP and DFS have high contents of total solids, protein, fat, ash, fiber, antioxidants activity, minerals and gross energy which are raised up with increasing the addition level. However the contents of moisture, pH, carbohydrate and Cu were decreased. Furthermore, addition of PPP and DFS alone or in a combination caused increases in acidity, specific gravity, weight per gallon, first dripping time, melting rate, melting resistance, and viscosity. While, a decrease in overrun values was observed compared to the control sample. Treatment of ice cream with PPP and DFS alone or in a combination showed decrease in total bacterial and psychrophilic count. In addition coliform bacteria, yeasts and mould counts were not detectable in all ice cream samples. The sensory evaluation showed that ice cream enriched with 0. 25% PPP and 2.5% DFS was the most acceptable treatment. While higher addition levels of PPP and DFS alone or in a combination contributed to progressive loss of sensory quality.

Keywords

Ice cream properties

Doum fruit syrup

Pomegranate peels powder

Antioxidants activity

Antimicrobial activity

1 Introduction

Ice cream is a valuable accompaniment to the normal diet for all age groups especially for children. It represents one of the most widely consumed dairy products. The quality and variety in ice cream manufacture has gained importance in dairy industry (De, 2006). Ice cream contains micronutrients, i.e. calcium and vitamins (E, D, A) as well as rich in macronutrients, i.e. fats, carbohydrates, and proteins. However is low in dietary fiber and natural antioxidants.

Recently researches have been concerned on healthy foods that have functional properties and high in nutraceuticals (Bhat and Bhat, 2012). By-products obtained from fruit processing wastes contain rich sources of bioactive compounds and dietary fibers (Balasundram et al., 2006). Pomegranate plant Punica granatum L. (Punicaceae) is one of the most fruit rich in phytochemical compounds i.e polyphenols and ellagic acid (Miguel et al., 2010) as well as protein, vitamins carbohydrates, amino acids, fatty acids, and pectin, (Li et al., 2006). Due to its high bioactive compounds, pomegranate has been called a nature’s power fruit that used as folk medicine (Yehia et al., 2011). Pomegranate fruits consume as fresh, or juice and even used in wine industry. The juice industry produces pomegranate peels and seeds wastes represent 78% and 22%, respectively which use as animal feed (Çam et al., 2013). Pomegranate peels contain high level of carotenoids, polyphenols, enzymes, vitamins, and dietary fibers that are considered as bioactive compounds. The peels are utilized as natural antibacterial and antioxidant due to their polyphenol’s compounds such as sugar-free oligomeric and monomeric ellagitannins (Negi et al., 2003). Studies on pomegranate compound discovered that its substances are useful to reduce some diseases hazard such as urinary tract infection, inflammation, fever, bronchitis, malaria, and stomachic. So, pomegranate peels powder is considered as a functional food (Jaiswal et al., 2010).

Doum palm is considered as a symbol of masculine strength and a sacred tree for Pharaohs in ancient Egypt because they belief that it provides food and water for the person after death. The outer layer of the fruit is edible and can be prepared either in a sliced or in a powder form that is added to many foods as flavoring compounds (Abd El-Rashid and Hassan, 2005). In Egypt, some people use Doum as a medicinal plant for the treatment of several diseases and hypertension. The Doum palm, the major one of its plant families, provides human with carbohydrates, dietary fibers, and antihypertensive substances as well as it contains high amount of essential linoleic acid, proteins, minerals, and antioxidants (Cook et al., 2000; Hsu and Coupar, 2006). Therefore, this study was conducted to demonstrate the possibilities of utilizing Pomegranate peels and Doum fruit syrup (Dibis) as fiber and antioxidants supplements to produce functional ice cream with acceptable rheological and sensory attributes.

2 Materials and methods

2.1 Materials

Fully ripe Pomegranate (P. granatum L.) and Doum fruits (Hyphaene thebaica) were provided from a local producer (El-Kharga City, New Valley Governorate, Egypt). Fresh cow’s milk (containing 4% fat, 8.22% SNF, 3.02% protein, and 0.68% ash) was obtained from a dairy farm, El-kharga City, New Valley Governorate, Egypt. Fresh cream (30% fat), sugar (sucrose), gelatin and vanilla powder were purchased from native market (El-kharga City, New Valley Governorate, Egypt). Skim milk powder (97% TS) was a product of Dairy AmericaTM. All chemicals and reagents obtained from Sigma-Aldrich Co. (St. Louis, Mo., U.S.A.).

2.2 Methods

2.2.1 Preparation of pomegranate peel powder

Mature pomegranate fruits were washed many times by distilled water and cut by hand to separate the peel and seeds. The peels separated cut into small pieces then dried at room temperature and ground to a fine powder

2.2.2 Preparation of Doum fruit syrup (Dibis)

According to Ferweez, and Ismail (2018), Doum fruit was Soaked in distilled water and the pulp was separated from kernel by using knife, then warm water (70 °C) was added to Doum pulp with a ratio of 3:1 for one hour with stirring at intervals to extract the pulp. The produced juice was filtered in cheese clothes (double layer) and concentrated using water bath (70 °C) and stir it occasionally to avoid burning at the bottom until total soluble solids (TSS%) reach 70% as called doum fruits syrup (DFS) and then kept in refrigerator at 4 ± 1 until it uses.

2.2.3 Ice cream preparation

Ice cream samples were prepared according to the formula illustrated in Table 1.as follow gelatin was added and mixed with skim milk powder and sugar, the later mixture was added intervals slowly to the mixture of cream and milk under vigorous agitation at 45 °C. Then the mixture was pasteurized for 10 min in water bath (80 °C), and was cooled in ice bath (4 °C). At this stage, the required amounts of vanilla followed by different levels of PPP and DFS (which already pasteurized) were blended. The ice cream samples enriched with PPP and DFS were aged at 4 °C for 24 h. Afterwards the samples were whipping-freezing in ice cream marker (Feller ice cream marker, Model IC 100, Feller, China). Ice cream samples were packaged in cups (150 ml) and immediately, frozen at −18 °C in a freezing cabinet for at least 24 h before assessment. Nine treatments of ice creams were prepared with the following combinations: C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS. C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Ingredients (Amount/100 g)

Treatments

C

T1

T2

T3

T4

T5

T6

T7

T8

Cow milk

65.50

65.29

65.00

62.68

62.39

62.11

59.82

59.53

59.22

Sucrose

14.00

14.00

14.00

14.00

14.00

14.00

14.00

14.00

14.00

Cream

18.00

17.96

18.00

18.31

18.36

18.39

18.68

18.72

18.78

Skim milk powder

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

2.00

Gelatin

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

Doum syrup (Dibs)

–

–

–

2.50

2.50

2.50

5.00

5.00

5.00

pomegranate peel powder

–

0.25

0. 50

–

0.25

0. 50

–

0.25

0. 50

2.2.4 Chemical composition

Total solids, moisture, protein, fat, ash, total soluble solid (TSS) and fiber content were determined according to the recommended methods of AOAC (2005). Total carbohydrates content was calculated by difference {total solid – (protein + fat + crude fiber + ash)}. TSS content was measured using a refractometer (Abbe Hergestellt in der DDR, Germany) at 20 °C with values expressed as Brix. The antioxidant activity was determined by method described by Lee et al. (2003)

2.2.5 Minerals content

Minor (iron, manganese and copper) as well as major elements (calcium and magnesium) of pomegranate peel powder, doum fruit syrup and ice cream were determined (AOAC, 2007), using Atomic Absorption Spectrophotomet, while sodium and potassium contents were measured by Flame Photometer (CORNING 400, serial No. 4889. UK).

2.2.6 Physical properties of ice cream samples

Ice cream samples after aging and after freeze -whipping were analyzed. The acidity and pH values were determined according to the recommended methods of AOAC (2005). Specific gravity at 20 °C was determined according to the recommended methods of Arbuckle (1986). Freezing point was measured by thermometer that is special for low temperature. Gross energy of ice milk was calculated using the following equation (Dougherty et al., 1988).

. Overrun of ice cream (%) was determined as methods reported by Arbuckle (1986) by the following equation:

2.2.7 Rheological properties of ice milk

Full time of the first drop was determined by method described with Arbuckle (1986), and melting rate was determined by Güven and Karaca (2002). The melting resistance was evaluated according to the method of El-Nagar et al. (2002). The viscosity of the ice cream was evaluated at 20 °C using Brookfield viscometer (Model RVDVII, Brookfield Engineering Laboratories, INC., MA, USA) according to Hegedusic et al. (1995).

2.2.8 Microbiological analyses

Total plate counts, psychrophilic, coliforms, moulds and yeasts determination were carried out according to APHA (1992).

2.2.9 Organoleptic properties

Samples of ice cream after 24 h. hardening at −18 °C were organoleptically examined by 10 semi-trained panelists of the Dairy Science Department, Faculty of Agriculture, New Valley University in Egypt. The organoleptic properties were evaluated at room temperature for 10 min prior to sensory testing. The samples were scored for flavor (45), body and texture (30), melting quality (15 points) and colour (10 points) as described by Arbuckle (1986).Total score of flavour, body and texture, melting quality and colour were defined as total acceptability.

2.2.10 Statistical analysis:

All samples were analyzed in triplicate and the data were measured by One-way analysis of variance (ANOVA) using SPSS (version 16 SPSS Inc., Chicago, IL, USA) with probability (P ≤ 0.05) level of significance. All data were presented as an average of triplicate ± SD.

3 Results and discussion

3.1 Chemical composition of (PPP) and (DFS)

Chemical composition of PPP and DFS are given in Table 2. Results revealed that PPP contain high level of carbohydrate being 67.00%, crude fiber 9.13%, protein 5.57% and fat 4.66%. On the other side, the same sample had low concentration of ash and TSS being 3.32% and 0.9%, respectively. This composition may be agreed or differed from that presented in previous studies (Ullah et al., 2012; Kushwaha et al., 2013; Rowayshed et al., 2013). These differences studies explained that region and season of growth responsible for variations in PPP chemical composition. On the other hand, DFS has high-quality TSS 70%, carbohydrates 53.27%, crude fat 12.42%, and crude protein 3.86% but low of ash content 1.54% and crude fiber 0.27%. The high content of TSS is due to the high level of sugars and relatively low moisture content. These results conformed to those given by El-Deeb et al. (2017). Results showed that PPP displayed good antioxidant activities being (93.28 DPPH %) which were agreement with those reported by Yasoubi et al. (2007). Also DFS demonstrated high level of antioxidant activities being (45.69 DPPH %), and it is very close to that found by Aamer (2015) who focused on exploiting DFS in food industry as natural antioxidants. On the other hand, PPP had low pH and high acidity values, conversely, DFS had high pH and low acidity values as described by Ullah et al., (2012) and El-Deeb et al., (2017). Table 3 shows the average mineral contents of PPP and DFS. The major mineral constituents for PPP (mg/100 g) i.e. K, Ca, Na, P, Mg, Fe, Cu and Mn were 1269.66, 265.73, 109.03, 47.68, 23.04, 2.07, 0.370 and 0.285, respectively. While, for DFS they were 664.59, 231.11, 106.10, 23.12, 21.66, 3.63, 0.86 and 0.261, respectively. Data shows that K mineral had the higher level of PPP and DFS as described by Abd El-Rashid and Hassan (2005). Feng and MacGregor (2008) reported that K plays important role the some physiological functions of the human body. It was also reported that increasing the K consumption in the daily diet may benefit and protect people from sensitive to high quantities of Na against hypertension (Erkaya et al., 2012). Also, Na/K ratio in the present study for PPP and DFS were less than one (0.086 and 0.160 mg/100 g, respectively). The Na/K ratio suggested being less than one; imbalance in this ratio can not only lead to hypertension but also contribute to a number of other diseases, including: heart disease and stroke, Kidney stones, Memory decline, Cataracts, Ulcers and stomach cancer as well as rheumatoid arthritis (Aremu et al., 2006). In general, it could be concluded that pomegranate fruits peel was characterized with their richness with the most determined nutritious minerals and considered a good source of major and minor elements. Therefore, they should be utilized in food fortification. These results are in agreement with Rowayshed et al. (2013) and Aamer (2015). Means of three determinations ± S.D.

Component (%)

Pomegranate peel powder (PPP)

Doum fruit syrup (DFS)

Moisture

10.32 ± 0.41

28.17 ± 0.23

Total solids

89.68 ± 0.52

71.83 ± 0.45

Protein

5.57 ± 0.18

3.86 ± 0.16

Fat

4.66 ± 0.34

12.42 ± 0.86

Ash

3.32 ± 0.22

1.54 ± 0.17

Fiber

9.13 ± 0.4

0.27 ± 0.04

Carbohydrates

67.00 ± 0.43

53.27 ± 0.31

Total soluble solid (TSS)

0.9 ± 0.06

70 ± 0.63

DPPH

93.28 ± 3.01

45.69 ± 1.45

pH values

3.74 ± 0.11

5.10 ± 0.16

Acidity values

4.75 ± 0.15

0.48 ± 0.01

Mineral (mg/100 g)

Pomegranate peel powder (PPP)

Doum fruit syrup (DFS)

Potassium (K)

Major

1269.66

664.59

Calcium (Ca)

265.73

231.11

Sodium (Na)

109.03

106.10

Phosphorus (P)

47.68

23.12

Magnesium (Mg)

23.04

21.66

Na/K ratio

Minor

0.086

0.160

Iron (Fe)

2.07

3.63

Copper (Cu)

0.370

0.86

Manganese (Mn)

0.285

0.261

3.2 Effect of adding DFS and PPP on ice cream chemical composition

The effect of PPP and DFS on chemical composition of the ice cream samples is illustrated in Table 4. It is obvious from the data that, there are lower differences between all ice cream with PPP and DFS alone or in a combination in moisture content compared to control ice cream without enriched. Also, there were slightly higher in the total solid content (TS) of the formulas. The increase in PPP and DFS alone or in a combination had real and positive effects on TS values of all ice cream samples. A similar trend was detected for fat, and protein content of the samples, in which they are increased by increasing the addition of PPP and DFS alone or in a combination. Ash content recorded clear differences between the control and others. The control sample recorded lower than samples enriched with PPP and DFS alone or in a combination and significantly increased with increasing the addition ratios due to the high content of fat, protein, and ash in both PPP and DFS. The highest fat and ash values were observed in the ice cream sample with treatment (T8). The same results were found by Temiz and Yesilsu (2010).Additionally, fibers and carbohydrates are inversely related, so increasing one of them is decreasing in the other. The results indicated that enriched ice cream with PPP and DFS had higher fibers and lower carbohydrates content than control ice cream, in especially enriched ice cream with PPP had higher fiber content compare to enrich with DFS. Nevertheless, ice cream enriched using a combination of PPP and DFS caused an increase in the fiber and develop in carbohydrate values of the final products (P < 0.05). In the same Table 4 it could be noticed that TSS values of ice cream enriched with DFS were higher than control. While those obtained with addition PPP was the lowest TSS. These results may be due to PPP rich in fiber that leads to a few soluble solids values, while DFS has high level of sugars. These data are in being through with those obtained by Vani and Zayas (1995). The results also indicated that incorporation of both DFS and PPP in ice cream formulas leads to raising TSS values than control sample. This increment was proportional with increasing ratios of DFS. Our results were agreement with (Aamer, 2016). The control of TSS is important for ice cream quality via balance ice creams ingredients, hence, influencing lactose crystallization (Tamime, 2007). The antioxidant contents are evaluated as free radical-scavenging ability of various samples (Amarowicz et al., 2004). In the same table, antioxidant activity (DPPH) of ice cream fortified with PPP and DFS alone or in a combination increased comparing with control. The overall trend was an increase in antioxidant activity as the ratios of PPP and DFS increased in the mix. It could be noticed that PPP and DFS are rich source of total phenolic and free radical scavenging activity. These results conformed to those obtained by Çam et al. (2013) and El-Deeb et al. (2017). Mean values ± standard deviation. C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Ingredients (%)

Treatments

C

T1

T2

T3

T4

T5

T6

T7

T8

Moisture

68.7 ± 0.44

67.80 ± 0.36

67.83 ± 0.09

66.49 ± 0.2

67.39 ± 0.52

66.92 ± 0.43

65.67 ± 0.55

65.80 ± 0.52

64.82 ± 1.14

Total solid (TS)

31.3 ± 0.31

32.2 ± 0.12

32.17 ± 0.43

33.51 ± 0.21

32.61 ± 0.37

33.08 ± 0.25

34.33 ± 0.07

34.2 ± 0.09

35.18 ± 0.01

Fat

8.06 ± 0.32

8.74 ± 0.86

8.75 ± 0.78

8.84 ± 0.41

8.91 ± 1.01

8.92 ± 0.48

9.14 ± 0.63

9.41 ± 0.84

9.76 ± 0.35

Protein

3.39 ± 0.14

3.55 ± 0.14

3.88 ± 0.14

4.29 ± 0.14

4.21 ± 0.25

4.29 ± 0.14

5.43 ± 0.25

5.35 ± 0.37

5.02 ± 0.51

Ash

0.92 ± 0.35

0.95 ± 0.15

1.80 ± 0.32

2.65 ± 1.12

2.68 ± 1.10

2.73 ± 1.41

2.65 ± 1.12

2.65 ± 1.12

2.75 ± 1.05

Fiber

0.54 ± 0.41

1.13 ± 0.78

1.32 ± 0.60

0.68 ± 0.41

0.95 ± 0.73

1.27 ± 0.63

0.56 ± 0.45

0.74 ± 0.54

0.91 ± 0.31

Carbohydrate

18.39 ± 0.15

17.83 ± 0.21

16.42 ± 0.23

17.05 ± 0.23

15.86 ± 0.32

15.87 ± 0.30

16.55 ± 0.20

16.05 ± 0.27

16.74 ± 0.31

TSS

23.50 ± 0.71

20.75 ± 0.35

20.25 ± 0.35

25.75 ± 1.06

26.00 ± 0.71

25.25 ± 0.35

26.00 ± 0.00

27.50 ± 0.71

26.00 ± 0.00

Antioxidants

18.90 ± 0.27

24.70 ± 0.25

32.05 ± 0.07

28.30 ± 0.23

29.70 ± 0.17

30.30 ± 0.01

28.70 ± 0.19

33.40 ± 0.9

36.70 ± 0.21

3.3 Mineral contents of ice cream samples

Table 5 illustrates the major and minor elements (mg/100 g) detected in the samples. In general, the K, Ca, Na, P, Mg, Fe, and Mn contents increased, whereas Cu content decreased in all enriched samples with PPP as compared control ice cream. These results agreement with those investigated by Aboshora et al. (2014). The decrease in the concentration of Cu in the enriched ice cream samples was due to the low Cu content of the PPP, DFS and milk. On the other hand, the increase in the previous traits might be attribute to that PPP and DFS were a good source of essential minerals such as K, Ca, Na, P, Mg, Fe, and Mn contents. The obtained data confirmed with that mentioned by Aboshora et al. (2014) and Kushwaha et al. (2013). The values of Ca/P ratio of ice cream enriched with PPP and DFS alone or a combination similar control ice cream. Establishment of dietary phosphorus intake recommendations on an optimal calcium-to phosphorus ratio, usually 1.5–2.0:1 (Abrams and Atkinson, 2003). These high ratios hinder the development of hypocalcaemia and secondary hyperparathyroidism in the newborn, while low Ca: P ratio reason toxicity disease and it may also lead to bone loss (Fomon, 1993) and (Murray et al., 2000). C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Mineral content (mg/100 g)

Treatments

C

T1

T2

T4

T3

T5

T6

T7

T8

K

Major

190.29

205.49

215.57

264.31

230.02

225.43

228.36

234.36

250.64

Ca

213.28

228.33

274.47

281.92

277.33

257.22

263.12

215.74

271.74

Na

53.13

53.19

53.30

60.72

53.93

63.57

65.69

93.03

100.30

P

67.93

78.19

70.40

72.86

73.03

74.75

80.89

83.86

85.67

Mg

24.19

26.33

27.96

34.43

33.58

28.71

37.17

42.68

48.88

Ca/P ratio

Miner

3.14

2.92

3.90

3.87

3.80

3.44

3.25

2.57

3.17

Fe

4.73

4.93

5.27

5.24

5.28

5.35

5.29

5.45

5.92

Cu

0.273

0.271

0.184

0.173

0.174

0.183

0.215

0.156

0.143

Mn

0.090

0.090

0.092

0.095

0.094

0.097

0.095

0. 132

0. 134

3.4 Effect of adding DFS and PPP on ice cream physical properties

Some physical properties of ice cream mixes enriched with DFS and PPP at different levels are presented Table 6. It can be noticed that pH and acidity values of the ice cream are statistically significant (P ≤ 0.05) as a result of incorporation of PPP and DFS into the formulations. The pH value of ice cream samples increased and acidity decreased in parallel of control as compared with treatments samples. As well as that change of pH values decreased and acidity increased with increasing DFS and PPP levels. However, ice cream enriched with only PPP had lower pH value than that in samples enriched with DFS only. On the contrary, an acidity value of the ice cream with PPP was higher than control and with DFS. This might have been due to the high acidity of PPP than DSF. Additional incorporation PPP and DFS dripped pH values in ice cream treatments. Similar results reported by Abd El-Rashid and Hassan (2005) when they utilize Doum palm fruits in ice cream making. Rowayshed et al. (2013) whom studied the effect of pomegranate fruit peel and seeds powders addition on nutritional and chemical composition of ice cream and Çam et al. (2013) whom studied the functional properties of ice cream enriched with pomegranate seed oil and peel. The high acidity contributes to the excess viscosity, decreased inferior flavor, whipping ability and less stable mix causing coalescence of the micelles and denaturation of proteins during destabilization of casein micelles (Bajad et al., 2016; Gastaldi et al., 1996). Mean values ± standard deviation having different superscript letter(s) in each row differs significantly (P ≤ 0.05), C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Parameter

Treatment

C

T1

T2

T3

T4

T5

T6

T7

T8

Ice cream mix

pH value

6.77 ± 0.06a

6.53 ± 0.02c

6.43 ± 0.02d

6.69 ± 0.01b

6.49 ± 0.02 cd

6.46 ± 0.03 cd

6.59 ± 0.02 cd

6.46 ± 0.03 cd

6.45 ± 0.04d

Titratable acidity

0.21 ± 0.02e

0.27 ± 0.01 cd

0.29 ± 0.01abc

0.24 ± 0.01de

0.29 ± 0.03ab

0.31 ± 0.01ab

0.25 ± 0.00bcd

0.30 ± 0.01ab

0.32 ± 0.02a

Specific gravity (g cm-3)

1.022 ± 0.01a

1.044 ± 0.02a

1.045 ± 0.03a

1.027 ± 0.01a

1.028 ± 0.06a

1.031 ± 0.05a

1.033 ± 0.01a

1.037 ± 0.03a

1.068 ± 0.04a

Weight per gallon (kg)

4.647 ± 0.03a

4.743 ± 0.07a

4.750 ± 0.12a

4.667 ± 0.05a

4.673 ± 0.25a

4.686 ± 0.23a

4.697 ± 0.02a

4.711 ± 0.12a

4.854 ± 0.19a

Freezing ponied

2−.46 ± 0.01abc

−2.43 ± 0.01ab

−2.42 ± 0.01ab

−2.49 ± 0.02c

−2.49 ± 0.03 cd

−2.47 ± 0.01 cd

−2.50 ± 0.01 cd

−2.53 ± 0.01d

−2.50 ± 0.02 cd

Ice cream

pH value

6.730 ± 0.17a

6.47 ± 0.05bc

6.37 ± 0.07bcd

6. 50 ± 0.01b

6.34 ± 0.14bcd

6.21 ± 0.04d

6.38 ± 0.11bcd

6.25 ± 0.01cd

6.235 ± 0.05d

Titratable acidity

0.245 ± 0.01e

0.28 ± 0.01d

0.305 ± 0.02bc

0.265 ± 0.01de

0.330 ± 0.01b

0.360 ± 0.01a

0.280 ± 0.01 cd

0.370 ± 0.01a

0.385 ± 0.01a

Specific gravity (g cm-3)

0.737 ± 0.01d

0.781 ± 0.01 cd

0.803 ± 0.02 cd

0.799 ± 0.02 cd

0.783 ± 0.03 cd

0.808 ± 0.04c

0.836 ± 0.04bc

0.889 ± 0.03ab

0.927 ± 0.03a

Weight per gallon (kg)

3.349 ± 0.05d

3.549 ± 0.06dc

3.651 ± 0.12 cd

3.631 ± 0.10cd

3.558 ± 0.13cd

3.674 ± 0.17c

3.800 ± 0.17bc

4.040 ± 0.13ab

4.213 ± 0.14a

Total energy

159.66 ± 0.47b

164.18 ± 1.34b

159.95 ± 1.47b

164.92 ± 1.29b

160.47 ± 0.62b

160.92 ± 1.39b

170.18 ± 1.48a

170.29 ± 0.21a

174.88 ± 5.58a

Overrun %

38.77 ± 1.09a

33.65 ± 0.14b

30.12 ± 0.65bc

28.54 ± 1.88c

31.30 ± 2.21bc

27.52 ± 0.46cd

23.71 ± 4.97d

16.63 ± 0.73e

15.20 ± 0.82e

The specific gravity value, which is closely related to the weight per gallon, is increased by addition of DFS and PPP (Table 6). The values were increased when the ratio of PPP is more than DFS. The results indicated that, adding of PPP and DFS to ice cream lead to increase the consequently weight per gallon (kg) and specific gravity that in a similar trend with the results of El-Kholy (2015), when he studies the effect of fat replacement by PPP on frozen yoghurt quality. The air also has an enormous effect on the ice cream density for that incorporation of air in ice cream mix during the pre-freezing process decreased the specific gravity of the resultant ice cream, thus specific gravity of ice cream mix higher than that is in ice cream resulting. This may be due to specific gravity of formula components in addition to mix ability to hold the air bubbles and overrun percent in the resultant ice cream these outcome data are in agreement with those mentioned by Abd El-Rashid and Hassan (2005).

The freezing points of ice cream were significantly high by adding DFS to ice cream recipes (p ≤ 0.05). PPP ice cream treatments showed the lowest freezing points among all treatments, while that with incorporating DFS and PPP showed the higher freezing point compared to control sample. The results obtained are in line with these of Abd El-Rashid and Hassan (2005) for ice cream produced with Doum powder addition at different levels. The dwindling freezing point in treatments with PPP could be due to the increase in molecular weight and/or the decrease in serum phase concentration of solutes (Hartel, 2001).

Furthermore, it was noticed from the same table that the overrun values of ice creams being highest in control compared with other treatments. There are significantly differences for overrun values (p ≤ 0.05) between control and those of other ice cream enrichment. The highest mean overrun value was observed in the control, it was followed by (T1) and (T4) samples, but (T7) and (T8) had overrun values climb down. Depending on the results, increasing the ratio of PPP and DFS decreasing the overrun values. This decreased probably due to decreased air bubbles stability, which is been confirmed by Erkaya et al. (2012) results. Decreasing overrun of ice cream enriched with PPP and DFS are in agreement with the findings reported by Abd El-Rashid and Hassan (2005) and El-Kholy (2015). Moreover, the addition of PPP and DFS raises the amounts of organic acids causing the poor foaming capacity of ice cream (Temiz and Yesilsu, 2010). However, higher overrun values of ice creams containing PPP than DFS may be due to PPP rich fibers could be attributed to their rheological properties. An adverse trend among of the specific gravity and overrun of the resultant ice cream with adding PPP and DFS was observed. The decreasing of overrun and increasing of both specific gravity and weight per gallon of ice cream by increment of levels of PPP may be due to increasing of mix’s viscosity lead to extremely effects on whipping rate of mixes (Arbuckle, 1986). Overrun and melting can attendant with the volume of air implicated during the manufacturing process, therefore influence the product quality (Cruz et al., 2009). This phenomenon property may be attribute to the air included in ice cream that can affect on some physical hardness and melting due to their light texture

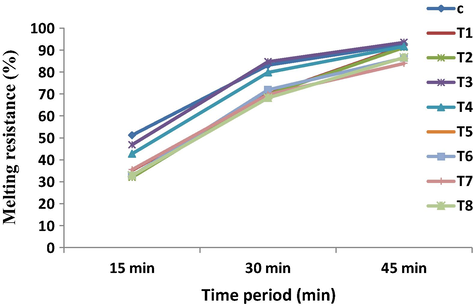

3.5 Rheological properties of ice cream

The effects of PPP and DFS on the rheological properties such as first dripping time, melting rate, melting resistance and viscosity of the ice cream are illustrated in Table 7. The meltdown of ice cream is affected by its composition as well as on the meltdown properties that is effect on sensory possessions of ice cream (Tharp et al., 1998). First dripping time and melting rate of ice milk as affected by addition of PPP and DFS. The first dripping time (min) was significantly variation (p ≤ 0.05) between the control and ice cream enrichment samples. The results show that ice cream samples containing PPP one and mixed with DFS (T1, T2, T4, T5, T7, and T8) took long time to melt, and it was followed by control ice cream but ice cream containing DFS (T3, and T6) had the shortest time. The first dripping time is longed by increasing the percentage of PPP levels and is shorted by increasing the levels of DFS. Previously, it was observed that DFS ice cream exhibits a faster melting speed and smoother texture when compared to ice cream enriched with PPP and control. Concerning the melting rate, the adding PPP in the ice cream causing decrease in the melting rate compared to control and those within DFS. Addition of DFS provided a very significant growing in the melting ratio of samples. This may be due to the consequence weakening of the structural network. These results were agreement with the finding of El-Samahy et al. (2009). Ice creams that had a combination of PPP and DFS would be expected to melt more slowly than control sample and other treatments. The lower melting rate relates to the withstanding of the ice cream’s shape, which usually indicates the good quality of ice cream (Tharp et al., 1998). These results may be due to the pomegranate peel pectin as an emulsifying agent (Yang et al., 2018). Also, PPP, which has a high amount of fiber, absorbed the water and the melting of ice cream was retarded. In another study, it was mentioned that the meltdown amount of ice cream reduced with increasing the citrus fiber concentration (Dervisoglu and Yazici, 2006). From the found results, the physical properties of DFS formed a large texture leading to the water molecules moved freely, hence decreased the melting time values of ice cream samples (Sakurai et al., 1996). Melting resistance was known as the loss in weight % of the initial weight of the examined samples. The melting resistance of ice cream enriched with PPP and DFS is presented in Table 7 and Fig. 1. According to the results, increasing the amount of PPP decreased the melting resistance more than both ice cream enriched with DFS and control. A great association was observed with the overrun and melting properties of ice cream fortified with PPP. Therefore, the higher consistency index and melting resistance of ice creams containing PPP compared with the other samples may have been responsible for their reduced melted resistance. The DFS caused a different structure of ice cream leading to a smoother and softer in texture. It should be noted that these variations are statistically significant (p ≤ 0.05). Meltdown is one of the major properties of ice cream which play important role in sensory quality and its affected by its constituents and the amount of air commingled (Koxholt et al., 2001). Mean values ± standard deviation having different superscript letter(s) in each column differs significantly (P ≤ 0.05), C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Treatments

Parameter

Ice cream mix

Ice cream

Viscosity (CP)

Viscosity (CP)

First drop (min)

Melting rate (min)

Melting resistance (%)

15 min

30 min

45 min

C

20,000

2499

4.68 ± 0.68ab

20.79 ± 1.73ab

51.20 ± 10.40a

83.14 ± 6.90ab

92.70 ± 3.22a

T1

26,000

3200

5.53 ± 1.06ab

17.49 ± 0.50b

35.16 ± 1.92b

69.94 ± 1.98c

91.66 ± 5.86a

T2

37,600

23,200

6.28 ± 0.73a

17.43 ± 0.33b

32.00 ± 4.00b

69.72 ± 1.32c

91.24 ± 1.28ab

T3

2400

800

4.04 ± 0.04ab

21.18 ± 0.55ab

46.84 ± 1.36a

84.72 ± 2.20ab

93.52 ± 2.08a

T4

8800

2400

5.98 ± 3.25a

19.96 ± 0.06b

42.74 ± 2.18ab

79.82 ± 0.26ab

91.68 ± 2.28a

T5

77,600

88,000

6.03 ± 2.61a

17.98 ± 0.94b

32.70 ± 3.58b

71.90 ± 3.74c

86.42 ± 0.50bc

T6

18,400

1600

3.02 ± 0.02b

21.44 ± 0.96a

47.14 ± 3.42a

85.76 ± 3.84a

95.76 ± 1.84a

T7

28,000

25,600

5.63 ± 0.90ab

17.42 ± 0.21b

35.50 ± 4.21b

69.68 ± 0.85c

83.92 ± 0.00c

T8

78,400

28,800

5.74 ± 0.20ab

17.05 ± 0.28b

32.83 ± 8.72b

68.20 ± 1.11c

86.65 ± 1.83bc

Melting resistance (%) of ice cream products enriched with Pomegranate peel powder (PPP) and Doum fruit syrup (DFS). C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Viscosity is an important characteristic of ice cream; it chaperons the desirable texture (Innocente et al., 2002). On the other hand, viscosity has real effect on melting resistance of ice cream and overrun (Muse and Hartel, 2004). Data in the Table 7 show that addition of PPP and DFS affected the ice cream viscosity. There were significant differences in viscosities between samples containing DFS and PPP. The viscosity values of ice cream mixes decreased significantly with added DFS and increased with PPP in the formulation of ice cream samples (P ≤ 0.05). Mounting adding of ratio PPP lead to significantly (p ≤ 0.05) raised the viscosity. As can be seen the highest viscosity was recorded to be 78,400 (CP) for the (T8) sample, whereas the lowest it was determined to be 2400 (CP) for the sample (T3). Decreases in the viscosity of enriched ice cream samples might be due to the high water content of DFS incorporated into the samples. Similar results were reported for ice creams supplemented with persimmon puree (Karaman et al., 2014). The increase in the viscosity values of samples enriched with PPP can be attributed to the higher content of fiber for PPP, which are characterized by its high water hydration capacity. These results were consistent with those reported by Vani and Zayas (1995). The incorporate PPP and DFS in ice cream formula can be a potential alternative to control in this phenomenon, acting as stabilizing agents by increasing the viscosity of the serum phase and hence limiting water diffusion. The presence of air cells occurred in ice creams cases increasing in the viscosity values during processing as it is. Similarly reported by Yükse et al., (2017)

3.6 Microbiological quality

As can be seen in Table 8 microbial load of ice cream treatment as affected by addition of PPP and DFS, the total bacterial and psychrophilic bacteria counts in experimental samples were minus compared to those in control. Enriched with PPP and DFS have an inhibiting effect on the microorganisms and this inhibiting increase effect was disappeared with the increasing levels of addition. The present data are in agreement with those mentioned by Singh et al. (2002), that phenolic compounds cased cell death via: a) disrupt membrane proteins b) degradation of the cytoplasmic membrane c) degradation of the cell wall d) interaction with membrane-integrated enzymes. Ice cream samples enriched with DFS showed higher antibacterial activity than that enriched with PPP. In the same side, a combination between PPP and DFS highest the increasing of microbial inhibition. This may be due to the antibiotic plant extracts compounds (Moniharapon and Hashinaga, 2004). Regulation on the quality of ice cream, Official Standard of Egypt (2005) was specified as follows: total plate count (TPC) shouldn’t be high than 150.000 CFU/gm. The data of this study were in approval with this regulation. All treatments of ice cream samples were free coliform group, moulds and yeasts. These results are nearly in according with those found by Abd El-Rahim (1999), Singh et al. (2014) and Ali et al (2016). This is could be attributing to the seriousness of heat treatments of ice cream mixes. *ND not detected, C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Microbiological quality

Microbial counts of ice-cream treatments (Cfu/g)

Control

T1

T2

T3

T4

T5

T6

T7

T8

Total bacterial count

3.6 × 102

2.2 × 102

1.8 × 102

1.7 × 102

1.6 × 102

1.3 × 102

0.8 × 102

0.7 × 102

0.5 × 102

Psychrophilic bacteria

1.1 × 102

1.0 × 102

0.8 × 102

0.5 × 102

0.5 × 102

0.3 × 102

0.2 × 102

0.1 × 102

0.1 × 102

Total molds & yeasts

ND

ND

ND

ND

ND

ND

ND

ND

ND

Coliform bacteria

ND

ND

ND

ND

ND

ND

ND

ND

ND

3.7 Sensory evaluation of ice cream:

Sensory panel evaluation is one of indicator of potential consumer preferences and most closely linked to the choice of food products. Flavor, body texture, melting, and color properties of ice cream enriched with PPP and DFS were evaluated as sensory characteristics Table 9. The results obtained showed a significant (p ≤ 0.05) differences were observed between control and treatments ice cream. The highest total score recorded for ice cream enriched mixing 0.25%PPP and 2.5% DFS (T4) as compared with all treatments and control and the score significantly decreased by increasing the addition ratio of PPP and DFS. However, incorporation of PPP and DFS into the ice cream had characterized by creamy colour, acceptable flavour and described with soft body and texture and higher scores of sensory parameters. These results are in accordance with data reported by Abd El-Rashid and Hassan (2005). The control ice creams showed a comparable to overall acceptability results with the enriched ice cream (T4). In opposite, the treatments which have 5% of DFS (T6) followed by the combination of 0.5%PPP and 5% DFS (T8) gained the lower scores than other treatments and control ice cream. This probably increase the ratio of DFS product ice cream color, Doum aroma and flavor intensities lead to dispersed milky flavor. Addition of PPP into ice cream samples up to 0. 5% caused astringent taste and loose texture of samples as well as their content from high punicalagins molecular (Çam et al., 2013). The least record of overall acceptability out of ice cream traits (T6) and (T8). However, incorporation of PPP and DFS into the ice cream had real significant effects (P ≤ 0.05) on texture properties ; a smoother and softer texture. These results came in same with those reported by El-Kholy (2015) for frozen yoghurt prepared with 50%, 75% and 100% replacement of fat by Doum palm powder. Mean values ± standard deviation having different superscript letter(s) in each column differs significantly (P ≤ 0.05), C, control not enriched; T1, enriched with 0.25% PPP; T2, enriched with 0.5% PPP; T3, enriched with 2.5% DFS; T4, enriched with 0.25% PPP and 2.5% DFS; T5, enriched with 0.5% PPP and 2.5% DFS; T6, enriched with 5% DFS; T7, enriched with 0.25% PPP and 5% DFS; T8, enriched with 0.5% PPP and 5% DFS.

Treatments

Parameter

Flavor (45)

Body and texture (30)

Melting (15)

Colour (10)

Acceptability (100)

C

42.33 ± 0.58a

25.67 ± 0.58a

12.33 ± 0.58a

9.67 ± 0.58a

90.00 ± 1.00a

T1

39.00 ± 1.00bc

23.67 ± 0.58b

12.33 ± 0.58a

7.67 ± 0.58bc

82.33 ± 1.53c

T2

32.33 ± 2.52e

22.00 ± 1.00c

12.33 ± 0.58a

7.00 ± 1.00cd

74.00 ± 5.00ef

T3

40.33 ± 0.58ab

20.00 ± 1.00d

9.67 ± 0.58b

6.33 ± 0.58de

76.33 ± 1.53de

T4

44.00 ± 1.00a

25.00 ± 1.00b

12.00 ± 0.00a

9.33 ± 0.58b

90.33 ± 0.58b

T5

37.00 ± 1.00cd

21.00 ± 1.00cd

12.33 ± 0.58a

8.00 ± 1.00bc

78.33 ± 2.52d

T6

36.00 ± 1.00d

21.00 ± 1.00cd

8.00 ± 1.00c

6.33 ± 0.58de

71.67 ± 0.58f

T7

33.67 ± 0.58e

22.00 ± 1.00c

10.33 ± 0.58b

6.33 ± 0.58de

72.33 ± 1.53f

T8

27.00 ± 2.00f

21.00 ± 1.00cd

11.67 ± 0.58a

5.67 ± 0.58e

65.00 ± 1.00 g

4 Conclusion

This research was performed to throw the light on the ability of incorporation Doum fruit syrup (dibs) and pomegranate peels as by-products in ice cream processing which having high nutritional value include; fat, protein, fiber, ash, antioxidant activity and minerals content as well as a better acceptability for consumer and good safe hygienic quality. The overall acceptability scores were highest at 0.25 and 2.5% level incorporation of pomegranate peel powder and Doum fruit syrup, respectively. Increasing levels of PPP and DFS negatively influenced the sensory scores of ice cream.

Acknowledgements

The authors are grateful to Benha, New Valley, and Mansoura University, Egypt. Also, Faculty of Applied Sciences, Umm Al-Qura University, 21955 Makkah, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Physicohemical properties of Doum (Hyphaene thebaica) fruits and utilization of its flour in formulating some functional foods. Alex. J. Food. Sci. Technol.. 2015;12(2):29-39.

- [Google Scholar]

- Characteristics of aqueous doum fruit extract and its utilization in some novel products. Ann. Agric. Sci.. 2016;61(1):25-33.

- [Google Scholar]

- Abd El-Rahim, A.M., 1999. Utilization of some ingredients in the manufacture of ice cream. M.Sc. Thesis, Faculty of Agriculture, Assiut University.

- Potential utilization and healthy effects of doum palm fruits in ice cream and sesame butter (tehena) Alex. J. Food. Sci. Technol.. 2005;2(1):29-39.

- [Google Scholar]

- Physicochemical, nutritional and functional properties of the epicarp, flesh and pitted sample of Doum fruit (Hyphaene thebaica) J. Food Nutrit. Res.. 2014;2:180-186.

- [Google Scholar]

- Calcium, magnesium, phosphorus and vitamin d fortification of complementary foods. J. Nut.. 2003;133:2994S-2999S.

- [Google Scholar]

- Functional, antioxidant and sensory qualities of ice-Cream from pomegranate seed powder. Asian J. Chem.. 2016;28(9):2013-2016.

- [Google Scholar]

- Free-radical scavenging capacity and antioxidant activity of selected plant species from the Canadian prairies. Food Chem.. 2004;84(4):551-562.

- [Google Scholar]

- Official Methods of Analysis (18th ed.). Washington DC: Association of Official Analytical Chemists; 2005.

- Official Methods of Analysis (18th ed.). Gaithersburg, MD, USA: Association of Official Analytical chemists; 2007.

- Compendium of Methods for the Microbiological Examination of Foods. Washington: American Public Health Association; 1992.

- Ice Cream (fourth ed.). Westport, Connecticut, USA: AVI Publishing Co. Inc.; 1986.

- A comparative study on the chemical and amino acid composition of some Nigerian under-utilized legume flours. Pakistan J. Nutrit.. 2006;5:34-38.

- [Google Scholar]

- Impact of physico-chemical properties of mix on the final quality of ice-cream. Asian J. Dairy Food Res.. 2016;35(4):293-297.

- [Google Scholar]

- Phenolic compounds in plant and agri-industrial by-products: antioxidant activity, occurrence, and potential uses. Food Chem.. 2006;99:191-203.

- [Google Scholar]

- Enrichment of functional properties of ice cream with pomegranate by-products. J. Food Sci.. 2013;78(10):C1543-C1550.

- [Google Scholar]

- Nutritional and chemical composition of 13 wild plant foods of Niger. J. Food Compos. Anal.. 2000;13:83-92.

- [Google Scholar]

- Outlines of Dairy Technology: Ice Cream (1st ed.). New Delhi: Oxford University Press; 2006. p. :182-183.

- Note. The effect of citrus fibre on the physical, chemical and sensory properties of ice cream. Food Sci. Technol. Int.. 2006;12:159-164.

- [Google Scholar]

- Oat fiber low caloric breads soft type cookies and pasta. Cer. Food World.. 1988;33:424-427.

- [Google Scholar]

- Egyptian Standards for Ice Cream. 2005. Milk and water ice (Ice Cream) Part: 1 Milk Ice, ES: 1185-1/2005. Ministry of Industry and Technological Development, Egypt.

- Production of flavoured fermented camel milk. Ismailia J. Dairy Sci. Technol.. 2017;5(1):9-20.

- [Google Scholar]

- Effect of fat replacement by Doum palm fruits on frozen yoghurt quality. World J. Dairy Food Sci.. 2015;10(1):74-81.

- [Google Scholar]

- El-Nagar, G., Glowes, G., Tudorică, C.M., Kuri, V., Brennan, C.S., 2002. Rheological quality and stability of ice cream with added inulin. Int. J. Dairy Technol. 55, 89–93.

- El–Samahy, S.K., Youssef, K.M., Moussa–Ayoub, T.E., 2009. Producing ice cream with concentrated cactus pear pulp: A preliminary study. J. Prof. Assoc. Cactus Develop. 11, 1–12.

- Influence of cape gooseberry (Physalis perimiana) addition on the chemical and sensory characteristics and mineral concentration of ice cream. J. Food Res. Int.. 2012;45:331-335.

- [Google Scholar]

- Beneficial effects of potassium on human health. Physiol. Plant.. 2008;133(4):725-735.

- [Google Scholar]

- Efficacy of fortification and replacement by different levels of milk and dibs on physiochemical and sensory evaluation of date compote. Nutrit. Food Toxicol.. 2018;3(2):617-632.

- [Google Scholar]

- Fomon, S.J., 1993. Nutrition of normal infants. Mosby, St. Louis.

- Micellar transition state in casein between pH 5.5 and 5.0. J. Food Sci.. 1996;61:59-65.

- [Google Scholar]

- The effects of varying sugar content and fruit concentration on the physical properties of vanilla and fruit ice cream type frozen yogurts. Int. J. Dairy Technol.. 2002;55:27-31.

- [Google Scholar]

- Crystallization in Foods. Gaithersburg: Aspen Publishers; 2001.

- Influence of phase transition (freezing and thawing) on thermophysical and rheological properties of apple puree – like products. Acta – Alimentaria. 1995;22:337-349.

- [Google Scholar]

- Antioxidant activity of hot water extract from the fruit of the Doum palm (Hyphaene thebaica) Food Chem.. 2006;98:317-328.

- [Google Scholar]

- Proteose peptone whey fraction as emulsifier in ice-cream preparation. Int. Dairy J.. 2002;12(1):69-74.

- [Google Scholar]

- Anthocyanins and polyphenoloxidase from dried arils of pomegranate (Punica granatum L) Food Chem.. 2010;118:11-16.

- [Google Scholar]

- Karaman, S., Toker, Ö, S., Yüksel, F., Çam, M. Kayacier, A., Dogan, M., 2014. Physicochemical, bioactive, and sensory properties of persimmon-based ice cream: Technique for order preference by similarity to ideal solution to determine optimum concentration. J. Dairy Sci. 97, 97–110.

- Effect of the fat globule sizes on the meltdown of ice cream. J. Dairy Sci.. 2001;84:31-37.

- [Google Scholar]

- Nutritional composition of detanninated and fresh pomegranate peel powder. IOSR J. Environ. Sci., Toxicol. Food Technol.. 2013;7(1):38-42.

- [Google Scholar]

- Screening of medicinal plant extracts for antioxidant activity. Life Sci.. 2003;73:167-179.

- [Google Scholar]

- Evaluation of antioxidant properties of pomegranate peel extract in comparison with pomegranate pulp extract. Food Chem.. 2006;96:254-260.

- [Google Scholar]

- Pomegranate (Punica granatum L.): a medicinal plant with myriad biological properties—a short review. J. Med. Plant Res.. 2010;4(25):2836-2847.

- [Google Scholar]

- Antimicrobial activity of Atung parinarium glaberrimum Hassk fruit extract. Pakistan J. Biolog. Sci.. 2004;7:1057-1061.

- [Google Scholar]

- Harper’s Biochemistry (25th ed.). USA: McGraw-Hill Health Profession Division; 2000.

- Ice cream structural elements that affect melting rate and hardness. J. Dairy Sci.. 2004;87:1-10.

- [Google Scholar]

- Antioxidant and antimutagenic activities of pomegranate peel extracts. Food Chem.. 2003;80:393-397.

- [Google Scholar]

- Nutritional and chemical evaluation for pomegranate (Punica granatum L.) fruit peel and seeds powders by products. Middle East. J. Appl. Sci.. 2013;3(4):169-179.

- [Google Scholar]

- Effect of production conditions on ice cream melting resistance and hardness. Milchwissenschaft. 1996;51:451-454.

- [Google Scholar]

- Studies on the antioxidant activity of pomegranate (Punicagranatum) peel and seed extracts using in vitro models. J. Agric. Food. Chem.. 2002;50(1):81-86.

- [Google Scholar]

- Effect of storage period on the physicochemical, sensory and microbiological quality of bakery flavoured ice cream. Int. J. Eng. Res. Appl.. 2014;4(8):80-90.

- [Google Scholar]

- Structure of dairy products. Oxford: Society of Dairy Technology Book Series; 2007.

- Effect of pekmez addition on the physical, chemical and sensory properties of ice cream. Czech J. Food Sci.. 2010;28:538-546.

- [Google Scholar]

- Tharp, B.W., Forrest, B., Swan, C., Dunning, L., Hilmoe, M., 1998. Basic factors affecting ice cream meltdown. In: Buchheim, W. (Ed.). Ice Cream, International Dairy Federation, Brussels, pp. 54–64.

- Ullah, N., Ali, J., Khan, F.A., Khurram, M., Hussain, A., Inayat-ur-Rahman, Zia-ur-Rahman, Shafqatullah, 2012. Proximate composition, minerals content, antibacterial and antifungal activity evaluation of Pomegranate (Punica granatum L.) peels powder. Middle-East J. Sci. Res. 11(3), 396–401.

- Wheat germ protein flour solubility and water retention. J. Food Sci.. 1995;60:845-849.

- [Google Scholar]

- Pomegranate peel pectin can be used as an effective emulsifier. Food Hydrocolloids. 2018;85:30-38.

- [Google Scholar]

- Total Phenolic contents and antioxidant activity of Pomegranate (Punica granatum L.) peel extracts. J. Agric. Sci. Technol.. 2007;9:35-42.

- [Google Scholar]

- Antimicrobial activity of pomegranate rind peel extracts. Afr. J. Microbiol. Res.. 2011;4(22):3664-3668.

- [Google Scholar]

- Determination of certain physicochemical characteristics and sensory properties of green tea powder (matcha) added ice creams and detection of their organic acid and mineral contents. GIDA. 2017;42(2):116-126.

- [Google Scholar]