Translate this page into:

Environmental remediation and generation of green electricity using constructed wetlands coupled with microbial fuel cell model system

⁎Corresponding authors. bosalvee@yahoo.com (Munawar Iqbal), anmalik77@gmail.com (Arif Nazir)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Antibiotic residues in wastewater are considered lethal to the crops and aquatic life. One of the promising way to treat this kind of wastewater is the use of constructed wetlands coupled with microbial fuel cell (CW-MFC). In this treatment, bacterial action and redox operation occurs at anaerobic anode and aerobic cathode respectively. Four different configurations of CW-MFCs was applied for comparison. This study focusses on the investigation of the removal of Co-trimoxazole (CMX), other co-existing pollutants and furthermore, the generation of green electricity with low hydraulic retention time (HRT) was studied. Results revealed that the effluent from configuration 1 (gravel based) had lower (CMX) concentration. This removal performance may be associated to greater electrode absorption capacity for (CMX). The removal efficiency was 92.58% at HRT of 3d and effluent concentration was 4 mg/L. On the other hand, CW-MFC1 exhibited the BOD removal (60.60%) regardless of the increasing effluent antibiotic concentration. Pure strain of Geobactor sulfereducens, adjusted with anaerobic sludge increased the bio-film growth. Maximum power density of 480.2 mW/m−3 observed for CW-MFC1. Electricity generation characteristic were also found to be effected with HRT.

Keywords

Constructed wetlands

Environmental remediation

Microbial fuel cell

Hydraulic retention time

Green power production

1 Introduction

Water is the basic need of all living organism and under the current scenario of water pollution, there is need to reverse the water resources for future generations. A sufficient supply of portable water and electricity always been a socioeconomic concern in under developed countries. (Ateba et al., 2020; Wang et al., 2022; Ma et al., 2022). A wide range of antibiotics were found in waste water treatment plant effluent, including analgesics, endocrine agitators, β-lactams, and sulfonamides. Antibiotics are generally used to medicate bacterial ailments, as growth boosters in livestock farming and to shield human health (Wen et al., 2020; Azzam et al., 2022; Masood et al., 2022; de Ilurdoz et al., 2022). Poor absorption and partial digestion of antibiotics in humans and livestock lead to the excretion of number of unchanged vigorous antibiotic residues in water reservoirs (Zaman et al., 2021; Sharif et al., 2021). Long term existence of antibiotics in waste water stimulate the synthesis of antibiotic resistance genes which further give rise to the synthesis of antibiotic resistance bacteria also called powerful bacteria (Zhang et al., 2017). Presence of antibiotics as major water pollutant attracted global attention.

Co-trimoxazole (CMX) pharmaceutically intense ingredient of waste water that is delivered synergistically under the brand name “septrin” (Mathenge et al., 2017) used to treat bacterial infections, urinary tract infections and administer to HIV-AID patients to reduce mortality rate (Mulenga et al., 2007). CMX is a combination of sulfamethoxazole (SMX) and trimethoprim (TMP). SMX is a broad spectrum antibiotic and usually detected in waste water that designate it is hard to eliminate, for it is resistant to commonly existing bacteria (Howe and Spencer, 1996). Long term stay of CMX promotes its bioaccumulation in food chain and poses health hazards to humans, aqua culture, and natural eco-system. Reduction of CMX is necessary to lower the toxic effects to aquatic environment (Thuy et al., 2011). As CMX is resistant towards natural degradation, therefore an eco-friendly cost effective method is required to degrade the CMX residues into least harmful metabolites. CMX is a broad spectrum antibiotic, resistant towards natural removal and by WWTP. Compared to the values obtained in the influent samples, increased concentrations are observed in the biologically treated effluent for trimethoprim, sulfamethoxazole and ciprofloxacin, mainly as a result of treatment (Plósz et al., 2010).

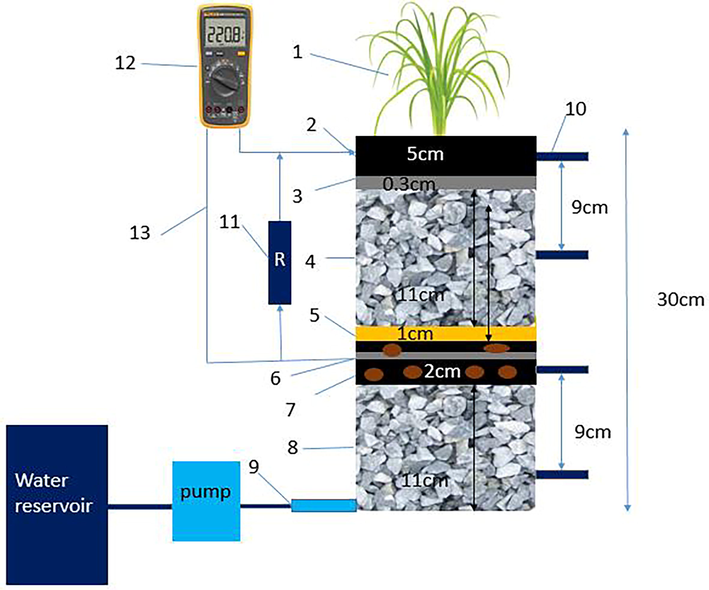

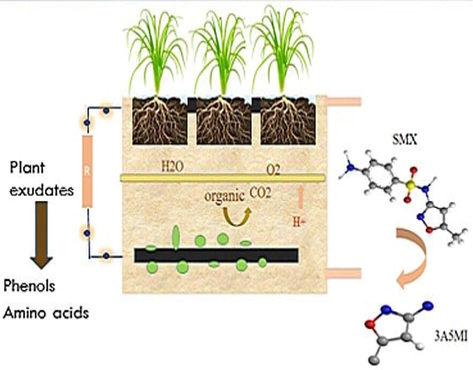

In comparison to other chemical methods, biodegradation is preferred due to it is cost effectiveness and general applicability (Zhang et al., 2018). Constructed wetlands coupled with microbial fuel cell (CW-MFC) has recently been originated as optimistic technique (Fig. 1) for the removal of diversity of pollutants including drugs, azo dyes, nitro benzene. Other inorganic compounds (boron and nitrogen) and conventional pollutants like COD, BOD are also reduced to some extent as well for electricity generation (Wen et al., 2020) due to its low cost and eco-friendliness (Xu et al., 2021). Plenty of dissolved oxygen at aerobic cathode and redox reactions at anaerobic anode by microbes generates sufficient potential gradient that establishes the required conditions of MFC (Song et al., 2018). According to the working mechanism of CW-MFC organic matter is degraded by microorganisms to generate electrons. Oxidation at anode generates electrons which pas through the external circuit to reach to cathode for reduction.

Schematic diagram of CW-MFC (1) cymbopogon nardus, (2) GAC cathode, (3) stainless steel mesh, (4) gravel middle layer, (5) glass wool, (6) GAC anode, (7) bacterial strain, (8) gravel bottom layer (9) influent, (10) effluent sampling ports (11) resistance (12) digital multimeter, (13) copper wires.

At Anode

At Cathode

The maintenance of anaerobic condition is essential factor for the proper functioning of CW-MFC as the presence of oxygen impede electricity production. (4) This sharp gradient and resulting electrons helps in the removal of many refractory and toxic compounds including CMX due to sequence of biological processes including sorption/chemisorption by plant and degradation of organic matter occur by microorganism. Thus, embedded system (CW-MFC) is feasible as waste water provides wetlands with organic matter which stimulates sharp gradient in two layers (aerobic and anaerobic) and lead to the implementation of MFC into wetlands (Abdulwahab et al., 2021). Herein, dissemination of dissolved oxygen and working of microorganisms attaining the key significance for perceiving the mechanism of biodegradation and green energy outputs by CW-MFC (Wang et al., 2017; Bhatti et al., 2018).

Previous studies reveal that effectiveness of this blended system depends upon number of factors in terms of electricity generation and waste water treatment (chemical oxygen demand), (biological oxygen demand), microbial community and its load, wetland plant, hydraulic retention time (HRT), flow type, substrate type and circuit operation mode. Available literature supports the removal of SMX (a part of CMX) maximum (>99.99%) with bio-electrochemical reactor (BER) with influent concentration up to milligrams (Zhang et al., 2017). Different CW-MFCs based on wetland macrophytes, scirpus validus, typha orientalis, jancuss effuses which effects overall pollutant removal (Wang et al., 2017; Patel et al., 2017).

Since few studies supports the removal potentiality of CMX in open circuit that pile up on electrodes than in closed circuit mode under different HRT (Song et al., 2018). Different HRT introduced different CMX loads on electrodes and effects removal efficiency. Moreover as HRT increases internal resistance of the system increases which ultimately decrease the electricity outputs. Therefore, effect of HRT over CMX removal and electricity generation requires further attention.

In this study three experiments were performed (with three concentrations of antibiotic) by using four different combinations of constructed wetlands microbial fuel cells (CW-MFCs) to evaluate the removal efficiency of CMX. The goal of this study is to investigate the (1) effect of different configuration of system on removal of CMX, (2) to evaluate the impact of plant and circuit mode on CMX removal along with BOD under different influent concentration. Configurations of system (CW-MFCs) were designed on the basis of same electrode material (GAC) and different material between the electrodes to evaluate the best configuration. Citronella (Cymbopogon nardus) the mosquito repellent specie was selected as wetland plant owing to its properties e.g., enhanced electrical conductance, antioxidant properties, allopathic properties, analgesic properties and excellent root features (Gebashe et al., 2020; Suwitchayanon and Kato-Noguchi, 2014; Abena et al., 2007) (3) effect of plant and influent antibiotic concentration on electricity production, (4) to evaluate the effect of HRT on CMX removal and power production. Results of this study will aid the reader to understand the effect of HRT, circuit operation mode on removal efficiency and will provide guidance for assembly designing and application of CW-MFC for antibiotic containing waste water.

2 Material and methods

2.1 Basic principle

Basic working principle of CW-MFCs is to generate sharp potential gradient by providing organic matter to wetlands to produce free electrons. This sharp gradient helps to degrade toxic pollutants from waste water.

2.2 Assembly design of CW-MFCs

Five congruous lab scale constructed wetlands microbial fuel cells (CW-MFCs) consisted of single circular polyacrylic plastic buckets (Fig. 2), the dimension of each was (30 cm height and 12.5 cm internal diameter) containing four layers from top to bottom (Fang et al., 2015). Five CW-MFCs labelled as CW-MFC1, CW-MFC2, CW-MFC3 and CW-MFC4 (acts as experimental groups) and CW-MFC5 (Acts as control group). With reference to graphical abstract location of each component and dimension in CW-MFC1 are mentioned (Table 2). Main matrix of electrode is granular activated carbon (GAC) and stainless steel mesh buried inside electrodes because of its better electrical conductance. Each assembly differ in middle and bottom layer (Table 2). CW-MFC5 was designed as the control group of assembly CW-MFC1. Each assembly follow the same dimensions as CW-MFC1. To separate anode and cathode or to maintain anaerobic condition glass wool (1 cm thick) placed between anode and middle layer. The anode layer inoculated with anaerobic sludge leaded out with copper wire passing through center of the reactor and connected to cathode by means of resistance of 1000 Ω. Distance between two parallel electrodes kept 12 cm. In the beginning period three plants of Cymbopogon nardus planted in all around air cathode after they had been developed for 35 days with ¼ of Hoagland solution preparation referred to (Table 1) (Guo et al., 2002) at an ambient temperature of 28 °C (Wen et al., 2020). All experiments continue to proceed for four months indoor at a temperature of 28 ± 5 °C (Song et al., 2018).

Photograph of five reactors with different configurations of Constructed wetlands microbial fuel cells (CW-MFCs) designed by Cymbopogon nardus.

Reactors

cathode

Middle layer

Glass wool

anode

Bottom layer

CW-MFC1

GAC (5 cm)

Gravel (11 cm)

1 cm

GAC (2 cm)

Gravel (11 cm)

CW-MFC2

GAC (5 cm)

Gardening Soil (11 cm)

1 cm

GAC (2 cm)

Gardening soil (11 cm)

CW-MFC3

GAC (5 cm)

Sand (11 cm)

1 cm

GAC (2 cm)

Sand (11 cm)

CW-MFC4

GAC (5 cm)

Sand (3.7 cm)Soil

(3.7 cm)Gravel

(3.7 cm)1 cm

GAC (2 cm)

Sand(3.7 cm)Soil

(3.7 cm)Gravel

(3.7 cm)

Sr. #

Chemicals

Formula

Mol. Wt. (g)

Nutrient Solution

Macronutrients

1

Potassium nitrate

KNO3

101.1

5 mL of 1M

2

Calcium nitrate

CaCO3

236.15

5 mL of 1M

3

Mono potassium phosphate

KH2PO4

136.09

2 mL of 1M

4

Magnesium phosphate

MgSO·7H2O

246.47

5 mL of 1M

Micronutrients (1mL of stock solution)

5

Boric acid

H3BO3

61.83

2.86g

6

Manganese chloride 4hydrate

MnCl2·4H2O

197.9

1.81g

7

Zincsulfate-7 hydrate

ZnSO4·7H2O

287.54

0.22g

Copper sulphate. 5hydrate

CuSO4·5H2O

249.7

0.08g

85% molybdic acid

M2O5·H2O

161.95

0.02g

8

Iron chelate

Fe-EDTA

1–5 mL of 1000mg/L

2.3 Bacterial strain and activated sludge

Activated sludge (consists of multi-culture microbial species required to oxidize organic matter) collected from sewage plant of Mujahid Hospital located in city Faisalabad, Pakistan. Bacterial strain (Geobacter sulfurreducens) acclimatized with anaerobic sludge and used as electron source. G. sulfurreducens serve as a catalyst in CW-MFC and was cultured with Geobacter nutrient media (S1). Activated sludge pretreated with 1 M NaOH and 1 M HCl to ensure anaerobic conditions (S2). Pretreated anaerobic sludge (60 g/L) along with (Geobacter sulfereducens) used to inoculate anode by blending with GAC. Before the start of conventional experiment wetland macrophyte (Cymobopogon nardus) acclimatized for 35 days against bacterial culture (Geobacter sulfereducens along with anaerobic sludge) by refreshing synthetic waste water (except CMX) after every 3 days. All the experimental reactors were operated under continuous up-flow mode with hydraulic retention time (HRT) of 3 days. HRT was maintained as 2 mL/min via peristaltic pump and drip irrigation system (Xu et al., 2018). The wastewater was fed to the reactors continuously after every three days. (Fang et al., 2015). The operation carried for 90 days until the system produced reproducible voltage outputs. Digestion of root exudates or glucose by bacterial strain promote the oxidation reaction at anaerobic anode (Kabutey et al., 2019).The release electrons pass through the external circuit via copper wires sealed with epoxy resin to cathode (Fig. 3). Reduction of oxygen occurs at cathode by reacting with electrons and protons to generate water and green electricity (Wen et al., 2021). Voltage output of the system (CW-MFC) record and measured by Hewlett-Packard multimeter (DT830D) digital multimeter (S3).

Working operation of constructed wetland microbial fuel cell.

2.4 Sampling and evaluation

The total volume of injected water was 4.50L with an effective volume (water storage of anode) of 350 mL. To collect the sample from each layer sampling ports were arranged accordingly from bottom to cathode layer. Stoppers are used to close the open ends of sampling ports (Yadav et al., 2012). Influent water sample was collected at the start of experiment and effluents samples were collected after every 3d. After stable voltage production reactors were fed with synthetic waste water including CMX (4 mg, 10 mg and 20 mg/L respectively (for 3-trials). Methanol was used to dissolve CMX. pH and electrical conductivity (EC) was measured by water quality analyzer (DDS-22C) (Wen et al., 2020) and electrochemical response of different water samples was measured by Gamry Potentiostate. Effluent samples (100 mL) were collected after every three days. Degradation rate of Co-trimoxazole was measured by UV–VIS (UV-2550) Spectrophotometer at 496 nm. Synthetic waste water with particular BOD was fed to all reactors at initial. To evaluate the BOD removal, effluents samples (100 mL) collected after every 3d until ten days. Effluent samples were analyzed by BOD analyzer (Aqua Lytic 600BD). Current and open circuit potential (OCP) was measured by Hewlett-Packard digital multimeter (DT830D). After stabilization of voltage, polarization curves were drawn by adopting a range (0–1000 Ω) of resistance to find maximum power density and current density at specified resistance. All the data calculation and analysis was performed by using MS excel 2013 and showed as mean ± and standard deviation.

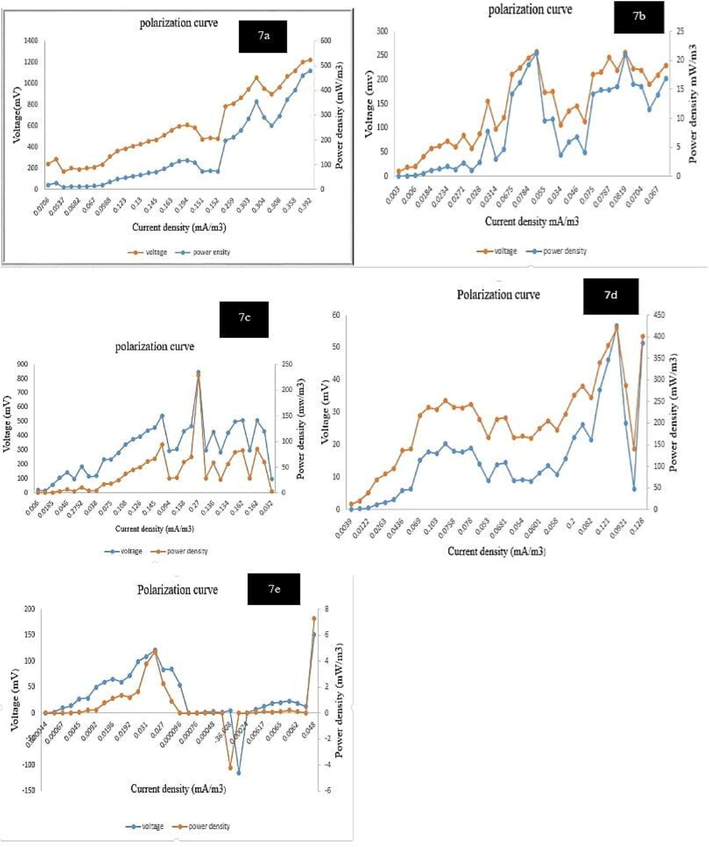

2.5 Polarization curve

For the analysis and characterization of plant microbial fuel cell polarization curve found to be an excellent tool. It signifies the difference of both the voltage and the power density against the current density. The performance polarization curve was prepared for all reactors of CW-MFC with variable resistance ranging from (0-1KΩ) to evaluate the best resistance for each type of the electrodes so as to obtain the maximum value of electrical power (Abdulwahab et al., 2021). To draw polarization curves potential values were noted from digital multimeter (DT830D). Polarization curves were drawn by MS Excel. The current density (Idensity) and power densities (Pdensity) were calculated using the following equations.

Where I, P, Idensity and Pdensity denote current, power, current density and power density respectively. The surface area of anode was equal to 3.125 m3. Fig. 4 represents the polarization for current density and power density for each of the configuration of CW-MFCs.

Polarization curves to analyze current and power density obtained with different configurations of CW-MFCs.

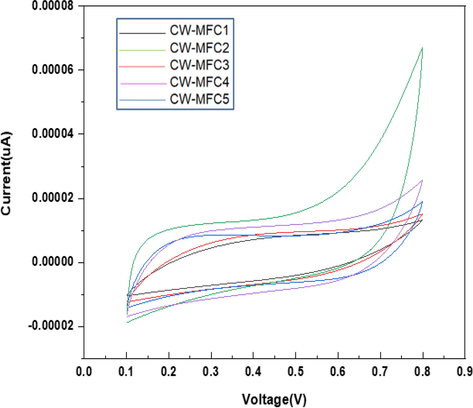

2.6 Electrochemical response

Cyclic voltammetry is an electrochemical technique that is used to describe the electrochemical behavior of a constructed wetlands microbial fuel cell (CW-MFC). It computes the current of cell by applying a series of voltages to the electrode. Gamry Potentiostat used to assess the redox potential of the CW-MFC using silver-silver chloride (Ag/AgCl) as reference electrode.

2.7 BOD removal efficiency

At startup period of working operation each reactor of CW-MFC fed with synthetic waste water with specific BOD value. BOD concentrations were analyzed by analyzer (Aqua Lytic 600BD). To analyze BOD removal efficiency 100 mL of effluent samples were collected from cathodic regions of each reactor. The concentration of BOD in effluents samples from each type of reactor decrease sharply on day 1 then decrease gently till day 5 (S4). It indicated that the oxidation of glucose generated maximum number of electrons which caused reduction of S - N bonds in the drug to a large extent.

3 Results and discussion

3.1 Degradation of Co-trimoxazole in CW-MFCs

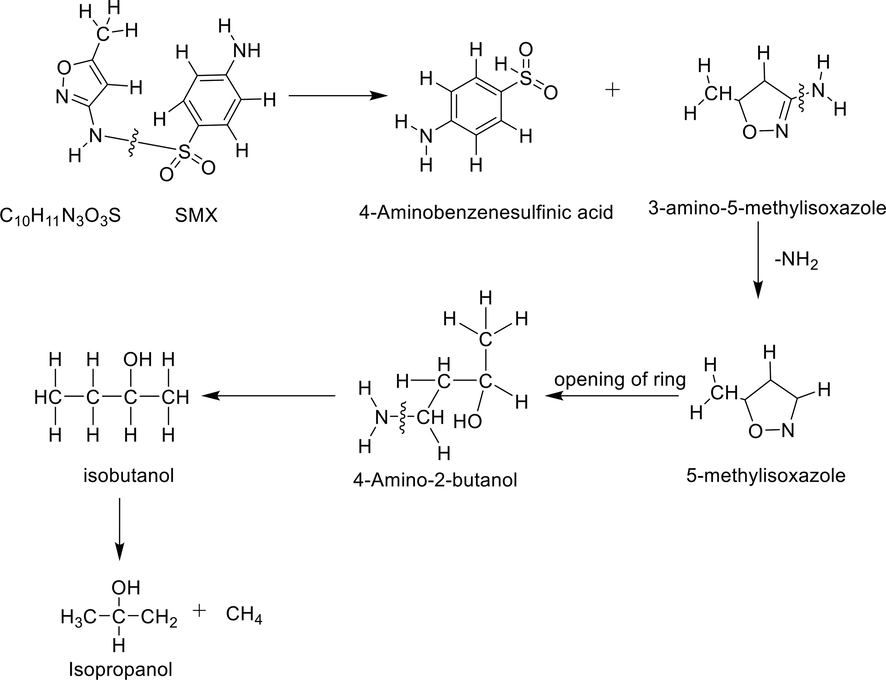

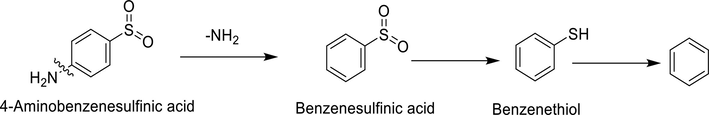

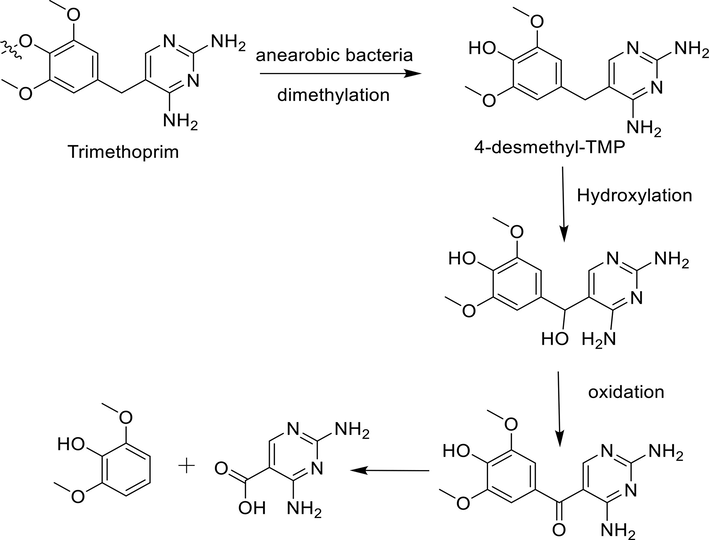

According to supposed biodegradation mechanism of SMX eight different products were found with less toxicity (Zhang et al., 2017). SMX first metabolized into 3-amino-5-methlyisoxazole (3A5MI) and 4-aminobenzene sulficinc acid by breakage of S-N bond. Nitrogen is removed as amonia and (3A5MI) is further transformed into 5-methyl-isoxazole. 5-methyl-isoxazole ring cleaved to open chain structure, 4-amino-2-butanol which further degraded by microbs and transformed to isopropanol. Isopropanol mineralized to methane under anoxic condition (Fig. 5). 4-aminobenzene sulficinc acid is further transformed into 4-aminobenzenethiol by cleavage of S—C bond. 4-aminobenzenethiol is mineralized into benzene (Fig. 6). TMP Quantification wasn’t possible as the reference standards were not available. In the high dilution experiment, TMP residues were observed but there was no detailed supposed mechanism for TMP degradation. One TMP product is formed by a hydroxylation, while other is formed by hydroxylations and several subsequent redox reactions (Fig. 7) (Jewell et al., 2016).

Schematic representation of conversion of isopropanol to methane under anoxic set up.

Scheme showing the conversion of 4-aminobenzenesulfinic acid to benzene.

Scheme showing the reaction mechanism for degradation of TMP.

3.2 Removal of Co-trimoxazole in CW-MFCs

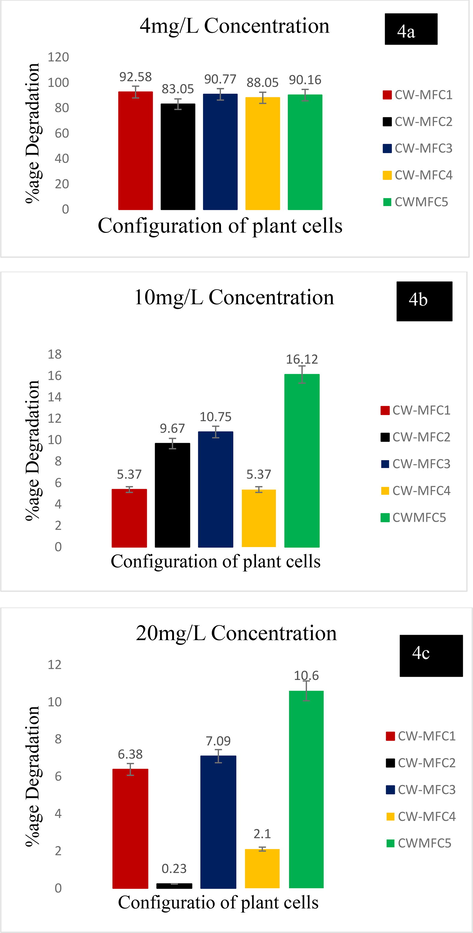

Evaluation of percentage removal was done by UV–VISIBLE spectrophotometer through absorption. Elimination potential of Co-trimoxazole was evaluated in five different CW-MFCs under three different concentrations and results are illustrated in Fig. 8. Effluent concentration in Trial 1(4 mg/L CMX), in CW-MFC1 decrease sharply at HRT of 1d then decrease gently until the values reaches below the detection limit, till HRT reach 6d. The order of CMX (4 mg) removal in five CW-MFCs was CWMFC1 > CW-MFC3 > CW-MFC4 > CW-MFC5 > CW-MFC2 (Fig. 8a,). Remarkable decrease in effluent concentration of CMX observed only in Trial 1 at day 1 with CW-MFC1 among all other reactors. With the increase in influent concentration in trial 2 effluent concentration increases and thorough degradation was observed at day 2. As we continued to increase influent concentration, system started taking long time accordingly for removal. The order of CMX (10 mg) removal in five CW-MFCs was CWMFC5 > CW-MFC3 > CW-MFC2 > CW-MFC1 > CW-MFC4 (Fig. 8b). Increase in influent CMX concentration (20 mg) showed decrease in effluent concentration at day3 among all reactors of CW-MFCs. The order of CMX (20 mg) removal in five CW-MFCs was CWMFC5 > CW-MFC3 > CW-MFC1 > CW-MFC4 > CW-MFC2 (Fig. 8c). Total highest CMX removal percentage was with least concentration (4 mg) observed to be 85.32% for configuration (1) at day 1 and reached to be 92.58% on day 6 after which the degradation rate remained constant which described that whole concentration of drug had been degraded into respective metabolites. The degradation rates observed at day1 were to be 67.32% 73.97%, 84.87% and 80.33% for configuration (2), (3), (4), (5) respectively, that reached to be 83.05%, 89.10%, 88.50% and 90.16% respectively on sixth day.

Degradation %age of CMX by CW-MFCs under different influent concentration; (4a) least concentration: 4 mg/L, (4b) medium concentration: 10 mg/ L, (4c) highest concentration: 20 mg/L. Error bars represents standard deviation and values represent the mean by three replicates.

3.3 Open circuit potential and green electricity generation

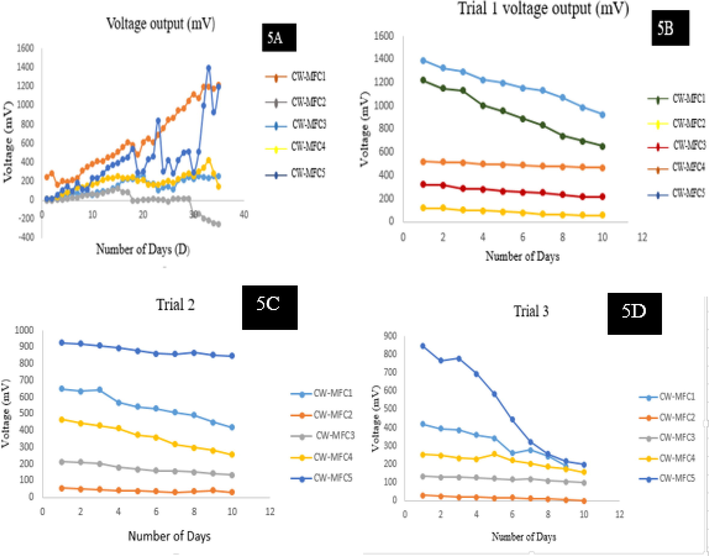

The open circuit potential (OCP) indicates the growth of microbe and maxima in voltage was observed due to maximum resistance. The biofilm was allowed to develop for almost thirty-five days at 35 °C. Fig. 9A shows the variation of open circuit potential of five configurations of CW-MFCs during development of biofilm prior the formal experiment. With external resistance of 1000 Ω, average voltage of (CW-MFC1, CW-MFC2, CW-MFC3, CW-MFC4 and CW-MFC5) rose to a maximum value of 1222 mV, 117.2 mV, 323 mV, 519 mV and 1393 mV respectively (Fig. 10) after an interval of eighteenth day to thirtieth day on account of the addition of glucose which started to decline slowly. The voltage decreased up to thirty fifth day after which it remained constant and the growth solution was refreshed. The constant value of voltage indicated the whole consumption of substrate (glucose) and the complete development of bacterial biofilm. After stable voltage production different concentration of antibiotic were added into synthetic waste water during three trials Fig. 9. Average noted values of voltage of CW-MFC1 for three trials were, 650 mV ± 135, 418 mV ± 104 and 234 mV ± 92 respectively. Similarly, average voltages outcomes among all reactors in three trials were 117.2 ± 24 mV, 29.2 ± 12 mV and 0.24 mV (CW-MFC2), 323 mV ± 67, 133 mV ± 41 and 98 mV ± 13 (CW-MFC3), 519 mV ± 72, 252 mV ± 30 and 156 mV ± 12 (CW-MFC4), 1393 mV ± 298, 927 mV ± 147 and 198 mV ± 17 (CW-MFC5) respectively. Among all the reactors, CW-MFC1 always showed fair performance due to large surface area of gravel that provided greater sites for attachment while CW-MFC2 exhibited least performance. Proceeding to Trial 3 voltage output of CW-MFC2 dropped to negative as soil particles provided least surface area for removal. The voltage decreased up to thirty fifth day after which it remained constant and the growth solution was refreshed. The constant value of voltage indicated the whole consumption of substrate (glucose) and the complete development of bacterial biofilm. Voltage decrease in all three trials could be relate with low consumption of organic matter by bacterial content, which lead to lower value of electrical conductivity (EC). It was noted that decrease in EC related to antibiotics concentration high antibiotics concentrate contribute to drop of EC irrespective of the presence of plant. Observed EC values during trial 1 were (3.28 ms/cm, 18.93 ms/cm, 8.36 ms/cm, and 4.78 ms/cm). Likewise, in trial 3 EC values observed to be (3.21, 4, 2.60, 2.33 and 2.44 ms/cm). Drop in EC values for five reactors during three trials was noted to be 97% 21% 31% 74% 51% respectively from 1 to 5 reactors.

Open circuit potential (OCP) of all reactors (5A), Voltage drop in all reactors of (CW-MFCs) after Trial 1 (5B), Voltage drop in all reactors after Trial 2 (5C), Voltage drop in all reactors after Trial 3 (5C).

Maximum average voltage output of five different configurations of CW-MFCs.

3.4 Polarization curve

The results indicated current density of 0.392 mA/m3 and power density of 477.85 mW/m3 (due to 3D nature of electrodes e.g length, width and height units were modified from (A/m2 to mA/m3) for current density and (mW/m2 to mW/m3) for power density. Results found to be higher at voltage of 1222Mv (Fig. 4a), with configuration 1 in comparison to other four configurations. The current and power densities were observed to be highest owing to the competition between reduction of antibiotic residues and the movement of electrons towards external circuit. The current and power densities were observed to be highest owing to the competition between reduction of antibiotic residues and the movement of electrons towards external circuit. Fig. 4a-e shows the polarization curve for the configuration 1 (gravel based CW-MFC), configuration 2 (soil based CW-MFC), configuration 3 (Sand based CW-MFC), configuration 4 (Soil, sand and gravel mixture CW-MFC) and configuration 5 (gravel based control configuration (contains only anaerobic sludge except geobacter sulferreducens culture) respectively. Fig. 4b shows the maximum current density of 0.037 mA/m3 and power density of 6.62 mW/m3 at voltage of 117 mV for configuration 2. In Fig. 4(c) maximum current density of 0.103 mA/m3 and power density of 33.38 mW/m3 at voltage of 323 mV obtained for configuration 3. Fig. 4d shows the maximum current density of 0.166 mA/m3 and power density of 86.19 mW/m3 at voltage of 519 mV for the configuration 4 and Fig. 4e shows the maximum values of current density 0.445 mA/m3 and power density 620.94 mW/m3 obtained at voltage of 1393 mV for control group.

3.5 Electrochemical response

The potential of the vacant cell devoid of the bacterial culture and electron acceptor solution was observed to be 3.28 V at 1.093 mA. The potential was found to be 2.169 V at 2.507 µA current value. The antibiotic solution (4 mg/L) was added in four layers of plant microbial fuel cells to assess the redox potential of the cells. Fig. 11 shows the voltammogram of anode effluent of CW-MFC1 CW-MFC2, CW-MFC3, CW-MFC4 and CW-MFC5 indicating the potential and current flow to be 1.200 V and 10.81µA, 120.1 mV and 594.9µA, 239.9 mV and 72.38µA, and 1.100 V and 7.648µA respectively after the addition of antibiotic solution with concentration of 4 mg/L in Fig. 11. The scan rate is fixed and the voltage is swept between two limits. The upper half curve indicated the oxidation potential producing electrons which cause the generation of electric current while the lower half depicted the reduction potential consuming electrons thus moving back to the initial voltage.

Electrochemical respones of effluents collected from anodic region of each type of reactor.

3.6 BOD removal efficiency of CW-MFCs

The BOD removal was noted to be 15% on first day which reached to 35% on second day. A little increment was observed and reached to 50% till sixth day after which it remained constant. Rate of removal efficiency in all reactors were as follow CW-MFC5 > CW-MFC2 > CW-MFC4 > CW-MFC3 > CW-MFC1 in all trials. Removal percentage for five reactors from (CWMFC1-CWMFC5) were 39%, 55.88%, 51.28%, 53.33%, 56.57% respectively (S4). This analysis indicated that antibiotic had not been fully degraded owing to the possible formation of other metabolites which need further degradation. Under the current scenario of environmental pollution, the proposed approach for the removal of antibiotics and possibly the other drugs are an efficient procedure (Shokri, 2018; Jamal et al., 2015; Arfaeinia et al., 2022; Singh and Dash, 2020).

4 Conclusions

This study thoroughly investigated the effect of Cymbopogon nardus and circuit operation mode on the removal efficiency of different concentration of Co-trimoxazole along with green electricity production in CW-MFCs. Main conclusions of designed study were: (1) both plants and open circuit connection amplify Co-trimoxazole removal in MFC-CWs (2) open-circuit MFC-CWs showed preferable BOD removal performance irrespective of the increasing antibiotic concentrations; (3) both plant and circuit mode accelerated the bioelectricity generation performance, voltage, power density and electrical conductivity); of gravel based CW-MFCs than other configurations. Comprehensively, the results indicated that the plant and circuit operation mode of CW-MFCs greatly affect the removal of antibiotic, BOD and green electricity generation performance. Future study can be planned to analyze the detailed effect of temperature on all parameters electricity generation, voltage, power density, electrical conductivity and elimination of CMX.

Acknowledgments

This work was supported by Researchers Supporting Project number (RSP2023R100), King Saud University, Riyadh, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Improving the Performance of Constructed Wetland Microbial Fuel Cell (CW-MFC) for Wastewater Treatment and Electricity Generation. Baghdad Sci. J.. 2021;18(1):0007.

- [Google Scholar]

- Comparative chemical and analgesic properties of essential oils of Cymbopogon nardus (L) Rendle of Benin and Congo. Afr. J. Tradit. Complement. Altern. Med.. 2007;4(3):267-272.

- [Google Scholar]

- Bioaccessibility-based monitoring and risk assessment of indoor dust-bound PAHs collected from housing and public buildings: Effect of influencing factors. Environ. Res.. 2022;204:112039

- [Google Scholar]

- Occurrence of antibiotic-resistant bacteria and genes in two drinking water treatment and distribution systems in the North-West Province of South Africa. Antibiotics. 2020;9(11):745.

- [Google Scholar]

- Construction of porous biochar decorated with NiS for the removal of ciprofloxacin antibiotic from pharmaceutical wastewaters. J. Water Process Eng.. 2022;49:103006

- [Google Scholar]

- Biocomposite application for the phosphate ions removal in aqueous medium. J. Mater. Res. Technol.. 2018;7(3):300-307.

- [Google Scholar]

- Antibiotic removal processes from water & wastewater for the protection of the aquatic environment - a review. J. Water Process Eng.. 2022;45:102474

- [Google Scholar]

- Electricity production from Azo dye wastewater using a microbial fuel cell coupled constructed wetland operating under different operating conditions. Biosens. Bioelectron.. 2015;68:135-141.

- [Google Scholar]

- Phytochemical profiles and antioxidant activity of grasses used in South African traditional medicine. Plants. 2020;9(3):371.

- [Google Scholar]

- Evidence of association of salmonellae with tomato plants grown hydroponically in inoculated nutrient solution. Appl. Environ. Microbiol.. 2002;68(7):3639-3643.

- [Google Scholar]

- Photo-degradation of monoazo dye blue 13 using advanced oxidation process. Chem. Int.. 2015;1(1):12-16.

- [Google Scholar]

- New insights into the transformation of trimethoprim during biological wastewater treatment. Water Res.. 2016;88:550-557.

- [Google Scholar]

- An overview of plant microbial fuel cells (PMFCs): configurations and applications. Renew. Sustain. Energy Rev.. 2019;110:402-414.

- [Google Scholar]

- Selective and high-efficient removal of tetracycline from antibiotic-containing aqueous solution via combining adsorption with membrane pre-concentration. J. Water Process Eng.. 2022;50:103281

- [Google Scholar]

- Removal of anti-biotics from veterinary pharmaceutical wastewater using combined Electroflocculation and Fe-Zn loaded zeolite 5A based catalytic ozonation process. J. Water Process Eng.. 2022;49:103039

- [Google Scholar]

- Trimethoprim and Sulfamethoxazole Residues in Untreated Wastewater used for Irrigation in Peri-urban Farms in Nairobi County, Kenya. Nat. Environ. Pollut. Technol.. 2017;16(4):989-994.

- [Google Scholar]

- Effect of cotrimoxazole on causes of death, hospital admissions and antibiotic use in HIV-infected children. AIDS. 2007;21(1):77-84.

- [Google Scholar]

- Kinetic and thermodynamic properties of pharmaceutical drug (Gabapentin) by potassium bromate (KBr O3) in presence of micro amount of Ir (III) chloride as catalyst in acidic medium. Chem. Int.. 2017;3(2):158-164.

- [Google Scholar]

- Diurnal variations in the occurrence and the fate of hormones and antibiotics in activated sludge wastewater treatment in Oslo, Norway. Sci. Total Environ.. 2010;408(8):1915-1924.

- [Google Scholar]

- Coagulation of metallic pollutants from wastewater using a variety of coagulants based on metal binding interaction studies. Z. Phys. Chem.. 2021;235(4):467-481.

- [Google Scholar]

- Application of Sono–photo-Fenton process for degradation of phenol derivatives in petrochemical wastewater using full factorial design of experiment. Int. J. Ind. Chem.. 2018;9(4):295-303.

- [Google Scholar]

- An environmental remediation: study of molecular interactions of the poorly soluble pharmaceutical drug ibuprofen in aqueous media. Biointerface Res. Appl. Chem.. 2020;10(2):5061-5067.

- [Google Scholar]

- Fate of sulfadiazine and its corresponding resistance genes in up-flow microbial fuel cell coupled constructed wetlands: effects of circuit operation mode and hydraulic retention time. Chem. Eng. J.. 2018;350:920-929.

- [Google Scholar]

- Allelopathic activity of leaves, stalks and roots of Cymbopogon nardus. Emirates J. Food Agric. 2014:436-443.

- [Google Scholar]

- Antibiotic contaminants in coastal wetlands from Vietnamese shrimp farming. Environ. Sci. Pollut. Res.. 2011;18(6):835-841.

- [Google Scholar]

- Bioenergy generation and rhizodegradation as affected by microbial community distribution in a coupled constructed wetland-microbial fuel cell system associated with three macrophytes. Sci. Total Environ.. 2017;607:53-62.

- [Google Scholar]

- Removal and distribution of antibiotics and resistance genes in conventional and advanced drinking water treatment processes. J. Water Process Eng.. 2022;50:103217

- [Google Scholar]

- Treatment of typical antibiotics in constructed wetlands integrated with microbial fuel cells: Roles of plant and circuit operation mode. Chemosphere. 2020;250:126252

- [Google Scholar]

- Removal of sulfamethoxazole and tetracycline in constructed wetlands integrated with microbial fuel cells influenced by influent and operational conditions. Environ. Pollut.. 2021;272:115988

- [Google Scholar]

- Electricity production and evolution of microbial community in the constructed wetland-microbial fuel cell. Chem. Eng. J.. 2018;339:479-486.

- [Google Scholar]

- Simultaneous reduction of antibiotics leakage and methane emission from constructed wetland by integrating microbial fuel cell. Bioresour. Technol.. 2021;320:124285

- [Google Scholar]

- Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal. Ecol. Eng.. 2012;47:126-131.

- [Google Scholar]

- Experimental modeling, optimization and comparison of coagulants for removal of metallic pollutants from wastewater. Z. Phys. Chem.. 2021;235(8):1041-1053.

- [Google Scholar]

- Degradation of sulfamethoxazole in bioelectrochemical system with power supplied by constructed wetland-coupled microbial fuel cells. Bioresour. Technol.. 2017;244:345-352.

- [Google Scholar]

- A system composed of a biofilm electrode reactor and a microbial fuel cell-constructed wetland exhibited efficient sulfamethoxazole removal but induced sul genes. Bioresour. Technol.. 2018;256:224-231.

- [Google Scholar]

Appendix A

Supplementary material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.arabjc.2023.104941.

Appendix A

Supplementary material

The following are the Supplementary data to this article:Supplementary data 1

Supplementary data 1