Translate this page into:

Addition of Whole Barley Flour as a Partial Substitute of Wheat Flour to Enhance the Nutritional Value of Biscuits

⁎Corresponding author at: Department of Chemistry – Faculty of Applied Science, Umm Al-Qura University, Makkah, Saudi Arabia. ahmed.abdelfatah@fsed.bu.edu.eg (Ahmed M. Hameed) amhameed@uqu.edu.sa (Ahmed M. Hameed)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

Barley has widely known as an excellent source of dietary fiber. In this investigation, biscuits were prepared by substituting wheat flour (WF) with whole barley flour (WBF) at levels 20 and 40% as an attempt to improve the nutritional and functional quality of biscuits. Chemical, antioxidant, rheological, sensory and microbial properties were assessed. The blending with WBF, even at low ratio of inclusion (20%), caused an increase in protein, ash and crude fiber contents. The antioxidant activity was 41.5% in barley flour whereas it was only 2.03% in wheat flour, it was lowered to 1.35% in control biscuits and reached to the maximum 12.6% in biscuits prepared with 40% WBF. Water absorption, dough development and arrival time increased progressively with the elevation in WBF ratio. The lower level of WBF (20%) increased the stability of the dough. Extension, expansibility rheology and the dough energy were shortened with the increasing of WBF ratio. WBF-wheat biscuits up to the replacement ratio 40% possessed a high acceptance rating but the higher level (40%) resulted in lowering the surface color and appearance scores. The higher level (40%) incorporated into biscuits decreased the microbial load (Total bacterial, Spore-forming bacteria & Mold and yeast counts) during storage period.

Keywords

Wheat flour

Barley flour

Antioxidant

Rheological properties

Biscuit processing

Microbial load

1 Introduction

Barley is mainly exploited to produce animal feed and make malt to prepare beer but recently inclusion of barley in many bakery products and extruded food including extruded snacks, breads, biscuits and chapattis etc. became popular (Gill et al., 2002, Gujral et al., 2002, Sharma et al., 2013). Barley crop is mainly classified as hulled and hull-less barley. Hull-less or de-hulled barley requires little or no effort to remove the hull during processing or threshing and it is more suitable for cooking and soaking purposes (Shaban et al., 2006). Hull-less barley has nutritional components like starch, protein, β-glucan, total dietary fiber and amino acids relative to hulled barley (Boros et al., 1996). Barley has substantial popularity due to its dietary fiber and non-starch polysaccharides contents (Baik et al., 2008). In recent times, previous investigations have proved that barley consumption correlated with decreasing serum cholesterol levels (Bourdon et al., 1999). In the United States despite several efforts to decrease cardiovascular disease (CVD), it’s considered one of the main reasons of death. Consumption of diets enriched in whole grains has been reported to have considerable health benefits including the reduction in the danger of CVD (Rimm et al., 1996; Truswell et al., 2002). Barley species with the highest levels of β-glucan content are nearly twice the content present in oats, concentrated β-glucan derived from barley reduce serum cholesterol levels in hypercholesterolemia animal patterns such as hamsters. Thus, ingestion of diet which is rich in barley found to be necessary for experiments pertained decreases in serum cholesterol levels (Kahlon et al., 1993; German et al., 1996). In addition, barley grain is characterized by its content from antioxidants including phenolic acids, tannins, proanthocyanidins, chalcones, flavonols, flavones, lignans, flavanones and amino phenolic compounds thereby incorporating of barley in wheat- based products can augment the nutritious value of wheat flour and products derived from it (Holtekjolen et al., 2008; Sharma et al., 2014) and barley competes well with other main grains such as wheat, rice, oat and rye in terms of various and unique phenolic compounds for instance the existence of all eight tocol vitamins which are usually not complete in some grains (Panfili et al., 2003). Wheat is considered a staple source of carbohydrate for majority people in the world. 20% of the daily energy requirement comes from consuming wheat. The outer husks of wheat grain contain the most of the nutrients and these nutrients are removed during grinding and the flour is left with the starch only so the wheat products should be produced from the whole meal flour which keeps most of the nutrients instead of the zero flour (Ötles et al., 2006). Numbers of studies have revealed that barley can be widely included in varied processed food for instance several types of bread, Asian noodles, biscuits, cookies and muffins (Izydorc- zyk et al., 2008; Skendi et al., 2010; Collar et al., 2014). Addition barley to wheat flour raises β-glucan content in the final product (Holtekjolen et al., 2008; El Yamlahi et al., 2013). The extraction and precipitation of β-glucan fractions are very costly for commercial edible use so dry grinding and sieving would be more economical method to get barley fractions containing 6–23% β -glucan (Ragab et al., 1995). It is worth mentioning that after the removing of the outer bran layer by milling, the β-glucan remains in the barley flour as it is one of the consistent of cell walls of the endosperm (Araki et al., 2009). In last few decades, people tend to consume at mass scale more healthy and nutritious food category and supplemented baked products are good vehicle for nutritional value enrichment and fortification (Nagi et al., 2012). Bakery-based products are exploited as a source to inclusion of several nutritionally concentrated items for diversification more especially, grain -based confectionery products include substantial products that vary in production mechanisms, composition and organoleptic properties. They are preferable and consumed by all levels of people ingesting before and after meals through- out human lives due to easy availability, varied taste, availability in vast array of varieties, affordable cost. Also, they possessed longer shelf-life which makes them preferentially convenient for consumption. They also account as a concentrated food because of their contents from fats, carbohydrates and low level of moisture contents and hence they are good source of energy. It’s often comprising of 7–20% of moisture 30–70% of sugar and 30– 60% of fat. Industrially produced hard biscuits and tea cookies mainly include 2.0–7.5% of water, 5.3–15.4% of proteins, 3.1–30% of fat, 2.2–3.1% of dietary fibers and 51–78% of carbohydrates (Kaić -Rak et al., 1990; Hooda et al., 2005; Sudha et al., 2007). Substituting wheat flour with WBF will definitely decrease the wheat gluten proteins and biscuits are a low somewhat volume product and generally don’t require gluten protein as with breads which demand more gluten content as its main effect on loaf volume so barley flour could be a raw convenient choice for preparing nutritional and functional biscuits (Sharma et al., 2014). This study aims to evaluate the rheological properties namely farinograph and extinsograph indices of wheat flour supplemented with different concentrations of whole barley flour (20, 40%). as well as effect additional whole barley flour on dough and final sensory evaluation of biscuits produced. Moreover examine the Microbial load (total bacterial count, spore forming bacteria and molds & yeasts counts) for biscuits produced from wheat flour supplemented with different levels of whole barley flour during storage period (3 months) at room temperature (25 °C ± 2).

2 Materials and methods

2.1 Materials

Hull-less barley grains (Hordeum vulgare) were purchased from crops research department, field research institute, A.R.C., Giza, Egypt. Wheat flour 72% extraction rate was provided from the local market in Cairo, Egypt. Chemicals used in this study obtained from Elgomhoria Company, Cairo, Egypt.

2.2 Methods

2.2.1 Technological methods

2.2.1.1 Milling process

Hull-less barley grains were moistened to14% moisture for 24 h and then milled by hammer mill to whole meal barley flour (100% extraction) as shown in Fig. 1.

Hull-less barley grains processing and grinding.

2.2.1.2 Preparation of biscuits

The supplements were prepared as mentioned by Škrbic et al. (2011) through substituting wheat flour with barley flour at 20, 40%. Different mixtures were blended according to the recipe presented in Table 1 by using a food mixer with a spiral hook to form homogenate dough. The water was added gradually to form consistent dough. An experienced baker evaluated subjectively stickiness and dough consistency. The dough was flatted on a board to produce a uniform width of 6 mm and formed into 5 cm in a diameter and then baked for 10–15 min at 180 °C. Biscuits left to cool for 30 min in room temperature on racks as shown in Fig. 2 and then stored in polypropylene bags before further analysis. WBF: Whole barley flour.

Ingredients

Samples

Control biscuits

Biscuits 20% WBF

Biscuits 40% WBF

Refined flour

100 g

80 g

60 g

WBF

Zero

20 g

40 g

Sugar

30 g

30 g

30 g

Margarine

30 g

30 g

30 g

Salt

2 g

2 g

2 g

Baking powder

0.5 g

0.5 g

0.5 g

Distilled water

20 ml

20 ml

20 ml

Biscuits prepared by using whole barley flour as a partial substitute of wheat flour.

2.2.2 Analytical methods

2.2.2.1 Moisture, protein, crude lipids, fibers and ash

Moisture, protein, crude lipids, fibers and ash were estimated using the method of AOAC (2000) % Carbohydrates = 100 - (%Protein + %Moisture + %Ash + %Lipids + %Fiber).

2.2.2.2 Antioxidant activity

Radical scavenging activity (DPPH) was estimated according to the method mentioned by Ismail et al. (2020).

2.2.3 Rheological properties

Farinograph and Extensograph were used to test rheological properties of the dough according to the method illustrated by Aly (2019).

2.2.4 Sensory evaluation of biscuits

Sensory attributes of prepared biscuits were determined by ten panelists from our laboratory and the scoring card of sensory properties included the following parameters: appearance, odor, texture, color and taste according to the method described by Aly (2019) and Patel et al. (2019).

2.2.5 Microbiological methods

Total bacterial count, Spore-Forming bacteria and total molds & yeasts were determined according to Marshall (1992). 1 gm of sample was homogenized in 10 ml saline Solution. Dilutions were prepared by mixing 1.0 ml of the homogenate in 9.0 ml of the sterile diluent to get 10−1 dilution then diluting up to 10−2 and 10−3. Sterilization were carried out by autoclaving at 121 °C for 20 min. Total count bacteria were estimated by pour plating on nutrient agar plates and enumerating the colony forming units (cfu) after culturing at 37 °C for 48 hrs. Mold & Yeast count determined by using the formula of malt extract agar medium: (Malt extract 30 gm, Agar (15 gm), Peptone 5 gm distilled water (1000 ml) and PH (3.5–4.5 ± 0.2).

2.2.6 Statistical analysis

The statistical analysis was estimated as method described by Aly et al. (2020) using Excel (ANOVA) by test by a significance (P ≤ 0.05).

3 Results and discussion

3.1 Chemical composition

3.1.1 Chemical composition of whole barley flour and wheat flour

Data presented in Table 2 shows that the moisture contents were almost the same in flours which were 10.11 ± 0.64 in WF and 10.46 ± 0.52 in WBF. Barley flour was a slight higher in protein content 11.3% than wheat flour 10.5%. Whole barely flour was characterized by higher ash content (2.81%) relative to wheat flour (0.60%) these findings are consistent with Abou-Raya et al. (2014) who reported that ash contents were higher in barley flour (2.40%) in comparison to wheat flour (1.45%). In addition, results were in confirmed by Koletta et al. (2014) who mentioned that the barley flour had a higher content of ash 1.26 g/100 g than pure wheat flour 0.63 g/100 g. On the other hand, it can be noticed that whole barley flour had a higher content of fat (2.69%±0.28) as compared with wheat flour (1.73%±0.06). These reduction of ash content in wheat flour compared with barley flour can be attributed to a removing of the germ and bran from the endosperm in white flour during the grinding process. Likewise, Shaban et al. (2006) mentioned that the milling and sieving process caused partial separation of germ which has higher oil content than the hull. As it is expected, whole barley flour possessed a higher level of the crude fiber (4.2%) than wheat flour (0.09%). Wheat flour (72% extraction) had a higher content of carbohydrate as compared with whole barley flour. These findings are in close to agreement with that mentioned by El-Taib et al. (2018) who found that the protein, lipids, ash and crude fiber of barley flour (85% extract.) were higher compared with wheat flour 13.63%, 3.18%, 2.77% and 4.53, respectively. Whereas these contents in wheat flour were 12.26, 0.49, 1.21 and 0.59, respectively and Maray et al. (2018) revealed that wheat flour (72% extraction) had 12.30, 0.84, 10.0, 0.62, 0.38 and 88.16% of moisture, lipids, protein, crude fiber, ash and total carbohydrates and these values were 11.80, 1.81, 11.11, 2.72, 2.04 and 82.32%, respectively in whole meal barley (naked barley). Different letters (a, b) within row show significant differences between values (p < 0.05). Data are indicated as: average (for three replicates) ± standard deviation (SD); % on dry weight basis.

Properties

Wheat flour 72%

Whole barley flour

LSD*0.05

Moisture

10.11 ± 0.64 a

10.46 ± 0.52 a

1.32

Protein

10.5 ± 0.05b

11.3 ± 0.36a

0.6

Fat

1.73 ± 0.06b

2.69 ± 0.28a

0.5

Ash

0.60 ± .08b

2.81 ± 0.32a

0.68

Crude fiber

0.09 ± 0.02b

4.21 ± 0.28a

0.44

Carbohydrate

76.1 ± 0.84a

69.3 ± 1.3b

2.4

3.1.2 Chemical composition of biscuits

The obtained data of the chemical composition of biscuits are displayed in Table 3. Biscuits were prepared by blending WBF with WF at levels 20 WBF/80WF and 40 WBF/60 WF. Supplementation caused a significant increase in moisture contents which were 2.92 ± 0.14, 3.29 ± 0.10 and 3.86 ± 0.08 for control, 20% and 40% WBF-wheat biscuits, respectively. An increased barley inclusion caused a slight but significant raise in protein contents. On the same line, the increasing in WBF resulted in an elevation in ash and crude fibers contents of biscuits which were 2.03% and 1.67% in 40% WBF, followed by biscuits prepared from 20% WBF biscuits (1.5 and 0.80%) while the control biscuits recorded the least for these values (0.51 and 0.46%). There were not significant differences in fat content between samples. Substituting led to a decrement in carbohydrate contents. These results are in accordance with Škrbic et al. (2011) who stated that biscuits supplemented with barley flour were higher in protein, ash and crude fiber than control ones. The current results showed that the incorporation of barley in bakery products likely to enhance the nutritional value of these products by increasing the protein, ash, fiber and decreasing the carbohydrate content. WBF: Whole barley flour. Different letters within row show significant differences between values (p < 0.05). Data are indicated as: average (for three replicates) ± standard deviation; % on dry weight basis.

Properties

Control biscuits

20% WBF biscuits

40% WBF biscuits

LSD*0.05

Moisture

2.92 ± 0.14c

3.29 ± 0.10b

3.86 ± 0.08a

0.24

Protein

8.3 ± 0.26b

8.7 ± 0.2b

9.2 ± 0.25 a

0.48

Fat

17.67 ± 0.52NS

17.98 ± 0.07NS

18.25 ± 0.19NS

0.46

Ash

0.51 ± 0.26c

1.52 ± 0.26b

2.03 ± 0.07a

0.44

Crude fiber

0.46 ± 0.05c

0.80 ± 0.2b

1.67 ± 0.2a

0.28

Carbohydrate

70.1 ± 0.64 a

67.7 ± 0.2b

64.95 ± 0.2c

0.8

3.2 Antioxidant activity (DPPH free radical scavenging activity)

DPPH free radical scavenging activity has been used greatly for the estimation of antioxidant activity for different grain crude extracts and pure antioxidant compounds (Goupy et al., 1999; ). Table 4 shows the antioxidant activity of WBF-wheat biscuit. Free radical scavenging activity of whole barley flour reached to 41.5% whereas in wheat flour was only 2.03%. The antioxidant activity of control biscuit was lowered to 1.35% after preparing biscuits and reached to 12.6% in biscuits prepared by blending wheat flour with 40% level. These results are in confirmed with Sharma et al. (2014) who demonstrated the antioxidant activity of wheat flour blending with whole meal barley at levels 25, 50, 75, 100% and the resultant data illustrated that the antioxidant activity was raised progressively from 8.8 to 16.03% as a result of the supplementation with whole barley flour. In addition (Amarowicz et al., 2007; Sharma et al., 2012) reported that barley extract could have free-radical scavenging activities at 43.6% efficacy, exhibited strong DPPH radical scavenging activity higher than those of the extracts prepared from wheat, rye, rice and triticale caryopses. Likewise, Hamli et al. (2017) studied the radical scavenging and phytochemical screening properties of three durum wheat species, including Gaviota, Bousselam, and Vitron durum, and one barley specie, namely Fouara and the authors found that anti-oxidant activity of crude extracts from seeds of durum wheat and barley species was as following: Vitron seeds crude extract 0.18% ± 0.10, durum wheat Bousselam specie 36.9% ±0.41, durum wheat Gaviota specie 38.0% ±0.28, barley Fouara 54.8% ±0.34. In this respect, Bondia-Pons et al. (2009) mentioned that one of the health influences of cereal crops is attributed to numerous polyphenols that they have which can have anti-inflammatory, anti-oxidative and anti-cancirogenic properties. Thereby, it is suggested that grain phytochemicals can be a prophylactic agent against degenerative diseases. Different letters within column show significant differences between values (p < 0.05). Data are indicated as: average (for three replicates) ± standard deviation; % on dry weight basis.

Samples

DPPH radical scavenging activity (%)

Wheat flour

2.03 ± 0.83b

Whole barley flour

41.5 ± 2.5a

LSD*0.05

3.7

Control biscuits

1.35 ± 0.31c

Biscuits (20WBF + 80%WF)

10.1 ± 0.4b

Biscuits (40WBF + 60%WF)

12.6 ± 0.6a

LSD*0.05

0.8

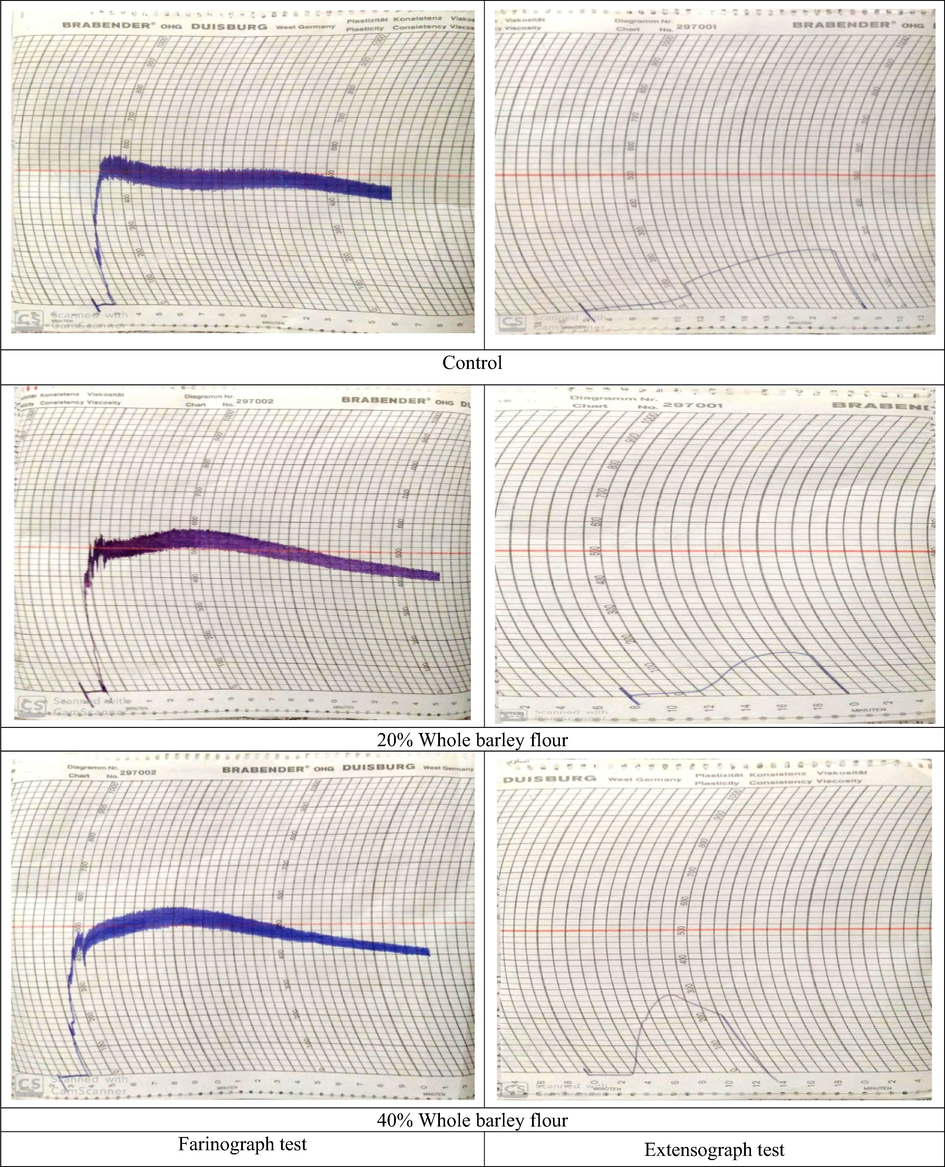

3.3 Rheological properties

3.3.1 Farinograph test

All measured values of rheological attributes (Farinograph and extinsograph) of wheat flour supplemented with whole barley flour are shown in Table 5 and Fig. 3. Water absorption gradually increased with supplemented by WBF, it increased from 60.5% for control wheat flour sample to 66.2% and 71.0%, respectively for wheat flour supplemented with 20 and 40% whole barley flour. It is well known that the increasing in fiber content in a dough caused an increase in water absorption (Sudha et al., 2007), The hydroxyl groups of fiber structure cause an interaction between water and hydrogen bonds and this illustrated the increase in tendency of flour to hold water (Rosell et al., 2001). Likewise, dough development time increased and reached to 3.0 min for WF blended with 40% WBF as compared to corresponding control (1.5 min). On the other hand, dough stability time (min) was shortened in the dough supplemented with 40%WBF because the existence of fiber particle resulted in a disruption of starch-gluten network and thus a decrease in dough stability time while this value increased and reached to the maximum in the dough substituted with 20% WBF as compared with corresponding control. The dough stability is better when the time is longer (Mehfooz et al., 2018) rather findings were previously mentioned by Urooj et al. (1998) and Hussein et al. (2006) who demonstrated that the high concentration of barley flour mixed with refined white flour led to a progressive elevation in water absorption, dough stability time and arrival time. Degree of softening (B.U) increased with the increasing in WBF and reached to the maximum in the dough blending with 40% WBF. El-Taib et al. (2018) support our findings when they found that the degree of weakening (BU) was raised progressively by the increasing ratios of barley flour and it can be attributed to lower the wheat gluten content in the dough (Mekhael, 2005). WBF: Whole barley flour. WF: wheat flour.

WBF

(%)Water absorption

Arrival time(min.)

Dough development (min)

Stability (min)

Degree of softening (B.U)

Control (0%)

60.5

1

1.5

10.5

40

(20%WBF + 80%WF)

66.2

1

2.0

11.5

50

(40%WBF + 60%WF)

71.0

2.0

3.0

9.5

70

Farinograph and extensograph test of wheat flour supplemented with different concentrations of whole barley flour.

3.3.2 Extenograph test

Data is shown in Table 6 and Fig. 3. illustrated that the elasticity of the dough was reduced with the increase in WBF and the same phenomena was observed in the extensibility, these data are on the same line with El-Taib et al. (2018) who mentioned that the dough extensibility showed a pronounced retard as the percentage of WBF increased. Mixtures that have an increased distance before rupture (high extensibility) whereas the increasing in force demanded to rupture the dough (high maximum resistance to elasticity) are likely to have good bread making characteristics (Sullivan et al., 2010) they also stated that the extension of the dough lowered with the addition of barley flour level. It can be noticed that proportional number (P.N) increased from 2.42 for control sample to 3.20, 3.56, respectively at levels 20, 40% of WBF. These data was in agreement with Naeem et al. (2002) who demonstrated that the proportional number increased as the levels of barley flour increased. Concerning the dough energy (cm2), the values were reduced by increasing of WBF proportion suggesting that the incorporation of barley flour make dough more suitable for making biscuits (Shaban et al., 2006). WBF: Whole barley flour. WF: wheat flour.

WBF

Elasticity (B.U)

Extensibility (mm)

Proportional number (P.N)

Energy (cm2)

Control (0%)

230

95

2.42

35

(20%WBF + 80%WF)

160

50

3.20

11

(40%WBF + 60%WF)

160

45

3.56

12

3.4 Sensory attributes of biscuits

Consumer acceptability, or preference of final product is popular carried out by affective parameters (Lawless et al., 1993, Meilgaard et al., 2007, Svensson, 2012). Evaluation of sensory properties of supplemented biscuits are listed in Table 7. Supplementation with whole barley flour affected significantly on the sensory characteristics of biscuits. It could be noticed that almost all the sensory parameters of biscuits prepared from 80%WF + 20% WBF were not statistically significant from control biscuits. Biscuits prepared from 60%WF + 40% WBF had a score for odor and taste higher than control sample. However, the minimum values of appearance and color were observed in biscuits 60%WF + 40% WBF but the textures of supplemented biscuits were comparable to the control. Further elevation in barley flour level decreased the scores of surface color. The control sample had the maximum score for these parameters. The color of biscuit was pale cream up to 20% level thereafter the color became brown golden in 40% level. These results are confirmed by Newman et al. (1998) who showed that the incorporation of barley flour in products exhibited acceptable organoleptic attributes, in particular if included at low and moderate ratios. Also, Sharma et al. (2014) stated the sensory properties of cookies prepared with 25, 50, 75, 100% barley flour added to wheat flour. The resultant data showed that the highest surface color score was recorded in cookies prepared with 25% barley flour, however barley flour significantly decreased the surface of color. The surface appearance was also reduced as increasing in barley inclusion over 25%. On the same line, the texture was lowered as the increasing of level of barley flour. The overall acceptability of the cookies decreased as a consequence of increasing barley flour substitution though the cookies prepared with 100% barley flour exhibited an overall acceptability. Different letters (a, b) within row show significant differences between values (p < 0.05). Data are indicated as: average (for ten replicates) ± standard deviation.

Characteristics

Biscuits samples supplemented with different levels of whole barley flour

LSD*0.05

Control

Biscuits 20% barley flour

Biscuits 40% barley flour

Appearance (10)

9.00 ± 0.41a

9.25 ± 0.42a

8.6 ± 0.6b

0.5

Color (10)

9.45 ± 0.44a

9.20 ± 0.26a

8.40 ± 0.4b

0.4

Texture (10)

9.30 ± 0.42a

9.1 ± 0.46a,b

8.9 ± 0.3b

0.4

Taste 10

8.60 ± 0.66b

8.4 ± 0.6b

9.20 ± 0.6a

0.6

Odor (10)

8.90 ± 0.52b

9.00 ± 0.2b

9.50 ± 0.58a

0.4

Overall acceptability (10)

8.00 ± 0.4b

8.60 ± 0.7a

7.70 ± 0.7c

0.6

3.5 Microbial load of produced biscuits during storage period at room temperature (25 °C ± 2) for 3 months

In polypropylene bags, the samples of biscuits were stored after grinding them to fine powder for 0, 1, 2 and 3 months for microbiological observation. Microorganisms are considered the major causes of food spoilage types, there are many economic losses for manufacturers and consumers due to spoilage of microbial growth (Needham et al., 2004). Limits of microorganisms load have been indicated in most food to maintain them safe for consumption (Ogunjobi et al., 2010). Bacteria load often growth in a food as a consequence of the method of processing of the food as well as the duration of processing, the storage of the food and handling. Other factors include the microbial growth in the raw ingredients used to prepare the food. Thereby, to keep product against the spoilage and subsequent growth of deleterious microorganisms, it should be well packaged in suitable materials after processing. The data in Table 8 illustrates that after 1 month of storage, the highest count of TCB was observed in biscuits control (3.8 × 103 cfu/gm) while the lowest one was observed in biscuits prepared from 40%WBF (2.8 × 103 cfu/gm). TCB increased during storage period due to the increase in moisture content. After 3 months, biscuits control recorded the highest value (8.7 × 103 cfu/gm) and biscuits 40%WBF was the lowest (6.03 × 103 cfu/gm). Hussain et al. (2018) support our findings, the authors studied the microbial properties of multigrain biscuits during storage and found that the incorporation of barley in biscuits decreased TCB as compared with corresponding control biscuits. NC: No colonies were observed. Data are indicated as: average (for three replicates) ± standard deviation. Different letters (a, b) within row show significant differences between values (p < 0.05).

Microbial parameters (Cfu/gm)

Storage period

Microbial counts of biscuits supplemented with whole barley flour

Control

Biscuits supplemented with 20% WBF

Biscuits supplemented with 40% WBF

Total bacterial count

Zero Time

LSD 1.8(5.0 × 102 ± 1.0)a

(3.0 × 102 ± 1.0)b

(1.3 × 102 ± 0.6)c

1 month

LSD 0.76(3.8 × 103 ± 2.6)a

(3.7 × 103 ± 3.5)a

(2.8 × 103 ± 4.9)b

2 month

LSD 0.75(5.5 × 103 ± 5.03)a

(5.2 × 103 ± 3.2)a

(4.1 × 103 ± 2.6)b

3 month

LSD 1.4(8.3 × 103 ± 6.4)a

(7.9 × 103 ± 9)a

(6.03 × 103 ± 5.5)b

Spore-Forming bacteria

Zero Time

LSD 1.2(2.30 × 102 ± 0.6)a

(1.3 × 102 ± 0.6)a,b

(0.3 × 102 ± 0.6)b

1 month

LSD 1.5(4.00 × 102 ± 1.00)a

(3.7 × 102 ± 0.6)a

(1.33 × 102 ± 0.6)b

2 month

LSD 2.2(6.00 × 102 ± 0.1)a

(6.3 × 102 ± 1.5)a

(3.3 × 102 ± 0.6)b

3 month

LSD 2.7(10 × 102 ± 1.7)a

(9.3 × 102 ± 0.6)a

(6.3 × 102 ± 1.5)b

Mold and yeast

Zero Time

NC

NC

NC

1 month

LSD 1.5(8.3 × 102 ± 0.6)a

(8 × 102 ± 1.00)a

(6.3 × 102 ± 0.6)b

2 month

LSD 2.3(13 × 102 ± 1.00)a

(12.6 × 102 ± 1.5)a

(9 × 102 ± 1.00)b

3 month

LSD 2.2(17.7 × 102 ± 1.5)a

(17 × 102 ± 1.00)a

(13.3 × 102 ± 0.60)b

Likewise, spore-forming bacteria increased during storage period. After 3 months of storage the highest count of spore forming bacteria was recorded in biscuits control (10.00 × 102 cfu/gm) while the lowest one was in biscuits prepared from 40%WBF (6.33 × 102 cfu/gm). In this respect, spore-forming bacteria are characterized by resistance against extreme conditions including extreme heat or cold, drought, pressure, biocides, UV irradiation and starvation (Moeller et al., 2008). It is well known as thermotolerant or thermophilic bacteria and accounts one of popular factors of food spoilage (Andréet al., 2017). The fresh biscuits have no detected of growth mold and yeast at zero time under ambient temperature as the processes of roasting and baking at high temperature as well as low amount of water activity in biscuits which suppressing the growth of micro-organisms. In this respect, Horner et al. (1973) stated that in many bakery products, moisture content is the most prominent single index influencing the rate and sort of micro-organisms spoilage. Mold and yeast count increased during storage period and increasing the whole barley level in biscuits recorded a slight reduction but significant in mold and yeast load. After 3 months of storage, 40% WBF biscuits had the least count of mold and yeast (13.3 × 102 cfu/gm) whereas control biscuits had the maximum count (17.7 × 102 cfu/gm). This antimicrobial effect may be attributed to the high levels of phytochemicals and antioxidant properties of barley grains relative to the more widely ingested grains daily as with rice and wheat (Sharma et al., 2012).

4 Conclusion

The aim of this investigation was to maximize the nutritional promoting characteristics of barley- containing products although its direct utilization as processed food is so limited, but it can be easily blended with other flours to prepare healthy rich products. Inclusion of barley at low or moderate ratios, results in biscuits with considerable acceptable sensorial and technological characteristics. The incorporation of whole barley flour into wheat-based bakery products found to supply superior nutritious value to these products in terms of increased fiber, ash and its content from antioxidant with the possibility to affect human health. Therefore, we can enhance the potential explosion of barley as a functional food. Supplementation also decreased the microbial load during storage period. Furthermore, the expansion in barley inclusion into wheat products can bridge the food cavity resulting from the lack of wheat production and not to rely on importing wheat grains from other countries.

Acknowledgements

The authors are grateful to Benha University, Egypt. Also, Faculty of Applied Sciences, Umm Al-Qura University, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Effect of adding barley and oat flour on the rheological properties of bread dough. J. Food Dairy Sci.. 2014;5:641-652. https://www.researchgate.net/publication/336844808

- [Google Scholar]

- Chemical, rheological, sensorial and microbial evaluation of supplemented wheat flour biscuit with guava seeds powder. J. Food and Dairy Sci., Mansoura. 2019;10(5):147-152.

- [Google Scholar]

- Effect of addition sesame seeds powder with different ratio on microstructural and some properties of low fat labneh. Arabian J. Chem.. 2020;13(10):7572-7582.

- [CrossRef] [Google Scholar]

- Antioxidant and radical scavenging activities of a barley crude extract and its fraction. Czech J. Food Sci.. 2007;25(No. 2):73-80.

- [Google Scholar]

- Spore-forming bacteria responsible for food spoilage. Res. Microbiol.. 2017;168(4):379-387.

- [CrossRef] [Google Scholar]

- AOAC, 2000. Association of Official Analytical Chemists. Official Methods of Analysis. AOAC, Washington, DC, USA

- Araki, S., Ito, K., Aoe, S., Ikegami, S., 2009. Physiological functions of barley and the health claims on food labels. The Jpn. J. Nutr. Dietetics 67, 235–251. https://www.researchgate.net/deref/http%3A%2F%2Fdx.doi.org%2F10.5264%2Feiyogakuzashi.67.235

- Barley for food: characteristics, improvement and renewed interest. Critical review. Cereal Sci.. 2008;30:1-10. https://www.researchgate.net/publication/222577594

- [Google Scholar]

- Rye phenolics in nutrition and health. J. Cereal Sci.. 2009;49(3):323-336.

- [CrossRef] [Google Scholar]

- A note on the composition and nutritional value of hulless barley. J. Animal Feed Sci.. 1996;5(4):417-424. https://doi.org/10.22358/jafs/69619/1996

- [Google Scholar]

- Postprandial lipid, glucose, insulin, and cholecystokinin responses in men fed barley pasta enriched with Β-glucan. The Am. J. Clin. Nutr.. 1999;69(1):55-63.

- [CrossRef] [Google Scholar]

- Nutritional and functional performance of high Β-glucan barley flours in breadmaking: mixed breads versus wheat breads. Eur. Food Res. Technol.. 2014;238(3):459-469. https://www.researchgate.net/publication/260813195

- [Google Scholar]

- Effect of barley flour on wheat bread quality. Arab Universities J. Agricultural Sci.. 2018;26:1109-1119.

- [CrossRef] [Google Scholar]

- Effect of barley (Hordeum Vulgare L.) flour incorporation on the baking quality of wheat (Triticum Aestivum L.) flour. J. Chem. Pharm. Res.. 2013;2(5):162-170. https://www.researchgate.net/publication/286577875

- [Google Scholar]

- Effect of dietary fats and barley fiber on total cholesterol and lipoprotein cholesterol distribution in plasma of hamsters. Nutr. Res.. 1996;16(7):1239-1249.

- [CrossRef] [Google Scholar]

- Wheat bread quality as influenced by the substitution of waxy and regular barley flours in their native and extruded forms. J. Cereal Sci.. 2002;36(2):219-237.

- [CrossRef] [Google Scholar]

- Antioxidant composition and activity of barley (hordeum vulgare) and malt extracts and of isolated phenolic compounds. J. Sci. Food Agric.. 1999;79(12):1625-1634.

- [CrossRef] [Google Scholar]

- Effects of barley flour, wet gluten and liquid shortening on the texture and storage characteristics of chapati. J. Texture Stud.. 2002;33(5):461-469.

- [CrossRef] [Google Scholar]

- Phytochemical screening and radical scavenging activity of whole seed of durum wheat (Triticum Durum Desf.) and barley (Hordeum Vulgare L.) varieties. Jordan J. Biol. Sci.. 2017;10(4):323-327. https://www.researchgate.net/publication/342420689

- [Google Scholar]

- Antioxidant properties and sensory profiles of breads containing barley flour. Food Chem.. 2008;110(2):414-421.

- [CrossRef] [Google Scholar]

- Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chem.. 2005;90(3):427-435.

- [CrossRef] [Google Scholar]

- Combined effects of water activity, Ph and temperature on the growth and spoilage potential of fung. Appl. Bacteriology. 1973;36:427-436.

- [CrossRef] [Google Scholar]

- Effect of barley flour and some of their functional ingredients on quality of pan bread. Minufiya J. Agric. Res. 2006;31:877-897. https://www.researchgate.net/publication/331850117

- [Google Scholar]

- Development and evaluation of functional biscuits from underutilised crops of ladakh. Int. J. Curr. Microbiol. App. Sci.. 2018;7(3):2241-2251. https://www.researchgate.net/publication/323962522

- [Google Scholar]

- Rheological, physio-chemical and organoleptic characteristics of ice cream enriched with doum syrup and pomegranate peel. Arabian J. Chem.. 2020;13(10):7346-7356.

- [CrossRef] [Google Scholar]

- Physicochemical properties of hull-less barley fibre-rich fractions varying in particle size and their potential as functional ingredients in two-layer flat bread. Food Chem.. 2008;108(2):561-570.

- [CrossRef] [Google Scholar]

- Cholesterol-lowering effects in hamsters of beta-gluca N-enriched barley fraction, dehulled whole barley, rice bran, and oat bran and their combinations. Cereal Chem.. 1993;70(4):435-440. https://europepmc.org/article/agr/ind20372035

- [Google Scholar]

- Kaić -Rak, A., & Antonić, K. (1990). Tablice o sastavu namirnica i pića (Food composition tables). Zagreb, Croatia: Zavod za zaštitu zdravlja Hrvatske.

- Physicochemical and technological properties of highly enriched wheat breads with wholegrain non wheat flours. J. Cereal Sci.. 2014;60(3):561-568.

- [CrossRef] [Google Scholar]

- The central dogma in sensory evaluation. Food Technol.. 1993;47:139e146. https://agris.fao.org/agris-search/search.do?recordID=US9409300

- [Google Scholar]

- Effect of the partial replacement of wheat flour with barley flour on quality attributes of bread and biscuits. J. Recent Adv. Food Sci.. 2018;1 https://www.researchgate.net/publication/324149850

- [Google Scholar]

- Standard Methods for the Examination of Dairy Products. Washington, DC: American Public Health Association; 1992. https://agris.fao.org/agrissearch/search.do?recordID=US19950104912

- Effect of barley husk addition on rheological, textural, thermal and sensory characteristics of traditional flat bread (chapatti) J. Cereal Sci.. 2018;79:376-382.

- [CrossRef] [Google Scholar]

- Mekhael, E.K., 2005. “Biochemical and Techno-Logical Studies on Balady Bread Made from Durun Wheat Mixed with Some Cereals and Cereal by Products.” M.Sc. Thesis, Cairo Univ., Egypt., 65-67.

- Meilgaard, M.C., Civille, G.V., Carr, B.T., 2007. “Sensory evaluation techniques” (4th ed.). USA: CRC Press, Taylor and Francis group. https://doi.org/10.1201/b16452

- Role of DNA protection and repair in resistance of <em>Bacillus subtilis</em> spores to ultrahigh shock pressures simulating hypervelocity impacts. Appl. Environ. Microbiol.. 2008;74:6682.

- [CrossRef] [Google Scholar]

- Mixing properties, baking potential, and functionality changes in storage proteins during dough development of triticale-wheat flour blends. Cereal Chem.. 2002;79(3):332-339.

- [CrossRef] [Google Scholar]

- Effect of storage period and packaging on the shelf life of cereal bran incorporated biscuits. Am. J. Food Technol.. 2012;7(5):301-310.

- [CrossRef] [Google Scholar]

- Early detection and differentiation of spoilage of bakery products. Sens. Actuators, B. 2004;106(1):20-23.

- [CrossRef] [Google Scholar]

- Fibre enrichment of baked products with a barley milling fraction. Cereal Foods World. 1998;43(1):23-25. https://agris.fao.org/agris search/search.do?recordID=US1997054705

- [Google Scholar]

- Physicochemical and sensory properties of cassava flour biscuits supplemented with 66 cashew apple powder. J. Food Technol.. 2010;8(1):24-29. https://medwelljournals.com/abstract/?doi=jftech.2010.24.29

- [Google Scholar]

- Cereal based functional foods and nutraceuticals. Acta Sci. Pol. Technol. Alignment. 2006;1(5):107-112. https://www.researchgate.net/publication/312911498

- [Google Scholar]

- Normal phase high-performance liquid chromatography method for the determination of tocopherols and tocotrienols in cereals. J. Agric. Food Chem.. 2003;51(14):3940-3944.

- [CrossRef] [Google Scholar]

- Effect of baking temperatures on the proximate composition, amino acids and protein quality of de-oiled bottle gourd (Lagenaria Siceraria) seed cake fortified biscuit. LWT - Food Sci. Technol.. 2019;106:247-253.

- [CrossRef] [Google Scholar]

- Ragab, O.S., 1995. “Biochemical Studies on Glucan Fractions.” M.Sc. Thesis, Biochemistry Dept., Fac. of Agric., Cairo University.

- Vegetable, fruit, and cereal fiber intake and risk of coronary heart disease among men. JAMA. 1996;275(6):447-451.

- [CrossRef] [Google Scholar]

- Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids. 2001;15(1):75-81.

- [CrossRef] [Google Scholar]

- Shaban, N.M., 2006. Chemical And Technological Studies On Some Products Produced From Barley, M.Sc. Thesis, Nutrition and Food Science, Faculty of Home Economics , Minufiya University, Cairo, Egypt.

- Cookie making behavior of wheat- barley flour blends and effects on antioxidant properties. LWT—Food Sci. Technol.. 2014;55(1):301-307.

- [CrossRef] [Google Scholar]

- Extrusion of hulled barley affecting Β-glucan and properties of extrudates. Food Bioprocess Technol.. 2013;6(6):1374-1389.

- [CrossRef] [Google Scholar]

- Antioxidant potential of wheat flour chapattis as affected by incorporating barley flour. LWT - Food Sci. Technol.. 2014;56(1):118-123.

- [CrossRef] [Google Scholar]

- Antioxidant activity of barley as affected by extrusion cooking. Food Chem.. 2012;131(4):1406-1413. https://www.researchgate.net/publication/251575260

- [Google Scholar]

- Effect of two barley B-glucan isolates on wheat flour dough and bread properties. Food Chem.. 2010;119:1159-1167.

- [CrossRef] [Google Scholar]

- The enrichment of wheat cookies with high-oleic sunflower seed and hull-less barley flour: impact on nutritional composition, content of heavy elements and physical properties. Food Chem.. 2011;124(4):1416-1422.

- [CrossRef] [Google Scholar]

- Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem.. 2007;104(2):686-692.

- [CrossRef] [Google Scholar]

- Fundamental rheological and textural properties of doughs and breads produced from milled pearled barley flour. Eur. Food Res. Technol.. 2010;231(3):441-453.

- [CrossRef] [Google Scholar]

- Svensson, L., 2012. Design and performance of small scale sensory consumer tests, M.Sc. Thesis, 30hec, Second cycle, A2E. Publikation/Sveriges Iant- bruksuniversitet, Institutionen, for livsmedelsvetenskap, no. 354. Uppsala: The € Faculty of Natural Resources and Agricultural Sciences, Swedish University of Agricultural Sciences. https://stud.epsilon.slu.se/5045/

- Cereal grains and coronary heart disease. Eur. J. Clin. Nutr.. 2002;56(1):1-14.

- [CrossRef] [Google Scholar]

- Effect of barley incorporation in bread on its quality and glycemic responses in diabetics. Int. J. Food Sci. Nutr.. 1998;49(4):265-270.

- [CrossRef] [Google Scholar]