Translate this page into:

Electrospun Casein fibers obtained from revalued milk with mechanical and antibacterial properties

⁎Corresponding authors. soto_zarazua@yahoo.com.mx (Genaro Martín Soto-Zarazúa), lespana@cideteq.mx (Beatriz Liliana España-Sánchez)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

The present study describes the harnessing of revalued cow milk (denoted as waste milk) for fabricating casein fibers (CAS) with enhanced mechanical performance and antibacterial properties by the electrospinning method. For this purpose, polyethylene oxide (PEO) was employed (10 and 20 wt%) as a binder for the appropriate electrospun CAS fibers. Different amount of tannic acid (TA) was incorporated into casein/polyethylene oxide fibers (CAS/PEO) as a crosslinker agent, bringing filaments with a diameter of ca. 2 µm. The incorporation of 4 wt% of TA promotes the fibers' reticulation, forming a stable three-dimensional network. Also, the mechanical performance of CAS/PEO fibers was improved, where the tensile strength was increased from 0.91 MPa to 1.88 MPa with 4 % of TA, while the breaking elongation was increased from 93.74 % to 274.56 %. This behavior benefits the processing of fibers by electrospinning. Furthermore, the TA addition during the electrospun of CAS/PEO fibers enhances fibers' wettability properties and thermal stability induced by the crosslinker agent. Additionally, the antibacterial activity (AA) test demonstrates that CAS fibers can inhibit the growth of Gram-positive S. aureus and Gram-negative E. coli after 0.5 h, 1.5 h, 3 h, and 24 h of contact, which is generated by the TA addition. Our results suggest that the electrospun fabrication of CAS/PEO fibers with TA as a crosslinker agent represents an innovative harnessing of waste milk to produce functional textiles with potential biological application.

Keywords

Revalued milk

Casein

Electrospinning

Mechanical properties

Antibacterial

Crosslinker agent

1 Introduction

Milk has been considered a perfect food for human consumption due to the high source of nutrients, including water (87 %), total solids (13.1 %), fats (4.0 %), proteins (3.4 %), lactose (4.8 %) and minerals (0.8 %) (Alichanidis et al., 2016; Foroutan et al., 2019). However, about 83 % of daily production worldwide comes from cows, where between 4 and 11 million tons are considered waste products (Ahmad et al., 2019). In particular, revalued milk, commonly mentioned as “waste milk,” has been known to contain drug residues such as antibiotics, representing a significant health risk to human consumption, including allergic reactions and antibiotic resistance. Therefore, human consumption is restricted (Beyene, 2016; Sachi et al., 2019). Several technologies have been employed to extract, purify or reuse materials to generate bioproducts with high added value, such as textiles (Stenton et al., 2021), aiming to develop alternatives based on the circular economy and the appropriate harnessing of wastes with potential application in biomedicine (Orejuela-Escobar et al., 2021; Tham et al., 2019). In particular, casein (CAS) is a protein constituted by three polypeptide chains (αS1, αS2, and β) and represents 80 % of milk composition (Davoodi et al., 2016; Raak and Corredig, 2021). The chemical structure includes phosphoproteins in their molecular arrangement as a random spiral with the presence of polar groups (phosphate groups bonded to serine units), demonstrating high lipophilic properties (Lopes et al., 2007). It also possesses high barrier properties to non-polar molecules and has been considered a candidate for fabricating paper coatings, adhesives, food packaging, textiles, and fibers (Audic et al., 2003; Belkhir et al., 2021a; Wusigale et al., 2020). It has been claimed that CAS fibers represent a significant challenge in manufacturing non-toxic and biodegradable materials for biomedical and textile applications (Thill et al., 2021). Due to their resistance to UV radiation can be feasibly blended with other fibers such as cotton. In addition, it is biocompatible in contact with skin and presents antimicrobial characteristics (Ali et al., 2020). However, the processing of CAS fibers could be compromised due to low mechanical properties, poor water resistance, and brittle texture; therefore, is required to add additives to maintain the intrinsic properties and durability of the final product, such as plasticizers, binders, and crosslinker agents (Ghosh et al., 2009). The primary function of plasticizers (i.e., glycerol) is the conformation of a porous 3D network structure with enhanced permeability, elasticity, and swelling properties, producing an appealing platform for specific biological applications (Mbituyimana et al., 2021).

One of the innovative and low-cost trends for processing the revaluated CAS is the manufacture of filaments, which can be used in the textile sector or biomedicine due to their biocompatibility and degradability (Belkhir et al., 2021b; Liu et al., 2018). In this sense, electrospinning is a versatile technique capable of producing fibers from 50 nm to 500 µm, with high control of morphology and arrangement. The system is based on the polymer solution in a syringe (as a cathode) charged with a high voltage source to generate droplets by electrostatic attractions, forming a characteristic Taylor cone. As a result, the trusted polymer solution is ejected at a specific distance to form uniform filaments and collected on a surface (as an anode), where parameters such as polymer solution and the equipment configuration play an essential role in successfully obtaining fibers. Furthermore, the electrospun process from biopolymers such as CAS allows water as a solvent to disperse the polymer solution with relatively fast evaporation, with the possibility of natural biomimetic structures. However, the intrinsic chemical nature of these materials could interfere with the native conformation of biopolymers and have low spinnability potential (Wilk and Benko, 2021). The fabrication of electrospun CAS filaments with other polymers as support has been reported to improve their spinnability characteristics, such as polyethylene oxide (PEO) (Minaei et al., 2019), pullulan (Tomasula et al., 2016), and polyvinyl alcohol (Bairagi et al., 2021). According to Mo et al. 2021 (Mo et al. 2021), PEO is an uncharged synthetic polymer and multifunctional binder due to its high flexibility and ionic conductance in concentrations ca. 1–20 wt% respect to the material. Significant advantages of PEO during the electrospun process include high adhesive performance, low cost, and environmental friendliness. This phenomenon is attributed to the low repulsive forces between the PEO and the continuous phase (i.e., biopolymer), allowing the nanofibers conformation (Hu et al., 2015).

Aiming to improve mechanical performance and the functionality and the of CAS fibers, tannic acid (TA) has been proposed as a crosslinker agent due to water-solubility features such as antioxidant and antimicrobial capacity, commonly used in biomedical and food-packaging applications. In this regard, TA reported high affinity with support polymers such as PEO and polyvinyl acid (PVA), suggesting the possible enhancement of physic-mechanical characteristics (Bairagi et al., 2021). Furthermore, TA is a polyphenol obtained from a mixture of polygalloyl glucose molecules commonly obtained from plants, with an empirical formula C76H52O46 (Sahiner et al., 2016), and recently has been proposed as an additive for membrane technology applications due to their hydrophilic and antifouling characteristics, and performing the surface interface of polymer membranes (Yan et al., 2020). Also, TA has been directly formulated to produce crosslinked fibers due to antioxidant, anti-inflammatory, and antibacterial properties, suggesting their application as wound dressing material (Sahiner et al., 2021).

According to the above, our study describes the harnessing of revalued cow milk from the CAS extraction and their formulation to produce fibers by the electrospinning method. For this purpose, purified CAS was formulated with PEO as a binder and incorporated different amounts of TA as a crosslinker agent. The goal was to focus on the optimal exploitation of waste milk to produce electrospun fibers, aiming to build a stable 3D network with optimal mechanical performance and antibacterial properties desirable for biomedical applications.

2 Experimental

2.1 Materials

Revaluated milk denominated as “waste milk” was obtained from Holstein cows of dairy farms (Querétaro). For the CAS extraction and purification, anhydrous acetic acid, ethanol, and triethanolamine were purchased from J.T. Baker and used as received. Polyethylene oxide (PEO, Mv 4,000,000) and tannic acid (purity 98 %, Mw 1701.20 g/mol) were purchased from Sigma Aldrich for electrospun fibers formulation. CAS extraction from waste milk was performed according to previous reports (D Kaveendi Chandrasiri et al., 2019; Siroěić et al., 2016), and the procedure was explained in the Supporting information (S1). Antibacterial activity (AA) of CAS filaments was evaluated using strains of Gram-positive Staphylococcus aureus # 6538 and Gram-negative Escherichia coli # 25922 from American Type Cell Culture (ATCC). Both microorganisms were grown in Luria Bertani media (BD Bioxon). Phosphate buffer solution (PBS) pH 7.1 was employed for bacterial survival recovery.

2.2 Formulation of CAS solution for electrospinning

1 g of CAS powder was mixed with 0.5 mL of triethanolamine (0.5 %) in 9.5 mL of deionized water (w/v). Triethanolamine was employed as a pH regulator. The obtained solution was stirred at room temperature for 12 h. PEO solution was used as a binder to promote the formation of the fibers. For this purpose, 0.7 g of PEO was dissolved in 9.3 mL of deionized water (0.7 % w/v) and stirred for 12 h at room temperature. A mix of CAS/PEO solution was prepared in a relation 90/10 and 80/20, respectively, and stirred 60 min before the electrospinning process. From CAS/PEO solutions, TA solution (2 and 4 wt%) was added to evaluate the reticulation process. Table 1 shows the formulation of CAS/PEO samples Table 2

Sample

TA concentration

CAS content (%)

TA content (%)

CAS/PEO 90/10

–

90

10

CAS/PEO 80/20–2 %TA

2 %

80

20

CAS/PEO 90/10–2 %TA

2 %

90

10

CAS/PEO 90/10–4 %TA

4 %

90

10

Sample

Surface roughness (Rq, nm)

Surface roughness (Ra, nm)

Young modulus

Max

(MPa)Young modulus

Mean

(MPa)

CAS/PEO 90/10

8.57 ± 0.80

6.23 ± 0.48

145.51 ± 55.16

32.57 ± 4.54

CAS/PEO 80/20–2 %TA

6.22 ± 2.19

5.02 ± 2.15

340.59 ± 68.79

113.28 ± 62.96

CAS/PEO 90/10–2 %TA

11.71 ± 10.92

8,28 ± 7.23

272.17 ± 138.09

75.64 ± 17.74

CAS/PEO 90/10–4 %TA

5.86 ± 3.20

4.07 ± 1.97

549.26 ± 315.59

150.08 ± 34.62

2.3 Electrospun of CAS/PEO fibers

The electrospinning process was performed using GIGA IE® electrospinning equipment placed inside a humidity control cabinet (ca. 40 %). First, 5 mL of each sample was placed in a syringe and injected at 220 µL/h, with a voltage of 15 kV and 13 cm distance. Then, the electrospun process to obtain fibers was performed for 8 h. Fibers were collected using a rotatory collector at 3000 rpm, using aluminum foil as a substrate for fiber deposition.

2.4 CAS/PEO fibers characterization

Surface morphology and average diameter of CAS/PEO fibers were performed by Scanning Electron Microscopy (SEM) using a JEOL JSM-6610LV in SEI mode, with a work distance of 10 mm and 15 kV. Fourier Transform Infrared Spectroscopy (FTIR) was determined using a Perkin Elmer Spectrum Gx in a fully attenuated ATR mode range of 4000 to 400 cm−1. The mechanical performance of electrospun CAS/PEO fibers was evaluated using a tensile testing machine, Zwick/Roell model Z005, according to the ASTM D3822. Tensile loads of each sample were adjusted through the crosshead displacement, connected to a 500 N load cell, aiming to determine the constant elongation rate (CRE). The tensile assay was performed using 500 mm/min thin film clamps. Complementary mechanical and topographical properties at the nanoscale were analyzed by atomic force microscopy (AFM) using an AFM Park NX10 Park system, Sowon, South Korea. The measurements were carried out by pinpoint mode with a cantilever (Al-coated, 0.2 N/m, 25 kHz) with a 256 × 256 pixels resolution. Contact angle measurements (CA) were performed for biological purposes to determine the water affinity in CAS/PEO fibers using a goniometer KRUSS model DSA30. A drop of deionized water was placed at the surface of 1 cm2 of each sample, and the CA value was determined after 30 s. Thermogravimetric analysis of electrospun CAS/PEO fibers was performed in a TGA/DSC 2 STARe System Mettler Toledo, at a temperature of 25–600 °C, rate of 20 °C/min, under a nitrogen atmosphere. Antibacterial activity (AA) kinetics of electrospun fibers was evaluated according to the standard AATCC 100 “Antibacterial evaluation of textiles” against S. aureus and E. coli, with slight modifications. Briefly, samples were cut into squares (1 cm2), sterilized by UV irradiation for 10 min, and placed in a sterile Petri dish conditioned as a humidity chamber under sterile conditions. Each microorganism's bacterial inoculum was grown in Luria Bertani media (LB) for 16 h and adjusted to the final concentration of 1x105 colony forming unit per milliliter (CFU/mL). 20 µL of bacterial suspension was placed at the surface of each sample and incubated for 0.5 h, 1.5 h, 3 h, and 24 h, respectively, at 37 °C with 40 % humidity. After bacterial-CAS/PEO fibers interaction, each sample was washed with 3 mL of PBS, and an aliquot of 50 µL was plated in LB dishes to obtain the survival bacteria. The experiments were performed for three independent experiments by duplication. To calculate the AA, we use the following equation:

Where the Co is the reference of bacterial growth (as control), and C is each CAS/PEO fiber.

3 Results and discussion

Functional textiles obtained from revalued sources have gained attention, aiming to develop sustainable materials and reduce the carbon footprint of the conventional textile fabrication process. In this regard, casein (CAS) obtained from waste cow milk was purified, and their chemical composition was determined by FTIR comparing the purification methods of obtained CAS using different solvents (ethanol and a mix of 1:1 ethanol/ether) with casein hydrolysate as a reference (Supporting information, S2). The characteristic vibrations of obtained CAS from waste milk were found and are associated with an appropriated CAS extraction. A slight decrease of OH/NH vibrations suggests that ethanol and ethanol/ether extraction decrease the final water content in CAS. To select the lower cost of CAS purification, CAS washed with ethanol was employed for the electrospun process.

3.1 Morphology of CAS/PEO fibers by SEM

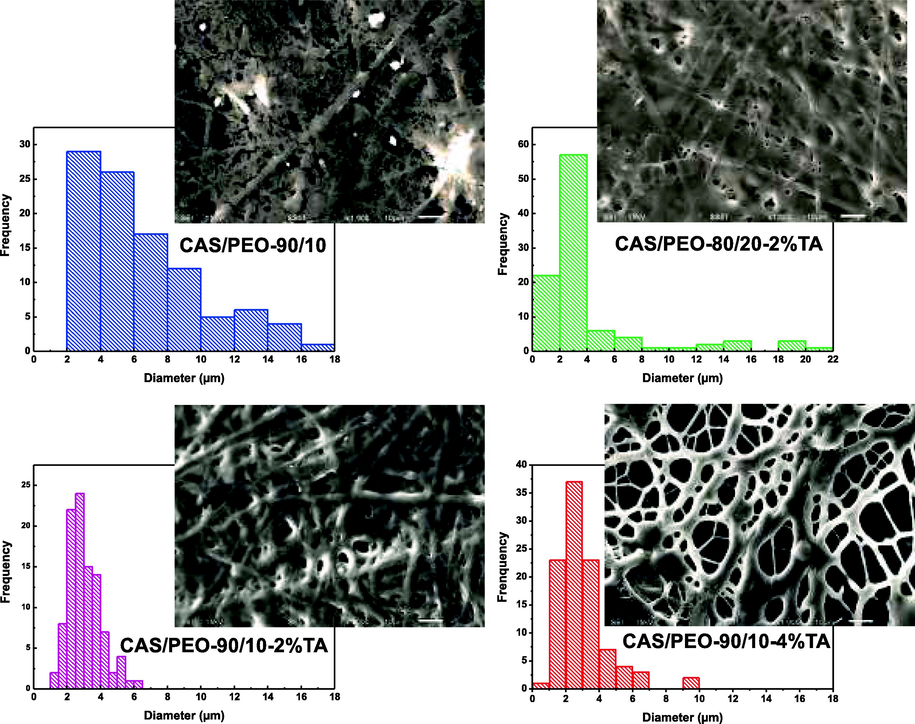

SEM micrographs were obtained to determine electrospun fibers' structural morphology and size (Fig. 1). It can be seen that pristine CAS/PEO solution (Fig. 1a) presents fibers with a characteristic matted and irregular morphology, with a diameter of 2 to 16 µm. Although the CAS solution itself is not spinnable, the presence of PEO promotes filament formation. However, it is important to note that CAS/PEO fibers are susceptible to the electron beam of an SEM microscope (15 kV), associated with the poor physicochemical stability of biopolymer and low viscoelasticity (Xie and Hsieh, 2003). Therefore, incorporating TA in the CAS/PEO solutions increases the formation of the fibers (Fig. 1b, 1c, and 1d) and improves the uniformity of filaments. Also, TA addition maintains the fiber diameter ca. 2 µm, which is not modified by the TA concentration (2 and 4 wt% respectively). Furthermore, in the higher TA concentration (Fig. 1d), it is clear that a 3D network is obtained, corroborating the successful reticulation of CAS fibers. This behavior suggests that TA, as a natural phenolic compound, interacts with the CAS solution, promoting their interaction through hydrogen bonds between the CAS polymer chains (Zhang et al., 2010), generating a well-defined fibers network, aiming to improve their mechanical performance (Xie and Hsieh, 2003).

SEM micrographs and diameter size histograms of CAS/PEO fibers obtained by electrospinning method: a) CAS/PEO 90/10, b) CAS/PEO 80/20–2 %TA, c) CAS/PEO 90/10–2 %TA, and d) CAS/PEO 90/10–4 %TA.

3.2 The role of TA incorporation into CAS/PEO fibers by FTIR

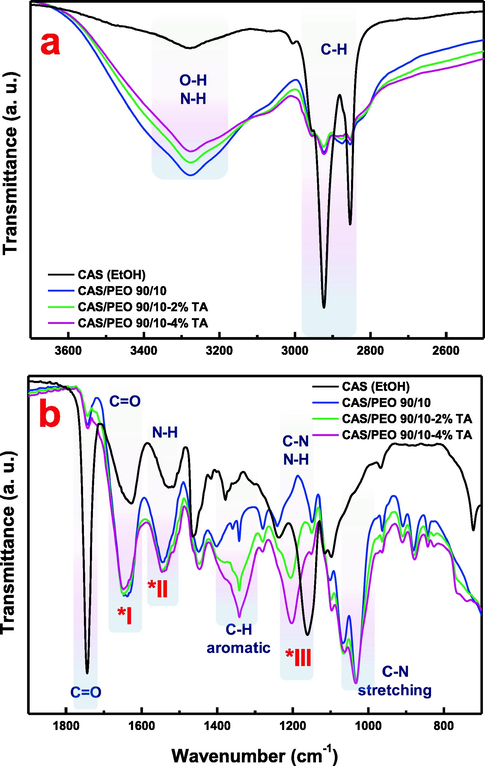

FTIR spectra were obtained (Fig. 2) to determine the incorporation of TA as a crosslinker agent into CAS/PEO fibers. For CAS/PEO fibers, characteristic vibrations located at 1647 cm−1, 1545 cm−1, and 1230 cm−1 correspond to amide I (C⚌O stretching), amide II (N—H bending), and amide III (C—N and N—H stretching) vibrations of an α-helical structure of casein (Picchio et al., 2018), as observed in Fig. 2b. Furthermore, the TA incorporation increase the signal located at 3280 cm−1 associated with the availability of the NH/OH groups (Fig. 2a), suggesting the reticulation of CAS during the electrospun process. Also, the vibrations located at 1446 cm−1 (associated with the carboxylate group O—C—O) and 1714 cm−1 are increased by the aromatic esters presented in TA (Wahyono et al., 2019). As a consequence, the effect of TA as a crosslinker (ca. 2–4 wt%) is presented in the shifted signals located at 1351 cm−1 and 1193 cm−1, attributed to the interaction of hydroxyl groups of the phenolic structure of TA and the amine groups present of CAS (Minaei et al., 2019; Picchio et al., 2018; Zhang et al., 2010). According to Sahined et al. (Sahiner et al., 2016)(Sahiner et al., 2021), the TA shows a characteristic peak at ca. 3600–3000 cm−1 associated with the O—H vibration of the phenolic compounds, the C⚌O vibration at 1697 cm−1, the stretching of aromatic vibrations at 1612, 1521 and 1426 cm−1 and the benzene peaks located at 1016 and 1175 cm−1. The –OH availability of CAS/PEO fibers slightly decreases with the TA incorporation percentage, suggesting the successful reticulation of CAS/PEO fibers obtained from the electrospun process.

FTIR spectra of CAS/PEO fibers and the effect of TA incorporation as a crosslinker agent. a) Region to 4000 cm−1 from 2500 cm−1 and b) Region to 1900 cm−1 from 700 cm−1.

3.3 Mechanical performance of CAS/PEO fibers

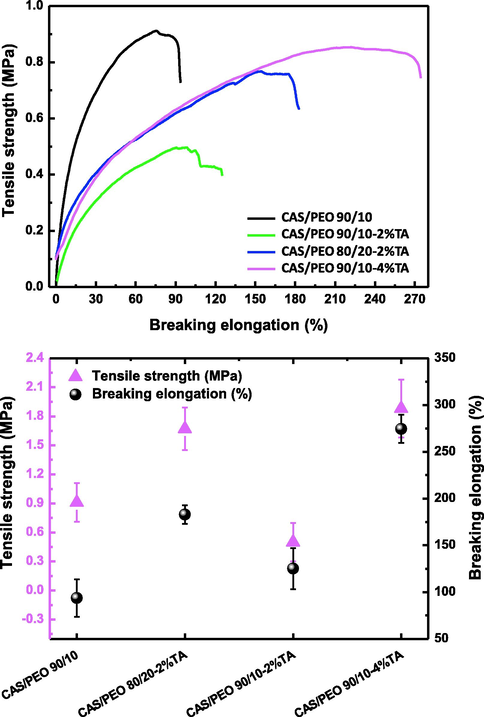

The mechanical performance of CAS fibers provides information about the electrospun fiberś integrity and stability with the incorporation of TA as a crosslinker agent, where their resistance (Tensile strength, TS) and flexibility (Breaking elongation, BE) are important to obtaining functional textiles for biomedical applications. Fig. 3a shows the stress–strain curves of CAS/PEO fibers, indicating that the CAS formulation with a different amount of TA intervenes in the mechanical performance of electrospun fibers. It can be seen that CAS/PEO 90/10–4 % TA demonstrates a higher mechanical performance, as compared with the other formulations, associated with the crosslinking reaction induced by the TA addition and corroborated by SEM analysis (Fig. 2d) and coincide with the reported by Wagh et al. 2014 (Wagh et al., 2014), where CAS films were mechanically improved by the addition of glycerol as a plasticizer. Fig. 3b shows the mechanical performance comparison between CAS/PEO samples with different amounts of TA. The lower mechanical performance of CAS fibers (CAS/PEO 90/10–2 % TA) is due to the water solubility of CAS and lower molecular weight (Yang and Reddy, 2012), associated with the high interactive forces between polar amino acids, resulting in shrinker filaments with brittle features. The performance in the mechanical strength induced by the reticulation between the TA and the CAS chains (Picchio et al., 2018; Yang and Reddy, 2012) is reflected in CAS/PEO 80/20–2 % TA and CAS/PEO 90/10–4 %TA values (Supporting information, S3). According to Picchio et al. [22], organic plasticizers are commonly employed in biodegradable polymers due to their capacity to provide high mechanical properties and elasticity, desirable in food package applications. According to the above, our results suggest that the TA incorporation in CAS/PEO fibers improves their physical characteristics and stability, offering their potential use as functional textiles for biomedical applications.

Mechanical performance of CAS fibers and the incorporation of TA as crosslinker agent, obtained by electrospinning method. The top graph shows the strain vs stress curves of electrospun CAS/PEO fibers, and the bottom graph shows the mechanical comparison of CAS/PEO fibers.

3.4 Surface topography of CAS/PEO fibers by AFM

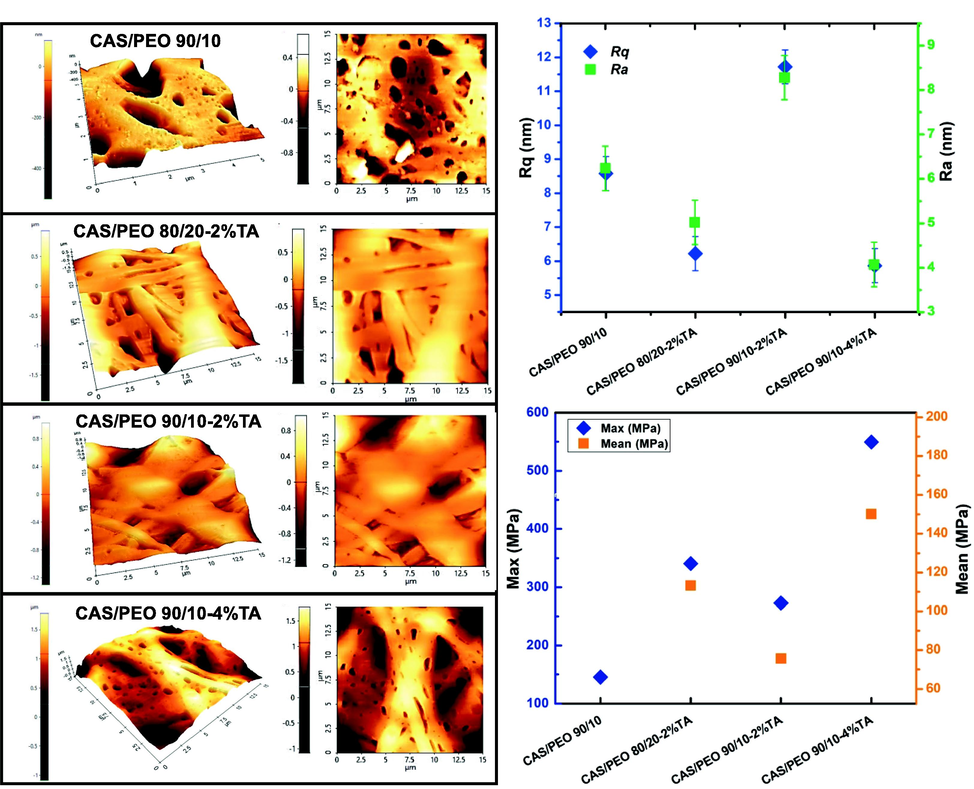

The surface topography of CAS/PEO filaments and their mechanical performance at the nanoscale were analyzed by atomic force microscopy (AFM), as seen in Fig. 4. 2D and three-dimensional micrographs of CAS/PEO fibers were obtained. For CAS/PEO 90/10, the surface roughness values of root mean square (Rq) and surface roughness (Ra) is ca. 8.75 nm, respectively, suggesting the formation of partially smooth fibers. In particular, the presence of TA in CAS/PEO 80/20 slightly decreases the value of Ra to ca. 6.22 nm. However, for CAS/PEO 90/10–2 %TA, the surface roughness slightly increases to ca. 12 nm Comparison of surface roughness between CAS/PEO fibers is presented in Fig. 4 (upper right). The results denote that the formulation of CAS fibers with different TA concentrations intervenes in the reticulation of fibers, increasing the surface roughness of filaments. Furthermore, since CAS fibers present low humidity resistance, the final surface roughness could affect filaments' hydrophobic/hydrophilic properties (Xu et al., 2012). In addition, the surface porosity of CAS/PEO fibers was obtained. The pore diameter varies for CAS/PEO 90/10, ranging from ca. 241.90 nm to 1068 nm. However, the TA addition generates a decrease in the pore diameter, ranging from 44.5 nm to 187.53 nm (CAS/PEO 80/20–2 %TA), from 367.31 nm to 1029 nm (CAS/PEO 90/10–2 %TA), and 192.21 nm to 820.36 nm in CAS/PEO 90/10–4 %TA, respectively (Table 2). The above indicates that the crosslinking reaction induced by the TA intervenes in the pore diameter distribution. Mechanical properties t the surface of CAS/PEO fibers were obtained by AFM (Fig. 4 lower right), where the Young Modulus of electrospun CAS/PEO fibers was determined. As a result, the maximum mechanical strength before the break is enhanced with the TA incorporation (Zhang et al., 2020a, 2020b), in agreement with the mechanical performance in bulk obtained in Fig. 3.

AFM analyses of CAS/PEO fibers obtained by the electrospun process. Left shows the 3D images of surface topography at 15 µm2; upper right shows the surface roughness analysis of Root Mean Square (Rq) and surface roughness (Ra) values (nm), and lower right shows the mechanical strength (MPa) of CAS/PEO fibers.

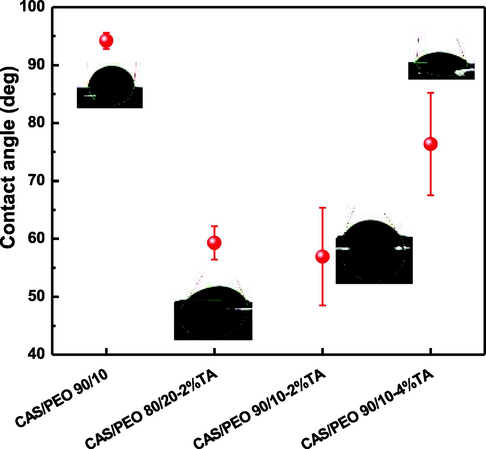

3.5 Wettability properties of CAS/PEO fibers

It has been claimed that CAS protein shows high water solubility. This behavior could compromise the physical stability of filaments and functionality (Nishat Tasnim, 2019). However, the design of functional filaments for biomedical issues requires an able surface to promote cellular growth, optimal for scaffold use (Yang and Reddy, 2012). In this sense, the wettability properties of electrospun CAS/PEO fibers combined with mechanical performance are crucial to developing optimal fibers. Therefore, contact angle measurements (CA) were performed with deionized water to determine the surface polarity of electrospun CAS/PEO fibers. Measurements were performed for 30 s to ensure drop stability during the measurement. It can be seen in Fig. 5 that the CA of CAS/PEO 90/10 at ca. 94 ± 1.37° is associated with a partially hydrophobic surface (Yao et al., 2019). We include representative photographs of each CA measurement, which were inset in Fig. 5, to ensure the drop stability during the evaluation. Despite the TA incorporation inducing a three-dimensional rigid network, the formulation of CAS/PEO 80/20–2 %TA demonstrates a CA of 60 ± 8.43°. However, for CAS/PEO 90/10–2 %TA, the CA slightly decreased to ca. 58 ± 2.7°. Finally, it can be seen that with the highest amount of TA (CAS/PEO 90/10–4 %TA), the CA increases to 75 ± 8.83°, suggesting that the forming network could prevent water from soaking through the electrospun fibers. According to Yao et al. (Yao et al. 2019), the reinforcement of CAS matrix with polymers such as gelatin-coupled cellulose allows producing a stable composite with enhanced hydrophilic properties, suggesting that the mechanical tensile strength and Younǵs modulus increase ca. 3.5–6 times, compared with the raw material. The wettability characteristics of electrospun membranes allow the evaluation of the surface energy performance in contact with aqueous media. This parameter is vital for obtaining functional membranes, such as water treatment systems (Lu et al., 2021). Therefore, the hydrophilic properties performed with the TA incorporation into CAS/PEO fibers could enhance the interaction with bacteria suspended in liquid media, promoting their direct contact with the 3D network produced by CAS/PEO fibers.

Contact angle measurements (CA) of electrospun CAS/PEO fibers with different amount of TA. A) CAS/PEO 90/10, B) CAS/PEO 80/20–2% TA, C) CAS/PEO 90/10–2% TA and D) CAS/PEO 90/10–4% TA. Photographs of representative CA measurements were inset into the graph.

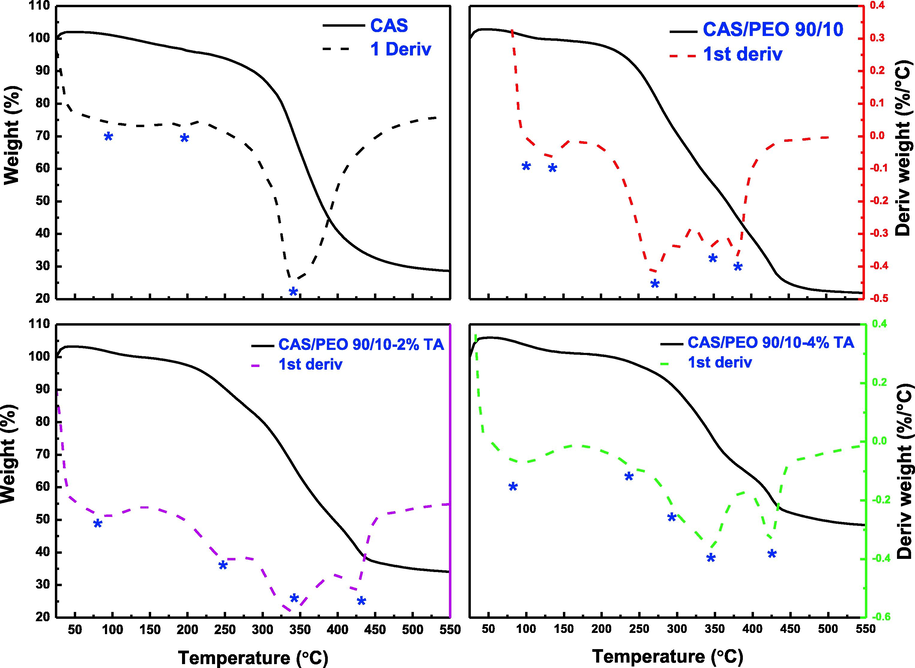

3.6 Thermal stability of CAS/PEO fibers by TGA

The thermal stability of CAS, CAS/PEO fibers, and the TA incorporation at different concentrations (2 and 4 %) was determined by TGA measurements (Fig. 6). According to the thermograms, a slight loss is observed at ca. 94–105 °C, attributed to the water embedded in CAS. The analysis of 1st derivative of CAS shows two losses at 194.95 °C and 338.59 °C. However, the incorporation of PEO and TA in CAS promotes the apparition of weight losses at different temperatures, i.e., CAS/PEO shows five losses (107.0 °C, 131.35 °C, 270.83 °C, 347.25 °C, and 383.66 °C); CAS/PEO with 2 % of TA shows 4 losses (94.29 °C, 249.78 °C, 336.84 °C, and 425.0 °C) and CAS/PEO with 4 % of TA shows five losses (89.3 °C, 236.18 °C, 297.91 °C, 342.98 °C, and 424.45 °C. The above suggests that the reticulation phenomena allow thermal degradation to occur in several stages, increasing the thermal stability of electrospun filaments. Also, the weight percentage of CAS and electrospun CAS/PEO fibers at 270 °C, 392 °C, and 430 °C were obtained, as seen in Table 3. At 270 °C, CAS shows a weight loss of 8.17 %, while the PEO incorporation in CAS fibers shows a slight decrease of 16.88 %. However, with the incorporation of TA at the highest concentration (CAS/PEO 90/10–4 %TA), the weight loss is only 4.56 %, suggesting that the crosslinking process induced by the TA improves the thermal degradability behavior of CAS/PEO fibers. In addition, at 430 °C, the final weight % of CAS is ca. 34.97 %, while with the TA as crosslinker increases to 39.58 % (with 2 wt% TA) and 54.27 % (with 4 wt% TA), respectively. The above establishes that the thermal stability of electrospun CAS/PEO fibers can be improved by the intermolecular forces promoted through the hydrogen bonds between CAS/PEO and TA. According to Wu et al. (Wu et al., 2018), crosslinker agents such as transglutaminase demonstrate a lower weight degradation and higher degradation temperature, attributed to the high hydrophobicity and the less accessible and bond water produced by the reticulation process.

Thermogravimetric analysis of CAS and electrospun CAS/PEO fibers with TA as crosslinker agent.

Sample

Weight (%)

at 270 °CWeight (%)

at 392 °CWeight (%)

at 430 °C

CAS

91.83

39.95

34.97

CAS/PEO 90/10

83.12

38.22

28.48

CAS/PEO 90/10–2 %TA

86.21

48.29

39.58

CAS/PEO 90/10–4 %TA

95.44

62.82

54.27

Our results showed significant differences in the thermal stability and mechanical performance between the highest TA formulation (CAS/PEO 90/10–4 %TA) and pristine CAS/PEO electrospun filaments. In particular, the mechanical performance was improved under our experimental conditions, suggesting the potential harnessing of waste-cow milk for the electrospun fabrication of innovative and non-toxic electrospun fibrous membranes from biocompatible CAS desirable for biomedical issues. According to Table 4, using protein-based biopolymers for textile fabrication by electrospinning allows for obtaining filaments with an average diameter of ca. 50–150 µm. However, the mechanical performance only is enhanced with the presence of polypropylene, an engineering polymer commonly used for biomedical devices. Under similar conditions of reticulation (using citric acid and glutaraldehyde as crosslinker agents), the tensile strength properties are similar to our results. However, the average diameter of filaments increases to ca. 50–150 µm. The above suggests that our obtained filaments can be potentially used in biomedical applications, such as antimicrobial textiles or scaffolds for tissue engineering. N.R. not reported.

Type of protein

Reticulate agent

Fiber’s diameter (µm)

Tensile strength (MPa)

Breaking elongation (%)

Biological application

Reference

Casein (PP/CAS 95:5)

Hydrolyzed with HCl

N.R.

1190 ± 70

N.R.

Antibacterial against S. aureus and K. pneumoniae

(Belkhir, Kedafi; Pillon, Caroline; Cayla, Aurélie; Campagne, 2021)

Casein (24 wt%)

Citric acid

Ca. 150

60 ± 5.0

5 ± 2.0

Scaffold for fibroblast growth

(Yang and Reddy, 2012)

Starch/Casein

PEO

Ca. 0.174

1.23 ± 0.39

99.0 ± 5.9

Antibacterial against B. cereus and S. typhimurium

(Cui et al., 2022)

Silk fibroin

Ethanol

Ca.50

1.6 ± 0.3

0.35 ± 0.03

Biomimetic fibers

(Madurga et al., 2017)

Collagen

Glutaraldehyde

Ca.150

Ca. 45

N.R.

Suture strings for surgery

(Zhang et al., 2020a, 2020b)

Casein

Glutaraldehyde

Ca. 50

75 ± 10

N.R.

Suture strings for surgery

(Zhang et al., 2020a, 2020b)

Soy

PEO

Ca. 0.25

N.R.

N.R.

Wound healing scaffolds

(Pereira et al., 2021)

Zein with PCL

Arabic gum

0.449 ± 0.242

1.5 ± 0.5

45 ± 5

Skin tissue engineering

(Pedram Rad et al., 2019)

Casein (CAS/PEO 20:80)

Di-isocyanate

Ca. 0.358

0.59 ± 2.42

156.3 ± 16.2

N.R.

(Minaei et al., 2019)

Casein (CAS/PEO 90:10)

TA (4 %)

Ca.2.0

1.88

274.56

AA against S. aureus and E. coli.

This work

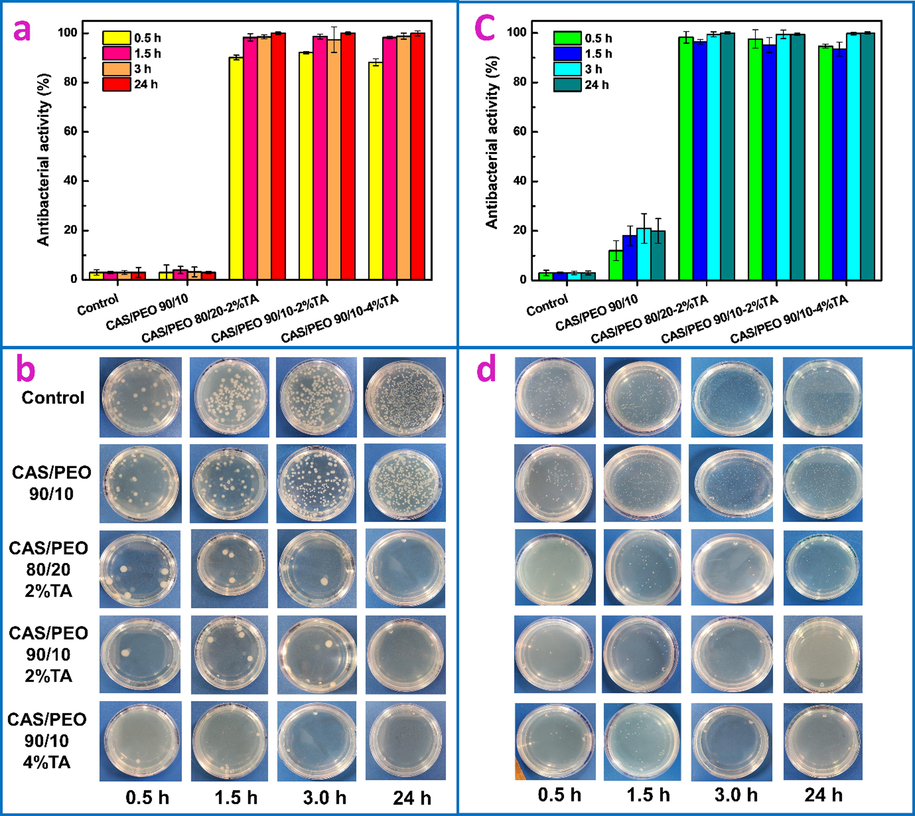

3.7 Antibacterial activity of CAS/PEO fibers

Antibacterial activity kinetics (AA) was performed to determine the potential biological application of obtained electrospun CAS/PEO fibers, incorporating different amounts of TA (2 and 4 wt%). AA was evaluated against Gram (+) S. aureus and Gram (-) E. coli bacteria and compared with a reference growth (control), as observed in Fig. 7. It can be seen that CAS/PEO 90/10 fibers do not show AA against in all tines evaluated (Fig. 7A). However, with the TA addition, the AA is ca. 95–99.99 % in 0.5, 1.5, and 3 h, with a complete bacterial inhibition after 24 h of contact. This behavior is observed in Fig. 7b through the plates of the survival CFU obtained after each time evaluated. For the Gram (-) E. coli, a slight AA is observed in CAS/PEO 90/10 fibers (ca. 20–25 %)., which is increased in the contact time (as seen in Fig. 7c). As expected, high AA behavior is presented in the fibers with the TA incorporation, and observed through the representative AA photographs (Fig. 7d). The above indicates that TA incorporation is critical for the AA behavior of the electrospun CAS fibers. TA, as a polyphenolic compound obtained from natural sources, has demonstrated significant AA against a broad bacterial spectrum such as S. aureus, E. coli, P. aeruginosa, K. Pneumoniae, S. pyogenes, E. faecalis, among others, representing an excellent additive to biomaterials due to their capacity to promote the cell proliferation and tissue regeneration in wound dressing systems (Kaczmarek, 2020), and therefore, does not represent a harmful effect on health. Our results suggest that the TA incorporation of CAS/PEO fibers combines the crosslinking effect to improve the mechanical behavior and the antibacterial characteristics, generating a functional textile for potential biomedical applications.

Antibacterial activity kinetics (AA) of CAS/PEO fibers against Gram (+) S. aureus and Gram (-) E. coli grown in LB media: a) AA of S. aureus, b) AA of E. coli, c) representative photographs of the AA of S. aureus and d) representative photographs of the AA of E. coli.

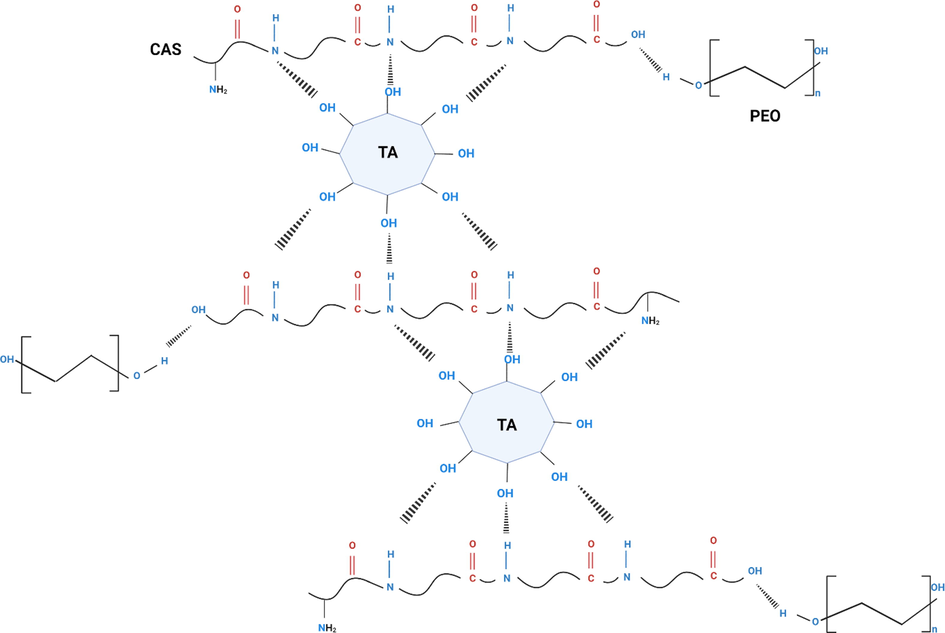

3.8 Reticulation mechanism of CAS/PEO fibers with TA incorporation

Electrospun of natural proteins such as CAS, obtained from revalued sources, have been explored to develop a biocompatible and biodegradable material with enhanced mechanical performance and thermal stability, with potential application in tissue engineering (Dai et al., 2022; Lelkes et al., 2008; Selvaraj et al., 2018; Yang and Reddy, 2012; Zhang et al., 2020a, 2020b). In this regard, the intrinsic chemical nature of CAS contains inside polar groups (–COOH, –NH2, and –OH), enabling the formation of intra/intermolecular hydrogen bonds (Eigel et al., 1984; Xie and Hsieh, 2003). This feature is responsible for the fact that CAS cannot form filaments by the electrospinning method, so using polymers as binders is key to appropriate filament fabrication (Picchio et al., 2018; Selvaraj et al., 2018). In particular, it has been claimed that polyethylene oxide (PEO) is characterized by its high ionic conductivity, flexibility, adhesion, and easy processing (Xu et al., 2012), thus is commonly used as a co-spinning polymer to improve the spinnability of CAS solution in water, suggesting the formation of hydrogen bonds (Dai et al., 2022). According to Xie, J., and Hsieh, Y.L. (Xie and Hsieh, 2003), the strong interaction between CAS and PEO through hydrogen bonds is due to their high compatibility during the solution preparation. Therefore, the interaction between the both polymers is key to obtain a low phase separation. In addition, the incorporation of tannic acid during the solution preparation, previous to electrospun process, improve the fibers reticulation, where it is clear the interaction of CAS/PEO with TA by interconnected polypeptide chain of CAS, capable to form hydrogen bonds interaction (Picchio et al., 2018). As a result, a stable three-dimensional network is obtained, with enhanced mechanical performance. A representative scheme of CAS interaction with PEO and the reticulation process by TA addition is presented in Fig. 8.

Representative scheme of CAS interaction with PEO and their reticulation with TA.

4 Conclusions

Revalued waste milk was harnessed to produce electrospun fibrous membranes from a natural protein (CAS) with improved thermo-mechanical and antibacterial properties. In this regard, CAS/PEO fibers incorporating tannic acid (TA) as a crosslinker agent was performed, obtaining filaments with a slightly irregular morphology with a diameter of ca. 2 µm, capable of forming a stable three-dimensional network non-soluble in water. Furthermore, TA induces chemical changes associated with the reticulation process in electrospun filaments, as observed in the availability of OH/NH2 polar groups of CAS using FTIR measurements. This behavior enhances the mechanical performance and the thermal stability of electrospun CAS/PEO fibers associated with the TA concentration. Although the CAS/PEO solution was prepared under aqueous conditions (deionized water), this allowed obtaining electrospun fibrous membranes from revalued waste milk. AA results demonstrate high antibacterial properties of CAS/PEO fibers with the incorporation of TA against S. aureus and E. coli. Our results suggest the possibility of harnessing revalued waste sources to produce functional textiles with potential application in biomedical issues.

Acknowledgments

The author acknowledges the financial support of CONACYT through the Basic Science Project A1-17842, and the support of CONACYT through Grant 315878 (LANI AUTO) is greatly appreciated. Furthermore, the authors acknowledge R.A. Mauricio-Sánchez (CINVESTAV) for her technical support in FTIR characterization and Gerardo Antonio Fonseca-Hernández (CFATA-UNAM) for his technical support in mechanical performance characterization. Acknowledgments to Isabel Nieto and Vanesa Oviedo (Faculty of Engineering, Amazcala Campus. the Autonomous University of Querétaro) for their support in CAS extraction.

References

- Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol.. 2019;88:361-372.

- [CrossRef] [Google Scholar]

- Imparting antibacterial activity, UV-protection properties and enhancing performance of casein modified polyester fabrics. J. Textile Inst.. 2020;112:1436-1448.

- [CrossRef] [Google Scholar]

- Composition and Properties of Non-cow Milk and Products. Non-Bovine Milk Milk Prod.. 2016;81–116

- [CrossRef] [Google Scholar]

- Non-food applications of milk components and dairy co-products: A review. Lait. 2003;83:417-438.

- [CrossRef] [Google Scholar]

- New Insights toward Casein/Polyvinyl Alcohol Electrospun Nanofibrous Webs as a Piezoelectric-Cum-Triboelectric Energy Harvester. ACS Appl. Electron. Mater.. 2021;3:4348-4361.

- [CrossRef] [Google Scholar]

- Antibacterial Textile Based on Hydrolyzed Milk Casein. Mater.. 2021;14:251.

- [CrossRef] [Google Scholar]

- Antibacterial Textile Based on Hydrolyzed Milk Casein. Materials (Basel).. 2021;14:1-14.

- [CrossRef] [Google Scholar]

- Veterinary Drug Residues in Food-animal Products: Its Risk Factors and Potential Effects on Public Health. J. Vet. Sci. Technol.. 2016;7

- [CrossRef] [Google Scholar]

- Antibacterial and physical effects of cationic starch nanofibers containing carvacrol@casein nanoparticles against Bacillus cereus in soy products. Int. J. Food Microbiol.. 2022;364:109530

- [CrossRef] [Google Scholar]

- Controlled release and antibacterial properties of PEO/casein nanofibers loaded with Thymol/β-cyclodextrin inclusion complexes in beef preservation. Food Chem.. 2022;382:132369

- [CrossRef] [Google Scholar]

- Health-Related Aspects of Milk Proteins. Iran. J. Pharm. Res. IJPR. 2016;15:573.

- [CrossRef] [Google Scholar]

- Nomenclature of Proteins of Cow’s Milk: Fifth Revision. J. Dairy Sci.. 1984;67:1599-1631.

- [CrossRef] [Google Scholar]

- Chemical Composition of Commercial Cow’s Milk. J. Agric. Food Chem.. 2019;67:4897-4914.

- [CrossRef] [Google Scholar]

- Effect of Cross-Linking on Microstructure and Physical Performance of Casein Protein. Biomacromolecules. 2009;10:1681-1688.

- [CrossRef] [Google Scholar]

- Electrospun sodium alginate/polyethylene oxide fibers and nanocoated yarns. Int. J. Polym. Sci.. 2015;2015

- [CrossRef] [Google Scholar]

- Tannic Acid with Antiviral and Antibacterial Activity as A Promising Component of Biomaterials—A Minireview. Mater. (Basel).. 2020;13

- [CrossRef] [Google Scholar]

- Study on the use of various concentration of acetic acid and different precipitation duration on casein characteristics. IOP Conf. Ser. Earth Environ. Sci.. 2019;343:12035.

- [CrossRef] [Google Scholar]

- Electrospinning of natural proteins for tissue engineering scaffolding. Nat. Polym. Biomed. Appl.. 2008;446–482

- [CrossRef] [Google Scholar]

- Structural characteristics and biocompatibility of a casein-based nanocomposite for potential biomedical applications. J. Mater. Sci.. 2018;53:3959-3971.

- [CrossRef] [Google Scholar]

- Cloud point extraction applied to casein proteins of cow milk and their identification by mass spectrometry. Anal. Chim. Acta. 2007;590:166-172.

- [CrossRef] [Google Scholar]

- Multifunctional Applications of Blow-Spinning Setaria viridis Structured Fibrous Membranes in Water Purification. ACS Appl. Mater. Interfaces. 2021;13:22874-22883.

- [CrossRef] [Google Scholar]

- Straining flow spinning: production of regenerated silk fibers under a wide range of mild coagulating chemistries. Green Chem.. 2017;19:3380-3389.

- [CrossRef] [Google Scholar]

- Bacterial cellulose/glycolic acid/glycerol composite membrane as a system to deliver glycolic acid for anti-aging treatment. J. Bioresour. Bioprod.. 2021;6:129-141.

- [CrossRef] [Google Scholar]

- The fabrication and characterization of casein/PEO nanofibrous yarn via electrospinning. E-Polymers. 2019;19:154-167.

- [CrossRef] [Google Scholar]

- Polyethylene Oxide as a Multifunctional Binder for High-Performance Ternary Layered Cathodes. Polym. 2021;13:3992.

- [CrossRef] [Google Scholar]

- Second generation biorefining in Ecuador: Circular bioeconomy, zero waste technology, environment and sustainable development: The nexus. J. Bioresour. Bioprod.. 2021;6:83-107.

- [CrossRef] [Google Scholar]

- Calendula officinalis extract/PCL/Zein/Gum arabic nanofibrous bio-composite scaffolds via suspension, two-nozzle and multilayer electrospinning for skin tissue engineering. Int. J. Biol. Macromol.. 2019;135:530-543.

- [CrossRef] [Google Scholar]

- Photo-crosslinked soy protein-based electrospun scaffolds. Mater. Lett. X. 2021;12:100115

- [CrossRef] [Google Scholar]

- Casein films crosslinked by tannic acid for food packaging applications. Food Hydrocoll.. 2018;84:424-434.

- [CrossRef] [Google Scholar]

- Caseins, caseinates and micellar casein. Encycl. Dairy Sci. Third Ed.. 2021;5:8-17.

- [CrossRef] [Google Scholar]

- Antibiotic residues in milk: Past, present, and future. J. Adv. Vet. Anim. Res.. 2019;6:315-332.

- [CrossRef] [Google Scholar]

- Biodiverse Properties of Tannic Acid-Based Fibers. Fibers Polym.. 2021;2211(22):2986-2994.

- [CrossRef] [Google Scholar]

- Degradable tannic acid/polyethyleneimine polyplex particles with highly antioxidant and antimicrobial effects. Polym. Degrad. Stab.. 2016;133:152-161.

- [CrossRef] [Google Scholar]

- Electrospinning of casein nanofibers with silver nanoparticles for potential biomedical applications. Int. J. Biol. Macromol.. 2018;120:1674-1681.

- [CrossRef] [Google Scholar]

- Characterization of casein fractions - Comparison of commercial casein and casein extracted from cow’s milk. Chem. Biochem. Eng. Q.. 2016;30:501-509.

- [CrossRef] [Google Scholar]

- The Potential for Regenerated Protein Fibres within a Circular Economy: Lessons from the Past Can Inform Sustainable Innovation in the Textiles Industry. Sustain.. 2021;13:2328.

- [CrossRef] [Google Scholar]

- Eco-friendly Manufacturing Process of Casein Fiber with It’s Sustainable Features & Comfortable Uses. Am. J. Environ. Eng.. 2019;9:31-35.

- [Google Scholar]

- Recovery of Protein from Dairy Milk Waste Product Using Alcohol-Salt Liquid Biphasic Flotation. Process.. 2019;7:875.

- [CrossRef] [Google Scholar]

- A regenerated fiber from rennet-treated casein micelles. Colloid Polym. Sci.. 2021;299:909-914.

- [CrossRef] [Google Scholar]

- Short communication: Electrospinning of casein/pullulan blends for food-grade applications. J. Dairy Sci.. 2016;99:1837-1845.

- [CrossRef] [Google Scholar]

- Preparation and characterization of milk protein films and their application for packaging of Cheddar cheese. J. Food Sci. Technol.. 2014;51:3767-3775.

- [CrossRef] [Google Scholar]

- Fourier Transform Mid-Infrared (FTIR) Spectroscopy to Identify Tannin Compounds in The Panicle of Sorghum Mutant Lines. IOP Conf. Ser. Mater. Sci. Eng.. 2019;546:42045.

- [CrossRef] [Google Scholar]

- Advances in Fabricating the Electrospun Biopolymer-Based Biomaterials. J. Funct. Biomater.. 2021;12

- [CrossRef] [Google Scholar]

- Improved mechanical properties and thermal-stability of collagen fiber based film by crosslinking with casein, keratin or SPI: Effect of crosslinking process and concentrations of proteins. Int. J. Biol. Macromol.. 2018;109:1319-1328.

- [CrossRef] [Google Scholar]

- Casein and pectin: Structures, interactions, and applications. Trends Food Sci. Technol.. 2020;97:391-403.

- [CrossRef] [Google Scholar]

- Ultra-high surface fibrous membranes from electrospinning of natural proteins: casein and lipase enzyme. J. Mater. Sci.. 2003;3810(38):2125-2133.

- [CrossRef] [Google Scholar]

- Preparation and Properties of Electrospun Soy Protein Isolate/Polyethylene Oxide Nanofiber Membranes. ACS Appl. Mater. Interfaces. 2012;4:4331-4337.

- [CrossRef] [Google Scholar]

- Applications of tannic acid in membrane technologies: A review. Adv. Colloid Interface Sci.. 2020;284:102267

- [CrossRef] [Google Scholar]

- Properties and potential medical applications of regenerated casein fibers crosslinked with citric acid. Int. J. Biol. Macromol.. 2012;51:37-44.

- [CrossRef] [Google Scholar]

- Preparation and characterization of homogeneous and enhanced casein protein-based composite films via incorporating cellulose microgel. Sci. Reports. 2019;91(9):1-11.

- [CrossRef] [Google Scholar]

- Chemical Modification of Gelatin by a Natural Phenolic Cross-linker. Tannic Acid. J. Agric. Food Chem.. 2010;58:6809-6815.

- [CrossRef] [Google Scholar]

- Biological fibers based on naturally sourced proteins: mechanical investigation and applications. Mater. Today Adv.. 2020;8:100095

- [CrossRef] [Google Scholar]

- Robust Biological Fibers Based on Widely Available Proteins: Facile Fabrication and Suturing Application. Small. 2020;16:1907598.

- [CrossRef] [Google Scholar]

Further reading

- Dairy production and products: Gateway to dairy production and products [WWW Document], n.d. URL https://www.fao.org/dairy-production-products/en/ (accessed 2.4.22).

Appendix A

Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.arabjc.2022.104201.

Appendix A

Supplementary data

The following are the Supplementary data to this article:Supplementary Data 1

Supplementary Data 1