Translate this page into:

Amino Acids, Solubility, Bulk Density and Water Holding Capacity of Novel Freeze-Dried Cow’s Skimmed Milk Fermented with Potential Probiotic Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6

⁎Corresponding author.at: Department of Analytical Chemistry, Faculty of Applied Science, Umm Al-Qura University, Makkah, Saudi Arabia. amhameed@uqu.edu.sa (Ahmed M. Hameed),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 showed a potential probiotic role in vivo and in vitro in a preliminary unpublished work. This study demonstrated that Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 mediated modifications of the physicochemical properties of fermented skimmed cow’s milk. Skim milk was inoculated with 1% (w/v) of Lactobacillus plantarum Bu-Eg5 (T1), 1% (w/v) of Lactobacillus rhamnosus Bu-Eg6 (T2) and 1% (w/v) of 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 (T3). After that, fresh skimmed milk control (C), T1, T2, and T3 were freeze-dried (Zirbus Technology model: VaCo 5-D, S/N: COM98754, Germany). The resulting freeze-dried fresh and fermented milks powders were evaluated for their solubility index, bulk density and water holding capacity (WHC). The amino acids compositions of the freeze-dried treatments were analyzed using High Performance Amino Acid Analyzer (Biochrom 30). The microbiological quality of freeze-dried fresh and fermented milks powders was measured by enumerating lactic acid bacteria, yeast & mould and coliform bacteria. The total protein content of fresh freeze-dried skimmed milk (38.69%) was higher than that of fermented freeze-dried skimmed milk powders. The bulk density was 16.67 g/mL for all treatments. The solubility of fresh freeze-dried skimmed milk was the highest (100%), followed by the other treatments (78.95%). The WHC of fresh freeze-dried skimmed milks (11.16%) was lower than the other samples. The highest total essential amino acids were observed in fresh freeze-dried skimmed milk sample (17.26%) followed by the freeze-dried skimmed milk fermented with Lactobacillus plantarum Bu-Eg5 (16.22%) while the lowest recorded in the freeze-dried skimmed milk sample fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 (12.87%), there was a very low bacterial count in the control treatment (1.09 log CFU/ml). Yeast & mould and coliforms were not detected in all samples.

Keywords

Lactobacillus

Freeze-drying

Skim milk

Amino acids

Solubility index

Bulk density

1 Introduction

Understanding of the good diet today is not only to supply the body with the right quantities of nutrient components, but also, to play a physiological role against different diseases (Domínguez Díaz et al., 2020).

Fermented milks are broadly manufactured in numerous nations. This kind of procedure is probably the most seasoned technique utilize to broaden the shelf life of usability of milk and drilled by individuals for millennia (Pederson, 1971).

Fermented milks have a chemical composition which gives a helpful sign of the expected health benefit of these items. The primary parts are protein, fat, sugar, minerals, and nutrients. Be that as it may, the bioactive peptides ingredients (eg. immuno-peptides, casomorphins, α-and β-lactorphin, phosphor peptides or lactoferricin), which are professed to be wellbeing improving segments, ought not be disregarded (Meisel & Bockelmann, 1999).

The helpful wellbeing characteristics of fermented milks and their utilization in the Therapy of body infirmities traces all the way back to not many thousands years prior; they have been likewise referenced in Biblical sacred writings, and some old researchers have endorsed it as medication for relieving metabolic issues of the digestive tract and stomach (Oberman & Libudzisz, 1998).

Probiotics were defined as “live microorganisms which when administered in adequate amounts confer a health benefit on the host” (FAO/WHO, 2002)

Probiotics were added to many kinds of foods, mainly cheese, yoghurt and other fermented milks. In the past few decades, the consumption of foods containing probiotics increased gradually to become a billion dollars industry worldwide (Suez et al., 2019).

Several isolates of lactic acid bacteria were classified as probiotics. The selection probiotics criteria should be differentiated as the ability to live through its way in the digestive system, and at reduced pH, bile salts and enzymes, and the rate of surviving must be not less than 106 CFU/g (Hosseini et al., 2009).

The freeze-drying technique is commonly successfully used to provide ready to preserve of cultures and to use highly concentrated starter cultures (Martos et al., 2007; Velly et al., 2014; Gul et al., 2020)

This technique entails freezing and drying the aqueous solution containing cells in order to remove water by ice sublimation, likely ice crystal formation, and DNA denaturation due to osmolality, resulting in damaged cells (Conrad et al., 2000; Han et al., 2018).

Several studies have revealed that the utilization of skimmed milk to decrease cell damage due to the low temperatures during freeze-drying treatment and after freezing. The Freeze-drying technique of skim milk has an important positive effect due to reducing cellular cell viability by protecting cells during freeze-drying via a viscous layer which resulted by milk proteins on the surface of cells and stabilizing cell membrane. Hence, hydroxyl or amino groups that can replace water on the proteins molecules and membrane lipids (Hubalek, 2003; Carvalho et al., 2004; Chen et al., 2015; Lu et al., 2017; Stefanello et al., 2019; Niu et al., 2016).

The aim of this project was to understand the effects of adding Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 on gross chemical composition, solubility index, bulk density, water holding capacity (WHC), and amino acids of fermented freeze-dried cow’s skimmed milk.

2 Materials and methods

2.1 Materials

2.1.1 Raw milk

Fresh cow’s milk was obtained from the herd of the Faculty of Agriculture, Moshtohor, Benha University, Egypt. The chemical composition of milk was 3.4% fat, 3.2% protein, 5% lactose and 0.61% ash.

2.1.2 Lactic acid bacterial strains

Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 were obtained from the culture collection of Dairy Science Department, Faculty of Agriculture, Moshtohor, Benha University, Egypt. These strains were activated three times on MRS broth medium (HIMEDIA, pvt. Ltd, India), then transferred to heat treated skim milk (121 °C/5 min) at a rate of 1% and incubated at 37 °C until coagulation.

2.1.3 Preparation of fermented milks

Cream was separated from cow’s milk in the dairy pilot plant of the Faculty of Agriculture, Moshtohor, Benha University and yielded cream with 22% fat and skim milk with 0.05% fat. The skimmed milk was divided into 4 portions and filled into sterile glass containers (1L each) then heat treated at 121 °C for 5 min. in the autoclave. Heat treated skim milk was allowed to cool to room temperature, then 4 portions were marked as follows: The 1st portion is control (C), the 2nd portion was inoculated with 1% (w/v) of Lactobacillus plantarum Bu-Eg5 (T1), the 3rd portion was inoculated with 1% (w/v) of Lactobacillus rhamnosus Bu-Eg6 (T2) and the 4th portion was inoculated with 1% (w/v) of 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 (T3). The inoculation was carried out under aseptic conditions. The inoculated skim milk was incubated at 37 °C until coagulation (∼24 h). The resulting fermented milks were evaluated for their microbiological properties by counting lactic acid bacteria on MRS (HIMEDIA, Pvt. Ltd, India), yeast & moulds were counted on potato dextrose agar and coliforms were counted on violet red bile agar media.

2.2 Methods

2.2.1 Freeze-drying of skimmed milk

Freeze-drying of fresh and fermented skimmed milk was done using freeze dryer (Zirbus Technology, S/N: COM98754, model: VaCo 5-D, Germany) at − 40 °C under vacuum at a minimum pressure of 0.011 kPa Fig. 1. The operation of freeze drying was completed in 72 h according to the methods described by Ismail et al., (2020) and the freeze-dried skimmed milk was weighed before and after freeze drying to calculate the yield of freeze-dried fermented milk Fig. 2 according to the following Eq. (1):

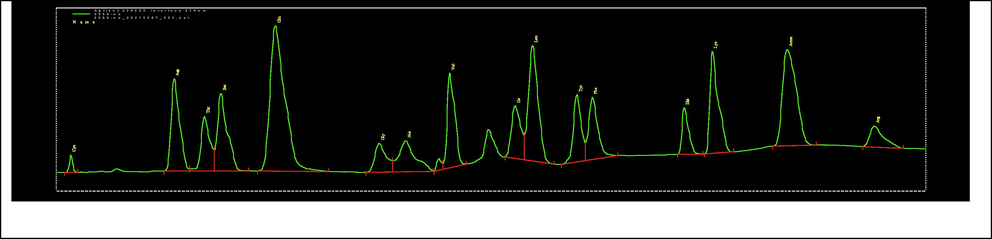

Chromatogram of amino acids content of freeze-dried fermented milks with Lactobacillus.

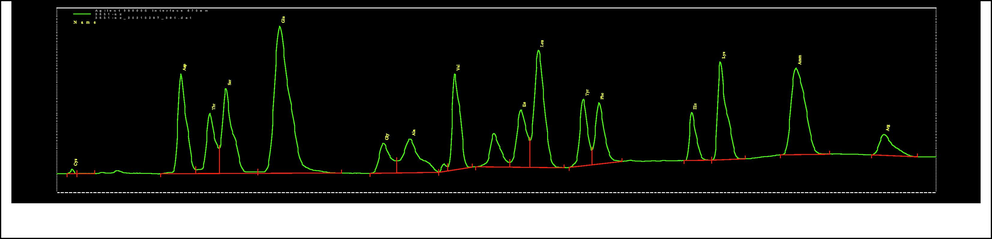

Chromatogram of amino acids content of freeze-dried fermented milks with Lactobacillus plantarum Bu-Eg5.

2.2.2 Solubility index of freeze-dried of fresh and fermented skimmed milk powder

Powder solubility was examined according to the method mentioned by as following Eq. (2) according to the method mentioned by Ismail et al., (2020)

2.2.3 Bulk density of freeze-dried of fresh and fermented skimmed milk powder

Bulk density of freeze-dried of fresh and fermented skimmed milk powder was examined according to the method mentioned by Akash and Yugal (2017) and calculated as following Eq. (3)

2.2.4 Water holding capacity (WHC)

The water holding capacity (WHC) was determined according to the method of Akalın et al. (2012) as follows: 20 g of freeze-dried of fresh and fermented skimmed milk powder were centrifuged at 5000g and 20 °C for 10 min.

The water holding capacity was calculated as following Eq. (4):

2.2.5 Gross chemical composition of freeze-dried skimmed milk treatments

Gross chemical composition (moisture, protein, fat and ash) of freeze drying skimmed milks were determined according to AOAC (2019). The carbohydrate content was calculated by difference.

2.2.6 Determination of amino acid composition

Amino acids composition of freeze-dried fresh and fermented skim milk powders analyzed by (Biochrom 30), hydrolysis were estimated in conical flask via ten milligram of protein was added and 5 ml. of per formic acid was added and the mixture placed in bath for 16 h then sodium disulfite to the oxidized the mixture, the flask adjust the pH to 2.20 by hydroxide solution, the samples injected in Biochrom 30 column according to the method described by Aly et al., (2020) at Food Tech. Res. Inst., Agric. Res. Center, Giza, Egypt. The uncertainty represents an expanded uncertainty (Typ A) expressed at approximately the 95% confidence level using a coverage factor of k = 2.

2.2.7 Microbiological analysis

Lactic acid bacteria were analyzed according to standard procedures as mentioned by Ismail et al., (2020a) Yeast and mould counts and coliform counts were computed according to standard procedures Ismail et al., (2020b) at the Faculty of Agriculture, Moshtohor, Benha University, Egypt.

2.2.8 Statistical analysis

Statistical analysis of data was analyzed statistically as mean ± SD of triplicate according to Aly et al., (2021).

3 Results and discussion

3.1 Gross chemical composition of freeze-dried skimmed milk treatments

Data revealed in Table1 shows the gross chemical composition of freeze-dried fresh and fermented skim milks. The total protein contents were higher in fresh freeze-dried skimmed milk than in fermented freeze-dried skimmed milks. These values reached 38.69% for control sample (fresh freeze-dried skimmed milk) and recorded 36.75%, 34.42% and 32.47% for skimmed milk fermented with Lactobacillus plantarum Bu-Eg5 (T1), freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6 (T2) and freeze-dried skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 (T3). This decrease in protein content of fermented freeze-dried skimmed milk might be attributed to its use during Lactobacillus bacteria growth. Total fat, moisture, total carbohydrates, and ash contents did not changed in all examined treated variants (see Table 2). Values are means ± standard deviation. C: Control (Fresh freeze-dried skimmed milk); T1: skimmed milk fermented with Lactobacillus plantarum Bu-Eg5; T2: freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6; T3: freeze-dried skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6. Values are means ± standard deviation. C: Control (Fresh freeze-dried skimmed milk); T1: skimmed milk fermented with Lactobacillus plantarum Bu-Eg5; T2: freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6; T3: freeze-dried skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6.

Gross chemical composition

Treatments

C

T1

T2

T3

Moisture

5.33 ± 0.76

5.30 ± 0.10

5.40 ± 0.40

5.20 ± 0.10

Protein

38.69 ± 0.89

36.75 ± 0.58

34.42 ± 0.58

32.47 ± 0.34

Fat

1.32 ± 0.13

1.33 ± 0.15

1.27 ± 0.25

1.30 ± 0.10

Ash

8.10 ± 0.17

8.44 ± 1.10

8.81 ± 0.58

8.84 ± 0.50

Carbohydrates

46.55 ± 0.19

48.18 ± 0.12

50.11 ± 0.13

52.19 ± 0.15

Treatments

Yield (%)

C

14.88 ± 0.47

T1

15.25 ± 0.59

T2

14.68 ± 0.26

T3

14.99 ± 0.66

3.2 Yield of fresh freeze-dried skimmed milk treatments

The evaluation of freeze-dried skimmed milks powder produced after the freeze-drying process is shown in Table 3. The yield of freeze-dried skimmed milks powder produced ranged from 14.68% in skim milk fermented with Lactobacillus rhamnosus Bu-Eg6 to 15.25% in skim milk fermented with Lactobacillus plantarum Bu-Eg5. These data are confirmed by Santos et al. (2018) and Ismail et al., (2020) reported that the yield of yoghurt after freeze drying was 18% and 16.99%. C: Control (Fresh freeze-dried skimmed milk); T1: skimmed milk fermented with Lactobacillus plantarum Bu-Eg5; T2: freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6; T3: freeze-dried skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6.

Treatments

Bulk density (g/mL.)

Solubility (%)

Water holding capacity (WHC %)

pH values

Zero time

After 24 h

C

16.67

100

11.16

6.573

6.504

T1

16.67

78.95

30.23

6.481

4.111

T2

16.67

75

28.37

6.511,2

4.423

T3

16.67

78.95

31.16

6.542,3

4.322

3.3 Bulk density, solubility and water holding capacity of fresh freeze-dried skimmed milks and fermented with Lactobacillus

3.3.1 The bulk density and solubility index of freeze-dried skimmed milk treatments

The Bulk density of fresh freeze-dried skimmed milks and fermented with Lactobacillus was 16.67 g/mL. and there were no changes in bulk density of all treatments of fresh and freeze-dried fermented skim milks with Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 under investigation. The solubility index of fresh freeze-dried skimmed milk (C) was 100%, followed by 78.95% for skimmed milk fermented with Lactobacillus plantarum Bu-Eg5 and fermented with a 1:1 mixture of Lactobacillus plantarum Bu-Eg5 (T2) and Lactobacillus rhamnosus Bu-Eg6 (T3). The lowest solubility was 75% for the freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6 (T2) and Ismail et al., (2020) found that the average bulk density of freeze-dried yoghurt powders was 1.475 g/mL. and the highest solubility index of freeze-dried yoghurt reached to 86.01%, 84.4 and 84.35% for yoghurts. The changes in in bulk density and solubility index of freeze-dried skimmed milk treatments may be due to differences in structures of treatments. Akash and Yugal (2017) reported that fermented powder had bulk density than milk powder.

3.3.2 The water holding capacity (WHC) of freeze-dried skimmed milk treatments

Water holding capacities (WHC) of freeze-dried skimmed milks are shown in Table 3. WHC in all fresh freeze-dried skimmed milks was 11.16% lower than in skimmed milks fermented with Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6. Differences in WHC are due to differences between fresh freeze-dried skimmed milk and skimmed milks fermented with Lactobacillus structures. This reduction in WHC of freeze-dried skimmed milk (control sample) may be due to the high water trapping in the protein matrix of it resulted from its higher total solids content compared to skimmed milks fermented with Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6. These foundations confirmed with those mentioned with Ismail et al., (2020) and Akalın et al., (2012) reported yoghurts have high WHC fortified with whey protein concentrate (WPC).

3.3.3 pH values of freeze-dried skimmed milks fermented with Lactobacillus

The pH values of all treatments were decreased after 24 h of fermentation (Table 4), this reflects the increase in acidity and the conversion of lactose to lactic acid by the used microorganisms. The pH of the control recorded 6.57 initially and 6.50 after 24 h of incubation at 37 °C. Mixed ANOVA statistical analysis of pH data showed that, pH levels decreased over the fermentation period in all treatments, but less in the control. There was a statistically significant interaction between the intervention and time on the pH levels p < 0.0005 but not for the control. The main effect of treatment on the pH levels showed significant statistical differences. C: Control (Fresh freeze-dried skimmed milk); T1: skimmed milk fermented with Lactobacillus plantarum Bu-Eg5; T2: freeze-dried skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6; T3: freeze-dried skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6.

Amino acids (%)

Control

T1

T2

T3

Essential amino acids

Therionine

(Thr)

1.47

1.50

1.40

1.03

Valine

(Val)

2.25

2.09

2.11

1.72

Methionine

(Met)

0.00

0.00

0.00

0.00

Isoleucine

(Ile)

1.84

1.95

1.93

1.46

Leucine

(Leu)

3.28

3.15

3.16

2.53

Tyrosine

(Tyr)

2.23

1.96

1.97

1.49

Phenyalanine

(Phe)

2.10

1.85

1.86

1.42

Lysine

(Lys)

3.04

2.73

2.72

2.36

Histidine

(His)

1.05

0.99

1.00

0.86

Total essential amino acids

17.26

16.22

16.15

12.87

Non-essential amino acids

Aspartic

(Asp)

2.63

2.61

2.55

2.13

Serine

(Ser)

1.81

1.89

1.67

1.24

Glutamic

(Glu)

7.05

6.75

6.69

5.42

Proline

(Pro)

3.16

3.23

3.25

3.18

Glycine

(Gly)

0.66

0.63

0.63

0.54

Alanine

(Ala)

0.98

0.99

0.99

0.75

Cystine

(Cys)

0.17

0.04

0.31

0.61

Arginine

(Arg)

1.18

1.10

1.14

0.86

Total non-essential amino acids

17.64

17.24

17.23

14.73

Total amino acid

34.9

33.46

33.38

27.60

3.4 Amino acids content of freeze-dried skimmed milk

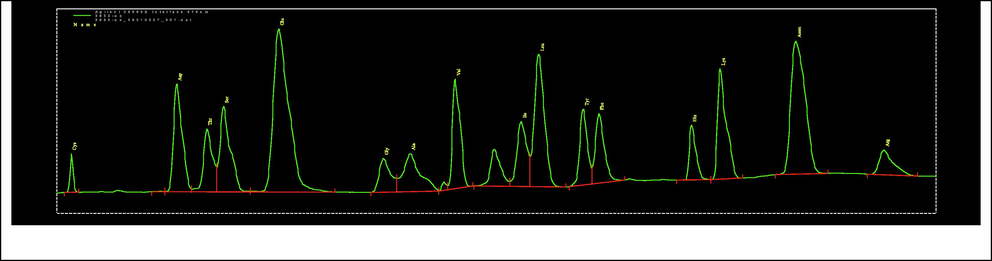

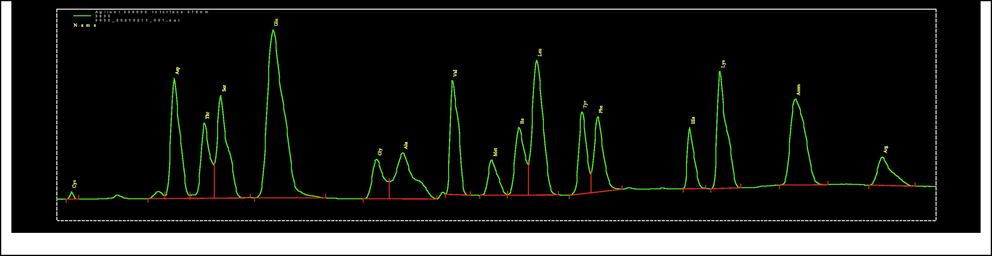

The effect of different ratio of Lactobacillus added on essential and non-essential amino acids content of freeze-dried skimmed milk treatments is shown in Table 4 and Figs. 1–4. In various freeze-dried skimmed milk samples, the major essential amino acid was Leucine acid (3.28%), followed by Lysine acid (3.04%) but Valine acid content (2.25%) was the lowest in freeze-dried fresh skimmed milk sample. On the other hand, the highest non-essential amino acids was Glutamic acid (7.05%), followed by Proline acid (3.16%) and Aspartic acid (2.63%). On the contrary, Cystine acid (0.17%) had the lowest content than the other amino acids. From the same Table 4 the highest total essential amino acids were observed in freeze-dried of fresh skimmed milk sample (17.26%) followed by freeze-dried of skimmed milk sample fermented with Lactobacillus plantarum Bu-Eg5 (16.22%) while the lowest recorded in freeze-dried skimmed milk sample fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 (12.87%). It could also be noticed that Lactobacillus need sufficient amount from essential and non-essential amino acids to survive, moreover inoculation of Lactobacillus plantarum Bu-Eg5 with Lactobacillus rhamnosus Bu-Eg6 to ferment skim milk take or consumption more amounts of amino acids compared with Lactobacillus plantarum Bu-Eg5 or Lactobacillus rhamnosus Bu-Eg6 only, these results may be due to the competitiveness to life between them.

Chromatogram of amino acids content of freeze-dried fermented milks with Lactobacillus rhamnosus Bu-Eg6.

Chromatogram of amino acids content of freeze-dried fermented milks with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6.

3.5 Microbiological evaluation of skimmed milks fermented

Lactic acid bacteria counts, yeast and mould counts and coliform counts of skimmed milks fermented tabulated in table 5. Despite the heat treatment of skim milk (121 °C for 5 min), there was a little count in the control treatment (1.09 log CFU/ml). Yeast &mould and coliforms were not detected due to the sanitary conditions during the work. ND*= not detected; C: Control (Fresh skimmed milk); T1: skimmed milk fermented with Lactobacillus plantarum Bu-Eg5; T2: skimmed milk fermented with Lactobacillus rhamnosus Bu-Eg6; T3: skimmed milk fermented with 1:1 Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6.

Microbial count type

Log CFU/ ml

C

T1

T2

T3

Lactic acid bacteria counts

1.09

7.94

7.68

7.94

Yeast and mould counts

ND*

ND*

ND*

ND*

Coliform counts

ND*

ND*

ND*

ND*

4 Conclusion

Lactobacillus plantarum Bu-Eg5 and Lactobacillus rhamnosus Bu-Eg6 were used to ferment skim cow milk and a laboratory freeze dryer used as freeze-drying fresh and fermented milks. Powders were evaluated for their solubility index, bulk density, water holding capacity (WHC), chemical composition, amino acids and microbiological counts (Lactic acid bacteria, Yeast and mould counts and coliform counts). The obtained data mentioned that the major essential amino acid was Leucine acid (3.28%) while Glutamic acid (7.05%) was the highest non-essential amino acids followed by Proline acid (3.16%). Despite the heat treatment of skim milk (121 °C for 5 min), there was a little count in the control treatment (1.09 log CFU/ml). Yeast &mould and coliforms were not detected due to the sanitary conditions during the work. The results showed that the total protein content was 38.69% for fresh freeze-dried skimmed milk and this value was higher than the fermented freeze-dried skimmed milks. Bulk density of freeze-dried skimmed milks was 16.67 g/mL. The solubility was100% for fresh freeze-dried skimmed milks the highest followed by 78.95% for each skimmed milk fermented with Lactobacillus plantarum Bu-Eg5 and fermented with 1:1 Lactobacillus plantarum Bu-Eg5 (T2) and Lactobacillus rhamnosus Bu-Eg6(T3). The water holding capacity of fresh freeze-dried skimmed milks was lower than other samples.

Acknowledgements

The authors greatly appreciate the Scientific Research Support Programs of Benha University, Ain Shams University and Mansoura University, Egypt. Also, Faculty of Applied Sciences, Umm Al-Qura University, College of Science and Humanities, Shaqra University, Afif. The authors gratefully acknowledges financial support from Taif University Researchers Supporting Project number (TURSP-2020/135), Taif University, Taif, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Microstructural, textural, and sensory characteristics of probiotic yogurts fortified with sodium calcium caseinate or whey protein concentrate. J. Dairy Sci.. 2012;95(7):3617-3628.

- [Google Scholar]

- Study of quality of milk powder in sterling agro industries limited- nova. Acta Chemia Malaysia. 2017;1(2):8-10.

- [Google Scholar]

- Addition of whole barley flour as a partial substitute of wheat flour to enhance the nutritional value of biscuits. Arab. J. Chem.. 2021;14(5):103112.

- [CrossRef] [Google Scholar]

- Effect of addition sesame seeds powder with different ratio on microstructural and some properties of low fat Labneh. Arab. J. Chem.. 2020;13(10):7572-7582.

- [CrossRef] [Google Scholar]

- AOAC, 2019. Official Methods of Analysis (OMA). Association of Official Analytical Chemists. Official Methods of Analysis. AOAC, Washington, DC, USA. https://www.aoac.org/official-methods-of-analysis-21st-edition-2019/.

- Relevant factors for the preparation of freeze-dried lactic acid bacteria. Int. Dairy J.. 2004;14(10):835-847.

- [CrossRef] [Google Scholar]

- Response surface optimization of lyoprotectant for Lactobacillus bulgaricus during vacuum freeze-drying. Preparat. Biochem. Biotechnol.. 2015;45(5):463-475.

- [CrossRef] [Google Scholar]

- Stabilization and preservation of Lactobacillus acidophilus in saccharide matrices. Cryobiology. 2000;41(1):17-24.

- [Google Scholar]

- An international regulatory review of food health-related claims in functional food products labeling. J. Funct. Foods. 2020;68:103896.

- [CrossRef] [Google Scholar]

- FAO/WHO Working Group, 2002. Guidelines for the evaluation of probiotics in food. FAO/WHO Working Group, pp. 1–11.

- Storage stability and sourdough acidification kinetic of freeze-dried Lactobacillus curvatus N19 under optimized cryoprotectant formulation. Cryobiology. 2020;96:122-129.

- [Google Scholar]

- Optimization of a protective medium for enhancing the viability of freeze-dried Bacillus amyloliquefaciens B1408 based on response surface methodology. Cryobiology. 2018;81:101-106.

- [Google Scholar]

- Molecular and probiotic characterization of bacteriocin-producing Enterococcus faecium strains isolated from nonfermented animal foods. J Appl Microbiol. 2009;107(4):1392-1403.

- [Google Scholar]

- Protectants used in the cryopreservation of microorganisms. Cryobiology. 2003;46(3):205-229.

- [Google Scholar]

- Quality and microstructure of freeze-dried yoghurt fortified with additives as protective agents. Heliyon. 2020;6(10)

- [CrossRef] [Google Scholar]

- Rheological, physio-chemical and organoleptic characteristics of ice cream enriched with Doum syrup and pomegranate peel. Arab. J. Chem. (10):7346-7356.

- [CrossRef] [Google Scholar]

- Optimization of a cryoprotective medium to increase the viability of freeze-dried Streptococcus thermophilus by response surface methodology. LWT. 2017;80:92-97.

- [Google Scholar]

- Effects of protective agents on membrane fluidity of freeze-dried Lactobacillus delbrueckii ssp. bulgaricus. Lett. Appl. Microbial.. 2007;45(3):282-288.

- [CrossRef] [Google Scholar]

- Meisel, H., Bockelmann, W., 1999. Bioactive peptides encrypted in milk proteins: proteolytic activation and thropho-functional properties. In: Konings, W.N., Kuipers, O.P., In’t Veld, J.H.J.H. (Eds.), Lactic Acid Bacteria: Genetics, Metabolism and Applications: Proceedings of the Sixth Symposium on lactic acid bacteria: genetics, metabolism and applications, 19–23 September 1999, Veldhoven, The Netherlands. Dordrecht: Springer Netherlands, pp. 207–215. https://pubmed.ncbi.nlm.nih.gov/10532380/.

- Optimization of a protective medium for freeze-dried Pichia membranifaciens and application of this biocontrol agent on citrus fruit. J. Appl. Microbiol.. 2016;121(1):234-243.

- [CrossRef] [Google Scholar]

- Fermented milks. In: Wood B.J.B., ed. Microbiology of Fermented Foods. Boston, MA: Springer, US; 1998. p. :308-350.

- [Google Scholar]

- Microbiology of Food Fermentations. Westport, Connecticut, USA: AVI Publishing Co., Inc.; 1971.

- Santos, G.d., Pagani, A.A.C., Rosenthal, A., Nunes, T.P., Silva, M.A.A.P.d., 2018. Development and acceptance of freeze-dried yogurt “powder yogurt”. https://www.researchgate.net/publication/326836982_Development_and_acceptance_of_freeze-dried_yogurt_powder_yogurt.

- Survival and stability of Lactobacillus fermentum and Wickerhamomyces anomalus strains upon lyophilisation with different cryoprotectant agents. Food Res. Int.. 2019;115:90-94.

- [Google Scholar]

- Cell growth and resistance of Lactococcus lactis subsp. lactis TOMSC161 following freezing, drying and freeze-dried storage are differentially affected by fermentation conditions. J. Appl. Microbiol.. 2014;117(3):729-740.

- [Google Scholar]