Translate this page into:

Decamethylcyclopentasiloxane-based sustainable and recyclable polyester fabric whitening using OB-1 fluorescent brightener

⁎Corresponding authors. linalin@wtu.edu.cn (Lina Lin), xiongxiaorong@hgnu.edu.cn (Xiaorong Xiong), vnaddeo@unisa.it (Vincenzo Naddeo)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Abstract

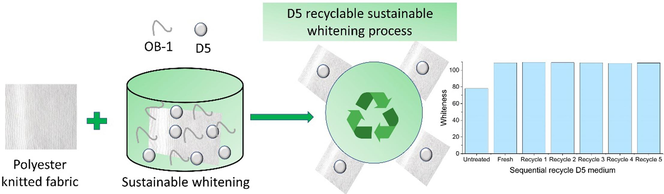

Fluorescent whitening agent OB-1 (OB-1) has non-toxicity, chemical stability, exceptional heat resistance, and light stability, and it is widely used in plastic products. However, raw OB-1 is difficult to apply in textiles by exhaustion process. The present investigation employed raw OB-1 without adding an auxiliary to bestow a whitening effect on polyester fabric in a sustainable medium of decamethylcyclopentasiloxane (D5). The Taguchi methodology was employed to optimize the whitening parameters. An L16 orthogonal array was utilized to investigate the optimal conditions for whitening temperature, whitening time, and OB-1 mass, with four whiteness levels. The signal-to-noise ratio was optimized using a larger-is-better approach to enhance the parameter responses. The study analyzed the main effect and interaction plot of multiple factors. The findings indicate that the temperature of the whitening process significantly impacts the whiteness of the polyester fabric (P < 0.05), with a 98.4 % contribution percentage. Under the optimal conditions, a whiteness value of 109.9 was observed for the polyester fabric. Subsequently, various analytical techniques, including FT-IR, SEM, TGA, and XRD, were employed to characterize the treated fabric. The results indicate that using D5 medium was viable for whitening polyester fabric. The study also examined the duration of washing and rubbing to determine their whitening performance. The study evaluated the whitening efficacy of polyester fabric treated with recycled D5 medium and demonstrated its potential for application at the pilot scale in the textile sector.

Keywords

Fluorescent whitening agent

Polyester

OB-1

D5

Whiteness

1 Introduction

The fluorescent whitening agent (FWA) is an organic compound, and it can absorb ultraviolet light (330–380 nm) and emit visible blue light (400–450 nm) (Al-Sayed and Abdelrahman, 2021, Um, 2007). The emitting blue light is complementary to the yellow light of the substrate, resulting in a whitening effect. FWAs are widely used in textiles (Cardamone and Marmer, 1995), paper (Murray, 1996), detergent, plastic, food, cosmetics, and so on.

Generally, a white substrate has a property of little absorption of blue light, which causes blue light insufficiency in the visible reflect light; thus, the white substrate appears slightly yellowish and has an old feeling. In order to deal with this yellowish color shade, a whitening treatment is applied to the textile, such as bluing whitening and chemical bleaching. The addition of blue colorant in the textile is beneficial for whitening, i.e., bluing whitening, but its effect is limited (Sfameni et al., 2023, Vik et al., 2022). Meanwhile, because the bluing whitening treatment reduces the total amount of reflected light, it darkens the color of the textile. While chemical bleaching whitens textiles mainly through the redox method to destroy the impurity colorant and accompanies avoiding less fiber damage. Fluorescent whitening is an alternative method to whiten and brighten the textile without fiber damage, such as cotton, jute, silk, viscose, polyester, etc. (Taheri et al., 2019, Zhang et al., 2022).

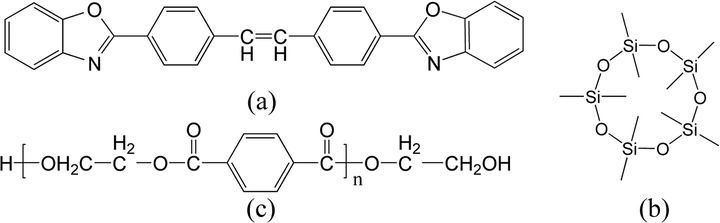

Fluorescent whitening agent OB-1 (OB-1, Fig. 1a) is the best variety of oxazole whitening agents. Since it has no toxicity, good chemical stability, excellent heat resistance, and light stability, OB-1 is abundantly used in plastic products (Kabir et al., 2014, Salas et al., 2019). In addition, OB-1 is also ideal for the dope whitening of polyester fiber owing to its washing fastness and whitening effect. However, wet processing makes it hard to whiten polyester fiber because of its low solubility and poor dispersion in water. OB-1 molecules have high planarity, which makes the OB-1 molecules easily aggregate through the van der Waals interaction forces (Saad et al., 2022, Shariful Islam et al., 2019).

Molecular structure of (a) fluorescent whitening agent OB-1, (b) decamethylcyclopentasiloxane, and (c) polyester.

In order to apply OB-1 in polyester fiber by exhaust method, the OB-1 raw powder was milled with surfactants to reduce the particle size of OB-1, and the treated particle of OB-1 successfully whitened the polyester fiber (Cai et al., 2023). However, it took about 4 h to prepare the milled particles with many mass of surfactants, which hints that these surfactants were discharged and caused a potential water pollution issue after whitening treatment. Thus, an alternative sustainable wet process of OB-1 whitening polyester is highly desired.

In recent years, decamethylcyclopentasiloxane (D5, Fig. 1b), rather than alkane-based solvents, has recently been selected as a suitable continuous phase medium for use in the reverse micelle dyeing technique (Hossain et al., 2022, Hossain et al., 2021). D5 may be recovered and reused after the dyeing process by simply statically separating it from the aqueous portion, which comprises water, ethyl alcohol, and D5 essentially (Saleem et al., 2023, Tang and Kan, 2020, Zhang et al., 2023). Accordingly, many studies have described synthetic dyes in a D5 dyeing system, but far less attention has been paid to the whitening of textile fibers using D5. As a result, a new approach employing the D5 solvent to increase the efficiency with raw OB-1 particles for whitening polyester fiber (Fig. 1c) was experimented with, excluding surfactant application to exhibit its sustainability.

The efficacy of whitening procedures is subject to multiple variables, including the duration of the procedure, the temperature at which it is conducted, and the quantity of whitening agent employed. Therefore, it is imperative to establish a methodical framework for the design, execution, and assessment of the process to achieve optimal outcomes. The design of experiments, or DOE, is a method that systematically determines the causal relationship between process inputs and outputs (Hossain et al., 2021, Pervez et al., 2018). The Taguchi method is widely regarded as a robust technique due to its utilization of an orthogonal array (OA) design. The Orthogonal Array (OA) is a quantitative tool that is utilized to identify the appropriate parameters and levels. Its application reduces the number of trials, experiment duration, cost, and human energy expenditure. The Taguchi methodology emphasizes the signal-to-noise (S/N) ratio and variance (ANOVA) table analysis for statistical significance determination. It employs a response table to identify optimal conditions with the most influential factors. Confirmation tests have subsequently been employed to validate experimental designs' practicability (Morshed et al., 2020, Shafiq et al., 2018, Zhang et al., 2022). While certain researchers have utilized Taguchi's experimental design approach to enhance the quality of the textile dyeing process, there has been a relative lack of focus on the whitening process.

Therefore, the current study aims to investigate the anhydrous fluorescent whitening performance of polyester fabric with raw OB-1 in D5 medium and to produce high whiteness via the optimization of the exhaust method for the first time. The experiment optimization was acquired using a sixteen Taguchi orthogonal array (L16) with four levels and three parameters to ensure the replicability of this work. Finally, the characterization of the treated fabrics was determined through analytical techniques, i.e., SEM, FTIR, TGA, and XRD.

2 Experimental

2.1 Materials

Fluorescent whitening agent OB-1 (raw powder) was supported by Hubei Hongxin Chemical Co., Ltd, China. A scoured polyester knitted fabric was supported by TST Group Holding Limited, China. Non-ionic detergent (Luton 500) was purchased from Dalton UK Company. Decamethylcyclopentasiloxane (D5) was obtained from the Chinese manufacturer Jiangxi Bluestar Xinghuo Silicones Corporation.

2.2 Whitening process

The polyester fabric was whitened with varied raw OB-1 mass from 0.00125 to 0.05 % o.m.f (on mass of fabric) at a varied maintaining temperature from 90 to 140 °C for a period of 0 to 120 min at various liquor-to-goods ratios (liquor ratio) of 10:1 to 100:1 in D5 medium with an infrared dyeing machine (Ronggui Huibao dyeing and finishing machinery factory, Foshan, China). The temperature was increased at a heating rate of 2 °C/min and decreased from 5 °C/min to 30 °C. After whitening, the fabric was washed with alcohol at room temperature for 2 min to remove residual D5 in the treated fabric and subsequently soaped in a solution containing 2 g/L of non-ionic detergent at a liquor ratio of 50:1 at 95 °C for 15 min with the dyeing machine. Finally, the sample was dried in an oven at 90 °C.

2.3 Characterization

2.3.1 Whiteness measurement

The whiteness of polyester fabric was measured randomly at 10 positions using the WI (CIE) method installed in a spectrophotometer (Hangzhou Chnspec Technology Co., Ltd.) at a D65 light source and 10° field of view. The average of 10 whiteness was expressed as the whiteness value of the sample, and the whitening uniformity was characterized by the standard deviation of 10 whiteness values.

2.3.2 Particle size measurement

For the particle size measurement, the residual OB-1whitening solution under the optimum conditions was centrifugalized for 5 min at 10,000 r min−1 (Cence H1650, Hunan Xiang Yi Laboratory Instrument Development Co., Ltd, China), and then the clean solution was examined for the particle size of OB-1 by an analyzer (Nanotrac Wave II, Microtrac, USA). For comparison, the particle size of OB-1 in water was also measured, where OB-1 was treated at 130 °C for 60 min in water, followed by centrifugalization.

2.3.3 FTIR analysis

The FTIR analysis of the sample scissored into powder form was carried out with a Fourier transform infrared spectroscopy (FTIR, Nicolet iS5, Thermo Fisher Scientific, USA) in transmission mode.

2.3.4 SEM analysis

The sample's scanning electron microscope (SEM) was assessed by a field-emission scanning electron microscope (Philips SEM 515, Germany). The sample for SEM measurement was coated with gold and observed at 10 kV accelerated voltage.

2.3.5 TG analysis

The thermogravimetric analysis of the sample scissored into powder form was carried out with a thermogravimetric analyzer (TGA/DSC1, Mettler-Toledo, LLC, Shanghai, China) from 50 to 800 °C with a temperature increment of 10 °C min−1.

2.3.6 XRD analysis

The XRD analysis of polyester fiber scissored into powder form was examined by a Rigaku Ultima III X-ray diffractometer with CuKα radiation (λ = 1.54056 Å) (Tokyo, Japan). The XRD pattern of polyester fiber was recorded from 5 to 80° of 2θ with a step size of 0.02°.

2.3.7 Whitening performance duration

The whitening performance durations of washing and rubbing were examined according to the ISO 105-C06: 2010 and ISO 105-X12:2001 standard methods, respectively.

3 Results and discussion

3.1 Influencing factors

3.1.1 Whiteness influenced by whitening temperature

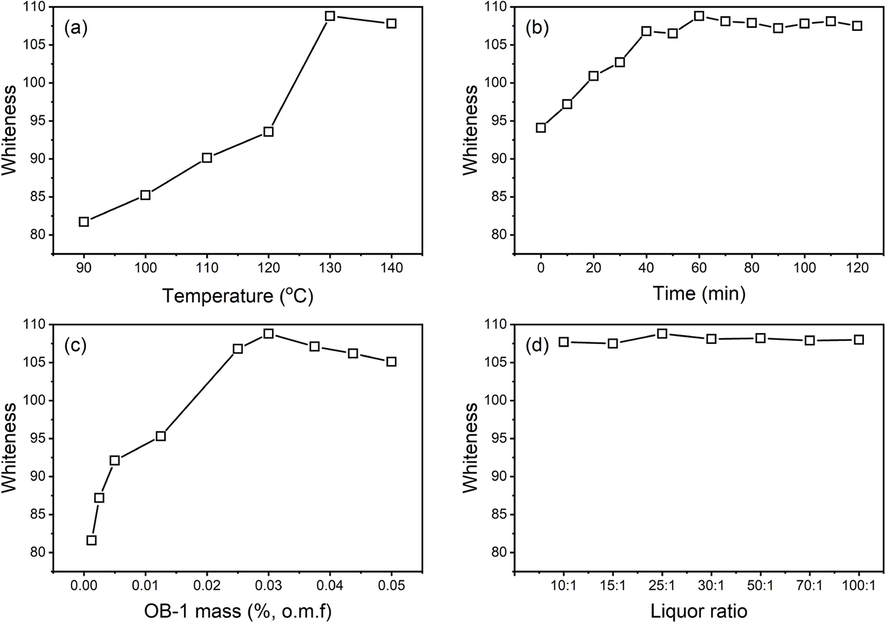

The polyester fabric was whitened in D5 medium at a liquor ratio of 25:1 with 0.03 % o.m.f of OB-1 at various temperatures of 90–140 °C for 60 min, and the whitening results are shown in Fig. 2a. Obviously, the whiteness increased with an increase in whitening temperature. This whitening tendency of polyester fabric with OB-1 in D5 is similar to the disperse dyeing of polyester fiber (Yu et al., 2022). Compared to the 78.1 whiteness of the original polyester fabric, the whitening treatment at 90 to 120 °C slightly contributed to the whiteness, with values ranging from 81.7 to 93.6. While the whiteness dramatically increased to 108.8 at 130 °C, followed by a little decline at 140 °C. Thus, it indicates that 130 °C was the best temperature for the whitening. The polyester fiber swelled well with increasing whitening temperature, and the OB-1 particles gradually dissolved in D5 (Zhang et al., 2022). Subsequently, the dissolved OB-1 particles were transferred to the fiber surface and migrated into the fiber interior until adsorption equilibrium. The OB-1 particles were dissolved better at high temperatures in a D5 medium, producing fine OB-1 particles, which contributed to its even distribution in PET and the fluorescent performance.

Influence of (a) treating temperature, (b) treating time, (c) OB-1 mass, and (d) liquor ratio on the whiteness of polyester fabric treated by OB-1 in D5 medium.

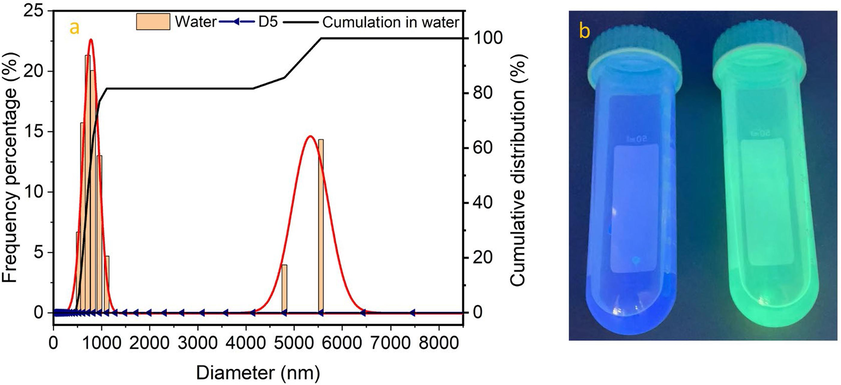

The particle size of OB-1 in D5 at 130 °C was too small to detect by the analyzer, while the OB-1 particle can be detected in water at 130 °C (Fig. 3a). The particle size of OB-1 in water mainly exists in two zones, i.e., ranges from 459 to 1106 nm and 4800 to 5560 nm. Besides, the particle size of OB-1 in D5 treated at 30 °C was too small to identify as well, but it did not show a fluorescent effect (Fig. 3b). The possible reason could be that the OB-1 was not dissolved in D5 at 30 °C due to the low temperature, rather than its small particles suspended in the D5 medium after the centrifugalization. In other words, the aggregated OB-1 particle resulted in a self-quenching.

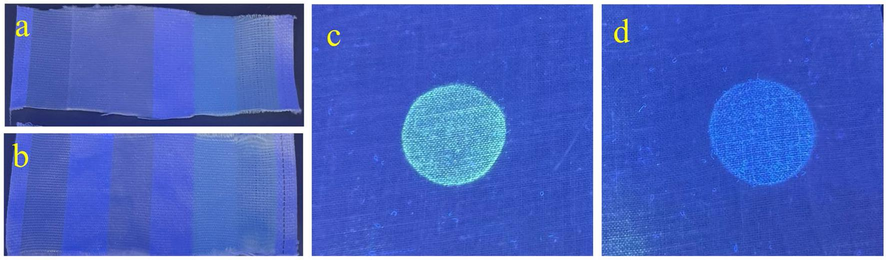

Particle size analysis and fluorescent performance, (a) particle size of OB-1 in water and D5 and (b) OB-1 in D5 solvent at 30 °C (green) and 130 °C (blue). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

3.1.2 Whiteness influenced by whitening time

The polyester fabric was whitened in D5 medium at a liquor ratio 25:1 with 0.03 % o.m.f of OB-1 at 130 °C for various whitening times from 0 to 120 min. The whitening results are shown in Fig. 2b. The whiteness of the treated polyester fabric increased with the whitening time extension. The whiteness reaches a maximum value of 108.8 with 60 min whitening time, i.e., the adsorption of OB-1 arrived at equilibrium. Compared with the disperse dyeing of polyester fiber in a D5 medium (Yu et al., 2022), this adsorption process is faster to equilibrium due to its low mass of OB-1 usage. The whiteness of the samples that were treated for more than 60 min slightly decreased and fluctuated. Thus, the results imply that the whitening performance of polyester treated at 130 °C for 60 min is satisfactory.

3.1.3 Whiteness influenced by OB-1 mass usage

The polyester fabric was whitened in D5 medium at a liquor ratio 25:1 with OB-1 mass varied from 0.00125 to 0.05 % o.m.f at 130 °C for 60 min, and the whitening results are shown in Fig. 2c. The whiteness of polyester increased from 81.6 with 0.00125 % o.m.f to a peak value of 108.8 with 0.03 % o.m.f and gradually decreased to 105.1 with 0.05 % o.m.f. Meanwhile, the treated samples gradually appeared green shade (OB-1 powder color, Fig. 1c) when the amount of OB-1 used was larger than 0.03 % o.m.f. The L*, a*, and b* values of the whitened samples are listed in Table S1. The absolute a* values of treated samples increased with an increase of OB-1 mass, which hints that the color shade of samples gradually became more greenish because of excessive OB-1 molecules in the polyester fiber. Besides, the excessive OB-1 molecules in the substance easily generated a high interaction between the molecules and formed a multilayer (Zhang et al., 2022), causing a fluorescent extinction or self-quenching, i.e., reduction of whitening performance (Zhao et al., 2014). Therefore, it concludes that the OB-1 mass usage should be less than 0.03 % o.m.f for whitening the polyester.

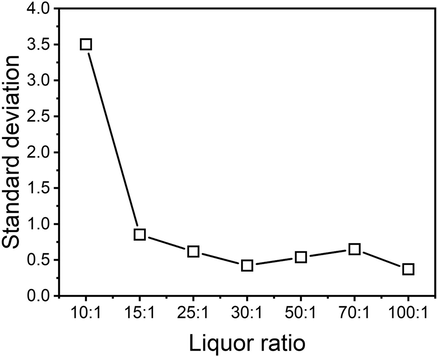

3.1.4 Whiteness influenced by liquor ratio

The polyester fabric was whitened in D5 medium at various liquor ratios from 10:1 to 100:1 with 0.03 % o.m.f of OB-1 at 130 °C for 60 min, and the whitening results are shown in Fig. 2d. Generally, the influence of the liquor ratio on the whiteness is ignorable because the whiteness of polyester fabric treated with a liquor ratio from 10:1 to 100:1 is little fluctuation, which ranges from 107.7 to 108.8, and a maximum whiteness is 108.8 at 25:1 of liquor ratio. In addition, an uneven whitening performance was easily generated at a lower liquor ratio of 15:1, which was characterized by the standard deviation in Fig. 4. The standard deviation of whiteness of the sample treated at a 10:1 liquor ratio is 3.5, which hints at an uneven whitening performance. It is far from the other liquor ratios, which are 0.4–0.9, indicating uniform whitening performance on these fabrics (Lin et al., 2022). At a low liquor ratio, the concentration of OB-1 in D5 was relatively higher, which easily proceeded the interaction between OB-1 molecules and then generated multilayers (Zhang et al., 2022); thus, an uneven whitening phenomenon occurred. While at a high liquor ratio, the concentration of OB-1 in D5 was low. The OB-1 molecules were facilely adsorbed and desorbed during the whitening treatment. Thereby, the samples whitened with a high liquor ratio have better uniformity of whitening. In summary, due to the whiteness and the even whitening performance, the liquor ratio was fixed at 25:1 for the subsequent investigation, i.e., the orthogonal experimental scheme.

Uneven whitening performance (standard deviation of whiteness values) of polyester fabric whitened by OB-1 in D5 medium with various liquor ratios.

3.2 Taguchi model analysis and validation

An orthogonal experimental scheme using an L16 (4^3) array was carried out to obtain the experimental data for the Taguchi analysis, where the liquor ratio at 25:1 was fixed. Table S2 displays the values and ranges of the parameters used in the orthogonal experimental design. Followingly, the L16 (4^3) array of the orthogonal experimental scheme and their whiteness and S/N ratio values are presented in Table S3.

3.2.1 S/N ratio assessment

Under Taguchi's design, determining the best conditions is one of the primary requirements for maximum whiteness. In this case, measuring the signal-to-noise ratio (S/N) is crucial to the Taguchi method. The S/N value revealed the distinctive nature of the final product. The S/N ratio was calculated based on the characteristics’ deviation values from the ideal result. The primary goal of this project was to develop sustainable whitening based on the D5 medium.

Among the three possible S/N ratios, “the-larger-the-better” (Eq. (1) was chosen since it was best suited to the goals of this investigation (higher whiteness).

Level

A

B

C

1

37.26

38.83

38.97

2

38.51

38.96

39.04

3

39.39

38.92

38.92

4

40.58

39.04

38.82

Delta

3.31

0.21

0.22

Rank

1

3

2

Figure S1 also shows the major impacts plot of the process parameters for S/N ratios in the whiteness of polyester fabric. The productivity of different process parameters is indicated by comparing their values to a straight line. An insignificant effect on the whitening procedure is indicated if a process parameter is close to the solid line. Contrarily, a parameter with a steeper slope has a more significant impact on the treatment procedure. Therefore, among the assessed factors, temperature (A) was demonstrated to have a statistically significant effect on whiteness, while OB-1 mass (B) and time (C) had a very small impact on whiteness. Since the greatest possible whiteness reflects the most efficient whitening performance, the best circumstances are indicated as A4B4C2, which resulted in the highest possible whiteness when utilizing the Taguchi approach. Moreover, residual plot assessment, fittrd plot assessment and interpretation plots are described in Text S1-S3.

3.2.2 ANOVA

The application of the Taguchi technique may determine the sensitivity analysis of the variables. Because of this, analysis of variance, often known as ANOVA, is the statistical method of choice when attempting to differentiate between the effects of different levels and variables on experimental outcomes. An ANOVA is used to identify the process characteristics statistically crucial in whiteness efficiency and their confidence level and interactions. A sum of squares (SS) distribution of measures was initially planned, with subtraction to be done using SS factors obtained from the experiment results. The ratio of MS values was utilized to calculate the F-value for Fischer's test since it reveals the most important factor in the model. The threshold for a meaningful p-value is 0.05; therefore, only factors with a p-value below that will be considered. The results of the ANOVA are shown in Table 2 below. It is shown that the temperature substantially influenced whiteness performance, with an F-value as high as 255.65 and a p-value of 0.00 (statistically significant). As for other factors, such as OB-1 mass and whitening time, the F-values were 1.11 and 0.98, respectively. However, both factors were statistically insignificant (p-value > 0.05), as observed by their p-values around 0.41 and 0.46, respectively.

Source

DF

SS

MS

F

p-value

Remarks

P (%)

A

3

23.50

7.83

255.65

0.00

Significant

98.42

B

3

0.09

0.03

0.98

0.46

Insignificant

0.38

C

3

0.10

0.03

1.11

0.41

Insignificant

0.43

Residual Error

6

0.18

0.03

0.77

Total

15

23.88

Additionally, the percentage contribution (P%) of a factor or interaction between variables is the proportion of the overall variation in experimental results that can be attributed to that component. The P% is calculated by adding the squares of all the significant components in question. It indicates a factor's proportionate effect in reducing the variance in the data. Suppose the amounts of the factors can be carefully controlled. In that case, the total variance in an experiment may be reduced by a value that is represented by the percentage contribution, and this reduction would be possible (D'Souza et al., 2022). The P% data for each factor is shown in Table 2. It is observed that the whitening temperature contributed the most, with a P% around 98 %, OB-1 mass contributed 0.43 %, and whitening time contributed 0.38 %, implying that the whitening temperature most significantly influences whiteness, followed by the Ob-1 mass and whitening time.

3.2.3 Validation

The Taguchi technique requires a validation test to be performed to shed light on the findings obtained, and doing such a test is strongly recommended for statistical approaches. The primary purpose of this investigation is to establish whether or not the questionnaires and replies are reliable. The results of the validation trials are detailed in Table S4. After determining the parameters under which optimum performance may be achieved, the following step is to validate whether or not the process has been improved. Using MINITAB software, the predicted values were calculated and determined. Consequently, the experiment was carried out using the ideal parameters, and it was found that a sufficient improvement in the S/N ratio had been attained. The major objective of this study was accomplished, as shown by the fact that the whiteness was increased (leading to an increase in the S/N ratio of 0.089). According to these results, better performance might be attained by utilizing an experimental design that consistently adheres to statistical standards.

3.3 Mechanism of whitening PET fabric with OB-1 in D5 medium

At 130 °C of the whitening temperature, the OB-1 was dissolved well, and PET fiber was adequately swelled. During the treatment process, the PET fiber became soft and possessed more gaps between the polymer chains, which was beneficial for OB-1 adsorption. The OB-1 was gradually transferred to the surface of PET fiber from the D5 medium and subsequently migrated inside the swelled PET fiber with a uniform distribution in the gaps (Rowley et al., 2020). The adsorption continued until equilibrium, i.e., no more OB-1 was absorbed in PET fiber. Next, with a decrease in treating temperature, the swelled PET gradually exhibited normally, accompanied by fixation of OB-1 in PET since the gaps produced by swelling were closed. Finally, the OB-1 firmly existed in PET fiber and exhibited a fluorescent performance (Mishra et al., 2021).

3.4 Characterization

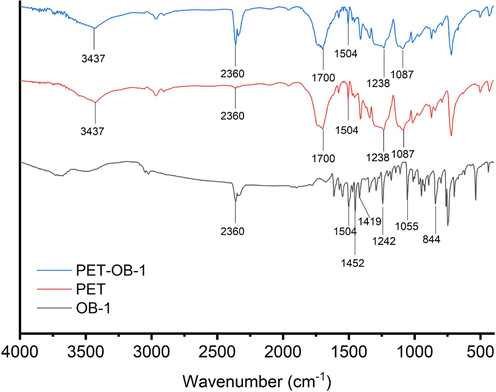

3.4.1 FT-IR analysis

The FT-IR spectra of OB-1, original polyester fabric (PET), and polyester whitened in D5 with 0.0275 % o.m.f of OB-1 at 130 °C for 70 min (PET-OB-1) were shown in Fig. 5. The characteristic peaks of the FT-IR spectrum of OB-1 at 1504 cm−1 and 1452 cm−1 were attributed to the bending vibration bonds of C = C in the phenyl ring and at 844 cm−1 to the vibration C–H bonds of the phenyl ring. The bending vibration bond of -C = N (1420 cm−1) and the stretching vibration bond of -C-O (1242 cm−1 and 1055 cm−1) are identified in the literature (Pan et al., 2021). The characteristic peaks of the ester linkage in PET are present at 1700 cm−1 (stretching vibration band of C = O) and at 1087 cm−1 and 1238 cm−1 (C-O-C stretching vibration band). The unreacted stretching vibration of hydroxyl groups in PET exhibits weak broadband in the region 3437 cm−1 (Natarajan and Moses, 2012). The peak at 1504 cm−1 is attributed to the symmetric structure of the benzene ring (Xiao et al., 2009). The FT-IR spectrum of PET-OB-1 is similar to the PET’s because the low concentration of OB-1 in PET was not identified.

FT-IR spectra of OB-1, PET, and PET-OB-1.

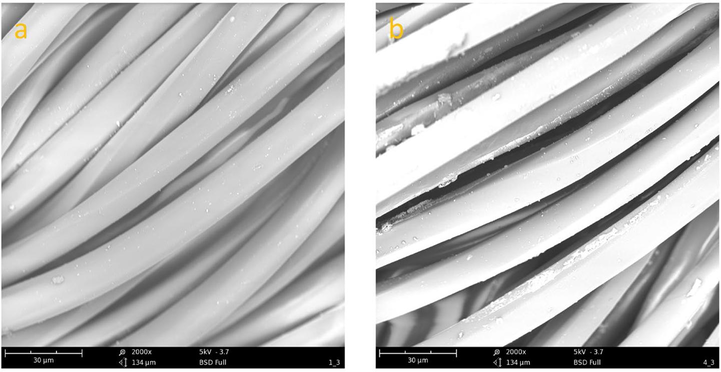

3.4.2 Surface topography analysis

The surface topographies of the PET and PET-OB-1 fabric were investigated by SEM and shown in Fig. 6. The SEM images of the original polyester fiber exhibit an even and smooth surface (Fig. 6a), while the surface of PET-OB-1 was stained with OB-1 particles without any erosion (Fig. 6b) after the whitening treatment in the D5 medium. This phenomenon can be ascribed to the OB-1 aggregation caused by its nonpolar and flat molecular structure since, after treatment in D5, the surface of polyester fiber is clean (Li et al., 2021).

SEM images of (a) PET fabric with 2000 magnification and (b) PET-OB-1 fabric with 2000 magnification.

3.4.3 Thermogravimetric analysis

The TG and DTG curves (Figure S2) were used to characterize the influence of the dyeing process on the thermal stability of whitened polyester fiber. The thermal decomposition behaviors of the polyester before and after whitening are similar, in which thermal decomposition occurred at 340 °C, the maximum decomposition rate was at 425 °C, and arrived at a stable decomposition at 490 °C. However, the residual weight percentage of polyester before whitening was slightly lower than that after whitening, which possibly ascribed to the OB-1 in the polyester and D5 solvent treatment (Cheng et al., 2021).

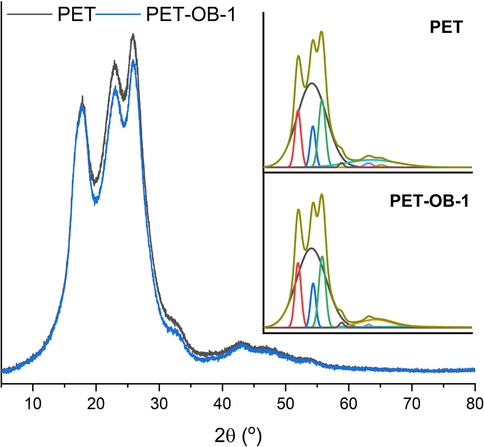

3.4.4 XRD analysis

The XRD peaks and their corresponding deconvolution of original (PET) and OB-1 whitened (PET-OB-1) polyesters were shown in Fig. 7, in which the diffraction peaks and shapes of both samples are similar. The parameters of crystallinity are listed in Table S5. The interplanar spacing (d), crystallite size (S), and crystallinity index (CI) were calculated by Eq. (2) (Wang et al., 2019), Eq. (3) (Raza and Anwar, 2016), and Eq. (4) (Liang et al., 2021), respectively. Where λ is CuKα radiation, i.e., λ = 1.54056 Å; θ is Bragg angle; β is the radian of full width at half maximum (FWHM); AC and AA are the crystallinity area and amorphous area of the sample, respectively.

XRD patterns of the PET and PET-OB-1.

The 2θ of the main diffraction of crystallinity peaks for both samples were around 17.4°, 22.8°, and 26.1°, and the interplanar spacing and crystallite size are coincident with the previous report (Cheng et al., 2021). Besides, the CI of PET and PET-OB-1 are 28.0 % and 29.9 %, respectively, and CI values fit their XRD diffraction profile (Murthy et al., 1994). The distinction of CI values is ignorable, indicating that PET's morphological structure was not changed by the OB-1 whitening in the D5 medium (Li et al., 2021).

3.4.5 Whitening performance durations of washing and rubbing

After the washing test, the whiteness of the sample and the multifiber fabric were measured and shown in Figure S3. First, the whiteness of the sample after testing is close to that before testing, and it is the same as the multifiber fabric (Fig. 8). Thus, it indicates that the washing duration of the whitening performance of PET fabric was adequately stable, and it impossibly caused a staining issue (Fan et al., 2022).

Test fabrics detected under UV light in color box, (a) original multifiber fabric, (b) multifiber fabric after the washing test, (c) cotton test fabric after drying the rubbing test, and (d) cotton test fabric after the wet rubbing test.

In addition, after rubbing testing (rubbing 60 times in 1 min), the whiteness of PET fabric slightly decreased to 106.7 and 105.5 for wet rubbing and dry rubbing from 108.8, respectively. Also, OB-1 stained the cotton test fabric, and its whiteness changed from 70.5 to 72.2 and decreased to 68.7 for the wet rubbing and drying rubbing, respectively. It is interesting that the whiteness of cotton fabric decreased after staining with a fluorescent whitening agent. The L* values of the test cotton fabric in wet rubbing and dry rubbing were similar. However, the a* and b* values of the cotton test fabric in dry rubbing is more negative and positive than that in wet rubbing, respectively, i.e., the shade of cotton test fabric after the dry rubbing is greenish and yellowish, compared to that after the wet rubbing, which is listed in Table S6. Furthermore, in the drying rubbing test, the OB-1 was transferred and easily aggregated on the cotton test fabric's surface, resulting in a fluorescent self-quenching. While in the wet rubbing test, the water content was beneficial for swelling the cellulosic fiber of the cotton test fabric. The OB-1 molecules transferred from the whitened PET sample were evenly distributed on the cotton test fabric; thereby, the shade of the cotton test fabric exhibited a fluorescent performance, which is shown in Fig. 8. Summerly, these factors changed the colorimetric values of the cotton test fabric, slightly decreasing whiteness (Al-Ahmed et al., 2023, Chowdhury and Pandit, 2022).

3.5 Whitening polyester fabric with recycled D5 medium

The residual whitening solution and soaped solution were collected to recycle the D5 medium only by static separation for 48 h. The top layer of clean D5 medium was obtained because the OB-1 dissolved in residual whitening D5 solution was precipitated out in the aqueous solution layer. The sequential recycle D5 medium was used to whiten the polyester under the optimum conditions for investigating its stability, and the whiteness is shown in Figure S4. The whiteness of the treated PET fabric with a difference recycle number from 0 (fresh) to 5 is similar, which promoted 108.8, 109.4, 109.1, 108.8, 108.2, and 108.6 from 78.1 of the untreated PET fabric, respectively. The standard deviation of these whiteness values is 0.3760, indicating a high uniformity and repeatable performance. In addition, the whitened samples are exhibited in Figure S5, which were detected in a color box under the combination of UV65 and UV lights. It shows a brilliant shade on the whitened PET fabrics. Thus, it concludes that the recycled D5 medium can whiten PET fabric with OB-1 (Hayashi et al., 2021, Saleem et al., 2021).

3.6 Environmental aspects of polyester fabric whitening in an organic solvent medium

Utilizing a solvent medium with the potential for reuse in the textile wet process can decrease chemical consumption and eliminate waste effluents. Notably, significantly prosperous trials have been observed recently when applying solvent in the dyeing procedure of textiles (Alebeid et al., 2020, Saleem et al., 2021). Followingly, this study implemented a sustainable method for whitening PET within a D5 environment.

The PET fabric was significantly whitened with OB-1 in D5 organic solvent without adding textile auxiliaries, which are essential for the aqueous whitening process, such as dispersing and leveling agents. Traditionally, the dyeing of PET is a resource-intensive process with difficult wastewater treatment problems (Xu et al., 2016). The elimination of auxiliaries reduces the pressure of wastewater treatment and environmental hazards. Besides, the whitening PET in D5 is an anhydrous process, and it can reduce water consumption at least 6–10 times the treating fabric weight, i.e., it decreases water pollution. Moreover, the D5 organic solvent has the potential to be recycled for multiple whitening cycles, with a five times recycling rate exceeding 99 %. Prior studies suggest that approximately 70–80 % of textile effluent from the traditional water-based medium can be reclaimed (Pei et al., 2021). The environmental implications analysis indicated that solvent whitening of PET, as a water- and effluent-free method, is valuable in improving environmental performance and economic sustainability.

Based on the aforementioned factors pertaining to the solvent whitening procedure, it can be inferred that the newly developed eco-friendly whitening technique represents a noteworthy approach toward achieving a more pristine and purified production of PET.

4 Conclusions

The present study established a method for sustainable whitening of polyester fabric using Ob-1 in a D5 medium, considering the environmental issues currently affecting the textile industry. Subsequently, the utilization of the Taguchi methodology facilitated the acquisition of the most favorable conditions for whitening (A4B4C2), characterized by a whitening temperature of 130 °C, a whitening duration of 70 min, and an OB-1 mass of 0.0250 %, o.m.f. Subsequently, an ANOVA analysis was conducted, which indicated that the primary factor responsible for the observed outcome was the whitening temperature, accounting for 98.42 % of the variance. The study analyzed the phenomenon of whiteness under optimal conditions, revealing a greater amount (109.9) in comparison to the initial conditions (108.7). This outcome can be linked to the photographic representation of the sample treated with OB-1. The analytical characterization results indicate that PET's morphological structure remained unaltered following the application of OB-1 whitening in the D5 medium. Furthermore, the color fastness to washing and rubbing properties exhibited satisfactory results. The D5 medium's recyclability demonstrated high consistency and reproducibility, making it a promising avenue for advancing a sustainable textile whitening system based on D5.

CRediT authorship contribution statement

Yingjie Cai: Conceptualization, Formal analysis, Writing – original draft, Writing – review & editing. Tianjie Wang: Data curation, Investigation, Methodology. Le Li: Data curation, Investigation, Methodology. Xiaolong Huang: Data curation, Investigation, Methodology. Md. Nahid Pervez: Conceptualization, Formal analysis, Writing – original draft, Writing – review & editing. Ai Chen: Data curation, Investigation, Methodology. Xiaohua Zhao: Data curation, Investigation, Methodology. Lina Lin: Conceptualization, Formal analysis, Funding acquisition, Project administration, Supervision, Writing – review & editing. Xiaorong Xiong: Funding acquisition, Project administration, Supervision, Writing – review & editing. Vincenzo Naddeo: Funding acquisition, Project administration, Supervision, Writing – review & editing.

Acknowledgments

This work was financially supported by Hubei Hongxin Chemical Co., Ltd.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- An anticounterfeiting strategy based on photochromic nonwoven polyester fabric by plasma-assisting spray coating with ultraviolet-responsive silica@strontium aluminate nanoparticles. Appl. Organomet. Chem.. 2023;37:e7035.

- [CrossRef] [Google Scholar]

- Study the dyeing behavior of wool fabric using henna extract in decamethyl cyclopentasiloxane (D5) medium. J. Text. Inst.. 2020;112:358-362.

- [CrossRef] [Google Scholar]

- Al-Sayed, W., Abdelrahman, S.H., Sustainable Chemistry in textile processes (Pretreatment, Coloration and Chemical finishing), in Green Chemistry for Sustainable Textiles, 2021, Woodhead Publishing, 93-111.

- The optimization of whiteness of polyester fabric treated with nanoparticles of 2,2′-(vinylenedi-p-phenylene)bis-benzoxazole (OB-1) by the Taguchi method. Colloids Surf. A Physicochem. Eng. Asp.. 2023;676:132320

- [CrossRef] [Google Scholar]

- Cardamone, J.M., Marmer, W.N., The whitening of textiles, in Chemistry of the Textiles Industry, 1995, Springer Netherlands, Dordrecht, 46-101.

- Sustainable pilot scale disperse dyeing in a waterless silicone medium dyeing system for no discharge of wastewater. J. Clean. Prod.. 2021;321:128953

- [CrossRef] [Google Scholar]

- Chemical processing of knitted fabrics. In: Advanced Knitting Technology. Woodhead Publishing; 2022. p. :503-536.

- [Google Scholar]

- Process parameter optimization for ultimate tensile strength of friction stir welded joint of Al-10Mg-8Ce-3.5Si aluminium alloy plates using Taguchi technique. Mater. Today:. Proc.. 2022;52:772-779.

- [CrossRef] [Google Scholar]

- Construction of photonic crystals with high color stability on white polyester fabrics. Opt. Mater.. 2022;134:113104

- [CrossRef] [Google Scholar]

- Chemically recyclable bio-based polyester composed of bifuran and glycerol acetal. Eur. Polym. J.. 2021;145:110242

- [CrossRef] [Google Scholar]

- Adsorption, kinetics, and thermodynamic studies of cacao husk extracts in waterless sustainable dyeing of cotton fabric. Cellul.. 2021;28:2521-2536.

- [CrossRef] [Google Scholar]

- Effluent-free deep dyeing of cotton fabric with cacao husk extracts using the Taguchi optimization method. Cellul.. 2021;28:517-532.

- [CrossRef] [Google Scholar]

- Green and sustainable method to improve fixation of a natural functional dye onto cotton fabric using cationic dye-fixing agent/D5 microemulsion. J. Nat. Fibers. 2022;19:11283-11298.

- [CrossRef] [Google Scholar]

- Extraction of cyclic oligomer and their influence on polyester dyeing in a silicone waterless dyeing system. Polymers. 2021;13:3687.

- [Google Scholar]

- Post-treatment of reactive dyed cotton fabrics by caustic mercerization and liquid ammonia treatment. Cellul.. 2021;28:7435-7453.

- [CrossRef] [Google Scholar]

- Combination of pre- and post-mercerization processes for cotton fabric. Materials. 2022;15:2092.

- [Google Scholar]

- The thermo-mechanical and fluorescent properties of polyesters: A review. Polym. Sci., Ser. B. 2021;63:621-639.

- [CrossRef] [Google Scholar]

- Statistical modeling and optimization of heterogeneous Fenton-like removal of organic pollutant using fibrous catalysts: a full factorial design. Sci. Rep.. 2020;10:16133.

- [CrossRef] [Google Scholar]

- Murray, S.G., Dyes and fluorescent whitening agents for paper, in Paper Chemistry, 1996, Springer, Dordrecht, 161–193.

- Resolution enhancement of polymer X-ray diffraction scans using maximum entropy methods: Poly(ethylene terephthalate) Macromolecules. 1994;27:1484-1488.

- [CrossRef] [Google Scholar]

- Surface modification of polyester fabric using polyvinyl alcohol in alkaline medium. Indian J. Fibre Text. Res.. 2012;37:287-291.

- [Google Scholar]

- Direct identification and quantitation of fluorescent whitening agent in wheat flour based on multi-molecular infrared (MM-IR) spectroscopy and stereomicroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc.. 2021;250:119353

- [CrossRef] [Google Scholar]

- Sustainable pilot scale reactive dyeing based on silicone oil for improving dye fixation and reducing discharges. J. Clean. Prod.. 2021;279:123831

- [CrossRef] [Google Scholar]

- Multi-response optimization of resin finishing by using a taguchi-based grey relational analysis. Materials. 2018;11:426.

- [Google Scholar]

- Impregnation of zinc oxide mediated chitosan nano-composites on polyester fabric for performance characteristics. Fibers Polym.. 2016;17:1378-1383.

- [CrossRef] [Google Scholar]

- Covalent polyester colouration by in situ chromophore creation. Chem. Commun.. 2020;56:6360-6363.

- [CrossRef] [Google Scholar]

- Polyester fabric with fluorescent properties using microwave technology for anti-counterfeiting applications. J. Fluoresc.. 2022;32:327-345.

- [CrossRef] [Google Scholar]

- Respirometric study of optical brighteners in textile wastewater. Materials. 2019;12:785.

- [Google Scholar]

- Sustainable dyeing of nylon fabric with acid dyes in decamethylcyclopentasiloxane (D5) solvent for improving dye uptake and reducing raw material consumption. J. Clean. Prod.. 2021;279:123480

- [CrossRef] [Google Scholar]

- Use of quaternary ammonium salt as a dye fixing agent and antimicrobial agent in sustainable, single-step single-bath dyeing and finishing. Text. Res. J.. 2023;93:554-564.

- [CrossRef] [Google Scholar]

- Inorganic finishing for textile fabrics: recent advances in wear-resistant, UV protection and antimicrobial treatments. Inorganics. 2023;11:19.

- [Google Scholar]

- Structural relationships and optimization of resin-finishing parameters using the Taguchi approach. Cellul.. 2018;25:6175-6190.

- [CrossRef] [Google Scholar]

- Identifying the values of whiteness index, strength and weight of cotton spandex woven fabric in peroxide bleaching of different concentration. Fibers Textiles. 2019;26:96-109.

- [Google Scholar]

- A review on the application of optical brightener agents in textile industry. J. Stud. Color World. 2019;9:65-78.

- [Google Scholar]

- Non-aqueous dyeing of cotton fibre with reactive dyes: A review. Color Technol.. 2020;136:214-223.

- [CrossRef] [Google Scholar]

- The synthesis and properties of benzoxazole fluorescent brighteners for application to polyester fibers. Dyes Pigm.. 2007;75:185-188.

- [Google Scholar]

- Vik, M., Mukthy, A.A., Viková, M. Whiteness Perception under LED Source with High Content of UV Radiation. in Key Engineering Materials. 2022. Trans Tech Publ.

- Conversion of renewable vanillin into high performance polyimides via an asymmetric aromatic diamine derivation. Polym. Degrad. Stab.. 2019;167:67-76.

- [CrossRef] [Google Scholar]

- Surface modification of polyester nonwoven fabrics by Al2O3 sol–gel coating. J. Coat. Technol. Res.. 2009;6:537-541.

- [CrossRef] [Google Scholar]

- An environmentally responsible polyester dyeing technology using liquid paraffin. J. Clean. Prod.. 2016;112:987-994.

- [CrossRef] [Google Scholar]

- Substituent-dyeing properties relationship of disperse dyes on polyester in low pressure waterless dyeing system. Fibers Polym.. 2022;23:443-449.

- [CrossRef] [Google Scholar]

- Enhanced fluorescent performance of modacrylic/cotton blended fabric by pretreatment with sodium chlorite bleaching. Text. Res. J.. 2022;92:4722-4735.

- [CrossRef] [Google Scholar]

- Investigation from molecular packing to application of azobenzene disperse dyes on polyester fabrics to realize waterless dyeing. J. Mol. Liq.. 2022;349:118133

- [CrossRef] [Google Scholar]

- Distribution mechanism of disperse dyes with similar substituents in a waterless dyeing system based on molecular dynamic simulation. Dyes Pigm.. 2022;202:110264

- [CrossRef] [Google Scholar]

- Study from molecular dynamics simulations to dyeing behavior of disperse dyes with different substituents in D5 dyeing system. Fibers Polym.. 2023;24:1359-1365.

- [CrossRef] [Google Scholar]

- Toward improved performance of reactive dyeing on cotton fabric using process sensitivity analysis. Int. J. Clothing Sci. Technol.. 2022;34:469-484.

- [CrossRef] [Google Scholar]

- Coloring properties of novel 1, 4-distyrylbenzene and 4, 4′-distyrylbiphenyl fluorescent brighteners and their arrangement in cotton and polyester fiber. Cellul.. 2014;21:2937-2950.

- [Google Scholar]

Appendix A

Supplementary material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.arabjc.2024.105759.

Appendix A

Supplementary material

The following are the Supplementary data to this article:Supplementary data 1

Supplementary data 1