Thermophysical properties of nanofluids and their potential applications in heat transfer enhancement: A review

⁎Corresponding authors. sunilthakur@shooliniuniversity.com (Sunil Kumar), dan.dobrota@ulbsibiu.ro (Dan Dobrotă)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Colloidal suspensions of nanoparticles in a base fluid, known as nanofluids, have become increasingly popular in recent years due to their unique thermophysical features and promising heat transfer applications. This article provides an in-depth look at the latest developments in the field of nanofluids, covering everything from their synthesis techniques to their thermophysical characteristics. The advantages and disadvantages of nanofluids and their prospective uses in heat exchangers were also discussed. Study reveals that hybrid nanofluids are good alternatives in different heat exchangers as compared to simple fluids because of their better thermal performance. The stability of the thermal system not only influences the system's thermophysical parameters but also influences the system's performance. It has also been compared to how well nanofluids and conventional fluids function in heat exchangers. In conclusion, this article is a great reference for scientists and engineers who want to learn more about the use of nanofluids in heat transfer.

Keywords

Nanofluids

Thermophysical properties

Heat Exchanger

Nomenclature

- Symbols

-

Units

-

-

Nusselt number, Dimensionless

-

-

Reynolds number, Dimensionless

- Cp

-

Specific Heat Capacity,

-

-

Thermal conductivity of Nanofluid,

- Kp

-

Thermal conductivity of the particles,

-

-

Thermal conductivity of base fluid,

- T

-

Temperature,

-

-

Base fluid Viscosity,

-

-

Maximum particles packing fraction, Dimensionless

-

-

Nanofluid Viscosity, Pa/s

-

-

Volume fraction of particles, Dimensionless

-

-

Viscosity, Pa/s

-

-

Temperature of Nanofluid, K

Greek Symbols

- Bf

-

Base fluid

- CNT

-

Carbon Nano Tube

- HE

-

Heat Exchanger

- HT

-

Heat Transfer

- HTC

-

Heat Transfer Coefficient

- HNF

-

Hybrid Nanofluid

- MWCNT

-

Multi-walled carbon nanotube

- NFs

-

Nanofluids

- NPs

-

Nanoparticles

- PEG

-

Polyethylene-glycol

- PAS

-

Primary alkyl sulphate

- SDS

-

Sodium Dodecyl Sulphate

- SDBS

-

Sodium Dodecyl Benzene Sulphonate

Abbreviations:

1 Introduction

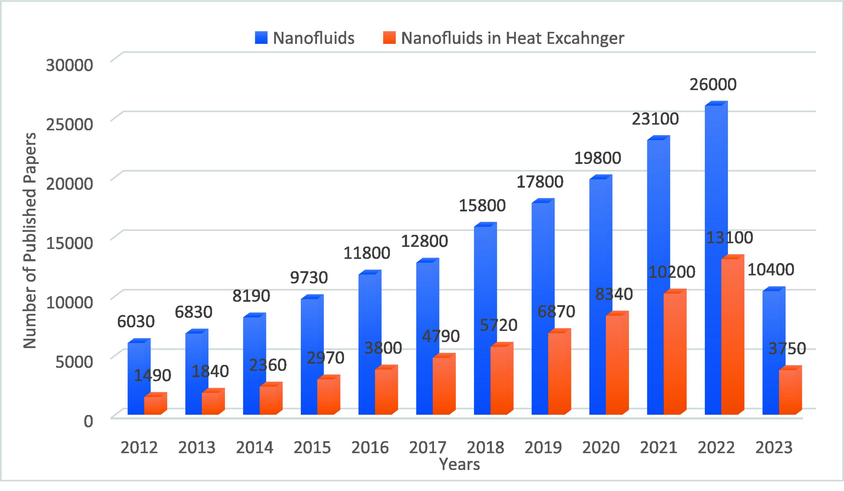

Nanofluid is an attractive heat transfer fluid for use in better heat transfer (HT) applications due to its excellent thermal conductivity and rheological properties (Mikkola et al. 2018). When these millimeter or micrometer-sized particles are added to the base fluid, the base fluid's thermophysical properties change, making heat transfer better (Sundar et al. 2017). The unique properties of nanofluids, such as improved heat transfer performance, and increased stability, have led to their application in various fields. Adding nanoparticles to the base fluid alter its properties, resulting in improved performance compared to traditional fluids (Salman et al. 2020). The heat transfer rate and efficiency improved thermal performance of heat sinks for cooling electronic processors by using nanofluids (Afshari & Muratçobanoğlu, 2023). The application of nanofluids is broadly classified into two categories: heat transfer and non-heat transfer applications. In HT applications, nanofluids are used as coolants in industries such as automotive, aerospace, and electronics (Saidina et al. 2020). The enhanced thermal conductivity of nanofluids results in improved HT performance and reduced energy consumption (Kumar et al. 2022b). Overall, the application of nanofluids is a rapidly growing area that could have many different uses in various industries. The unique properties of nanofluids make them promising alternatives to traditional fluids, and ongoing research is focused on optimizing their performance for different applications in heat exchangers. The stability of the nanofluids and sedimentation of particles are operated in the field of heat exchanger by nanofluids (Afshari et al. 2022). Over the past ten years, the significance of Nanofluid research has become more apparent, as shown in Fig. 1, which lists the number of articles published since 2012 that mention nanofluids. These studies cover those that deal with their preparation, thermophysical properties measurement, and use in several applications. The information in Fig. 1 was discovered by looking through titles, abstracts, and keywords in Google Scholar for the terms “Nanofluids” and “Nanofluids in Heat Exchanger” over the time displayed. The search revealed that 26,000 papers were circulated in 2022 alone, and this trend is expected to continue in the years to come.

- The popularity of Nanofluids in last ten years. (Google Scholar for the search of Nanofluids, April 2023).

The novelty of this review paper would lie in its focus on the latest development in the synthesis, characterization, and application of developing applications for nanofluids in areas including energy storage and desalination and biomedical engineering, highlighting the potential for these materials to enable new technologies and solutions for important social challenges.

This review article aims to provide a comprehensive summary of the current state of the art in the subject of nanofluids and their potential to enhance heat transfer in heat exchangers. In section 2 included an overview of NFs and their preparation. Section 3 outlined nanofluids' discussed most important properties such as thermal conductivity, viscosity, density, and specific heat capacity are all vital thermophysical qualities. Section 4 reviewed various nanofluids' applications related to heat exchangers, desalination, and bio-medical applications. The 5th section showed the challenges in nanofluid applications. Lastly, the section shows some concluding remarks and suggestions for future research.

2 Nanofluid, preparation and stabilization

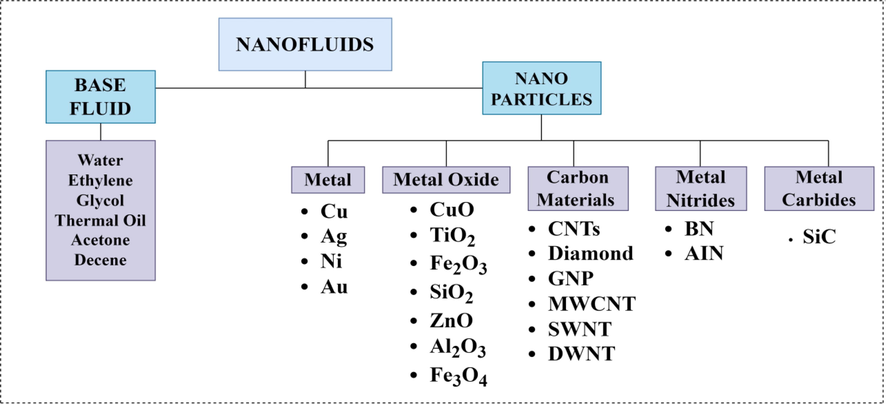

Nanofluids are a type of fluid that has been engineered to have nanoparticles suspended in them. This suspension gives the nanofluid enhanced properties, such as increased heat transfer (HT) efficiency and thermal conductivity. NFs can be used to improve the performance of heating and cooling systems, increase the efficiency of solar cells, and even enhance the delivery of drugs to specific targets in the body (Nobrega et al. 2022). NFs are promising new technology that could revolutionize many industries in the future.

There are many nanofluids which are prepared by the mixture of nanoparticles and base fluids (BFs), like Copper oxide (CuO), Alumina

- Illustration of Various Base Fluids and Nanoparticles (Sajid & Ali, 2019).

2.1 Preparations of nanofluids

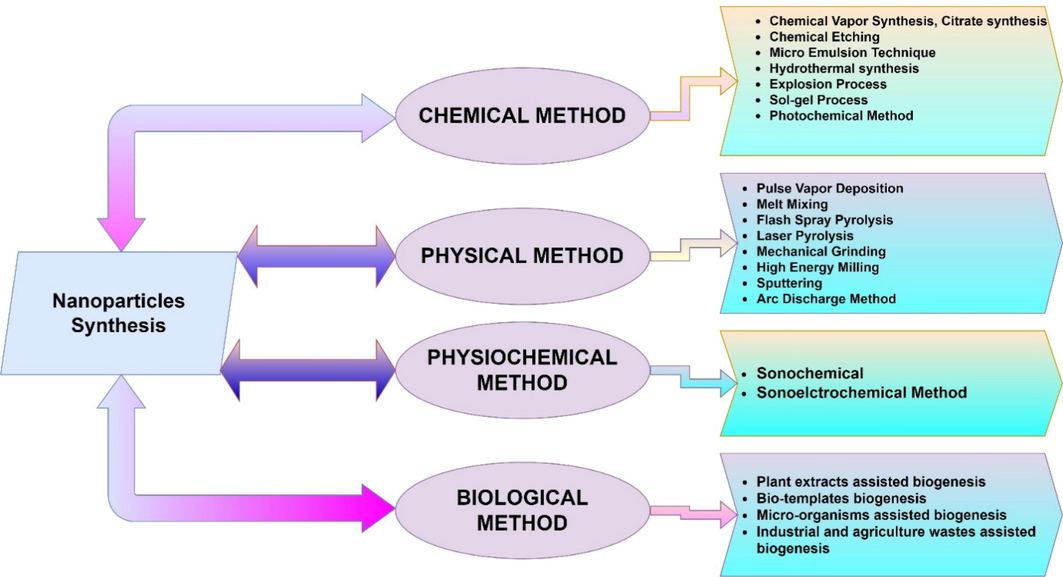

The preparation of nanofluid is essential because it determines their stability. In general, researchers created nanofluids using the one-step and two-step method. The one-step method makes and disperses nanoparticles in BFs. This method avoids nanoparticle drying, storage, transportation, and dispersion. NFs have better thermal conductivity, diffusivity, convective HTC and viscosity than water or oil (Bakthavatchalam et al. 2020). NFs combine carbon, metal, oxide, and ceramic NPs with BFs, including,

- Different methods of synthesizing nanoparticles (Bakthavatchalam et al. 2020).

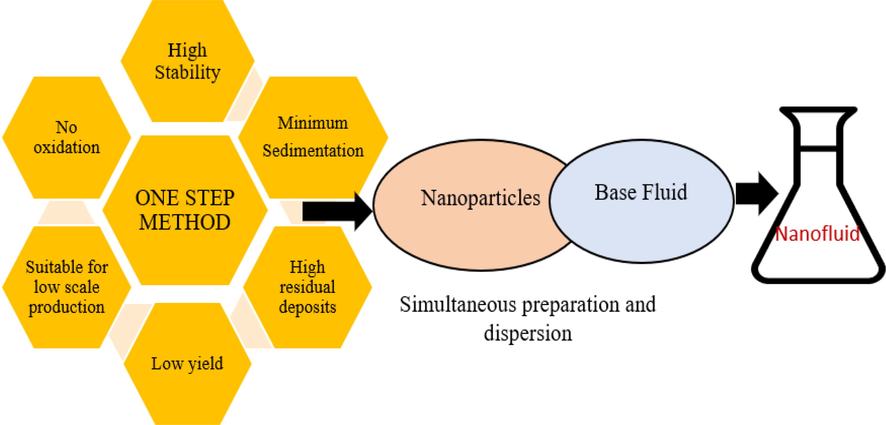

2.1.1 One step method

In a one-step method, the -size particles are made and dispersed into BFs simultaneously, which usually leads to less agglomeration (Chakraborty & Panigrahi 2020). Fig. 4 demonstrates the synthesis and dispersion of nanoparticles through this method. The one-step process had good dispersion stability compared to the two-step method (Aberoumand & Jafarimoghaddam 2018). The benefits and drawbacks of the one-step approach are laid out in Table 1. The most popular one-step method includes microwave radiation, laser ablation in liquid (LAL) etc. Microwave radiation includes microwave irradiating of microwave radiation includes microwave irradiating the initial solution utilizing the presence of a reducer. Energy for heating the fluid and driving the nucleation process comes from microwave irradiation(Zhu et al. 2004).

- One-Step Method (Bakthavatchalam et al. 2020).

| One-Step Method | Double-Step Method | ||

|---|---|---|---|

| Advantages | Disadvantages | Advantages | Disadvantages |

| No StorageNo Drying | High deposit of residual reactants | Most simple and economical | Need surfactant or functionalisation |

| No oxidationNo transportation | Suitable for low-pressure base liquids | Ideal for large scale | Increase of self-weight |

| No Re-dispersionrequirement | Not scaled up for large-scale production | Suitable for oxide nanoparticles | Rapid sedimentation, Quick agglomeration |

| Less agglomerationHigh Stability | The synthesis method is expensive | Cost-effective production | High surface energy |

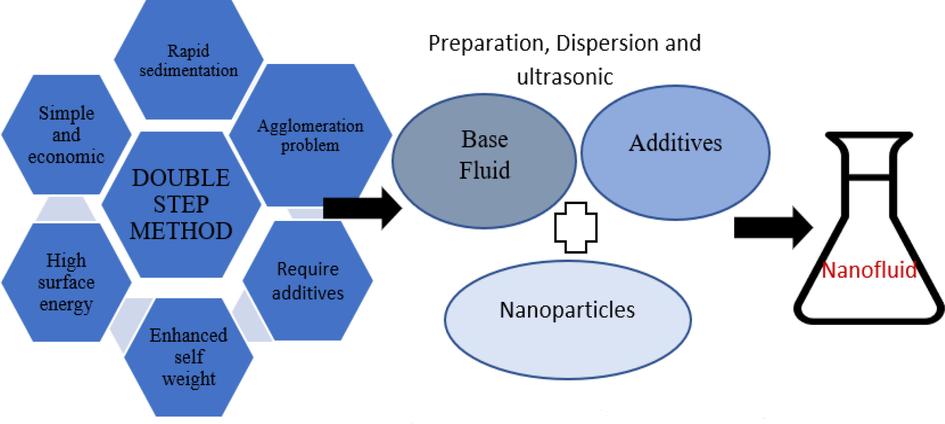

2.1.2 Double-Step method

The double-step method involves the dispersion of these nanoparticles in the BFs using various techniques like ultrasonication, high shear mixing and mechanical or magnetic stirring. The NPs are produced first and subsequently dispersed into BFs (Chakraborty & Panigrahi 2020). This method is highly effective in achieving better performance than the one-step method. However, when preparing nanofluid using the double-step method, it tends to result in high, agglomeration, leading to reduced stability compared to the One-step method (Mohammadpoor et al. 2019). Then, the dry powder nanoparticles are merged into the BFs using ultrasonic agitation and mixing, as shown in Fig. 5. There are some advantages and disadvantages of the double-step method which are shown in Table 1.

- Double-Step Method (Bakthavatchalam et al. 2020).

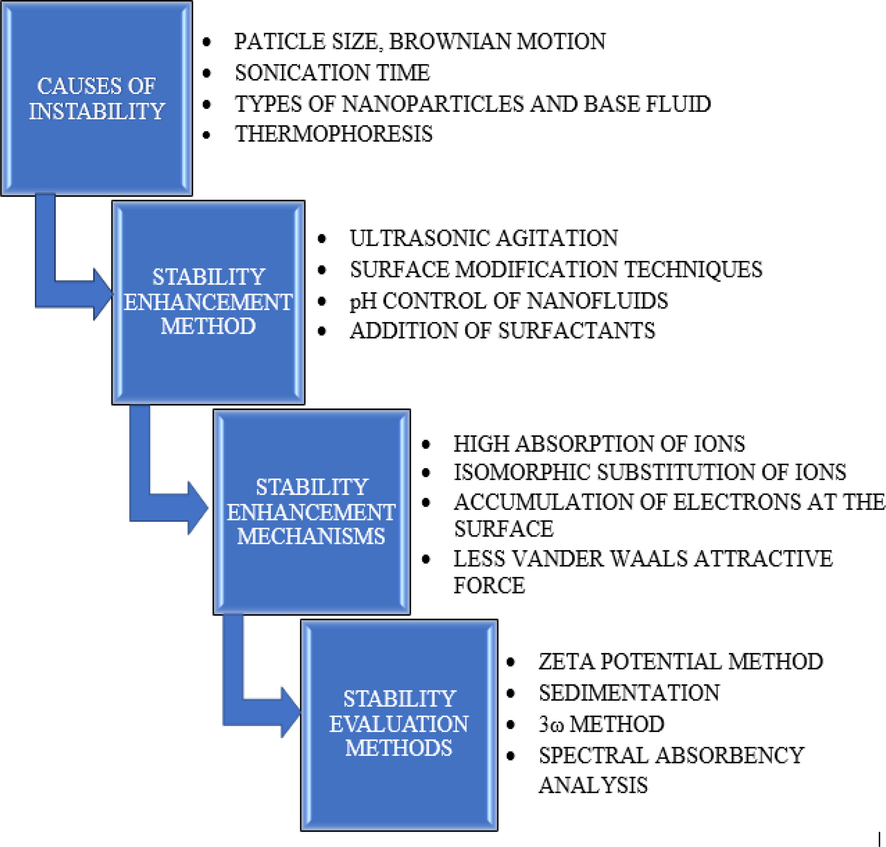

2.2 Stabilization of nanofluids

To prevent this undesirable behaviour and enhance the stability of nanofluids, surfactant are often used. Surfactants help prevent the agglomeration of NPs by reducing the surface tension between the NPs and the BFs (Gülmüş et al. 2023). Surfactants are containing both hydrophilic and hydrophobic region in their molecular structure. They absorb at the liquid–gas or liquid–liquid interfaces, reducing surface tension and improving the dispersion and stability of nanofluids. The stability of nanofluids is directly connected to their properties (Mukherjee et al. 2018). There are different types of surfactants to stabilize nanofluids like cationic, anionic, amphoteric and non-ionic. They also function as wetting agents, preventing the formation of droplets on the surface of solid particles suspended in a liquid. Other standard methods of stabilization include the use of shear thinning agents, the addition of electrolytes, and high-frequency ultrasound. There are some important aspects of stability shown in Fig. 6.

- Important aspects for the stability of NFs (Bakthavatchalam et al. 2020).

There are some drawbacks of using surfactants. Surfactants may exhibit significantly changes in their properties, particularly at elevated temperature. These changes can impact their effectiveness in stabilizing nanofluids potentially leading to reduced stability (Anggraini et al. 2020).

3 Thermophysical properties of nanofluids

To predict the HT behaviour of NFs, knowledge of their thermophysical properties is crucial. There is no contention that the addition of NPs, which have distinct thermophysical properties, alters the thermophysical properties of typical working fluids. There are some thermophysical properties of nanofluids like thermal conductivity, viscosity, specific heat capacity and density. By including nanoparticles into the BF, its thermal conductivity, viscosity, density, and specific heat can be considerably improved, all of which have an impact on the convective HT. The size, shape, concentration, and type of NPs as well as the qualities of the Bf all have an impact on the thermophysical parameters of NFs. This section gives a comprehensive and up-to-date review of the thermophysical characteristics and influencing factors of various BFs and nanoparticles (Said et al. 2021).

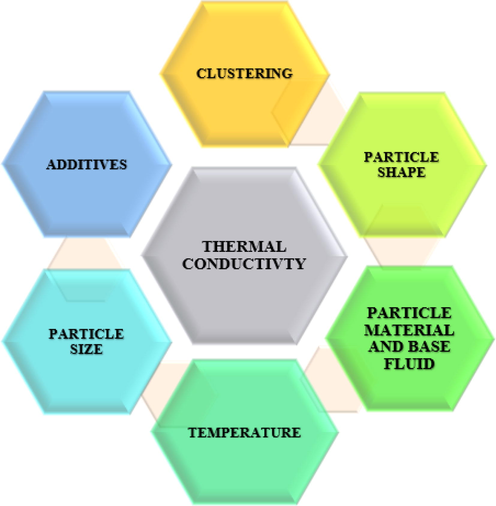

3.1 Thermal conductivity

The variation in nanofluids' thermal conductivity has been the subject of extensive theoretical and experimental study. As can be shown in Fig. 7, the thermal conductivity of NFs is affected by a wide range of parameters, including particle (size, shape, and material) and Bf, additives, and temperature. The thermal conductivity of NFs appears to be the most researched attribute in the existing literature. NFs are distinct from regular BFs because of their improved thermal conductivity and other novel thermophysical features (Okonkwo et al. 2021). For the thermal conductivity of nanofluid, extensive experimental research was carried out utilizing various methodologies, which are discussed below.

- Factors affecting the thermal conductivity of NFs (Gupta et al. 2017).

3.2 Previous studies on thermal conductivity of nanofluids

Besides the numerical studies, there are so many experimental studies which different researchers have taken out to investigate the thermal conductivity of NFs using different types of BFs. How dispersant concentration and other parameters such as mass fraction, temperature, and standing time influenced CNT-nanofluid thermal conductivity. They discussed and observed the 20–60 °C range for temperature and

Other various researchers have shown numerous theoretical studies to study the changes in the thermal conductivity of NFs (Yu and Choi (2003); Khdher et al. (2016); Yang et al. (2017); Pare & Ghosh (2021)). Maxwell (1873) presented the first correlation to compute suspension thermal conductivity of constituent phases and solid phase volume fraction. However, the correlation was only applicable to spherical particles. Hamiliton and Crosser (1962) suggested a modified Maxwell model with an empirical shape factor to extend the correlation to non-spherical particles. Xue (2005) calculated effective thermal conductivity using the very large axial ratio and spatial distribution of CNTs. Alawi et al. (2018) investigated the thermal conductivity of metallic oxide NFs for various NPs shapes and concentrations to enhance thermal system performance. Different researchers have created different theoretical and experimental models for determining the thermal conductivity of NFs, and a summary of these approaches is provided in Table 2.

| Researchers | Model | Remarks |

|---|---|---|

| (Maxwell, 1873) |

|

The effective thermal conductivity of NFs is a function of the particle size distribution, BF content, and volume concentration. |

| (Hamiliton and Crosser, 1962) |

|

The proposed combined liquid–solid mixture of various non-spherical particles has a thermal conductivity rate of the particles and BFs greater than 100. |

| (Xue, 2005) |

|

They discussed for the important properties of carbon-nano tube (CNT) |

| (Yu and Choi, 2003) |

|

The influence of ordered nanolayers on NFs is accounted for in the revised important nanofluid Maxwell equation for effective thermal conductivity. |

| (Khdher et al. 2016) |

|

The thermal conductivity of BFs was shown to be a linear function of concentration, temperature, and the newly developed correlation. |

| (Yang et al. 2017) |

|

New thermal conductivity model for nanorod-based NFs. |

| (Yang & Xu, 2017) |

|

Modified Hamilton–Crosser model predicts effective thermal conductivity of CNT-based NFs. |

| (Alawi et al. 2018) |

|

Metallic oxide nanofluid thermal conductivity ratio increases with temperature and NPs volume%, but intensity increases as NPs size reduces. |

| (Pare & Ghosh, 2021) |

|

They discussed and implemented artificial neural network model to predict thermal conductivity of NFs were measured between 20 °C and 90 °C |

3.3 Viscosity

The viscosity (μ) of nanofluids has been studied a great deal in recent decades because it could be useful in many industrial and medical fields. The accumulation of nanoparticles to the BF can increase its viscosity due to high surface area and interparticle solid forces (Girard et al. 2021). The viscosity of NFs is affected by several factors such as type, concentration, size, and surface characteristics of NPs, as well as the type of BFs. Moreover, the temperature also affects the viscosity of NFs, with increasing temperature resulting in decreasing viscosity (Suresh et al. 2011). Several experimental studies have been shown on the viscosity of NFs, which are further discussed in the following section.

3.4 Previous studies on viscosity of nanofluids

There are numerous experimental studies in addition to the numerical ones that different researchers have carried out to investigate the

| Researchers | Model | Remarks |

|---|---|---|

| (Einstein, 1906) |

|

This expression was assumed to be a spherical particle of very low volume fraction

|

| (Brinkman, 1952) |

|

This formula is only applicable for low particle concentration (

|

| (Krieger & Dougherty, 2014) |

|

Semi-empirical viscosity relation for particle

|

| (Wang & Xu, 1999) |

|

Predict the viscosity of NFs. |

| (Nguyen et al. 2008) |

|

Together the Brinkman and Batchelor formulas strictly underestimate the NFs viscosity unless the particle

|

| (Avsec & Oblak, 2007) |

|

Using the exponential formula to calculate the viscosity of NFs. |

| (Masoumi et al. 2009) |

|

Predicting the viscosity of NFs. |

| (Klazly & Bogn, 2022) |

|

New correlation standardized to BF dynamic viscosity. |

3.5 Specific heat capacity (Cp)

To a large extent, the NFs heat transfer rate is determined by its specific heat capacity (Cp). That fluid are suspensions containing NPs dispersed into BF. Several factors influence the Cp of NPs, including their type and concentration of NPs, their size and shape, and the properties of BFs. One notable effect of incorporating NPs into BF is increased thermal conductivity of NFs, which can lead to higher Cp values compared to BFs alone.

3.5.1 Previous studies on the specific heat of nanofluids

There have been a lot of earlier investigations on the specific heat capacity of nanofluids Xi & Pan (2017). Table 4 presents theoretical equations for nanofluid-specific heat capacity that have been studied both experimentally and theoretically. Benigno Barbe et al. (2012) derived equation from the data of Cp measurements of

| Researchers | Model | Remarks |

|---|---|---|

| (Barbe et al. 2012) |

|

The first law of thermodynamics accurately justifies nanofluid Cp. |

| (Sekhar & Sharma, 2015) |

|

The Cp of the nanofluid reduced as particle concentration increased due to an increase in thermal diffusivity. |

| (Cabaleiro et al. 2015) |

|

New correlation was found of specific heat capacity |

| (Alklaibi et al. 2021) |

|

Specific heat correlation for nanodiamond/water NFs. |

| (Sundar et al. 2021) |

|

Specific heat connection for nanodiamond +

|

3.6 Density

Density is a thermophysical properties that affects nanofluid heat transfer performance. It impacts Re, friction factor, pressure loss, and

3.6.1 Previous studies on density of Nanofluids

Density affects flow parameter and friction factor, hence it must be evaluated and used in HT. The increase in density of NFs is primarily due to the additional mass of the nanoparticles. NPs have a much higher density than most BFs, and their addition can significantly increase the overall density of the nanofluid (Said et al. 2021). As may be seen, earlier equations on the density of NFs are displayed in Table 5.

| Researchers | Model | Remarks |

|---|---|---|

| (Vsajjha et al. 2009) |

|

Determined the value of ρ (Density) of various nanofluids |

| (Alklaibi et al. 2021) |

|

A density correlation for water nanofluids was developed. |

| (Sundar et al. 2021) |

|

Density relation for nanodiamond + Fe3O4/60:40% water and EG mixture created on the HNF. |

| (Saleh & Sundar, 2021a) |

|

Density relation for nanodiamond + Fe3O4/water HNF. |

4 Applications of nanofluids

Nanofluids, which are liquids containing nanoparticles of metals, oxides, or other materials, have established much interest in recent years because of their potential to improve HT capabilities. Here are some of the applications of nanofluids.

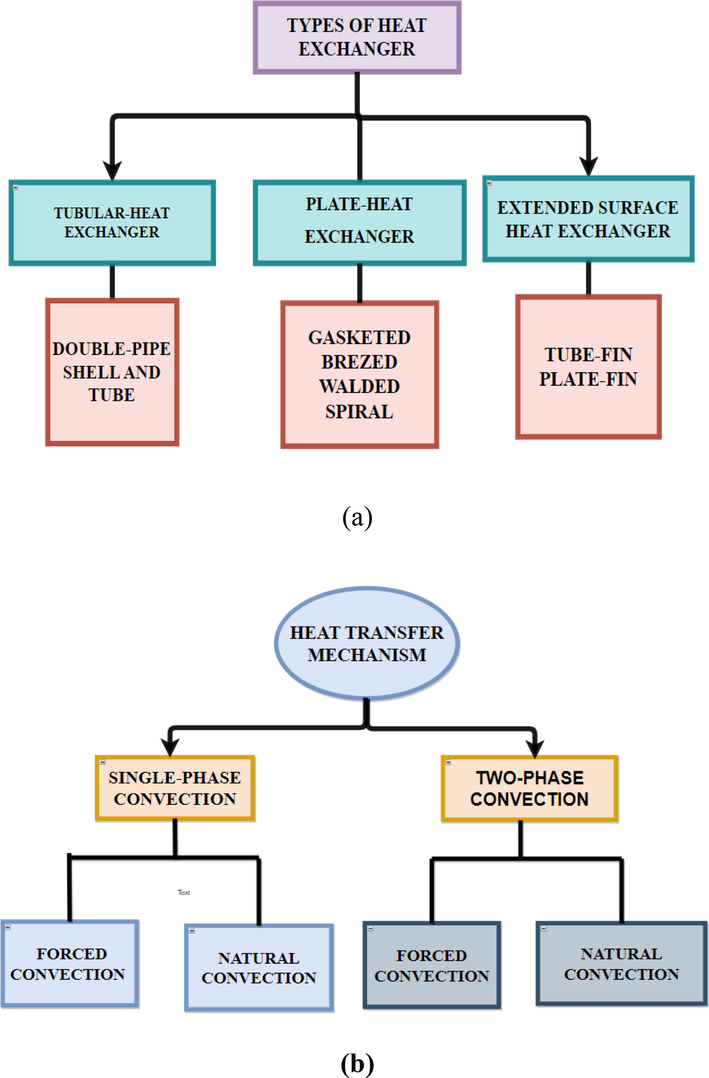

4.1 Application in different heat exchangers

Transferring thermal energy from one fluid to another is the primary function of heat exchangers. HT devices, such as heat exchangers, typically use NFs as working fluids. Classifying HEs according to the HT method used is seen in Fig. 8. When it comes to heat exchangers, there are two main types: direct contact and indirect contact. Nonetheless, the HT technique can be utilised to further categorise these tools. Vallejo et al. (2022) performed independently on mono or HNF for single and two-phase convective HT applications. The usage of NFs in various types of HE has been researched and described further below.

- (a) Types of heat exchanger and (b) classification of heat exchanger according to heat transfer mechanism (Vallejo et al. 2022).

4.1.1 In Double–Tube heat exchanger (DTHE)

The DTHE is a popular choice for many commercial and industrial processes, such as those involved in the manufacture of chemicals and beverages. A greater overall heat transfer coefficient (HTC) and more efficient HE can be achieved by incorporating NPs into the BFs in order to improve their thermal conductivity (J. Zhao et al. 2022). In addition, the use of NFs can reduce the size and weight of the HE, which can be particularly beneficial in applications where space is limited. The thermal performance of

4.1.2 In plate heat exchanger (PHE)

PHE are widely used in various industries for heat transmission applications, and the use of nanofluids in these HE can enhance their performance. Many research have been conducted to study the use of NFs in PHE and the outcomes revealed significant increases in HT rates. Alklaibi et al. (2022) investigated MWCNT-

4.1.3 In shell and tube heat exchanger

Heat exchangers (HEs) of the shell and tube variety feature a cylinder with a number of tubes inside it. Inside the shell, the tubes (often metal) are organised in a specific pattern. Barzegarian et al. (2017) deliberate the HT performance under laminar regime in horizontal shell-and-tube HE is with water-based

| Reference | NFs | Test section | Flow regime | Nano additives concentration | Remarks |

|---|---|---|---|---|---|

| (Naddaf et al. 2019) | OA-MWCNT/diesel oil | Tube | Laminar | 0.05–0.5 wt% | 0.5 wt% OA-MWCNT/diesel oil mono nanofluid increases ΔP by 9.9%. |

| (Hashemzadeh & Hormozi, 2020) |

|

Minichannel heat sink | Laminar | 0.05–0.2 vol% |

|

| (V. Kumar & Sarkar, 2020a) |

|

Minichannel heat sink | Laminar | 0.01 vol% | MWCNT/

|

| (Bhattad et al. 2019) |

|

Plate heat exchanger | Laminar | 0.01 vol% | MWCNT/

|

| (Bhattad et al. 2020) |

|

Plate heat exchanger | Laminar | 0.01 vol% |

|

| (Klazly et al. 2022) |

|

– | Laminar | 1 vol% |

|

| (Esfe et al. 2022) |

|

Tube | Laminar | – | HT rate and average

|

| (Omri et al. 2022) | CNT-

|

Microchannel heat exchanger | Laminar | 0-5 vol% | CNT nanofluid and triangular fins significantly improve HE. |

| (Zhong et al. 2020) | DW/

|

Multiport mini channel | Laminar and turbulent | 0.5 – 1 vol% | HT performance is improved for

|

4.2 Desalination application

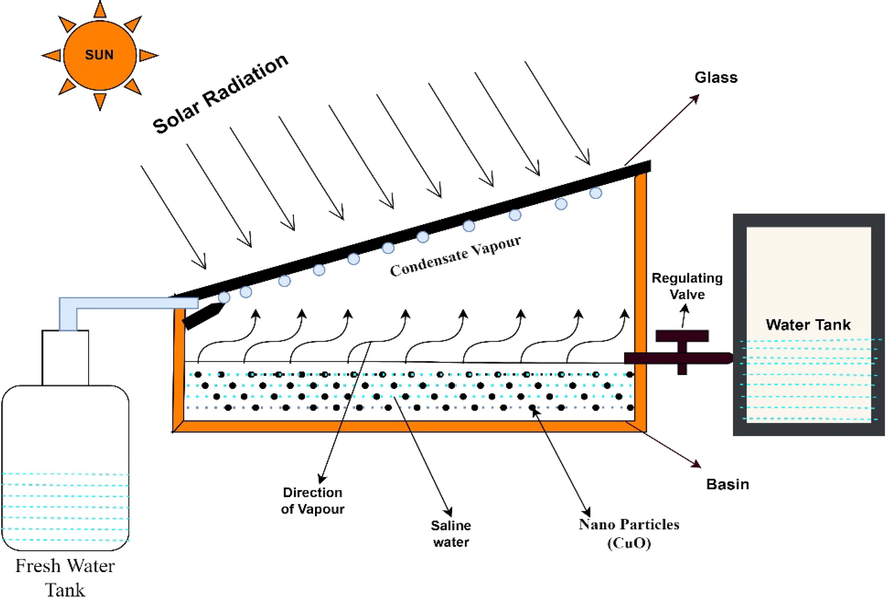

Nanofluids offers a promising solution for improving HT rates in desalination expedient and freshwater manufacture rates. This process is critical to providing the proper freshwater quantities for humanity (Lee et al., 2011; Patel & Modi, 2020). Various researchers have proposed different techniques to enhance freshwater manufacture, but these often come with increased energy consumption. In contrast, researchers like (Masoud et al. 2020; Sha et al. 2020; Iqbal et al. 2021; He et al. 2022) have explored the use of solar energy-driven desalination system to produce clean water. Solar-powered desalination systems demonstrated significant improvement by employing NFs to enhance system performance. The design of the desalination system is displayed in Fig. 9.

- Schematic illustration of the solar desalination system (Iqbal et al. 2021).

4.3 Bio-medical application

The biomedical industry relies heavily on nanoparticles and nanofluids for a variety of important applications. The importance of NP suspension fluids in various medical industry areas like drug-delivery, disease diagnosis, antibacterial cases, bio-medical component cooling, cryopreservation, sterilisation processes, and micro-pumping systems for drug and hormones has been reported in studies. However, NFs must be used securely by carefully examining parameters, including features, uniform suspension, shape, size, biocompatibility, and crystallinity (Mojgan Sheikhpour et al. 2020).

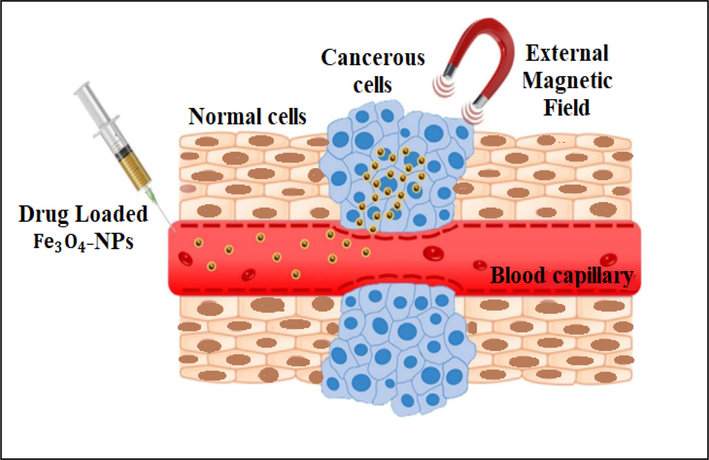

4.3.1 Drug delivery

In recent decades, drug delivery-based nanofluids have been studied to enhance effectiveness and specificity. Surface modification of MNP can improve its biological significance by improving cellular recognition, biocompatibility, and drug release of numerous treatments (Lucena et al. 2016). Jampilek and Kralova (2021) suggested using graphene-based nanofluids in anticancer medication delivery devices. Pin et al. (2020) examined the biological applications of

- Schematic depiction of the mechanism for delivering drugs to specific organs (Pin et al. 2020).

4.3.2 Diagnosis

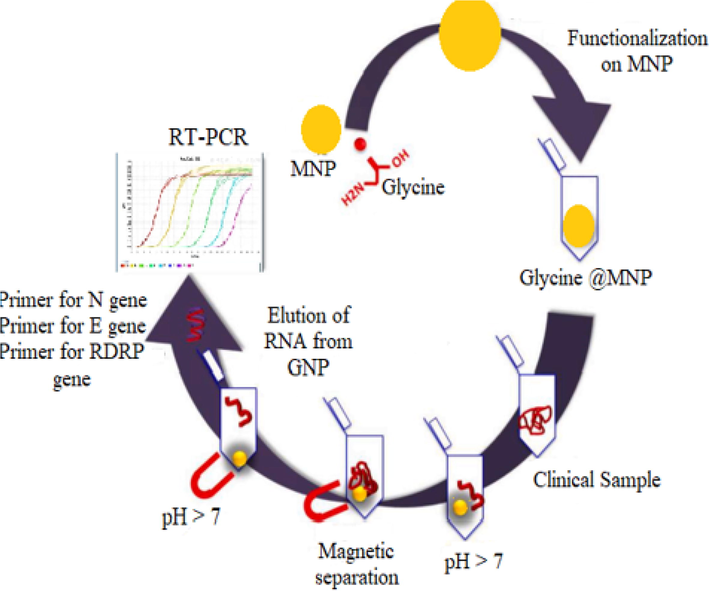

In recent decades, nanofluids have been investigated for diagnosis-based applications in the field of biomedical and molecular biology research. The diagnosis and treatment of COVID-19 caused by the SARS-CoV-2 virus have also been studied, with several novel management strategies being developed. Traditional nucleic acid extraction for COVID-19 diagnosis can be time-consuming, and several studies have explored the use of nanotechnology to make the process more efficient. Weiss et al. (2020), Torres et al. (2020) developed a method that uses magnetic nanoparticles to extract viral RNA, which can be used for diagnosis and treatment. For instance, Z. Zhao (2020) investigated the use of poly amino easter-coted

- Illustration of the Magnetic Nanoparticle-Based Approach for SARS-CoV-2 RNA Detection and Diagnosis of COVID-19 (Prashant et al. 2022).

4.3.3 In solar collectors

To increase the collector's efficiency, nanofluids can be utilised to increase the HT rate from the heated plate to the working fluid. Several studies have focused on improving parabolic trough collector performance (PTC). PTC are installed more than other concentrated solar power technologies worldwide. The latest HT fluids utilised in PTC and nano-enhanced HT fluids with better characteristics are compared (Krishna et al. 2020) where Mashhadian et al. (2021) inspected the environmental performance of a direct absorption PTC using a water-dispersed mixture of

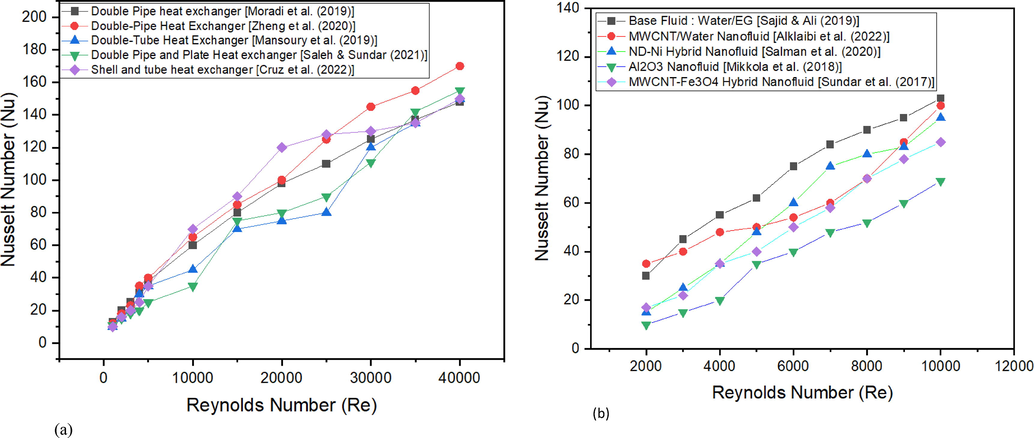

5 Comparative study

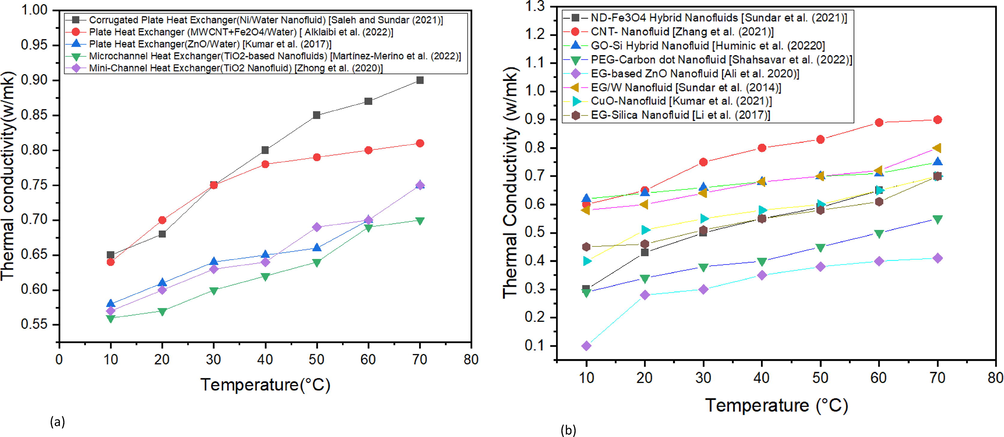

This section displays the comparison of previous published studies on Nanofluid and different types of HE. Fig. 12 (a) and (b) represents the comparison of

- Comparison of

Fig. 13(a) and (b) describe the comparison of Thermal conductivity with Temperature for different heat exchangers (corrugated plate heat exchanger, plate heat exchanger) and various NFs (ND-

- Comparison of Thermal Conductivity and Temperature for (a) Different Heat Exchangers, (b) Different NFs.

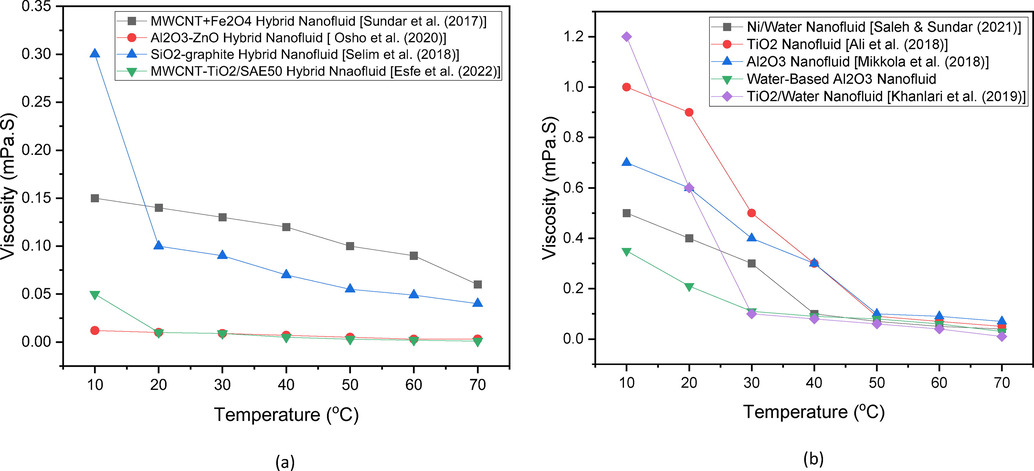

Fig. 14(a) and (b) characterised the comparison of viscosity with Temperature range (10 °C–70 °C) for different hybrid nanofluids (MWCNT-(

- Comparison of Viscosity and temperature for (a) Different Hybrid Nanofluids, (b) Different NFs.

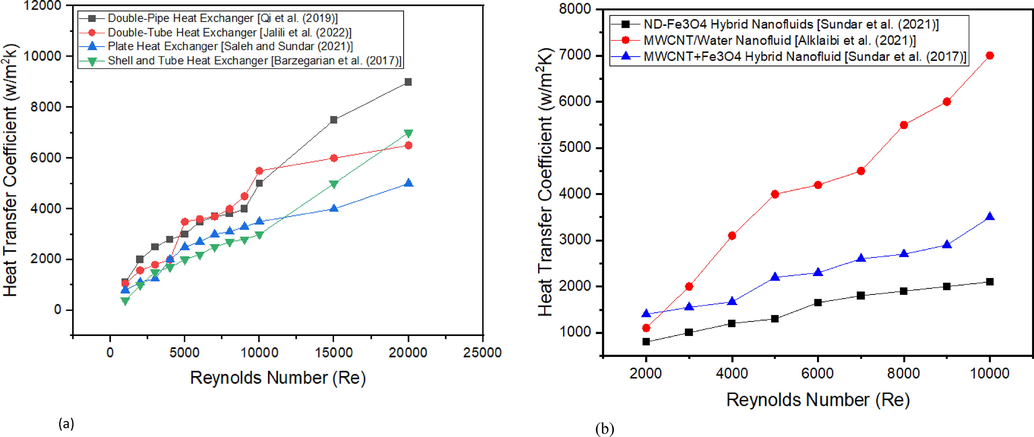

- Comparison of Heat Transfer Coefficient and Reynolds Number for (a) Different Heat Exchanger, (b) Different NFs.

Fig. 15(a) and (b) represent the ratio of HTC to Re for various types of HE (and various NFs (ND-

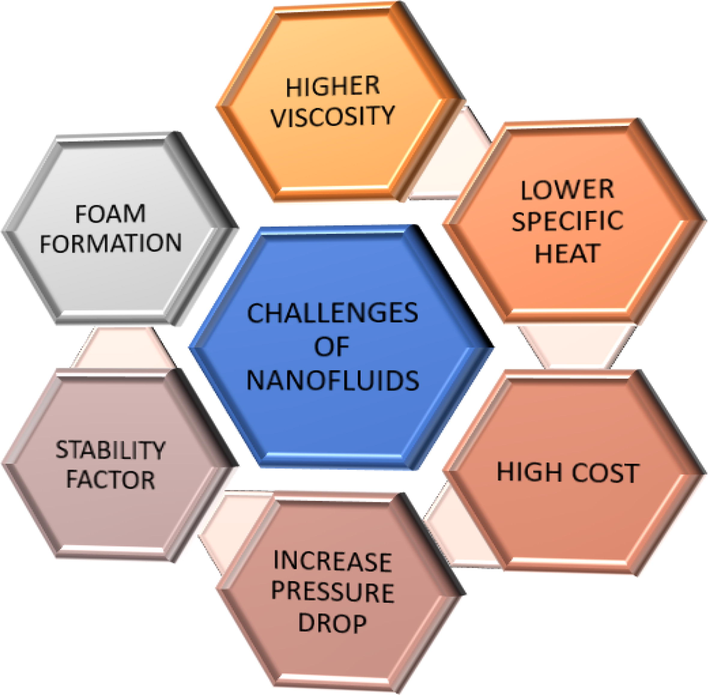

6 Challenges in nanofluid applications

The goal of this review is to examine many challenges in nanofluid applications. The research on NFs has exposed that the implementation of nanofluids HT faces many difficulties. NFs technology has significant opportunities for developing further highly efficient and cost-effective cooling technology, particularly in the fields of defence, transportation, electronics, and manufacturing. The most significant issue for traditional nanofluid conduction, convection, and boiling models is that recorded experimental values always exceed the stated microscopic theories. The common difficulties in using NFs in real-world applications are covered in the following section. Challenges in NFs applications are shown in Fig. 16.

- Challenges in NFs Applications (Said et al. 2021).

6.1 Stability factor of NFs

The ability of nanoparticles to agglomerate in a critical problem faced in the practical application of nanofluids. The Agglomeration affects nanofluid characteristics and heat transmission. Several factors, including time, can affect the size and shape of agglomerates. The factors that affect the stability of a NFs dispersion must be researched and analysed. Laboratory-scale research has difficulty producing stable nanofluids made up of monosized nanoparticles (Said et al. 2021). The exact merit of NFs has not been decided using various mechanical approaches and chemical stabilisers. More challenges associated with using nanofluids include corrosion, clogging, fouling, and compatibility.

6.2 High cost of NFs

The production of nanofluids in huge quantities at an affordable price will be the most challenging goal of any future direction. The cost of NFs is high due to the high cost of NPs. The cost of NPs is driven by the cost of raw materials used to make them, such as rare earth metals and other rare elements (Esfe et al. 2014). The cost of production is also high due to the specialized equipment and processes needed to create NFs. Additionally, NFs are relatively new technology, and the cost of research and development is still high, contributing to the entire cost. Because of their immense price, many consumers do not prefer NFs. Although if manufacturing processes allow for expanded production of NPs and ionic liquids, the cost will stay high.

6.3 Formation of foam

Foam formation in nanofluids is highly challenging because the presence of nanoparticles causes the surface tension of the fluid to increase to an extreme amount. The presence of NPs decreases foam formation because they raise the surface tension of the NF (Bakthavatchalam et al. 2020). The foam formation can be reduced by adding surfactants to the NF, which help to reduce the surface tension. The choice of BF and NPs type can also affect the foam formation.

6.4 Environmental concerns and safety

If nanoparticles are not handled properly, they can be toxic to the environment and have long-term effects if not disposed of properly. NPs can get into the lungs and, the skin, which can cause breathing problems, inflammation, and diseases that can lead to cancer. So, the right rules or parameters must be set up to make and work with NFs (Bakthavatchalam et al. 2020). In the future, nanofluid engineers will have to think about and create NFs by choosing nanoparticles that are not harmful to the environment, human health, or safety. This will allow NFs to be made in large quantities and used in many industries.

7 Conclusions

This article includes a review on the use of NFs for thermophysical properties and applications of NFs in various fields. The purpose is to gain an understanding of the thermophysical features that NFs possess, particularly the thermal conductivity, viscosity, and specific heat capacity of nanofluids. In addition, the paper's conclusion supplies point-by-point observations, which include the whole of the following content:

-

The use of nanofluids in MRI (Magnetic Resonance Imaging), the most exciting imaging and diagnosis technique, has expanded in recent years. In the MRI, the role of the contrast agent is crucial, where some NFs such as

-

The addition of NFs to the desalination system can raise the amount of freshwater produced by between 30 and 40%. The

-

Nanofluids comprising small number of nanoparticles have significantly higher thermal conductivity than those of BFs. The thermal conductivity enhancement of NFs depends on the particle volume fraction, size, type of base fluids and NPs, pH value of nanofluids.

-

Nanofluids can improve heat transmission in base fluids. The concentration of nanoparticles impacts HT because of their higher heat capability from the hot fluid source and the increased enhancement when utilising a high concentration.

-

The hydrothermal performance of HNFs is better than other fluids. It was found that hybrid nanofluids are good alternatives in plate heat exchangers as compared to simple fluids because of their better thermal performance.

-

The stability of NFs continues to be the primary challenge that prevents the application of these fluids in a variety of different industries. The stability of the thermal system not only influences the system's thermophysical parameters but also influences the system's performance. As a result of their instability, NFs gradually lose their functional capabilities over time.

8 Future recommendation

These are some of the reasonable possibilities that investigators can work on nanofluids in the future to propagate their usage in a variety of applications, and these are some of the directions that are being discussed here.

-

There have only been a few of research done on the thermal conductivity of nanofluids at high temperatures. Thus, additional research is required to characterise the thermal conductivity of nanofluids at high temperatures.

-

To better anticipate thermal conductivity and the effect of other characteristics, further research is needed to develop new models and correlations. There is a need for further generalized correlations to be created in respect to the increase of heat transmission by NFs for practical applications.

-

Several studies have used ionic liquid hybrid nanofluids, which could be explored further.

-

Using nanofluids as solar collectors is becoming an increasingly attractive field of study. Several parabolic trough collectors (PTC) research with nanofluids have been published. However, they primarily consider nanofluids with a water and temperatures below 100 °C.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Tungsten (III) oxide (WO3) – Silver/transformer oil hybrid nanofluid: Preparation, stability, thermal conductivity and dielectric strength. Alex. Eng. J.. 2018;57(1):169-174.

- [CrossRef] [Google Scholar]

- Afshari, F., Manay, E., Rahimpour, S., Sahin, B., Muratçobanoğlu, B., Teimuri-Mofrad, R., 2022. a Review Study on Factors Affecting the Stability of Nanofluids. In: Heat Transfer Research, vol. 53, Issue 18, pp. 77–91. https://doi.org/10.1615/HEATTRANSRES.2022041979.

- Thermal analysis of Fe3O4/water nanofluid in spiral and serpentine mini channels by using experimental and theoretical models. Int. J. Environ. Sci. Technol.. 2023;20(2):2037-2052.

- [CrossRef] [Google Scholar]

- Thermal conductivity and viscosity models of metallic oxides nanofluids. Int. J. Heat Mass Transf.. 2018;116:1314-1325.

- [CrossRef] [Google Scholar]

- Preparation techniques of TiO2 nanofluids and challenges: a review. Appl. Sci. 2018

- [CrossRef] [Google Scholar]

- Experimental analysis of exergy efficiency and entropy generation of diamond/water nanofluids flow in a thermosyphon flat plate solar collector. Int. Commun. Heat Mass Transfer. 2021;120:105057

- [CrossRef] [Google Scholar]

- Experimental investigation on the performance of hybrid Fe3O4 coated MWCNT/Water nanofluidas a coolant of a Plate heat exchanger. Int. J. Therm. Sci.. 2022;171(April 2021):107249

- [CrossRef] [Google Scholar]

- Anggraini, R., Putri, V., Ibadurrohman, M., 2020. Development of nanofluid biodegradable detergent from palm kernel oil and TiO2. 020026 (June).

- Recent advances in preparation methods and thermophysical properties of oil-based nanofluids: a state-of-the-art review. Powder Technol.. 2019;352:209-226.

- [CrossRef] [Google Scholar]

- Avsec, J., Oblak, M., 2007. The Calculation of Viscosity and Thermal Conductivity for Nanofluids on the Basis of Statistical Nanomechanics The calculation of thermal conductivity , viscosity and thermodynamic properties for nanofluids on the basis of statistical nanomechanics. October 2007. https://doi.org/10.1016/j.ijheatmasstransfer.2007.01.064.

- Preparation and evaluation of stable nanofluids for heat transfer application: a review. Exp. Therm Fluid Sci. 2016

- [CrossRef] [Google Scholar]

- Thermohydraulic characteristics of a micro plate heat exchanger operated with nanofluid considering different nanoparticle shapes. Appl. Therm. Eng.. 2020;179:115621

- [CrossRef] [Google Scholar]

- Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: a review on current and future perspective. J. Mol. Liquids. 2020;305

- [CrossRef] [Google Scholar]

- Barbe, B., et al., 2012. Thermal conductivity and specific heat capacity measurements of Al2O3 nanofluids Thermal conductivity and specific heat capacity measurements. https://doi.org/10.1007/s10973-012-2534-9.

- Thermal performance augmentation using water based Al2O3-gamma nanofluid in a horizontal shell and tube heat exchanger under forced circulation. Int. Commun. Heat Mass Transfer. 2017;86:52-59.

- [CrossRef] [Google Scholar]

- Experimentation on effect of particle ratio on hydrothermal performance of plate heat exchanger using hybrid nanofluid. Appl. Therm. Eng.. 2019;162(April):114309

- [CrossRef] [Google Scholar]

- Hydrothermal performance of plate heat exchanger with an alumina – graphene hybrid nanofluid : experimental study. J. Braz. Soc. Mech. Sci. Eng.. 2020;42(7):1-10.

- [CrossRef] [Google Scholar]

- Hydrothermal performance of different alumina hybrid nanofluid types in plate heat exchanger: Experimental study. J. Therm. Anal. Calorim.. 2020;139(6):3777-3787.

- [CrossRef] [Google Scholar]

- The viscosity of concentrated suspensions and solutions. J. Chem. Phys.. 1952;571:1-2.

- [CrossRef] [Google Scholar]

- International Journal of Heat and Mass Transfer Specific heat of metal oxide nanofluids at high concentrations for heat transfer. Int. J. Heat Mass Transf.. 2015;88:872-879.

- [CrossRef] [Google Scholar]

- Computational Fluid Dynamics (CFD) analysis of the heat transfer and fluid flow of copper (II) oxide-water nanofluid in a shell and tube heat exchanger. Digital Chem. Eng.. 2022;3(February):100014

- [CrossRef] [Google Scholar]

- Colloids and Surfaces B : Biointerfaces Recent advances in magnetic fluid hyperthermia for cancer therapy. Colloids Surf. B Biointerfaces. 2019;174(October 2018):42-55.

- [CrossRef] [Google Scholar]

- Eine neue Bestimmung der Moleküldimensionen. Annalen der Physik. 1906;324(2):289-306.

- [CrossRef] [Google Scholar]

- Thermophysical properties, heat transfer and pressure drop of COOH-functionalized multi walled carbon nanotubes/water nanofluids. Int. Commun. Heat Mass Transfer 2014

- [CrossRef] [Google Scholar]

- Numerical study of heat transfer of U-shaped enclosure containing nanofluids in a porous medium using two-phase mixture method. Case Stud. Thermal Eng.. 2022;38(June):102150

- [CrossRef] [Google Scholar]

- Evidence-based guidelines for the ultrasonic dispersion of cellulose nanocrystals. Ultrason. Sonochem.. 2021;71

- [CrossRef] [Google Scholar]

- Experimental and numerical investigation of flow and thermal characteristics of aluminum block exchanger using surface-modified and recycled nanofluids. Int. J. Numer. Meth. Heat Fluid Flow. 2023;33(8):2685-2709.

- [CrossRef] [Google Scholar]

- A review on thermophysical properties of nanofluids and heat transfer applications. Renew. Sustain. Energy Rev.. 2017;74:638-670.

- [CrossRef] [Google Scholar]

- Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam.. 1962;1(3):187-191.

- [CrossRef] [Google Scholar]

- An experimental study on hydraulic and thermal performances of hybrid nanofluids in mini-channel: a new correlation for viscosity of hybrid nanofluids. J. Therm. Anal. Calorim.. 2020;140(3):891-903.

- [CrossRef] [Google Scholar]

- Energy and AI Artificial intelligence application in a renewable energy-driven desalination system: a critical review. Energy and AI. 2022;7:100123

- [CrossRef] [Google Scholar]

- Ibrahim, Nguyen, H. M., Bakhtiyari, A.N., Asadi, A., 2019. Feasibility of ANFIS-PSO and ANFIS-GA models in predicting thermophysical properties of.

- Evaluation of the nanofluid-assisted desalination through solar stills in the last decade. J. Environ. Manage.. 2021;277(July 2020):111415

- [CrossRef] [Google Scholar]

- Novel usage of the curved rectangular fin on the heat transfer of a double-pipe heat exchanger with a nanofluid. Case Stud. Thermal Eng.. 2022;35(May):102086

- [CrossRef] [Google Scholar]

- Josef Jampilek and Katarina Kralova. (2021). Advances in Drug Delivery Nanosystems Using. 1–39.

- The effects of tape insert material on the flow and heat transfer in a nanofluid-based double tube heat exchanger: two-phase mixture model. Int. J. Mech. Sci.. 2019;156(December 2018):397-409.

- [CrossRef] [Google Scholar]

- Simulation and experimental analysis of heat transfer characteristics in the plate type heat exchangers using TiO2/water nanofluid. Int. J. Numer. Meth. Heat Fluid Flow. 2019;29(4):1343-1362.

- [CrossRef] [Google Scholar]

- An experimental determination of thermal conductivity and electrical conductivity of bio glycol based Al2O3 nanofluids and development of new correlation. Int. Commun. Heat Mass Transfer. 2016;73:75-83.

- [CrossRef] [Google Scholar]

- Klazly, M., Bogn, G., 2022. A novel empirical equation for the effective viscosity of nanofluids based on theoretical and empirical results. 135 (April). https://doi.org/10.1016/j.icheatmasstransfer.2022.106054.

- Comparison of single-phase Newtonian and non-Newtonian nanofluid and two-phase models for convective heat transfer of nanofluid flow in backward-facing step. J. Mol. Liq.. 2022;361:119607

- [CrossRef] [Google Scholar]

- A mechanism for non-newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol.. 2014;137(1959)

- [CrossRef] [Google Scholar]

- State-of-the-art heat transfer fluids for parabolic trough collector. Int. J. Heat Mass Transf.. 2020;152

- [CrossRef] [Google Scholar]

- A comprehensive review of preparation, characterization, properties and stability of hybrid nano fluids. Renew. Sustain. Energy Rev.. 2018;81(February 2017):1669-1689.

- [CrossRef] [Google Scholar]

- Selection of optimal parameters using PSI approach of a dimpled-V pattern roughened solar heat collector. Mater. Today: Proc.. 2022;64(xxxx):1229-1233.

- [CrossRef] [Google Scholar]

- Effect of dimpled rib with arc pattern on hydrothermal characteristics of Al2O3-H2O nanofluid flow in a square duct. Sustainability (Switzerland). 2022;14(22)

- [CrossRef] [Google Scholar]

- Experimental hydrothermal behavior of hybrid nanofluid for various particle ratios and comparison with other fluids in minichannel heat sink. Int. Commun. Heat Mass Transfer. 2020;110:104397

- [CrossRef] [Google Scholar]

- Particle ratio optimization of Al2O3-MWCNT hybrid nanofluid in minichannel heat sink for best hydrothermal performance. Appl. Therm. Eng.. 2020;165(August 2019):114546

- [CrossRef] [Google Scholar]

- Enhanced heat transfer using oil-based nanofluid flow through conduits: a review. Energies. 2022;15(22):1-28.

- [CrossRef] [Google Scholar]

- Exergy analysis of various solar thermal collectors. Mater. Today: Proc.. 2022;69(xxxx):323-327.

- [CrossRef] [Google Scholar]

- A review of reverse osmosis membrane materials for desalination—Development to date and future potential. J. Membrane Sci.. 2011;370(1):1-22.

- [CrossRef] [Google Scholar]

- International Journal of Heat and Mass Transfer Thermo-physical properties of water and ethylene glycol mixture based SiC nanofluids : An experimental investigation. Int. J. Heat Mass Transf.. 2016;101:412-417.

- [CrossRef] [Google Scholar]

- Case Studies in Thermal Engineering Experimental study of viscosity and thermal conductivity of water based Fe3O4 nanofluid with highly disaggregated particles. Case Stud. Thermal Eng.. 2022;35(May):102160

- [CrossRef] [Google Scholar]

- Surface engineering of magnetic nanoparticles for hyperthermia and drug delivery. Med. Devices Sensors. 2016

- [CrossRef] [Google Scholar]

- Effect of Al2O3/water nanofluid on performance of parallel flow heat exchangers: an experimental approach. J. Therm. Anal. Calorim.. 2019;135(1):625-643.

- [CrossRef] [Google Scholar]

- Numerical study of TiO2-based nanofluids flow in microchannel heat sinks: effect of the Reynolds number and the microchannel height. Appl. Therm. Eng.. 2019;161(June):114130

- [CrossRef] [Google Scholar]

- MoS2-based nanofluids as heat transfer fluid in parabolic trough collector technology. Renew. Energy. 2022;188:721-730.

- [CrossRef] [Google Scholar]

- Improving environmental performance of a direct absorption parabolic trough collector by using hybrid nanofluids. Energy Conver. Manage.. 2021;244:114450

- [CrossRef] [Google Scholar]

- First approach on nano fl uid-based solar still in high altitude for water desalination and solar water disinfection (SODIS) Desalination. 2020;491(June):114592

- [CrossRef] [Google Scholar]

- Masoumi, N., Sohrabi, N., Behzadmehr, A., 2009. A new model for calculating the effective viscosity of nanofluids. 055501. https://doi.org/10.1088/0022-3727/42/5/055501.

- A Treatise on Electricity and Magnetism. XXX: Oxford University; 1873. p. :60.

- Influence of particle properties on convective heat transfer of nano fluids. Int. J. Therm. Sci.. 2018;124(October 2017):187-195.

- [CrossRef] [Google Scholar]

- Investigating heat transfer properties of copper nanofluid in ethylene glycol synthesized through single and two-step routes. Int. J. Refrig. 2019;99:243-250.

- [CrossRef] [Google Scholar]

- An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J. Therm. Anal. Calorim.. 2019;137(5):1797-1807.

- [CrossRef] [Google Scholar]

- Stability of heat transfer nanofluids – A review. Chem. Bio. Eng. Rev.. 2018;5(5):312-333.

- [CrossRef] [Google Scholar]

- An experimental study on heat transfer performance and pressure drop of nanofluids using graphene and multi-walled carbon nanotubes based on diesel oil. Powder Technol.. 2019;352:369-380.

- [CrossRef] [Google Scholar]

- Viscosity data for Al2O3 – water nanofluid — hysteresis : is heat transfer enhancement using nanofluids reliable ? Int. J. Thermal Sci.. 2008;47:103-111.

- [CrossRef] [Google Scholar]

- Recent developments on the thermal properties, stability and applications of nanofluids in machining, solar energy and biomedicine. Appl. Sci. (Switzerland). 2022;12(3)

- [CrossRef] [Google Scholar]

- An updated review of nanofluids in various heat transfer devices. J. Thermal Anal. Calorimetry. 2021;145(6)

- [CrossRef] [Google Scholar]

- A new microchannel heat exchanger configuration using CNT-nanofluid and allowing uniform temperature on the active wall. Case Stud. Thermal Eng.. 2022;32(November 2021)

- [CrossRef] [Google Scholar]

- Experimental and numerical investigations of thermal performance of Al2O3/water nanofluid for a combi boiler with double heat exchangers. Int. J. Numer. Meth. Heat Fluid Flow. 2019;29(4):1300-1321.

- [CrossRef] [Google Scholar]

- A unique thermal conductivity model (ANN) for nanofluid based on experimental study. Powder Technol.. 2021;377:429-438.

- [CrossRef] [Google Scholar]

- Techniques to improve the performance of enhanced condensation area solar still: a critical review. J. Clean. Prod.. 2020;122260

- [CrossRef] [Google Scholar]

- Green biosynthesis of superparamagnetic magnetite Fe3O4 nanoparticles and biomedical applications in targeted anticancer drug delivery system: a review. Arab. J. Chem.. 2020;13(1):2287-2308.

- [CrossRef] [Google Scholar]

- Multifunctional surface functionalized magnetic iron oxide nanoparticles for biomedical applications: a review. Appl. Surf. Sci. Adv.. 2022;11(May):100303

- [CrossRef] [Google Scholar]

- Effect of mono/hybrid nanofluids and passive techniques on thermal performance of parabolic trough solar collector: a review. Energy Sources Part A. 2023;45(1):1686-1709.

- [CrossRef] [Google Scholar]

- Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Conver. Manage.. 2019;197(July):111877

- [CrossRef] [Google Scholar]

- Smart Materials in Manufacturing High entropy alloy coatings for biomedical applications: a review. Smart Mater. Manuf.. 2023;1(August 2022)

- [CrossRef] [Google Scholar]

- Thermal and rheological characteristics of CuO – Base oil nano fluid flow inside a circular tube. Int. Commun. Heat Mass Transfer. 2012;39:152-159.

- [CrossRef] [Google Scholar]

- Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2021

- [CrossRef] [Google Scholar]

- Metal oxide nanofluids in electronic cooling: a review. J. Mater. Sci. Mater. Electron.. 2020;31(6):4381-4398.

- [CrossRef] [Google Scholar]

- Recent advances in application of nanofluids in heat transfer devices: a critical review. Renew. Sustain. Energy Rev.. 2019;103:556-592.

- [CrossRef] [Google Scholar]

- Entropy generation and exergy ef fi ciency analysis of ethylene glycol-water based nano diamond + Fe3O4 hybrid nano fluids in a circular tube. Powder Technol.. 2021;380:430-442.

- [CrossRef] [Google Scholar]

- Experimental study on heat transfer, friction factor, entropy and exergy efficiency analyses of a corrugated plate heat exchanger using Ni/water nanofluids. Int. J. Therm. Sci.. 2021;165(March):106935

- [CrossRef] [Google Scholar]

- Hybrid nano fluid flow and heat transfer over backward and forward steps: a review. Powder Technol.. 2020;363:448-472.

- [CrossRef] [Google Scholar]

- Study of viscosity and specific heat capacity characteristics of water-based Al2O3 nanofluids at low particle concentrations. J. Exp. Nanosci.. 2015;10(2):86-102.

- [CrossRef] [Google Scholar]

- Performance improvement of thermal-driven membrane-based solar desalination systems using nano fluid in the feed stream. Sustain. Energy Technol. Assessments. 2020;39(February)

- [CrossRef] [Google Scholar]

- Assessment of thermal conductivity of polyethylene glycol-carbon dot nanofluid through a combined experimental-data mining investigation. J. Mater. Res. Technol.. 2022;19:2695-2704.

- [CrossRef] [Google Scholar]

- M. Sheikhpour et al. (2020). Role of Nano fluids in Drug Delivery and Biomedical Technology : Methods and Applications.

- Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: Numerical simulation. Adv. Powder Technol.. 2019;30(7):1356-1365.

- [CrossRef] [Google Scholar]

- Sundar, L.S., Mesfin, S., Ramana, E.V., 2021. Experimental investigation of thermo-physical properties, heat transfer , pumping power , entropy generation , and exergy efficiency of nanodiamond + Fe3O4/60:40 % water-ethylene glycol hybrid nanofluid flow in a tube. 21(August 2020). https://doi.org/10.1016/j.tsep.2020.100799.

- Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nano fl uids for heat transfer applications: an experimental study ☆. Int. Commun. Heat Mass Transfer. 2014;56:86-95.

- [CrossRef] [Google Scholar]

- Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor – A review. Renew. Sustain. Energy Rev.. 2017;68(March 2016):185-198.

- [CrossRef] [Google Scholar]

- Synthesis of Al2O3-Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf. A Physicochem. Eng. Asp. 2011;388(1–3):41-48.

- [CrossRef] [Google Scholar]

- Optimized and scalable synthesis of magnetic nanoparticles for RNA extraction in response to developing countries ’ needs in the detection and control of SARS - CoV - 2. Sci. Rep.. 2020;0123456789:1-10.

- [CrossRef] [Google Scholar]

- Vajjha, R.S., Das, D.K., Mahagaonkar, B.M., 2009. Petroleum Science and Technology Density Measurement of Different Nanofluids and Their Comparison With Theory Density Measurement of Different Nanofluids. November 2012, 37–41. https://doi.org/10.1080/10916460701857714.

- Hybrid or mono nanofluids for convective heat transfer applications. A critical review of experimental research. Appl. Therm. Eng.. 2022;203(November 2021):117926

- [CrossRef] [Google Scholar]

- Weiss, C., Carriere, M., Fusco, L., Capua, I., Regla-nava, J.A., Pasquali, M., Scott, J.A., Vitale, F., Unal, M.A., Mattevi, C., Bedognetti, D., Merkoc, A., Gogotsi, Y., Stellacci, F., Delogu, L. G., 2020. Toward nanotechnology-enabled approaches against the COVID-19 pandemic. https://doi.org/10.1021/acsnano.0c03697.

- Optimal concentration of alumina nanoparticles in molten Hitec salt to maximize its specific heat capacity. Heat Mass Transfer. 2017;70(October)

- [CrossRef] [Google Scholar]

- Model for thermal conductivity of carbon nanotube-based composites. Phys. B Condens. Matter. 2005;368(1–4):302-307.

- [CrossRef] [Google Scholar]

- A renovated Hamilton-Crosser model for the effective thermal conductivity of CNTs nanofluids. Int. Commun. Heat Mass Transfer. 2017;81:42-50.

- [CrossRef] [Google Scholar]

- A new thermal conductivity model for nanorod-based nanofluids. Appl. Therm. Eng.. 2017;114:287-299.

- [CrossRef] [Google Scholar]

- The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J. Nanopart. Res.. 2003;5(1–2):167-171.

- [CrossRef] [Google Scholar]

- Experimental investigation and prediction of changes in thermal conductivity of carbon nanotube nanofluid. Int. Commun. Heat Mass Transfer. 2021;127:105526

- [CrossRef] [Google Scholar]

- Hydro-thermal and economic analyses of the air/water two-phase flow in a double tube heat exchanger equipped with wavy strip turbulator. Case Studies in Thermal Engineering. 2022;37(July):102260

- [CrossRef] [Google Scholar]

- Zhao, Z., 2020. A simple magnetic nanoparticles-based viral RNA extraction method for efficient detection of SARS-CoV-2. 518055.

- Effect of Al2O3/water nanofluid on heat transfer of turbulent flow in the inner pipe of a double-pipe heat exchanger. Heat and Mass Transfer/Waerme- Und Stoffuebertragung. 2020;56(4):1127-1140.

- [CrossRef] [Google Scholar]

- Investigation on the thermal properties, heat transfer and flow performance of a highly self-dispersion TiO2 nanofluid in a multiport mini channel. Int. Commun. Heat Mass Transfer. 2020;117

- [CrossRef] [Google Scholar]

- A novel one-step chemical method for preparation of copper nanofluids. J. Colloid Interface Sci.. 2004;277(1):100-103.

- [CrossRef] [Google Scholar]