Translate this page into:

A novel modification of ionic liquid mixture density based on semi-empirical equations using laplacian whale optimization algorithm

⁎Corresponding authors. hbagheri@uk.ac.ir (Hamidreza Bagheri), m.hosseini@vru.ac.ir (Mohammad Sadegh Hosseini)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The main motivation of this study is development of density prediction of mixture including ionic liquid (IL) using semi-empirical and cubic equations of state (CEoS). The considered systems are contained of 51 ILs, 41 solvents and 4626 data point in the wide temperature range (278.15–348.15 K), ionic liquid mole fraction (0.0040–0.9977) and atmospheric pressure. Six simple semi-empirical equations with different mixing rules and two CEoSs (Soave-Redlich-Kwong EoS and Patel-Teja EoS) is investigated to predict the IL-mixture density. For each semi-empirical equation, the coefficients are optimized using laplacian whale optimization algorithm based on cation-family. These generalized modifications have not been used to ILs beforehand consequently, the accuracy and appropriateness of these equations to predict IL-mixture density are unsknown until now. The obtained results based on semi-empirical equations indicate that the performed modification provides low deviation of experimental data and can be applied by confidence in engineering and thermodynamic calculations. However, the results based on two CEoS show inacceptable accuracy.

Keywords

Density

Equation

Ionic liquid

LXWOA

PT

SRK

Nomenclature

-

Attractive term parameter of equation of state [cm6/mol2]

- ai

-

Fitting parameters (i = 0, 1, 2, 3, 4)

- AAPD

-

Average absolute percent deviation [-]

-

Repulsive term(co-volume) parameter of equation of state [cm3/mol]

- bi

-

Fitting parameters (i = 0, 1, 2, 3, 4)

- B

-

Dimensionless repulsive term parameter of equation of state [-]

- c

-

Volume-translated parameter [cm3/mol]

- ci

-

Fitting parameters (i = 0, 1, 2, 3)

-

Dimensionless volume-translated parameter of equation of state [-]

- kij

-

Binary interaction parameter [-]

-

Solid molecular weight [g/mol]

- N

-

Number of experimental data point

- P

-

Pressure [bar]

- R

-

Ideal gas constant [bar.cm3/K.mol]

- T

-

Temperature [K]

- Tr =T/Tc

-

Reduced temperature [-]

- V,v

-

Molar volume [cm3/mol]

- x

-

Mole fraction [-]

-

Compressibility factor [-]

-

Temperature dependency coefficient of attractive term

-

Calculated critical compressibility factor [-]

-

Density [g/cm3]

-

Patel-Teja Equation of state parameter coefficient

-

Acentric factor [-]

Greek letter

- c

-

Critical

- EoS

-

Equation of state

- Exp.

-

Experimental

- m

-

Mixture

Subscript

- Calc.

-

Calculated

- E

-

Excess

- EoS

-

Equation of state

- i

-

Component i

- j

-

Component j

Superscript

1 Introduction

In current years, the attention in green technology has led to the extension of a novel class of highly tunable and unique components that are called ionic liquids (IL). The ILs are the components that have revolutionized the corresponding researches and chemical industries. They are investigated as green chemical components that play a very significant role as a solvent to decrease applying of harmful, toxic and hazardous chemical components for the environment (Nishan et al., 2021). The main reason of increased considers on ILs is the aim of researchers to look for an appropriate alternative for volatile conventional organic solvents among the industries. Indeed, volatile conventional organic solvents are main environmental pollution resource in chemical industries (El shafiee et al., 2021). Although, all ILs are not completely considered as green solvents, some of ILs are even considerably toxic. Ionic liquids have involved a significant interest throughout the last three decades in the industrial and academic fields due to their unique properties (Agafonov et al., 2020; Omar et al., 2021). ILs are usually composed of inorganic or organic anions and an organic cation (Lian et al., 2016). According to cations, ILs are categorized to several categories like sulfonium, amino acids, phosphonium, guanidinium, ammonium, pyridazinium, piperazinium, oxazolidinium, tetrazolium, morpholinium, uranium, thiazolium, isoquinolinium, pyrroline, piperidinium, pyrrolidinium, pyridinium and imidazolium. Moreover, nitrate, perchlorate, bromide and chloride are simple anions and bis((trifluoromethyl)sulfonyl) imide, trifluoromethanesulfonate and lactate are complex anions (Bagheri et al., 2021; Evangelista et al., 2014; Xu et al., 2009). The ionic liquids properties will depend on the special combination of the anion and cation. The significant physicochemical features of ionic liquids like high electrochemical, thermal and chemical stability, non-flammability, low melting point and low vapor pressure (non-volatility) at moderate temperatures and pressures, high solvating power for non-polar and polar compounds have made ILs the exploration subject in many applications (Mohammadzadeh et al., 2020).

Designing equipment and chemical processes that involve ILs, needs accurate data on ILs thermo-physical features. The knowledge of ILs chemical and physical features is fundamental for ILs applications. Consequently, a number of scientists have investigated the thermodynamic properties of pure ILs and binary IL-mixture systems (Mesquita et al., 2019; Bagheri and Mohebbi, 2017). Until now, most investigations related to features of IL are limited to pure ones like viscosity, heat capacity, conductivity, surface tension and density. But, the usage of IL-mixture in engineering applications needs accurate detail about thermodynamic and physical features of ILs. The volumetric features refer to be related by substance volume change, such as expansibility, compressibility, excess molar volume, partial molar volume and density. ILs density is one of the most basic ILs volumetric features that is necessary in process design and calculations of metering of IL and it is interpreting interactions of intermolecular between solvent and ILs molecular (Tao et al., 2020). It is possible to calculate the ILs density accurately using experimental methods. However, as the experimental calculations are usually difficult, time consuming and costly consequently, the experimental calculations are not continuously possible (Tao et al., 2020; Bagheri et al., 2019; Paiva et al., 2019). Indeed, to develop process based on IL from the laboratory scale to industrial applications, the sufficient theoretical models to calculate ILs thermo-physical features must be considered (Bagheri and Ghader, 2017). In point of fact, the equipment design like liquid–liquid and vapor–liquid separation, energy and material balances including liquids, tower height calculations, rebuilders and condensers and storage vessels sizing, all need accurate liquid density values. Furthermore, other ILs features like surface tension or heat capacity, are sometimes correlated by density, so the reliable values of density permit one to calculate the mentioned features by an acceptable accuracy (Lian et al., 2016).

It is difficult to calculate features of all substances especially at various temperature and pressure or expensive and toxic components that maybe cause serious injuries for environment and human health. Thus, it is required to find out a method to calculate substances features. To solve the mentioned problem several estimation method was presented to estimate pure and IL-mixture. The presented methods are different from one case to another one and such correlations are based on some adjustable parameters, some of them are based on group contribution methods, equations of state and or machine learning methods (Abumandour et al., 2020; Yang et al., 2020; Bagheri et al., 2021).

Several semi-empirical equations were presented to calculate IL pure density such as Redlich-Kister polynomial equation, Lorentz-Lorenz equation, Tait equation and Wright equation and they have some fitting parameters (Lampreia et al., 2003; Valderrama and Zarricuetac, 2009; Geppert-Rybczyńska et al., 2010; I. Bahadur I, N. Deenadayalu, , 2011; Matkowska and Hofman, 2013; Bahadur et al., 2013; Govinda et al., 2013; Govinda et al., 2013; Singh et al., 2014; Huang et al., 2015). However, Hosseini et al. (Hosseini et al., 2013) presented the modified version of Spencer and Danner equation to predict IL-mixture density. The used data set was including 854 experimental data points and 14 binary mixtures. The obtained results indicated the performed modification had acceptable performance to predict IL-mixture density. Equations of state (EoS) and group contribution (GC) EoS are other sets of equations which were used to estimate the IL binary mixture (Abareshi et al., 2009; Wang et al., 2010; Li et al., 2011; Shen et al., 2011; Shahriari et al., 2012; Oliveira et al., 2012; Hosseini et al., 2012; Yousefi, 2012; Sheikhi-Kouhsar et al., 2015). EoSs are important tool to design in chemical engineering and supposed a developing role in the consideration of the fluid mixtures phase equilibria. However, the accuracy of some CEoSs is low to predict features of thermodynamic in a wide range of pressures and temperatures (Liu et al., 2020; Kamath et al., 2010; Ghoderao et al., 2019; Coquelet et al., 2016). The binary mixtures containing IL are complex systems, due to depend not only on molecular-molecular interaction, but also on the ion-molecular and ion-ion interactions. Cubic EoSs (CEoSs) consider only the attraction and repulsive interaction and they are unable to consider the other intermolecular forces (Panayiotou et al., 2019; Farrokh-Niae et al., 2008; Kukreja et al., 2021; Secuianu et al., 2008; Lopez-Echeverry et al., 2017). Therefore, the obtained results of IL-mixture density based on CEoSs have systematic deviation. Although some corrections like volume-translated to decrease systematic deviation was performed (Sheikhi-Kouhsar et al., 2015). The statistical associating fluid theory (SAFT) family EoS is according to perturbation theory. The SAFT family EoSs consider almost all intermolecular forces and presented the real form of intermolecular forces of components. However, computer programing of SAFT family EoSs are time consuming and need advance numerical methods (Perdomo et al., 2021; J. Gross J, G. Sadowski, , 2002; Bülow et al., 2021). Also, GC method required an accurate and perfect knowledge of the IL structure and it is time consuming and complex. Furthermore, the model fails and is considerably limited when applying large substructures as group parameters (Qiao et al., 2010; Peng et al., 2017; Chen et al., 2019). Machine learning method is another advantageous tool to predict properties pure and mixture IL and it is extensively accepted as estimation technique (Venkatraman and Alsberg, 2017). The relationship between the properties is nonlinear and the machine learning method is a significantly able algorithm to estimate certain properties like density by learning the relation between the input data (for instance temperature, pressure and critical features) and output data (like density) (Zhang et al., 2006; Yusuf et al., 2021). Also, the accuracy of the obtained results depends on the size of the training data set and the most important weakness of the machine learning method is low capability to predict the future performance of the network (generalization) (Low et al., 2020).

Density is one of the basic features of ionic liquid mixtures that would be useful in understanding intermolecular interactions between molecules of ionic liquid and solvent. The main purpose of this study is to develop a more accurate and reliable methods for estimating density of IL + solvent binary system. Consequently, the density of 130 various IL + solvent binary mixture (4626 data point) including 11 different cation-family (BuPy, C2mim, C3mim, C4mim, C6mim, C8mim, Hmim, Mmim, Moim, OcPy and Omim) in the wide range of temperature, IL mole fraction and in the atmospheric pressure is modeled using two methods, i.e. cubic equations of state (Soave-Redlich-Kwong (SRK) EoS as two-parameter CEoS and Patel-Teja (PT) EoS as three-parameter CEoS) and six semi-empirical equations. The semi-empirical equations had fitting parameters and the they were obtained for each cation-family, separately. To obtain the fitting parameters of semi-empirical equations, the improved laplacian whale optimization algorithm (LXWOA) was applied.

2 Materials and methods

2.1 Data set

The values of molecular weight (Mw), critical molar volume (Vc), acentric factor (ω), critical pressure (Pc) and critical temperature (Tc) for each IL and solvent and as model input variables are necessary. Consequently, the mentioned properties of 51 ILs and 41 solvents that are used in this investigation, are provided in Table 1. The ILs critical properties were from references (Bagheri and Mohebbi, 2017; Bagheri and Ghader, 2017; Sheikhi-Kouhsar et al., 2015; Valderrama et al., 2008) and the critical properties of solvents were from references (Danesh, 1998; Green and Southard, 2019).

No.

Substance

Mw

Tc (K)

Pc (bar)

Vc (cm3/mol)

Zc

ω

Reference

1

[BuPy][BF4]

223.019

597.600

20.30

648.1000

0.2682

0.8307

11

2

[BuPy][NO3]

198.225

815.890

26.59

639.0367

0.2537

0.5981

15

3

[C2mim][BF4]

197.970

585.300

23.60

557.8230

0.2740

0.7685

15

4

[C2mim][C2SO4]

236.300

968.100

40.40

676.8000

0.3441

0.8142

15

5

[C2mim][CH3SO4]

222.268

1053.610

45.91

602.6700

0.3200

0.3400

15

6

[C2mim][CH3(OCH2CH2)2OSO3]

310.000

1162.900

28.10

862.3000

0.2539

0.5176

15

7

[C2mim][DCA]

177.210

999.000

29.10

597.8000

0.2122

0.7661

15

8

[C2mim][EtSO4]

236.290

1061.100

40.40

578.6822

0.2684

0.3368

11

9

[C2mim][[L-lactate]

200.241

965.989

26.32

620.1200

0.2059

0.9467

15

10

[C2mim][NO3]

173.174

918.398

33.30

531.68

0.2349

0.5678

39

11

[C2mim][OAc]

170.210

807.100

29.20

544.0000

0.2398

0.5889

15

12

[C2mim][OTf]

260.200

898.800

35.80

653.4000

0.3171

0.7509

59

13

[C2mim][TFA]

224.200

824.670

28.86

593.4675

0.2530

0.6808

59

14

[C2mim][triflate]

260.200

992.300

35.80

636.3977

0.2797

0.3255

59

15

[C3mim][Br]

205.099

815.601

32.97

526.1600

0.2591

0.4505

15

16

[C3mim][Glu]

200.263

992.821

26.41

765.56

0.2481

1.0174

11

17

[C4mim][BF4]

226.020

632.300

20.40

671.9651

0.2641

0.8489

15

18

[C4mim][CH3SO4]

250.000

1081.600

36.10

716.9000

0.2915

0.4111

11

19

[C4mim][Cl]

175.000

789.000

27.80

568.8000

0.2442

0.4908

11

20

[C4mim][ClO4]

238.669

722.540

22.64

716.5103

0.2735

0.8418

15

21

[C4mim][EtSO4]

264.349

1096.084

32.55

774.0000

0.2801

0.4497

15

22

[C4mim][Glu]

286.354

1231.847

20.32

892.4346

0.1793

1.4083

15

23

[C4mim][Gly]

214.290

1012.794

24.29

701.7463

0.2050

1.0513

15

24

[C4mim][HSO4]

236.300

1103.800

43.40

664.9000

0.3185

0.7034

59

25

[C4mim][L-lactate]

228.295

1005.090

24.60

734.3400

0.2190

1.0172

59

26

[C4mim][MeSO4]

250.320

1081.600

36.10

643.4045

0.2616

0.4111

59

27

[C4mim][OcSO4]

349.000

1189.800

20.20

1116.7000

0.2310

0.7042

11

28

[C4mim][PF6]

284.180

708.900

17.30

779.4230

0.2317

0.7553

15

29

[C6mim][BF4]

254.070

690.000

17.90

772.7525

0.2442

0.9625

15

30

[C6mim][Br]

247.200

841.100

26.70

728.4475

0.2817

0.6070

39

31

[C6mim][Cl]

202.720

829.200

23.50

683.0308

0.2358

0.5725

39

32

[C6mim][EtSO4]

292.403

1125.917

27.14

888.2200

0.2609

0.5314

11

33

[C6mim][MeSO4]

278.376

1110.838

29.61

831.1100

0.2699

0.4899

59

34

[C6mim][PF6]

312.200

754.300

15.50

848.1796

0.2123

0.8352

59

35

[C8mim][BF4]

282.100

727.400

15.78

884.3653

0.2337

0.9956

59

36

[C8mim][Br]

275.23

746.554

30.92

846.2769

0.4271

0.8065

59

37

[C8mim][Cl]

230.780

869.400

20.30

797.0536

0.2267

0.6566

15

38

[C8mim][C1OSO3]

250.310

1081.600

36.10

716.9000

0.2915

0.4111

15

39

[C8mim][PF6]

340.000

810.800

14.00

990.8609

0.2084

0.9385

15

40

[Hmim][BF4]

254.000

706.300

17.90

786.2000

0.2428

0.6221

15

41

[Hmim][FAP]

612.298

861.545

88.70

1385.0400

1.7377

0.9062

15

42

[Hmim][PF6]

312.230

764.900

15.50

893.7091

0.2206

0.8697

15

43

[Hmim][NTf2]

447.420

1287.300

22.20

929.7630

0.1953

1.3270

39

44

[Mmim][CH3SO4]

208.000

1040.000

52.90

610.1200

0.3781

0.3086

11

45

[Mmim][MeSO4]

208.240

1040.000

52.90

448.8029

0.2781

0.3086

11

46

[Moim][BF4]

282.140

737.000

16.00

883.4000

0.2337

1.0287

11

47

[Moim][CH3(OCH2CH2)2OSO3]

394.538

1257.282

18.44

1204.9900

0.2153

0.7786

59

48

[OcPy][BF4]

279.133

692.340

15.99

876.5600

0.2467

0.9795

59

49

[OcPy][NO3]

254.332

986.900

20.05

856.2795

0.2119

0.7495

59

50

[Omim][BF4]

282.100

726.100

16.00

822.2359

0.2207

0.9954

59

51

[Omim][PF6]

340.260

810.800

14.00

1007.4940

0.2119

0.9385

59

52

Acetone

58.080

508.200

47.01

206.6908

0.2329

0.3070

60

53

Acetonitrile

41.053

545.000

48.30

170.3680

0.1839

0.3380

61

54

Amino acid

200.900

710.350

19.19

743.3000

0.2447

0.5425

61

55

Benzaldehyde

106.120

694.750

46.50

335.5608

0.2736

0.3050

61

56

Benzyl alcohol

108.138

720.150

43.74

335.4608

0.2482

0.3631

61

57

Butanone

72.110

536.750

42.10

266.5694

0.2547

0.3200

61

58

Butyl acetate

116.158

575.400

30.90

383.5359

0.2509

0.4394

60

59

Butyl amine

73.140

531.950

42.00

290.0000

0.2790

0.3290

60

60

DEGMME 1

120.150

630.050

35.40

366.8700

0.2511

0.8707

60

61

Dichloromethane

84.932

510.000

60.80

182.4035

0.2649

0.1986

60

62

Diethyl carbonate

118.100

576.050

33.90

356.1248

0.2553

0.4848

60

63

Di-EGMEE

134.180

602.050

28.60

421.9985

0.2442

0.5748

61

64

Dimethyl carbonate

90.330

529.950

31.38

374.5837

0.2702

0.2711

61

65

Dimethyl sulfoxide

78.139

729.000

56.50

227.0000

0.2143

0.2806

61

66

EGMEE 2

91.020

567.050

42.30

293.9262

0.2671

0.7591

61

67

EGMME 3

76.100

562.050

50.10

241.9265

0.2627

0.7311

61

68

Ethanol

46.069

513.900

61.48

164.6178

0.2399

0.6450

60

69

Ethyl acetate

88.106

523.300

38.80

282.2150

0.2549

0.3660

60

70

Ethylene glycol

62.068

720.000

82.00

191.0000

0.2650

0.5068

60

71

Iso-butanol

58.140

408.100

36.48

262.7000

0.2861

0.1810

60

72

Methanol

32.042

512.600

80.97

116.3652

0.2239

0.5640

60

73

Methyl acetate

74.079

506.600

47.50

224.9187

0.2569

0.3310

60

74

Methyl methacrylate

100.116

566.000

36.80

319.3081

0.2529

0.2802

60

75

Pentanone

86.132

560.950

37.40

292.9209

0.2379

0.3448

61

76

PGMEE 4

104.150

554.127

45.32

294.0736

0.2930

0.7238

61

77

PGMME 5

90.140

553.050

43.40

293.9384

0.2810

0.7219

61

78

Pyridine

79.100

620.050

56.20

246.7049

0.2724

0.2430

61

79

Nitromethane

61.040

588.200

63.10

173.0000

0.2261

0.3480

61

80

MDEA 6

119.630

677.050

37.00

313.3000

0.2086

0.9970

61

81

β-Pyridine

93.129

645.050

46.50

311.0000

0.2732

0.2706

61

82

1-Butanol

74.123

535.900

41.88

273.0054

0.2599

0.5692

61

83

1-Decanol

158.281

688.000

23.08

645.0000

0.2636

0.6070

61

84

1,3-Dichloropropane

112.980

560.000

42.40

291.0000

0.2684

0.2564

61

85

1,4-Dioxane

88.110

587.000

52.08

234.9209

0.2539

0.2793

61

86

1-Hexanol

102.175

611.300

34.46

377.0160

0.2589

0.5586

61

87

1-Octanol

130.228

652.300

27.83

509.0000

0.2646

0.5697

60

88

1-Propanol

60.096

536.800

51.69

216.4515

0.2539

0.6209

60

89

2-Propanol

60.096

508.300

47.65

217.0849

0.2479

0.6544

60

90

Tetrahedrofuran

72.110

504.200

51.90

224.0000

0.2809

0.2254

61

91

Tri-EGMEE

178.240

679.120

24.80

567.1593

0.2523

1.0590

61

92

Water

18.015

647.100

220.50

55.1466

0.2289

0.3450

60

To calculate the density of IL + solvent binary systems, the enormous data set that covers a wide range of temperature, mole fraction, solvent and IL was provided. This data set was applied to developed the suggested models, contains 4626 experimental data point in the temperature range of 278.15–353.15 K, IL mole fraction range of 0.0040–0.9854 and atmospheric pressure. The data set was collected from references (Mokhtarani et al., 2009; Wang et al., 2012; Rilo et al., 2009; Solanki et al., 2013; Bhagour et al., 2013; Bhattacharjee et al., 2012; Wang et al., 2011; Bhujrajh and Deenadayalu, 2007; Quijada-Maldonado et al., 2012; Rodriguez and Brennecke, 2006; Wang et al., 2011; Zhao et al., 2012; Vercher et al., 2007; Sadeghi et al., 2009; Tong et al., 2009; Iglesias-Otero et al., 2008; Gao et al., 2009; Patel et al., 2016; Domańska et al., 2006; Kumar et al., 2012; Mokhtarani et al., 2008; Matkowska and Hofman, 2013; Gao et al., 2010; Jiang et al., 2013; Singh et al., 2013; Pau and Panda, 2012; Wandschneider et al., 2008; Zhong et al., 2007; Fan et al., 2009; Pal and Kumar, 2011; Pal et al., 2010; Kermanpour and Sharifi, 2012; Kermanpour, 2012; Kermanpour and Niakan, 2012; Pal and Kumar, 2012; Zhu et al., 2011; Gomez et al., 2006; Malek et al., 2014; Ijardar and Malek, 2014; Akbar and Murugesan, 2013; Akbar et al., 2016; González et al., 2012; Pereiro et al., 2006; Pereiro and Rodriguez, 2007; Jiang et al., 2012) and the more details are prepared in Table 2. The provided data set contains several chemical compounds (51 ILs and 41 solvents) and 130 binary systems. Also, ILs are counting 11 various cations and 25 various anions.

No.

System

T (K)

xIL

ND*

Reference

1

BuPyBF4 + water

283.15–343.15

0.1440–0.8900

104

62

2

BuPyNO3 + water

298.15

0.0091–0.9018

16

63

3

C2mimBF4 + water

298.15

0.0040–0.7774

17

64

4

C2mimBF4 + pridine

293.15–308.15

0.1225–0.9349

72

65

5

C2mimBF4 + β-pyridine

293.15–308.15

0.1217–0.9317

72

65

6

C2mimBF4 + acetone

293.15–308.15

0.1214–0.9203

72

66

7

C2mimBF4 + dimethylsulphoxide

293.15–308.15

0.1319–0.9249

72

66

8

C2mimC2SO4 + water

283.15–343.15

0.1017–0.9977

49

67

9

C2mimCH3SO4 + methanol

298.15

0.0500–0.9389

12

68

10

C2mimCH3(OCH2CH2)2OSO3 + methanol

298.15–313.15

0.0380–0.9830

45

69

11

C2mimCH3(OCH2CH2)2OSO3 + water

298.15–313.15

0.1110–0.9780

45

69

12

C2mimDCA + water

298.15–343.15

0.0992–0.9067

40

70

13

C2mimDCA + ethanol

298.15–343.15

0.1059–0.8666

40

70

14

C2mimEtSO4 + water

278.15–348.15

0.0084–0.7888

64

71

15

C2mimL-lactate + water

298.15

0.0059–0.9390

17

72

16

C2mimNO3 + ethanol

298.15

0.0995–0.9000

9

73

17

C2mimNO3 + methanol

298.15

0.1000–0.8995

9

73

18

C2mimOAc + water

298.15–343.15

0.0992–0.9067

40

70

19

C2mimOAc + ethanol

298.15–343.15

0.1059–0.8666

40

70

20

C2mimOTf + water

278.15–348.15

0.0076–0.7705

64

71

21

C2mimTFA + water

278.15–348.15

0.0088–0.7950

64

71

22

C2mimtriflate + methanol

278.15–318.15

0.0505–0.9489

65

74

23

C2mimtriflate + water

278.15–338.15

0.0178–0.9498

133

74

24

C3mimBr + acetonitrile

288.15–308.15

0.01578–0.9782

60

75

25

C3mimBr + dimethyl sulfoxide

288.15–308.15

0.02769–0.9854

55

75

26

C3mimGlu + amino acid

283.15–338.15

0.0390–0.5427

216

76

27

C4mimBF4 + ethanol

298.15

0.0517–0.8295

11

77

28

C4mimBF4 + nitromethane

298.15

0.0512–0.8634

13

77

29

C4mimBF4 + 1,3-dichloropropane

298.15

0.0536–0.9028

15

77

30

C4mimBF4 + ethylene glycol

298.15

0.0517–0.9083

14

77

31

C4mimBF4 + water

298.15

0.0017–0.9005

27

64

32

C4mimBF4 + ethanol

298.15

0.0986–0.9059

12

64

33

C4mimBF4 + benzaldehyde

298.15–313.15

0.1000–0.8990

36

78

34

C4mimBr + ethylene glycol

293.15–323.15

0.0969–0.897

63

79

35

C4mimCH3SO4 + 1-butanol

298.15

0.0745–0.9622

10

80

36

C4mimCH3SO4 + 1-decanol

298.15

0.0603–0.9569

10

80

37

C4mimCH3SO4 + 1-hexanol

298.15

0.0602–0.9714

10

80

38

C4mimCH3SO4 + 1-octanol

298.15

0.0497–0.9605

10

80

39

C4mimCH3SO4 + ethanol

298.15

0.0713–0.9614

10

80

40

C4mimCH3SO4 + methanol

298.15

0.0507–0.9308

10

80

41

C4mimCH3SO4 + water

298.15

0.0498–0.9783

12

80

42

C4mimCl + ethylene glycol

298.15–318.15

0.0132–0.9126

36

81

43

C4mimClO4 + ethanol

283.15–343.15

0.1400–0.9000

71

82

44

C4mimEtSO4 + ethanol

283.15–328.15

0.0495–0.9020

32

83

45

C4mimEtSO4 + methanol

283.15–328.15

0.0501–0.8485

32

83

46

C4mimGlu + benzylalcohol

298.15–313.15

0.1001–0.9001

36

84

47

C4mimGly + benzylalcohol

298.15–313.15

0.1000–0.9000

36

84

48

C4mimHSO4 + water

303.15–343.15

0.1012–0.9917

35

67

49

C4mimL-lactate + 1-butanol

298.15–318.15

0.1000–0.8997

27

85

50

C4mimL-lactate + ethanol

298.15–318.15

0.0992–0.8974

27

85

51

C4mimL-lactate + methanol

298.15–318.15

0.0997–0.8981

27

85

52

C4mimL-lactate + water

298.15–318.15

0.1002–0.9010

27

85

53

C4mimMeSO4 + methanol

298.15–313.15

0. 0422–0.9526

44

86

54

C4mimMeSO4 + 1-propanol

298.15–313.15

0.0482–0.9510

44

86

55

C4mimMeSO4 + 2-propanol

298.15–313.15

0.0482–0.9531

40

86

56

C4mimMeSO4 + 1-butanol

298.15–313.15

0.0425–0.7996

32

86

57

C4mimMS + water

298.15–323.15

0.2000–0.8000

30

87

58

C4mimNTf2 + 1-butanol

298.15

0.0941–0.8986

11

88

59

C4mimNTf2 + 1-propanol

298.15

0.0941–0.8986

10

88

60

C4mimOcSO4 + 1-butanol

298.15

0.0798–0.9450

10

80

61

C4mimOcSO4 + 1-hexanol

298.15

0.0999–0.8672

9

80

62

C4mimOcSO4 + 1-octanol

298.15

0.2472–0.9508

8

80

63

C4mimOcSO4 + 1-decanol

298.15

0.0627–0.9723

10

80

64

C4mimOcSO4 + methanol

298.15

0.0088–0.9080

10

80

65

C4mimPF6 + benzaldehyde

298.15–313.15

0.0523–0.8996

40

89

66

C4mimPF6 + methyl methacrylate

283.15–353.15

0.0993–0.9014

117

90

67

C4mimPF6 + EGMEE

288.15–318.15

0.0507–0.8949

70

91

68

C4mimPF6 + di-EGMEE

288.15–318.15

0.0523–0.9059

70

91

69

C4mimPF6 + tri-EGMEE

288.15–318.15

0.0558–0.9075

70

91

70

C4mimPF6 + PGMME

288.15–308.15

0.0553–0.9574

24

92

71

C4mimPF6 + PGMME

288.15–308.15

0.0526–0.9468

24

92

72

C4mimPF6 + DEGMME

288.15–308.15

0.0864–0.8992

24

92

73

C6mimBF4 + 1-propanol

293.15–333.15

0.1006–0.8894

35

93

74

C6minBF4 + 2-propanol

293.15–333.15

0.0835–0.8507

45

94

75

C6mimBF4 + isobutanol

303.15–338.15

0.0536–0.8908

72

95

76

C6mimBF4 + EGMME

288.15–318.15

0.0530–0.9099

72

96

77

C6mimBF4 + butanone

298.15

0.0492–0.8931

13

97

78

C6minBF4 + butylamine

298.15

0.0492–0.8787

13

97

79

C6mimBF4 + ethylacetate

298.15

0.0498–0.8908

13

97

80

C6mimBF4 + tetrahedrofuran

298.15

0.0498–0.8925

13

97

81

C6mimBr + EGMME

288.15–318.15

0.0541–0.9050

70

96

82

C6mimCl + water

298.15–343.15

0.0583–0.8726

32

98

83

C6mimEtSO4 + ethanol

293.15–333.15

0.0554–0.8533

32

83

84

C6mimEtSO4 + methanol

283.15–328.15

0.0520–0.9139

32

83

85

C6mimMeSO4 + ethanol

293.15–333.15

0.0503–0.7699

32

83

86

C6mimMeSO4 + methanol

283.15–328.15

0.0612–0.9285

32

83

87

C6mimPF6 + EGMME

288.15–318.15

0.0503–0.9094

72

96

88

C6mimPF6 + butylacetate

293.15–323.15

0.0956–0.9354

70

99

89

C6mimPF6 + ethylacetate

293.15–323.15

0.0905–0.9560

70

99

90

C8mimBF4 + 1,4 dioxane

298.15–318.15

0.0859–0.8893

27

100

91

C8mimBF4 + tetrahedrofuran

298.15–318.15

0.0963–0.8612

27

100

92

C8mimBr + ethylene glycol

293.15–323.15

0.1023–0.8983

63

79

93

C8mimCl + ethylene glycol

298.15–318.15

0.0077–0.9583

36

81

94

C8mimCl + water

298.15–343.15

0.0365–0.8516

36

98

95

C8mimC1OSO3 + ethylene glycol

298.15–318.15

0.0052–0.9244

36

81

96

C8mimPF6 + butylacetate

293.15–323.15

0.1078–0.8946

63

99

97

C8mimPF6 + ethylacetate

293.15–323.15

0.1056–0.8895

63

99

98

HmimBF4 + ethanol

298.15

0.0980–0.9000

9

64

99

HmimBF4 + water

298.15

0.3032–0.9002

7

64

100

HmimBF4 + N-methyldiethanolamine

303.15–323.15

0.1176–0.9030

55

101

101

HmimFAP + N-methyldiethanolamine

303.15–328.15

0.1007–0.8993

54

102

102

HmimNTf2 + 1-propanol

298.15–328.15

0.0578–0.9594

33

103

103

HmimNTf2 + 2-propanol

298.15–328.15

0.0527–0.9379

33

103

104

HmimNTf2 + acetone

288.15–298.15

0.0528–0.9483

33

103

105

HmimNTf2 + acetonitrile

298.15–328.15

0.0503–0.9247

33

103

106

HmimNTf2 + ethanol

298.15–328.15

0.0518–0.9351

36

103

107

HmimNTf2 + dichloromethane

288.15–298.15

0.0570–0.9699

33

103

108

HmimNTf2 + methanol

298.15–313.15

0.0198–0.9462

24

103

109

HmimPF6 + acetone

298.15

0.0462–0.9518

12

104

110

HmimPF6 + butanone

298.15

0.0579–0.9483

11

104

111

HmimPF6 + diethyl carbonate

298.15

0.0098–0.9498

12

104

112

HmimPF6 + dimethyl carbonate

298.15

0.0524–0.9500

11

104

113

HmimPF6 + ethanol

293.15–303.15

0.0198–0.9920

34

105

114

HmimPF6 + butylacetate

298.15

0.0365–0.9496

11

104

115

HmimPF6 + ethylacetate

298.15

0.0585–0.9477

11

104

116

HmimPF6 + methylacetate

298.15

0.0411–0.9499

11

104

117

HmimPF6 + pentanone

298.15

0.0538–0.9519

11

104

118

MmimCH3SO4 + 1-butanol

298.15

0.0583–0.9698

12

80

119

MmimCH3SO4 + ethanol

298.15

0.0511–0.9551

11

80

120

MmimCH3SO4 + methanol

298.15

0.0660–0.9198

10

80

121

MmimCH3SO4 + water

298.15

0.0206–0.9376

14

80

122

MmimMeSO4 + ethanol

293.15–303.15

0.0738–0.9512

33

105

123

MoimBF4 + ethanol

298.15

0.1012–0.9014

9

64

124

MoimCH3(OCH2CH2)2OSO3 + methanol

298.15–313.15

0.1100–0.9090

18

69

125

OcPyBF4 + water

283.15–348.15

0.2170–0.9000

112

62

126

OcPyNO3 + methanol

298.15

0.1026–0.9360

8

106

127

OcPyNO3 + ethanol

298.15

0.2000–0.8760

8

106

128

OcPyNO3 + 1-butanol

298.15

0.1245–0.8990

8

106

129

OmimBF4 + ethanol

283.15–343.15

0.2470–0.9190

78

82

130

OmimPF6 + ethanol

293.15–303.15

0.0447–0.9502

33

105

Total number of data

4626

2.2 Equation of state

In 1873 van der Waals presented the first modification of ideal gas EoS by including in attraction and repulsive intermolecular forces (Bagheri et al., 2018; Soave, 1984). After that, many modifications have been presented to improve the van der Waals EoS by change in attraction and repulsive intermolecular forces to predict phase equilibrium behavior and thermodynamic properties. For instance, Redlich and Kwong (Redlich and Kwong, 1949) modified van der Waals EoS attractive term, Soave (Soave, 1972; Soave et al., 1993) modified the temperature dependency of the Redlich and Kwong EoS and Peng and Robinson (Peng and Robinson, 1976) modified the attractive term. The mentioned cubic EoS are known as two-parameter EoS. The two-parameter EoSs predict the same critical compressibility factor for all components, but for example, critical compressibility factor for hydrocarbons component are in the of range 0.2–0.3. Also, in many cases the accuracy of two-parameter EoSs to calculate density and vapor pressure of components is unacceptable consequently, using of third parameter to modify the attractive term was supposed (Gaffney et al., 2018; Bagheri et al., 2019; Yang et al., 2018; Yokozeki and Shiflett, 2010; Bagheri et al., 2019; Kumar and Upadhyay, 2021). For example, Schmidt and Wenzel EoS (Schmidt and Wenzel, 1980) and Patel-Teja EoS (Patel and Teja, 1982) are two well-known three-parameter cubic EoSs. They used acentric factor ( ) as the third parameter.

The pressure explicit Patel-Teja (PT) EoS is as following (Bagheri and Mohebbi, 2017; Danesh, 1998; Patel and Teja, 1982):

Furthermore, the SRK EoS based on compressibility factor as follows (Danesh, 1998):

The coefficients a, b and c for mixtures are obtained from van der Waals type I mixing rule (Bagheri et al., 2018; Ghalandari et al., 2020):

2.3 Semi-empirical equation

There is a great change of analytical expressions, which permit predicting and correlating the density of liquids. Such correlations are usually according to apply of adjustable parameters for each component (Geppert-Rybczyńska et al., 2010; Singh et al., 2014). But, the mentioned types of generalized correlations were not developed for IL-mixture systems. Several semi-empirical equations were presented to predict pure IL density. In this communication, through several presented semi-empirical equations, six semi-empirical equations were selected and the details are given as following (Elbro et al., 1991; Mchaweh et al., 2004; Gunn and Yamada, 1971; Hankinson and Thomson, 1979; Poling et al., 2001; Sandler, 2017; Kontogeorgis and Folas, 2009 Dec 1):

Also, the Nasrifar-Moshfeghian (NM) equation was used to predict the density of binary IL + solvent. The equation is expressed by (Nasrifar and Moshfeghian, 1998; Rabari et al., 2014; Mathias and Copeman, 1983):

As mentioned, the presented semi-empirical equations, for first time, were used for pure liquids (except Eq. (24)). Subsequently, to develop them to IL-mixture systems the mixing rules must be applied. There are five thermodynamic properties in equations (20) - (27) i.e. acentric factor, critical temperature, critical pressure, critical volume and molecular weight. In this study, various mixing rules were considered. The details of all mixing rules and the final mixing rules that were applied, are provided in Table 3.

Property

Tested mixing rule

Final mixing rule

,

,

,

,

,

,

2.3.1 Pre-processing of the train and test

The AI learning approaches used to estimate the target parameters applying input parameters are widely nonlinear and depend mainly on the learning database (Memarzadeh et al., 2020; Ali et al., 2018; Nguyen-Huy et al., 2018). In cases where we are dealing with large-scale data processing, dimensionality reduction and subset selection methods can be necessary and useful tools in model development (Xu et al., 2019; Riahi-Madvar and Seifi, 2018). Important points that are essential in designing the precise prediction model for the AI model include the selection of appropriate input and data clustering techniques due to the diversity of the data set (Riahi-Madvar and Seifi, 2018; Loey et al., 2021; Mueller and Massaron, 2021). In order to achieve reliable data subsets for training and testing, the subset selection of maximum dissimilarity method (SSMD) was used to select training and testing subsets through a random manipulation of these data sets. Selecting the most appropriate train sets in the proposed preprocessing strategy is the most important task in SSMD-based approaches for data selection, which extremely depends on the expansion of the data (Riahi-Madvar and Seifi, 2018). In the SSMD method, data selection is not focused only on a specific area. Although these data are very different from each other, they can still show the statistical features of the original dataset (Lajiness and Watson, 2008). The data must first be normalized. Thus, the process of normalization and then de-normalization of the initial data set is performed by Eq. (28), respectively.

The Kennard-Stone (KS) algorithm is used to describe the SSMD in which a subset of N points in j dimensional space is selected (Kennard and Stone, 1969). The candidates of subset for training can be defined by the following matrix Y:

where Y represents a data set as Y = (y1; y2; · · · ; yj) that contains j factor and a set of N points in j dimensional space defined by j factors (Kennard and Stone, 1969). The selection of design points is done sequentially (Riahi-Madvar et al., 2019). The goal in each step is to select points that are evenly spaced along the object area at each step of the algorithm. The first point is selected close to the average of the dataset and the second point is chosen so that it has the greatest distance from the first point. Eventually, the third point is selected so that it has the longest distance from the aforementioned two points. The training subcomponent involves these aspects of data points, in addition, the test subset includes the remaining data points (Wu et al., 1996). The subsets are selected by maximizing the minimum distance between the train dataset and the rest of the data points in the original dataset. The statistical features of the subsets obtained from the SSMD method are depicted in Table 4. As it can be seen from Table 4; all parameters have approximately the same distributions over train and test datasets, which is in accordance with the equal scale of standard deviation, kurtosis, skewness. Moreover, a wide range of

is observed from the longitudinal dispersion data in both training and testing stages. Note: The subscript 1 is related to IL and the subscript 2 is related to solvent.

Parameter

Mean

Mode

SD

Min

Median

Maximum

Skewness

Kurtosis

Total data set

ρ

X1

T

Mw1

Tc1

ω1

Vc1

Mw2

Tc2

ω2

Vc2

1.110

0.459

305.470

236.916

862.300

0.712

689.000

59.080

589.171

0.4997

195.2601.0836

0.200

298.150

236.30

968.100

0.8140

676.80

18.020

647.100

0.345

55.9000.121

0.298

15.583

51.811

162.090

0.209

146.162

56.734

83.601

0.178

186.5300.772

0.0009

278.150

107.110

571.300

0.308

298.240

18.020

506.550

0.198

55.9001.120

0.406

303.150

236.300

898.800

0.814

676.800

46.070

562.050

0.564

16701.398

0.997

353.15

648.867

1376.1

1.408

1983.5

350

837.15

1.106

1175−0.481

0.220

0.687

0.636

0.054

−0.226

0.988

3.552

0.942

0.477

3.7903.000

1.739

3.241

10.208

1.759

2.264

13.758

18.205

3.302

2.667

20.000

Testing data set

ρ

X1

T

Mw1

Tc1

ω1

Vc1

Mw2

Tc2

ω2

Vc2

1.1025

0.453

306.686

238.119

851.230

0.7174

696.919

64.049

590.359

0.526

213.4771.083

0.200

298.150

236.300

968.100

0.814

676.800

18.020

647.100

0.345

55.9000.114

0.280

15.593

54.294

164.862

0.214

154.383

64.633

85.869

0.183

214.0800.772

0.0009

278.150

107.110

571.300

0.308

298.240

18.020

506.550

0.198

55.9001.108

0.409

303.150

240.000

802.145

0.814

701.300

46.070

562.050

0.564

167.0001.398

0.997

353.15

648.867

1376.100

1.408

1983.500

350.000

837.150

1.106

1175.000−0.350

0.213

0.687

0.364

0.280

−0.142

0.670

3.220

1.024

0.374

3.3563.131

1.852

3.224

7.896

1.777

2.258

10.302

14.377

3.490

2.649

15.254

Training data set

ρ

X1

T

Mw1

Tc1

ω1

Vc1

Mw2

Tc2

ω2

Vc2

1.129

0.474

302.654

234.107

888.174

0.699

670.528

47.478

586.395

0.436

152.7411.029

0.242

298.150

236.300

968.100

0.814

676.800

18.020

647.100

0.345

55.9000.134

0.335

15.195

45.385

152.386

0.198

122.960

28.090

78.008

0.149

80.3460.780

0.0009

278.150

107.111

571.30

0.325

298.24

18.02

506.55

0.198

55.9001.167

0.400

298.150

236.300

968.100

0.814

676.800

41.050

560.000

0.345

167.0001.395

0.990

353.150

648.867

13761.000

1.357

1983.500

134.178

802.050

0.870

422.000−0.796

0.187

0.714

1.623

−0.527

−0.501

2.187

0.760

0.655

0.527

0.4042.989

1.481

3.288

20.296

2.167

2.153

32.166

2.565

2.424

2.106

2.442

2.3.2 LXWOA theories and formulation

To determine the coefficient of the semi-empirical equation using experimental data of IL-mixture, optimization algorithms must be used. Some of the algorithms that used to obtain the coefficients of semi-empirical equations are genetic algorithm, artificial bee colony algorithm, imperialist competitive algorithm, particle swarm optimization, and simulated annealing (Singh, 2019). The whale optimization algorithm is a nature-inspired metaheuristic optimization algorithm, which is inspired by the search behavior of humpback whales. The main difference between LXWOA and WOA is the improved convergence of the algorithm. The LXWOA algorithm is a combination of the WOA and Laplace crossover algorithms, which was introduced by Singh for the first time (Singh, 2019). The whale optimization algorithm is a novel nature-inspired meta-heuristic optimization method, which was presented by Mirjalili and Lewia (Mirjalili and Lewis, 2016). The WOA method is inspired by the social behavior and the bubble-net hunting strategy of humpback whales in which the bubble-net hunting behavior is used to prey hunting. One of the advantages of the WOA method is that it does not need a large amount of initial information. This feature makes the method have a small number of adjustment parameters that can be easily tuned for a great variety of applications. The LXWOA algorithm consists of the following steps: In the first step, an initial population of size Np is generated randomly from the data set. In the second step, the WOA method is first followed by the LXWOA in each iteration, then two agents are chosen (Singh, 2019). The best agent is determined by the first agent and the second agent is randomly chosen from the present population. In the third step, laplace crossover operators are used to create two offspring by combining the best and randomly selected agents. The fitness of each offspring over the worst agent in the present population is evaluated one by one. If offspring has better fitness over the worst agent, it is then replaced by the worst particle. The best search agent is then updated and iteration is increased. Finally, this process is followed by the algorithm till termination criteria is satisfied (Liakos et al., 2018).

2.3.2.1 Whale optimization algorithm

Searching for a prey, encircling prey, and spiral bubble-net feeding maneuver are two main phases that are used by humpback whales to prey hunting. In the searching for a prey (the first phase), a random search is done to explore the prey depending on the position of each other (exploration phase). In the encircling prey and spiral bubble-net attacking (the second phase), the location of prey is perceived by the humpback whales after encircling them and the spiral updating position are implemented (exploitation phase). Since the optimal solution is not known in the a priori search space, the best current candidate solution is considered by the WOA algorithm as the target prey or close to the optimum target point. The WOA algorithm has received a lot of attention in recent years due to its advantages such as simple principle, simple operation, easy implementation, few adjustment parameters, and strong robustness, and many valuable research results have been obtained in this field. Moreover, the research results show that the WOA algorithm significantly outperformed other optimization algorithms, such as differential evolution and gravitational search in terms of solution accuracy and algorithm stability. Therefore, according to the above explanations, this algorithm was used in the present study. After the position of the best search agent is defined by the algorithm, the position of the other search agents will be updated towards the best search agent. The mathematical model of WOA is provided as follows: let NP be the population size and Mitr be MaxIter (Mirjalili and Lewis, 2016; Liakos et al., 2018; Kotsiantis et al., 2006; Dutton and Conroy, 1997; Maxwell et al., 2018). The method consists of two adjustable parameters a and b, which the value of the parameter a linearly decreases in the range 2 to 0 through iterations and the value of the parameter b reduces from −1 to −2. Next, the coefficients Ai, Ci and a random number li are calculated for agent i by the following equations (Singh, 2019):

where r1, r2 and r3 represent three random numbers that are uniformly distributed on the interval from 0 to 1. Next, a random number pr is generated in (0; 1). If 0.5 ≥ pr and |Ai| ≥ 1, the dth particle of the next position (

) is updated by the ith agent through the

agent as follows (Singh, 2019):

where

indicates a random position of ith agent in dth dimension at time t. Now, If pr < 0.5 and |Ai| < 1, the dth particle of next position (

) is updated by the ith agent through the

agent as follows (Singh, 2019):

Next, if pr ≥ 0.5 the following spiral model is generated by evaluating the distance between the whale postion (xi) and prey postion (xbest (t)) in dth dimension

at iteration t to imitate the helix-shaped movement of humpback whales (Singh, 2019):

The Laplace crossover (LX) is proposed by Deep and Thakur for the first time in which two off-springs i.e.

and

are generated from a pair of parents i.e.

and

in such a way that both of the off-spring have a symmetric position over the parents position. Next, two uniformly distributed random numbers ui 2 [0; 1] and vi 2 [0; 1] are firstly generated (Mirjalili and Lewis, 2016; Kotsiantis et al., 2006). Then, a random number li is generated by simply inverting the distribution function of Laplace distribution as follows:

where p ∊ R and q > 0 are called the location parameter and the scale parameter, respectively.

The off-springs are generated as follows:

If for some of i the created off-spring are outside the search space i.e.

or

, a random number is then selected from

for yi as the generated off-spring. For smaller values of q, LX produces the off-spring close to the parents and for greater values of q; LX produces the off-springs away from the parents. For fixed values of p and q, LX dispenses off-springs according to the parents dispersion (Mirjalili and Lewis, 2016; Liakos et al., 2018). An equation for ρ is firstly defined based on previous literature to run the algorithm. The parameters obtained from the equation are then used as variables for the LXWOA algorithm. Moreover, a suitable objective function will be defined for the implementation of the algorithm in the following section. In this regards, at the end of each iteration, the best value of

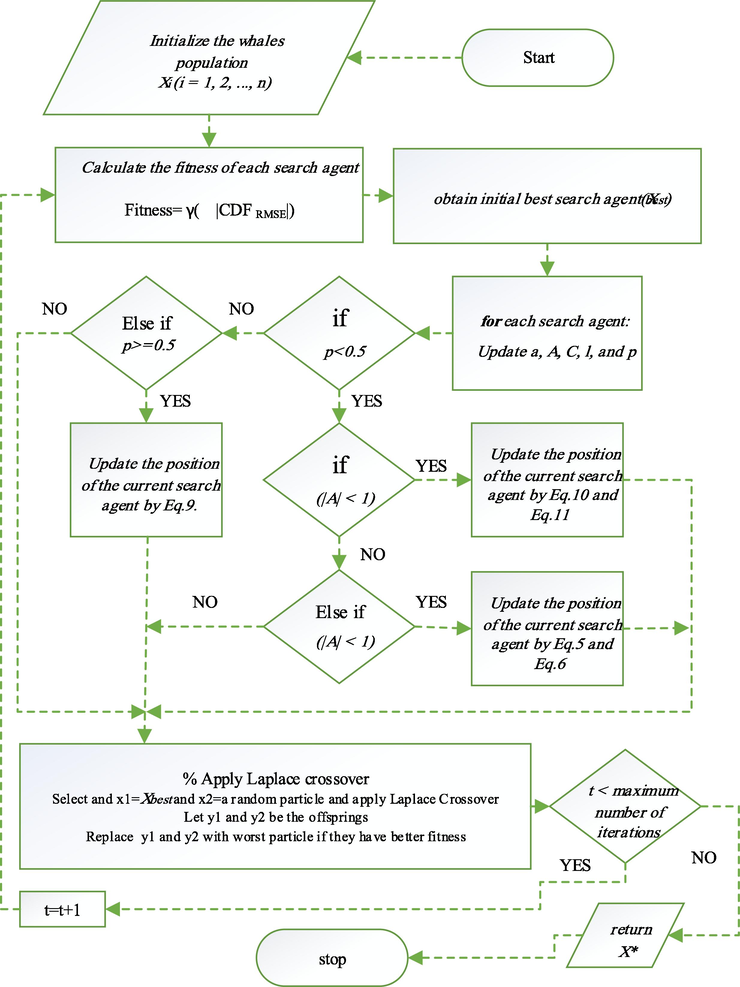

must be found by the algorithm through changing the values of the variables. Eventually, the optimal solution rapidly converges towards a local optimum after a couple hundred times of running the algorithm. Eventually, after running the program a couple of hundred times, the convergence towards the optimal solution is achieved by the algorithm. This means that the hunting location has been identified and surrounded by the humpback whale. The flowchart of the implied algorithm is noticed in Fig. 1.

The algorithm of LXWOA method.

The main contribution of the proposed LXWOA algorithm is addressed in this subsection. After performing repeated runs of the optimization algorithm, it was found that it is not feasible to provide an equation that covers all the data. This creates some difficulty; first of all, the algorithm will not converge properly. The second problem is that the error value R2 will increase because the algorithm has insisted on synchronizing and fitting itself overall data despite the high errors. Thus, a solution must be provided to prevent this problem at the various stages of the learning process. This means that one should try to converge the proposed model to less error data as much as possible. In this regard, the cumulative distribution function (CDF) function of the errors is defined as an objective function for the LXWOA optimization algorithm. Therefore, the objective function is considered as a coefficient (γ = 0.8) of CDF for the error defined as follows:

Indeed, some of the data generated by the LXWOA model may differ significantly from the actual data. Therefore, there is a lot of error in this data. This portion of the data may contain up to 10 to 20 percent of total data per run of the optimizer program. Therefore, if we want to present the cost function in the optimization algorithm in such a way that it puts pressure on all data to reduce the total error, it causes the model to move away from convergence in data with less error at the cost of achieving a lower error. In this regard, we try to reduce the model pressure on high errors each time the optimization process is performed. For this purpose, the CDF of the errors is first obtained. Part of the errors (with a coefficient (0.8)) is then considered as a criterion for the cost function.

3 Results and discussion

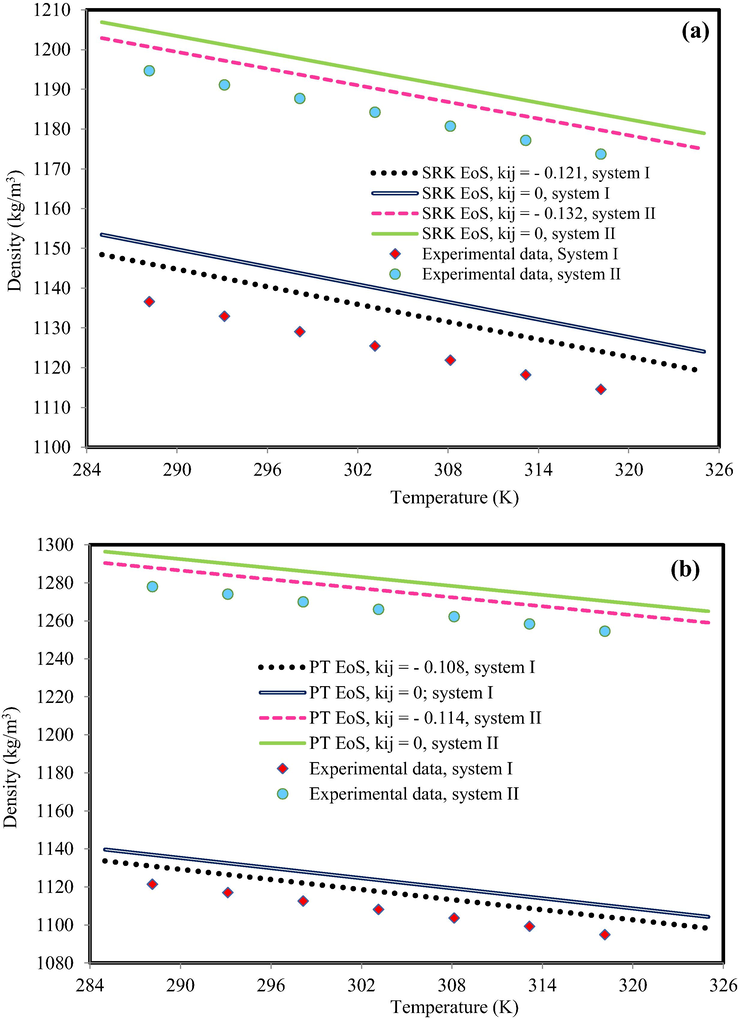

No CEoS can prepare exact descriptions of behavior of real-fluid in all interest regions. Both SRK EoS and PT EoS consider only the attractive and repulsive intermolecular force between molecules. However, they have fundamental challenge to pure and mixture liquid density and the modification has been made to improve CEoS capability using modifying the repulsive and attractive terms (Sheikhi-Kouhsar et al., 2015). In this study, in the first step, the accuracy of SRK EoS and PT EoS was investigated. For example, Fig. 2 indicates the density behavior of C6mimBr + EGMME at xIL = 0.3990 and xIL = 0.7003 and C6mimPF6 + EGMME at xIL = 0.2006 and xIL = 0.8019 and at atmospheric pressure based on SRK EoS and PT EoS. Both CEoSs could not predict the mixture density with satisfactory accuracy. To decrease the deviation, the binary interaction parameter (kij) was used for both of them; however, the effect of interaction parameter on improving the modeling results was insignificant.

The density behavior of (a) C6mimBr + EGMME (system I: xIL = 0.3990; system II: xIL = 0.7003) and (b) C6mimPF6 + EGMME (system I: xIL = 0.2006; system II: xIL = 0.8019). The experimental data are from Pal and Kumar (Pal and Kumar, 2012).

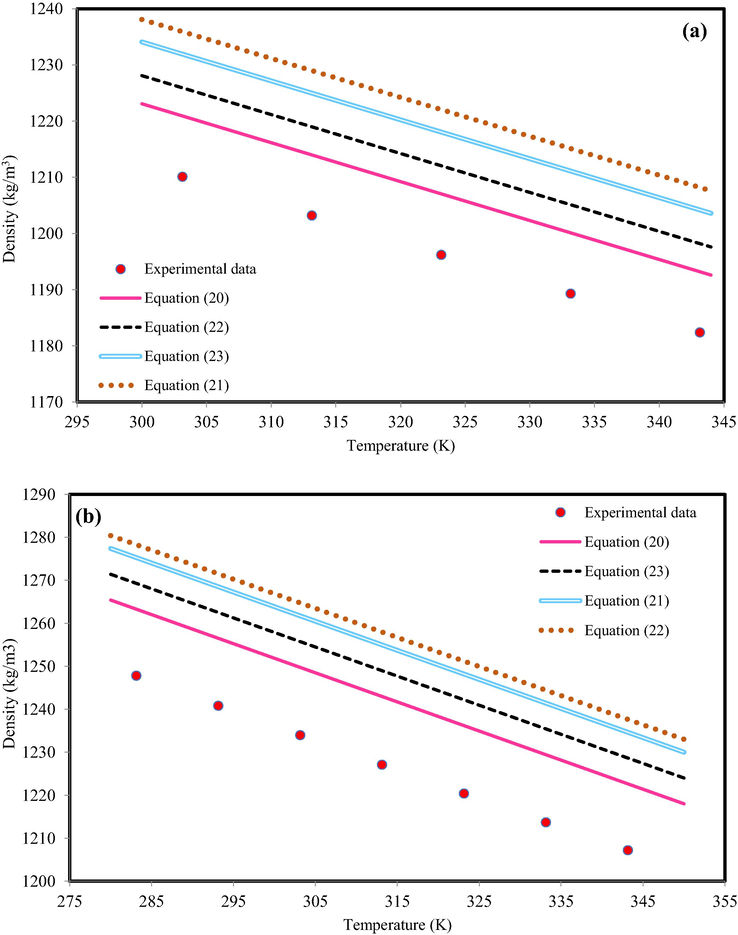

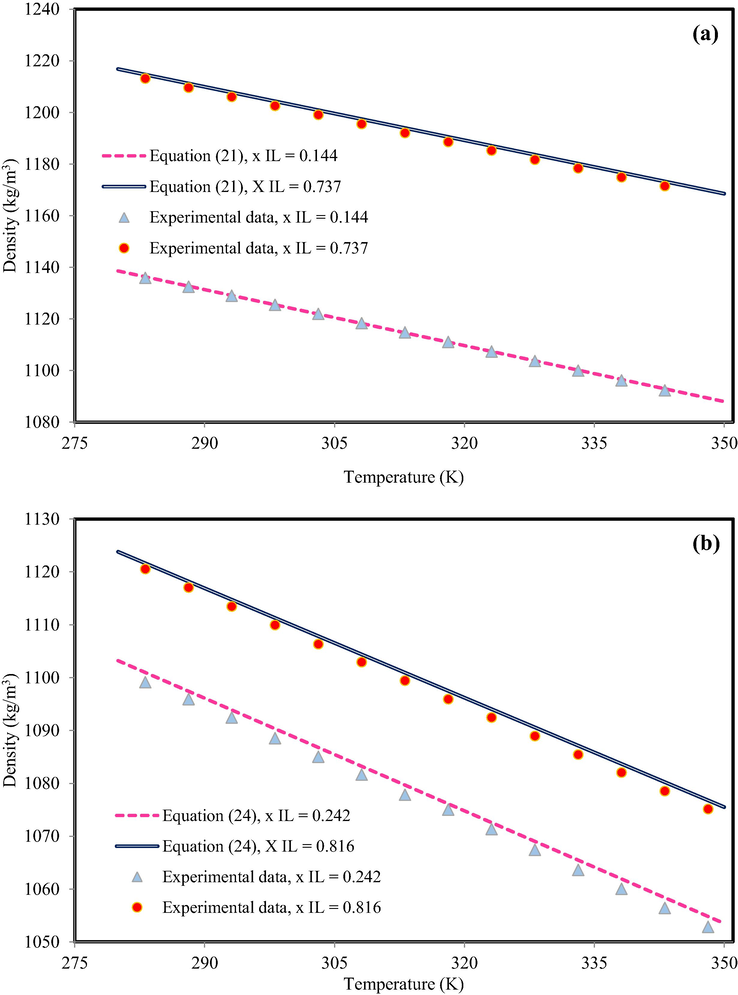

As another suggestion to model the IL-mixture density, application of semi-empirical equations was studied. The various semi-empirical equations were developed in this communication (see Appendix A). The semi-empirical equation parameters are determined by matching prediction density (based on semi-empirical equation) with experimental data. To model the density of IL-mixture systems based on semi-empirical equations, two methods was considered. In the first method, the coefficients of Eqs. (20) - (24) that were presented by authors (Valderrama and Zarricuetac, 2009; Hosseini et al., 2013) with all mixing rules that are provided in Table 3, was applied. The obtained results indicated presented coefficients was not appropriate idea to predict IL-mixture systems. For instance, Fig. 3 indicates the results of C4mimHSO4 + water at xIL = 0.2066 and C2mimC2SO4 + water xIL = 0.8775 using Eqs. (20) - (24) with available coefficients in the literature (Valderrama and Zarricuetac, 2009; Hosseini et al., 2013). The behavior of all equations is out of experimental data. Indeed, this behavior was predictable. Due to the presented coefficients by authors (Valderrama and Zarricuetac, 2009; Hosseini et al., 2013) were obtained based on pure experimental data.

The density behavior of (a) C4mimHSO4 + water, xIL = 0.2066 and (b) C2mimC2SO4 + water, xIL = 0.8775. The experimental data are from Bhattacharjee et al. (Bhattacharjee et al., 2012).

In the second method, the coefficients of Eqs. (20) - (25) was optimized using improved laplacian whale optimization algorithm. ILs composed of various cation structures and due to the behavior of each cation-family is similar, subsequently; to present a comprehensive IL-mixture density model, the semi-empirical equation coefficients of each cation-family were obtained, separately. In order, to obtain the coefficients, 70% of experimental data of each cation-family were used (according to SSMD method) and the rest of them were applied to investigate the accuracy of presented modification. Table 5 indicates the obtained results of coefficients of each cation-family.

BuPy

C2mim

C3mim

C4mim

C6mim

C8mim

Hmim

Mmim

Moim

OcPy

Omim

Eq. (20)

1.4276

1.4333

3.4141

2.5435

1.5269

2.2006

1.2667

1.4437

2.6180

1.6672

1.4351

−24.4288

−12.1559

−16.3907

−20.5247

−18.5703

−25.5447

–22.8585

−19.3457

−17.1898

−27.4722

−25.7281

90.4586

89.7786

96.8990

100.7207

110.7657

91.6898

79.7247

111.2392

101.9145

85.9381

98.3142

−200.1014

−198.2336

−210.2945

−187.1111

−167.4654

−179.7048

−202.6287

−206. 6067

−199.7036

−188.7557

−208.7630

289.1036

375.1405

318.5853

302.9995

297.3273

360.1928

350.1520

325.2051

378.4956

398.9698

341.7952

−265.4304

–222.9168

−238.7594

−274.5659

−205.1692

−297.9199

−301.6974

−269. 9160

−241.8707

−250.9096

−225.3736

79.9026

91.1474

99.8885

86.3146

55.1304

69.2458

92.8226

64.1757

95.4982

79.2156

80.3134

12.2575

10.1718

30.4343

23.3592

20.1003

17.1419

11.2923

9.6965

16.8973

21.0296

15.2065

−125.2630

−140.5759

−145.0790

−150.5398

−134.8022

−120.1509

−138.4204

−145.5454

−124.7027

−117.9474

−115.4756

400.2939

505.1158

477.5352

563.3992

489.2882

471.6863

523.9821

512.4536

469.5230

485.1155

530.7250

−925.9014

−999.6598

−851.6390

−874.8194

−905.6473

−963.5568

−812.2813

−887.7445

−945.4015

−824.9164

−911.4074

1241.7436

1300.4585

1225.7009

1150.4076

1281.2225

1200.4156

1269.2198

1250.3201

1195.2240

1312.8904

1275.3236

−707.6116

−714.8203

−680.4270

−750.7814

−697.3104

−760.1877

−720.8627

−777.6309

−685.1064

−711.8785

−730.7766

177.1086

197.4633

164.1537

185.7426

155.2871

161.8064

149.8930

185.8250

123.4602

201.9203

134.9338

Eq. (21)

1.1278

0.7955

0.8490

1.0164

0.9630

0.9295

1.0516

0.9245

0.9888

1.0989

1.1354

0.9789

0.8439

0.7985

0.8510

1.1044

1.2000

0.7999

1.2331

0.1219

1.1945

1.1182

1.3484

1.6776

1.3846

1.8330

1.8698

1.7689

1.2860

1.3067

1.9288

1.2168

1.7321

−2.3143

−2.6155

−2.4477

−2.5247

−1.9864

−1.9550

−2.7765

−1.8697

−2.5991

−2.1273

−2.2932

1.6046

2.1912

1.7298

1.9164

2.3200

2.3160

1.6645

2.3982

2.5198

2.5117

1.8912

Eq. (22)

0.1704

0.5795

0.9418

0.1931

0.3159

0.5941

0.7740

0.8810

0.7598

0.6996

0.2748

−0.1017

−0.0466

−0.3398

−0.0315

−0.2359

−0.0914

−0.1694

−0.1151

−0.1340

−0.0485

−0.0911

0.1616

0.2553

0.1452

0.1492

0.3222

0.4515

0.2805

0.3075

0.3060

0.3693

0.4205

−0.1258

−0.1900

−0.8515

−0.0369

−0.0239

−0.0760

−0.0427

−0.0710

−0.0232

−0.0564

−0.2085

−0.0431

−0.1971

−0.0895

−0.0472

−0.1643

−0.0712

−0.0977

−0.0832

−0.0353

−0.0595

−0.0504

0.7512

0.9699

1.1848

0.6585

0.8582

1.5507

1.2532

0.9266

0.8858

0.9616

0.9090

1.5863

0.9602

0.8349

1.2209

1.3500

1.3130

1.3322

1.5338

1.6114

1.4690

1.6237

−0.9008

−0.6452

−0.2955

−0.4415

−0.3555

−0.5366

−0.7005

−0.8023

−0.5367

−0.9498

−0.5369

−1.2906

−1.1832

−0.9130

−1.6756

−1.5181

−0.6977

−2.4936

−1.9311

−2.4297

−1.2415

−1.1341

1.1196

1.5928

1.0380

1.4301

1.3295

1.6635

0.8577

1.7030

1.6049

1.6873

1.6685

Eq. (23)

0.9237

0.9546

0.8591

1.0457

1.0078

1.1426

1.0658

1.1769

1.1013

1.0215

0.9991

−1.5944

−1.8065

−1.0305

−1.7807

−1.5123

−1.2685

−1.6932

−1.8750

−1.9345

−1.1633

−1.2911

1.4910

1.1961

1.4801

1.6313

1.7802

1.9290

1.6889

1.5471

1.9232

1.5406

1.5774

−0.5045

−0.9082

−0.5401

−0.8468

−1.2402

−0.7031

−1.2997

−1.3899

−0.6139

−1.4053

−0.9271

0.1691

0.2583

0.8386

0.1172

0.2183

0.1331

0.1459

0.1639

0.2663

0.4048

0.5017

−0.1475

−0.4908

−0.2453

−0.2381

−0.1930

−0.2464

−0.1167

−0.2775

−0.3877

0.2138

0.2800

0.3936

0.6255

0.7937

0.8723

0.9885

0.3403

0.9230

0.5377

0.5324

0.1234

0.3024

−0.0788

−0.0958

−0.4074

−0.0130

−0.0344

−0.0412

−0.0212

−0.0715

−0.0950

−0.0812

−0.1439

−0.0247

−0.0444

−0.5809

−0.0571

−0.0986

−0.0653

−0.0826

−0.0673

−0.0325

−0.0559

−0.0197

0.8583

0.8467

0.9535

0.9651

1.0002

0.9752

0.9736

1.0066

0.9032

1.1348

0.8155

Eq. (24)

0.2460

0.4161

0.4562

0.2525

0.3958

0.3565

0.1419

0.2463

0.3942

0.3905

0.3069

0.1202

0.1873

0.1806

0.1746

0.2739

0.2780

0.1672

0.1348

0.1415

0.3984

0.3195

0.3704

0.3878

0.8206

0.9808

0.4860

0.7096

0.6277

0.7660

0.5270

0.5532

0.2534

0.7872

0.1991

0.4587

0.6378

0.3589

0.3845

0.3397

0.4229

0.8887

0.6658

0.3048

Eq. (25)

0.4359

0.4119

0.4195

0.1330

0.8724

0.0561

0.6827

0.3716

0.6354

0.8796

0.4114

0.7885

0.1887

0.9206

0.6706

0.9045

0.9032

0.1506

0.4059

0.7984

0.6710

0.5605

−0.5214

−0.1829

−0.1358

−0.2606

−0.5895

−0.6440

−0.5259

−0.3548

−0.3120

−0.6672

−0.6436

1.5579

1.7272

1.5768

1.5816

0.8496

2.1506

2.1369

1.5607

20.1661

1.3143

0.8827

The statistical validation of optimized coefficients was investigated by introducing four statistical parameters of correlation factor (R2), average absolute percent deviation (AAPD), standard deviation (STD) and root mean squared error (RMSE). These parameters are formulated as following and the values of them are provided in Table 6.

BuPy

C2mim

C3mim

C4mim

C6mim

C8mim

Hmim

Mmim

Moim

OcPy

Omim

Eq. (20)

R2

0.9843

0.9826

0.9810

0.9672

0.9965

0.9610

0.9850

0.9660

0.9882

0.9817

0.9779

RMSE

0.0151

0.0268

0.0658

0.0235

0.0425

0.0630

0.0409

0.0604

0.0563

0.0634

0.0261

Mse × 103

0.1459

0.4930

0.1256

0.5311

0.3114

0.6735

0.2278

0.1295

0.5176

0.4596

0.3616

AAPD

0.6203

0.1036

0.5026

0.2572

0.3013

0.3208

0.1818

0.0895

0.2943

0.2166

0.2724

STD

1.2825

0.8968

0.7412

0.9432

0.6912

1.2285

0.8310

0.6492

0.5619

0.9588

1.0348

Eq. (21)

R2

0.9694

0.9877

0.9866

0.9665

0.9765

0.9671

0.9622

0.9891

0.9820

0.9889

0.9796

RMSE

0.0490

0.0417

0.0980

0.0186

0.0332

0.0246

0.0678

0.0568

0.0542

0.0178

0.0203

Mse × 103

0.5543

0.2363

0.6750

0.6876

0.3615

0.1061

0.6381

0.1885

0.2560

0.3759

0.2241

AAPD

0.2200

0.3742

0.7296

0.8094

0.2403

0.1911

0.2633

0.2744

0.5545

0.1070

0.4451

STD

0.6077

1.0013

1.3647

0.7242

0.8031

0.7237

1.2732

0.9935

0.9702

0.6824

1.2029

Eq. (22)

R2

0.9648

0.9874

0.9902

0.9611

0.9814

0.9829

0.9879

0.9798

0.9894

0.9969

0.9874

RMSE

0.0602

0.0236

0.0820

0.0465

0.0329

0.0677

0.0191

0.0102

0.0605

0.0515

0.0772

Mse × 103

0.5845

0.1933

0.4885

0.6527

0.2146

0.5924

0.6365

0.1818

0.2674

0.6023

0.2503

AAPD

0.6905

0.1205

0.3155

0.7333

0.2660

0.3034

0.8785

0.2799

0.3015

0.2622

0.1240

STD

0.8942

0.5669

0.4012

0.6171

1.2187

0.6396

1.2972

1.2513

0.5196

0.7305

0.8006

Eq. (23)

R2

0.9780

0.9671

0.9856

0.9683

0.9975

0.9744

0.9727

0.9822

0.9631

0.9927

0.9839

RMSE

0.0243

0.0233

0.0642

0.0660

0.0592

0.0306

0.0114

0.0298

0.0456

0.0598

0.0600

Mse × 103

0.2669

0.1757

0.7953

0.6583

0.5247

0.2842

0.6188

0.4152

0.5709

0.3258

0.1862

AAPD

0.0726

0.6398

0.2103

0.2083

0.2473

0.8620

0.1735

0.0448

0.5440

0.7945

0.9860

STD

0.6415

0.8807

0.6718

1.0162

0.7894

0.9218

0.6626

0.8150

0.7477

0.8000

0.8267

Eq. (24)

R2

0.9834

0.9629

0.9600

0.9725

0.9838

0.9812

0.9793

0.9633

0.9940

0.9865

0.9909

RMSE

0.0168

0.0574

0.0419

0.0217

0.0496

0.0196

0.0622

0.0135

0.0286

0.0589

0.0641

Mse × 103

0.3712

0.2964

0.8294

0.3186

0.2629

0.1378

0.2661

0.3379

0.4493

0.5525

0.6964

AAPD

0.1296

0.1990

0.7658

0.3636

0.4531

0.8402

0.2328

0.2751

0.1893

0.5120

0.0473

STD

0.6227

0.9080

1.0767

1.0769

0.7726

0.8680

0.6457

1.1202

0.5200

0.7332

0.8881

Eq. (25)

R2

0.9874

0.9953

0.9705

0.9864

0.9806

0.9634

0.9818

0.9694

0.9868

0.9850

0.9878

RMSE

0.0529

0.0387

0.0952

0.0571

0.0569

0.0529

0.0282

0.0508

0.0474

0.0142

0.0350

Mse × 103

0.6510

0.2341

0.8651

0.6813

0.3055

0.3780

0.1360

0.4671

0.2850

0.5357

0.2802

AAPD

0.0558

0.6734

0.5588

0.4156

0.9137

0.6346

0.0422

0.2637

0.2711

0.0939

0.6510

STD

1.0151

0.6302

1.0973

0.5869

0.6230

1.1140

0.6719

0.9082

0.8108

1.0359

0.6241

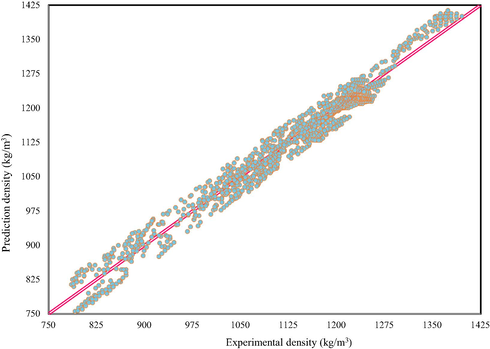

For example, Fig. 4 indicates the total results of the correlation factor based on Eq. (20) and C4mim-family with applying test data subcategories. The solid 45° line shows the details of fitting between the experimental data and the related ones, whereas circles point show the comparison between the obtained results based on Eq. (20) and the experimental density data. The R2 value is 0.9856. Indeed, closeness of the circle points to the solid line in Fig. 4 demonstrates the presented modification technique has acceptable ability to predict IL-mixture density.

Predicted versus experimental IL density mixtures for test datasets. The reported results are related to Eq. (23) and C4mim-family.

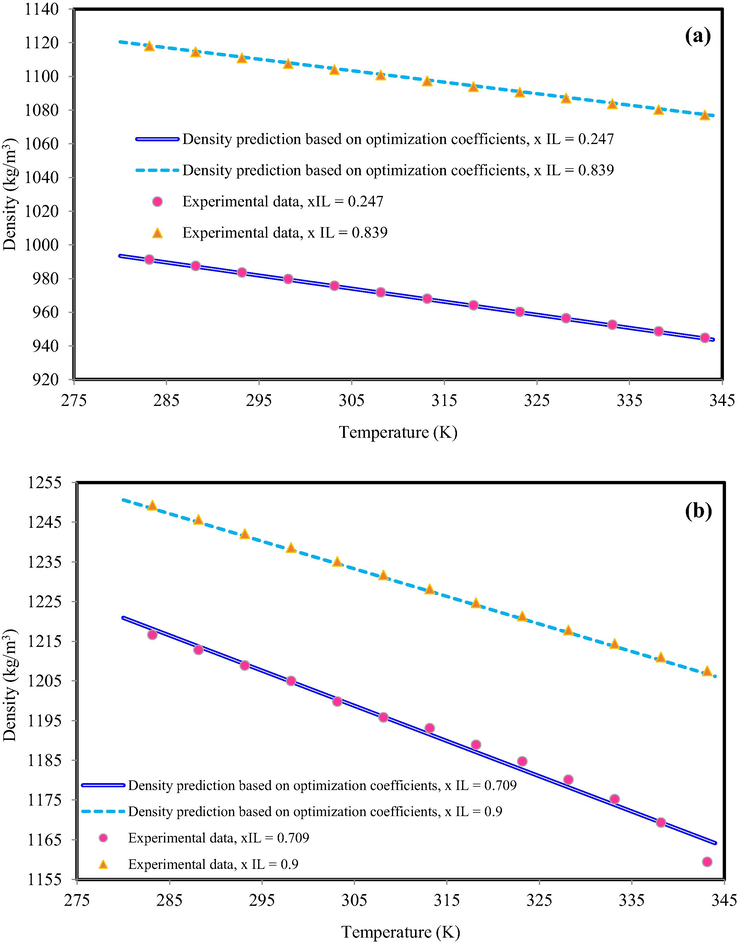

The six semi-empirical equations gave different results and any cation-family presented various results to predict the density of IL-mixture system at all temperatures. For example, Fig. 5 indicates the density behavior of OmimBF4 + ethanol (xIL = 0.247 and xIL = 0.839) and C4mimClO4 + ethanol (xIL = 0.709 and xIL = 0.900) based on semi-empirical equations (using test data). According to Fig. 5, the semi-empirical equations could predict the mixture density with acceptable accuracy. All semi-empirical equations have similar behavior and they could predict the mixture density with acceptable accuracy.

The density behavior of (a) OmimBF4 + ethanol, xIL = 0.247 and xIL = 0.839 (b) C4mimClO4 + ethanol, xIL = 0.709 and xIL = 0.900. The obtained results based on Eq. (20) with optimized coefficients. The experimental data are from Mokhtarani et al. (Mokhtarani et al., 2008).

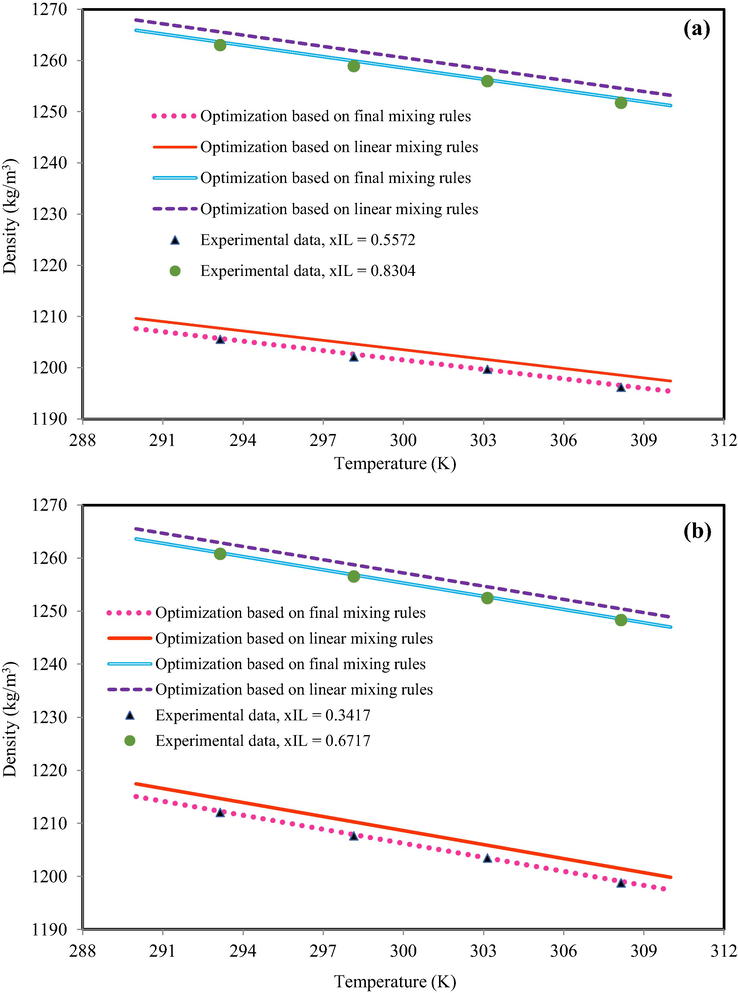

All semi-empirical equations, except Eq. (24), only were used to predict pure IL density up to now. For first time, we have examined the capability of these equations to predict the density of IL-mixture system at various mole fractions and temperatures. Subsequently, mixing rules had significant role in this development and they show the effect of component mole fraction. According to Table 3 various mixing rules, at least three mixing rules for each property, was investigated. The mixing rule of all thermodynamic properties except acentric factor and critical temperature, was linear. The experimental data density mixture are function of mole fraction and temperature and all semi-empirical equations are function of reduced temperature (Tr), therefore, critical temperature mixing rule have remarkable influence on accuracy of obtained results based on semi-empirical equations. Several critical temperature mixing rules have been investigated but non-linear ones indicated better results. This mixing rule is function of second power of mole fraction and also second order of radical of both IL and solvent critical temperature ( ).