Translate this page into:

Comprehensive review of liquid chromatography methods for fumonisin determination, a 2006–2022 update

⁎Corresponding authors. angelesrc@uaem.mx (M. Ángeles Ramírez-Cisneros), myolanda@uaem.mx (Maria Yolanda Rios)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Abstract

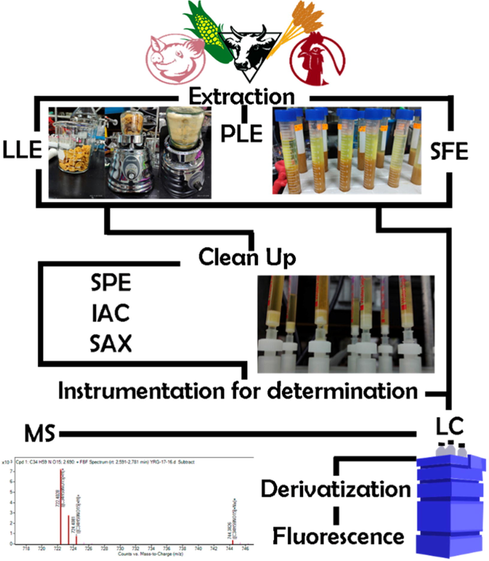

Fumonisins are mycotoxins present worldwide. They are mainly found in corn and its derived foods; however, they also have an important presence in other grains, fruits, and vegetables. Their consumption in excessive amounts can affect animal and human health. The most abundant of these is fumonisin B1, associated with a range of toxicological effects in animals, including equine leukoencephalomalacia, porcine pulmonary edema, and rodent carcinogenicity. In humans this mycotoxin has been shown to increase rates of esophageal cancer. The International Agency for Research on Cancer has classified FB1 within the 2B group, considering it a possible human carcinogen. Thus, analytical methods that identify/quantify fumonisins become a necessity to ensure adequate control of food and crops. An analytic method needs to be sensitive, selective, and robust to provide reliable data that can aid in monitoring risk assessment, quality control, and research. Recently, colorimetric methods which use immunologic and molecular approaches based on dyes, enzymes and aptamers have gained attention; some of these using nanomaterials. However, these methods are still in development. Currently, chromatographic methods remain the most confident and robust analytic tool, especially for quantification purposes. There is a great deal of information reported in the literature regarding these methods; despite this, there has not been a compilation of the methods for fumonisin analysis to facilitate its consult since 2005. Being the most common method for fumonisin detection worldwide, the present review focuses on the compilation of liquid chromatography methods published between 2006 and 2022 organized by matrix, analytes, instrument, and method conditions, using diverse detectors including MS, fluorescence, and an evaporative light scattering detector. Additionally, These techniques have been applied to diverse matrices, namely food and beverages, including grains, milk, meat, beer, wine; as well as biological samples such as urine, plasma, serum, and tissues. Other aspects pertaining to legislation, extraction, cleanup (selective pressurized liquid extraction, strong anion-exchange, immunoaffinity chromatography, and QuEChERS), derivatization procedures, limit of detection and quantification of fumonisins are also included. This review had compiled and organized 88 chromatographic methods for fumonisins analysis, and the analysts can consult all the procedures with detail.

Keywords

Fumonisins

Fumonisin B1

Fumonisin analysis

Food analysis

Mycotoxins analysis method

1 Introduction

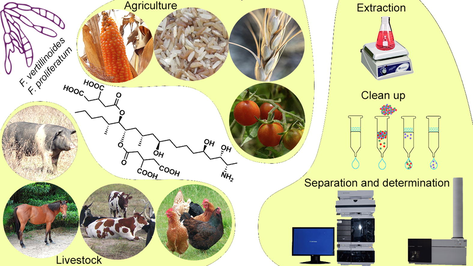

Despite the current improvement in processing, packing and labeling activities, food safety is still an important concern, not only for human consumption, but also for crop control, fresh food quality and safety. Fungi contamination of these and other products is a paramount problem, as it can cause diverse ailments to humans and animals, as well as compromise production yield of the different crops and livestock. Mycotoxins are small secondary metabolites (molecular weight -MW- ∼ 700) produced by microfungi; these are naturally occurring substances that are responsible for detrimental effects to the host, and are, for the most part, resistant to food processing (Bullerman and Bianchini, 2007, Turner et al., 2009). These compounds can be carcinogenic, nephrotoxic, hepatotoxic, neurotoxic, immunosuppressant, and can modify estrogen production (Jia et al., 2014). An important aspect pertaining to the consumption of mycotoxins is their ability to accumulate within an organism. Thus, different sources such as grains: wheat (Headley, 2022 in graphical abstract), oats, rice (Toro 2022 in graphical abstract), barley, and corn (Diogo 2011 in graphical abstract), fresh vegetables (Cumming 2022 in graphical abstract) and fruits (apples, raisins, and nuts) contribute to increase the amount of accumulated toxins in the host. This phenomenon continues in livestock whereby the ingestion of contaminated food sources increases the levels of toxins within their organisms, and are passed on to their derivatives (i.e. meat, milk, eggs, among others). As a result, human consumption of these products multiplies the chain of transmission, as crops and livestock (Embrenhar 2022 in graphical abstract) become saturated of mycotoxins from different sources; this is known as a carryover effect (Marasas 2001). Hence, contamination by mycotoxins has been recognized as a health problem, with special attention being put on aflatoxins, ochratoxins and fumonisins by their direct or accumulated toxicity (Requena et al., 2005).

Mycotoxins are generally characteristic to a specific genus. Some of the main genus producing mycotoxins are Aspergillus (aflatoxins and ochratoxins), Penicillium (patulin, ochratoxin A, citrinin, penicillic acid, cyclopiazonic acid, and penitrem), and Fusarium (trichothecenes and fumonisins) (Grajewski et al., 2012). Among aflatoxins, ochratoxins, and fumonisins, these last ones have been associated with important human diseases such as esophageal cancer (Marasas 2001), with an increased incidence of human immunodeficiency virus (HIV) infection (Williams 2010), liver and kidney disease, and growth impairment (Chen 2018). Some reviews have compiled the toxicity and mechanism of action of FB (Chen 2021, Stockmann-Juvala 2008). It has been estimated that mycotoxins are present in at least a quarter of the world’s agricultural products, and their stability at high temperatures guarantee their integrity even after passing through cooking and industrial procedures (Williams 2010). Despite these considerations, not all countries have legislation that regulate their concentration in food. The number of mycotoxins that are known to exert a toxic effect on human and animal health is constantly increasing, for this reason, generation and observance of legislation that ensures minimization of mycotoxins exposure is needed to ensure the quality of food (Bueno 2015). Diverse detection methods have been used to evaluate fumonisins, and some new methods have a promising future for easier and faster methodologies. Enzyme-linked immunosorbent assay (ELISA) methods based on antigens are specific and commercially available, however these have expiration date and need to be stored under refrigeration. Some enzymes have been proposed for colorimetric methods intended for more analytes, however these demonstrate low selectivity. Nanomaterials have arisen as a promising tool for mycotoxin detection, using immunoreactions or aptamers for detection. Despite this, for research purposes, characterization of nanomaterials is required, and instrumentation is expensive. Thus, this method may only prove favorable for future commercial applications if a high specificity, especially in real samples, can be achieved. These techniques have been recently reviewed (Majdinasab et al., 2021) and remain out of the scope of the present paper. In general, the most extensively used technique for mycotoxin determination is liquid chromatography associated with different detectors (Bueno 2015). This is because it has a well established and robust methodology that has been proven for all kinds of matrices. There is a considerable number of articles regarding fumonisin analysis (including reviews); however, there has been no compilation of this information available since 2006. This review aims to compile and organize the advances in the field from 2006 to 2022 in a single document including liquid chromatography coupled to mass spectrometry (LC-MS) and ultra-performance liquid chromatography (UPLC) methods currently used. Additionally, matrices, pretreatment procedures and instrument conditions are also reported, so that readers can easily find a method close to their needs in a single article.

2 Fusarium genus

Fusarium genus (syn Giberella) was first described by Link in 1803. It belongs to the Nectriaceae family and is widely spread in soil. Fusarium includes more than 150 species of filamentous fungi, classified into nine categories, and is considered one of the most mycotoxigenic genus. Fusarium phylogeny and morphology has been recently reviewed generating an online identification database (Crous 2021). It is of agricultural concern for its capacity to grow on plants, particularly crops, but also in fruits, contaminating food and feed (Tapia 2014, Grajewski et al., 2012). Approximately 20 species are considered pathogenic for their capacity to produce mycotoxins that affect plants, animals, and humans. F. verticillioides and F. proliferatum are the main producers of fumonisins (Gelderblom 1988); F. solani and F. oxysporum have been reported to cause minor health problems directly to humans, producing keratitis, endophthalmitis, onychomycosis, cutaneous and subcutaneous infections, sinusitis, arthritis and mycetoma. In immunocompromised patients, however, especially those with hematological disorders, they can cause severe disseminated infections that can reach mortalities of almost 100% (“Fungal Infections. Fusarium Solani” https://www.life-worldwide.org/fungal-diseases/fusarium-solani; “Fungal Infections. Fusarium Oxysporum,” https://www.life-worldwide.org/fungal-diseases/fusarium-oxysporum). Prolonged exposition to these fungi can also lead to chronic diseases such as cancer (Shier 2000). The distribution of Fusarium species has been studied mainly in commercial substrates, and particularly for certain geographical areas such as F. graminearum and F. culmorum in Europe (Pasquali 2016), F. oxysporum in Israel and Middle East (Maymon 2020), and F. oxysporum worldwide (Dita 2018).

3 Fumonisins

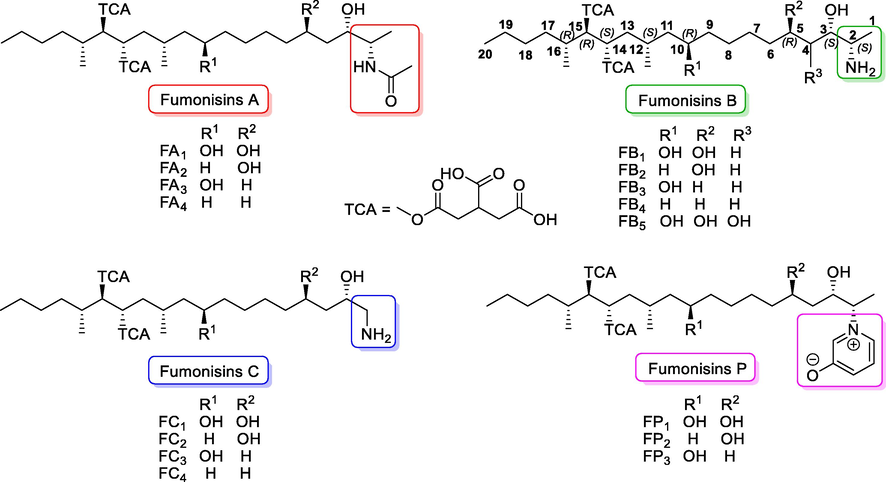

The first report regarding fumonisins was published in 1988 when they were first isolated by Gelderblom et al (Gelderblom 1988). The chemical structure of these mycotoxins was first proposed in the same year as a result of the collaboration between the Programme on Mycotoxins and Experimental Carcinogenesis (PROMEC) and the Council for Scientific and Industrial Research (CSIR) (Marasas 2001). Structurally, fumonisins are characterized by a long chain of polyhydroxy alkylamines containing two propane tricarboxylic acid moieties (tricarballylic acid, TCA) that are esterified to hydroxyl groups on adjacent carbon atoms. Currently twenty-eight different structures of fumonisins have been described (Agriopoulou 2020), which have been classified into four series: Series-A corresponds to amides, Series-B exhibits a free amine group and a terminal methyl, Series-C includes a terminal amine group, and Series-P incorporate an 3-hydroxypiridinium residue in their structures (Yazar 2008, Braun 2018).The fumonisins most frequently isolated from Fusarium are illustrated in Fig. 1.

Selected chemical structures of fumonisins.

Within these groups of natural compounds, fumonisins B (FB1, FB2, FB3) are the most relevant because they have been found on various food products and crops (Arranz 2004). FB1 is the most abundant and toxic fumonisin of the group. Its chemical structure is a 2S-amino-12S,16R-dimethyl-3S,5R,10R,14S,15R-pentahydroxyeicosane, in which hydroxyl groups at C-14 and C-15 are substituted with a propane-1,2,3-tricarboxylic acid (TCA) residue. FB2 does not have the hydroxyl group at C-10. FB2 and FB3′s structural isomers, differ only in the location of an hydroxyl group (Fig. 1) (Bryła 2013). The FUM genes have been identified as the responsible for fumonisin biosynthesis (Alexander 2009).

3.1 Fumonisins in food

Fumonisins are present in a wide number of food products around the world. Cereals are the group with the highest documented concentration of these toxins (Kamle 2019). Maize, and maize-based products are particularly affected (Stępień 2011), with as much as an estimated 50% of products contaminated in varying degrees (Pagliuca 2005), depending mainly on agroclimatic and storage conditions (Bryła 2013). In particular, FB1 has been found in different types of food such as asparagus, garlic (Seefelder 2002), barley (Park 2002), beers (Kawashima 2007), dried figs (Heperkan 2012), and milk (Gazzotti 2009). Additionally, FB1 and FB2 have been reported in ‘black oats’ feed from Brazil, and forage grass in New Zealand. They have also been found in home-grown corn consumed in rural areas of Southern Africa, and in commercial corn-based human food products from retail outlets (Norhasima 2009).

Concentrations of FB1 and FB2 vary widely between products. They have been found in corn meal up to 2.98 µg FB1/g and 0.92 µg FB2/g, and in corn grits up to 2.55 µg FB1/g and 1.07 µg FB2/g, respectively. In contrast, Switzerland, the United States, and South Africa have reported very low concentrations of these toxins, being lower than 0.06 µg/g, in products such as corn breakfast cereal (Norhasima 2009). A meta-analysis including contamination of cereal-based foods revealed the highest concentration of fumonisins in corn-based products, followed by wheat-based products, other cereals, and barley-based foods. Regarding the occurrence, it was reported widely in other cereal-based foods, followed by corn-based foods, rice-based foods, and wheat-based foods (Farhadi 2021).

3.2 Stability

The integrity of fumonisins depend on a combination of conditions that include temperature, pH, humidity, biotic or abiotic conditions, matrix and, time in these conditions. Several studies on fumonisin stability were performed in the 90′s. It has been shown that FB1 is partially hydrolyzed at acidic or basic conditions, or at 100–125 °C, and completely degraded at 200 °C for 60 min in the absence of a matrix (Jackson 1996). Thus, the extent of FBs degradation, and their toxicity in food depend primarily on the cooking and processing conditions (Humpf 2004). FBs are known to be relatively heat stable and are minimally affected during food processing techniques such as baking, frying, broiling or extrusion cooking, where temperatures can reach 150–200 °C (Humpf 2004). In maize flour, at neutral and acidic conditions, FBs were reported stable at temperatures greater than 220 °C (25 min) (Bryła 2017). Selection and disposal of damaged grains, along with soaking and/or washing corn reduced the concentration of FBs by eliminating it from food material (Saunders 2001). Dry milling has been shown to maintain FB1 mostly intact (Kamle 2019), however, wet milling has been shown to produce products suitable for animal and human consumption (gluten, fiber, germ, and starch), as the water used in the process causes FB1 deterioration (Saunders 2001). Fumonisins can also interact with aminoacids, proteins or reducing sugars to form covalent bonds during heat processes. For instance, FB1 reacts with D-glucose, present in corn grits, during extrusion cooking at 160–180 °C and forms the reaction product N-(carboxymethyl) fumonisin B1 known as NCM (Seefelder 2002, Taylor 2012).

3.3 Toxicological effects

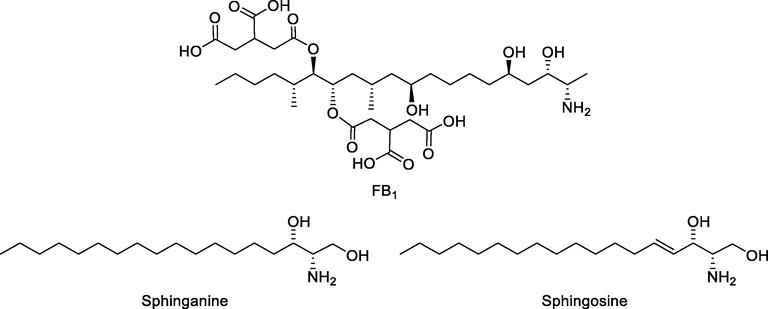

Fumonisin has been proven to induce growth and lipid disruption in plants, animals, and humans, especially FB1. Additionally, immunotoxicity, organ toxicity (liver, kidney, intestinal tract, heart, lungs, brain) and reproductive toxicity has been reported (Chen 2021). Structural similarity between sphingosine, sphinganine and fumonisin (e.g. FB1, Fig. 2) is cited as the key for their toxic effects, however oxidative stress, endoplasmic reticulum stress and altered tumor necrosis factor (TNF) signaling pathway, has also been recognized as a mechanisms of their toxicity (Chen 2021; Stockmann-Juvala 2008).

Chemical structures of sphinganine, sphingosine and FB1.

In banana plants, FB1 decreases the activity of certain enzymes such phenylalanine ammonia lyase (PAL), β-1,3-glucanase (GLU), and chitinase (CHI). It also enhances reactive oxygen species like malondialdehyde (MDA) and hydrogen peroxide, as well as transcription of genes associated to cell death (Xie 2021). In maize, FB1 competitively inhibits ceramide synthetase (CerS) disturbing lipid equilibrium and cell protection (Beccaccioli 2021).

In animals, the presence of FBs has been found to impair immune function, cause liver and kidney damage, decrease weight and increase mortality rate (Akande 2006). Fumonisins can cause an ample range of animal diseases, including leukoencephalomalacia (LEM) in horses (Lockett 2022 in graphical abstract) and rabbits, hemorrhage in rabbits, pulmonary edema in pigs, and liver cancer in rats. In addition, they are toxic to turkey poults and have been associated with diarrhea and reduced body weight in broiler chicks (Ghiasian 2009). Different species of fish are affected by FB1, in general, they induce weight and hematocrit reduction, as well as liver and kidney damage similar to other animal species (Oliveira 2020).

Fumonisins are associated with an increased risk of esophageal and liver cancer in humans (Liu 2017), and with a general increase of cancer incidence in regions where maize is the population’s dietary base (Martins 2012). The inhibition of CerS causes the accumulation of the sphingoid bases sphinganine (Sa) and sphingosine (So), and a decrease of complex sphingolipids (Cano-Sancho 2012). Currently, the interference with sphingolipid biosynthesis remains the main cause of toxicity in humans and animals (Soriano del Castillo 2007). Sphingolipids have recently been associated with control of cell growth and proliferation of cancer cells. Ceramide has an important role in limiting cancer progression by inducing cell death (Ogretmen and Avenue 2018). Thus, its inhibition by fumonisins can potentially enhance the development of cancer, which is why the International Agency for Research on Cancer (IARC) has classified FB1 as a probable carcinogenic to humans (group 2B) (Duarte-Vogel 2006). Exposure to fumonisins has also been shown to increase the risk of neural tube defects (NTD) in humans (Seyed Amir Ghiasian 2006). Furthermore, some studies have suggested a possible link between exposure to fumonisins and an increase in the mortality of infection by human immunodeficiency virus (HIV) in sub-Saharan Africa (Williams 2010). More recently, a preliminary study has demonstrated the presence of hydrolyzed FB1 (aminopentol) in the urine of women infected with human papillomavirus (HPV) and its absence in healthy women (Ramírez-Cisneros 2020).

Fusarium produces fumonisin to facilitate its entrance to the cell by producing lipid disruption in the host cell. As a corollary, cells affected by fumonisins become a target for other infection agents such as viruses. Additionally, this lipid disruption leads to alterations in cell metabolism that can lead to cancer and cell death.

Hydrolyzed fumonisins are structurally more similar to Sa and So, however their toxic effects are still unknown. Toxicodynamic studies, especially in humans are necessary to establish dose–response of fumonisins and their hydrolyzed forms.

3.4 Toxicokinetics

The bioavailability, distribution, and toxicokinetic studies in several animal species including laboratory rodents, primates, swine, ruminants, and poultry have shown that fumonisins are poorly absorbed and have a very low bioavailability. However, little amounts of fumonisins accumulate in tissues and organs (Shier 2000). The bioavailability for FB1 administered orally in non-human primates has been reported as < 5 % of the dose with Tmax = 1.02 h. Elimination half-live was found to be T1/2 = 3.15 h for plasma, T1/2 = 4.07 h for liver and T1/2 = 7.07 h for kidney. In contrast, when administered with feed, concentrations in the kidneys increase approximately 10-fold compared to liver concentrations; suggesting an increase in the rate of elimination (Voss 2017). Bioavailability studies have demonstrated that, of the total concentration of FBs (FB1+2+3) in the liver or kidney of rats, FB1 shows the highest concentration, finding FB2 and FB3 in very minor concentrations (Voss 2017). In contrast, FB1 is only detected in plasma and tissues at low levels, suggesting that its absorption is negligible.

Indeed, in cows and laying hens, systemic absorption of orally given FB1 is<1% (Bouhet 2007). Fumonisins were mostly excreted, almost unchanged, in feces and only a small percentage was excreted in urine. Nevertheless, urine is the most acceptable, and easiest, medium to investigate compared to feces (Van Der Westhuizen 2013).

Even though fumonisins have poor absorption, they have been demonstrated to be an important factor in the development of livestock and human diseases (Shier 2000). This poses the interesting question of why they have proven toxic effects despite their low bioavailability. Several investigations have tried to explain this phenomenon, including in vitro studies using Caco-2-cells to prove the absorption of FB1 in enterocytes. A study has established that the only form readily absorbed corresponds to the completely hydrolyzed form of FB1 (aminopentol). Another study using radiolabeled FB1, performed in nonhuman primates, demonstrated that after 24 h of administration, the intestinal epithelial cells contained 25% of the dose (Shephard 1992). Furthermore, recent data has indicated an interaction between FB1 and cholesterol and/or bile salts, which may lead to the incorporation of FB1 into mixed micelles. Thus, the metabolism of fumonisins could lead to an increased bioavailability (Bouhet 2007).

Some aspects of fumonisin toxicokinetics remain unknown, however, and pigs have been suggested as a model because of its similarity with fumonisin metabolism in humans (Schelstraete 2020).

4 Limits and legislation

Removal of mycotoxins from food products has proven to be a difficult process; therefore, maximum acceptable levels have been established for human consumption to ensure the safety of these products. Guidelines have been published in response to this need, that dictate the maximum concentration of these compounds that can be tolerated. There is a varied range of permissible amounts of mycotoxins in food according to different guidelines, encompassing ranges from 200 to 4000 μg/kg (Ponce-García 2018). Many organizations worldwide oversee strict regulations for mycotoxin control, and possible food contamination. Some of these are global organizations such as the Joint Expert Committee on Food Additives (JECFA); the scientific advisory board of the World Health Organization (WHO) and the Food and Agriculture Organization (FAO). Others are limited to geographical areas such as the European Food Safety Authority (EFSA) in the European Union, which gives counseling to European Commission; and the Food and Drug Administration (FDA) in the United States of America (Pereira 2014).

In 1997, fumonisins as a subgroup of mycotoxins, were subject to regulations in only one country (FAO, 1997). In 2005, the number of countries regulating fumonisins increased to six, and the limit for their presence in maize was established as a maximum of 3000 mg/kg (Panel 2015).

Currently, many countries have implemented several regulations to control the presence of fumonisins in food products by implementing prescribed acceptable and maximum limits (WHO-Department of Food Safety and Zoonoses 2018). The JECFA established a maximum tolerable daily intake (PMTDI) of 2 µg/kg b.w./day for FB1, FB2, and FB3 (alone or in combination). On the other hand, the European Union (EU Regulation 1126/2007) and the US, proposed acceptable upper limits of 4000 µg/kg for FB1 and FB2 (Agriopoulou 2020). These established safe limits are not homogenous as different countries change them mainly in relationship to food products. For example, the maximum permissible levels (MPL) for the combination of FB1 + FB2 is 4000 μg/kg for unprocessed maize; whereas for maize intended for direct human consumption is 1000 μg/kg; 800 μg/kg for maize-based breakfast cereals/snacks; and 1400/2000 μg/kg for maize milling fractions of particle size greater/<500 μm respectively. The Codex Alimentarius Commission on Food Contaminants recommends a limit of 5000 μg/kg for combined FB1 + FB2 + FB3 MPL for unprocessed corn grain and 2000 μg/kg MPL for processed maize-based products including flour (Bryła 2013) (WHO-Department of Food Safety and Zoonoses 2018). The main purpose of these legislations is to prevent the consumption of food that is potentially contaminated with mycotoxins, ensuring the protection of the inhabitants of developed countries (Alberts 2017). At present, there are limits established for raw maize (4000 µg/kg), as well as for maize flour and semolina (2000 µg/kg) (Alimentarius 2019). The European Commission has regulated acceptable levels of fumonisins with its most recent modification in 2010 indicating 2000 µg/kg for raw maize, 1000 µg/kg for maize products for coction, 400 µg/kg for direct ingest maize products and, 200 µg/kg for babies and kinder food (European Comission 2007). In contrast, countries with emerging economies lack similar regulations or have poor standards; this can lead to problems with overconsumption of food with high levels of mycotoxins, including fumonisins (Ponce-García 2018). To control and/or verify fumonisin presence in food and feed products, analytical methods are needed for a wide variety of matrices. These have been proven to affect fumonisin stability and thus, bioavailability (Tables 1-3). (ACN) Acetonitrile, (AcOH) Acetic acid, (AE) Appearance energy, (AmAc): ammonium acetate, (AmFo) Ammonium formate, (CaV) Capillary voltage, (CaT) Capillary temperature, (CGF) Cone gas flow, (CoG) Collision gas, (CUR) Curtain gas, (DG) Drying gas, (DGF) Desolvation gas flow, (DGT) Desolvation gas temperature, (EV) Extractor voltage, (FA) Formic acid, (Frag Vol) Fragmentor Voltage, (GF) Gas flow, (GT) Gas Temp, (LIT) linear ion tramp, (MeOH) Methanol, (MSPD) Matrix Solid Phase Dispertion, (NG) Nebulizer gas, (NR) Not reported, (PLE) Pressurize Liquid Extraction, (RT) Room temperature, (ST) Source temperature, (SV) Source voltage, (tan) analysis time, (tTot) total time including column conditioning. (ACN) Acetonitrile, (AcOH) Acetic acid, (AE) Appearance energy, (AmAc): ammonium acetate, (AmFo) Ammonium formate, (CaV) Capillary voltage, (CaT) Capillary temperature, (CGF) Cone gas flow, (CoG) Collision gas, (CUR) Curtain gas, (DG) Drying gas, (DGF) Desolvation gas flow, (DGT) Desolvation gas temperature, (EV) Extractor voltage, (FA) Formic acid, (Frag Vol) Fragmentor Voltage, (GF) Gas flow, (GT) Gas Temp, (LIT) linear ion tramp, (MeOH) Methanol, (MSPD) Matrix Solid Phase Dispertion, (NG) Nebulizer gas, (NR) Not reported, (PLE) Pressurize Liquid Extraction, (RT) Room temperature, (ST) Source temperature, (SV) Source voltage, (tan) analysis time, (tTot) total time including column conditioning. (ACN) Acetonitrile, (AcOH) Acetic acid, (AE) Appearance energy, (AmAc): ammonium acetate, (AmFo) Ammonium formate, (FA) Formic acid, (Hex) Hexane, (MeOH) Methanol, (MSPD) Matrix Solid Phase Dispertion, (NR) Not reported, (PBS) Phosphate Buffer Solution, (PLE) Pressurize Liquid Extraction, (RT) Room temperature, (tan) analysis time, (tTot) total time including column conditioning.

Ref

FBs

MatrixSample (g)

Sample treatment

Extraction procedureLC conditions

Column / Injection volume / Mobile Phase

Flow / Analysis TimeMS conditions, Limits

Mass Conditions / Limits

Maize and corn-based products

(Zitomer et al. 2008)

B1, B2, B3

Maize leaf0.01

Extraction: 1.-Add 2 mL ACN/H2O 1:1 (5% FA); 2.- Gently shaken for 3 h; 3.- Centrifugate to 15000 g; 4.- Filter; 5.- Dilute 1:10

Metachem Inertsil ODS-3, 150 x3 mm, 5 µm

Inj vol 20 µL, A) H2O/ACN/FA 97:2:1, B) H2O/ACN/FA 2:97:1.

70-50% B in 9 min, 50-100% B in 2 min, keep 10 min; initial conditions for 10 min

Flow: 0.20 mL/min, Time: tan=21 min, tTot=31 min

QTrap

CaT : 210°C

LOD: 0.01 µg/kg all FBs

(De Girolamo et al. 2014)

B1, B2, PHF (B1, B2), HF (B1, B2)

Maize based products20

Extraction: 1.- 100 mL MeOH/ACN/citrate-phosphate buffer 25:25:50; 2.- Shake 1h; 3.- Dilute 1:10 with MeOH/H2O 80:20 with 0.5% AcOH; 4.- Filter

Gemini C18, 150 x 2.0 mm, 5 µm at 40 °C

Inj vol 20 µL, A) H2O, B) MeOH, both with 0.5% AcOH

40-60% B in 30 min, 60 to 40% B in 1 min; initial conditions for 9 min

Flow: 0.2 mL/min, Time: tan=30 min, tTot=40 min

Orbitrap

CaV 45 V; SV 4 kV; RF Lens 75 V; ST 300 °C; CaT: 300 °C; SG 30 U; GF 10 skimmer V 18 V

LOD: 5 µg/kg, LOQ: 10 µg/kg all FBs

(Beltrán et al. 2009)

B1, B2

Maize, kernel, dry pasta, baby food2.5

Extraction: 1.- Add ACN/H2O 80:20 + 0.1% AcOH, 2.-shake 90 min, 3.-centrifuge to 4000 rpm, 10 min; 4.-dilute 1:2 with H2O, 5.-filter (0.22 mm nylon filter)

Acquity UPLC BEH C18, 50 x 2.1 mm, 1.7 µm at 40°C

Inj vol 20 µL, A) H2O, B) MeOH, both with 0.5 mM AmAc and 0.1% AcOH

10-90 % B in 4 min, initial conditions for 3 min

Flow: 0.3 mL/min, Time: tan=4 min, tTot=7 min

QQQ

CaV 3.5 kV; DGT 500°C; ST 120 °C; T 40 °C; DGF 1200 L/h, CoG 4 x 10-3 mbar

LOD: 1 µg/kg, LOQ: 3.5 µg/kg

(C. Dall’Asta et al. 2008)

B1, B2, B3

Maize, maize-based products25

Extraction LLE: 1.- Add 100 mL H2O/ACN/MeOH 50:25:25, 2.- blend (6000 rpm/5 min); 3.- take 4 mL; 4.- filter; 5.- dry N2; 6.- reconstitute 1mL in H2O/ACN 1:1; 7.- filter

XTerra C18, 250 × 2.1 mm, 5 µm at 30°C

Inj vol 10 µL, A) H2O, B) MeOH, both with 0.1% FA

0% B for 3 min, 0-45% B in 2 min, keep 5 min, 45-85% B in 15 min, keep for 10 min, initial conditions for 10 min

Flow: 0.2 mL/min, Time: tan=35 min, tTot=45 min

QQQ

CaV 3.2 kV; CV 30 V; EV 3 V; ST 120 °C; DGT 160 °C; CGF 70 L/h; DGF 650 L/h (N2 for both)

LOD: B1, B2 1 µg/kg, FB3 8 µg/kg

LOQ: B1, B2 5 µg/kg, FB3 12 µg/kg

(Arroyo-Manzanares et al. 2018)

B1, B2 and other toxins

Wheat, maize2

QuEChERS: 1.-Add 8 mL of H2O; 2.-shake 10 s; 3.-add 10 mL 5% FA in ACN; 4.-shake 2 min; 5.-add 4 g MgSO4 + 1 g NaCl; 6.-shake 1 min: 7.-vortex 2 min; 8.-centrifuge to 4500 rpm, 5 min, 4 °C; 9.-take 5 mL; 10-dry under N2 at 40 °C; 11.-reconstitute (0.2 mL MeOH/H2O 1:1); 12.-centrifuge to 14000 g, 5 min, 4 °C

ACQUITY HSS UPLC T3, 150 x 2.1 mm, 1.8 µm at 30 °C

Inj vol 10 µL, A) H2O, B) MeOH, both with 0.3% FA and 5 mM AmF

5% B, keep 0.5 min, 5-94% B in 19.5 min, keep 1 min, 94-5% B in 3 min; initial conditions for 4 min

Flow: 0.4 mL/min, Time: tan=21 min, tTot=28 min

QQQ

ST 150 °C; DGT 400 °C; NG 7 bar (N2); CGF 150 L/h; DGF 1000 L/h

LOD; 1.28 B1, 0.25 FB2, 0.27 B3 µg/kg LOQ: 4.24 B1, 0.82 FB2, 0.89 B3 µg/kg

(Chiara Dall’Asta, Galaverna, et al. 2009)

B1, B2, B3

Corn-based products5

Extraction: 1.- Add 50 mL H2O/MeOH 30:70; 2.- Blend to 6000 rpm, 10 min; 3.- Stir for 60 min; 4.- re-extract the solid (same way); 5.- Filter; 6.- Dry 4 mL; 7.- Dissolve in 2 mL MeOH

Xterra C18, 250 x 2.1 mm, 5 µm, at 30 °C

Inj vol 5 µL, A) H2O, B) MeOH, both with 0.2% FA

30% B for 2 min, 30-45% B in 3 min, 45-90% B in 20 min, keep for 10 min, 30% B in 1 min; initial conditions for 20 min

Flow: 0.2 mL/min, Time: tan=35 min, tTot=56 min

QQQ

CaV 3.2 kV; EV 3 V; ST 120 °C; DGT 160 °C; CGF 70 L/h; DGF 650 L/h (N2, both)

LOD: FB1 4 µg/kg, B2, FB3 8 µg/LOQ: B1 B2 5, B3 12 µg/kg

(Chiara Dall’Asta, Mangia, et al. 2009)

B1, B2, B3

Ground corn5

Extraction: 1.- Add 50 mL H2O/MeOH 30:70; 2.-Blend to 6000 rpm, 10 min; 3.- Stir for 50 min; 4.- Centrifuge to 3500 g, 15 min; 5.- Filter (2 mL)

Xterra C18, 250 x 2.1 mm, 5 µm at 30°C

Inj vol 10 µL, A) H2O, B) MeOH, both with 0.1% FA

30 % B for 2 min, 30-45% B in 3 min, 45-90% B in 20 min, keep for 10 min; initial conditions for 15 min

Flow: 0.2 mL/min, Time: tan=35 min, tTot=50 min

QQQ

CaV 4 kV; EV 2 V; ST 120°C; DGT 350 °C; CGF 50 L/h; DGF 600 L/h

LOD: 5 µg/Kg

(Chiara Dall’Asta, Mangia, et al. 2009)

B1, B2, B3

Corn-based products5

Extraction: 1.- Add 2 ml H2O/ACN/AcOH 20:79:1; 2.- Extract 90 min in rotatory shaker; 3.- Centrifuge 3000 rpm, 3 min; 4.- Take aliquot 350 µL and dilute 1:1 with extraction solvents

Gemini C18, 150 x 4.6 mm, 5μm at 25 °C

Inj vol 5 µL, A) H2O/ACN/AcOH 89:10:1, B) H2O/ACN/AcOH 2:97:1, both with 5 mM AmAc

0% B for 2 min, 0-100% B in 12 min, keep for 3 min; initial conditions for 4 min

Flow: 1.0 mL/min, Time tan=17 min, ttotal=21 min

QQQ

CaV 4.0 kV; EV 3 V; ST 550 °C; CUR 10 psi

LOD: 8 µg/kg

(G. B. de Oliveira et al. 2017)

B1, B2

Maize1

Extraction: 1.- Add 1 g Silica gel as dispersant; 2.- Mix in polypropylene cartridges, MSPD; 3.- Elute with 16 mL of 20 mM AmFo buffer:MeOH 9:1 (pH 7); 4.- Collect 2 mL fractions; 5.- Centrifuge to 4000 rpm, 10 min; 6.- Filter

Poroshell, C18, 100 x 3 mm, 2.7 µm, 40 °C

Inj vol 10 µL, A) Ultrapure H2O, B) ACN, both with 0.1% FA

20-90% B in 3 min, keep 0.4 min, 90-20 % B in 0.1 min; initial conditions for 6 min

Flow: 0.5 mL/min, Time: tan=3.4 min, tTot=9.5 min

QQQ

CaV 4.5 kV; EP 10 V; DGT 650 °C; NG 40 CUR 18 a.u,

LOD: B1 514, B2 176 µg/kg

LOQ: B1 594, B2 210 µg/kg

(D’Arco et al. 2008)

B1, B2, B3

Corn-based baby food3

Extraction: 1.- Add 100 µL of a 5 µg/mL Fbs solution (0.5 µg) and keep 15 min at RT; 2.-pack into 11 mL PLE pressure resistant stainless steel extraction cell; 3.-elute with 22 mL of MeOH 60% at 40°C and 34 atm, 2 min of preheating, 5 min of static time, 60 s of purge time; 4.-concentrate to 5 mL (40 °C and 80 mbar); 5.-transfer to a 15 mL conical tube; 6.-evaporate to dryness at 55°C with N2 ; 7.reconstitute 1 mL MeOH/H2O 50:50; 8.-filter

Luna C18, 150x4.6 mm, 5 µm (Temp NR)

Inj vol NR, A) H2O, B) MeOH, both with 0.5% FA

65% B for 3 min, 65-95% B in 4 min, keep 3 min, initial conditions in 10 min

Flow: 0.30 mL/min, Time: tan=10 min, tTot=20 min

QQQ

CaV 3.20 kV; CoV 50 V; EV 3 V; RF lens 0.2 V; ST 125 °C; DGT 300 °C; DGF 500 L/h; CGF gas 50 L/h

LOD: 0.7 B1 and B2, 1.5 µg/kg B3 LOQ: 2 B1 and B2, 5 µg/kg B3

(Chiara Dall’Asta, Mangia, et al. 2009)

B1, B2, B3

Raw corn100

Extraction: 1.- Add 50 mL KOH 2M; 2.-Centrifuge to 6000 rpm, 10 min; 3.- Stir (50 min); 4.- Add 50 mL ACN; 5.- Stir 10 min; 6.- Separate 20 mL and dry under N2; 7.- Redissolve in 50 mL KOH 2M; 8.- Centrifuge to 3500 rpm, 15 min; 9.- Dry under N2; 10.- Redissolve in H2O/MeOH 30:70

Hypersil C18, 150 x 2.1 mm, 5 μm at 25°C

Inj vol 10 µL, A) H2O, B) MeOH, both with 0.2% FA

20% B for 1 min, 20-100% B inwalnut 5 min, keep 3 min, initial conditions for 4 min

Flow: 0.6 mL/min, Time: tan=8 min, tTot=13 min

QQQ QTrap

CaV 4 kV; CoV 50 V; ST 425°C; DGT 350°C; CGF 50 L/h; DGF 600 L/h (N2, both)

LOD: <15 µg/kg

(Hu et al. 2019)

B1, B2

Raw maize1

Extraction: 1.- 10 mL ACN/H2O/AcOH 70:29:1; 2.- Shake 30 min; 3.- Centrifuge to 4500 rpm, 10 min; 4.- Filter supernatant; 5.- Take 1 mL; 6.- Add 10 µL, 1 µg/mL 13C-34 FB1 and 13C-34 FB2

Luna C18, 150 x 2 mm, 3 µm at 40°C

Inj vol 5 µL, A) H2O, B) MeOH, both with 2 mM AmAc

40-90% B in 6 min, keep 1 min, 90-100% B in 1 min, keep 1 min, 100-40% B in 2 min; initial conditions for 4 min

Flow: 0.2 mL/min, Time: tan=9 min, tTot=15 min

Qtrap

CaV 5.5 kV; EP 10 V; ST 600°C; CUR 40 psi; CoV 10 V; dwell time 100 ms

LOD: 7 B1; 6 B2 µg/kg

LOQ: 28 B1; 27 B2 µg/kg

(Bergmann, Hübner, and Humpf 2013)

B1

Maize10

Extraction: 1.- Add 20 mL ACN/H2O 70:30 with 1% FA; 2.-Vortex 30 s; 3.- Sonicate 10 min; 4.- Shake 15 min; 5.- Centrifugate to 8000 g, 15 min, 25 °C; 6.- Dilute 1:1 1% FA; 7.- Filter if necessary

Hyperclone C8 BDS, 150 x 2.0 mm, 3 µm at 40° C

Inj vol 20 µL, A) H2O, B) ACN, both with 1% FA

65% B for 4 min, 37.5% B for 0.5 min, 5% B for 2 min, keep for 0.5 min, initial conditions for 4 min

Flow: 0.30 mL/min, Time: tan=7 min, tTot=11 min

QTrap

CaV 5.5 kV; DG 350 °C; NG 35 psi; DG 45 psi; CUR (N2) 30 psi; CoG 5 x 10−5 Torr; QTrap CUR 20 psi

LOD: 53 µg/kg, LOQ: 188 µg/kg

(de Matos et al. 2021)

B1, B2, HB1, HB2

Corn products5

Extraction: 1.- Add ACN:H2O:FA 75.24:1; 2.- shake for 2 min; 3.- sonicate for 10 min; 4.- centrifuge at 3000 rpm for 7 min; 5.-take 0.05 mL of extract; 6.- dilute with 0.95 mL 0.05% of AF in MeOH:H2O 1.1; 7.- filter

ACQUITY BEH C18 100 x 2.1 mm, 1.7 μm at 35°C

Inj vol 5 μL, A) H2O (0.1% FA), B) MeOH

65-80% B in 3 min, hold for 1 min, 100% B in 1 min, initial condition for 2 min

Flow 0.3 mL/min, Time: tan= 5 min, tTot= 7 min

QQQ

CaV: 3kV; DGT: 400 °C; ST: 150 °C; CGF: 15 L/h; DGF:750 L/h

LOD: (B1: 0.43-1.98, FB2 0.19-1.37, HB1 0.72-1.39, HB2 0.36-0.70) μg/Kg

LOQ: (B1:1.43-6.59, FB2 0.60-4.60, HB12.40-4.60, HB2 1.20-2.30) μg/Kg

(Lin et al. 2011)

B1, B2

Corn5

Extraction: 1.- Add 25 mL MeOH/H2O 3:1; 2.-Ultrasonic bath for 10 min at RT, output powder 120 W; 3.- Centrifugate to 5000 g, 5 min; 4.- Filter (0.22 mm nylon filter)

Zorbax Eclipse XDB-C18, 150 x 2.1 mm, 3.5 µm at 30°C

Inj vol 10 µL, MeOH/H2O/FA 75:25:0.2

Flow: 0.20 mL/min, Time tan= tTot = 4 min

Q

CaV 3.5 kV; CoV 50 V; ST 120 °C; DGT 350°C; DGF 600 L/h

LOD: 3.5 B1, 2.5 µg/kg B2

LOQ: 11.7 B1, 8.3 µg/kg B2

(A. S. Silva et al. 2019)

B1, B2

Maize flour2

Extraction: 1.- Add 10 mL ACN 80%; 2.- Shake at 110 rpm, 1h; 3.- Centrifuge to 3000 rpm, 10 min; 4.- Remove supernatant; 5.- Re-extract the solid, same way; 6.- Centrifuge to 3000 rpm, 10 min; 7.- Dilute 1:1 with H2O; 8.- Filter

Zorbax Eclipse Plus C18, 2.1 x 50 mm, 1.8 µm at 30 °C

Inj vol 20 µL, A) 0.1% FA, B) ACN

10-70% B in 12 min, 70-90% B in 1 min, keep 1 min, 90-10% B in 1 min, initial conditions for 2 min

Flow: 0.5 mL/min, Time: tan=14 min, tTot=17 min

TOF

CaV 5.5 KV; ST 575 °C; CUR 30 psi; Gas 1 and Gas 2, 55 psi both; DP 100 V; Full scan 100-750 Da

LOD: 62.5 µg/kg,LOQ: 125 µg/kg all FBs

Other cereal and seeds

(Bartók et al. 2006)

B1, B2, B3, its analogs

Rice3

Extraction: 1.- Add 25 mL of ACN/H2O 75:25; 2.- Centrifuge to 13,500 rpm, 1 min; 3.- Shake 1 h; 4.- Centrifuge to 10,000 g, 10 min; 5.- Filter

Supelcosil ABZ Plus, 250 x 2.1 mm, 5 µm at 40 °C

Inj vol 1 µL, A) H2O, B) ACN, both with 0.1% FA

25-40 % B in 22 min, 40-100% B in 5 min, keep for 3 min.

Flow: 0.3 mL/min, Time: tan=27 min, tTot=30 min

QTrap

CaV 3.5 kV; EV 200 V; HED Voltage 7 kV; NG 40 psi; DGF 9 L/min; DGT 350 °C; trap drive 53.9; max accumulation time 300 ms; full scan 50-1100 m/z

LOD / LOQ: NR

(Soleimany, Jinap, and Abas 2012)

B1, B2

Cereals10

Extraction: 1.- Add 40 mL H2O/ACN/AcOH 20:79:1; 2.- Shake 60 min; 3.- Centrifuge the supernatant at 3000 rpm, 10 min; 4.- Dilute 1:1 in H2O/ACN/AcOH 79:20:1; 5.- Filter

Thermo Scientific C18, 150 x 4.6 mm, 3 µm at 30°C

Inj vol 20 µL; A) H2O, B) MeOH both with 0.1% AcOH

5% B for 8 min, 5-90% B in 14 min; 90-5% B in 3 min

Flow: 0.25 mL/min, Time: tan=22 min, tTot=25 min

QQQ

CaV 3 kV; ST 120°C; DGT 400 °C; spray gas N2

LOD: 20 ng/g, LOQ: 40 ng/g

(Rausch, Brockmeyer, and Schwerdtle 2020)

B1, B2, B3 and other toxins

Cereals1

QuEChERS: 1.- Add 2 mL H2O, 2.-mix 1 min, RT, 10 min; 3.- extract with 8 mL ACN/FA 75:5; 4.- Shake 15 min; 5.- add 4 g anhydrous MgSO4, 1 g NaCl, 1 g Na2HCit 1.5 H2O, Na3Cit 2 H2O, 6.- Mix 1 min; 7.- Shake 15 min; 7.- Centrifuge to 2140 g, 2 min; 8.- Filter; 9.- Take 500 µL, dry; 10.- Redissolved in 250 µL MeOH/H2O 20:80

Raptor Fluoro Phenyl 50 x 2.1 mm, 2.7 µm in series with

Raptor Biphenyl 50 x 2.1 mm, 2.7μm at 30 °C

Inj vol 10 µL, H2O, 0.3% FA, B) MeOH, both with 5 mM AmFo

20% B for 0.6 min, 20-40 % B in 0.4 min, 40-90% in 8 min, keep 1 min, initial conditions for 3.5 min

Flow: 0.4 mL/min

Time: tan=10 min, tTot=13.5 min

QQQ

CaV 4.5 kV; ST 500 °C; CUR 40 psi; ISG 1 60 psi; ISG 2 65 psi

LOQ: depending on the matrix, FBs 4-15 µg/kg

(Aurelien Desmarchelier et al. 2010)

B1, B2 and other mycotoxins

Cereals5

QuEChERS: 1.- Add 10 mL H2O + 10 mL 0.5% AcOH in ACN; 2.- Shake at 300 rpm, 5 min; 3.- Add 5 g MgSO4/NaCl 4:1, 4.- Shake; 5.- Centrifuge to 4000 g, 15 min, RT; 6.- Take 5 mL; 7.- Shake at 200 rpm, 5 min; 8.- Centrifuge to 4000 g, 1 min; 9.- Dry 1 mL at 40 °C (N2); 10.- Add 75 µL MeOH; 11.- Sonicate; 12.- Add 75 µL H2O, mix; 13.- Centrifuge to 8500 g, 10 min, RT; 14.- Dilute 60 µL with 140 µL H2O; 15.- Centrifugate to 8500 g, 10 min, RT

Zorbax Bonus-RP, 150 x 2.1 mm, 3.5 µm

Inj vol NR, A) H2O 0.15% FA, 10 mM AmFo, B) MeOH 0.05% FA

15% B 0.5 min, 15-100% B 8.5 min, keep for 6 min, 15% B in 1 min, initial conditions for 9.5 min

Flow: 0.25 mL/min, Time: tan=15 min, tTot=25.5 min

QTrap SRM

ST 550 °C; NG 50 psi; CUR 40 psi; TG 30 psi; CoG 1.2 x 10-4 psi

LOQ: 50 µg/kg all FBs

(Liao et al. 2013)

B1, B2 and other toxins

Finished grain, nut products1

Extraction: 1.-Add 5 mL H2O/ACN 15:85; 2.-shake to 1550 rpm, 30 min; 3.-centrifugate to 4500 rpm, 5 min; 4.-take 500 µL; 5.-add 20 µL of 13C-34 FB1 (25 µg/mL) + 480 µL 20 mM FA; 6.-vortex 15 s; 7.-filter

Ultra-Aqueous C18, 100 x 2.1 mm, 3 μm, at 40 °C

Inj vol 10 µL, A) H2O, B) MeOH, both with 0.1% FA+ 10 mM AmFo

10 % B for 1 min, 10-100% B in 6 min, keep for 3 min, initial conditions for 5 min

Flow: 0.5 mL/min, Time: tan=10 min, tTot=15 min

QTrap

Conditions NR

LOD: FBs 2.2-2.9 µg/kg, LOQ: FBs 7.3-9.6 µg/kg, depending on the matrix

(Bartók et al. 2010)

Isomers of B1

Rice1

Extraction: 1.-8 mL MeOH/H2O 75:25; 2.-homogenize 9,500 rpm, 4 min: 3.-centrifuge to 10,000 rpm, 10 min, 4.-filter

YMC-Pack J’sphere ODS H80, 250 x 2.1 mm, 4 µm, 40 °C

Inj vol 1 µL, A) H2O, B) ACN, both with 0.1% FA

24-40% B for 79 min, 40-100 % B for 15 min, keep for 10 min

Flow: 0.20 mL/min, Time: tan=79 min, tTot=104 min

TOF, full scan MS

CaV 3.5 kV; Fragmentor 170 V; skimmer 70 V; DGT 350 °C; DGF 10 mL/min; NG 20 psi; full scan 100-1700; acquisition rate 250 ms/spectrum

LOD/LOQ: NR

(Oueslati et al. 2012)

B1, B2

Cereals, derived products5

Extraction: 1.- Add 10 mL ACN/H2O 80:20; 2.-vortex 2 min, shake 60 rpm x 10 min; 3.-centrifuge to 5000 rpm, 5 min; 4.-filter 2 mL (0.20 μm, Millipore)

Acquity UPLC BEH C18, 100x2.1 mm, 1.7 µm at 30°C

Inj vol 5 µL, A) H2O with 5 mM AmFo, B) MeOH

25-75% B in 3 min, 75-100% B in 2 min, keep for 1.5 min, 100-25% B in 1 min; initial conditions for 1 min

Flow: 0.35 mL/min, Time: tan=6.5 min, tTot=8.5 min

QQQ

CaV 3.5 kV; CoV FB1 45 V, FB2 55 V; EV 3 V; ST 120 °C; DGT 350 °C; CGF 50 L/h; DGF 650 L/h

LOD: B1 and B2 1 µg/kg

LOQ: B1 and B2 5 µg/kg

(Rausch, Brockmeyer, and Schwerdtle 2021)

B1, B2, B3, HB1, HB2, HB3

Cereals2.5

Extraction: 1.- Add ACN:H2O:FA 79.20:1; shake for 15 min at RT; 3.- Add 20 µL of Deuterated internal standard; 4.- rotary agitation for 30 min; 5.- centrifuge at 1902 g, 6.- take an aliquot of supernatant, 7.- filter

First dimension: YMC-Pack Diol-NP C18 100 × 2.1 mm, 5 μm at 40 °C.

Vol. inj: 10 μL of sample, A) H2O, B) ACN:H2O 90:10 Both (0.1% FA, 10 mM AmFo)

100% B in 2.5 min, 100-90% B in 0.5 min, 90-20 % B in 0.8 min, hold for 3.8 min, 20-100% B in 0.20 min. initial condition for 17.20 min.

Second dimension: 2 columns connected in series Raptor FluoroPhenyl, 50 × 2.1 mm, 2.7 μm and Raptor Biphenyl 50 × 2.1 mm, 2.7 μm,

5% B for 1.2 min, 5-0% B in 0.10 min, hold for 7.15 min, 0-5% B in 0.05 min, 5-50% B in 1.1 min, 50-70% B in 4.4 min, 70-85% B in 2.5 min, 85-100% B in 3 min, hold for 2 min, 100-5% B in 0.10 min, initial condition for 4 min

Flow 0.2 mL/ min, 0.3 ml/min, Time: tan = 7.6 min tTot = 25 min, Time: tan = 15.50 min tTot = 25 min

QQQ

CaV: 4.5 kV; CUR: 40 psi; ST: 500 °C;

LOQ: (B1-3: 10, HB1-3: 100) μg/Kg

Other samples

(Škrbić, Živančev, and Godula 2014)

B1, B2 and other toxins

Crude extracts of nuts10

Extraction: 1.- Add 40 mL ACN/H2O/AcOH 79:20:1; 2.- Shake 1h; 3.- Filter; 4.- Take 20 mL; 5.- Add 20 mL hexane; 6.- Mix 2 min; 7.- Centrifuge to 5000 rpm, 5 min; 8.- Eliminate hexane phase. 9.- Filter aqueous phase

Hypersil GOLD C18, 50 x 2.1 mm, 1.9 µm at 25 °C

Inj vol 10 µL, A) H2O, B) MeOH, both with 1% AcOH and 5 mM AmAc

5 % B for 0.5 min, 5-95 % B in 2.5 min, keep 2 min, 95-5% B in 1.2 min, initial conditions for 1.8 min

Flow: 0.50 mL/min, Time: tan=6 min, tTot=8 min

QQQ

CaV 3.4 kV; ST 350 °C; SG 40 arbitrary units; aux gas 10 arbitrary units; CaT 270 °C

LOD: 0.24 B1, 0.05 B2 µg/kg

LOQ: 0.8 B1, 0.17 B2 µg/kg

(Yibadatihan, Jinap, and Mahyudin 2014)

B1, B2 and other toxins

Palm kernel cake5

Extraction: 1.- Add 20 ml H2O/ACN/FA 20:79:1; 2.- Shake 60 min; 3.- Centrifuge supernatant to 3000 rpm, 10 min; 4.-Dilute 1:4 with water; 5.-Filter

Symmetry C18, 150 x 2.0 mm, 3μm, 30 °C

Inj vol. 25 µL, A) H2O, 0.2% FA, B) MeOH

10% B for 8 min, 10-90 % B in 2 min, keep 7 min, from 90-10% B in 3 min, initial conditions for 5 min

Flow: 0.20 mL/min, Time: tan=17 min, tTot= 25 min

QQQ

CaV 3 kV; ST 120 °C; DGT 350 °C

LOD both: Std 5.6 µg/kg LOQ both: Std 18 µg/kg

LOD both: Samples 17.5 µg/kg LOQ both: samples 58 µg/kg

(Qian et al. 2018)

B1, B2 and other toxins

Feed2

QuEChERS: 1.- Add 1.5 g NaCl + 10 mL 3% AcOH in ACN/H2O 80:20; 2.-Vortex 1 min, 3.-Ultrasound 20 min; 4.-Add 2 g anh MgSO4; 5.-Vortex 1 min; 6.-Centrifuge to 8000 rpm, 5 min; 7.-Dry (N2, 40 °C); 8.-Dissolve in MeOH:H2O 1:1; 9.-Filter

ACQUITY UPLC HSS T3, 100 x 2.1 mm, 1.8 µm at 40°C

Inj vol. 5 µL, A) H2O, 0.1% FA, 1 mM AmAc; B) MeOH}

0-10% B in 1 min, 10-20% B in 2 min, 20-99% B in 8 min, keep 2.5 min; 99-10% B in 0.1 min; initial conditions for 5 min

Flow: 0.3 mL/min, Time: tan=13.5 min, tTot= 18.5 minQQQ

CaV 5.5 kV; ST 550°C; Auxiliary gas 40 psi

LOQ: 0.4 µg/kg for both B1 y B2

(Spanjer, Rensen, and Scholten 2008)

B1, B2, B3 and other toxins

Peanut, pistachio, wheat, maize, cornflakes, raisins, figs25

Extraction: 1.- Add 100 mL ACN/H2O 80:20, 2.- Shake 2h; 3.-Dilute 1:4 with H2O; 4.- Filter if necessary

(For raisins and figs use MeOH)

Alltima C18, 150 x 3.2 mm, 5 µm at 30 °C

Inj vol 20 µL, A) H2O, B) ACN, both with 0.1% FA10-70% B in 12 min (curve 1), keep 4 min, 70-90 % B in 1.5 min (curve 6), keep 2.5 min, 90-10 % B in 1 min (curve 1)

, initial conditions for 5 min

Flow: 0.3 mL/min, Time: tan=20 min, tTot=25 min

QQQ

CaV 2.5 kV; CoV 75 V; DGT 450°C; CGF 100 L/h (N2); DGF 600 L/h

LOQ: depending on the matrix, B1 5-100 µg/kg, B2 1-100 µg/kg

(Aurélien Desmarchelier et al. 2014)

B1, B2 and other toxins

Cereals, cocoa, oil, spices, infant formula, coffee, nuts25

Extraction: 1.- Add 50 mL H2O, 2.- Homogenize 1 min 10000 rpm, 3.-Take 5 g of sample (peanut, green cofee, cocoa, paprika) or 2 g (infant formula, sunflower oil), 4.-Add 100 µL of 13C-FB standard (FB1 and FB2 each 10 µg/mL), 5.-Add 10 mL H2O and 10 mL ACN, 0.5% AcOH, 6.- Add 5 g MgSO4:NaCl 4:1 Centrifuge 4000g, 15 min, 7.-Defat 5 mL ACN phase with 5 ml hexane. 8.- Take 1 mL of ACN phase, dry, 9.-Reconstitute in 150 µL H2O/MeOH 1:1, 10.-Centrifuge 8500 g, 10 min, 11.-Take 60 µL, add 140 µL H2O, 12.-Centrifuge 8500 g, 10 min

Zorbax Bonus-RP C18, 150 x 2.1 mm, 3.5 µm at 50 °C

Inj vol 20 µL, A) H2O, 0.15% FA, 10 mM AmFo, B) MeOH, 0.05% FA

15% B for 0.5 min, 15-100 % B in 6 min, keep for 4.5 min, 100-15% B in 0.5 min, initial conditions for 7.5 min

Flow: 0.35 mL/min, Time: tan=11 min, tTot= 19 min

QTrap, QQQ

ST 550 °C; CUR 40 psi, Nebulizer 50 psi; Turbo gas 30 psi

LOD/LOQ: NR

(Shar et al. 2020)

B1, B2 and other toxins

Feed, its ingredients5

Extraction: 1.- Add ACN/H2O/FA 79:20:1; 2.- Shake for 90 min to 180 rotations/s; 3.-Centrifuge to 4000 rpm, 2 min, 4.-Filter

Acquity C18, 100 x 2.1 mm, 1.8 µm, 40 °C

Inj vol 20 µL, A) H2O, 1% FA, B) MeOH/H2O/FA, 97:2:1, both with 10 mM AmFo.

0% B for 2 min, 0-50% B in 0.5 min, 50-100% B in 3.5 min, keep 1 min, initial conditions in 1 min, seal wash for 5 min

Flow: 0.5 mL/min, Time: tan=7 min, tTot= 8 min

sQ

CaV 2.79 kV; ST 150 °C; DGT 350 °C; CGF 50 L/h; CGF 600 L7h

LOD B1: 0.07 µg/kg,LOQ B1: 0.22 µg/kg

LOD B2: 0.03 µg/kg,LOQ B2: 0.08 µg/kg

(Frenich et al. 2009)

B1, B2

Maize, walnut, breakfast cereal, biscuit5

Extraction: 1.- Add 10 mL ACN/H2O 80:20 (for biscuit add 20 mL); 2.- Vortex 2 min; 3.- Shake to 60 rpm, 10 min; 4.- Centrifuge to 4500g, 5 min; 5.- Take and filter 2 mL

Acquity C18, 100 x 2.1 mm, 1.7 μm at 30°C

Inj vol 5 µL, A) H2O with AmFo 5 mM, B) MeOH

25-75% B in 3 min, 75-100% B in 2 min, keep for 1.5 min, 100- 25% B in 1 min; initial conditions for 1 min

Flow: 0.35 mL/min, Time: tan=6.5 min, tTot=8.5 min

sQ

CaV 3.5 kV; EV 3 V; ST 120°C; DGT 350°C; CGF 50 L/h; DGF 650 L/h (N2 for both)

LOD maize: B1 0.1 µg/kg, B2 0.2 µg/kg,LOQ maize: B1 0.5 µg/kg, B2 0.6 µg/kg; LOD breakfast cereal: B1 2.1 µg/kg, B2 0.7 µg/kg LOQ breakfast cereal: B1 6.2 µg/kg, B2 2.5 µg/kg

Beverages

(Rubert et al. 2011)

B1, B2, B3 and other toxins

Beer10 mL

Extraction: 1.- Sonicate 25 min, 2.-Condition SPE Oasis HLB cartridges with 5 mL ACN/MeOH 1:1; 3.- 5 mL H2O; 4.- 10 mL sample into cartridge; 5.-Wash with 5 mL H2O; 6.- Dry 30 min; 7.- Eluate with 4mL ACN:MeOH 1:1; 8.- Dry (N2, 35 °C), 9.- Reconstitute in 1 mL (ACN/MeOH 1:1); 10.-Filter

Gemini C18, 150 x 2.0 mm, 5 µm, at 35 °C

Inj vol 10 µL, A) H2O, 0.1% FA, B) MeOH, both with 5 mM AmFo

5-95% B in 10 min, 95-80% B in 5 min, initial conditions 5 min

Flow: 0.2 mL/min, Time: tan=10 min, tTot= 20 min

QQQ Orbitrap XL

CaV 30 V; SV 4 kV; Source Temp 275 °C; Capillary gas sheat 35 units; auxiliary gas 30 arbitrary units

LOD: 30-35 µg/L, LOQ: 90-105 µg/L all Fbs depending of the beer type

(Huang et al. 2018)

B1, B2 and other toxins

Liquorice2

QuEChERS: 1.-Add 100 µL of D-atrazine (60 µg/L), 15 mL acetate buffer pH 3.0, 10 mL 5% FA in ACN; 2.- Shake; 3.- Extract with ultrasonic (53 KHz, 5 min, 20°C); 4.- Add 4 g MgSO4 + 1 g NaCl + 0.5 g Na2HCit·1.5H2O, 1 g Na3Cit·2H2O; 5.- Shake to 1500 strokes/min, 5 min; 6.- Ice bath 10 min, 7.-Centrifuge to 18514 g, 10 min; 8.- Take 6.0 mL; 9.- Transfer supernatant into 15 mL centrifugation tube containing 900 mg MgSO4, 600 mg C18, 150 mg PSA, 150 mg Si; 10.- Shake 5 min, 11.- Centrifuge 10 min; 12.- Take 2 mL, reduce volume <0.5 mL with N2; 13.- Complete to 1 mL with H2O/MeOH 80:20; 14.-filter

Poroshell EC-C18, 150 x 3 mm, 2.7 µm at 20°C

Inj vol 5 µL, A) H2O, B) MeOH, 0.2% FA and 2 mM AmF

20% B for 2 min, 20-50% B in 2 min, 50-100% B in 7 min, keep 1 min, 100-20% B in 1 min, initial conditions for 2 min

Flow: 0.45 mL/min, Time: tan=12 min, tTot= 15 min

QQQ

CaV 5.5 kV; DP 150 eV; EP 10 eV; CUR 30 psi; GS1: 50 psi, turbo gas (gas 2) 50 psi, GT: 450°C

LOD: B1, B2, 0.05 µg/kg

LOQ: B1. B2, 0.125 µg/kg

(Tamura et al. 2012)

B1, B2, B3 and other toxins

Wine5 mL

Extraction: 1.-Add 25 mL AmAc 10 mM, mix, 2.-wash in Oasis HLB SPE Cartridge conditioned with 5 mL AmAc 10 mM, 3.-elute with 5 mL AmAc 10 mM/ACN 1:1, 4.-elute 5 mL ACN, mix, dry N2 40°C, 5.-dissolve in 1mL H2O, 6.-60 µL FA + 5 mL ACN, mix, 7.-apply to multistep #229 Ochra cartridge. 8.-Dry 4 mL of eluate with N2 40°C, 9.-dissolve in 500 µL AmAc 10 mM/ACN 85:15, 10.-filter

Acquity UPLC BEH C18, 100 x 2.1 mm, 1.7 µm at 40°C

Inj vol 5 µL, A) H2O; B) MeOH, with 2% AcOH, 0.1 mM AmAc

55-80% B in 5 min, initial conditions for 2 min

Flow: 0.3 mL/min, Time: tan=5 min, tTot= 7 min

QQQ

CaV 3 kV; ST 120°C; DGT 450 °C; CGF 50 L/h; DGF 800 L/h

LOD: 0.30 µg/L, LOQ: 1 µg/L all Fbs

(Miró-Abella et al. 2017)

B1, B2 and other toxins

Plant-based beverages10 mL

Extraction: 1.- Add 10 mL 1% FA in ACN in a 50 mL centrifuge tube, 2.- Shake 3 min; 3.- Add 4 g MgSO4 + 1 g NaCl; 4.- Shake vigorously 3 min; 5.- Centrifuge to 10000 rpm, 5 min, 20°C, 6.-dilute 1:1 with phase A 7.-filter

Cortecs UHPLC C18, 100 x 2.1 mm, 1.6 μm at 40°C

Inj vol 5 µL, A) H2O, B) MeOH, both with 0.1% AcOH, 5 mM AmAc

10-50% B in 4.5 min, 50-95% in 7.5 min, keep 2.5 min

Flow: 0.45 mL/min, Time: tan= 14.5 min, tTot= NR

QQQ

CaV 4 kV; DGF 18 L/min; DGT 160°C; nebulizer 35 psi; nozzle voltage 0.5 kV; Frag Vol 380 V

LOD: 0.80; LOQ: 2.68 µg/kg all Fbs

(B. Zhang et al. 2018)

B1 and other toxins

Grapes, wines5

Extraction: 1.- Add 5 mL distilled H2O, 10 mL 1% AcOH in ACN; 2.- Shake to 3000 rpm; 3.- Add 1 g NaCl + 4 g MgSO4, 4.- Centrifuge to 13000 rpm, 5 min, 10 °C; 5.- Transfer into 10 mL polypropylene tube containing 450 mg MgSO4; 6.- Shake 30 s; 7.-Centrifuge to 5000 rpm, 5 min, 10 °C

ZORBAX RRHD Eclipse Plus C18, 50 x 2.1 mm, 1.8 µm at 30°C,

Inj vol 2 µL, A) H2O, B) ACN, both with 0.1% FA

10-42% B in 2.4 min, 42-51% B in 3.6 min, 51-95% B in 0.2 min, 95-10% B for 0.8 min, initial conditions for 5 min

Flow: 0.3 mL/min, Time: tan=6.2 min, tTot= 12 min

QQQ

CaV 4 kV; DG temperature 350 °C; DG flow 10 L/min; Nebulizer 40 psi

LOD: 1 µg/L, LOQ: 3 µg/L

(Pizzutti et al. 2014)

B1, B2, B3 and other toxins

Wines5

Extraction: 1.- Add 5 mL H2O, 10 mL 1% AcOH in ACN, 25 µg/mL of: FB1 (ACN/H2O 1:2), FB2 (CAN/H2O 1:3), and FB3 (ACN); 2.-Mix to 300 rpm, 1 min; 3.- Add 3 g anh. MgSO4; 4.- Shake 1 min; 5.- Centrifuge 13000 rpm, 5 min, 6.-Take 3 mL of superior phase; 6.- Mix with 450 mg anh. MgSO4; 7.- Mix 10 s, centrifuge 4000 rpm, 4 min, 10 °C; 8.- Filter and dilute 1:1 with MeOH

Acquity UPLC BEH C18, 100 x 2.1 mm, 1.7 µm, 50 °C

Inj vol 5 µL A) H2O, B) ACN, both with 0.1% FA

10-70% B in 10 min, 90 % B for 2 min, initial conditions for 1 min

Flow: 0.4 mL/min, Time: tan=12 min, tTot= 13 min

QQQ

CaV 2 kV; ST 120 °C; DGT 400 °C; DGF 100 L/h; CGF 700 L/h

LOQ: 50 µg/kg all Fbs

(Pérez-Ortega et al. 2012)

B1 and other toxins

Wine4 mL

Extraction: Oasis HLB, Bond Elut Plexa 1.- SPE cartridges preconditioned with 4 mL MeOH, 2.- 4 mL H2O at 2 mL/min; 3.- Add sample into cartridge; 4.- Elute with MeOH/H2O 5:95; 5.- Dry in vacuum 1 min; 6.- Elute twice/4 mL MeOH, 1 mL/min; 6.- Evaporate (N2, 37°C); 7.-Reconstitute (1 mL MeOH:H2O 2:8); 8.- Filter

Zorbax Eclipse XDB-C18, 50 x 4.6 mm, 1.8 µm, temp NR

Inj vol 20 µL, A) H2O, 0.1% FA; B) ACN

10 % B for 2 min, 10-50% B in 3 min, 50-100% B in 10 min, keep 3 min

Flow: 0.5 mL/min, Time: tan=18 min, tTot= NR

TOF

CaV 4kV; NGP 40 psi; DGF 9 L/min; DGT 325 °C; Frag Vol 190 V; range 50 -1000

LOD: 0.8 µg/L, LOQ: 2.68 µg/L

Samples of animal origin

(Cao et al. 2018)

B1, B2

Urine, plasma200 µL urine

200 µL

plasma

Extraction: 1.- Add 50 µL β-glucuronidase + 20 µL SI (13C34-FB1 1 mg/mL); 2.-incubate 37 °C overnight; 3.-centrifuge to 10000 rpm, 5 min; 4.-take supernatant, add 730 µL H2O/ACN 90:10; 5.-filter1.- Add 50 µL β-glucuronidase + 20 µL SI

(13C34-FB1 1 mg/mL); 2.-incubate 27°C overnight; 3.-add 1mL ACN:AcOH 99:1; 4.-vortex 30 s; 5.-centrifuge to 5000 rpm, 10 min; 6.-dry at 45°C; 7.-reconstitute in 200 µL of H2O:ACN 9:1; 8.-mix 30 s; 9.-filter

Kinetex C18, 100 x 2.1 mm, 2.6 µm, 40°C

Inj vol 10 µL A) H2O, 0.2 mmol/L AcOH; B) MeOH

25% B for 1 min, 25-70% B in 2 min, 70-25% B in 0.5 min, initial conditions for 1.5 min

Flow: 0.2 mL/min, Time: tan=3 min, tTot= 5 min

QQQ, TISP

CUR 20 psi; CoG (CAD) 8 psi; GS1 20 psi; GS2 15 psi; GT 600℃; EP 10.0; CP 12.0

LOD B1: urine 0.12 µg/L, LOQ B1: urine 0.45 µg/L

LOD B1: plasma 0.19 µg/L, LOQ B1: plasma 0.39 µg/L

(Devreese et al. 2012)

B1 and other toxins

Pig plasma250 µL

Extraction: 1.- Add 12.5 µL 13C-34 FB1 (25 µg/mL in ACN) + 750 µL ACN (deproteinization); 2.-vortex 15 s; 3.-centrifuge to 8517 g, 10 min, 4°C; 4.-evaporate supernatant (N2, 45 °C); 5.-reconstitute with 200 µL H2O/MeOH 85:15; 6.-vortex 15 s, 7.-filter

Hypersil Gold C18, 50 x 2.1 mm, 1.9 μm at 45 °C

Inj vol 2.5-10 µL, A) H2O with 0.1% AcOH, B) MeOH

35 % B for 1.5 min, 90 % B in 0.5 min, keep 1.5 min, 90-35 % B in 0.2 min, initial conditions 2.3 min

Flow:0.30 mL/min, Time: tan=3.5 min, tTot= 6 min

QQQ

CaV 4 kV, ST 300 °C; Aux gas 18 au; ISGP 4 au; SGP 23 au; VT 300 °C;

LOD: 0.8 µg/L, LOQ: 1 µg/L

(Arroyo-Manzanares, García-Campaña, and Gámiz-Gracia 2013)

B1, B2

Milk thistle Silybum marianum

2

QuEChERS: 1.- Add 8 mL of 30 mM NaH2PO4 (pH 7.1); 2.-vortex 10 s; 3.-add 5 mL ACN with 5% FA; 4.- shake 2 min; 5.-sdd 4 g MgSO4 + 1 g NaCl + 1 g NaCit + 0.5 g Na2HCit 1.5 H2O; 6.- shake 1 min; 7.-centrifuge to 4500 rpm, 5min); 8.-take 1 mL; 9.- dry; 10.-reconstitute with 1 mL MeOH/H2O 1:1; 11.-filter

Zorbax Eclipse C18, 50 x 2.1 mm, 1.8 μm at 35 °C

Inj vol 5 µL, A) H2O, B) MeOH, both with 0.3% FA, 5 mM AmFo

5-50% B in 1 min, 50-72 % B for 2 min, 72-80 % B for 2 min, 80-90 %B for 2 min, 90-5% B in 0.2 min

Flow: 0.4 mL/min, Time: tan=7.2 min

QQQ

ST 500 °C; CUR 30 psi; ISV 5 kV; gas 1 and gas 2 50 psi

LOD: B1 3.9 µg/kg,13.7 µg/kg

LOQ: B1 13.5 µg/kg, B2 45.7 µg/kg

(S. Zhang et al. 2022)

B1, B2, B3

Broiler Chicken Feed and Excreta5

Extraction: 1.- Add 20 mL of ACN:H2O; 2.- shake for 30 min; 3.- ultrasonic for 30 min; 4.- take 50 μL; 5.- centrifuge at 8000 rpm for 15 min; 6.- add 950 μL of H2O and vortex; 7.- take 50 μL; 8.- add 10 μL of IS 13C-FBs; 9.- dilute with 850 μL of in MeOH:H2O 1:9 (0.2 % -FA)

CORTEX C18 10 x 4.6 mm, 5 μm at 40 °C

Vol. Inj NR, A) H2O B) MeOH both with 0.2 % -FA 10-90%B in 6 min; hold for 2 min; initial condition for 2 min

Flow 0.4 mL/min, Time: tan= 8 min tTot= 10 min

QQQ

CaV 2.5 kV; CoG: 0.15 mL/ min, DGT 500 °C; DGF: 800 L/h;

LOD: 50 μg/Kg all Fbs LOQ 160 μg/Kg all Fbs

(Weiying et al. 2022)

B1, B2

Milk1

Extraction: 1.- Add IS (13C34-FB1 117 (13C34-FB1), 13C34-fumonisin B2 (13C34-FB2) mixed internal standard (25 μg/mL); 2.- add 5 mL of ACN:H2O (2% FA); 3.- vortex for 10 min; 3.- Centrifuge at 3900 rpm for 3 min; 4.- evaporate to dryness at 40 °C under N2; 5.- redissolved in 5 mL of H2O; 6.- Add 6 mg of DSPME MIL-101 (Cr); 7.-ultrasonic for 10 min; 8.- centrifuge at 1200 rpm for 5 min; 9.- filter

Shimadzu C18 100 × 2.1mm, 1.8 μ m at 40 °C

Vol. Inj. 3 μL of sample, A) H2O (1% FA), B) CAN 5% B for 1 min

5 -90 %B in 3.5 min; hold for 2.5 min; initial condition in 0.1 min; hold for 1.9 min

Flow 0.4 mL/min, Time: tan= 8 min tTot= 10 min

Qtrap

CaV: 5.5 kV; CoG: 35 psi; CUR: 35 psi; GS2: 45 psi

LOD: 1.5 μg/Kg all Fbs LOQ 5 μg/Kg all Fbs

(Flores-Flores and González-Peñas 2018)

B1 B2, B3

Milk1 mL

Extraction LLE: 1.- Add 4 mL 2 % FA in ACN, 2.-shake 15 min; 3.-centrifuge 5000 rpm, 10 min, 4.-take 4 mL supernatant, 5.-add 60 mg NaOAc, 6.-shake 15 min, 7.- centrifuge 5000 rpm, 5 min, 8.-take 3.5 mL of ACN phase, dry at 65°C, 9.-reconstitute in 200 μL of mobile phase, 10.-filter

Ascentis Express C18, 150 x 2.1 mm, 2.7 μm, 45°C

Inj vol 20 µL, A) H2O, B) MeOH/H2O 95:5, both with 0.1% FA and 5 mM AmFo

5-28% B in 5 min, 28-45 in 5.5 min, 45-60% B in 0.5 min, 60-90% B in 5 min, keep for 1 min, initial conditions for 13 min

Flow: 0.4 mL/min, Time: 16 min

QQQ

CaV 4 kV; DGT (high-purity N2) 350°C; DGF 9 L/min; 275.8 Pa, dry gas 40 psi

LOD/LOQ: FB1 10 µg/L, FB2 2.5 µg/L, FB3 0.625 µg/L

(Song et al. 2013)

B1 and other toxins

Pig, human urine5 mL

Extraction: 1.- Add 10 mL MgSO4 (2 M) with EtOAc/FA 99:1, shake 15 min; 2.-centrifuge to 4000 g, 15 min; 3.-take aqueous phase, add 5 mL ACN/FA 99:1; 4.-repeat extraction; 5.-dry (N2, 60°C); 6.-reconstitute with 500 µL 1:1 A:B; 7.-filter; 8.-centrifuge to 10000 g, 5 min

Symmetry C18, 150 x 2.1 mm, 5 μm at RT

Inj vol 20 µL, A) H2O, B) MeOH, both with 0.3% FA, 5 mM AmFo

5% B for 1 min, 5-25% B in 4 min, 25-60%B in 2 min, 60-80% B in 8 min, 80-100 B in 1 min, keep 6 min, 100-5 % B in 3 min

Flow: 0.25 mL/min, Time: tan=22 min, tTot= 25 min

QQQ

CaV 3.2 kV; DGF 800 L/h; CGF 20 L/h; DGT 350 °C; ST 120 °C

LOD: 0.05 ng/mL, LOQ: 0.17 ng/mL

(K. Zhang et al. 2013)

B1, B2, B3 and other toxins

Milk based infant foods0.5

Extraction: 1.- Add 25 µL IS (13C34 FB1, 13C34 FB2, 13C34 FB3 500 ng/mL); 2.- Vortex 30 s; 3.- Add 5 mL ACN/H2O 1:1; 4.- Shake 10 min at 30-35 pulsations/min; 5.- Take an aliquot of 2 mL; 6.- Filter 2 mL; 7.-Centrifuge to 4500 rpm, 30 min

Phenomenex Kinetex XB-C18, 100 x 2.1 mm, 2.6 μm, 40°C

Inj vol 5 µL, A) H2O, B) MeOH, both with 0.1% FA, 10 mM AmFo

5-40% B lineal in 2 min, 40-100% exponential B in 7 min, keep 2.5 min, 100-5% B in 0.5 min, initial conditions for 3 min

Flow: 0.3 mL/min, Time: tan=11.5 min, tTot= 15 min

QQQ-IT

CaV 5.5 kV; CUR 30 psi; ST 450 °C; gas 1 and gas 2 60 psi

LOQ B1: 2 µg/kg all fbs

(Abia et al. 2013)

B1, B2 and other toxins

Urine1 mL

Extraction: 1.- Centrifuge to 5600 g, 3 min; 2.-take 100 µL 3.-add 900 µL H2O/ACN 9:1

Gemini 150 x 4.6 mm, 5 µm

Inj vol 5 µL, A) H2O, B) ACN, both with 0.1% AcOH

5 % B for 2 min, 5-30 % B in 8 min, 30-96 % B in 4 min, keep 1 min, initial conditions for 2.25 min

Flow: 0.6 mL/min, Time: tan=15 min, tTot= 17.25 min

QTrap

ST 650 °C, CUR 30 psi, SG 80 psi, DG 80 psi

LOD: B1 and B2 0.5 µg/L, LOQ: B1 and B2 1.7 µg/L

(Nualkaw et al. 2020)

B1, B2 and other toxins

Swine, Poultry, Dairy Feeds1

QuEChERS: 1.-Add 10 mL H2O 1% FA, 2.-soak 30

min; 4.-add 10 mL ACN: 5.-shake to 240 rpm, 30 min; 6.-add 1 g NaCl + 4 g MgSO4; 7.-shake 30 s: 8.-centrifuge to 10000 rpm, 5 min; 9.-take 2 mL; 10.-add 0.1 g silica C18 + 0.3 g MgSO4; 11.-mix; 12.-centrifugate 1 min; 13.-dry at 40 °C, 14.-reconstitute in 960 µL MeOH 20% + 40 µL (250 ng/mL 13C-34 FB1+50 ng/mL 13C-34 FB2); 15.-filter

Accucore C18, 100 x 2.1 mm, 2.6 µm, 25 °C

Inj vol 3 µL, A) deionized H2O, 0.1% FA, 5mM AmF; B) MeOH

0-20% B in 4 min, 20-40% B in 5.5 min; 40-100% B in 10.5 min, keep 2.5 min; initial conditions for 3 min

Flow: 0.4 mL/min, Time: tan=22.5 min, tTot= 25.5 min

Qtrap

Needle voltage 4.5 kV; CUR 30 psi; nebulizer (Gas1), turbo gas (Gas2) 55 psi; turbo gas temperature 500 °C

LOD: B1 15 µg/kg, B2 4.5 µg/kg; LOQ: B1 30 µg/kg, B2 9 ng/kg

(Osteresch et al. 2017)

B1 and other toxins

Blood or serum100 µL

Extraction LLE:

1.-Spott 4 times on filter paper; 2.-dry overnight at RT, 3.-Extract with 1 mL H2O/acetone/ACN 30:35:35 in 2 mL safe-lock tubes; 4.-Sonicate 30 min; 5.-Take 800 μL; 7.-Dry at 50°C under reduced pressure; 8.-Reconstitute with H2O/ACN/AcOH 95:5:0.1; 9.-Centrifuge to 22000 g, 10 min

Gravity SB C18, 100 x 2.0 mm, 3 µm at 45°C

Inj vol 30 μL, A) H2O, 0.1% AcOH, B) ACN, 2% AcOH

3-15% B in 3 min, 15-55% B in 1.5 min, keep for 1.5 min, 55-100% B in 2 min, keep 10 min, initial conditions 1.5 min

Flow: 0.75 (0-6), 0.85 (6.1-10), 0.75 (10.1-11.5)

mL/min, Time: tan=10 min, tTot= 11.5 min

QTrap

CaV 5.5 kV; ST 500 °C; DP 125 V; CUR 40 psi; GS1 45 psi; GS2 50 psi

LOD: 0.521 ng/L LOQ: 2.5 ng/mL

Ref

FBs

MatrixSample

(g)Sample treatment

Extraction procedureLC conditions

Column / Injection volume / Mobile Phase

Flow / Analysis TimeMS conditions

Mass Conditions / Limits

Maize and corn-based products

(Ren et al. 2011)

B1, B2, B3

Maize2.5

Extraction: 1.- Add 200 µL of IS (2.5 µg/mL 13C34- FB1, 1 µg/mL 13C34-FB2, 13C34-FB3); 2.- Add 10 mL ACN/H2O 1:1; 3.- Extract with ultrasonic 1h; 4.- Centrifuge to 15 000 rpm, 6 min; 5.- Adjust pH to 7-9 with NaOH; 6.- Take an aliquot of 3 mL; 7.-Dilute with MeOH/H2O (66.7:33.3)

Clean up: 1.- Load the dilute sample in MultiSep 211 FUM cartridge; 2.-Pass 8 mL of MeOH/H2O (66.7:33.3); 3.- Pass 10 mL of MeOH (1% AcOH), collect; 4.- Transfer 10 mL to a tube; 5.- Dry (N2, 50°C); 6.- Redissolve in 1 mL of MeOH:AmAc 10 mM/L (1:1); 7.- Shake 30s; 8.- Filter

BEH C18, 100 x 2.1 mm, 1.7 μm, 35°C

Inj vol 2 µL, A) H2O, 0.1% FA, B) ACN/MeOH 1:1

30-70% B in 2.3 min, 70% B for 1.7 min, 70-100% B in 0.2 min, keep for 0.6 min, 100-30% B in 0.2 min., re-equilibrate for 2 min

Flow: 0.3 mL/min, Time: tan=4.8min, tTot=7 min

QQQ

CaV 3.5 kV; CoV 45 V; ST: 120; CGF: 50L/h DGT 350°C; DGF 500 L/h

LOD:

(B1 0.45, FB2 0.50, B3 0.10) µg/kgLOQ:

(B1 1.50, FB2 1.65, B3 0.40) µg/kg

(L. Silva et al. 2009)

B1, B2 and other toxins

Corn-based products25

Extraction: 1.- Add 40 mL MeOH/H2O 80:20; 2.- Centrifuge to 2500 g, 15 min 3.- Extract the remaining solid with 30 mL MeOH/H2O 80:20; 4.- Filter

Clean up: 1.- Dilute 10 mL of filtrate with 40 mL of PBS; 2.- Take 20 mL 3.- Add to a FumoniTestTM immunoaffinity; 4.- Wash with 10 mL PBS; 5.- Eluted twice with 1.5 mL of MeOH; 6.- Evaporate (N2, 60 °C); 7.- Reconstitute in 50 μL MeOH/H2O (1:1)

Luna C18, 250 x 4.6 mm, 5 μm

Inj vol 10 µL, A) H2O, B) MeOH both with 0.5% FA

65% B for 4 min, 65-95% B in 4 min, keep 7 min

Flow: 0.50 mL/min, Time: tan=tTot=15 min

QQQ

CaV 4 kV, GT 350°C; DGF 13 L/min; NG 30 psi

LOD: 40 µg/kg, LOQ:110 µg/kg all Fbs

(Cavaliere et al. 2007)

B1, B2 and other toxins

Maize1

Extraction: 1.- 10 mL ACN/H2O 75:25; 2.- homogenize 15s; 3.- Transfer on cartridge (6 mL) with 100 mg of C18; 4.-Wash the extract with 7 mL of ACN/H2O 75:25, twice; 5.- Collect 25 mL; 6.- Take 5 mL; 7.- Dilute with 500 mL of H2O.

Clean up: 1.- Load sample dilute on SPE-Carbograph-4 (500 mg); 2.- Wash with 10 mL of H2O; 3.- Pass 0.3 mL of MeOH; 4.- Elute with 1 mL MeOH and 8 mL of DCM:MeOH 8:2 (50 mM of FA); 5.- Evaporate to 100 µL; 6.- Add IS (FB1, FB2 in MeOH/H2O 1:1 (1 mg/mL); 7.- Evaporate to 100 µL; 8.- Dilute with 100 µL of LC mobile phase

Alltima C18, 250 x 2.1 mm, 5 µm, 45 °C

Inj vol 20 µL, A) H2O, B) MeOH, both containing 25 mmol/L FA, adjusted to pH 3.8 with ammonia

60% B for 3 min, 60-90% B in 5 min, 100% for 10 min

Flow: 0.2 mL/min, Time: tan= tTot=18 min

QQQ

CoV 5.5 kV; CUR 35; GS1 35; GS2 40; GT 350 °C

LOD/LOQ: 10 mg/kb for FB1 and 5ng/kg FB2

(Lattanzio et al. 2007)

B1, B2 and other toxins

Maize10

Extraction: 1.- Add 50 mL de PBS; 2.- Shake 60 min; 3.- Centrifuged to 3000 g, 10 min; 4.- filtrate 35 mL of PBS (extract A); 5.- Add 35 mL of MeOH, to the remain solid, containing 15 mLPBS; 6.- extract again 7.- Shake 60 min; 7.- Centrifuge to 3000 g, 10 min; 8.- Dilute 10 mL of extract with 90 PBS (extract B); 9.- Filter

Clean up:

1.-Load 50 mL of extract B to the IAC; 2.- Wash with 20 mL of PBS; 3.- Add 5 mL of extract A; 4.- Wash with 10 mL of water; 5.- Eluate both extracts with 1.5 mL MeOH twice; 6.- Dry at 50 °C; 7.- Reconstitute with 200

L MeOH/H2O 4:6 (1 mM AmAc and 0.1% AcOH)

Gemini C18, 150 x 2 mm, 5 µm, 40°C

Inj vol 20 µL, A) H2O (0.5% AcOH, 1 mM AmAc)

B) MeOH (0.5% AcOH, 1 mM AmAc

20-40% B in 3 min, 40-63% B in 35 min, keep constant for 11 min, initial conditions for 10 min

Flow: 0.200 mL/min, Time: tan=49 min, tTot=59 min

QTrap

GT 350 °C; CUR 30 PSI; CoV: 4.5 kV: GS1: 10 psi, GS2 30 psi.

LOD: B1 1.1 µg/kg, B2 0.4 µg/kg

(Y. Wang et al. 2013)

B1 and other toxins

Maize10

Extraction: 1.- Add 50 mL of ACN/H2O/AcOH (79:20:1); 2.- Stir for 10 min; 3.- Filter; 4- Evaporate 10 mL to dry; 5.- Redissolve in 100 µL of MeOH; 6.- Vortex 1 min; 7.- Add 1.9 mL of H2O 8.- Vortex again for 1 min

Clean up: 1.- Active the Oasis HLB SPE cartridges with 2 mL of MeOH; 2.- Equilibrate with MeOH/H2O (05:95); 3.- Load sample; 4.- Wash with 2 mL MeOH/H2O (05:95); 5.- Elute with 2 mL of MeOH; 6.- Dry (N2, 50°C); 7.- Redissolve in 1 mL MeOH/H2O (2:8)

Shimadzu XR-ODS 75 x 3.0 mm, 2.2μm, 30°C

Inj vol 20 µL, A) H2O, B) MeOH both with 0.1% AcOH, 1 mM AmAc

50% B for 5 min, 50-10% B in 5 min, keep constant for 10 min, 10-50% B in 1 min, keep constant for 4 min

Flow: 0.30 mL/min, Time: tan=21 min, tTot=25 min

QTrap

GT 450°C; CUR 10 psi; GS1 50 psi; GS2 50 psi; SV 5.5 kV

LOD: 0.64 μg/kg, LOQ: 2.12 µg/kg

Other cereals and seeds

(Bryła, Renata, et al. 2013)

B1, B2, B3

Cereal products25

Extraction: 1.-Add 100 mL ACN/MeOH/H2O (25:25:50); 2.- Stir 30 min; 3.- Centrifuge to 10730 g, 10 min; 4.- Dilute the supernatant 1:1 with 10 mL deionized H2O

Clean up: 1.- Transfer 8 mL of dilute extract to a FumoZon cartridge; 2.- Preconditionate with 4 mL of MeOH and H2O; 3.- Wash with 6 mL ACN/H2O (25:75); 4.- Eluate with 4 mL of 2% FA in MeOH; 5.- Evaporate to dry; 6.- Redissolve in 1 mL of MeOH/H2O/AcOH (1:8.9:0.1)

Kinetex PFP, 100x2.1mm, 2.6μm

Inj vol 25 µL, A) MeOH:H2O:AcOH (20:79.9:0.1) B) MeOH:H2O:AcOH (79:19.9:0.1)

20% B for 4 min, 20-55% B in 6 min, keep constant for 15 min, 55-100% in 5 min, keep constant for 10 min, initial conditions for 20 min

Flow: 0.15 mL/min, Time: tan=40 min, tTot=60 min

IT

GF 45 a.u.; AGF 10 a.u.; CoV 4.5 kV; CaV 40 V; ST 260 °C

LOQ: 25 µg/kg all FBs

(Vaclavikova et al. 2013)

B1, B2, B3 and other toxins

Cereals, nuts5

Extraction:1.- Add 20 mL of ACN/H2O/AcOH (79.5:20:0.5) for 60 min; 2.- Centrifuge to 5000 rpm, 2 min; 3.- Dilute 2 mL of sample with 33 mL of PBS

Clean up: 1.- Load the aliquot on IAC; 2.- Wash with 10 mL of ultrapure H2O; 3.- Elute with 3 mL of MeOH, evaporate; 4.- Reconstitute in 0.5 mL of MeOH/H2O (0.5% AcOH) (1:1); 6.- Filter

Acquity UPLC HSS T3 RP 100 x 2.1 mm, 1.7μm, 40°C

Inj vol 10 µL, A) H2O, B) MeOH both with 5 mM AmAc

5-50% B in 1 min, 50-100% B in 6 min, keep 1 min, initial condition for 2 min.

Flow: 0.4 mL/min, Time: tan=8 min, tTot=10 min

QTrap

ST 450°C; CaV 4.5kV; CUR 20 a.u.; GS1 55 a.u, GS2: 55 a.u

LOD: 5 μg/kg, LOQ: 10 µg/kg all FBs

(Arroyo-Manzanares et al. 2014)

B1, B2 and other toxins

cereals, spelt, rice2

QuEChERS: 1.- Add 8 mL H2O into test tube; 2.- Shake for 10 s; 3.- Add 10 mL 5% FA in ACN; 4.- Shake 2 min; 5.- Add 4 g MgSO4, 1 g NaCl, 1 g sodium citrate, 0.5 g Na2HCit 1.5 H2O; 5.- Shake for 1 min; 6.- Centrifuge to 4500 rpm, 5 min; 7.- Transfer 2 mL of upper layer to a vial; 8.- Evaporate; 9.- Reconstitute with 1 mL of MeOH/H2O 50:50; 10.- Filter

Zorbax Eclipse Plus RRHD C18, 50 x 2.1 mm, 1.8μm, 35°C

Inj vol 5 µL, A) H2O, B) MeOH both with 0.3% FA, 5 mM AmFo

5% B for 1 min, 5-50% B in 1 min, 50-72% B in 2 min, 72-80% B in 2 min, 80-90% for 2 min, initial conditions in 0.2 min.

Flow: 0.4 mL/min, Time: tan=8 min, tTot=8.2 min

QQQ

GT: 500°C; CUR: 30 psi; CaV 5 kV; GS1 and GS2 50 psi

LOD: B1 0.20, B2 0.30 µg/kg

LOQ: B1 0.65, B2 1.01 µg/kg

(Cendoya et al. 2019)

B1, B2

wheat-based products25

Extraction: 1.- Add 50 mL of MeOH/H2O 3:1; 2.- Shake for 30 min; 3.-Filter

Clean up: 1.- Precondition with 5 mL of MeOH and 5 mL MeOH/H2O 3:1; 2.- Load 10 mL of filtrated; 3.- Wash with 8 mL of MeOH/H2O 3:1, 3 mL of MeOH; 4.- Elute with 14 mL of MeOH with 0.5% AcOH ; 5.- Dry (N2, 40°C)

XBridge™ C18, 150 x 2.1 mm, 3.5μm, 20°C

Inj vol 45 µL, A) H2O, B) MeOH both with 1% FA

9.5% B for 2 min, 9.5-50% B in 1 min, 50-97.5% B in 11 min, keep for 3 min, initial condition for 5 min.

Flow: 0.2 mL/min, Time: tan=17 min, tTot=22 min

QQQ

CaV 3.0 kV; ST: 150 °C; DGT 200 °C; DGF: 726 L/h; GF 109 L/h

LOD 0.01 µg/kg LOQ: 0.05 µg/kg all FBs

Products of animal origin

(Gazzotti et al. 2009)

B1

Bovine milk10

Extraction: 1.- Centrifuge to 6000 rpm, 15 min; 2.- Dilute 5 mL of sample 1:1 with H2O

Clean up: 1.- Load the dilute sample to Vicam FumoniTestTM

Immunoaffinity at 1 drop/s; 2.- Wash with 20 mL of PBS buffer at 5 mL/min; 3.- Elute with 1.5 mL of MeOH; 4.- Pass 1.5 mL of H2O, collect 3 mL; 5.- Evaporate 3 mL of eluate to 1 mL (40°C, N2)

XTerra MS C18, 150 x 2.15 mm, 5μm, 35°C

Inj vol 10 µL, A) H2O/ACN (90:10) with 0.3% FA, B) ACN (0.3% FA)

Elute isostatically with 75% A-25%B for 2 min, wash 80% B for 3 min

Flow: 0.30 mL/min, Time: tan=2 min, tTot=5 min

QQQ

CaV 3.25 kV; CoV 50 V; IST 140°C; DGT 400°C

LOD: 0.003 μg/kg, LOQ: 0.1 µg/kg

(Gazzotti et al. 2011)

B1 B2, HFB1 HFB2

Pig liver1

Extraction: 1.- Homogenize in 6 mL of MeOH/H2O 80:20; 2.- Stir for 20 min; 3.- Centrifuge to 3000 rpm, 5 min; 4.- Wash twice with 6 mL of hexane; 5.- Evaporate aqueous phase; 6.- Reconstitute with 2 mL of aqueous buffer with 2% of AcOH, 0.1% Et3N (pH 3.4)

Clean up: 1.- Condition the Oasis HLB SPE cartridges with 2 mL of MeOH and 2 mL of H2O; 2.- Load the sample; 3.- Wash twice: first 1 mL MeOH/H2O (05:95), then 1 mL MeOH/H2O/AcOH (05:94:01); 4.- Elute with 2 mL of MeOH; 5.- Evaporate to 200 μL; 6.- Reconstitute in 1mL of mobile phase of LC

XTerra MS C18, 150 x 2.15 mm, 5μm, 35°C

Inj vol 10 µL, A) ACN/H2O (90:10); B) ACN both with 0.3% FA

25% B for 4 min, 25-40% B in 4 min, keep for 4 min,

initial condition for 5 min

Flow: 0.30 mL/min, Time: tan=12 min, tTot= 17 min

QQQ

CaV 3.25 kV; ST 140 °C; GT 400 °C; GF 50 L/h; DGF 890 L/h

LOD: 0.05 μg/kg, LOQ: 10 µg/kg all FBs and analogues

(Sørensen, Mogensen, and Nielsen 2010)

B1, B2

Meat products0.7

Extraction: 1.- Add 140 μL of IS (13C-FB2 0.5 μg/mL), 4.5 mL of H2O, 2.5 mL of ACN, 6 mL of pentane; 2.- Shake for 1 h; 3.- Centrifuge to 8000 g, 10 min; 4- Discard upper phase; 5.- Transfer 3.5 mL of lower phase; 6.- Add 9 mL of acetone; 7.- Shake; 8.- Centrifuge to 8000 g, 10 min; 10.- Collect 100 mL upper phase; 11.- Evaporate to 1.5 mL (45°C), reconstitute in 0.25 mL of MeOH

Clean up: 1.- Load sample in Oasis (MAX) SPE cartridges; 2.-condition with 1 mL of MeOH followed by 1 mL of H2O, wash with 1 mL of 1% aqueous ammonia; 1 mL of MeOH/H2O/HCl 37% (40:59:1); 3.- elute with 2 mL of 2% AcOH in MeOH; 4.- evaporate (N2, 45°C), re-dissolve in 200 µL ACN/H2O (1:2).

Gemini C6-phenyl 50 x 2 mm, 3μm, 40°C

Inj vol 1 µL, A) H2O, B) ACN both with 20mM FA

20-55% B in 6 min, then 100% in 0.5 min, keep for 2.5 min.

Flow: 0.30 mL/min, Time: tTot=9 min

QQQ

IST 120°C; DGF 700L/h; DGT 350°C

LOD: B1 64 µg/kg, B2 6 µg/kg,LOQ: B1 and B2 150 µg/kg

(Liliana J.G. Silva et al. 2010)

B1, B2

Urine10 mL

Extraction: 1.- Filter, 2.- Dilute 1:1 with 10 mL of PBS, 3.- Mix for 3 min

Clean up: 1.- Load the sample in FumoniTestTM immunoaffinity column; 2.- Wash with 10 mL PBS; 3.- Elute with 5 mL of MeOH; 4.- Dry (N2, 60°C); 5.- Redissolve in 1 mL of MeOH/H2O (1:1)

Luna C18, 150 x 4.6mm, 5μm, 30°C

Inj vol 20 µL, A) H2O, B) MeOH both with 0.5% FA

65% B for 3 min, 65-75% B in 4 min, keep for 8 min, initial condition for 10 min

Flow: 0.50 mL/min, Time: tan=15 min, tTot=25 min

QQQ

CaV 3.20 kV; ST 125 °C; DGT 300°C; DG 500 L/h

LOD: 5 µg/L LOQ: 10 µg/L all FBs

(Šarkanj et al. 2018)

B1 and other toxins

Urine500 µL

Extraction: 1.- Centrifuge to 5600 g, 3 min; 2.- Incubate with 500 µL PBS (200 mM, pH 7.4) containing 3000 U of β-glucuronidase, 16 h, 37 °C

Clean up: 1.- Precondition with 1mL MeOH, 1mL H2O; 2.- Add sample to Oasis PRiME HLB; 3.- Wash twice with 500 µL H2O; 4.- Eluate with 200 µL ACN x 3; 5.- Evaporated (N2); 6.- Reconstitute with 470 µL of 10% ACN, 0.1% AcOH, add 30 µL IS (0.38 ng/mL 13C-FB1)

Acquity HSS T3, 100 x2.1 mm, 1.8μm, 35°C

Inj vol 10 µL, A) H2O, B) ACN, both with 0.1% AcOH

10% B for 2 min, 10-50% B in 13 min., 50-95% B in 5 min, hold 4 min, initial condition for 3 min.

Flow: 0.1 mL/min, Time: tan= 24 min, tTot= 27 min

Qtrap

ISV 4.50 kV; ST 550°C; CUR 30 psi; SG 80 psi; DG 80 psi

LOD: 0.001 µg/L, LOQ: 0.01 µg/L

Bevearages

(Nakagawa et al. 2020)

B1, B2, B3

Domestic wine5 mL

Extraction: 1.- Add 0.1 mL of IS (13C34-FB1 0.2 mg/L in acetonitrile: water (1:1); 2.- adjusted volume at 10 mL with wine; 3.- mix; 4.- add 8mL of PBS (1% PEG, 5% NaHCO3; 5.- mix;

Clean up:

1.- Equilibrate with 3 mL of PBS; 2.- Load sample in cartridge; 3.- Wash 6 mL (3 mL x 2 times) of H2O (0.5% NaHCO3) and 6 mL (3 mL x 2 times) of 10 mM AmAc; 4.- Elute with 3 mL of MeOH (2% AcOH); 5.- evaporate to dryness; 6.- reconstitute in 0.2 mL ACN:H2O 1:1.

ZORBAX Eclipse XDB-C18 250×3 mm, 5μm, 40°C

Inj vol 3–20 μL, A) H2O, B) ACN, both with 0.1% FA

10% B for 3 min, 10-90% B in 15 min, hold for 5 min, initial conditions for 10 min.

Flow: 0.3 mL/min, Time: tan= 20 min, tTot= 30 min

Qtrap

CaV 5 kV; CUR 10 psi; GS1 70 psi; SG 60 psi; ST 500°C

LOD: 1 μg/Kg all Fbs LOQ 2

(Romero-González et al. 2009)

B1, B2

Beer10 mL

Extraction: 1.- Sonicate for 20 min

Clean up: 1.- Precondition with 5 mL ACN/H2O (60:40) and 5 mL of H2O; 2.- Load sample in C18 cartridge; 3.- Wash with 5 mL of H2O; 4.- Elute 2 mL ACN/MeOH 60:40; 5.-Filter

Acquity UPLC BEH C18, 100 x 2.1 mm, 1.7μm, 30°C

Inj vol NR, A) H2O, B) MeOH both with 5 mM AmFo

25 to 100% B in 3.75 min, keep 1.25 min, 100 to 25% B in 0.5 min, initial condition for 1 min

Flow: 0.35 mL/min, Time: tan= 5.5 min, tTot= 6.5 min

QQQ

CaV 3.5 kV; ST 120; DGT 350°C; CGF 80 L/h; DGF 600 L/min

LOD: B1 0.07, B2 0.09 µg/kg; LOQ: B1 0.23, B2 0.30 µg/kg

(Tamzura, Uyama, and Mochizuki 2011)

B1, B2, B3, and other toxins

Beer-based drinks10 mL