Translate this page into:

Synthesising injectable molecular self-curing polymer from monomer derived from lignocellulosic oil palm empty fruit bunch biomass: A review on treating Osteoarthritis

⁎Corresponding author. saiful-z@ukm.edu.my (Saiful Irwan Zubairi)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Osteoarthritis (OA) is a chronic and irreversible degenerative joint disease that most commonly affects individuals in their forties and fifties worldwide due to the continuously increasing life expectancy. Although joint replacement is an effective remedy for severe end-stage OA, the functional outcomes could be unsatisfactory, while the implants might have a limited lifespan. Due to the drawbacks and limitations of the joint replacement approach, bone Tissue Engineering (TE) is one of the promising bone tissue regeneration technologies that aid in cartilage repair and regeneration and has attracted the attention of experts. The advanced development of biopolymers, in particular biopolymer derived from Oil Palm Empty Fruit Bunch (OPEFB), has been utilised in the fabrication of scaffolds that serve as a crucial component in bone TE. The abundant supply of OPEFB biomass and the increasing trend of converting waste into wealth for environmental sustainability have also provided the opportunity and interest to fully apply biopolymer-derived materials for bone scaffolding and other applications. Therefore, this paper aimed to provide a review of the biopolymers derived from OPEFB for the treatment of OA and other related applications. A brief overview of the biomass sources in Malaysia was presented, followed by a discussion on the chemical compositions and pre-treatment methods of OPEFB by using organosolv pre-treatment and enzymatic hydrolysis for maximum glucose recovery, monomer derived from cellulose OPEFB and synthesizing self-curing polymer scaffold. Additionally, a detailed review of the polymeric biomaterials in bone TE for the fabrication of scaffolds were included in this review. Most importantly, the paper described the potential use of injectable polymeric biomaterials that provide a significant benefit in orthopaedic applications. Overall, this paper provides a perspective on the potential of OPEFB-derived injectable scaffolds as an alternative OA treatment and future bone TE applications.

Keywords

Lignocellulosic Biomass

Oil Palm Empty Fruit Bunch

Biopolymer

Scaffold

Injectable Scaffold

Bone Tissue Engineering

Osteoarthritis

- OA

-

Osteoarthritis

- OPEFB

-

Oil palm empty fruit bunch

- TE

-

Tissue engineering

- PHAs

-

Polyhydroxyalkanoates

- CNF

-

Cellulose nanofibre

- MPOB

-

Malaysian Palm Oil Board

- MPOC

-

Malaysian Palm Oil Council

- FFB

-

Fresh fruit bunch

- AIM

-

Agensi Inovasi Malaysia

- OPT

-

Oil palm trunk

- OPF

-

Oil palm frond

- PKS

-

Palm kernel shell

- MF

-

Mesocarp fruit fibre

- POME

-

Palm oil mill effluent

- PLA

-

Polylactic acid

- PHBV

-

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

- PHB

-

Polyhydroxybutyrate

- DP

-

Degree of polymerisation

- HA

-

Hyaluronic acid

- PLGA

-

Poly(lactic-co-glycolic) acid

- PCL

-

Polycaprolactone

- PEO

-

Polyethylene oxide

- ECM

-

Extracellular matrix

- CS

-

Chitosan

- HA

-

Hydroxyapatite

- n-HA

-

Nano-hydroxyapatite

- DFO

-

Desferrioxamine

- PEG

-

Poly(ethylene glycol)

- GBD

-

Global burden disease

Abbreviations

1 Introduction

Malaysia is blessed with a plentiful source of biomass given its tropical climate that favours agricultural activities as well as the dense tropical rainforest that provides an abundant natural source for the timber and wood manufacturing industry, which make up a crucial pillar of its economy every year. Biomass refers to all organic matter found in the ecosystem, whether it originates from plants, animals, or microorganisms (Houghton, 2008) and also include materials that are obtained through natural or artificial conversion. According to the Department of Statistics of Malaysia (2020), Malaysia's agricultural sector serves as the country’s economic backbone, which contributed 7.1% (RM 101.5 billion or approximately USD 21.6 billion) to the country's Gross Domestic Product (GDP) in 2019. The agricultural sector produced an enormous supply of biomass resources in various forms, including lignin-based biomass, starch-based biomass, and fibrous biomass. The use of biomass as a renewable energy source has the potential to address the negative environmental impacts and other issues associated with non-renewable fossil fuel energy sources. Traditionally, biomass wastes, such as rice husk, sawdust, and palm fibres, are used in the downstream process to generate power in the respective processing mills. After the possibility to generate wealth from lignocellulosic materials have been realised, the exploitation of biomass for commercialisation has led to the establishment of the biomass industry in the 1900s (MiGHT, 2013). Oil Palm Empty Fruit Bunch (OPEFB) is one of the most widely used agricultural biomass in Malaysia. In order to promote sustainability, various value-added products have been derived from OPEFB, including biomaterials that demonstrate the huge potential for medical applications.

While the modern world has managed to treat various illnesses and diseases, there is currently no cure available for Osteoarthritis (OA), which is one of the most common types of arthritis in the world that causes painful and chronic synovial joint disability (Kuyinu et al., 2016). The Global Burden Disease (GBD) study ranked OA among the foremost contributors to the global Years Lived with Disability (YLD). In fact, it was estimated that more than 240 million people worldwide suffer OA (Jeffery et al., 2021), where their quality of life has been impoverished by OA to the extent of limiting certain essential daily activities, including walking and running (Palazzo et al., 2016). Although arthritic joints can be replaced with mechanical joints through major surgery, the replacements using natural sources (autograft and allograft) are not only limited in their availability but also pose serious disadvantages, such as the possible immunological reactions or transmission of disease.

In view of this, bone Tissue Engineering (TE) has received increasing interest as an alternative approach for bone grafts. TE applies the principles of engineering and science towards the development of substitutes that restore, maintain, or improve tissue function. TE involves the use of a rich source of osteoprogenitor cells to repair defective bone tissue and a scaffold to encourage the attachment of the cells. Ideally, the scaffold should permit the newly-forming tissues to function during the period of regeneration and degrade by the time the tissues have matured. Thus, scaffolding is a necessity for cell attachment and assisting tissue growth, leading to the regeneration of functional bone tissues (Bettinger et al., 2006). A well-understanding of the bone defect site of the patient, the end user’s needs, and the deficiencies in the function that the materials are designed to address are important during the early stages of designing scaffold (Koons et al., 2020).

Despite those various materials have been proposed as biomaterials for bone TE, each material show certain drawbacks. For example, the lack of biodegradability is a major drawback for metal-based materials in scaffold fabrication. Moreover, the low mechanical stability, brittleness, and stiffness of ceramic-based materials are significant disadvantages that prevent their use in the regeneration of large bone defects. In contrast, bio-based polymeric materials are thermoplastics and have wide flexibility in terms of their physical properties, which permit them to be tailored to specific uses, and can be easily formed into desired shapes and sizes. Interestingly, biopolymer materials are the most commonly used in tissue growth due to their mechanical resemblance to the human bone structure. The majority of biopolymers can also degrade into natural compounds (Babbar et al., 2020). Hence, it is expected that value-added materials derived from OPEFB would offer a potential alternative in the development of bone scaffolding.

Therefore, this paper aimed to provide a review on the development of injectable molecular self-curing polymer derived from OPEFB for the treatment of OA. The first part of this paper presents an overview of the diverse range of biomass sources in Malaysia that can be converted into high-value end products for various applications. Next, the discussion focuses on the generation of biomass from the palm oil industry and the current utilisation of biomass-derived products, especially the current usage of OPEFB. A thorough review of the various properties and applications of OPEFB-derived biopolymer is provided, including the chemical composition of OPEFB, pre-treatment of OPEFB, and the optimum pre-treatment condition of OPEFB for the recovery of sugar from cellulose and hemicellulose, which can be further processed into various monomers to produce other biopolymer products. The second part of this paper includes a brief review of OA and its current studies using biopolymer materials comprising natural, synthetic, and OPEFB-derived polymer. Finally, the paper highlights the discussion on injectable scaffolds and their curing properties that is useful in cartilage tissue regeneration as one of the OA treatments. This review article would provide a full perspective of the potential use of biomaterial scaffolds from lignocellulosic biomass (in particular OPEFB-derived polymer) and further stimulate the increasing interest in the development of injectable biomaterial scaffolds for bone TE as well as for other applications.

2 Development and prospect of biomass in Malaysia

2.1 Overview of biomass sources in Malaysia

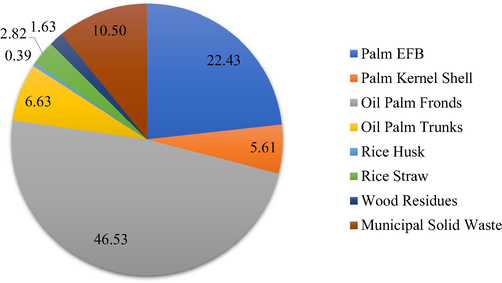

A wide array of biomass sources is available in Malaysia, including timber residue, oil palm biomass, rice husk residue, coconut fibres, and sugar cane waste (Abas et al., 2011). Additionally, Municipal Solid Waste (MSW) and waste streams originating from human activities are also classified as biomass due to their high content of organic matter. Note that MSW is considered biomass waste only if they are no longer usable for other applications (Kaltschmitt, 2013). Fig. 1 illustrates the annual quantity of biomass (million metric tonnes) generated in Malaysia up to the year 2015 (Jing, 2017). Out of 96.54 million tonnes (wet)/year of biomass produced, the palm oil industry in Malaysia generates the highest biomass waste with a total of 81.20 million metric tonnes in the form of Empty Fruit Bunch (EFB), Oil Palm Trunk (OPT), and Oil Palm Frond (OPF). Meanwhile, 15.34 million metric tonnes of biomass were generated from rice husk, rice straw, wood residues, and MSW. The generation of 38,563 tonnes/day of waste in 2015 was expected to increase to 49,670 tonnes/day by 2020 with an increased rate of 5.19% from 2015 to 2020 (SWM Malaysia Lab Report, 2015). Generally, most of the biomass wastes are left in the field to decompose naturally or are discarded in landfills, which do not only take up more land space but also cause severe environmental pollution, such as greenhouse gas emission and the deterioration of air quality.

Annual biomass availability in Malaysia up to 2015 (Jing, 2017).

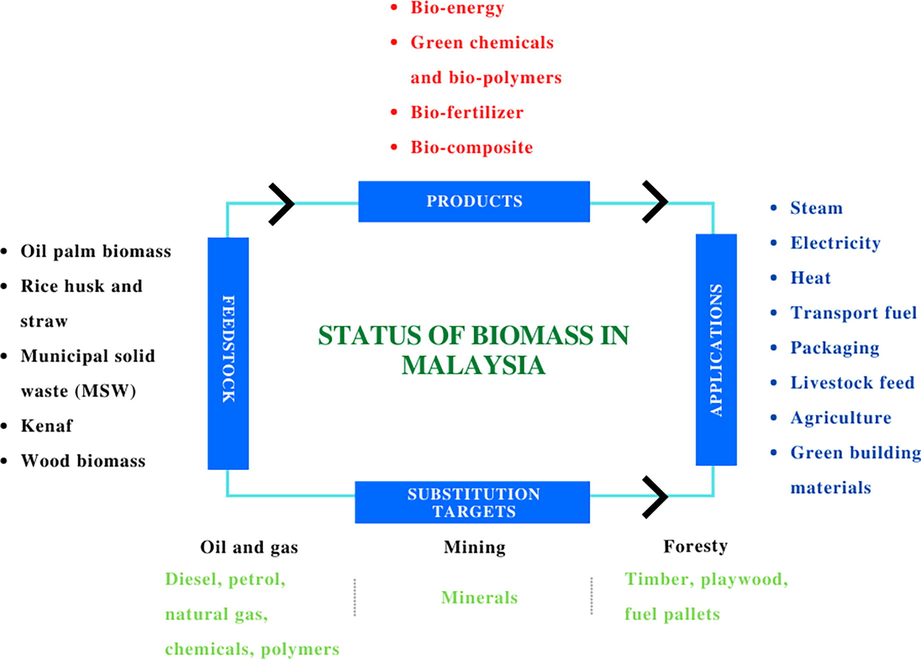

Previously considered as waste, biomass by-products are now regarded as high-value materials with enormous potential to generate an entirely new green industry. These organic materials have the potential to be used in the manufacturing sector to create value-added eco-products, such as green chemicals, biofertilisers, bioplastics, and biocomposites, or to generate renewable energy that would deliver additional revenue for the industry while also reducing the impact of fossil fuel-based energy on the environment (MBIC, 2021). Realising the potential application of biomass, the Malaysian government initiated the 2020 National Biomass Strategy in 2011 to provide a feasible framework to maximise profit on the biomass industry through higher-value downstream applications. The strategy outlines a list of action plans to meet its renewable energy target, including maximising the utilisation of biomass sources, reducing carbon emission, investigating the impact of biomass removal on soil fertility, and setting up 66,000 high-value job opportunities for the development of biomass value chain by 2020, as well as to contribute RM 30 billion through the Gross National Income (GNI). The utilisation of oil palm-based biomass, ranging from EFB to OPT and OPF, is the primary focus of this strategic plan. Fig. 2 shows the flow chart of biomass status in Malaysia and its high-end value products for various applications (Tang, 2014).

Status of biomass in Malaysia (Tang, 2014).

The second version of the National Biomass Strategy 2020 was launched in 2013 to focus more on other sources of biomass feedstock, such as rubber, wood, and rice husk (National Biomass Strategy 2020: New Wealth Creation for Malaysia’s Palm Oil Industry, 2011). The plan was to employ a short-term strategy that promotes the export of palm biomass pellets globally, which could generate instant benefits, as well as a long-term strategic approach that facilitates the development of bio-based liquid fuels and the biochemical sector through the involvement of plantation companies, technologist, and the palm oil industry. Given that the prospect evaluation of biomass demonstrates a significant business opportunity for the development of the Malaysian biomass industry (MiGHT, 2013), the Green Technology Financing Scheme (GTFS) extension was launched with a RM 2 billion grant, as announced in the 2019 budget by the Malaysia government to continuously offer competitive financing to deserving green technology entrepreneurs, including those in the biomass sector (MBIC, 2019). Despite its ample supply, the huge commercialisation potential, and continuous progress in research and development (R&D), biomass residues remain a burgeoning issue because they are not effectively managed and utilised. Table 1 presents a list of review articles on biomass utilisation in Malaysia and its key features over the past six years. Reviewed the biomass-based hydrogen production using various biological and thermochemical processes Provided an overview of the palm oil industry and the availability of its biomass wasteFocused on the thermochemical conversion (combustion, gasification, pyrolysis) of oil palm biomass, specifically the liquefaction mechanism Reviewed the potential of second-generation bioethanol yields from agricultural wastes, such as oil palm, paddy (rice), pineapple, banana, and durian The review focused on the utilisation of oil palm biomass via different technologies available and their R&D prospect Discussed the life-cycle and techno-economic analysis of biofuel production from oil palm and its biomass Reviewed heterogenous catalysts (alkali and acid catalyst) derived from bio-waste as well as other biocatalysts used in biodiesel production Reviewed the biogas development based on renewable energy and solid waste management policies Also elaborated the potential of biogas with the focus on harvesting biogas from MSW Reviewed on various types of pre-treatment lignocellulosic biomass (physical, physio-chemical, chemical, biological, and combination) to convert cellulose into fermentable sugar Highlighted the potential of biomass in supercapacitor application over other materials as well as advancements in the conversion of biomass into carbon nanofibre using various techniques The benefits and drawbacks of these techniques were also discussed Highlighted the potential of coal replacement using hydrothermal treatment of solid fuel from oil palm biomass and MSW for energy generation A detailed review of the use of oil palm biomass for the production of biofuels, chemicals, and biomaterials via various types of conversion Also focused on the potential of biorefinery development based on existing bioproducts for advanced fuel production and platform chemicals Focused on the production of biodegradable polymers, specifically polyhydroxyalkanoates (PHAs) from biomass via bacterial fermentation Discussed the potential of OPEFB biomass as a nanocellulose material in hydrogel production using different processes Also described the most recent advanced applications of nanocellulose in hydrogel products Presented a correlative evaluation of current research (from 2013 to 2018) that applied liquefaction and pyrolysis methods to produce bio-oil from various types of biomass Also discussed bio-oil utilisation in industries Reviewed the application of activated carbon from oil palm biomass for cadmium adsorbent The adsorption process was also discussed along with an evaluation of various types of adsorbent modification methods Highlighted the exploration and utilisation of palm oil residues as a modifier and substitute material in the pavement industry Also discussed the impact of palm oil residues on the reduction of carbon footprint and safety assessment in the pavement industry Presented an overview of the potential and challenges associated with woven kenaf reinforcement in thermoset polymer composites Emphasised on Cellulose Nanofibre (CNF) isolated from OPEFB for sustainable packaging applicationDiscussed the potential of CNF reinforced with Polypropylene Nanocomposite (PPNC) as a sustainable packaging material

Year

Reference

Key features

2015

Hosseini et al., 2015

Awalludin et al., 2015

2016

Aditiya et al., 2016

Kurnia et al., 2016

2017

Abdullah et al., 2017

Bong et al., 2017

2018

Ahmad Rizal et al., 2018

Azwar et al., 2018

2019

Hamzah et al., 2019

Ahmad et al., 2019

2020

Sen & Baidurah, 2020

Padzil et al., 2020

Ahmad et al., 2020

2021

Naihi et al., 2021

Yaro et al., 2021

Lee et al., 2021

Sarfat et al., 2021

2.2 Brief history of oil palm in Malaysia – Then and now

The oil palm (Elaeis guineensis), also known as African oil palm, is one of the three species belonging to the genus Elaeis in the Arecaceae family. This species exists in wild, semi-wild, or cultivated regions of Africa, South East Asia, and South and Central America (Henson, 2015). An oil palm tree reaches its maturity after 2.5–3 years of planting until the first Fresh Fruit Bunch (FFB) are ready for harvest, which the plant continues to produce fruits for up to 30 years. The oil palm’s fruit turns bright orange-red in colour when ripe and each fruit is made up of a hard kernel (seed) and enclosed in a shell (endocarp) that is encircled by a mesocarp (MPOC, 2021).

The oil palm was initially introduced into the then British Malaya in 1875 for decorative purposes. The first commercial planting was only cultivated in 1917 in Tannamaran Estate, Kuala Selangor. The oil palm cultivation grew at a relatively slow pace in the beginning and has only prospered in the last 50 years as a result of the extensive investment by the government, which saw the potential of the crop to expand the agriculture sector. Since the 1960s, the oil palm plantation area had increased rapidly as the government started to focus on various schemes and aid to steer the palm oil sectors into a successful industry. As a result, the industry's breeding and selection of palm oil have contributed to an improved yield and quality gains (Basiron, 2007). To date, several government agencies, councils and renowned institutions, such as the Malaysian Palm Oil Board (MPOB), Malaysian Palm Oil Council (MPOC), Palm Oil Research Institute of Malaysia (PORIM), Malaysian Agricultural Research and Development Institute (MARDI), and several universities (for R&D purposes) are responsible to lead the palm oil industry in Malaysia. A brief list of potentials of the palm oil industry that has catapulted Malaysia as one of the top palm oil producers in the world today is as follows:

-

One of the prominent agricultural industries in Malaysia that generates successive yearly economic growth and development. For instance, the country has an established industry to manufacture various palm oil products for export purposes (Szulczyk, 2013);

-

A high-value industry that ensures food security in terms of fats and oils (Khatun et al., 2017);

-

The largest contributor of lignocellulosic biomass in Malaysia (Loh, 2017). Oil palm plantations can produce up to 36.5 tonnes of dry matter per hectare every year, which is more than the natural rainforest with 25.7 tonnes (MPOB, 2011). Various high-value-added products have been produced from the conversion of this biomass using different technologies (Onoja et al., 2018);

-

Low-cost feedstock;

-

A promising potential source of renewable energy (Loh, 2017; Suzuki et al., 2017); and

-

Provide opportunities for green-based industries as biomass waste are categorised as organic wastes that are environmentally degradable

2.3 Production, products, and current utilisation of palm oil

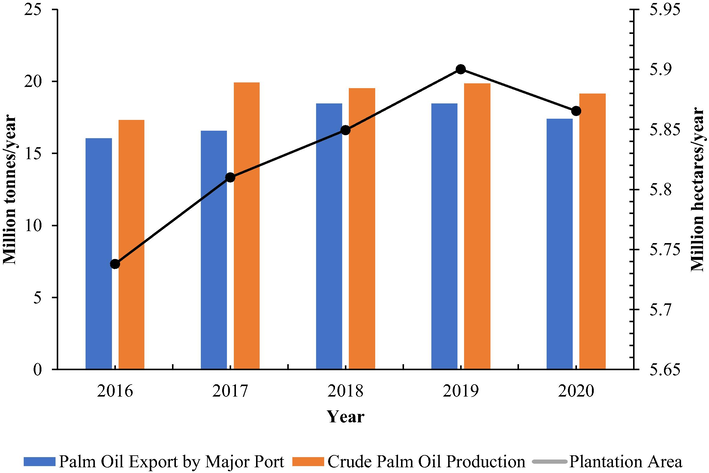

The palm oil industry is one of the top and booming industries in Malaysia with numerous oil palm plantations across both Peninsular and East Malaysia. Fig. 3 illustrates the general trend of the total plantation area, production of Crude Palm Oil (CPO), and export of palm oil from major ports in Malaysia, as reported by MPOB (2021) from 2016 to 2020 through various giant government companies and private sectors. Based on Fig. 3, the highest CPO production was recorded in 2017 at 19.92 million tonnes. According to Kushairi & Nambiappan (2018), the highest output production of CPO in 2017 was associated with the recovery phase following the El-Nino phenomenon that occurred in 2015–2016 as well as the higher processing volume of FFB compared to 2016.

Plantation area (million hectares), crude palm oil production (million tonnes) and palm oil export by major port (million tonnes) in Malaysia’s palm oil industry from 2016 to 2020 (MPOB, 2021).

By 2020, Malaysia has about 5.87 million hectares of oil palm plantation area with a total CPO production and total palm oil export of 17.39 million tonnes and 17.40 million tonnes, respectively. However, the plantation area in 2020 recorded a slight decline of 0.3% compared to 2019 (5.90 million hectares) due to the significant challenge as a result of the Movement Control Order (MCO) implemented by the government as a measure to control the 2019 novel coronavirus (COVID-19) pandemic, which restricted all sorts of activities, including agricultural practices, replanting, expansion of the oil palm plantation, and prolonged shortage of labour (Parveez et al., 2021). Overall, the production of CPO in 2020 was significantly lower (19.14 million tonnes) from 2019 (19.86 million tonnes) by 3.6%. The lower CPO production was also due to the lower number of FFB supply in 2019, which was 8.44 tonnes/hectare, compared to that of in 2020 at 7.85 tonnes/hectare (MBOB, 2021). Additionally, the dry weather condition in early 2019 and the lower application of fertiliser contributed to the decreasing number of FFB in 2020, thus, decreasing the total CPO production (CPOPC, 2020). Although the palm oil export volume slightly declined in 2020 (17.40 million tonnes) from the previous year, the total export revenue increased to RM 72.30 billion due to the increasing price of CPO after the MCO restriction was lifted in the second half of 2020 (MPOC, 2021).

On the global stage, MPOC (2019) reported that Malaysia is one of the largest producers (behind Indonesia) and exporter of palm oil in the world, accounting for 39% of the world palm oil production and 44% of the world palm oil export. In line with the industry's expansion, the increasing size of oil palm plantation areas would generate higher biomass volume (AIM, 2013). Additionally, in a study reported despite the large amount of palm oil production, the oil contributes to less than 25% by weight of the palm fruit bunch. Thus, for every kg of palm oil produced, approximately 4 kg of dry biomass is produced (Ng et al., 2012). In 2012 alone, 83 million tonnes of solid waste were produced from the oil palm sector, which is expected to rise to 85–110 million tonnes by 2020 to fulfil the market demand (AIM, 2013). Only 10% of the total biomass generated from the oil palm industry is converted into palm oil, while the remaining 90% is disposed of as waste materials (Shaharin & Farid, 2014). This problem would lead to disposal difficulties (transportation and logistics efficiency), a high operating cost of oil palm residues, and detrimental environmental impacts. Alternatively, the huge amount of oil palm biomass generated yearly in Malaysia can be utilised to produce various value-added products.

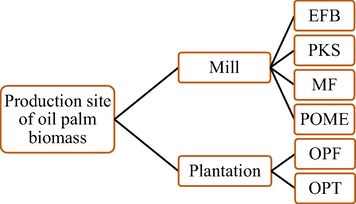

The two main activities in the palm oil mill, namely plantation management and oil milling, produces a variety of agricultural wastes (biomass), including EFB, OPT, OPF, Palm Kernel Shells (PKS), and Mesocarp Fibre (MF), which have high fibre content, as well as Palm Oil Mill Effluent (POME) that accumulates as liquid biomass (Aljuboori, 2013; Kurnia et al., 2016). Fig. 4 shows the availability of oil palm biomass at different production sites. About 25% of EFB, PKS, MF, and POME waste are present at the mill processing sites during the palm oil refining process, while the remaining 75% of the oil palm waste, such as OPF and OPT, are produced during replanting and punning activities, respectively. OPF are available throughout the year when the oil palm trees are pruned during the harvesting of the FFB (Hamzah et al., 2019). The palm oil mills in Malaysia produce a huge volume of POME, EFB, and decanter cake. About 60 tonnes per hour mill operation would produce approximately 500 m3 of POME, 200 tonnes of EFB (dry weight), and about 50 tonnes of decanter cake (MBIC, 2019).

Production site of oil palm biomass.

EFB is one of the most abundant solid wastes in the palm oil processing industry with nearly 1.07 tonnes produced for every tonne of palm oil processed and has a higher potential for commercial exploitation (Kasim et al., 2017). Furthermore, up to 22–23 million tons of OPEFB is abundantly generated as a residue annually in Malaysia (Padzil et al., 2020). Traditionally, agro-waste such as EFB were disposed of through burning in an incinerator and the ash was recycled back in the oil palm plantation for the mulching process. This route of disposal caused severe air pollution with zero net energy recovery (Abdullah & Sulaiman, 2013). Acknowledging the potential harm to the environment, the Malaysian government had banned open burning practices in 2000 under the Environmental Quality Act 1974 (EQA, 1974). In response, the guidelines on good agricultural practice for the palm oil industry was introduced (EQA, 1974), which set up certain replanting processes in its effort to lay the groundwork for sustainable oil palm cultivation (Alam et al., 2015).

In order to further promote sustainable practice in the palm oil industry and preserve the environment, lignocellulosic biomass waste must be fully utilised and exploit its advantages. Previous research and commercialisation activities have revealed that OPEFB has been subjected to the production of a wide range of products, such as xylose (Rahman et al., 2007; Mardawati et al., 2014), biocompost (Siddiquee et al., 2017), hydrogen gas (Inayat et al., 2012; Sivasangar et al., 2015; Chong et al., 2013), biofuel (Ferreira et al., 2020; Brunerová et al., 2018; Ibrahim et al., 2015; Abdullah et al., 2011; Sudiyani et al., 2013), cellulase production (Harun et al., 2013; Kim et al., 2014; Sinjaroonsak et al., 2020), activated carbon (Osman et al., 2016; Hidayu et al., 2013; Wirasnita et al., 2015), biosyngas (Li & Chen, 2018), briquette (Nazari & Idroas, 2019; Amrullah et al., 2020), composite materials, such as the hybrid composite between OPEFB and sugarcane bagasse biomass for the development of thermal insulation in walls (Ramlee et al., 2019), hybrid composite of OPEFB reinforced with rice husk to make fibre board and certain furniture (Abdul Karim et al., 2020), composite between EFB fibre, polybutylene succinate (PBS), starch, and glycerol (Ayu et al., 2020), composite between chitosan (CS) and cellulose derived from OPEFB for the removal of cadmium ion in polluted water (Rahmi et al., 2017), and bioplastic composite. Some of these products are intermediates that are further processed into complete finished goods. Apart from that, the production of biopolymers from OPEFB have also been intensely studied for various application. Recent research from 2016 to 2021 have reported the production of biopolymers from the main building blocks of OPEFB for various beneficial applications, as shown in Table 2. BPE followed the Arrhenius thermal activated model Electrochemical stability up to ∼2.9 V The addition of nanocrystalline cellulose at an appropriate amount in the polymer blend improved the morphology, flexural strength, and gas barrier properties Solubility of curcumin increased up to 147 ± 5.66 mg/L as the CMC increased to 2% (w/v) in PBS medium Elongation at break of film composite increased after the addition of CMC The cumulative drug release significantly increased with increasing CMC content in the film The enzymatic hydrolysis of cellulose yielded 167.4 g/L of glucose The bacterial fermentation of glucose produced 23.5 g/L of succinic acid The synthesised polyester showed great extant of biodegradation Produced 91.90 ± 0.64% of cellulose from OPEFB extraction Slightly higher thermal stability of thin composite reported in Thermogravimetric Analysis (TGA) analysis OPEFB was hydrolysed and neutralised to produce reducing sugars (xylose and glucose) Optimisation of maximum PHB production; 0.3 g/100 mL of (NH4)2SO4 at 30 °C 20 g/L of reducing sugar produced 55.4% PHB Tensile strength and elongation at break of the film increased as the loading of hemicellulose up to 60 wt% The structure of CMC still impacted even with the addition of hemicellulose Thermal stability of CMC increased after the addition of hemicellulose FTIR result showed LiClO4 undergoes complexation with CMC and hemicellulose, which helps to achieve ionic conductivity properties Highest mechanical strength at 3 wt% of LiClO4 Highest ionic conductivity at 5 wt% of LiClO4 Water Contact Angle (WCA) value increased with TL-PS sample in which the presence of TCMS increased the hydrophobic characteristic Oil sorption capacity approximately 40–52% up to seven days Scanning Electron Microscope (SEM) imaging showed a rough surface area of TL-PS, thus, providing large surface area and oil retention ability The combination of lignin enhanced the UV-A blocking and other physical properties of the film at all concentrations Antioxidant activity against 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenged radical: IC50 value of 3.87 mg/mL The synthesis of the composite was to quench the radical produced by TiO2 (TiO2 usually added into the sunscreen to absorb UV light) Excessive lignin content showed no radical scavenging improvement and produced a darker colour composite, which is unpleasant to use in cosmetic products

Composition of OPEFB

Polymers produced

Method

Results

Application

Reference

Cellulose

Biopolymer Electrolyte (BPE) film based on carboxymethyl cellulose (CMC)

Solution casting using magnesium acetate salt

Electrochemical device (alternative for lithium batteries)

(Rani et al., 2021)

Bionanocomposite film, blending of nanocrystalline cellulose with polylactic acid (PLA)/poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV)

Solution casting

Packaging material

(Dasan et al., 2016)

Film composite of PLA/CMC from OPEFB/curcumin (the purpose of this study was to improve the release of curcumin under intestinal alkaline conditions)

Solvent casting

Drug delivery

(Gunathilake et al., 2020)

Biodegradable polyester using succinic acid derived from cellulose OPEFB

Enzymatic polymerisation using Lipase Novozyme 435 (Candida antartica)

Production of polyester, including PBS, poly(glycerol succinate) (PGSu), and poly(ethylene succinate) (PES)

(Pasma et al., 2019)

Polyethersulfone-cellulose composite thin film

Solution casting (18 wt% of polyethersulfone, 0.5 wt% of cellulose OPEFB, and 81.5 wt% of N-methyl-2-pyrrolidine)

Fuel cell, proton exchange membrane, and membrane distillation

(Amelia et al., 2021)

Hemicellulose

Biodegradable Polyhydroxybutyrate (PHB)

Acid hydrolysis process using Bacillus cereus suaeda B-001

Medical application

(Yustinah et al., 2019)

Incorporation of hemicellulose derived from OPEFB with pure CMC (H-CMC) for film production

Solution casting with different thickness range

Green packaging material

(Weerasooriya et al., 2020)

H-CMC blended with lithium perchlorate (LiClO4)

Solution casting (different content of LiClO4)

Ion conductive biopolymer with a future application suitable for medical application

(Weerasooriya et al., 2021)

Lignin

Lignin-coated polystyrene/ Trichloromethylsilane (TL-PS) absorbent

Chemical vapour deposition method to bind TL-PS with TCMS

Oil spill clean up

(Azhar et al., 2020)

CMC-lignin composite film derived from OPEFB

Solution casting (mixture of glycerol, CMC, and lignin solution)

Antioxidant and UV-blocking properties

(Haqiqi et al., 2021)

Lignin derived from OPEFB/titanium oxide (TiO2) composite

Lignin extracted via kraft

(KL/TiO2) and soda (SL/TiO2) pulpingThe method was reported by Ishibashi et al. (2000)

Radical scavengers in sunscreen formulation

(Ibrahim et al., 2019)

2.4 Chemical composition and structure of OPEFB

OPEFB fibre is composed of cellulose (C6H10O5)n, hemicellulose (C5H10O5)n, and lignin (C10H11O3.5) bound together in a complex matrix, making it a suitable raw material for the fermentative production of various valuable chemicals and bioproducts, such as biofuels, polymers, bioenergy, and chemical building blocks (Abdullah et al., 2016; Rame, 2018; Padzil et al., 2020). Apart from the three components, OPEFB fibre contains trace amounts of nitrogenous compounds, pectin, and ash. Table 3 summarises the chemical composition in OPEFB according to previous studies. As shown in Table 3, cellulose forms the bulk component of OPEFB fibres (51.2%), followed by lignin (37.32%) and hemicellulose (24.97%). The proximate analysis is an assay that quantifies the percentage of fixed carbon, ash content, and volatile matter in OPEFB, whereas the ultimate analysis determines the percentage of elements found in OPEFB (carbon, hydrogen, nitrogen, oxygen, sulphur, and others). Note: (%a): Weight percentage based on the dry basis; (%b): Weight percentage based on the dry and ash-free basis.

Component

References

Ferreira et al. (2020)

Idris et al. (2021)

Muryanto et al. (2015)

Karunakaran et al. (2020)

Chemical composition (%a)

Cellulose

41.37 ± 2.8

51.20

36.60

32.00

Hemicellulose

15.68 ± 5.1

20.30

24.97

24.40

Lignin

37.32 ± 3.3

25.40

26.53

34.90

Proximate analysis (%a)

Fixed carbon

10.45 ± 1.1

24.06

–

–

Ash content

4.14 ± 0.0

2.30

1.79

4.10

Volatile matter

81.49 ± 1.0

69.95

–

–

Ultimate analysis (%b)

Carbon

50.24 ± 0.5

42.71

–

48.60

Hydrogen

8.06 ± 0.2

6.23

–

6.60

Nitrogen

0.65 ± 0.1

0.56

–

0.60

Sulphur

0.62 ± 0.4

0.07

–

0.40

Oxygen

36.03 ± 1.1

50.44

–

43.80

Others

–

–

10.11

–

The proximate analysis in Table 3 also shows that OPEFB contains a high amount of volatile matter (81.49%), followed by fixed carbon (24.06%), and ash content (4.14%). The high percentage of volatile matter in OPEFB is due to the presence of cellulose and hemicellulose in the building blocks. This parameter is an essential component in biomass as the final product yield (liquid form) relies on a higher amount of volatile matter (Shrivastava et al., 2020). In addition, the percentage of fixed carbon (which depends on the amount of volatile matter) indicates the amount of heat that is generated when the EFB biomass is burned, while ash is the solid residue that remains after the combustion (Chang, 2014). Meanwhile, the ultimate analysis of OPEFB demonstrates carbon with the highest percentage (50.24%), followed by hydrogen (8.06%), nitrogen (0.65%), and sulphur (0.62%).

Similar to many other natural fibres, OPEFB fibres are naturally-occurring polymeric composites made up of rigid, crystalline cellulose microfibrils surrounded in a soft, amorphous matrix of hemicellulose and lignin (Hassan et al., 2010). Cellulose is the major structural component of plant cell walls containing polymeric d-glucose units linked to one another by β-(1 → 4)-glycosidic bonds at positions C1 and C4 (Dussan et al., 2014). Every monomer unit is corkscrewed at 180° with respect to its neighbours, and the repeating unit of this part is a dimer of glucose, known as cellobiose, in addition to the Degree of Polymerisation (DP) of cellulose that ranges from several hundred to over 10,000 monomers (González-Domínguez et al., 2021). The DP of cellulose chains varies with the source and treatment of the raw material (Klemm et al., 2005). Each terminus of cellulose polymer is chemically different: one end is a D-glucose unit in symmetry with an aldehyde group (hemiacetal unit, reducing end), while the other end contains a hydroxyl group (non-reducing end).

Furthermore, the cellulose chain contains three reactive hydroxyl groups in each monomeric unit of Anhydroglucose Unit (AGU). The hydroxyl groups, the oxygen atom on the d-glucopyranose ring, and the glycosidic linkage interact with each other within the chain or adjacent cellulose chain via intramolecular and intermolecular hydrogen bonds. The hydrogen bonds are responsible for the rigidity and crystallinity structure of cellulose (Heinze, 2016). The degree of crystallinity of naturally-occurring cellulose ranges between 40% and 90%, while the remaining region is amorphous. A highly ordered or crystallised cellulose exhibits less solubility and lower degradability. Usually, a Three-Dimensional (3-D) linear cellulose structure forms a crystalline region at highly oriented chains; while randomly oriented chains are referred to as amorphous. The amorphous regions are the main site for enzymatic hydrolysis that enable the penetration and adsorption of enzymes (Das, 2017).

Hemicellulose is a group of structurally diverse polysaccharides with an amorphous structure, well-hydrolysed, and lower DP than cellulose (∼50–300) (Fengel & Wegener, 1989). It is the second-most abundant lignocellulosic component in plants and consist of different five-carbon monosaccharides and six-carbon monosaccharides, such as xylans, mannans, and glucans (Brunner, 2014). The branched heteropolymer building blocks in hemicelluloses are pentoses (arabinose and xylose), hexoses (galactose, glucose, and mannose), and hexuronic acids (glucuronic acid). Furthermore, the nomenclature of hemicelluloses is principally determined by the most occurring sugar unit in the backbone. These hemicelluloses act as a physical barrier, thus, limiting cellulosic fibre accessibility. The removal of lignin during pre-treatment can improve the conversion of cellulose by increasing the accessibility of enzymes to cellulose (de Oliveira Santos et al., 2018).

In comparison to cellulose and hemicellulose, lignin is a complex hydrocarbon that contains both aliphatic and aromatic compounds, does not dissolve in most universal solvents, and cannot be broken down into monomer units (Fengel & Wegener, 1989). The characteristics of lignin include amorphous, hydrophobic, highly branched network and crosslinked 3-D structure that provides rigidity to the cell wall for mechanical support, facilitates the transport of water and nutrients, and protects plant cells against chemical and biological attack (Lu et al., 2017). As an amorphous thermoplastic material, lignin has a relatively high glass transition (around 90 °C) and melting temperature around 170 °C (Fengel & Wegener, 1989). Lignin consists of a phenolic polymer of phenylpropane units, such as sinapyl, p-coumaryl, and coniferyl alcohol that are attached to hemicellulose and cellulose through different linkages (Achyuthan et al., 2010). The large complex structure of lignin contains cross-linked phenolic polymers that cover and protect the internal layer of hemicellulose and cellulose.

Overall, both cellulose and hemicellulose are polysaccharides that can be converted into sugar monomers, which can be used as fermentation substrates for the synthesis of various products. Nevertheless, the conversion of lignocelluloses (cellulose and hemicellulose) directly into sugar monomer is challenging and not straightforward due to the complex lignin structure and high processing temperature (above 250 °C) (Bhaumik & Dhepe, 2016). Aside from lignin, the accessibility of cellulose is hindered by the hemicellulose structure. It was proposed that a minimum of 50% of hemicellulose should be removed to significantly increase the cellulose recovery (Agbor et al., 2011). Therefore, the pre-treatment of lignocellulosic materials is a vital step for a higher conversion rate, which usually compromise between maximising lignin and hemicellulose recovery during the separation process (e.g.: delignification) and maintaining the cellulose structure for further degradation into its monomer unit (sugar/glucose) during the hydrolysis process.

2.5 Pre-treatment methods of lignocellulosic biomass

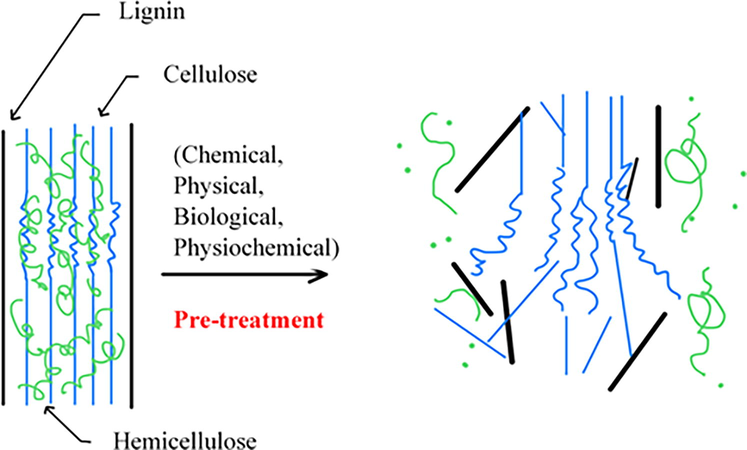

As previously stated, the lignocellulosic building blocks are recalcitrant to hydrolysis. Hence, pre-treatment is required to overcome this major bottleneck prior to the hydrolysis stage and enable the extraction of valuable products from the biomass (Kucharska et al., 2018). The main goal of pre-treatment of lignocellulosic biomass is to disrupt the complex or highly recalcitrant structure of the biomass (Baruah et al., 2018), as illustrated in Fig. 5 and make it accessible to enzymes (Brodeur et al., 2011). Major roles of pre-treatment on lignocellulosic biomass are listed as follows:

-

Remove or reduce the lignin structure in the lignocellulosic building blocks that prevent enzymes from reacting with the cellulose and hemicellulose (Islam et al., 2020; Chen et al., 2017);

-

Separate the cellulose and hemicellulose structure (Chen et al., 2017);

-

Decrease or remove the crystallinity of the cellulose structure and reduce the DP to increase the rate of hydrolysis process;

-

Increase the surface area and porosity of substrates (Abo et al., 2019); and

-

Remove the acetyl group that binds with hemicellulose via covalent ester bonds. Thus, will interfere with the degradation process (Bhatia et al., 2020).

- Disruption of lignocellulosic biomass structure due to pre-treatment process. Modified from Krishania et al. (2012).

Various pre-treatment approaches of lignocellulosic biomass have been reported, including physical, chemical, physiochemical, and biological methods or a combination of methods (Bhutto et al., 2017; Kumar et al., 2020). Despite the significant advantages, the pre-treatment of lignocellulose biomass has its demerits too, as presented in Table 4. As such, the majority of available pre-treatment methods fail to achieve the desired results, such as effective disruption of the total biomass structure and harsh reaction conditions (high temperature and/or high pressure). The selection of pre-treatment methods not only affects the efficiency and efficacy of the subsequent saccharification and fermentation process (Ren et al., 2020) but also affects the alteration structure of lignocellulosic biomass, as summarised in Table 5. An effective pre-treatment is also critical for optimal hydrolysis and downstream operations. According to Puligundla et al. (2016), the ideal lignocellulosic biomass pre-treatment should meet certain criteria, such as (1) minimise the requirement of energy and resource consumption, (2) inexpensive, (3) zero stream wastes produced, (4) zero or less generation of inhibitors, (5) promote high digestibility of cellulose, (6) low consumption of chemical during the pre-treatment process, (7) low sugar decomposition, and (8) promote cost-effective downstream processing. Sample size easily reduced and increased the specific surface area Decreased the cellulose crystallinity and particle size Additional pre-treatment (hot water or acid) is required to make this pre-treatment less energy-intensive Expensive pre-treatment Required low energy High shearing mechanical force to disintegrates biomass fibre into small size particle Expensive High cellulose and α-cellulose yield Complete separation of cellulose with punctures and pores on the surface Time-consuming High energy cost Low pre-treatment cost and short time processing High sugar recovery Low acid consumption Equipment damage from corrosion Formation of degradation by-products, such as furfural, which inhibit the fermentation process (for sugar recovery) Less effective in removing lignin compared to alkaline treatment Achieved high-extant removal of lignin and hemicellulose in a one-time process Increase the porosity and cellulose surface area The removal of lignin cannot be achieved completely, especially for ethanol organosolv treatment High energy consumption for organic solvent recovery Green solvent pre-treatment High energy efficiency due to low vapour pressure, emission profile, recyclability, and tuneable properties High viscosity of LI and highly cost operation Utilised at relatively low temperature and pressure, and can operate at ambient conditions Alkali conversion to irreversible salts, which may require further treatment Less effective to pre-treat highly recalcitrant biomass (eg: woody biomass) No chemical involvement Environmentally friendly Low energy input Require high pressure and high-temperature condition Incomplete degradation of lignin, thus making the biomass less digestible Inhibitors formation at high temperature Low temperature involved Suitable for large scale treatment due to the low-cost solvent used Minimising formation of degradation by product High energy needed due to the high involvement of water volume Production of solubilised products are high Green techniques and simple process Minimised down-stream process Enhances glucose yield effectively Size, type, origin, and composition of biomass greatly affect the pre-treatment under this condition Environmental-friendly and low energy needed Higher selectivity Most of the enzymes are not affected by the presence of inhibitors High-cost of enzyme and time-consuming process Improve the yield of fermentable sugars derived from the substrate Eliminates drawback (eg: metabolite repression) in single species treatment Cost-intensive Green, inexpensive, and no additional energy is needed Separate lignin effectively Slow processing for delignification, especially for large-scale sample Lost a part of cellulose and hemicellulose structure due to microorganism consumption + = Major effect; − = Minor effect; ND = Not determined; NA = Not applicable.

Type of pre-treatment

Advantages

Limitations

Reference

Physical

Mechanical (grinding and milling)

(Zhou et al., 2012)

Extrusion

(Pérez et al., 2002)

Ultrasonic

(Abdullah et al., 2016)

Chemical

Dilute acid hydrolysis

(Loow et al., 2016)

Organosolv

(Zhao et al., 2017)

Ionic Liquid (LI)

(Halder et al., 2019)

Alkaline

(Loow et al., 2016)

Physiochemical

Steam explosion (autohydrolysis)

(Agbor et al., 2011)

Liquid hot water

(Agbor et al., 2011)

Supercritical CO2

(Badgujar, 2021)

Biological

Enzymatic

(Koupaie et al., 2019)

Microbial consortium

(Ravindran & Jaiswal, 2016)

Fungal species (White rot fungi)

(Tian et al., 2012)

Combined

–

More effective than other pre-treatment depending on the operational combined methodology

–

?

Characteristic

Physical

Chemical

Physiochemical

Biological

Removal of lignin

NA

+

–

+ (selective)

Alteration of lignin structure

NA

+

+

NA

Increases accessible surface area

+

+

+

Decreases cellulose crystallinity and increases porosity

+

+

ND

NA

Hemicellulose solubilisation

NA

+

+

+

Presence of inhibitors (formation of by-product degradation)

NA

+

–

ND

Increases enzymatic digestibility

+

+

+

+

Different pre-treatments utilise different mechanisms to increase substrate digestibility. Nevertheless, the increase in cellulose accessibility is caused by the changes in chemical compositions in conjunction with the changes in the chemical structure (Zhao et al., 2012). The conventional chemical pre-treatment method, which employs acids and bases, is thought to be a low-cost single-step approach. However, current research has stated that by-products formed during chemical pre-treatment of lignocellulosic biomass must be purified and reused as value-added products (Kasmin et al., 2020). Most of these by-products, such as weak acids, phenolics, and furan, exhibit inhibitory effects on microbes, which require further detoxification steps before proceeding with the fermenting hydrolysate stage (Bhatia et al., 2020). Since the single-step pre-treatment method is not always effective, the combined pre-treatment methods have been recently considered as a promising approach to minimise the operational process and production of undesirable inhibitors (Kumar & Sharma, 2017).

The sugar recovery performance via the combined chemical (organosolv) and biological (enzymatic) pre-treatment of OPEFB biomass is summarised in Table 6. The selection of these combined method for OPEFB pre-treatment were based on the sugar yield as compared to others pre-treatment. The combination produced high hydrolysate sugar yield that can be further converted into monomers via the fermentation process, thus, producing biopolymeric high-end valuable products. In a study, a high yield of sugar has been produced by using organoslov and enzymatic hydrolysis method which is 696.92 mg/g (Tang et al. 2018) as can be observed in Table 6 compared to ionic liquid method which is 510.3 mg/g (Liu et al. 2021). Basically, organosolv pre-treatment is a delignification process involving organic solvents, such as ethanol, methanol, acetone, and ethylene glycol, or a mixture of organic solvent and water prior to the enzymatic hydrolysis of the cellulose fraction. The separation of lignin before the enzymatic hydrolysis of cellulose fraction could minimise the usage of the enzyme, thus, reducing the cost. In addition to improve the cellulose fibre accessibility, removing lignin beforehand reduces cellulase enzyme absorption to the lignin structure and increase the efficiency of enzymatic hydrolysis (Norrrahim et al., 2021).

Year

Initial pre-treatment parameters

Further pre-treatment parameters

Key findings

Reference

2021

Ultrasound- assisted peracetic acid (organosolv) and alkaline peroxide

(i) Peracetic acid

T = 35 °C

t = 3 hrs *(modified), 9 hrs (non-modified)

S/L = 1:20

Ultrasound = 53 kHz, 90 W

(ii) Alkaline peroxide

T = 35 °C

t = 10 hrs *(modified), 12 hrs (non-modified)

S/L = 1:20

Ultrasound = 53 kHz, 90 W

Enzymatic hydrolysis

Cellulase enzyme from Aspergillus niger (29,000 unit/g activity)

T = 50 °C

t = 48 hrs

rpm = 150Non-modified pre-treatment: cellulose (55.66% w/w), hemicellulose (27.29% w/w), and lignin (17.05% w/w). Modified pre-treatment: cellulose

(68.40% w/w), hemicellulose (18.33% w/w), and lignin (13.27% w/w)

8.25% increase of reducing sugar production in enzymatic hydrolysis of OPEFB pre-treated by modified pre-tratment compared to non-modified

Optimisation of enzymatic hydrolysis

(sugar production of 17.98 g/L with hydrolysis yield of 93.31%): 5 g/L of cellulase concentration, 6 hrs(Putri et al., 2021)

2020

Organosolv (C2H5OH)

T = 210 °C

t = 90 min

Conc. = 50%

S/L = 1:10

Washed lignin using black liquor

Enzymatic hydrolysis

Cellic® Ctec3 enzyme

T = 50 °C

t = 18 hrs

rpm = 125

Further action: The fractionation of biomass used as cultivation media for fungal growth0.62 ± 0.07 g/g of glucose for the hydrolysate cellulose fraction, 0.41 ± 0.02 g/g of fermentable sugar for the hydrolysate cellulose-hemicellulose fraction, and 0.61 ± 0.13 g/g of fermentable sugars for the hydrolysate hemicellulose fraction

(Marhendraswari et al., 2020)

2020

Acid-catalysed organosolv (C2H5OH)

T = 210 °C

t = 90 min

Conc. = 50% (v/v)

Catalyst = 0.07% sulphuric acid) H2SO4

S/L = 1:10

Enzymatic hydrolysis

Cellic® Ctec3 enzyme

T = 50 °C

t = 24 hrs74% and 80% of glucan purity and recovery, respectively

71% and 65% of lignin purity and recovery, respectively(Mondylaksita et al., 2020)

2020

Ultrasonic- assisted organosolv

T = 48.2 °C

t = 30 min

Sonication power = 192.5 W

Conc. = 20–60%

Catalyst = Sodium hydroxide (NaOH)

Enzymatic saccharificationCellulase

(Onozuka R-10)

T = 50 °C

t = 48 hrs44.4% of cellulose, 23.0%

of hemicellulose, and 23.2% of lignin

7.12 g/L of reducing sugar obtained from 356 mg/g of biomass(Lee et al., 2020)

2019

Organosolv (C2H5OH)

T = 120 °C

t = 60 min

Conc. = 80%

Catalyst = 0.2% w/w

Post treatment: 2% hydrogen peroxide (H2O2), 50 °C, 4 hrs

Enzymatic hydrolysis

Celluclast and Novozyme 188

T = 40 °C

t = 48 hrs

rpm = 145

91.7 ± 0.5% of glucose from cellulose OPEFB

36.5 g/L of glucose yield(Pasma et al., 2019)

2019

Organosolv (C2H5OH)

T = 120 °C

t = 60 min

Conc. = 55%

S/L = 1:10

Enzymatic hydrolysis

Cellulase Trichoderma reesi ATCC 26,921

T = 90 °C

t = 48 hrs152.51 mg/L of sugar yield

(Nurfahmi et al., 2019)

2018

a) Acetic acid-steam in pressurised chamber

Conc. = 5% v/v

T = 110 °C

t = 30 min

Enzymatic saccharification

Mixed cellulase and hemicellulose enzyme ratio of Cellic Ctec 2: Cellic Htec 2

(CC:CH)

Ratio = 6.9:3.1

T = 50 °C

t = 12–48 hrs

Buffer = 0.05 M citrate at pH 4.8699.47 ± 35.88 mg/g of xylan yield and 695.52 ± 37.7 mg/g of glucan yield

Total sugar recovery of 696.92 mg sugar/g carbohydrate

(Tang et al., 2018)

b) Acetic acid-glycerol

Conc. = 50% v/v acetic acid, 80% v/v glycerol

Solvent ratio = 97:3

T = 120 °C

t = 3 hrs

Enzymatic saccharificationMixed cellulolytic enzyme of Celluclast 1.5 L and Novozyme 188

(C:N)

Ratio = 7.8:2.2

T = 50 °C

t = 12–48 hrs

Buffer = 0.05 M citrate at pH 4.8373.63 ± 13.75 mg/g xylan yield and

651.57 ± 3.20 mg/g glucan yield

Total sugar recovery of 563.34 mg sugars/g carbohydrate

2014

Mild organosolv (C2H5OH)

T = 70 °C

t = 6 hrs

Conc. = 70%

S/L = 1:20

Post treatment: 4% H2O2, 45 °C, 16 hrs

Enzymatic hydrolysisCellulase

(T. reesei

RUT-C30 ATCC 56765)

t = 72 hrsOrganosolv pre-treatment reduced hemicellulose (24.3–18.6%) and lignin

(35.2–22.1%) but increased cellulose (40.5–59.3%)

36.01 g/L of glucose and 2.55 g/L of xylose recovered(Zhu et al., 2014)

2014

Formiline treatmet

(formic acid)

T = 100.8 °C (normal boiling point)

t = 1.5 hrs

Conc. = 58–88%

Pressure = atm

Post treatment: Deformylated with 2% lime (Ca(OH)2), 120 °C, 1 hr

Enzymatic hydrolysis

Cellulase and β-glucosidase

T = 50 ± 0.5 °C

t = 120 hrs

rpm = 130

Buffer = 0.1 M sodium acetate at pH 4.8The delignification process increased to 93.9% and increased solubilisation of xylan (up to 90%) and glucan (up to 13.72%) when the concentration of formic acid was 88%

Over 90% of polysaccharide was converted after digested by enzyme loading comprising 15FPU

(cellulase) + 10 CBU (β-glucosidase)/g solid for 48 hrs(Cui et al., 2014)

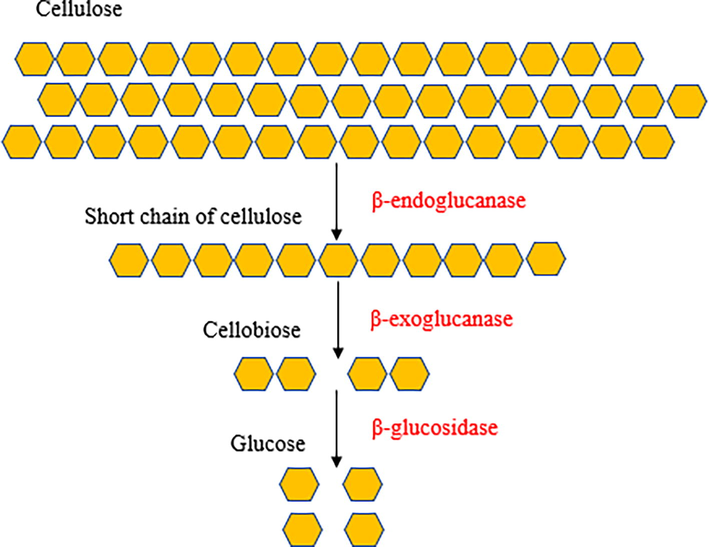

The goal of enzymatic hydrolysis is to liberate simple soluble sugars from crystalline cellulose and hemicellulose (Kucharska et al., 2018). Highly specific enzymes, such as cellulase and hemicellulose, are utilised in the enzymatic hydrolysis process to degrade the cellulose and hemicellulose building blocks in the lignocellulosic biomass. The mixture components of cellulase comprising endoglucanase, exoglucanase, and β-glucosidase hydrolyse cellobiose to produce glucose prior to the hydrolysis of cellulose into simple sugar (glucose). Meanwhile, xylanase and β-xylosidase enzymes attack the hemicellulose substrate to produce xylose monomers (Muktham et al., 2016). The schematic representation of cellulase enzymes reaction over the cellulose structure is shown in Fig. 6.

Schematic flow of cellulase enzymes over the degradation of the cellulose structure.

It was previously reported that the enzyme Cellic CTec2 (a commercial cellulase formulation) was used in the enzymatic hydrolysis of OPEFB biomass prior to the fermentation using Saccharomyces cerevisiae WLP099 to produce a valuable product (bioethanol). The highest sugar yield recorded was 76.6 ± 0.9% (Alfaro & Arias, 2020). In another study, the use of optimised parameters (temperature, kinetic parameters, and thermal deactivation of enzyme) was found to reduce utilisation of endoglucanase (for the hydrolysis of internal β-1,4-glycosidic bonds) and exoglucanase (for the removal of monomers and dimers or cellobiose from the end of the glucose chain) with up to 77.8% maximised glucose yield and 22.2% time-reduction (Fenila & Shastri, 2016). In previous studies reported the relationship between batch time, substrate concentration and temperature were studied in order to reach optimum parameter. The result showed when reducing batch time increased glucose concentration. For the batch time at 24 h, the final glucose concentration increased by 3.2%. Meanwhile, the sugar yield up to a temperature of 50 °C (Fenila & Shastri 2016, Kadam et al. 2004). Thus, optimization of kinetic parameters will affect the yield of sugar production. In addition, a recent study by Masran et al. (2020) reported that the combination between the enzyme laccase and cellulase successfully produced 10.9 g/L of reducing sugars. In short, the resulting mono-sugars (or glucose) from the pre-treatment of lignocellulosic biomass is a crucial carbon source for many fermenting organisms to produce a diverse range of valuable products that are applicable in the food, pharmaceutical, and biofuels industries. Organic acids (lactic, citric, acetic, succinic), glycerol, sorbitol, xylitol, 2,3-butylene glycol, fibre additives, and hydrogels are the most important value-added products (Mussatto & Teixeira, 2010). Nevertheless, the potential application of OPEFB biomass in biomedical studies is an exciting and growing area of research that is further discussed in the following section.

3 Osteoarthritis and the promising application of oil palm empty fruit bunch-derived scaffolding for bone tissue engineering treatment

3.1 Risk factors and treatment options of Osteoarthritis

Significant evidence indicates that OA is caused by the degradation or breakdown of articular cartilage in joints due to continuous inflammation and irregular joint loading that triggers the local release of inflammatory cytokines, which blocks the production of collagen type II and aggrecan (a major component of cartilage) (Harris & Crawford, 2015). Although OA is the most common musculoskeletal condition worldwide with substantial health, economic, and social effects, research efforts so far have not been able to define its exact aetiology. Most experts agree that OA represents a complex degenerative joint disease resulting from the interaction of numerous genetic and environmental factors, including an ageing population, tissue and cellular damage, sedentary lifestyle (obesity or overweight), overuse of joints, and genetic influence (Vina & Kwoh, 2018; O’Neill et al., 2018; Palazzo et al., 2016).

A recent study by Ashfaq et al. (2020) shows that out of 100 patients tested (62% female and 32% male), 61% of patients suffer from OA due to overweight or obesity with 35% of them were categorised as overweight with a BMI of 25–29.9 mg/m2 and the other 26% with a BMI of more than 30 mg/m2. The study concluded that female patients were more prone to developing symptomatic OA and suffered from OA compared to men based on joint pain, stiffness, and functionality. According to a cross-sectional and cohort study by Tschon et al. (2021) that analysed 268,956 OA patients worldwide (based on research papers from PubMed, Science Direct, and Web of Knowledge from 2010 to 2020), 31% of the patients were men and 61% were women. This study shows that in comparison to men, women appear to use more healthcare services, thus, have a higher occurrence of OA, clinical pain and inflammation, lower cartilage volume, physical difficulty, and smaller joint characteristics.

There is still no cure to effectively treat OA. So far, the main goal is to provide early treatment to reduce the pain and stiffness from OA, which include weight loss programmes, assistive devices, pharmacotherapy, Nonsteroidal anti-Inflammatory Drugs (NSAIDs), and intra-articular injections of glucocorticoid or hyaluronic acid (HA) (Shah et al., 2018). If the pain and symptoms persist, further treatment will be applied, which focuses on maintaining the physical function of the joint (Abramoff and Caldera, 2020). Under severe OA conditions, total joint replacement has been used as a last resort (Shah et al., 2018). Nevertheless, experts have proposed numerous approaches in search of a solution to treat OA. Among the focus of the OA therapy is via clinical phenotypes (observable traits) and specific treatment, such as drugs targeting treatment (eg: targeting pathway of cartilage anabolism and catabolism), regenerative therapies with stem cells (a promising study for OA management), therapeutics targeting of the OA subchondral bone (eg: bisphosphonates, drugs targeting bone cells, and vitamin D3 supplement), and targeting inflammatory mediators and pathways (eg: anti-cytokine, immune system target, and gene therapies). However, none of these therapies have shown significant OA reduction or successfully prevent patients from undergoing joint replacement in the advanced stage (Grässel et al., 2020).

The ability to naturally heal a degenerated articular cartilage back to its normal condition after a severe injury is limited (Musumeci et al., 2014). The latest ‘gold standard’ in bone generation/graft is the use of autografts (harvesting bone tissue from the same individual), where this approach integrates faster and completely, as well as allografts (transplanting a donor bone tissue from a different individual or a cadaver) (De Witte et al., 2018), which is used to treat severe OA patients who failed to respond to earlier treatment attempts, as mentioned earlier. However, the potential use of autografts is hampered by its limitations and disadvantages, which include costly operation, donor site morbidity, limited grafting material, insufficient source, longer surgical time, and high surgical risk, such as inflammation or infection (Wu et al., 2014). In addition, allografts and xenografts (a graft tissue taken from a donor of one species and grafted into a recipient of another species) may raise other concerns, in particular possible viral transmission, bacterial infection, and immune rejection in the recipient body (Delloye et al., 2007). This situation has created a platform for the thriving development of bone tissue regeneration approaches, such as bone TE, which facilitates cartilage repair and cartilage regeneration.

TE is an interdisciplinary field that applies engineering and science to create functional 3-D tissues comprising human cells, scaffolds, and bioactive molecules for bone regeneration. The ultimate goal of TE is to regenerate damaged tissues, instead of replacing them, through the development of biological substitutes that restore, maintain, or improve tissue function using the patient’s cells (Castells-Sala et al., 2013). The bone defect site (defect-related) and health status of the patient (patient-related) are important parameters that determine the structural and functional material properties to assure the usability of the selected technique. The characteristics of a healthy bone tissue that are crucial to its function also dictate the design of materials for bone TE. After taking into account the clinical criteria, the selection of the bone TE approach depends on whether the material is supposed to facilitate the production of new bones at the defect site (in vivo) or utilised to manufacture bone-like tissue (in vitro) before implanting the developed tissue into the body (Koons et al., 2020).

The scaffold provides a support matrix for the cell attachment while simultaneously permitting the newly forming tissues to function during the period of regeneration, and should be self-degradable when the tissues have matured (Chan & Leong, 2008). A successful scaffold design must fulfil the following properties: (i) high biocompatibility that mimics the natural Extracellular Matrix (ECM) in the newly-forming tissues to support cell attachment, differentiation, and proliferation (Wu et al., 2014); (ii) undergoes non-toxic biodegradation via safe substitution; (iii) sufficient mechanical properties to bear the weight of the growing tissues and prevent any potential collapse; (iv) present a high degree of porosity and pore size that is essential for proper cell growth and penetration, nutrient and waste flow, and vascularisation (O'brien, 2011); and (v) spatial controlled patterns on the surface of the scaffold for bioactive molecules or drugs delivery (Dang et al., 2018; Samorezov & Alsberg, 2015).

Scaffolds can be fabricated through various methods, including solvent casting and particulate leaching, gas foaming, freeze-drying, phase separation, laser sintering, stereolithography, 3-D printing, fibre bonding, and electrospinning (Chan & Leong, 2008). A successful scaffold for bone TE applications must have both osteoconductive and osteoinductive properties to enable the formation of ectopic bone. Osteoconduction refers to the process where the scaffolding provides an inward migration of cellular elements, such as mesenchymal cells, osteoblasts, osteoclast, and vasculature, to encourage bone formation; whereas the term osteoinduction is defined as the stimulation of osteoprogenitor cells to develop into bone-forming cell lineage (Nandi et al., 2010; Albrektsson & Johansson, 2001). The following section describes the development of biopolymer-based scaffolds for the treatment of OA.

3.2 Current studies on treating Osteoarthritis using biopolymer materials in bone tissue engineering

Polymers have long been the preferred materials for bone deformities and in the field of TE. Biopolymers are suitable materials for medical field applications, such as drug delivery systems, TE, surgical implantation, and wound healing products, due to their excellent properties, including non-toxic degradation end products, biocompatibility, low antigenicity, able to support cell growth and proliferation, able to form a complex structure with appropriate porosity, and favourable mechanical properties (strength and modulus) (Tan et al., 2015). For instance, bone tissue regeneration procedures using implanted materials made from biomaterial scaffolds do not only provide mechanical support and improve the skeletal tissue regeneration outcome but also enhance the biodegradation of the material (Zhang et al., 2017). Despite that such scaffolds are typically mechanically weaker for load-bearing compared to natural bone, biomaterials offer biological, mechanical, and structural stability for cell growth and differentiation, and are eventually designed to be replaced by the regenerated tissues with mechanical properties that are similar to that of natural bone (Feng et al., 2018). The loss of mechanical qualities of the bio-based scaffold is acceptable as long as the system's overall function is maintained (Koons et al., 2020).

The function of incorporated cells, as well as the patient's tissue, is influenced by the properties of the biopolymer and the scaffold design (Yoon & Fisher, 2009). In view of this, an ideal biodegradable material for a scaffold design should be non-toxic, easily metabolised and cleared out from the body (Daniel, 2021) so that it can function properly and achieve the desired goal of bone regeneration. In addition, the features of a polymer, such as its components, fabrication, and structure, have a significant impact on its biodegradation. The rate of degradation is also an important feature that needs to be considered during the fabrication of polymeric scaffolds. Furthermore, polymeric scaffolds that degrade correspondingly with the rate of tissue healing are more preferable (Yoon and Fisher, 2009). Scaffold materials can be divided into several categories based on their production and application. The scaffold may be natural or synthetic, depending on the source of the material (Prasadh & Wong, 2018). Both natural polymers, such as collagen, gelatine, silk, agarose, HA, alginate, and CS, and synthetic polymers, such as poly(glycolic acid) (PGA), Polylactic acid (PLA), poly(lactic-co-glycolic acid) (PLGA), poly ε-caprolactone, polyurethane, polycarbonate urethane, polyvinyl acetate, and polyethylene oxide (PEO), have been utilised in past studies as primary materials to fabricate bone scaffold (Li et al., 2021).

Previously, Huang et al. (2019) reported in vitro (degradation assay) and in vivo (osteogenesis and scaffold degradation) studies using polymeric composite scaffolds, which composed of three different polymers: PLGA, polycaprolactone (PCL), and polyamide 66 (PA66), and inorganic nano-hydroxyapatite (n-HA). The degradation of n-HA/PLGA recorded the fastest degradation rate (after 12 weeks) with weight loss from 100% to 87.66 ± 1.46% in the first 12 weeks and more rapidly to 20.39 ± 7.76% for another 12 weeks, followed by a slight degradation for the n-HA/PCL and no degradation for the n-HA/PA66 (after 24 weeks). For in vivo study, the results showed that the rapid degradation of the n-HA/PLGA scaffold, which initially achieved a greater formation of new bone in three months, caused the scaffold to lose structural integrity, resulting in a fall in bone volume after three months. Hence, the study demonstrated that the ideal characteristic of a scaffold to repair bone defects is the ability to maintain its structural integrity until the completion of the bone construction.

Meanwhile, a study by Remya et al. (2018) showed that the incorporation of PCL and water-soluble PEO via in vitro hydrolytic studies using PBS increased the weight loss as the volume of PEO increased to a 50:50 ratio of PCL and PEO after one month. In addition, the SEM micrograph revealed the degradation effects, as indicated by the presence of rupture and thinning, and the formation of pores on the fibre surface due to the incorporation of PEO. Moreover, the combination of PLA-co-trimethylene carbonate and natural polymer CS (PLA-TMC/CS) was reported to achieve a substantial scaffold degradation via an increased mass loss after four months of application for 15% and 20% incorporated CS polymer with PLA-TMC (Hu et al., 2020).

Another advantage of natural and synthetic polymers is that they can be derived from the ECM, thus, ensuring excellent biocompatibility, low toxicity release, and improved control of the physical properties (Aizad et al., 2021). A summary of the fabrication of natural and synthetic biopolymer scaffolds and their characteristics is presented in Table 7. Interestingly, biopolymer/biopolymer scaffolds can be fabricated from a mix of natural-natural, synthetic-synthetic, and natural-synthetic polymers to provide an ideal strength and toughness, and also enhance the properties of the scaffold compared to single-material scaffolds, as shown in Table 7. Several types of biopolymer from oil palm biomass residue have been produced such as OPEFB-carboxymethyl cellulose (CMC)/ chitosan (CS)/hydroxylapatite (HA) and filaments of PHBV and bleached fibres of palm residue (BFPR) which have high mechanical properties, biocompatibility and non toxic as described in Table 7. Other than that, previous work has reported the application of biopolymers from OPEFB as a biomedical material. Cellulose phosphate derived from OPEFB (OPEFB-CP) act as reinforcement to glass materials in fabricating good and flexible scaffold composite materials approached for bone scaffold. A 3-dimensional scaffold composite material consist of the CP and glass material was produced by using sol–gel technique. The results obtained indicated that the OPEFB-CP is non-cytotoxic in vitro, biocompatibility after 72 h exposure with an IC-50 value 45 mg/mL and proliferation rate up to 8 days with no change in cells morphology below the IC-50 concentration. Moreover, the results also showed that apatite formation was observed on OPEFB-CP surfaces after 30 days in Simulated Body Fluid (SBF with Ca:P ratio of 1.85) (Yusup et al. 2013). The polymer produced from lignocellulosic biomass, as discussed in the earlier section of this paper, can be used as biopolymer materials in TE to treat OA and is discussed further in the next section. Note: NA = Not Available.

Composition of scaffold

Fabrication technique

Degradation and compatibility rate

Outcome

Reference

Natural

Hyaluronic acid (HA)-collagen

Emulsion freeze-drying

The rate of degradation decreased as the concentration of HA and collagen increased

Compatibility rate: NALoaded with prednisolone as an anti-inflammatory agent

Pore size

(20–200 µm)

Mechanical properties increased as the concentration of HA and collagen increased: compression test (54.77 ± 0.31 kPa) after 4 days of water uptake (more than 1200%)(Mohammadi et al., 2018)

Silk Fibroin-Chitosan (SF/CS)

Biphasic scaffold (Glued silk fibroin film to porous silk fibroin/chitosan sponge using silk solution)

Degradation using lysozyme showed that the degradation rate increased as chitosan increased (SF/CS = 30:70)

Compatibility rate: NAMechanical properties: compressive strength (stress at maximum load) decreased as the percentage of chitosan increased

(Panjapheree et al., 2018)

Synthetic

PLGA- Mesoporous Silica Nanoparticles

(PLGA/MSNs)Low-temperature Deposition Manufacturing (LDM)

3-D printingNA

Mean pore size of scaffold:Big

(431 ± 32 μm), small (8 ± 2 μm)

The incorporation of MSNs improved the mechanical properties

(25.9 ± 1.3 MPa) and cell proliferation of scaffold(Cai et al., 2021)

Poly(3-hydroxybutyrate) (PHB)/poly(3-

hydroxyoctanoate)

Ratio examined = 1:0.25, 1:0.43, 1:0.67, and 1:1Electrospinning

Degradation rate showed higher molecular weight loss after one month compared to four months (for all ratio scaffold) and increasing amount P(3HO) reduced the degradation rate

Biocompatibility rate:Scaffolds (1:0.25, 1:0.43) showed a high degree of cell viability

(∼up to 98%) and produced hyaline-like cartilage matrix using human articular chondrocytes culturesScaffold at a ratio of 1:0.25 resembled the collagen fibrillar meshwork of the actual cartilage and matched the rigidity of the actual articular cartilage

(Ching et al., 2016)

Polymer from Oil Palm Biomass Residue

OPEFB-carboxymethyl cellulose (CMC)/ chitosan (CS)/hydroxylapatite

(HA)Co-solution and lyophilisation

NA

Mechanical properties: This scaffold had compressive elastic moduli in the range of 4–40 kPa

Porosity: All composites fabricated have interconnected pores and were suitable for bone ingrowth because all of them have minimum allowable pore size for regeneration of mineralised bone(Eliza and Shahruddin, 2018)

Filaments of PHBV and bleached fibres of palm residue (BFPR)

3-D printing

Degradation rate: NA

Biocompatibility rate: Cell viability of L929 cell above 95% for all systems evaluated (suitable for application in humans)

Non-toxicThe addition of BPFR to PHBV biopolymers slightly increased the nano hardness

The addition of BFPR

(above 5%) to the biopolymer improved the surface wettability and for fractions (great for cell adhesion process)(Zanini et al., 2021)

3.3 Injectable scaffold using polymeric biomaterials in bone tissue engineering