Translate this page into:

Effect of dry heat modification and the addition of Chinese quince seed gum on the physicochemical properties and structure of tigernut tuber starch

⁎Corresponding author. liuhuamin5108@163.com (Hua-Min Liu)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

To expand industrial utilization of tigernut starch and meet the demand for industrial starch, the influence of dry heat treatment (130 °C for 2 h and 4 h, 7% moisture) on the functional properties and structure of tigernut starch alone and mixed with Chinese quince seed gum (1% w/w) was investigated. Modifying the starch significantly (p < 0.05) increased peak, trough and final viscosity, and reduced the swelling power and gelatinization enthalpy. In addition, the freeze–thaw stability and pseudoplastic flow were enhanced by this modification process. Microscopic and crystalline structure results indicate that dry heat treatment without gum destroys the surface and the internal crystals of the starch granules, but when gum was present, the granule becomes more resistant to dry-heating. Overall, the treatment with dry heat and the addition of Chinese quince seed gum improved the physicochemical properties of tigernut starch, in particular by increasing freeze–thaw stability and viscosity to expand the application of the starch in food industry.

Keywords

Tigernut starch

Chinese quince seed gum

Dry heating

Pasting properties

Crystalline structure

1 Introduction

Starch is widely used in both non-food and food applications (Sarkheil and Rahbari, 2019). As industrial demand for starches increases, there is need to source alternative and new starches from agricultural raw materials (Chandanasree et al., 2016). Tigernut (Cyperus esculentus L.; Cyperaceae) is a monocotyledonous plant cultivated for its edible tubers which can be used as a source of starch and oil because of their high amounts of starch (30%) and oil (23%) (Li et al., 2017). Tigernut starch has functional and physicochemical characteristics lacking in maize or potato starches (e.g., binding and compatibility behaviors), and thus has potential for many industrial applications (Li et al., 2017).

When used for specific industrial purposes, native starches are often modified to improve desirable functional characteristics including heat tolerance, dispersion, and solubility. Chemical modifications used to improve such characteristics include derivatization (e.g., by cross-linking), esterification, and degradation (oxidization and acid hydrolysis of starch) (Singh et al., 2019; Ganesh et al., 2020). However, various factors, such as residual reactive compounds and associated environmental pollutants, can restrict the application of chemical modifications (Qiu et al., 2015b; Jain et al., 2020). Physical modifications for improving functional characteristics include dry heat treatment, moist heat treatment, and pregelatinization (Yan et al., 2020). Dry heat is a particularly promising method for preparing modified starches (Qiu et al., 2015b). In general, the starches are heated at temperatures of 110–150 °C for 1–4 h with a low moisture level (10%) (Oh et al., 2018b). Dry heat treatment of a starch damages its granules to a certain extent, which leads to structural changes in the amorphous and crystalline regions of the starch molecules (Lim et al., 2006). The treatment can also change functional properties such as viscosity, solubility and swelling power of the starch (Gou et al., 2019). Dry heat treatment is simple, inexpensive and nontoxic as compared with chemical modification (Sun et al., 2014).

Gums can alter the structural and chemical properties of starches, and many investigations have focused on heat treatment of starch in the presence of natural or modified hydrocolloids (gums). In industrial applications, xanthan gum, CMC (organic sodium carboxymethylcellulose), and sodium alginate, which are water soluble polysaccharides with large molecular weights, are the most common gums that react physically or chemically with starches (e.g., pea, potato, corn, and waxy maize starches), to improve morphological, thermal, and pasting properties (Lim et al., 2002; Sun et al., 2013; Oh et al., 2018a). According to the specific combination of starches and hydrocolloids, various combinations of starches and hydrocolloids under dry heat treatment can yield starches with improved functional characteristics (Oh et al., 2018a). Li et al. (2013) found that under dry heat treatment, the xanthan is attached to the surface of the starch granules and acts as a cross-linker to agglomerate the starch granules, resulting in improved rheological and thermal properties. Lim et al. (2003) reported that dry heat treatment at controlled pH of starches combined with ionic hydrocolloids increased paste viscosity significantly. The rise in viscosity was presumably due to esterification between the hydroxyl groups in the starch and carboxyl groups in the ionic hydrocolloids. However, the effect of anionic hydrocolloids is not universal. Dry heat treatment with the addition of an anionic hydrocolloid influenced the characteristics of waxy maize starch more than it did the characteristics of potato starch (Lim et al., 2002).

Chinese quince (Chaenomeles sinensis; Rosaceae) seed gum (CQSG) is a water-soluble, natural gum comprising high molecular weight heteropolysaccharides (Mw of 446.0 × 103 Da) which can be isolated from the surface of Chinese quince seeds (Wang et al., 2018). The seed hydrocolloid contains more uronic acid (31.7%) than other plant seed gums such as flaxseed gum (18.5%) and ordinary quince (Cydonia oblonga; Rosaceae) seed gum (18.7%), indicating that it has more carboxyl groups (Wang et al., 2019). CQSG possesses excellent rheological characteristics in terms of gelling, emulsification, and thickening. Seed gums, such as CQSG, have been added to starches to improve starch properties; however, at present, no one has investigated the influence of dry heat treatment on the functional characteristics of starch mixed with CQSG. Both CQSG and tigernut starch (TS) are natural compounds with important functional characteristics that are under-utilized in industry. Therefore, for better utilization of both TS and CQSG in various industries, the effect of dry heat treatment on the functional properties of tigernut starch with and without CQSG was investigated in the present study.

2 Materials and methods

2.1 Materials

TS used in the present study was isolated from tigernut tubers grown in Hebei Province of China. The tigernut tuber was ground into powder by a laboratory crusher to obtain the fractions below 0.425 mm sieve. The powder was dried at 60 °C for 24 h and stored at 4 °C. All solvents and chemicals used in the experiments were of analytical grade.

2.2 Preparation of tigernut starch and Chinese quince seed gum

The tigernut tuber powders were suspended in hexane (solid/liquid ratio of 1:3, g/mL) at room temperature for 24 h. After suspending, the supernatant was removed, and the residue was extracted twice using the same solvent and procedure. Then the residue was air-dried at room temperature to remove the residual solvent. The resulting residue was extracted using a 0.01 mol/L aqueous sodium hydroxide solution (solid/liquid ratio, 1:5, g/mL) at room temperature for 6 h with continuous stirring. The insoluble residues were obtained by centrifugation at 3000 × g for 20 min. After precipitating and re-suspending using the distilled water four times, the resulting starch was washed using 12.02 mol/L ethanol three times. The obtained starch was dried at 35 °C for 24 h, carefully ground, and passed through a 0.15 mm sieve. Eventually, about 13.25% of the tigernut starch was collected, and the purity of the starch was 88.9% (approximately), and the starch contained 6.9% moisture, 0.35% protein, 0.3% ash, and 0.6% fat, respectively.

CQSG was separated from the seeds of Chinese quince according to the method published previously by our laboratory (Wang et al., 2018). Chinese quince seeds (200 g) were immersed in plenty of water at room temperature with continuous stirring to separate the gum, and the mixed solution was centrifuged at 4500 × g to obtain mucilage (Jingli centrifuge, mod LD5-10, Beijing, China). The mucilage was removed small molecule polysaccharides using anhydrous ethanol (2 L), and the sediment was dissolved in a small amount of water and then freeze-dried using a Sihuan LGJ-10C freeze dryer (Beijing, China) to obtain the CQSG.

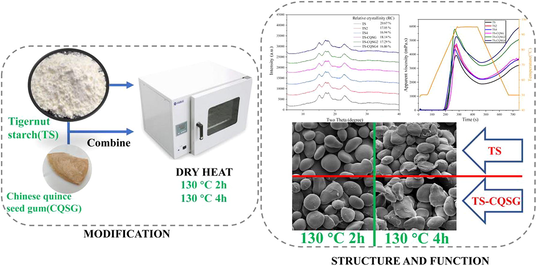

2.3 Starch modification by dry heat treatment with Chinese quince seed gum

Modification of TS was carried out by dry heating of starch with and without CQSG; the treatment protocols are presented in Table 1. CQSG (0.5 g, dry basis) was slowly dissolved in distilled water (100 mL) with vigorous stirring at 25 °C. TS (49.5 g) was dispersed in the prepared gum solutions and stirred using a magnetic stirrer (DLAB, mod MS7-H550-PRO, Beijing, China) for 2 h at 25 °C. The mixed solution was dried by using a vacuum dryer (Jinghong mod XMTD-8222, Shanghai, China) at 35 °C for 48 h. The dried mixtures of starch and gum were ground into powder and passed through a 0.15 mm sieve. The starch itself without the addition of gum was treated under identical conditions. The resulting starch and starch-gum powders were divided into three sample groups: Two were heated in an electric oven (Jinghong mod XMTD-8222, Shanghai, China) at set temperatures for either 2 h or 4 h, named as TS2 and TS4, and TS-CQSG2 and TS-CQSG4, respectively; one additional group of samples was not treated with dry heat and used as the control, named as TS and TS-CQSG, respectively. TS represents the tigernut starch; CQSG represents the Chinese quince seed gum.

Sample

TS (g)

CQSG (g)

Heating temperature (°C)

Heating time (h)

TS

50

–

–

–

TS2

50

–

130

2

TS4

50

–

130

4

TS-CQSG

49.5

0.5

–

–

TS-CQSG2

49.5

0.5

130

2

TS-CQSG4

49.5

0.5

130

4

2.4 Pasting properties

The pasting characteristics of native and modified TS were investigated by a rapid visco analyzer (RVA, Perten, mod 4500, Sweden). For a typing test, a starch sample (3 g) was added to 25 g distilled water, and the obtained starch suspension was subjected to heating and cooling cycles as reported previously (Guo et al., 2020). The temperature protocol was as follows: heated from room temperature to 50 °C; equilibrated for 1 min; heated to 95 °C at the rate of 9 °C/min and maintained for 5 min; cooled from 95 °C to 50 °C at the rate of 9 °C/min and maintained for 2 min. The initial paddle speed was set at 960 rpm for 10 s to ensure the slurry was well distributed in the water, and then held at 160 rpm. All experiments were replicated three times. Pasting parameters were calculated automatically by RVA software.

2.5 Rheological measurements

After the completion of the RVA experiment, the hot starch paste was left standing for 2 h. Then, a steady flow test was carried out by the method reported previously using a rheometer (Liu et al., 2021) (HAAKE MARS, Karlsruhe, Germany). Steady shear measurements were obtained at 25 °C in a parallel plate system (4 cm diameter, 1000 μm gap). A small amount of silicon oil was dropped on the edge of the parallel plate to prevent evaporation during the test process. Before starting the test, the paste was left on the parallel plate for 5 min. Next, the sample was sheared continuously from 0.1 to 100 s−1. Ostwald de Waele rheological formula was used to determine the flow behavior as follows: where τ, represents the shear stress, K represents the indexes of the consistency, n represents the flow behavior, and represents the shear rate.

2.6 Solubility and swelling power

Swelling power and solubility of the native and modified starches were measured following the method described previously (Duan et al., 2020). Each sample suspension (2%, g/mL) was prepared in a flask with a closed screw cap and heated to a set temperature (75 °C and 85 °C) with continuous stirring for 60 min. Then the starch solution was cooled to room temperature and centrifuged for 15 min at 3000 × g (Jingli centrifuge, mod LD5-10, Beijing, China). The sediment and supernatant were separated for further determination. The sediment was weighed. The supernatant was transferred to a surface dish and dried overnight at 105 °C. The resulting residue was weighed, and taken to represent the content of the sample solubilized in water. The solubility (SOL) and swelling power (SP) were calculated according to the following formulas:

2.7 Freeze-thaw stability

Freezing and thawing procedures to determine the syneresis were based on the methodology described in our previous paper (Miao et al., 2021). Each starch suspension (6%, w/w) was prepared in distilled water and heated in boiling water for 30 min with continuous stirring. After the gels cooled to room temperature, the samples were stored at 4 °C for 16 h and then frozen at –20 °C for 22 h. Next, the gels were thawed at room temperature for 2 h to reach an equilibration. The freeze–thaw cycle was repeated for up to five cycles. The water that separated from the gels was centrifuged at 3000 × g for 20 min and then weighed. Syneresis was calculated as the percentage of water separated based on the initial the weight of the starch paste.

2.8 Thermal properties

The thermal characteristics of the native and modified starches were determined using a Q20-type of differential scanning calorimetry (DSC, TA, USA). Starch sample (approximately 2.5 mg) was mixed with distilled water at a solid/water ratio of 1:3 (w/w) in an aluminum pan. Subsequently, the sample pan was hermetically sealed, stored at 4 °C for 1 h, and then heated from 40 °C to 120 °C at a rate of 10 °C/min. An empty pan was used as a reference.

2.9 X-ray diffraction analysis

X-ray diffraction measurements of all samples were carried out on an X-ray diffractometer (Bruker, mod D8, Karlsruhe, Germany) with nickel-filtered Cu Kα radiation (wavelength of 0.15406 nm). The X-ray generator was operated at 40 kV and 40 mA under room temperature. Measurements were carried out at a diffraction angle range of 5–40° (2 theta range) with a scanning rate of 0.02°/s. HighScore Plus was used to determine the relative crystallinity of the samples. The relative crystallinity (RC) was calculated using the equation:

RC × 100where Ac is the crystalline area and Aa is the amorphous area on the X-ray diffractograms.

2.10 Fourier transforms infrared spectroscopy (FT-IR)

The infrared spectra of all samples were recorded using an IR spectrometer (Thermo Scientific Nicolet, mod iS10, USA) in the range of 4000–400 cm−1. Each sample was mixed with KBr at the ratio of 1:100 (starch/KBr, w/w) and pressed to form a pellet. The pellet was then subjected to the IR spectrometer operating at a resolution of 4 cm−1. The spectra at 800–1200 cm−1 were deconvoluted and normalized using OMNIC 8.2 software (Thermo Nicolet Inc., USA), the peak width was 26 cm−1, and the enhancement factor was 2.4. Then, the ratio of absorbance at 1047 cm−1and 1027 cm−1 was calculated.

2.11 Scanning electron microscopy

Morphological features of all samples were recorded in a Model S-3000H scanning electron microscope (SEM, HITACHI, mod S-3000H, Japan). The dried starch powder was mounted on aluminum stubs and sputter-coated with gold powder. A low accelerating voltage of 2.0 kV was used for image observation.

2.12 Statistical analysis

The results of the pasting properties, freeze–thaw stability, and swelling power and solubility tests were reported as means ± standard deviation for three replications. Statistical difference was determined significant at p < 0.05 (Duncan’s new multiple range test). All data were analyzed using SPSS version 19 package (IBM, Armonk, NY).

3 Results and discussion

3.1 Pasting properties

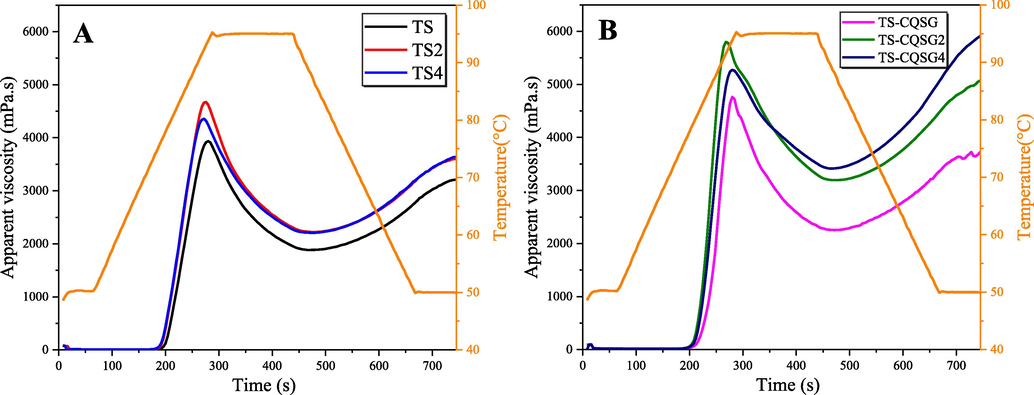

The pasting properties of TS showed significant differences (p < 0.05), particularly for the TS combined with CQSG (Table 2, Fig. 1). It is widely known that the addition of gum interferes with the swelling of starch and influences the viscosity characteristics of the starch through associations between gum and amylose (Nawab et al., 2014). The pasting temperature of the starch increased when the CQSG was present, from 76.0 °C to 78.3 °C, and the tendency is consistent with the presence of xanthan gum in normal maize starch (Nawab et al., 2014). This phenomenon could possibly be attributed to a mass of hydroxyl groups in CQSG reducing the swelling of starch granules during cooking by preventing the available free water from forming a starch paste (Lutfi et al., 2019). After the TS was dry heat-treated, the pasting temperature obviously decreased, possibly due to the destruction of hydrogen bonds of starches, and resulting in the incipient swelling of starch granules (Li et al., 2013). Additionally, the pasting temperature of TS-CQSG was also decreased by dry heating for 2 h, but obviously increased, ranging from 77.1 °C to 78.0 °C, with the increase of dry heating time to 4 h. Similar results have been reported by Sun et al. (2013). The phenomenon indicates that, when dry heat treatment exceeded 2 h, CQSG gradually but significantly improved the structural stability of TS. Date are means ± SD. Means in the same column with the same superscripts do not differ significantly (p < 0.05) (n = 3).

Samples

Pasting temperature(°C)

Viscosity (cP)

Peak

Trough

Final

Breakdown

Setback

TS

76.0 ± 0.6c

3947 ± 18e

1890 ± 10d

3206 ± 4d

2058 ± 8c

1317 ± 6c

TS2

74.8 ± 0.1d

4594 ± 111 cd

2209 ± 21c

3551 ± 66c

2385 ± 91b

1342 ± 45c

TS4

74.9 ± 0.1d

4299 ± 83d

2175 ± 44c

3589 ± 86c

2124 ± 40c

1415 ± 42c

TS-CQSG

78.3 ± 0.5a

4715 ± 66c

2234 ± 28c

3663 ± 137c

2481 ± 38b

1429 ± 109c

TS-CQSG2

77.1 ± 0.1b

5973 ± 243a

3230 ± 51b

5151 ± 124b

2743 ± 193a

1921 ± 74b

TS-CQSG4

78.0 ± 0.0a

5188 ± 123b

3387 ± 38a

5874 ± 101a

1801 ± 85d

2488 ± 63a

Pasting properties of TS (A) and TS-CQSG (B) before and after heat modification.

The paste viscosity (peak, trough, and final) of TS after dry heating increased compared with the native starch, and the presence of CQSG further enhanced the heating effects. The peak viscosity is the maximum viscosity before the decomposition of starch granules during gelatinization. As the length of treatment time increased, the peak viscosity of TS and TS-CQSG first increased and then decreased. After 2 h dry heat treatment, the peak viscosity of TS increased by 16% compared to native starch, and the peak viscosity of TS-CQSG increased by 26% compared to the unheated starch-gum blends. The increase in peak viscosity of TS-CQSG indicated that the cross-linking between the gum and amylose contributed to the viscosity in addition to the structural rearrangement of starch during the dry heat treatment (Qiu et al., 2015a). However, there was a decrease in the peak viscosity when treatment reached 4 h, which can probably be attributed to the destruction of glycosidic bonds and partial crystal melting (Gul et al., 2014; Oh et al., 2018b). For the TS-CQSG blends, the continuous dry heat weakened the effect of cross-linking was an important associated factor as well. The breakdown viscosity is used to determine the shear resistance and paste stability, and it is calculated as the difference between peak viscosity and trough viscosity. The breakdown value of TS4 (2124 cP) was lower than TS2 (2385 cP) and higher than TS (2058 cP), and the value of TS-CQSG4 (1801 cP) was lower compared to that of TS. These results showed that heating for 2 h destroyed the ordered structure of the starch, resulting in the decrease of paste stability. In contrast, heating for 4 h enhanced the cohesive forces between starch chains, resulting in the high resistance to the high temperature and shear (Zhang et al., 2021). This was especially true for the starch with CQSG. The setback reflects the retrogradation degree of starch paste, which is the difference between final viscosity and trough viscosity. The setback values of TS and TS-CQSG increased consistently as the duration of dry heat increased, ranging from 1317 cP to 1415 cP and from 1429 cP to 2488 cP, respectively. The increase in setback value of TS may be due to heating destroying the crystalline structure and facilitating re-association of linear amylose chains (Zhang et al., 2021; Lee et al., 2021), resulting in the final viscosity of paste increased. It was noteworthy that the starch treated with the combination of CQSG addition and dry heating exhibited higher setback value than those treated with dry heating alone. Presumably, gum added to starch dispersion was distributed in a continuous phase due to incompatibility between the two, resulting in an increase in the effective concentration of leached amylose and/or molecular chains broken by heating, accelerating the starch molecule interactions (Liu et al., 2021). Furthermore, gum makes an additional contribution to the viscosity of the system due to its own viscoelastic properties (Wang et al., 2018). Typically, the interaction between hydrocolloid and amylose could inhibit rearrangement of amylose to some extent and decrease the setback value (Lutfi et al., 2017). But, the inhibitory effect of the interaction between hydrocolloid and amylose on setback was less than facilitation effect brought by combination of CQSG and heating in this research. Overall, results of the current study suggest that the pasting properties of TS and TS-CQSG can be improved by controlled heating to serve different functional needs.

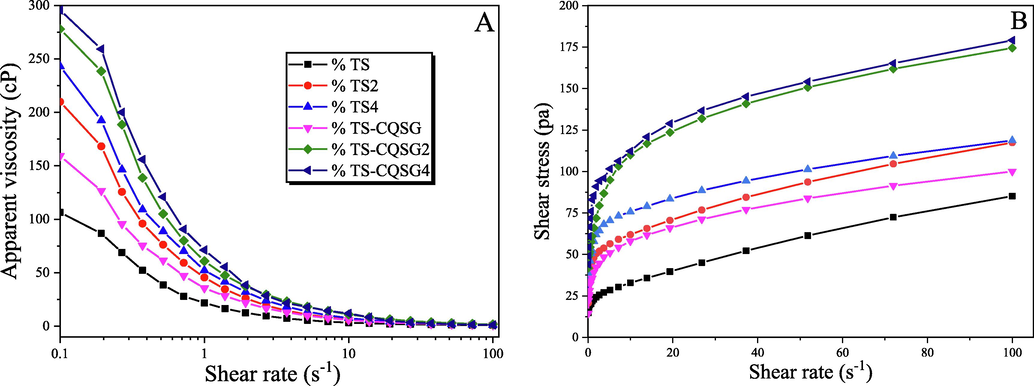

3.2 Rheological measurements

The steady shear flow curves of native and modified TS pastes are presented in Fig. 2. The addition of CQSG slightly increased the apparent viscosity of native starch (Fig. 2A). However, the apparent viscosity of both TS and TS-CQSG pastes significantly increased after dry heating, which was consistent with the results of the final viscosity assessments (Table 2). Furthermore, the apparent viscosities of TS-CQSG mixed pastes increased more pronouncedly than those of TS pastes. Similar results were found by Li et al. (2013). The phenomenon might be due to heat treatment decreased intermolecular force of CQSG caused the water molecules to interact better with the CQSG through hydrogen bonding, which further increased the viscosity values of mixed pastes.

(A) Apparent viscosity and (B) Steady shear flow of native and modified tigernut starch.

In order to further describe the flow behavior as a function of shear rate for the TS with and without CQSG heated for different lengths of time, the experimental data shear stress versus shear rate was fitted to the Ostwald de Waele rheological model (Fig. 2B). The rheological parameters obtained by this model are shown in Table 3. All the coefficients of determination (R2) between curves and regression equations were over 0.94, indicating that the Ostwald de Waele rheological model was well-fitted to the profile of rheological characteristics of the samples. The consistency coefficient (K) of starch pastes varied from 19.49 to 74.52 Pa.s. The K value of TS-CQSG4 starch paste is the highest, which was mainly attributed to the intermolecular entanglement or interaction between the hydrophilic gum and the starch molecules. In the presence of CQSG, the flow behavior index (n) of TS decreased from 0.29 to 0.22, indicating the pseudoplasticity increased, i.e., higher degree of structural breakdown in shearing, which was consistent with our previous research (Liu et al., 2021). After the TS and TS-CQSG were dry heat-treated, the n values consistently decreased as time increased (Table 3). This phenomenon was perhaps due to the glycosidic linkages and hydrogen bonds of starch granules being damaged by the continuous heating at high temperatures, leading to failure to maintain network structure and finally inducing gel collapse (Oh et al., 2018a). K represents the indexes of consistency, n represents the flow behavior, and R2 represents the coefficients of determination.

Samples

K (Pa.s)

n

R2

TS

19.49

0.29

0.94

TS2

41.55

0.21

0.97

TS4

50.90

0.18

0.98

TS-CQSG

34.89

0.22

0.99

TS-CQSG2

65.43

0.21

0.99

TS-CQSG4

74.52

0.17

0.95

3.3 Swelling power and solubility

Changes in swelling power and solubility of the starch with and without gum after heat treatment for different times are shown in Table 4. Starch is insoluble in cold water due to its crystalline nature. When it is dissolved in warm water and heated continuously, the granules gradually swell, but only up to a specific temperature. For the native starch, the swelling power increased as the temperature increased from 75 °C to 85 °C, and slightly decreased as the heat treatment was extended from 2 h to 4 h (18.3–17.5 g/g and 27.7–23.1 g/g, respectively). Pramodrao and Riar (2014) observed a similar phenomenon in potato and taro starches after dry heating for 2 and 4 h. The decrease in swelling power might be due to the destruction of starch granules by high temperature, resulting in restricted swelling, thus the decrease of swelling power (Gul et al., 2014), which is confirmed by SEM analysis as described in section 3.8 of this paper. Adding CQSG to native starch slightly decreased the swelling power of the starch, and significantly decreased it as the dry heating time was extended from 2 to 4 h (p < 0.05). This is probably due to the interaction between the gum and the amylose outside the starch granules, producing a complex matrix of hydrocolloid and amylose on the surface of the gelatinized granules (Pramodrao and Riar, 2014). Dry heat TS-CQSG can weaken the hydrogen bond between high molecular weight hydrocolloids and induce gum particles to promptly bound with water to form a gelatinous barrier layer during cooking, inhibiting the swelling inside the blends (Zeng et al., 2021). Date are means ± SD. Means in the same column with the same superscripts do not differ significantly (p < 0.05) (n = 3).

Sample

Swelling power (g/g)

Solubility (%)

75 °C

85 °C

75 °C

85 °C

TS

18.3 ± 0.5a

27.7 ± 1.1d

17.6 ± 0.3b

20.2 ± 0.4b

TS2

17.8 ± 0.4c

27.4 ± 1.6 cd

18.7 ± 0.4bc

23.3 ± 0.9c

TS4

17.5 ± 0.8bc

23.1 ± 2.4bc

20.2 ± 1.7c

25.1 ± 0.4d

TS-CQSG

17.9 ± 1.2c

25.0 ± 0.8b

15.4 ± 0.3a

17.2 ± 0.7a

TS-CQSG2

15.8 ± 0.5b

17.7 ± 0.7a

19.7 ± 0.8c

21.8 ± 1.4c

TS-CQSG4

13.8 ± 0.4c

16.5 ± 0.6a

20.6 ± 0.4c

22.8 ± 0.5c

It is reported that amylose can leak out through radial ‘channels’, created by semi-crystalline or amorphous material, during gelatinization (Pramodrao and Riar, 2014). The amount of amylose leaked is directly proportional to the solubility values (Gul et al., 2014). For the TS and TS-CQSG, with heating time from 2 h to 4 h, the solubility was found to increase consistently at 75 °C and 85 °C. The results can be attributed to the dry heat treatment destroying the structure of the starch granules and increasing the cross-sectional area of the channels, thus increasing the rate at which amylose was leaking out. In the presence of CQSG, the solubility was slightly decreased compared to that of the native starch at 75 °C and 85 °C, with a shift of approximately 2.2 and 3.0 % at those temperatures, respectively. These results were consistent with those of systems comprising sodium alginate blended with potato starch and xanthan and guar gums blended with cowpea starch (Pramodrao and Riar, 2014; Nawab et al., 2014). The phenomenon might be because the hydrocolloid and amylose complex matrix partially impedes the leakage of amylose.

3.4 Freeze-thaw stability

Starch-based processed foods are often subjected to freezing and thawing during storage and transportation. Thus, any starch to be used in such foods must be stable against freeze–thaw. When a starch gel is repeatedly frozen and thawed, the interchain interaction releases residual water in the gel matrices, i.e., syneresis occurs (Zhang et al., 2019). The syneresis of the six starches as a function of 1–5 freeze–thaw cycles are shown in Table 5. With an increase of cycle time to 5, the TS gel syneresis increased from 34.62 to 41.04%, indicating the native tigernut starch gel is not stable during repeated freezing and thawing. When TS was dry heat-treated, the syneresis value obviously increased as the duration of the heat treatment increased. Generally, heat-treated gels tend to have high syneresis values, because heat treatment increases the interaction between amylose and amylopectin, resulting in lower water retention capacity (Zhang et al., 2021). Adding a small amount of CQSG to native tigernut starch, without heat treatment, can effectively reduce gel syneresis. Additionally, the total syneresis value of TS-CQSG4 was 29.02%, which is significantly (p < 0.05) less than both TS (41.04%) and TS4 (51.96%). The probable explanation is that the CQSG distributed in the continuous phase reduced the formation of ice crystals in the gel network during refrigeration by competing with starch for water, thus interfering with the disruption of the gel structure and reducing the syneresis during thawing (Chen et al., 2015; Pongsawatmanit and Srijunthongsiri, 2008). In addition, the interactions between CQSG and amylose molecules may interfere with the formation of cross-linking between the polymer molecular chains and improve the water retention capacity of network structures, which was also a non-negligible factor that leads to the decrease in the syneresis (Chen et al., 2015; BeMiller, 2011). Date are means ± SD. Means in the same column with the same superscripts do not differ significantly (p < 0.05) (n = 3).

Sample

Syneresis (%)

1 day

2 day

3 day

4 day

5 day

TS

34.63 ± 3.32b

37.01 ± 4.69b

38.3 ± 4.74b

40.12 ± 4.93b

41.04 ± 4.92b

TS2

40.34 ± 0.23c

42.62 ± 1.74bc

43.99 ± 1.68bc

45.56 ± 1.57bc

47.07 ± 2.02bc

TS4

43.77 ± 0.99c

45.51 ± 0.13c

47.85 ± 1.51c

50.39 ± 3.06c

51.96 ± 2.41c

TS-CQSG

11.67 ± 0.27a

16.8 ± 2.86a

20.01 ± 3.62a

23.97 ± 2.08a

24.85 ± 2.26a

TS-CQSG2

14.16 ± 2.23a

22.19 ± 2.12a

23.77 ± 2.53a

26.38 ± 1.85a

28.76 ± 2.6a

TS-CQSG4

16.7 ± 3.86a

22.57 ± 5.03a

24.02 ± 4.49a

26.62 ± 3.39a

29.02 ± 3.52a

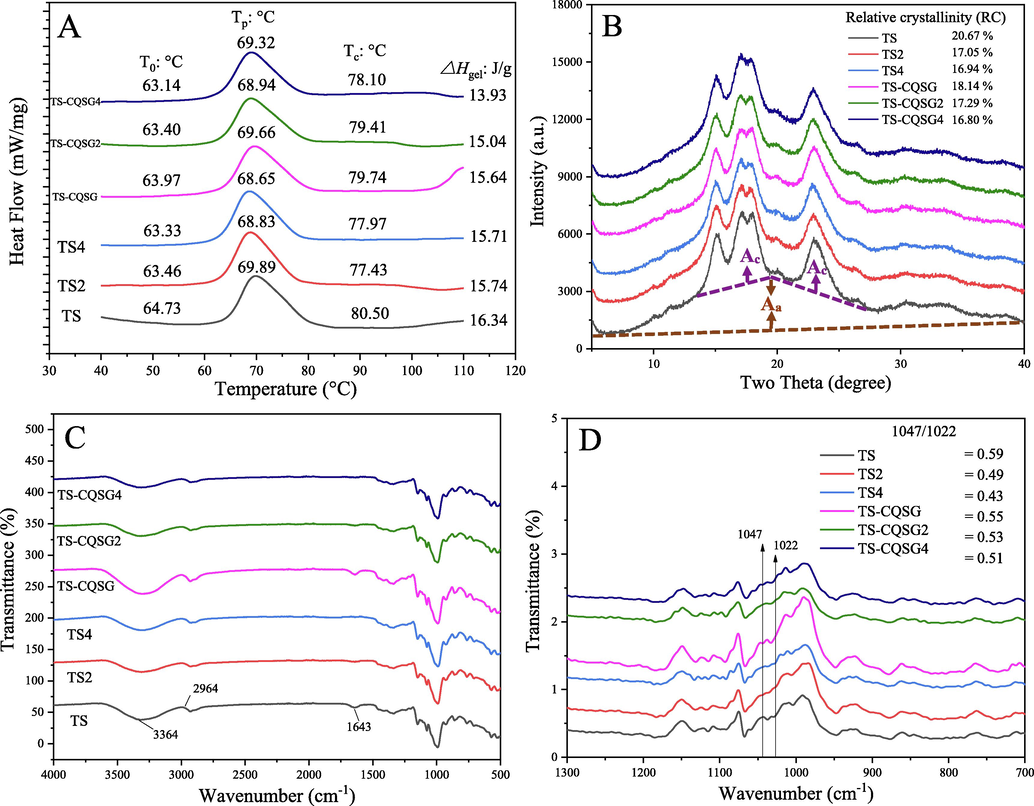

3.5 Thermal properties

The DSC curves of the six samples are presented in Fig. 3A. The gelatinization temperature, onset (To), peak (Tp), conclusion (Tc) and enthalpy change (△Hgel) of gelatinization are also shown in Fig. 3A. There was obviously a difference in gelatinization properties among the modified starch compared to the native starch. When TS was heated, the To and Tp decreased with an increase in heat treatment time from 2 h to 4 h (64.73–63.33 °C and 69.89–68.65 °C, respectively), which was attributed to structural disruption of starch granules as the temperature rose. Similar results have been reported for cassava starch by Chandanasree et al. (2016). In the presence of CQSG prior to heating, these values of To, Tp, and Tc all decreased slightly, which was similar to the results for corn starch with 0.1% corn fiber gum (Qiu et al., 2017). Upon dry heating with CQSG, the To and Tc also shifted to lower temperatures, indicating that the process facilitates the gelatinization of starch granules. Furthermore, based on the DSC curves, the enthalpy change (△Hgel) values of heat-treated TS and TS-CQSG were found to consistently decrease from 16.34 to 15.71 J/g and from 15.64 to 13.93 J/g, respectively. The reduction in enthalpy change indicates the decrease of heat absorbed as crystal and helical structures were destroyed during gelatinization. Thus, it can be inferred that the crystalline region of starch granules was destroyed by dry heating, which is confirmed by XRD analysis as reported in section 3.6 of this paper.

Thermal properties (A), X-ray diffraction spectra (B) and FT-IR spectra (C: Original spectra; D: Deconvoluted spectra) of native and modified tigernut starch.

3.6 XRD analysis

The X-ray diffraction patterns of the six samples are presented in Fig. 3B. All samples showed the typical A-pattern, which is representative of grain starches with strong peaks at 2θ of 15°, 17.2°, 18.1° and 23.1°, respectively. It was observed that the spectral patterns of TS after modification had no new diffraction peak, but the intensities representing the crystal structure changed slightly, mainly showing the decrease of relative crystallinity. The decrease of relative crystallinity caused by adding CQSG might be due to the existence of amorphous material (CQSG) in the blends. Heating might have destroyed starch crystallites and/or altered crystallite orientation (Sun et al., 2014). After heating for 4 h, the crystallinity of TS-CQSG decreased by only 7%, while that of TS decreased by about 18%. This result illustrated that the addition of CQSG reduced damage of the crystallization region, which was confirmed by electron microscopic (SEM) analysis (Fig. 4).

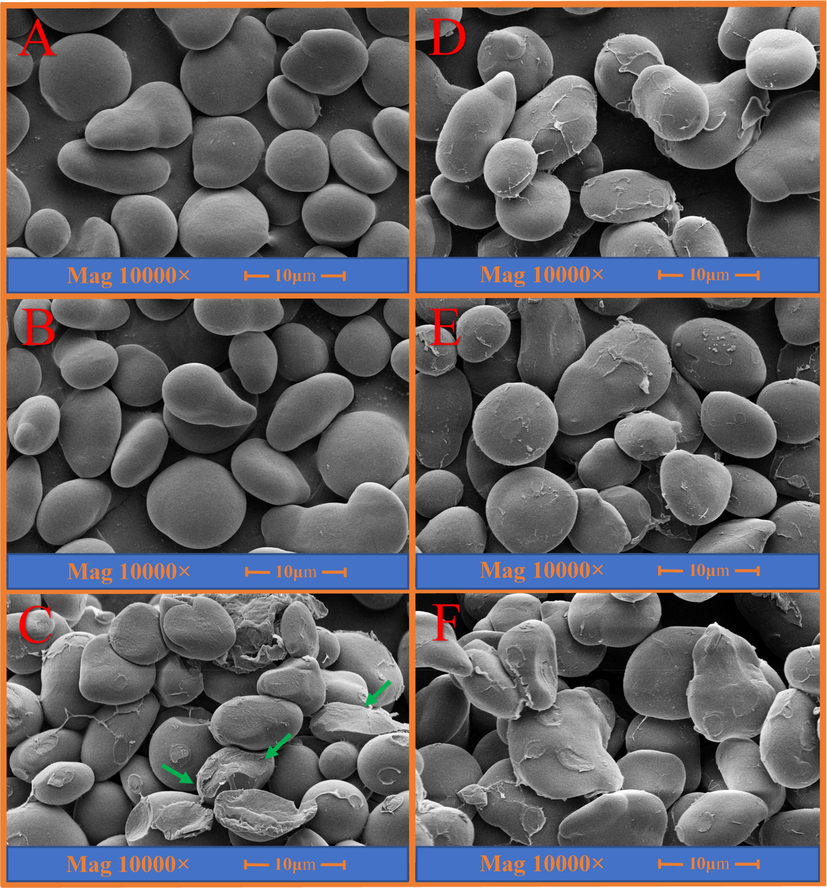

Scanning electron micrographs of TS (A), TS2 (B), TS4 (C), TS-CQSG (D), TS-CQSG3 (E) and TS-CQSG4 (F).

3.7 Ft-IR analysis

The FT-IR spectra of the TS and TS-CQSG with and without dry heat in the region of 500–4000 cm−1 are shown in Fig. 3C and D. The analysis of the infrared spectrum showed that no new absorption peaks formed in the treated starch, with only slight variations in peak intensity (Fig. 3C). These results agree with those of Sun et al. (2014) for normal and waxy corn starches after microwave-assisted dry heating. The absorption band at 3364 cm−1 was regarded as the O−H stretching of starch, and its width was related to the extent of inter- and intra-molecular hydrogen bond formation (Kalantari et al., 2019). The peak at 2964 cm−1 was attributed to the asymmetric stretching of C–H (CH2 group), and tightly bound water in starch was observed at 1643 cm−1 (Liu et al., 2017). FT-IR information in the region of 1300–700 cm−1 was attributed to the conformational and crystalline order of starch (Liu et al., 2017). The absorption peaks at 1047 cm−1 and 1022 cm−1 were associated with the crystalline and amorphous regions of starch, respectively (Liu et al., 2021). According to Liu et al. (2017), the absorption ratio of 1047/1022 could be used for measuring the ordered area in more crystalline regions. For the TS and TS-CQSG samples, the values of 1047/1022 continuously decreased as the duration of dry heat increased (Fig. 3D), indicating the destruction of ordered structure (crystalline regions) by heating; this is consistent with results of the relative crystallinity as assessed by XRD analysis (Fig. 3B). However, the value of 1047/1022 for TS-CQSG4 (0.51) was markedly higher than that of TS4 (0.43), which was contrary to the results of the XRD analysis. This might be because the FT-IR spectra of the starches is not only susceptible to changes in crystallinity, but also is sensitive to the water content of the starch granules and the retrogradation of starch chain conformation (Gou et al., 2019).

3.8 Scanning electron microscope analysis

Fig. 4 shows the microstructure of native and modified starches obtained through SEM. The starch micrographs accurately depict the granular structure of modified starches. The native tigernut starch granules appeared irregular with protruding horns, which was in accordance with the report of Liu et al. (2021). After heating for 2 h at 130 °C, no obvious change was found on the surface of the granules compared with natural starch (Fig. 4A and B). However, the structure of the starch was damaged, and the granules look fragmented and fractured after heating for 4 h at 130 °C (Fig. 4C). This indicated that the glycosidic bond and crystal structure in starch was destroyed by heating for 4 h, which was in agreement with the pasting properties analysis described above. In addition, it is worth noting that the starch granules were both clustered and agglomerated after heating for 4 h (Fig. 4C). Presumably, the loss of the smoothness and development of fractures were due to leaking of amylose and the effect of heating (Chandanasree et al., 2016). The addition of CQSG led to the surface of starch granules being partly wrapped or to entanglement between intact granules (Fig. 4D), which may be attributed to the fact that the CQSG with small diameter was more fully dispersed around the starch granules (Wang et al., 2018). However, no obvious damage was found in the microstructure of TS-CQSG after dry heat treatment for 2 h and 4 h compared with TS (Fig. 4E and F). This is because heating caused the amylose outside the starch granules to interact with hydrocolloids and produce a more complex matrix around the gelatinized granules (Chandanasree et al., 2016).

4 Conclusions

This study documented the pasting, rheological, freeze–thaw stability, solubility and swelling power properties and granule structure of tigernut starch (TS) as affected by modification with Chinese quince seed gum (CQSG) and dry heating. Incorporation of gum in starch, followed by dry heating, could lead to complex matrix formation between the gum and the leaked amylose, and loss of crystal structure. Functional properties results indicate that the peak and final viscosities and consistency coefficient (K) of TS was increased as the dry heat time increased, while the swelling power and enthalpy change decreased. A relatively small amount of CQSG enhanced the effects of the heat treatments, especially on the pasting properties. Additionally, the pseudoplastic flow and freeze–thaw stability were enhanced by this modification process. Increased peak viscosity of investigated starch makes it applicable for thickening agent in different types of food formulations, and enhanced freeze–thaw stability makes it useful for improvement of the starch-based products texture upon freezing, however this would require further studies.

CRediT authorship contribution statement

Wen-Bo Miao: Data curation, Methodology, Validation, Supervision. Yan-Yan Ning: Methodology, Data curation. Hong-Rui Huang: Methodology, Data curation. Hua-Min Liu: Methodology, Data curation, Project administration. Xiao-Shuang Cai: Methodology. Xue-De Wang: Supervision, Resources.

Acknowledgements

The research was carried out with financial support from the Self-science Innovation Fund Support Plan of Henan University of Technology (2020ZKCJ18).

References

- Pasting, paste, and gel properties of starch-hydrocolloid combinations. Carbohydr. Polym.. 2011;86(2):386-423.

- [Google Scholar]

- Effect of gum arabic on freeze-thaw stability, pasting and rheological properties of tapioca starch and its derivatives. Food Hydrocoll.. 2015;51:355-360.

- [Google Scholar]

- Effect of hydrocolloids and dry heat modification on physicochemical, thermal, pasting and morphological characteristics of cassava (Manihot esculenta) starch. Food Hydrocoll.. 2016;52:175-182.

- [Google Scholar]

- Effects of heat, drought and their combined effects on morphological structure and physicochemical properties of rice (Oryza sativa L.) starch. J. Cereal Sci.. 2020;95:103059.

- [CrossRef] [Google Scholar]

- Preparation of starch citrates using solvent free reaction and comparison with aqueous and ethanol mediated reactions. Starch-Stärke.. 2020;72(5-6):1900260.

- [CrossRef] [Google Scholar]

- Effects of repeated and continuous dry heat treatments on properties of sweet potato starch. Int. J. Biol. Macromol.. 2019;129:869-877.

- [Google Scholar]

- Effect of ionic gums and dry heating on physicochemical, morphological, thermal and pasting properties of water chestnut starch. LWT-Food Sci. Technol.. 2014;59(1):348-355.

- [Google Scholar]

- Effect of glutathione on gelatinization and retrogradation of wheat flour and starch. J. Cereal Sci.. 2020;95:103061.

- [CrossRef] [Google Scholar]

- Preparation and characterization of dicarboxylic acid modified starch-clay composites as carriers for pesticide delivery. Arabian J. Chem.. 2020;13(11):7990-8002.

- [Google Scholar]

- Heterogeneous catalysis in 4-nitrophenol degradation and antioxidant activities of silver nanoparticles embedded in Tapioca starch. Arabian J. Chem.. 2019;12(8):5246-5252.

- [Google Scholar]

- Effect of combination of dry heating and glucose addition on pasting and gelling behavior of starches. Int. J. Biol. Macromol.. 2021;183:1302-1308.

- [Google Scholar]

- Effect of dry heat treatment with xanthan on waxy rice starch. Carbohydr. Polym.. 2013;92(2):1647-1652.

- [Google Scholar]

- Preparation of low digestible and viscoelastic tigernut (Cyperus esculentus) starch by Bacillus acidopullulyticus pullulanase. Int. J. Biol. Macromol.. 2017;102:651-657.

- [Google Scholar]

- Physical modification of waxy maize starch by dry heating with ionic gums. J. Appl. Glycosci.. 2006;53(4):281-286.

- [Google Scholar]

- Modification of starch by dry heating with ionic gums. Cereal Chem.. 2002;79(5):601-606.

- [Google Scholar]

- Effect of dry heating with ionic gums at controlled pH on starch paste viscosity. Cereal Chem.. 2003;80(2):198-202.

- [Google Scholar]

- Effects of oligomeric procyanidins on the retrogradation properties of maize starch with different amylose/amylopectin ratios. Food Chem.. 2017;221:2010-2017.

- [Google Scholar]

- Improvement of functional and rheological features of tigernut tuber starch by using gum derived from Chinese quince seeds. LWT-Food Sci. Technol.. 2021;143:111180.

- [CrossRef] [Google Scholar]

- Influence of xanthan, guar, CMC and gum acacia on functional properties of water chestnut (Trapa bispinosa) starch. Int. J. Biol. Macromol.. 2017;103:220-225.

- [Google Scholar]

- Effect of NaCl on physicochemical properties of xanthan gum-Water chestnut starch complexes. Int. J. Biol. Macromol.. 2019;131:557-563.

- [Google Scholar]

- Effects of various roasting temperatures on the structural and functional properties of starches isolated from tigernut tuber. LWT-Food Sci. Technol.. 2021;151:112149.

- [CrossRef] [Google Scholar]

- Functional properties of cowpea (Vigna unguiculata) starch as modified by guar, pectin, and xanthan gums. Starch-Stärke.. 2014;66(9-10):832-840.

- [Google Scholar]

- Complexation of high amylose rice starch and hydrocolloid through dry heat treatment: Physical property and in vitro starch digestibility. J. Cereal Sci.. 2018;79:341-347.

- [Google Scholar]

- Effect of dry heat treatment on physical property and in vitro starch digestibility of high amylose rice starch. Int. J. Biol. Macromol.. 2018;108:568-575.

- [Google Scholar]

- Influence of xanthan gum on rheological properties and freeze-thaw stability of tapioca starch. J. Food Eng.. 2008;88(1):137-143.

- [Google Scholar]

- Comparative study of effect of modification with ionic gums and dry heating on the physicochemical characteristic of potato, sweet potato and taro starches. Food Hydrocoll.. 2014;35:613-619.

- [Google Scholar]

- Differences in physicochemical, morphological, and structural properties between rice starch and rice flour modified by dry heat treatment. Starch-Stärke.. 2015;67(9-10):756-764.

- [Google Scholar]

- Rheological properties and microstructure characterization of normal and waxy corn starch dry heated with soy protein isolate. Food Hydrocoll.. 2015;48:1-7.

- [Google Scholar]

- The addition of corn fiber gum improves the long-term stability and retrogradation properties of corn starch. J. Cereal Sci.. 2017;76:92-98.

- [Google Scholar]

- Fractal geometry analysis of chemical structure of natural starch modification as a green biopolymeric product. Arabian J. Chem.. 2019;12(8):2430-2438.

- [Google Scholar]

- Modification of moth bean starch using mixture of organic acids under dry heating. Starch-Stärke.. 2019;71(9-10):1900061.

- [CrossRef] [Google Scholar]

- Effect of dry heating with ionic gums on physicochemical properties of starch. Food Chem.. 2013;136(3-4):1421-1425.

- [Google Scholar]

- Effect of microwave-assisted dry heating with xanthan on normal and waxy corn starches. Int. J. Biol. Macromol.. 2014;68:86-91.

- [Google Scholar]

- Effect of plasma-activated water on the structure and in vitro digestibility of waxy and normal maize starches during heat-moisture treatment. Food Chem.. 2020;306:125589.

- [CrossRef] [Google Scholar]

- Chinese quince (Chaenomeles sinensis) seed gum: Structural characterization. Food Hydrocoll.. 2018;75:237-245.

- [Google Scholar]

- Chinese quince seed gum: Flow behaviour, thixotropy and viscoelasticity. Carbohydr. Polym.. 2019;209:230-238.

- [Google Scholar]

- Effect of xanthan gum co-extruded with OSA starch on its solubility and rheological properties. LWT-Food Sci. Technol.. 2021;147:111588.

- [CrossRef] [Google Scholar]

- Physical modification of potato starch using mild heating and freezing with minor addition of gums. Food Hydrocoll.. 2019;94:294-303.

- [Google Scholar]

- The influence of repeated versus continuous dry-heating on the performance of wheat starch with different amylose content. LWT-Food Sci. Technol.. 2021;136:110380.

- [CrossRef] [Google Scholar]