Translate this page into:

The impact of thermal extraction on the quality of Phyllanthus emblica Linn. fruit: A systematic study based on compositional changes

⁎Corresponding authors. hanliyx@163.com (Li Han), zhangdingkun@cdutcm.edu.cn (Dingkun Zhang), linjunzhi@cdutcm.edu.cn (Junzhi Lin)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

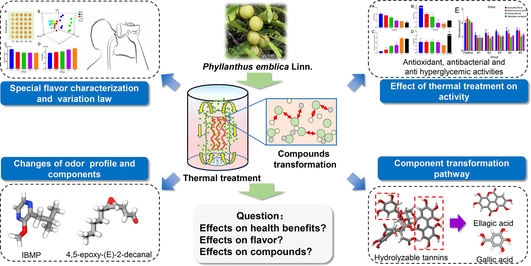

Phyllanthus emblica (PE) is a well-known tropical crop with a distinct flavor and several health advantages. From the standpoint of the transformation of volatile and nonvolatile components, the purpose of this paper is to investigate the impact of heat extraction on the flavor attributes and biological activity of PE. According to studies, thermal extraction can greatly enhance the amount of the molecule 4,5-epoxy-(E)-2-decanal with a green odor while removing offensive scents like 2-isobutyl-3-methoxy pyrazine. Temporal dominant description evaluation found that with the extension of thermal extraction time, the five flavors of PE are enhanced. According to high-resolution mass spectrometry studies, the primary reaction processes during thermal extraction were the hydrolysis and condensation of tannin and flavonoid glycosidic bonds. The main core groups of compound transformation were galloyl and hexahydroxydibenzoyl (HHDP), which led to the final product gallic acid and ellagic acid were significantly increased. Finally, it was found that thermal extraction can significantly enhance the antioxidant and antibacterial activities of PE.

Keywords

Phyllanthus emblica

Thermal extraction

Quality

1 Introduction

The fruit of Phyllanthus emblica Linn. (PE), which is a popular fruit tree belonging to the Phyllanthaceae family widely distributed in tropical and subtropical countries, such as India, Southwest China, Vietnam, Thailand and Indonesia, with thousands of years of edible history. In many Asian regions, PE is a chief source crop of vitamin C and minerals (Variya et al., 2016). As a fruit, its distinctive aftertaste sweetness and sour flavor are its most distinguishing flavor traits. These flavors can alleviate dry mouth and pharyngeal discomfort by providing long-lasting comfort to the tongue after a brief sour and astringent taste (Huang et al., 2021). Polyphenols, flavonoids, and amino acids are also abundant in PE. Particularly, polyphenols can make up as much as 33 % of the dry weight of PE (Avula et al., 2013). It has excellent antioxidant(Jhaumeer Laulloo et al., 2018) properties as well as anti-inflammatory, anti-diabetic, antibacterial, and anti-tumor effects due to the abundance of phenolic hydroxyl groups in it (Huang et al., 2021). PE is one of the three plants that are recommended by the WHO for planting internationally because of its distinctive flavor, abundant nutritional value, and exceptional efficacy. PE is currently widely employed in the production of dietary supplements, foods, pharmaceuticals, beverages, etc. due to its potent health advantages and distinctive flavor.

One of the crucial processes in the industrial processing of PE is thermal extraction. The PE extracting solution (PES) can be directly dried as PE extract (using microwave or spray drying), which can be employed as a step in the manufacturing and processing process. Therefore, PES will experience a thermal treatment process throughout the industrial extraction, drying, or sterilizing stages. The final product's flavor and activity may substantially depending on the process's time and temperature. Considering that PES is a common polyphenol solution (Yang and Liu 2014), PES's chemical reaction can be split into enzymatic and non-enzymatic reactions (thermal conversion), although thermal extraction inactivates the enzyme. The Arrhenius equation states that temperature is the primary determinant of a non-enzymatic reaction's outcome (Huang et al., 2019). Previous studies(Huang et al., 2019) discovered that polyphenols can primarily experience hydrolysis, oxidation, polymerization, and other reactions during the extraction process, which have a significant impact on their appearance, flavor, and activity. For instance, when heating tea soup, the change in appearance and flavor is more noticeable the higher the temperature and the longer the heating time (Zhu et al., 2020). Alcohol and coffee, both popular beverages, have similar reports (Li and Sun 2019). Some non-thermal extraction techniques, like ultrasonic, high hydrostatic pressure, pulsed electric fields, and non-thermal plasma, have recently gained popularity in the quest for authentic flavor and energy conservation. The flavor and biological activity of natural products are greatly influenced by the various extraction techniques. However, it has not been reported how different extraction techniques affect PES's flavor, taste, and bioactivity, and it is unclear how components transform during thermal extraction, which is a pressing issue that needs to be looked into.

To address the aforementioned issues, a rapid sensory evaluation research methodology for PES was established in this paper based on temporal dominant description taste evaluation and HS-SPME/GC-QQQ-MS/MS odor analysis technology. Additionally, the effects of the thermal extraction process on flavor, appearance, and physical and chemical properties were systematically investigated. Secondly, the primary difference indicators before and after heat extraction were discovered, and the primary transformation components and transformation pathways were hypothesized and confirmed based on multivariate statistical analysis. Finally, the component-activity correlation analysis method was utilized to uncover its quality markers after studying the transition laws of PES composition, flavor, taste, and activity. This is important for the processing and quality assessment of PES. In short, the purpose of this paper is to investigate the flavor and activity of PE after thermal processing, such as extraction, drying, or sterilization. We also hope that this study will serve as a guide for PE extraction and preparation in the pharmaceutical, food, and beverage, and other industries.

2 Materials and methods

2.1 Ethics statement

Volunteers were given written informed consent regarding the purpose of the study and their right to keep information confidential. Informed written consent was obtained from all participants.

2.2 Materials and chemicals

Milli Q water purification system (Millipore, Bedford, MA, USA). HPLC-grade methanol Fisher Chemical (Fisher Chemical, Pittsburg, PA, USA). HPLC-grade formic acid, Anhydrous Ethanol (Analytical purity), Vitamin C (Chengdu KeLong Chemical Factory, Chengdu, China). DPPH free radical scavenging ability test kit, ABTS buffer solution (Solaribio biotechnology Co., ltd. Beijing, China), α-Glucosidase (Sigma, USA), 4-Nitrophenyl-β-d-glucopyranoside (PNPG, Sigma, USA) Acarbose (Bayer, Germany). Standards of Citric acid, mucinous acid, malic acid Gallic acid (GA, No. CHB201131), Epicatechin gallate (ECG, No. CHB-B-081), Quercetin(Q, No. CHB-H-040), Corilagin (CR, No. CHB-K-004), Gallocatechin (GC, No.4051109), Catechin (C, No.14051508), Epigallocatechin gallate (EGCG, No.14121608), Gallocatechin gallate (GCG, No.14102009), Ellagic acid (EA, No. CHB-R-039), Chebulagic acid (CLA No. CHB-H-114), Chebulic acid (CA No. CHB-H-140), Chebulinic acid (CBA No. CHB-H-018) were purchased from Chengdu Biopurify Phytochemicals ltd. (Chengdu, China). The purity of the twelve standards was each above 98.0 %.

2.3 Preparation of sample solution

Take an appropriate amount of 6 batches of PE dried fruits (batch number: 190401; 201203; 200601Z; 201209; 210101; 200301) as parallel samples. Accurately weigh an appropriate amount of PE, add 10 times pure water, heat and reflow for 0 h (ultrasonic 30 min, E1), 0.5 h (E2), 1 h (E3), 1.5 h (E4), 2 h (E5), and make up for the weight loss after cooling. Then immediately centrifugate at high speed (9000 r) for 10 min, and take the supernatant as the sample solution.

2.4 Determination method of appearance and physicochemical parameters

Accurately suction 300 μL of the sample and added it to a 96-well plate. Then the flatbed scanner (Epson perfection V370 Photo) was used to obtain the scanned image. And the Photoshop CC was used to obtain the R, G, B values of the and make a color chart, and the data were analyzed by PCA. The surface tension was measured by DCAT-21 surface tension analyzer (DataPhysics, Germany). The temperature was set at 25 ℃, and added 30 mL PES. The surface tension was measured by Wilhelmy hanging plate method after temperature equilibrium. The solution viscosity was determined by LVDV-1 T viscometer (Shanghai Fangrui Instrument Co., ltd.), the temperature was set at 25 ℃, rotor 1 was selected, 20 mL PES was added, and the rotational speed was set at 12 r/min.

2.5 Electronic tongue analysis method

The signal acquisition parameters were set as follows: acquisition temperature 25 ℃, data acquisition time 120 s, acquisition cycle 1 s, stirring speed 1 R/s. The ultrapure water was used as cleaning solution, and the sensor was cleaned for 10 s before each measurement. The above PE solutions was filtered through a 0.45 μm microporous membrane and placed in a 50 mL matching beaker for determination. Each sample was determined 10 times in parallel according to the above method, in order to obtain stable results. For reliable data, the last three times of data are taken as the output value. The average of the three output values of each sample was taken as the post-processing data. The verification results show that RSD was<2 %, indicating that the instrument was stable. When the sample was measured, the PE sample solution was diluted to a concentration of 6 mg/mL for testing.

2.6 UPLC-QTOF-Mass conditions

2.6.1 Sample preparation

Precisely draw 0.1 mL of the above PE extraction solution to 5 mL volumetric flask, add 50 % methanol–water solution to the scale line and dissolve it by ultrasonic for 30 min as the sample solution. Appropriate amount of each reference substance was weighed and made into reference substance solution respectively. All solutions above were filtered through 0.22 μm membranes (Jinteng, Tianjin, China) before injection.

2.6.2 Chromatographic conditions

Samples were analyzed by Acquity UPLC I-class (Waters) ultraperformance liquid chromatography system. The Waters ACQUITY UPLC BEH C18 column (2.1 mm × 100 mm, 1.7 μm) was used for the analysis. The mobile phase A was 0.1 % formic acid aqueous solution, and the mobile phase B was acetonitrile solution. The gradient elution was 0–3 min, 2 %-2% B; 3–5 min, 2 %-7% B; 5–15 min, 7 % −21 % B; 15–20 min, 21 %-78 % B; 20–21 min, 78 %-85 % B; 21 % −24 % min, 85 %-95 % B; 24–26 min, 95 %-95 %B; 26–28 min, 95 %-2%B; 28–30 min, 2 %-2%. The column temperature was set as 40 ℃, and the flow rate was 0.3 mL/min, and the injection volume was 3 μL.

2.6.3 Mass spectrometry conditions

Samples were analyzed by SYNAPT XS (Waters) high-resolution time-of-flight mass spectrometer. The electrospray ion source (ESI) negative ion mode is used for detection and analysis. The spatial resolution was 120 μm, capillary voltage was 4 kV, cone voltage 50 V, ion source temperature 150℃. The atomizing gas was high-purity nitrogen, cone gas flow rate was 50 L/h, desolvention gas flow rate was set as 600 L/h, and the temperature was set as 250 ℃. The mass spectrum data was collected in MSE mode, ion scanning range was m/z100-1200. Leucine-enkephalin (LE) was used for calibration during data acquisition. LE [M−H]- accurate relative molecular mass was calculated as m/z 554.2615 in negative ion mode.

2.6.4 Data processing and multivariate analysis

Masslynx 4.1 was used to collect data, and the original data was imported into progenesis Qi (Waters, V2.0) for processing. The quality error parameter |ppm|<5 was set, and the peak comparison, selection and normalization were performed to obtain the retention time, m/z and peak intensity of each sample. The above information was imported into EZinfo 3.0 for principal component analysis (PCA) and partial least squares discriminant analysis (OPLS-DA) to find the different compounds. Finally, compounds with VIP > 1and P < 0.05 were selected as differential metabolites.

2.7 Temporal dominant description method

To evaluate the taste difference of PES, a human sensory test using the visual analog scale (VAS) was proposed to verify the results(Han et al., 2018). With the approval of the medical ethics committee of the Affiliated Hospital of Chengdu University of TCM, 10 well-trained and healthy volunteers (4 males and 6 females, aged 21–28) were selected. Volunteers were selected from graduate students at Chengdu University of Traditional Chinese Medicine. They had no smoking, drinking and other bad habits, no genetic history, no recent oral and throat diseases, and normal taste. All volunteers were voluntary and signed informed consent before the trail.

PES has five basic flavors, which are astringency, bitterness, sourness, saliva secretion and aftertaste-sweetness. It is necessary to establish a special method for PES taste and flavor evaluation, which is called temporal dominant description method(Li et al., 2019). During the training sessions, volunteers were trained with different concentrations of model solutions (Sucralose, 3.0, 5.0,7.0 mg/mL; Tannic acid, 0.5, 1.0,2.0 mg/mL; Citric acid, 0.5, 0.8,1.0 mg/mL; Quinine, 0.1, 0.2, 0.3 mg/ml), so they were accustomed to the evaluation scales and bitterness intensities. A drop of approximately 10 mL of each solution was applied to the upper surface of the tongue for 10 s. Then, the test solution was expectorated. Volunteers were asked to score the “bitterness, sweetness, astringency, sourness” using the 100 mm VAS by placing a mark along a 100 mm line 23. Between each test interval, the mouth was rinsed well with distilled water so that no bitter taste remained. Volunteers were given a break (at last 1 h or more) between each sample.

The taste intensity retention time was used to define the flavors duration (TIRT). The intensity of the PES's bitterness, astringency, and sourness (I) has been decreasing throughout the entire drinking process, whereas the aftertaste-sweetness and salivary secretion have been rising and then lowering throughout. To comprehensively describe TIRT, a coefficient reflecting time needs to be established to reduce the data dimension.

It was found through fitting calculation that the sensory intensity and retention time were linearly fitted (y = kx + b), and the fitting results were shown in Table 1. Thus, the slope k value could be easily obtained. The k value has the connotation that the shorter the taste retention period, the higher the absolute value of k must be. To characterize the flavor retention time, we now present its retention time coefficient K. The formula is as follows:

Batch

KB

R2

KS

R2

KA

R2

KAS

R2

E1

2.667

0.996

1.132

0.911

1.499

0.985

2.001

1.000

E2

1.600

0.989

1.062

0.879

1.350

0.885

1.538

0.903

E3

1.613

0.953

1.126

0.848

1.541

0.954

1.018

1.000

E4

1.395

0.929

1.013

0.833

1.301

0.973

1.177

1.000

E5

1.163

0.936

0.841

0.833

1.270

0.972

1.500

0.984

K represents the TIRT coefficient of 5 tastes, which are defined as: bitterness (KB), astringency (KA), sourness (KS), and aftertaste-sweetness (KAS). Salivary secretion is calculated by the sum of salivary secretion times. In the fitting process, the data starting from 5 s until the taste intensity is greater than or equal to 0.5 are regarded as fitting objects. This rule applies to sourness, bitterness and astringency, and the TIRT coefficient K and R2 can be directly obtained (k < 0, R2 > 0.800). However, the aftertaste-sweetness intensity increased first and then decreased. Their K value is the reciprocal of rising slope k1 minus the falling slope k2 (k1 > 0 k2 < 0). Finally, Multiply the above-mentioned sensory TIRT coefficient K by the sum of various sensory intensities (SI) at each time point to obtain the comprehensive taste coefficient T of each taste. The calculation formula is as follows:

n is the number of time points in the evaluation process.

2.8 HS-SPME/GC-QQQ-MS/MS conditions

2.8.1 HS-SPME conditions

The lyophilized sample was crushed into fine powder (passed through a No. 3 sieve). Accurately weighed 0.5 g PE fine powder and placed in a 20 mL inert headspace bottle, and then equilibrated at 50 °C for 40 min. Before and after sample injection, the Solid phase microextraction (SPME) head was automatically aged for 3 min in the 270 ℃ aging device, inserted into the headspace via a PTFE septum, without contact the sample. After extraction and adsorption at a constant temperature of 50 ℃ for 10 min, the SPME head quickly insert the GC–MS injection port in the pre-operation state, desorb at 250 ℃ for 2 min, and then perform GC–MS/MS analysis.

2.8.2 Chromatography and mass spectrometry conditions

The PE samples (lyophilized powder) were analyzed by a TQ8050 NX triple quadrupole GC–MS equipped with Aoc-6000 automatic sampler and an electron bombardment ion source (EI), a PAL heating magnetic stirring module and a PAL SPME Arrow solid phase microextraction sampler (1.5 mm × 120 μm × 20 mm, PN: ARR15-DVB/C-WR-120/20CT, CTC Analytics AG, Switzerland). The inertcap pure wax capillary column (30 m × 0.25 mm × 0.25 μm) was used as chromatographic column during analysis. The chromatographic conditions were set as follows: injection temperature was 250 ℃, split ratio was 5:1, injection pressure was 83.5 kPa; carrier gas was high purity helium, carrier gas control mode was constant pressure mode; purge flow was 3.0 % mL/min. The temperature program was set as follows: the initial temperature was 50 ℃ for 5 min, then raised from 10 ℃ to 250 ℃ for 10 min; the column equilibrium time was 2.0 min. The mass spectrometry conditions were set as follows: the ionization energy was 70 EV, the ion source temperature was 200 ℃, the mass spectrum transmission interface temperature was 250 ℃, the collision gas is argon; the mass spectrum monitoring mode is multi reaction monitoring (MRM), the detector voltage is + 0.3kv relative to the tuning result, and the solvent delay time is 1.3 min. In order to improve the sensitivity of the detection, the compounds were monitored by time segment.

2.8.3 Qualitative and quantitative method

Precisely draw 1 μL of a mixed solution (0.1 μg/mL) containing 3 kinds of internal standard substances for analysis to obtain the peak area of the internal standard substance, and finally measure the sample according to the above conditions. The qualitative of the target compound is confirmed by the qualitative and quantitative transition. The quantification of the target compound is quantified by the standard curve of 150 compounds built in the Shimadzu TQ8050 reanalysis software (The method parameters and sensory information (odor characteristics and odor threshold, etc.) of about 150 odor compounds were registered in the database.) combined with the measured peak area of the internal standard. Through the method package and database, it is very convenient to establish a variety of odor compounds screening methods, and use the built-in standard curve to semi quantify the detected compounds, and confirm the odor causing substances by comparing the results with their odor threshold.

The term ‘odor threshold’ describes the least concentration (pg/mg) of a substance that irritates people's sense of smell. The content and threshold work together to determine how well odor components perform in PE, rather than just the content alone. The ratio of the concentration to the threshold is called the odor activity values (OAV):

In the formula: C represents the component content (pg); M for the sample mass(mg); Th for the component’s odor threshold (pg/mg). Generally, the components with OAV > 0.1 should be considered to have an obvious impact on their odor.

2.9 Antioxidant and antihyperglycemic activities

The α-glucosidase and PNPG reaction system was used as a model for testing, and the specific operations were as follows: Added 10 μL of α-glucosidase solution (2 U/mL) and 10 μL of the sample solution to each reaction well in turn, mixed well and incubated in a 37 ℃ water bath for 15 min. Then, added 50 μL of PNPG (1 mmol/L), placed it in a 37 ℃ water bath and incubate for 30 min, and finally added sodium carbonate solution to stop the reaction. Each sample had 3 replicate wells. The absorbance was measured at 405 nm as soon as possible by a multifunctional microplate reader. Acarbose was used as a positive control, the concentration was 12, 14, 16, 18, 20, 22, 24, 26, 28, 30 mg/mL; the samples were set with 8 concentration gradients of 10, 50, 100, 250, 500, 750, 1000 and 2500 μg/ml and calculate the inhibition rate.

DPPH, ABTS radical scavenging activity (IC50) and FRAP total antioxidant capacity of the sample were measured according to the instructions of the kit (Solebo biotechnology Co., ltd.).

2.10 Determination of antibacterial and antifungal activity

Staphylococcus aureus, Escherichia coli, Aspergillus variegatus and Aspergillus flavus (purchased from Baina Biological Co., ltd., China) were inoculated and cultured for 3 generations. Under aseptic conditions, take 0.2 mL of bacterial suspension (the best concentration of bacterial solution is 1 × 106 CFU/mL) and spread it evenly on the surface of the agar plate. The positive group was gentamicin sulfate injection (diluted four times, 10 mg/mL). Take 2 mL of each sample solution (10 times water extract, filter sterilization) into a sterilized EP tube, and then put a 6 mm diameter neutral filter paper into the EP tube to soak for 4 h. Place the filter paper clockwise on the same plate, parallel three groups, and measure the average value after incubation at 37 ℃ for 24 h.

2.11 Data processing and analysis

Analysis was performed by using Heat map and Cor-Heatmap tools in Hiplot (https://hiplot.com.cn), a comprehensive web platform for scientific data visualization. Statistical analyses were performed using SPSS 22.0 package (SPSS Inc., Chicago, IL, USA) and Oringin 2018 (OriginLab, Hampton, Massachusetts, USA). PCA and OPLS-DA were analyzed by SIMCA-P11.0 (Umetrics AB, Umea, Sweden).

3 Results

3.1 PES physicochemical properties changes during thermal extraction

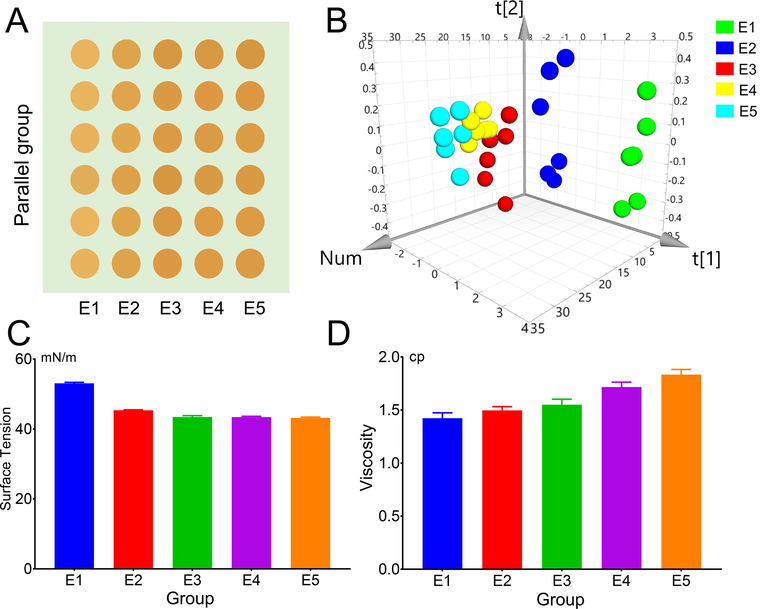

The physical properties and appearance of PES changed significantly during the extraction process, and the results are shown in Fig. 1 (E1 represent ultrasonic extraction or thermal extraction for 0 h; E2, E3, E4 and E5 stand for heating reflux extraction for 0.5 h, 1 h, 1.5 h and 2 h respectively).

Appearance and physical properties results, A the appearance of different extraction time, B PCA analysis of R, G, B values of different extraction time appearance, C variation of surface tension and D viscosity at different extraction time.

The results in Fig. 1 demonstrated that the color of PES deepened as extraction time increased, surface tension significantly decreased, and viscosity was favorably connected with extraction time. The metamorphosis of internal parts is intimately tied to this change in appearance and physical characteristics. Indicating that some components created after transformation have higher surface activity than the original components, such as polysaccharides and polyphenols (Zhan et al., 2018). Therefore, its physical and chemical properties are closely related to the transformation of its components.

3.2 Sensory evaluation results

3.2.1 Temporal dominant description results

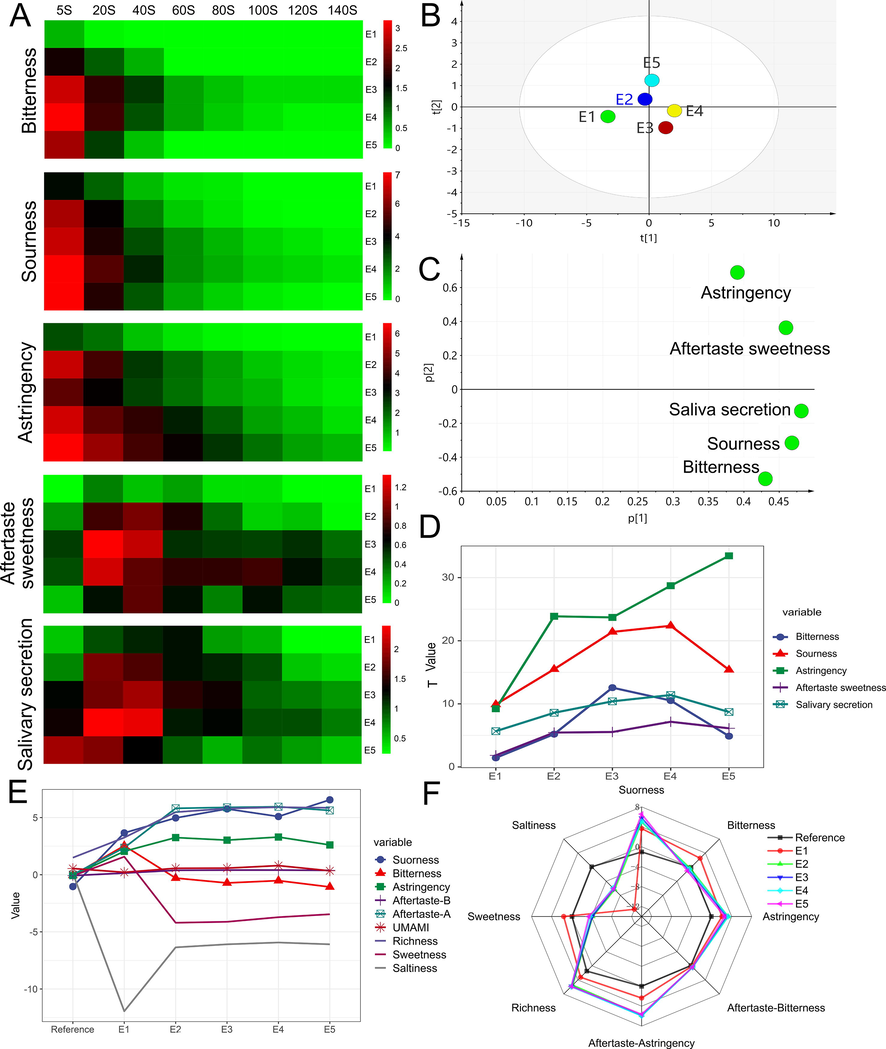

A temporal dominating description method (Li et al., 2019) to assess the sensory qualities of PES was established based on its taste characteristics, and it is capable of precisely and dynamically describing the flavor changes that occur in PES during the thermal extraction process.

Heat maps were used to examine the average scores of PES samples (E1 to E5) at various time intervals, and the results are displayed in Fig. 2A. Sourness, bitterness, and astringency dominated taste perception in the first 0–20 s, followed by aftertaste sweetness and saliva secretion in the second 20–60 s. As seen in Fig. 2B, PCA can clearly distinguish PES at five locations (R2 = 0.989, Q2 = 0.87), demonstrating that the model is capable of evaluating the sensory time intensity in its whole. The loading scatter plot can also show how extraction time affect PES tastes (The smaller the Euclidean distance, the greater the impact). The result of Fig. 2A and the distance of E1 from each point in Fig. 2C both indicate that E1′s tastes intensity are the weakest. Additionally, E4 has a stronger taste of saliva secretion and aftertaste-sweetness, whereas E3 is more noticeably impacted by bitterness and sourness. E5 has the most noticeable astringency. The smallest bitterness and astringency make E1 seem like the best option, but the aftertaste-sweetness is not obvious. The strength of the astringency and sourness soon decreased after spitting out PES, and the aftertaste-sweetness and salivation now predominate. The major elements that had the biggest influence on customer preferences is aftertaste-sweetness, a flavor that is most characteristic to PE. Considering the biological activity and flavor, E2 and E4 are the best choices.

Temporal dominant description method and electronic tongue results, A the VAS scores heat map of PES samples (E1 to E5) at different extraction time points, B PCA analysis results of T value, C loading scatter plot, D change tendency of T values, E, F electronic tongue measurement results.

Electronic tongue was employed as a benchmark to further validate the temporal dominant description method's findings. In all tastings, E1 could be recognized from other samples according to the radar map (Fig. 2 F). The aftertaste-sweetness and bitterness showed the highest value at the E1 time point, and then decreased to 0 or negative value with the extension of the extraction time, which was slightly different from the volunteers' results. The trend of sourness and astringency was consistent with the volunteer evaluation results (Fig. 2 E, F). The majority of participants believed PES to have very little bitterness, according to the results of the volunteer evaluation stage. The complexity of PES's components and the possibility that some bitter compounds go unrecognized by the electronic tongue may play a significant role in this discrepancy (Reis et al., 2020). Additionally, the cause of the aftertaste-sweetness in PES is unknown, however it is hypothesized that it may be due to ingredients like EC or EGC, which is similar to tea soup (Zhang et al., 2016). According to certain research (McBurney and Bartoshuk 1973), the aftertaste's sweetness could be a contrast effect and an oral cavity illusion. When the bitterness, sourness and astringency of PES continue to rise, the contrast effect is significantly enhanced, leading the brain to perceive the sweetness as stronger(Liu et al., 2023). This may be why the aftertaste-sweetness cannot be detected by the electronic tongue. As a result, the temporal dominant description method can be used to collect more plentiful sensory data.

3.2.2 Transformation of volatility components (Odor components)

One of the sensory qualities of PES is its distinct fragrance. It typically has a sweetness and aroma similar to caramel after thermal extraction, which may primarily be the result of the Maillard reaction during the heating and extraction process. Based on HS-SPME/GC-QQQ-MS/MS odor analysis technology, this paper established a rapid method to identify the chemical components in the special odor of PES, and explored the key differences in the odor components of different extraction time of PES.

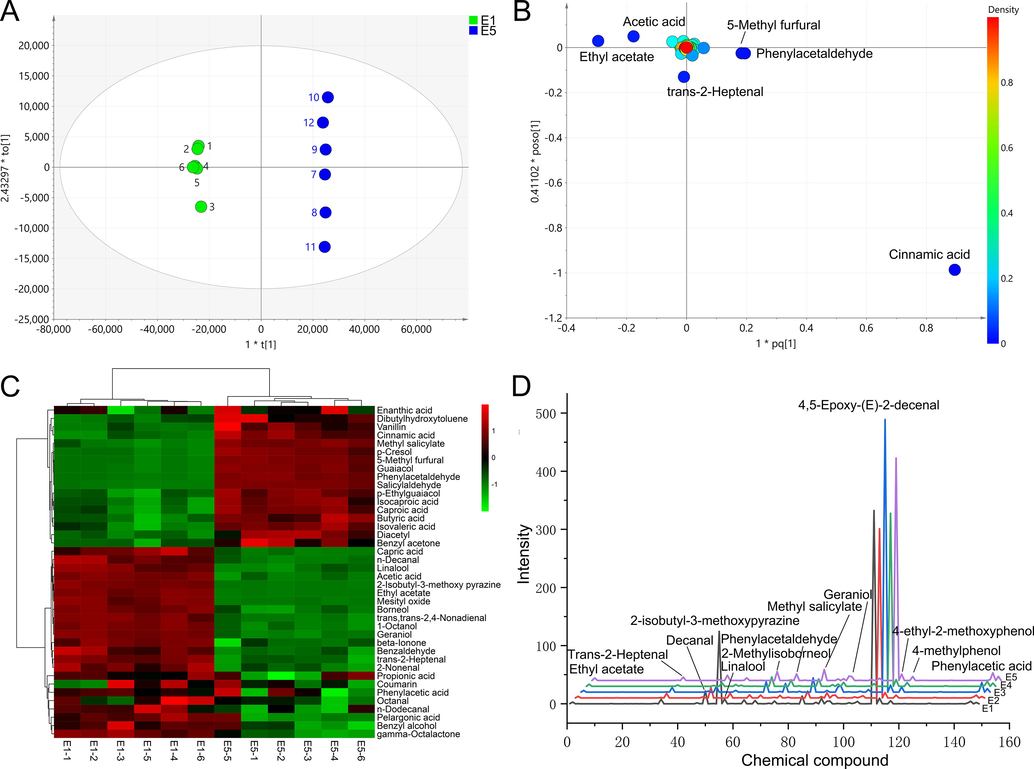

According to the OAV calculation formula, the odor components of different batches of PES were analyzed, and 44 components with OAV > 0.1 were found (Table.2). The primary difference markers before and after heating extraction can be quickly identified using the OAV combined with multivariate statistical analysis method (OPLS-DA, Fig. 3A), and significantly difference markers (VIP > 1, t < 0.05 and OAV > 0.1) were found in Fig. 3B and C, namely ethyl acetate, acetic acid, 5-methyl furfural, phenylacetaldehyde and cinnamic acid. ** t < 0.05, ***t < 0.01.

No

Compounds

Odor description

Threshold Th (pg/mg)

Rt(min)

Average content of different time points C (pg)

Difference marker

E1

E2

E3

E4

E5

1

Ethyl acetate

Pineapple fragrance

1000

2.104

17679.810

4978.099

4170.190

4812.597

3084.240

***, VIP > 1

2

Diacetyl

The smell of butter

10

2.844

2780.087

3044.103

3013.911

3565.254

4027.459

***,

3

Mesityl oxide

Sweet, chemical

10

5.885

219.310

114.199

109.183

58.015

97.774

***

4

Octanal

Sharp and powerful aromas of green and pungent fat and wax, with fruity and jasmine flavor

100

9.505

5042.463

3720.061

5249.689

3089.878

4270.557

**

5

trans-2-Heptenal

Fat, soap, almond

10

10.062

7576.881

6416.928

8467.292

2316.654

5600.729

***

6

Acetic acid

Sour taste

1000

12.214

155781.700

144864.600

165983.400

151018.900

146999.400

***, VIP > 1

7

n-Decanal

Soap, fat and wax, orange peel

1

13.100

1934.932

857.739

1010.537

647.460

914.326

***

8

Benzaldehyde

Almond, caramel

1000

13.311

17749.770

10876.730

23326.900

13415.560

15396.800

***

9

2-isobutyl-3-methoxypyrazine

Soil flavor, spice flavor, green pepper flavor

0.01

13.452

115.295

0.00

0.00

1.482

2.984

***

10

Propionic acid

Putrid, spicy, soy sauce

1000

13.494

28489.240

27113.080

32335.810

28386.72

27966.280

**

11

2-Nonenal

Paper smell

1

13.593

712.872

444.596

274.554

193.8355

364.596

***

12

Linalool

Fragrance of flowers and lavender

10

13.748

168.231

77.238

67.215

93.078

66.678

***

13

1-Octanol

Metal, burnt, chemical

100

13.890

2446.057

1112.965

1629.611

1039.398

1519.007

***

14

5-Methyl furfural

Almond, caramel

1000

14.045

18341.990

18410.610

30691.11

28451.61

27409.110

***, VIP > 1

15

2-Methylisoborneol

Stale and mouldy

0.1

14.412

55.292

21.092

16.1185

25.302

43.0823

**

16

Butyric acid

Putrid, cheese, sweat

1000

14.783

11648.820

10312.040

14454.66

12758.38

12293.490

***

17

Phenylacetaldehyde

Sweetness and honey

10

15.005

5273.081

11327.300

18975.170

15960.59

14878.980

***, VIP > 1

18

Isovaleric acid

Putrid, sweat, sour

100

15.333

8692.676

8011.605

10624.230

9697.376

9639.278

***

19

Salicylaldehyde

Herbal, toasted

1

15.477

421.378

474.004

1599.766

1080.489

1108.472

***

20

trans-2,4-Nonadienal

Green fragrance, wax and fat fragrance

10

15.830

140.112

67.627

121.844

37.979

56.982

***

21

Borneol

Stale and mouldy

1

15.843

115.335

145.7845

68.821

83.160

56.425

***

22

n-Dodecanal

It has a strong aroma similar to pine leaf oil and orange oil

10

15.973

934.002

910.518

1065.818

983.073

519.857

***

23

Methyl salicylate

mint

1

16.737

1200.007

843.041

2697.523

1253.449

1897.136

***

24

Isocaproic acid

Putrid, sweat, sour

100

17.007

1407.514

1540.538

1826.279

1804.966

1618.833

***

25

Caproic acid

The smell of sweat

100

17.485

23065.970

20280.700

28414.050

27251.1

25879.550

***

26

Geraniol

Geranium, rose

1

17.578

890.972

365.687

210.674

182.1175

322.966

***

27

Guaiacol

Sweetness, medicine, smoke

1

17.683

425.341

385.427

962.766

685.9205

749.733

***

28

Benzyl acetone

Fruity, ethereal

0.1

17.695

47.115

114.831

113.401

22.477

58.058

***

29

Benzyl alcohol

Sweet, fragrant

100

17.859

4497.089

2934.417

5527.015

3635.269

4164.503

***

30

gamma-Octalactone

Coconut aroma

1

18.339

171.964

114.652

152.928

63.7055

136.989

***

31

Dibutylhydroxytoluene

Phenol smell

10

18.373

283.703

143.2315

204.395

330.4785

361.382

***

32

beta-Ionone

There are aromas of violet, raspberry and seaweed

0.1

18.662

14.278

0.00

0.00

0.00

6.2183

***

33

Enanthic acid

Green, orange, soap, gasoline

10

18.718

3795.854

4339.398

4582.191

4744.185

3963.703

34

4,5-Epoxy-(E)-2-decenal

Green fragrance, metal smell

0.01

19.363

341.767

245.0385

491.539

261.4515

427.676

35

p-Ethylguaiacol

Spice and clove oil aroma

0.1

19.601

92.2110

97.9505

134.066

115.211

111.543

***

36

p-Cresol

It has the smell of smoke and herbal medicine

1

20.099

490.315

462.228

935.463

650.2635

673.653

***

37

m-Cresol

Plastic, faeces smell

0.1

20.184

605.872

562.249

1211.434

835.6695

865.460

38

2,3-Xylenol

Gasoline smell

1

20.789

2.356

14.049

20.419

15.59

10.696

39

Pelargonic acid

Green fragrance, oil fragrance

100

20.992

3084.561

3663.357

2449.716

3167.952

2207.319

***

40

Capric acid

Greasy, stale

10

22.030

747.462

974.287

561.2085

818.2395

434.442

***

41

Coumarin

Sweet and green

1

23.753

14.947

11.956

16.089

13.9845

14.070

***

42

Phenylacetic acid

Floral, honey

10

24.646

1686.522

1674.168

1839.024

1568.55

1629.066

***

43

Vanillin

Vanilla

1

24.681

490.291

448.2035

1731.433

785.6225

1445.416

***

44

Cinnamic acid

It has the fragrance of cinnamon

100

27.562

25344.500

35321.860

62970.090

49,981

69568.300

***, VIP > 1

Analysis results of odor components, A, OPLS-DA results for E1 and E5, B loading scatter plot (the marked components indicate VIP > 1), C difference compounds (t < 0.05, the threshold>0.1), D odor characteristic spectrum (OCS) of PES.

To precisely describe the odor differences, here we introduce the odor characteristic spectrum (OCS) to quickly and intuitively describe the odor profile of the sample. The OCS of PES is obtained in Fig. 3D by using the odor components as the abscissa and the OAV (Intensity) as the ordinate, and this allows us to quickly identify the components that are crucial in causing odor alterations. According to Fig. 3D, 2-isobutyl-3-methoxypyrazine is the distinctive odor of E1, which provides a clue as to whether it was extracted through heating. Wine often contains 2-isobutyl-3-methoxy pyrazine (IBMP), a substance that should be avoided because it is mostly produced by unripe grapes and can adversely impact the wine's overall flavor (Ling et al., 2021). Among them, 4,5-epoxy-(E)-2-decanal occupies the most conspicuous position. This substance has a green flavor, and its OAV keeps rising with the extension of heat extraction time. N-decanal and methyl salicylate are two more noteworthy components. While the latter's OAV value continuously rises, the former's falls during the extraction process (Table.3). Methyl salicylate is described as mint smell, which is frequently added to cosmetics to improve their aroma. Other flavor substances, such as methyl salicylate, geraniol, phenylacetaldehyde and vanillin, increase dynamically with the extension of extraction time, giving PES more distinctive flavor.

No

Compounds

Odor description

E1

E2

E3

E4

E5

1

beta-Ionone

Aroma of violets, raspberries, seaweed

1.428

0.473

0.617

0.710

0.622

2

Acetic acid

Sour

1.558

1.449

1.660

1.510

1.470

3

Phenylacetic acid

Floral scent, honey

1.687

1.674

1.839

1.569

1.629

4

gamma-Octalactone

Coconut aroma

1.720

1.147

1.529

0.637

1.370

5

Cinnamic acid

With cinnamon aroma

2.534

3.532

6.297

4.998

6.957

6

Caproic acid

Sweat smell

2.307

2.028

2.841

2.725

2.588

7

Diacetyl

Butter scent

2.780

3.044

3.014

3.565

4.027

8

Enanthic acid

Green, orange, soap, gasoline

3.796

4.339

4.582

4.744

3.964

9

Vanillin

Vanilla

4.903

4.482

17.314

7.856

14.454

10

Guaiacol

Sweet, medicinal, smoke

4.253

3.854

9.628

6.859

7.497

11

Salicylaldehyde

Herbal flavor, toast flavor

4.214

4.740

15.998

10.805

11.085

12

Benzyl acetone

Fruity, ethereal

4.712

11.483

11.340

2.248

5.806

13

p-Cresol

Smoky, herbal smell

4.903

4.622

9.355

6.503

6.737

14

Phenylacetaldehyde

Sweet, honey,

5.273

11.327

18.975

15.961

14.879

15

2-Methylisoborneol

Earthy, musty

5.529

2.109

1.612

2.530

4.308

16

trans-2-Heptenal

Fatty, soap, almond

7.577

6.417

8.467

2.317

5.601

17

Trans-2-nonanal

Papery

7.129

4.446

2.746

1.938

3.646

18

Geraniol

Geranium aroma, rose aroma

8.910

3.657

2.107

1.821

3.230

19

p-Ethylguaiacol

With spice and clove oil aroma

9.221

9.795

13.407

11.521

11.154

20

Methyl salicylate

Mint

12.000

8.430

26.975

12.534

18.971

21

n-Decanal

Soap, waxy, orange peel aroma

19.349

8.577

10.105

6.475

9.143

22

m-Cresol

Plastic, fecal smell

60.587

56.225

121.143

83.567

86.546

23

2-Isobutyl-3-methoxy pyrazine

Earthy, spice, green pepper

115.296

0.000

0.000

1.482

2.984

24

4,5-Epoxy-(E)-2-decenal

Green scent, metallic scent

341.767

245.039

491.539

261.452

427.676

3.3 Transformation of non-volatile components

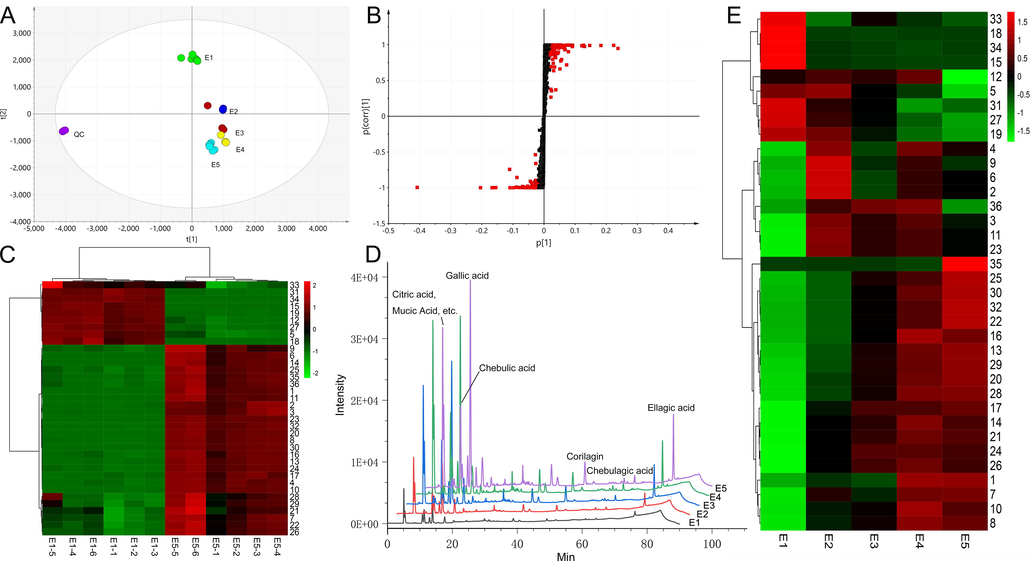

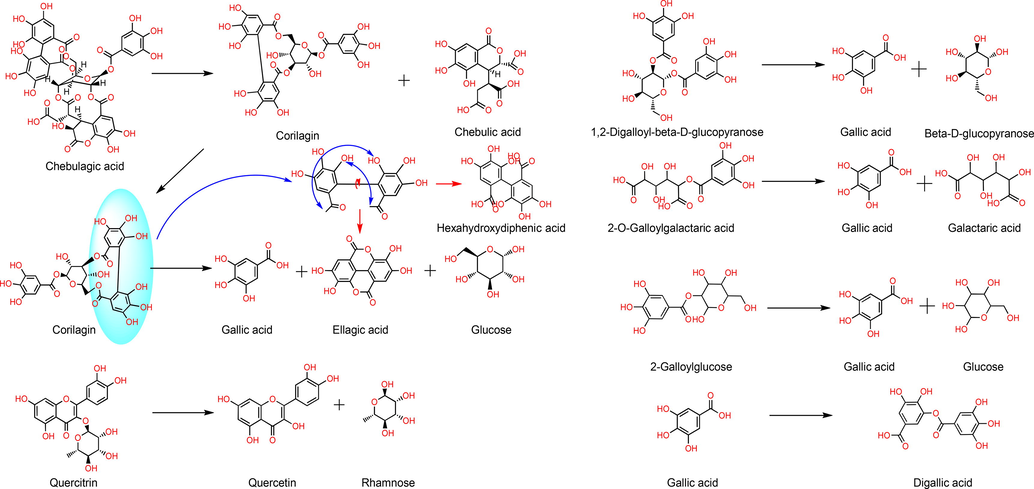

Heated extraction usually involves a non-enzymatic chemical reaction that facilitates the hydrolysis of tannins to produce low molecular weight molecules, including polyols, gallic acid, ellagic acid, and saccharides. However, under conditions of continued heating, these small molecular products will continue to react, leading to complex end products (Lu et al., 2008). PES has a molecular structure that has numerous active sites and active groups, including phenolic hydroxyl and carboxyl groups, acyl groups, etc. that allow for a range of complex reactions. According to results (Fig. 4), this process has the following characteristics: 1. The reaction process is intricate, involving both hydrolysis and polymerization; 2. The reaction is significant and rapid after heating; 3. A variety of end products with intricate structures are produced. With the help of high-resolution mass spectrometry, we focus on the following aspects:1. Determine the chemical change profile, such as reaction type, general reaction rules, etc.; 2. Identify the compounds with the most significant transformation; 3. Identify some representative basic transformation pathways; 4. Pay attention to the transformation of important active ingredients in PES, such as gallic acid and ellagic acid.

Analysis results of differential markers, A. PCA results, B S-plot, C difference marker heat map, D, HPLC chromatogram at different extraction times, E. change trends of differential markers.

Through Progenesis QI software, standard substance and literature information, 36 differential markers (VIP > 1, p < 0.05) were identified (Fig. 4 B, C), which represented the most significant transformed compounds in PES (Table.4). In differential markers, the decreased components may participate in transformation. The reaction pathway can be determined by analyzing the dynamic change trend of the compound in combination with literature reports and experiments.

No

Compound

Retention time (min)

Molecular formula

Measured (m/z)

Molecular ion

Error

(ppm)Isotope similarity

Content change

1

Quercetin

14.9703

C15H10O7

301.0344

M−H

−3.3317

91.4662

↓

2

3,4,8,9,10-pentahydroxy-6-oxo-6H-benzo[c]chromene-1-carboxylic acid

14.3442

C14H8O9

300.9983

M−H2O−H

−2.0450

89.5665

↑

3

Granatin B

14.3299

C41H28O27

951.0747

M−H

0.1397

81.9781

↑

4

Tellimagrandin II

14.1306

C41H30O26

937.0958

M−H

0.6183

83.46731

↑

5

Quercitrin

14.0949

C21H20O11

447.0923

M−H, 2 M−H

−2.1753

92.5691

↓

6

Bicornin

12.5511

C48H32O30

1087.091

M−H

0.7384

75.2856

↑

7

Ellagic acid

11.2482

C14H6O8

300.9982

M−H

−2.7505

95.0828

↑

8

Tercatain

10.5721

C34H26O22

785.0844

M−H

0.1668

82.8016

↑

9

Sanguiin H2

10.4656

C48H32O31

1103.086

M−H

0.1781

80.9349

↑

10

m-Trigallic acid

9.9388

C21H14O13

473.0362

M−H

0.1163

84.2970

↑

11

1-O-Galloylpedunculagin

9.5901

C41H28O26

935.0795

M−H

−0.1203

89.0098

↑

12

1,3,4-trigalloyl-beta-d-glucopyranose

9.5901

C27H26O19

635.0886

M−H2O−H

−0.5601

83.5092

↓

13

Corilagin

8.6509

C27H22O18

633.0738

M−H

0.7252

95.2451

↑

14

4,4,5,5,6,6′-hexahydroxy- [1, 1′-biphenyl]-2, 2-dicarboxylic acid

8.2307

C14H10O10

337.0193

M−H

−2.3119

90.7627

↑

15

6-[4-({[7,8,8,12,13,22-hexahydroxy-19-(hydroxymethyl)-3,6,16-trioxo-2,17,20,23-tetraoxapentacyclo[16.3.1.17,11.04,9.010,15]tricosa-4,10,12,14-tetraen-21-yl]oxy}carbonyl)-2,6-dihydroxyphenoxy]-3,4,5-trihydroxyoxane-2-carboxylic acid

5.6405

C33H30O25

807.0906

M−H2O−H

0.9501

91.6979

↓

16

6-({1-carboxy-3,8,9,10-tetrahydroxy-6-oxo-6H-benzo[c]chromen-4-yl}oxy)-3,4,5-trihydroxyoxane-2-carboxylic acid

4.7151

C20H16O15

495.0418

M−H

0.2367

87.2027

↑

17

3,4,5-trihydroxy-6-(3,4,5-trihydroxybenzoyloxy)oxane-2-carboxylic acid

4.7222

C13H14O11

327.035

M−H2O−H

−2.2045

89.54094

↑

18

Succinylacetoacetate

4.4806

C8H10O6

183.0294

M−H2O−H

−2.5031

95.4474

↓

19

1,2-Digalloyl-beta-d-glucopyranose

4.2812

C20H20O14

483.078

M−H, 2 M−H

−0.1006

89.7035

↑

20

3,4-dihydroxy-5-(3,4,5-trihydroxybenzoyloxy)benzoic acid

3.7045

C14H10O9

321.0246

M−H

−1.8258

91.0399

↑

21

4-[(6-carboxy-3,4,5-trihydroxyoxan-2-yl)oxy]-4′,5,5′,6,6′-pentahydroxy-[1,1′-biphenyl]-2,2′-dicarboxylic acid

1.5344

C20H18O16

513.0519

M−H

−0.6480

89.0181

↑

22

6-Methyl 2-galloylgalactarate

1.1723

C14H16O12

751.1207

2 M−H

−0.5153

98.4140

↑

23

Sanguiin H4

1.1366

C27H24O19

633.0735

M−H

0.2529

79.0543

↑

24

2-O-Galloyl-1,4-galactarolactone

1.0295

C13H12O11

343.0307

M−H

−0.0179

94.0372

↑

25

Gallic acid

1.0017

C7H6O5

169.0141

M−H

−0.7509

98.7058

↑

26

1-Methyl 2-galloylgalactarate

0.9517

C14H16O12

375.0566

M−H

−0.7721

89.8624

↑

27

2-Galloylglucose

0.8453

C13H16O10

331.0666

M−H, 2 M−H

−1.3246

96.4136

↓

28

5-O-Galloyl-1,4-galactarolactone

0.6953

C13H12O11

687.0699

M−H, 2 M−H

1.4303

93.2576

↑

29

Citric acid

0.6953

C6H8O7

191.0195

M−H

−1.1884

97.2197

↑

30

3,4,5,11,12,13,21,22,23-nonahydroxy-9,14,17-trioxatetracyclo[17.4.0.02,7.010,15]tricosa-1(23),2,4,6,19,21-hexaene-8,18-dione

0.6674

C20H18O14

481.0642

M−H

3.8702

88.7237

↑

31

Malic acid

0.5675

C4H6O5

133.0141

M−H

−1.4131

95.5124

↓

32

Chebulic acid

0.5389

C14H12O11

355.0314

M−H2O−H, M−H

1.2365

92.7179

↑

33

2-O-Galloylgalactaric acid

0.5318

C13H14O12

361.0419

M−H, 2 M−H

1.71817

94.8857

↓

34

Galactinol

0.5039

C12H22O11

341.1097

M−H

2.2280

90.6854

↓

35

D-2-Hydroxyglutaric acid

0.5039

C5H8O5

147.0296

M−H

−1.7772

96.0944

↑

36

2-Hydroxybutyric acid

0.5039

C4H8O3

85.02942

M−H2O−H

−0.7952

98.0449

↑

From the content change (peak area) before and after thermal extraction (Fig. 4 E), it is easy to find several components with the strongest transformation during the thermal extraction process. They are No. 27, 33, 28, 15, 19, 25, 13, 21, 7, 24, 29, 22 and 5 (from high to low). They almost all belong to Gallotannins and Ellagitannins (Lu et al., 2008). It is easy to deduce that aglycone (polyol), gallic acid, and hexahydroxybiphthalic acid are the core components of this reaction. They increase continuously in thermal extraction and become the end products of hydrolyzable tannins. Through the verification of standard model solutions, Fig. 5 shows the hydrolysis process of representative difference markers in PES during thermal extraction. It was shown that the content of some tannins increased during the heat extraction process, indicating that the polymerization event took place concurrently. For instance, during thermal treatment, 2-O-galloylgalactaric acid decomposes into gallic acid and galactic acid. It also reveals an increase of 5-O-galloyl-1,4-galactarolactone, which may be the result of the molecular rearrangement of 2-O-galloylgalactaric acid following hydrolysis.

Main differential compounds transformation pathways.

The pearson correlation analysis was used to examine the relationship between the differential markers and the sensory evaluation data of volunteers (highest value at each time point) at various extraction time points for the screening and identification of flavor compounds. Table.5 reveals that the majority of substances, including citric acid, gallic acid, and its derivatives, strongly correlate with sourness. Tellimagrandin II, ellagic acid, tercatain, 4,4,5,5,6,6′-hexahydroxy-[1,1′-biphenyl]-2,2-dicarboxylic acid, and other tannins are the primary astringency-related substances. More sophisticated factors, such as flavor contrast, may play a role in the development of the aftertaste's sweetness. Due to the fact that sour can produce salivation, sour components have a strong correlation with salivary secretion. Blank means not significant.

Compound number

Suorness

Bitterness

Astringency

Aftertaste-Sweetness

Salivary secretion

Hits

4

0.89

1

7

0.95

0.98

0.90

3

8

0.99

0.95

0.89

0.97

4

10

0.98

0.95

0.98

3

13

0.94

0.91

0.89

3

14

0.99

0.97

0.88

0.89

0.99

5

15

−0.95

−0.89

−0.90

−0.91

−0.91

5

16

0.90

0.90

0.90

3

17

0.98

0.96

0.88

0.94

4

18

−0.94

−0.88

−0.89

−0.91

−0.90

5

19

−0.89

1

20

0.97

0.92

0.92

0.91

4

21

0.99

0.97

0.89

0.89

0.98

5

22

0.89

1

24

0.97

0.97

0.94

0.96

4

25

0.90

1

26

0.98

0.97

0.93

0.98

4

27

−0.95

−0.87

−0.88

3

28

0.97

0.94

0.93

3

29

0.95

0.92

0.90

3

30

0.91

1

31

−0.97

−0.93

−0.87

−0.96

4

32

0.89

1

33

−0.97

1

34

−0.95

−0.89

−0.90

−0.91

−0.91

5

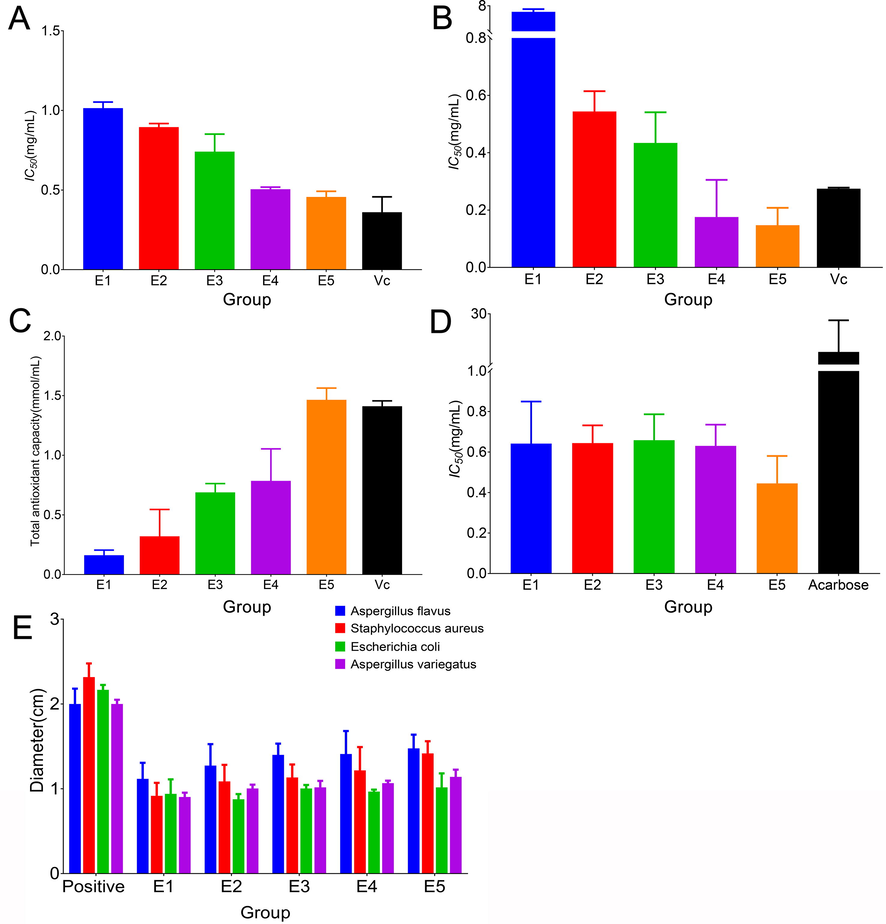

3.4 Study on PES activity changes and correlation analysis

The hypoglycemic activity of PE is primarily manifested in its inhibitory effect on α-glucosidase; while PES has strong antioxidant and antibacterial properties thanks to the abundance of phenolic hydroxyl groups. This study examines how relevant biological activities alter dynamically as a result of the PES heat extraction process. Fig. 6 makes it very evident that as extraction time is increased, several biological activities are also noticeably improved. Studies revealed that after hydrolysis, some hydrolyzed tannins will have dramatically increased biological activity, such as antibacterial activity (Aguilar-Galvez et al., 2014). Additionally, it is believed that hydrolysable tannins acquire their antibacterial properties from the presence of hexahydroxydiphenoyl and nonahydroxyterphenoyl moieties (Ekambaram et al., 2016). According to Taguri et al. (Taguri et al., 2006), the pyrogallol group is a crucial structural component of polyphenols' antibacterial action. The extra free galloyl group appeared to boost the ellagitannin's inhibitory actions on E. coli (Puljula et al., 2020). Under the conditions of heat extraction, rutin can hydrolyze to quercetin. But quercetin's weak water solubility might lessen its antibacterial power. In addition, polymerization also occurs during the extraction process and has the potential to result in the production of new hydrolyzed tannins. Therefore, the biological activity is always changing, but ultimately leads to the increase of the overall activity of PES.

The biological activity changes of PES with extraction time, A, B and C are ABTS, DPPH, and FRAP antioxidant capacity respectively, D, α Glucosidase inhibitory activity, E antibacterial activity, F correlation heat map of biological activity and differential markers.

The changes in biological activity and differential markers are strongly connected. The pearson correlation heat map analysis was utilized for correlation analysis in order to explore prospective biological activity indicators. The empty space denotes a poor significance test result (p > 0.05). It should be noted that the activity is stronger the lower the IC50 value. In Table 6, the more components hit, the more critical it is. For instance, the compounds Nos. 8, 13, 19, 20, 22, 25, 27, 29, 30 and 32 contain certain well-known bioactive substances, such as corilagin and gallic acid, which are now the most reported substances (Yang and Liu 2014). Escherichia coli has no correlation with all components, so it is not listed. Blank means not significant.

Compound number

Aspergillus flavus

Staphylococcus aureus

Aspergillus variegatus

DPPH

ABTS

FRAP

Anti hyperglycemia

Hits

1

0.89

0.92

−0.95

3

3

−0.90

1

5

−0.92

−0.89

0.93

−0.98

4

7

0.92

−0.91

2

8

0.95

0.87

0.92

−0.91

−0.93

5

10

0.91

0.88

−0.90

−0.91

4

11

−0.92

1

12

0.96

1

13

0.98

0.94

0.95

−0.98

0.90

5

14

0.93

−0.96

2

15

−0.88

1.00

2

16

0.90

0.88

−0.98

3

17

0.98

0.90

−0.96

3

18

1.00

1

19

−0.95

−0.93

−0.94

0.99

−0.93

5

20

0.98

0.94

0.96

−0.97

0.89

5

21

0.94

0.87

−0.97

3

22

0.95

0.98

0.97

−0.98

0.96

5

23

−0.92

1

24

0.94

−0.97

2

25

0.97

0.97

0.96

−0.97

0.96

5

26

0.93

−0.97

2

27

−0.97

−0.97

−0.99

0.97

−0.92

5

28

0.97

0.92

0.94

−0.97

4

29

0.98

0.94

0.96

−0.97

0.90

5

30

0.96

0.96

0.97

−0.99

0.95

5

31

−0.92

−0.91

0.95

3

32

0.95

0.98

0.97

−0.98

0.96

5

33

0.93

1

34

−0.87

1.00

2

35

−0.99

1

4 Conclusion

Due to the colloid that its polysaccharides produce, PES's surface tension decreases and its color and viscosity increase as the thermal extraction time lengthens. According to the temporal dominating description approach developed in this study, all taste intensities grew as heating time increased, but the comprehensive taste index revealed that E4 and E2 have better flavor. Additionally, it was discovered through OCS analysis that thermal extraction can get rid of unpleasant smells like IBMP, a type of green pepper flavor that ruins the flavor of foods and beverages, and increase significantly the intensity of the compound 4,5-epoxy-(E)-2-decanal, which gives PES a green smell. The hydrolysis and condensation of tannins were the two fundamental steps in the difficult transformation of non-volatile compounds. And practically all of them are connected to the hexahydroxydibenzoyl (HHDP) and galloyl chemical structures. This is a typical reaction that occurs during the thermal extraction of polyphenols, which are significant elements that affect PES’s activity and flavor. In the examination of biological activity, heat extraction was helpful in enhancing biological activity, which may be attributed to an increase in gallic acid, ellagic acid, corilagin, 2-galloylglucose, citric acid, and chebulic acid, among other compounds. In conclusion, PE's flavor and biological activity can be greatly enhanced by thermal treatment.

CRediT authorship contribution statement

Haozhou Huang: Methodology, Data curation, Writing – original draft. Mengqi Li: Methodology, Data curation, Writing – original draft. Qinchu Tan: Methodology, Data curation. Ce Tang: . Jihai Gao: . Xiaoming Bao: . Sanhu Fan: . Taigang Mo: . Li Han: Conceptualization, Supervision, Validation, Writing – review & editing. Dingkun Zhang: Conceptualization, Supervision, Validation, Writing – review & editing. Junzhi Lin: Conceptualization, Supervision, Validation, Writing – review & editing.

Acknowledgements

This study was supported by grants from the National Natural Science Foundation of China (81973493); Open Project of State key Laboratory of Innovation Medicine and High Efficiency and Energy Saving Pharmaceutical Equipment in Jiangxi University of Traditional Chinese Medicine (GZSYS202005); Sanajon Pharmaceutical Group Chengdu University of TCM production, study and Research Joint Laboratory Project (2019-YF04-00086-JH) and Sichuan Province Science and Technology Plan Funded Project (2021YFN0100). Thanks to Innovative Institute of Chinese Medicine and Pharmacy of Chengdu University of TCM for its technical support in mass spectrometry work.

Data Availability Statements

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Conflict of interest

Author Sanhu Fan and Taigang Mo were employed by company Sanajon Pharmaceutical Group. All other authors declare no competing interests.

References

- Potential of tara (Caesalpinia spinosa) gallotannins and hydrolysates as natural antibacterial compounds. Food chemistry.. 2014;156:301-304.

- [CrossRef] [Google Scholar]

- Simultaneous determination and characterization of tannins and triterpene saponins from the fruits of various species of Terminalia and Phyllantus emblica using a UHPLC-UV-MS method: application to triphala. Planta medica.. 2013;79:181-188.

- [CrossRef] [Google Scholar]

- Scope of Hydrolysable Tannins as Possible Antimicrobial Agent. Phytotherapy research : PTR.. 2016;30:1035-1045.

- [CrossRef] [Google Scholar]

- A novel quantified bitterness evaluation model for traditional Chinese herbs based on an animal ethology principle. Acta pharmaceutica Sinica. B.. 2018;8:209-217.

- [CrossRef] [Google Scholar]

- Exploration on the Approaches of Diverse Sedimentations in Polyphenol Solutions: An Integrated Chain of Evidence Based on the Physical Phase, Chemical Profile, and Sediment Elements. Frontiers in Pharmacology.. 2019;10:11.

- [CrossRef] [Google Scholar]

- Potential effect of tropical fruits Phyllanthus emblica L. for the prevention and management of type 2 diabetic complications: a systematic review of recent advances. European journal of nutrition. 2021

- [CrossRef] [Google Scholar]

- Phytochemical Screening and Antioxidant Properties of Phyllanthus emblica from Mauritius. Chemistry of Natural Compounds.. 2018;54:50-55.

- [CrossRef] [Google Scholar]

- Li, P., D. K. Zhang, J. Z. Lin, et al., 2019. [Optimized model for formulation prescription of traditional Chinese medicine buccal tablets based on temporal dominant description of sensations combined with multivariate statistical analysis:an example of Compound Caoshanhu Buccal Tablets]. Zhongguo Zhong yao za zhi = Zhongguo zhongyao zazhi = China journal of Chinese materia medica. 44, 3035-3041. https://doi.org/10.19540/j.cnki.cjcmm.20190410.303.

- Grape and wine polymeric polyphenols: Their importance in enology. Critical reviews in food science and nutrition.. 2019;59:563-579.

- [CrossRef] [Google Scholar]

- Ling, M., Y. Zhou and Y. Lan, 2021. Modification of Sensory Expression of 3-Isobutyl-2-methoxypyrazine in Wines through Blending Technique. 26, https://doi.org/10.3390/molecules26113172.

- Kinetics of non-catalyzed hydrolysis of tannin in high temperature liquid water. Journal of Zhejiang University. Science. B.. 2008;9:401-406.

- [CrossRef] [Google Scholar]

- Interactions between stimuli with different taste qualities. Physiology & behavior.. 1973;10:1101-1106.

- [CrossRef] [Google Scholar]

- Antimicrobial Activities of Ellagitannins against Clostridiales perfringens. Escherichia coli, Lactobacillus plantarum and Staphylococcus aureus.. 2020;25

- [CrossRef] [Google Scholar]

- Interaction of polyphenols with model membranes: Putative implications to mouthfeel perception. Biochimica et biophysica acta. Biomembranes.. 2020;1862:183133

- [CrossRef] [Google Scholar]

- Antibacterial spectrum of plant polyphenols and extracts depending upon hydroxyphenyl structure. Biological & pharmaceutical bulletin.. 2006;29:2226-2235.

- [CrossRef] [Google Scholar]

- Emblica officinalis (Amla): A review for its phytochemistry, ethnomedicinal uses and medicinal potentials with respect to molecular mechanisms. Pharmacological research.. 2016;111:180-200.

- [CrossRef] [Google Scholar]

- Composition and biological activities of hydrolyzable tannins of fruits of Phyllanthus emblica. Journal of agricultural and food chemistry.. 2014;62:529-541.

- [CrossRef] [Google Scholar]

- Bulk, Foam, and Interfacial Properties of Tannic Acid/Sodium Caseinate Nanocomplexes.. 2018;66:6832-6839.

- [CrossRef]

- Improving the sweet aftertaste of green tea infusion with tannase. Food chemistry.. 2016;192:470-476.

- [CrossRef] [Google Scholar]

- Microbial bioconversion of the chemical components in dark tea. Food chemistry.. 2020;312:126043

- [CrossRef] [Google Scholar]

- The material basis of astringency and the deastringent effect of polysaccharides: A review. Food chemistry.. 2023;405:134946.

- [CrossRef] [Google Scholar]