Translate this page into:

State-of-the-art review on various mathematical approaches towards solving population balanced equations in pharmaceutical crystallization process

⁎Corresponding author. aalahiq@nu.edu.sa (Ahmed A. Lahiq)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Crystallization is an important process, which possesses an undeniable role in many chemical industries. In recent years, significant endeavors have been made to increase the efficiency of this process via designing novel crystallizers. Development of numerical models and their efficient solutions is known as an important approach to justify the behavior of contributed mechanism in crystallization process. The emergence of various complexities towards the modeling of crystallization process is due to the existence of disparate mechanisms such as crystal birth, growth, and death processes. The prominent purpose of this study is to review various employed models to justify crystal birth, death, and growth in the crystallization process. Additionally, various numerical approaches like method of moments (MOM), discretized sizing technique (DST) and method of weighted residuals (MOWR) are presented in this review paper and their advantages and disadvantages to solve PBE are discussed in detail. At the end, future perspectives towards increasing the efficiency of various employed approaches foe solving population balance equation (PBE) in the crystallization process are presented, which can be of great interest for expert readers as well as non-expert investigators to be more acquainted with the undeniable role of mathematical modeling approaches in the crystallization process.

Keywords

Crystallization process

Mathematical modelling

Agglomeration

Crystal growth

1 Introduction

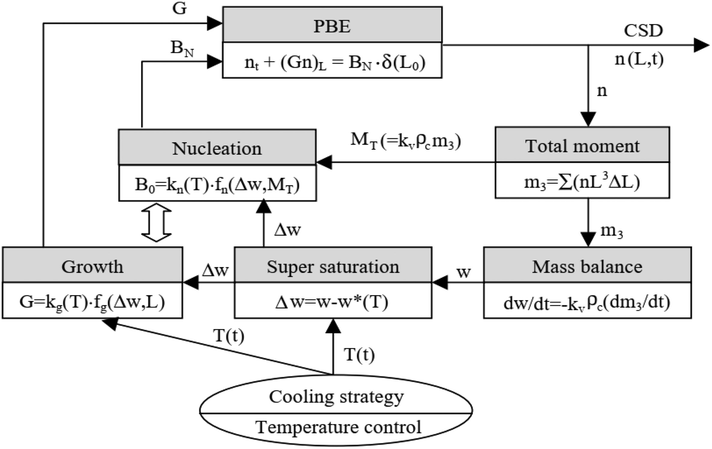

One of the most important chemical operations for separating solid materials is crystallization. This process includes two prominent steps including nucleation and subsequent crystal growth (Omar and Rohani, 2017; Auer and Kashchiev, 2022; Tavare, 2013; Cao, 2021). Primary nucleation often takes place from the super-saturated solution in the non-existence of pre-existing crystals, while secondary nucleation happens through the generation of new crystals in the presence of parent crystals. In comparison with primary nucleation, secondary nucleation needs a lower amount of energy owing to the fact that this process requires less super-saturation. Secondary nucleation possesses great potential of application in various industrial crystallizers (Kodera et al., 2019; Zhang, 2021; Agarwal and Gupta, 2022; Marjani, 2020). Employed operations in crystallization process are able to be implemented to control momentous parameters such as crystal size distribution (CSD), morphology and so on. (Sun, 2018; Roelands, 2006; Myerson et al., 2002). The CSD is of great importance in pharmaceutical industry due to its undeniable effect on some operational factors including process flow characteristics, bioaccessibility and tablet pressing properties (Wen et al., 2015; Abu Bakar, 2009; Zhang et al., 2013; Cao et al., 2021). A crystalline product may include various crystalline particles with disparate sizes. CSD is an important product property of a solid, which not only influences the suspension manner in the crystallizer, but also specifies the efficacy of the liquid–solid separation and subsequently drying step. Numerical solution of the CSD has been accelerated by the development of population balance equation (PBE) in the 1960 s (Randolph, 1962). Fig. 1 schematically demonstrates the CSD determination in the batch crystallization process.

Schematic illustration of CSD determination in the batch crystallization process. Reprinted from (Lim, 2002) with permission from Elsevier.

Temperature is considered as a momentous parameter in the crystallization process of biological macromolecules due to its undeniable impact on the nucleation and crystal growth (Christopher et al., 1998; Liu, 2019; Nguyen, 2022). Moreover, temperature has recently illustrated its important role in membrane protein crystallization. Therefore, suitable control of this important parameter during the optimization/manufacturing process of crystals would be of great importance for successful crystal growth of proteins. (McPherson, 2017; Caffrey, 2003; Babanezhad, 2021). It has been reported that increment or decrement of temperature significantly influences quantity, size, and crystals quality. An important advantage of temperature is the creation of rapid, accurate and reversible control of supersaturation. Apart from the application of standard crystallization variables, the use of temperature may significantly improve the possibility of crystals production for a sample (Kwon, 2014).

Recently, the emergence of mathematical modeling/computational-based approaches following with advancement in the particle size measurement techniques have significantly improved the interest of many researchers all over the world to employ PBEs for crystallization processes and other industries (Borchert, 2009; Farias, 2019; Bhoi and Sarkar, 2020; Marjani, 2021). PBEs is a well-known mathematical approach to deal with particulate systems. This technique includes formation, growth, breakage and aggregation of particles and possesses great ability of application in disparate industries such as polymerization, crystallization, aerosol reactors, biological processes, membrane-based separation, chemical reaction and fermentation (Costa et al., 2007; Pinar, 2021; Zhang et al., 2022; Pishnamazi, 2020; Babanezhad, 2020; Elveny, 2021; Babanezhad, 2020). The majority of crystalline entities existed in different industries (i.e., pharmaceutical) illustrate anisotropic morphologies (Ma et al., 2002). The PBEs interpreting these types of crystallization processes can be considered multi-dimensional. Mathematical-based solution of multi-dimensional PBEs is one of the greatest challenges in crystallization process, which results in the appearance of noteworthy difficulties towards appropriate control of this process. Owing to the accessibility of new computing tools, scientific investigations on PBEs have been revolutionized recently for various applications (Ma and Wang, 2008).

In this review paper, various approaches like MOM which is so-called method of moments, discretized sizing technique (DST), and Method of weighted residuals (MOWR) towards solving PBE in the crystallization process accompanying with their advantages and disadvantages are aimed to be discussed. Up to the knowledge of the authors, very few papers have comprehensively investigated all current advancements for solving PBEs in the crystallization process. Therefore, this paper may open new horizon for better perception of the indisputable role of mathematical-based modeling approaches to justify disparate contributed mechanisms in crystallization process and increase its efficiency and performance.

2 Population balance model (PBM)

Estimation of product quality in crystallization process needs comprehensive information about CSD. With the aim of achieving this knowledge, PBE must be solved to explain the progression of size distribution in the process. The main perception of PBE has been initially presented in 1962 (Randolph, 1962). Equation 1 presents the generalized PBE applied for computing the number distribution of the crystals as follows (Lewis, 2015):

breakage and nucleation. The terms and in equation 1 are respectively denoted as the arbitrary number of inlet and outlet streams.

Owing to the first-order nature of PBE regarding to time and length of crystal, a boundary condition following with an initial condition are needed to mathematically solve the PBE. Equations 2 and 3 present the boundary and initial conditions, respectively.

With the aim of solving PBE, the zero-size nucleation ratio can be applied as the boundary condition. By description of nucleation process via new crystals formation (B(L, t)) in a determined crystals size range (0

L

y), the birth term in equation 2 can be obtained using Equation 4 as follows:

2.1 The PBE for agglomeration and breakage

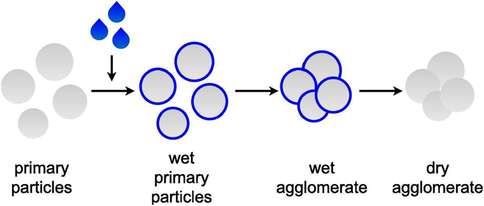

Agglomeration is an important mechanism in crystallization process. Although this mechanism significantly affects the particles number, it doesn’t change the overall volume of the particles. Fig. 2 schematically illustrates major steps of agglomeration.

Schematic demonstration of major steps of agglomeration including wetting, collision and drying. Reprinted from (Otto, 2021) with permission from Elsevier.

Therefore, formulation of PBE in the attendance of agglomeration regarding to volume coordinates isn’t challengeable. The agglomeration rate (ragg) relies on some momentous factors like the number of existed particles (n), the particles size participated in the process (v), the relative super-saturation (σ) and the power input P0 and can be derived by the following equation:

In this equation, βagg is a constant rate for agglomeration known as agglomeration kernel. By knowing the concept of the agglomeration mechanism in crystallization process, the following equations can be derived to define birth and death terms:

The number

in the birth equation is identified as a correction factor because of the integration of

from 0 to v. Substitution of the abovementioned equations for the birth and death rates with a determined size into the general form of PBE results in the derivation of the following equation for a system without any significant growth or breakage:

Substitution of equations 9 and 10 in the generalized form of PBE causes the derivation of Equation 11 for breakage:

Disparate forms of the agglomeration and breakage kernel models can be presented in Table 1.

Agglomeration

Expression

Ref.

(Qamar et al., 2009)

(Scott, 1968)

=

(Lister et al., 1995)

=

(Friedlander and Smoke, 1977)

(Tavare and Patwardhan, 1992)

Breakage

(Marchisio et al., 2003)

(Falola et al., 2013)

3 Crystallization models

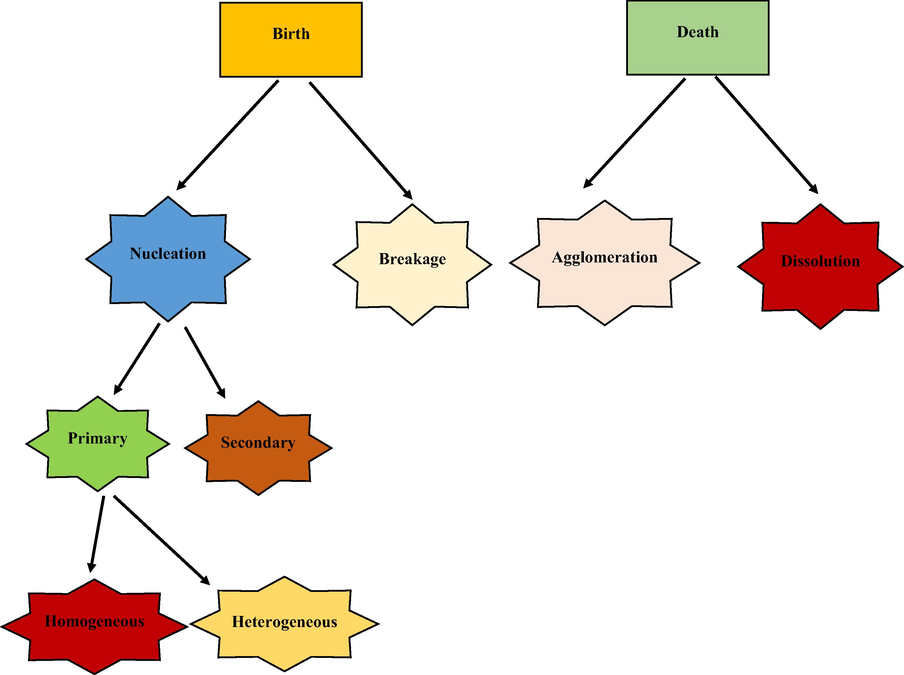

Crystallization models express disparate procedures of crystals generation, destruction and growth. Numerous formations of these equations are existed, which are usually derived applying a semiempirical technique. Fig. 3 schematically renders a flowchart illustrating all of the mechanisms related to crystals birth and death.

Schematic illustration of the mechanisms related to crystals birth and death. ().

Adopted from Omar and Rohani, 2017; El-Yafi and El-Zein, 2015

3.1 Crystal birth

3.1.1 Primary nucleation (PN)

PN takes place from the solution of its own kind at high super-saturation (Viedma, 2004). The relationship between PN and super-saturation is completely non-linear. It is near 0 when the level of super-saturation is negligible and quickly enhances by reaching the level of super-saturation to a specific critical value (Garside, 1985). Owing to the existence of weak reproducibility, appropriate control of PN is significantly hard. Poor reproducibility can be described by two main facets. The first aspect is based on the assumption of the deterministic essence of PN mechanism, which results in the occurrence of poor reproducibility owing to great sensitivity of the experimental circumstances. Hence, precise control of experimental conditions can eventuate in the appropriate control of nucleation. The second facet is according to the assumption of the stochastic nature of the nucleation process (Maggioni and Mazzotti, 2015; Sear, 2014; Sullivan, 2014). Classical nucleation theory (CNT) possesses great ability to provide an insight about the circumstance of nuclei formation from the solution (Cooper, 1974; Langer and k. Schwartz, 1980). Albeit various conducted experiments in recent years are basically different from the predictions provided by CNT. One of the most interesting theories, which has been recently of great attraction is the two-step nucleation theory (TSNT) (Vekilov, 2004; Vekilov, 2010). In CNT, a critical size exists, which profoundly relies on the super-saturation. In this theory, the cluster is of great stability and grows to a macroscopic size. In contrast, in TSNT, the recognition of molecules into a regular structure takes place with the aim of generating a nucleus after the cluster formation of solute molecules (Erdemir et al., 2009). Karthika et al has comprehensively evaluated both CNT and TSNT. They concluded that according to both evaluated theories, those operational parameters that influence the cluster formation may help or inhibit the process of PN. For instance, cluster formation can be declined or enhanced based on the intensity of mixing (Karthika et al., 2016). In an investigation, Forsyth et al. corroborated the significant impact of fluid shear on the PN mechanism. Based on their investigation, PN and growth rates were both relied on the shear rate. Additionally, they concluded that increment in the amount of average shear rate significantly declined the mean induction time (Forsyth, 2015). Application of acoustic cavitation (AC) with the aim of motivating PN mechanism is identified as another technique to influence cluster formation. This technique has been proposed by Virone et al. They concluded from their investigation that the presence of AC decreased the sensitivity against the average super-saturation. The derived pressure owing to the cavitation enforces a high local super-saturation that positively affects PN (Virone, 2006). About the ultrasound intensity, it is worth pointing out that low amounts of ultrasound irradiation restrains PN mechanism, while its high amounts motivates the PN process (Kurotani, 2009). Moreover, PN mechanism may be classified into two major divisions including homogeneous nucleation (HON) and heterogeneous nucleation (HEN). HON is defined as the spontaneous generation of nuclei from the solution. The pathway of HON is still ambiguous, which can be attributed to the great difficulty in direct observation. CNT doesn’t have eligibility to appropriately describe the nucleation process. In an experiment, Tan et al. demonstrated the insignificant role of density fluctuations to increase nucleation in HON (Tan et al., 2014). HEN process takes place in the existence of impurities (i.e., particles) that help the generation of a seed for a nucleus. HEN is more prevalent than HON owing to the requirement of low amount of energy to create the nuclei. Wall roughness and impurity type are among the most important operational factors that can control the presence of HEN (Omar and Rohani, 2017).

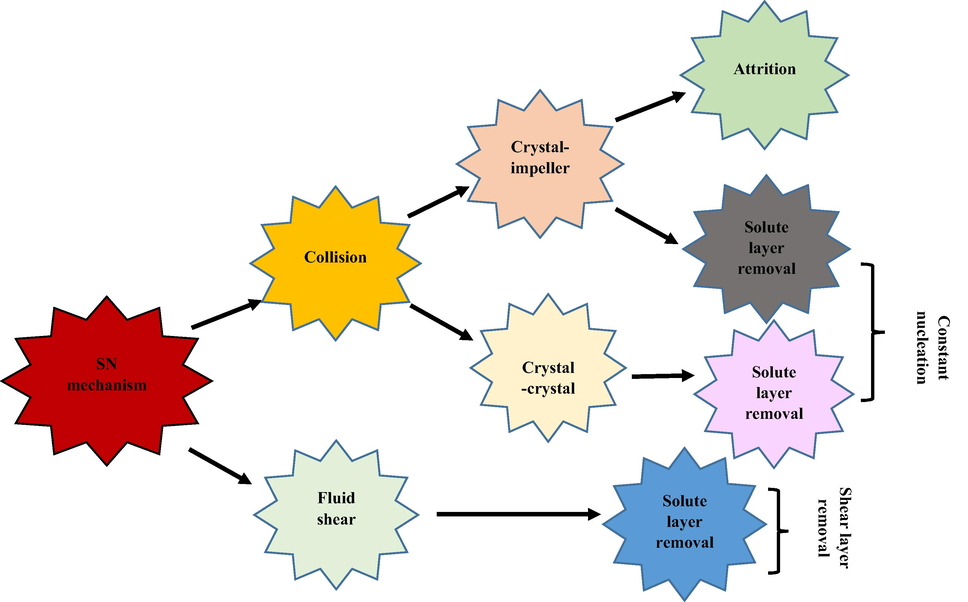

3.1.2 Secondary nucleation (SN)

SN takes place when pre-existing crystals exist. PN mechanism precedes SN (Viedma, 2004). SN mechanism can overcome the PN mechanism when the number of crystals reached to a sufficient amount. SN process takes place by two main mechanisms including shear and collision (Agrawal and Paterson, 2015). Fig. 4 demonstrates the mechanisms of SN process. The pre-existing crystals may be regarded as the nuclei source. Opposite of other mechanisms, attrition doesn’t have any dependency to the super-saturation. Various types of crystal can be formed on the surface of the pre-existing crystals by early removal of layer in the process. Albeit, by passing a sufficiently-long time, the solute layer can accept the shape of the seed crystal and therefore, the crystal configuration is similar to the seed (Agrawal and Paterson, 2015). The number of manufactured secondary nuclei within the contact nucleation process is in direct relation with the super-saturation and the contact energy (Denk and Botsaris, 1972). Review of various scientific papers illustrates the fact that faster growing materials increases the efficiency of nuclei (Tai et al., 1975). Contact nucleation possesses great potential of application as a suitable procedure to control the crystal size. In this procedure, the secondary nuclei size is able to be controlled via the flow rate of the feed solution (Wong et al., 2013). The occurrence of shear nucleation is exactly similar to contact nucleation mechanism. As like as contact nucleation mechanism, the removal of crystals surface layer results in its action as nuclei (Sung et al., 1973).

Principal mechanisms of SN process. ().

Adopted from Agrawal and Paterson, 2015

3.1.3 Breakage and attrition

Attrition / breakage is known as dissociation process of a particle into smaller compartments due to the induction of a physical force which could occur in the process of crystallization. These compartments act as nuclei and possess the potential of growth into bigger crystals (Omar and Rohani, 2017). The prominent discrepancy between breakage and contact nucleation is that in contact nucleation, the parent crystal doesn’t break, while in attrition process, the parent crystal is fractured into numerous segments in irreversible form. One of the most important parameters in crystal attrition mechanism is time. In an investigation, Mazzarotta et al. investigated the influence of time on attrition in a mixing tank. Based on their investigation, in the first minute, numerous small segments were manufactured, but rapidly after that the production process of small fragments became insignificant (Mazzarotta et al., 1996). Asakuma et al. applied momentous parameters of micro-hardness such as roundness and fracture strength to estimate attrition behavior. These factors had been applied to compute fracture energy and attrition coefficient that are of great importance in the estimation of attrition value (Asakuma, 2007). Crystal morphology/shape are two important parameters, which their investigation is of great importance. Compared to crystals with low aspect ratios, those with higher aspect ratios can be easier broken (Sato, 2008; Briesen, 2009). In a numerical study, Briesen developed a two-dimensional (size and shape of the crystals) model based on PBE that for shape dependent crystal attrition. They resulted that the PBE has great potential of application to mathematically model shape dependence (Briesen, 2009). Guo et al. studied the impact of ultrasound on attrition/breakage of crystals. Based on their investigations, ultrasound can influence the crystals in two different ways as follows (Guo, 2007):

1) Ultrasound enhances the collision rate between crystals and results in the contribution of cavitation to breakage.

2) Ultrasound possesses great potential to be applied in the nucleation process. If the ultrasound process lasts too long, it results in the breakage of crystal and consequently alteration in the obtained CSD.

3.2 Crystal death

3.2.1 Dissolution

Dissolution is a mechanism which takes place by reducing the relative super-saturation to an amount less than 1. Numerous functional/operational parameters of crystals such as growth, configuration, size and form along with the chemical essence of both crystal and solvent can have significant effect on dissolution mechanism (Blagden, 2007). The mechanism of dissolution takes place in two major steps including 1) surface reaction and detachment 2) Crystal-to-bulk solution mass transfer of components. Relying on the crystal solubility, either mass transfer or surface detachment of the species may be propounded as the rate-limiting step (Nagy et al., 2011). Shan et al. proposed a mathematical model for dissolution mechanism by considering both mass transfer and molecules detachment on the surface of crystal (Shan et al., 2002). In another study, Mangin et al. applied PBE to investigate dissolution mechanism in a stirred tank vessel. They concluded that at the time near the occurrence of dissolution mechanism, disaggregation agglomerated particles significantly accelerate the dissolution process (Mangin, 2006).

3.2.2 Aggregation and agglomeration

In crystallization process, the phenomenon of agglomeration is the process of contacting particles for an adequately long time with the aim of enabling the growth of a crystalline bridge between the particles (Lewis, 2015). Agglomeration of particles plays a vital role in the creation of bigger particles and therefore, is of great importance for industrial crystallization (Hollander, 2002). Aggregation is defined as the pre-nucleation process of molecules formation to supramolecular structures (Nichols, 2002). Based on the definition, aggregation can result in agglomeration. The occurrence of agglomeration is based on different steps, which can be explained as follows:

1) Proximity of two particles for the growth of an agglomerative bond; and.

2) Generation of the agglomerative bond.

In the second step, the bond is reinforced by passing the time but may be broken by other collisions. Surface configuration, quiddity of agglomerative bond, hydrodynamic and super-saturation effects and orientation of collisions can be considered as important parameters that affect agglomeration (Brunsteiner, 2005). Formation of the agglomerates is in close relationship with the size. If crystals have large sizes, the addition of a single crystal can increase the agglomerates size but if crystals have small size, the addition of smaller agglomerates can enhance the agglomerates size (David et al., 1995). David et al. proposed a new interpretation for agglomeration mechanism by mixing fluid mechanics with crystal engineering. They concluded based on employing their developed equation that agglomeration is a size-dependent mechanism and crystals with small size can favorably stick to large crystals in comparison with those crystals with similar size (David, 1991).

3.3 Crystal growth

Crystal growth is an important mechanism in crystallization process, which profoundly depends on the solute super-saturation. Appropriate control of super-saturation is an important process in crystal growth mechanism, which is possible employing some methods such as cooling of the supersaturated solution, addition of an anti-solvent, evaporation and change of the pH value. The prevalently employed mathematical model for crystal growth can be presented applying the power law relationship as follows (Briesen, 2006; Gunawan et al., 2004; Morris, 2015):

In this equation, and a are respectively expressed as the growth rate kinetic parameter and an empirical constant.

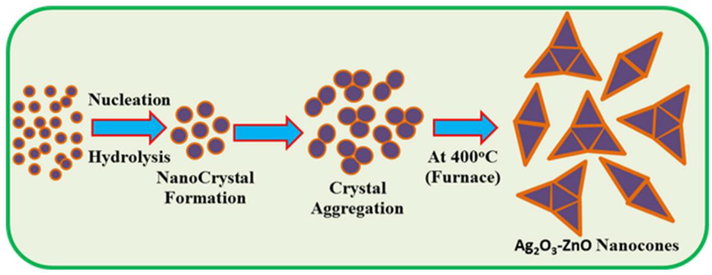

Impurities in mother liquor are considered as an important parameter, which significantly influence the crystal growth rate. Various impurities in mother liquor are of great importance in industrial crystallization owing to their unavoidable presence. Numerous investigations have been recently conducted to evaluate the impact of various impurities on the growth trend of pharmaceutical crystals (Garnier et al., 2002; Chong-Hui and Grant, 2002). Moreover, application of various types of additives may be beneficial for controlling crystal morphology. In an investigation, Thompson et al. studies the effect of additives on the growth/morphology of paracetamol crystals. They corroborated that the impurities’ structure possesses great importance on the growth process of crystals relying on the functional groups of the crystal faces (Thompson, 2004). Zhang et al. evaluated the influence of impurities via the development of a two-dimensional population balance model. They concluded the great performance of PBEs on solving population balance model for determining the shape evolution during crystal growth (Zhang, 2015). Fig. 5 schematically demonstrates the crystal growth mechanism of doped Ag2O3-ZnO NCs generated by wet-chemical process.

Schematic demonstration of crystal growth mechanism of doped Ag2O3-ZnO NCs generated via wet-chemical process. Reprinted from (Rahman, 2014).

4 Numerical approaches for PBE solution

4.1 Method of moments (MOM)

Three principal techniques for analyzing the PBE are the MOM, the discretization of the size domain interval (DSDI) and the weighted residuals (WRs) (Costa et al., 2007; Davidson and Aberle, 2004; Babanezhad, 2020). The MOM is identified as an old numerical approach that can convert the PBE into a series of ODEs via multiplying the PBE by Lj and integrating it. This numerical process results in deriving the following equations. Solution of these equations presents the moments of particle distribution as function of t (Ranodolph, 2012):

In the above-mentioned equations, B0 is expressed as the nucleation rate. By consideration of only nucleation and growth mechanisms, the moments is able to be created via the ordinary differential equation (ODEs) as follows:

The derivation process of ODEs when PBE is 2D is easy and can be obtained as follows:

4.2 Discretized sizing technique (DST)

The discretization approach, known as DST, discretizes independent variable in various intervals and apply the mean-value theorem to convert the continuous PBE into a series of equations. DSDI possesses the ability to turn the PBE to discretized population balance (DPB) (Costa et al., 2007; Kotsiantis and Kanellopoulos, 2006; Abbas and Romagnoli, 2007). The endeavors towards mathematical-based solution can be significantly declined by the assumption of a geometric progression for grids owing to significant decrement of the number of particles combinations required to evaluate the aggregation terms (Rigopoulos and Jones, 2003). Moreover, coarse discretization procedures are of great amenability to control applications due to its great speed to recognize, which method should be achieved particularly when fronts and discontinuities are not existed (Ramkrishna and Mahoney, 2002). Two momentous disadvantages can be highlighted during the implementation of this method as follows (Mahoney and Ramkrishna, 2002):

-

Both conservation in the mass and particles number is just warranted in the limit of infinite resolution

-

Creation of a sharp discontinuity, which rapidly develops via numerical diffusion in simulation.

Marchal et al. developed the Method of Classes (MOC) to numerically solve the agglomeration, breakage and length-dependent growth rate. This technique divides the size domain interval in some grids to create granulometric bins (Ci). MOC considers a fixed amount for the density function in each bin (Marchal, 1988). The main disadvantage of the MOC is the dependency of its density functions on the adopted grid. In recent years, Self-adaptive discretization (SAD) method has been developed to decline the number of differential equations considering no impact on results. Strong dependency of computation feasibility on the difficulty of the death and birth rates can be identified as another major disadvantages of MOC process (Costa et al., 2007). Puel et al. broadened the MOC procedure to 2D PBE and interpreted that some systems haven’t been of great potential to be rendered individually by one characteristic dimension. The bi-dimensional MOC estimates the time-variation of the crystal habit, which needs to be under profound attention in some applications. They offered the performance of an adaptive bi-dimensional algorithm to enhance the precision of the computation. They employed the LSODAR to solve the obtained ODEs (Puel et al., 2003).

4.3 Method of weighted residuals (MOWR)

Method based on weighted residuals contain some procedures that retake the distribution by predicting the solution with a series of trial functions (Finlayson, 2013). The weighted residuals are classified into two major procedures including weighted residuals with global functions (WRWGF) and finite element (FE). WRWGF method has been among the oldest techniques in PBE numerical solution. Despite its soon recognition in the field of PBE numerical solution, its application in the numerical solution of PBE has been limited due to showing sharp changes and discontinuities (Braatz, 2002). FE technique predict the solution via piecewise low-order polynomials that are flexible and qualified of taking highly irregular solutions (Rigopoulos and Jones, 2003). In WRWGF procedure, the population density function can be approximated using the following equation:

Where,

is a basis function. Moreover, the ambiguous ai’s can be obtained by placing former equation into the general PBE to define a residual R (L, t). The main objective of weighted residuals is to find those ai’s that compel the orthogonal residual to an opted set of weighting functions via the following equation:

In an investigation, Nicmanis and Hounslow employed Collocation and Galerkin FE algorithms to solve PBE steady state mode of operation applying Lagrange cubic interpolation polynomials and spaced nodes inside each element. They corroborated that this algorithm possesses great efficiency to precisely estimate the number density with small numbers of elements. Despite great efficiency, Galerkin algorithm needs additional integrations that results in increasing the computational price of this method compared to collocation method (Nicmanis and Hounslow, 1996; Nicmanis and Hounslow, 1998). The orthogonal collocation on finite elements (OCFE) is considered as another procedure applied by numerous investigators in the scientific field of emulsion polymerization. This numerical method applies Lagrange and Legendre interpolation polynomials (Doyle et al., 2003; Immanuel, 2002; Immanuel and Doyle Iii, 2003).

In a study, Mahoney and Ramkrishna applied two modifications in the Galerkin’s procedure on FE to solve PBEs for precipitation process with the aim of decreasing its traditional disadvantages as follows (Costa et al., 2007; Mahoney and Ramkrishna, 2002):

-

Choosing linear basis functions to overcome the difficulties towards managing discontinuities that are usually emerged in simulations of seeded crystallizers.

-

Precise adjustment of invariant integrals of separable aggregation models is an appropriate way to decline computational prices.

5 Conclusion and future outlook

The significant role of numerical modeling approaches in crystallization process and crystallizer control has motivated researchers all over the world to develop more efficient, economical and precise solutions to solve population balance equations. In recent decades, various types of numerical procedures have been evaluated to solve PBE. MOM is identified as one of the most common types of crystal popular solution that consists of the conversion of PBEs to ODEs applying a moment transformation. Application of MOM results in obtaining the mean particle sizes and distribution coefficient. DST is another commonly applied technique that provides the distribution. Despite its good performance to solve PBEs, high computational costs have restricted its extensive application in crystallization process. MOM technique possesses great ability of application as coupled with CFD software and especially when rapid calculations of the average crystal size are of great importance. The main purpose of this review paper is to present a state-of-the-art review in the mathematical-based solution of PBE in crystallization process and discuss the challenges towards solving it in the presence of disparate contributed mechanisms such as nucleation, growth, agglomeration, and attrition. This review paper presents the advantages and disadvantages of commonly employed approaches such as MOM, DST and MOWR for solving PBE in crystallization process. More investigations on PBEs have illustrated significant progression. As an outlook, more investigations must be carried out to evaluate the potential of phenomenological models instead of the semiempirical models. Additionally, development of more efficient aggregation/agglomeration and breakage kernels is of great importance for more appropriate description of the underlying processes. Furthermore, application of quantum mechanics modeling to solve PBE is a novel idea that can be evaluated by investigators in the future.

Acknowledgement

This study is supported via funding from Prince Sattam bin Abdulaziz University project number (PSAU/2023/R/1444).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Multiscale modeling, simulation and validation of batch cooling crystallization. Sep. Purif. Technol.. 2007;53(2):153-163.

- [Google Scholar]

- The impact of direct nucleation control on crystal size distribution in pharmaceutical crystallization processes. Cryst. Growth Des.. 2009;9(3):1378-1384.

- [Google Scholar]

- Computational Study of Crystallization. In: Advanced Computational Techniques for Heat and Mass Transfer in Food Processing. CRC Press; 2022. p. :211-234.

- [Google Scholar]

- Secondary nucleation: mechanisms and models. Chem. Eng. Commun.. 2015;202(5):698-706.

- [Google Scholar]

- Attrition behavior by micro-hardness parameters in suspension-crystallization processes. Powder Technol.. 2007;171(2):75-80.

- [Google Scholar]

- Two-step crystal nucleation kinetics: Solution of the master equation. J. Cryst. Growth. 2022;580:126469

- [Google Scholar]

- High-performance hybrid modeling chemical reactors using differential evolution based fuzzy inference system. Sci. Rep.. 2020;10(1):21304.

- [Google Scholar]

- Pattern recognition of the fluid flow in a 3D domain by combination of Lattice Boltzmann and ANFIS methods. Sci. Rep.. 2020;10(1):1-13.

- [Google Scholar]

- Developing intelligent algorithm as a machine learning overview over the big data generated by Euler-Euler method to simulate bubble column reactor hydrodynamics. ACS Omega. 2020;5(32):20558-20566.

- [Google Scholar]

- Performance and application analysis of ANFIS artificial intelligence for pressure prediction of nanofluid convective flow in a heated pipe. Sci. Rep.. 2021;11(1):1-18.

- [Google Scholar]

- Hybrid finite volume and Monte Carlo method for solving multi-dimensional population balance equations in crystallization processes. Chem. Eng. Sci.. 2020;217:115511

- [Google Scholar]

- Crystal engineering of active pharmaceutical ingredients to improve solubility and dissolution rates. Adv. Drug Deliv. Rev.. 2007;59(7):617-630.

- [Google Scholar]

- On the prediction of crystal shape distributions in a steady-state continuous crystallizer. Chem. Eng. Sci.. 2009;64(4):686-696.

- [Google Scholar]

- Braatz, R.D., Advanced control of crystallization processes. annual reviews in control, 2002. 26(1): p. 87-99

- Simulation of crystal size and shape by means of a reduced two-dimensional population balance model. Chem. Eng. Sci.. 2006;61(1):104-112.

- [Google Scholar]

- Two-dimensional population balance modeling for shape dependent crystal attrition. Chem. Eng. Sci.. 2009;64(4):661-672.

- [Google Scholar]

- Toward a molecular understanding of crystal agglomeration. Cryst. Growth Des.. 2005;5(1):3-16.

- [Google Scholar]

- Mathematical modeling and numerical simulation of CO2 capture using MDEA-based nanofluids in nanostructure membranes. Process Saf. Environ. Prot.. 2021;148:1377-1385.

- [Google Scholar]

- Numerical investigation of ibuprofen removal from pharmaceutical wastewater using adsorption process. Sci. Rep.. 2021;11(1):24478.

- [Google Scholar]

- Relationship between particle size and impurity incorporation during crystallization of (+)-pseudoephedrine hydrochloride, acetaminophen, and adipic acid from aqueous solution. Pharm. Res.. 2002;19(7):1068.

- [Google Scholar]

- Temperature-dependent solubility of selected proteins. J. Cryst. Growth. 1998;191(4):820-826.

- [Google Scholar]

- Considerations on the crystallization modeling: Population balance solution. Comput. Chem. Eng.. 2007;31(3):206-218.

- [Google Scholar]

- Considerations on the crystallization modeling: population balance solution. Comput. Chem. Eng.. 2007;31(3):206-218.

- [Google Scholar]

- Crystallization and precipitation engineering—III. A discrete formulation of the agglomeration rate of crystals in a crystallization process. Chem. Eng. Sci.. 1991;46(1):205-213.

- [Google Scholar]

- Modelling of agglomeration in industrial crystallization from solution. Chem. Eng. Technol.: Industrial Chem.-Plant Equip.-Process Eng.-Biotechnol.. 1995;18(5):302-309.

- [Google Scholar]

- An introduction to spectral domain method-of-moments formulations. IEEE Antennas Propag. Mag.. 2004;46(3):11-19.

- [Google Scholar]

- Doyle III, F.J., C.A. Harrison, and T.J. Crowley, Hybrid model-based approach to batch-to-batch control of particle size distribution in emulsion polymerization. Computers & Chemical Engineering, 2003. 27(8-9): p. 1153-1163.

- A state-of-the-art review on the application of various pharmaceutical nanoparticles as a promising technology in cancer treatment. Arab. J. Chem.. 2021;14(10):103352

- [Google Scholar]

- Technical crystallization for application in pharmaceutical material engineering. Asian J. Pharma. Sci.. 2015;10(4):283-291.

- [Google Scholar]

- Nucleation of crystals from solution: classical and two-step models. Acc. Chem. Res.. 2009;42(5):621-629.

- [Google Scholar]

- Extended method of moment for general population balance models including size dependent growth rate, aggregation and breakage kernels. Comput. Chem. Eng.. 2013;56:1-11.

- [Google Scholar]

- Coupling of the population balance equation into a two-phase model for the simulation of combined cooling and antisolvent crystallization using OpenFOAM. Comput. Chem. Eng.. 2019;123:246-256.

- [Google Scholar]

- Finlayson, B.A., The method of weighted residuals and variational principles. 2013: SIAM.

- Influence of controlled fluid shear on nucleation rates in glycine aqueous solutions. Cryst. Growth Des.. 2015;15(1):94-102.

- [Google Scholar]

- Friedlander, S.K., Smoke, dust and haze: Fundamentals of aerosol behavior. New York, 1977.

- Garnier, S., S. Petit, and G. Coquerel, Influence of supersaturation and structurally related additives on the crystal growth of α-lactose monohydrate. Journal of Crystal Growth, 2002. 234(1): p. 207-219.

- High resolution algorithms for multidimensional population balance equations. AIChE J.. 2004;50(11):2738-2749.

- [Google Scholar]

- High-speed observation of the effects of ultrasound on liquid mixing and agglomerated crystal breakage processes. Powder Technol.. 2007;171(3):146-153.

- [Google Scholar]

- Hollander, E.D., Shear induced agglomeration and mixing. 2002.

- Modeling of particle size distribution in emulsion co-polymerization: comparison with experimental data and parametric sensitivity studies. Comput. Chem. Eng.. 2002;26(7–8):1133-1152.

- [Google Scholar]

- Computationally efficient solution of population balance models incorporating nucleation, growth and coagulation: application to emulsion polymerization. Chem. Eng. Sci.. 2003;58(16):3681-3698.

- [Google Scholar]

- A review of classical and nonclassical nucleation theories. Cryst. Growth Des.. 2016;16(11):6663-6681.

- [Google Scholar]

- Experimental estimation of primary and secondary nucleation kinetics of antisolvent crystallization as measured by induction time. Org. Process Res. Dev.. 2019;23(12):2724-2732.

- [Google Scholar]

- Discretization techniques: a recent survey. GESTS Int. Trans. Comput. Sci. Eng.. 2006;32(1):47-58.

- [Google Scholar]

- Effect of ultrasonic irradiation on the behavior of primary nucleation of amino acids in supersaturated solutions. J. Cryst. Growth. 2009;311(9):2714-2721.

- [Google Scholar]

- Modeling and control of crystal shape in continuous protein crystallization. Chem. Eng. Sci.. 2014;107:47-57.

- [Google Scholar]

- Lewis A., ed. The population balance equation, in Industrial Crystallization: Fundamentals and Applications. Cambridge University Press: Cambridge; 2015. p. :151-177.

- Lewis A., ed. Agglomeration, in Industrial Crystallization: Fundamentals and Applications. Cambridge University Press: Cambridge; 2015. p. :130-150.

- On the solution of population balance equations (PBE) with accurate front tracking methods in practical crystallization processes. Chem. Eng. Sci.. 2002;57(17):3715-3732.

- [Google Scholar]

- Adjustable discretized population balance for growth and aggregation. AIChE J.. 1995;41(3):591-603.

- [Google Scholar]

- Low-temperature-gradient crystallization for multi-inch high-quality perovskite single crystals for record performance photodetectors. Mater. Today. 2019;22:67-75.

- [Google Scholar]

- Optimal control and simulation of multidimensional crystallization processes. Comput. Chem. Eng.. 2002;26(7):1103-1116.

- [Google Scholar]

- Crystal growth rate dispersion modeling using morphological population balance. AIChE J.. 2008;54(9):2321-2334.

- [Google Scholar]

- Modelling the stochastic behaviour of primary nucleation. Faraday Discuss.. 2015;179:359-382.

- [Google Scholar]

- Efficient solution of population balance equations with discontinuities by finite elements. Chem. Eng. Sci.. 2002;57(7):1107-1119.

- [Google Scholar]

- Modeling of the dissolution of a pharmaceutical compound. J. Cryst. Growth. 2006;286(1):121-125.

- [Google Scholar]

- Crystallization and precipitation engineering—I. An efficient method for solving population balance in crystallization with agglomeration. Chem. Eng. Sci.. 1988;43(1):59-67.

- [Google Scholar]

- Quadrature method of moments for aggregation–breakage processes. J. Colloid Interface Sci.. 2003;258(2):322-334.

- [Google Scholar]

- Modification of polyethersulfone membrane using MWCNT-NH2 nanoparticles and its application in the separation of azeotropic solutions by means of pervaporation. PLoS One. 2020;15(7):e0236529.

- [Google Scholar]

- Evaluation of potassium glycinate, potassium lysinate, potassium sarcosinate and potassium threonate solutions in CO2 capture using membranes. Arab. J. Chem.. 2021;14(3):102979

- [Google Scholar]

- Influence of time on crystal attrition in a stirred vessel. AIChE J.. 1996;42(12):3554-3558.

- [Google Scholar]

- McPherson, A., Protein crystallization. Protein crystallography: Methods and protocols, 2017: p. 17-50

- Estimation of nucleation and growth kinetics of benzoic acid by population balance modeling of a continuous cooling mixed suspension, mixed product removal crystallizer. Org. Process Res. Dev.. 2015;19(12):1891-1902.

- [Google Scholar]

- 2 - Crystals, crystal growth, and nucleation. In: Myerson A.S., ed. Handbook of Industrial Crystallization (Second Edition). Woburn: Butterworth-Heinemann; 2002. p. :33-65.

- [Google Scholar]

- Internal fines removal using population balance model based control of crystal size distribution under dissolution, growth and nucleation mechanisms. Cryst. Growth Des.. 2011;11(6):2205-2219.

- [Google Scholar]

- State-of-the-Art review on the application of membrane bioreactors for molecular micro-contaminant removal from aquatic environment. Membranes. 2022;12(4):429.

- [Google Scholar]

- A review of the terms agglomerate and aggregate with a recommendation for nomenclature used in powder and particle characterization. J. Pharm. Sci.. 2002;91(10):2103-2109.

- [Google Scholar]

- A finite element analysis of the steady state population balance equation for particulate systems: Aggregation and growth. Comput. Chem. Eng.. 1996;20:S261-S266.

- [Google Scholar]

- Finite-element methods for steady-state population balance equations. AIChE J.. 1998;44(10):2258-2272.

- [Google Scholar]

- Crystal population balance formulation and solution methods: a review. Cryst. Growth Des.. 2017;17(7):4028-4041.

- [Google Scholar]

- Kernel identification in continuous fluidized bed spray agglomeration from steady state data. Adv. Powder Technol.. 2021;32(7):2517-2529.

- [Google Scholar]

- Studies on population balance equation involving aggregation and growth terms via symmetries. Int. J. Nonlinear Sci. Numer. Simul.. 2021;22(3–4):437-446.

- [Google Scholar]

- Computational fluid dynamics simulation of NO2 molecular sequestration from a gaseous stream using NaOH liquid absorbent through porous membrane contactors. J. Mol. Liq.. 2020;313:113584

- [Google Scholar]

- Simulation and analysis of industrial crystallization processes through multidimensional population balance equations. part 1: a resolution algorithm based on the method of classes. Chem. Eng. Sci.. 2003;58(16):3715-3727.

- [Google Scholar]

- On the solution of population balances for nucleation, growth, aggregation and breakage processes. Chem. Eng. Sci.. 2009;64(9):2088-2095.

- [Google Scholar]

- Selective divalent cobalt ions detection using Ag2O3-ZnO nanocones by ICP-OES method for environmental remediation. PLoS One. 2014;9(12):e114084.

- [Google Scholar]

- Population balance modeling. promise for the future. Chem. Eng. Sci.. 2002;57(4):595-606.

- [Google Scholar]

- Size distribution dynamics in a mixed crystal suspension. Iowa State University; 1962.

- Ranodolph, A., Theory of particulate processes: analysis and techniques of continuous crystallization. 2012: Elsevier.

- Finite-element scheme for solution of the dynamic population balance equation. AIChE J.. 2003;49(5):1127-1139.

- [Google Scholar]

- Analysis of nucleation rate measurements in precipitation processes. Cryst. Growth Des.. 2006;6(6):1380-1392.

- [Google Scholar]

- Two-dimensional population balance model with breakage of high aspect ratio crystals for batch crystallization. Chem. Eng. Sci.. 2008;63(12):3271-3278.

- [Google Scholar]

- Quantitative studies of crystal nucleation at constant supersaturation: experimental data and models. CrstEngComm. 2014;16(29):6506-6522.

- [Google Scholar]

- Dissolution kinetics of crystals in suspension and its application to L-aspartic acid crystals. Chem. Eng. J.. 2002;88(1–3):53-58.

- [Google Scholar]

- Revealing the roles of desolvation and molecular self-assembly in crystal nucleation from solution: benzoic and p-aminobenzoic acids. Cryst. Growth Des.. 2014;14(5):2689-2696.

- [Google Scholar]

- Modeling Olanzapine Solution Growth Morphologies. Cryst. Growth Des.. 2018;18(2):905-911.

- [Google Scholar]

- Secondary nucleation of magnesium sulfate by fluid shear. AIChE J.. 1973;19(5):957-962.

- [Google Scholar]

- Visualizing kinetic pathways of homogeneous nucleation in colloidal crystallization. Nat. Phys.. 2014;10(1):73-79.

- [Google Scholar]

- Industrial crystallization: process simulation analysis and design. Springer Science & Business Media; 2013.

- The effects of additives on the growth and morphology of paracetamol (acetaminophen) crystals. Int. J. Pharm.. 2004;280(1–2):137-150.

- [Google Scholar]

- Dense liquid precursor for the nucleation of ordered solid phases from solution. Cryst. Growth Des.. 2004;4(4):671-685.

- [Google Scholar]

- The two-step mechanism of nucleation of crystals in solution. Nanoscale. 2010;2(11):2346-2357.

- [Google Scholar]

- Experimental evidence of chiral symmetry breaking in crystallization from primary nucleation. J. Cryst. Growth. 2004;261(1):118-121.

- [Google Scholar]

- Primary nucleation induced by ultrasonic cavitation. J. Cryst. Growth. 2006;294(1):9-15.

- [Google Scholar]

- Drug delivery approaches in addressing clinical pharmacology-related issues: opportunities and challenges. AAPS J.. 2015;17(6):1327-1340.

- [Google Scholar]

- Contact secondary nucleation as a means of creating seeds for continuous tubular crystallizers. Cryst. Growth Des.. 2013;13(6):2514-2521.

- [Google Scholar]

- Two dimensional population balance modelling of crystal growth behaviour under the influence of impurities. Adv. Powder Technol.. 2015;26(2):672-678.

- [Google Scholar]

- Secondary nucleation in polymer crystallization: a kinetic view. Polym. Crystall.. 2021;4(3):e10173.

- [Google Scholar]

- Population balance modeling of homogeneous viral aggregation. Chem. Eng. Sci.. 2022;247:117035

- [Google Scholar]

- Synthesis of zeolite NaA at room temperature: the effect of synthesis parameters on crystal size and its size distribution. Adv. Powder Technol.. 2013;24(3):689-696.

- [Google Scholar]