Translate this page into:

Fast fabrication of High-Yield WS2 nanoscrolls via ultrasound sonication

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Transforming the bulk of tungsten disulfide (WS2) into one-dimensional (1D) nanoscrolls has potential applications in a variety of fields. The current methods for fabricating (1D) WS2 nanoscrolls suffer from low yields, high temperatures, a complicated fabrication process, and the use of surfactants. We have reported a facile and cost-effective approach for fabricating WS2 nanoscrolls in high yield using ultrasound probe sonication (20 KHz) from bulk WS2 in dimethylformamide (DMF) in two hours. Importantly, this simple method achieves a 90 % WS2 nanoscroll yield. This depends on critical experimental parameters such as the choice of solvent, the initial concentration of WS2, and the sonication time. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) measurements confirm that the nanoscrolls have a closely uniform shape, with an interlayer spacing of ∼ 0.62 nm between adjacent layers of WS2 nanoscrolls. Atomic force microscopy (AFM) reveals that the nanoscrolls have a length of approximately 650 nm and a height profile of 5–10 nm, indicating their formation from multiple layers of WS2. We further investigate the fabricated nanoscrolls using other techniques such as X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), and Raman spectroscopy.

Keywords

WS2

Nanoscroll

Probe ultrasonication

High yield

Exfoliation

1 Introduction

In recent years, intense interest has been paid to the layered two-dimensional (2D) transition metal dichalcogenides (TMDs). 2D atomically thin nanosheets of transition metal dichalcogenides (TMDs) have attracted attention as one of the most promising materials for various applications owing to their low cost, easy preparation, large surface areas, and unique chemical and physical properties (Manzeli et al., 2017; Han et al., 2018).

Converting two-dimensional (2D) nanosheets into one-dimensional (1D) nanoscrolls is an interesting method of fabricating new nanomaterials (Li et al., 2017; Han et al., 2018; Lv et al., 2015; Dong et al., 2021). The tubular structures of nanoscrolls are different from 2D thin nanosheets and exhibit outstanding physical and chemical properties, as predicted in many theoretical studies (Sharifi et al., 2013; Lai et al., 2016; Wang et al., 2020). Transforming 2D tungsten disulfide (WS2) nanosheets into 1D WS2 nanoscrolls by rolling opens the door for 1D tubular-structured materials with unique properties (Aftab,Iqbal,and Rim, 2023), such as superior electronic and electromechanical properties. These WS2 nanoscrolls can be used in many applications including tribology, field-effect transistors, catalysis, and energy storage (Li et al., 2017; Han et al., 2018; Lv et al., 2015; Dong et al., 2021).

TMDs nanoscrolls have been fabricated using different chemical and physical strategies, including strain-induced scrolling (Zhou et al., 2019; Hao,Yang,and Gao, 2016), supercritical fluids (Thangasamy and Sathish, 2016), amphiphilic organic molecules (Choi and Suh, 2018), argon plasma (Meng et al., 2016), alkaline droplets (Wang et al., 2020), vortex fluidic device (VFD) (Alharbi et al., 2022; Alharbi et al., 2018), and organic solvents (Fang et al., 2018; Cui et al., 2018; Deng et al., 2019). Among the fabrication methods, chemical vapor deposition (CVD) has been widely used to synthesize atomically flat WS2 nanosheets, following which a few drops of an organic solvent are added to the flat WS2 sheets, making them fold to form the structure of a nanoscroll (Fang et al., 2018; Wang et al., 2020). Zhao et al. successfully fabricated WS2 nanoscrolls with a length of 10 µm using CVD-grown monolayer WS2 nanosheets (Zhao et al., 2022). Ethanol, as an organic solvent, was dropped on the WS2 flat nanosheets, and during ethanol evaporation, the WS2 nanosheet edge rolled up to form the scroll structure (Fang et al., 2018).

Another approach for fabricating nanoscrolls structure is sonication. Sonication is a simple and fast technique and has been widely used to fabricate nanoscrolls under ambient conditions because of its advantages such as low cost and mass production. Pradeep et alused an ultrasonicatior for the fabrication of graphene nanoscrolls in a mixture of ethanol and water (Pradeep et al., 2021). Additionally, Purkait et al successfully fabricated graphene oxide nanoscrolls with tunable dimensions via low-frequency sonication (20 KHz) (Sontakke and Purkait, 2020). However, these approaches have some limitations, for example, some methods require high temperature, complex steps or use surfactants and harsh chemicals that can potentially damage the properties of the fabricated material and generate a waste stream. Therefore, a low-cost and simple technique for fabricating WS2 nanoscrolls is required.

To the best of our knowledge, there have been no previous attempts to directly scrolling WS2 from bulk WS2 in high yield using an ultrasonicator in dimethylformamide (DMF). This study reports the fabrication of WS2 nanoscrolls from bulk WS2 using DMF only, thereby avoiding the use of harsh chemicals and surfactants. WS2 nanoscrolls were successfully fabricated via probe ultrasonication at room temperature using a single solvent, namely, DMF. The fabricated WS2 nanoscrolls were characterized using different techniques including SEM, AFM, TEM, STEM, XRD, Raman and XPS.

2 Experimental section

2.1 Chemicals and materials

A WS2 powder with a lateral dimension size in the range of 2 µm was purchased from Sigma-Aldrich. Ultrapure water (18.2 MΩ cm; Milli-Q Direct 8) was used in all experiments. DMF (purity = 99 %) was purchased from Sigma-Aldrich, and toluene (purity = 99 %) was purchased from Alfa Aesar.

2.2 Materials fabrication

The fabrication of WS2 nanoscrolls from bulk WS2: Bulk WS2 with a lateral dimension size of ∼ 2 µm was dispersed in DMF. Briefly, 300 mg of the WS2 powder was added to 60 mL of DMF in a 100-mL beaker and sonicated using a bath sonicator for 15 min to make a colloid suspension. No change in the WS2 structure was observed at this stage. Then, the WS2 solution was sonicated using the probe ultrasonicator (ultrasonic processor SONIC Vibra cell with a probe Model 18) for 2 h (2 h) at a low frequency of 20 KHz. The solution was placed in an ice bath to ensure its temperature remained close to room temperature (<30 °C). After 2 h, the product comprising high quantities of WS2 nanoscrolls was collected. The yield of WS2 nanoscrolls was 90 %, which is calculated using the volume and concentration of the bulk WS2 (5 mg/mL) and the quantity of the isolated and dried nanoscrolls of WS2, the processed solution of WS2 nanoscrolls was centrifuged at 9980 g for 10 min to remove unscrolled sheets. About 90 % of the top supernatant was then collected by micropipette and from this the yield was estimated to be 90 %.

2.3 Characterization

WS2 nanoscrolls were characterized using scanning electron microscopy (SEM; FEI Quanta 450 high-resolution field-emission scanning electron microscope; voltage = 10 kV). The morphology of WS2 nanoscrolls was characterized using atomic force microscopy (AFM; Nanoscope 8.10; tapping mode) and transmission electron microscopy (TEM; TECNAI 20 microscope, operating at 120 and 200 kV). Scanning TEM (STEM) analysis and compositional mapping were performed using an aberration-corrected FEI Titan Themis transmission electron microscope operating at 200 kV equipped with an energy-dispersive X-ray detector. The chemical composition of the WS2 nanoscrolls was also studied via X-ray photoelectron spectroscopy (XPS), and a hemispherical analyzer (SPECS) was performed using an X-ray source with Mg Kα line (hv = 1253.6 eV) with a base pressure of a few 10−10 mbar. X-ray powder diffraction (XRD) data were collected using a Bruker Advanced D8 diffractometer (capillary stage) using Cu Kα radiation (λ = 1.5418 Å, 50 kW/40 mA, 2θ = 10–80°). Raman measurements were recorded at an excitation wavelength of 532 nm (≤5mW) at room temperature.

3 Results and discussion

3.1 Fabrication of WS2 nanoscrolls

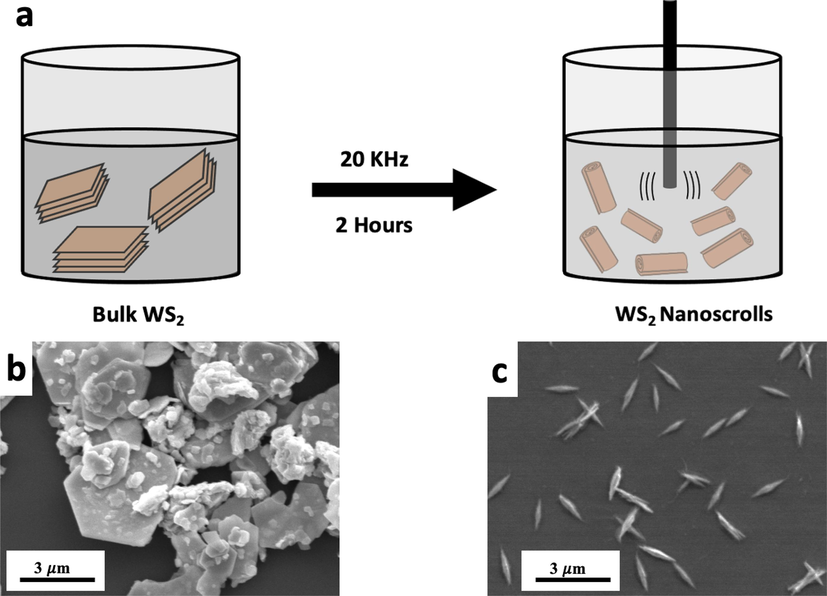

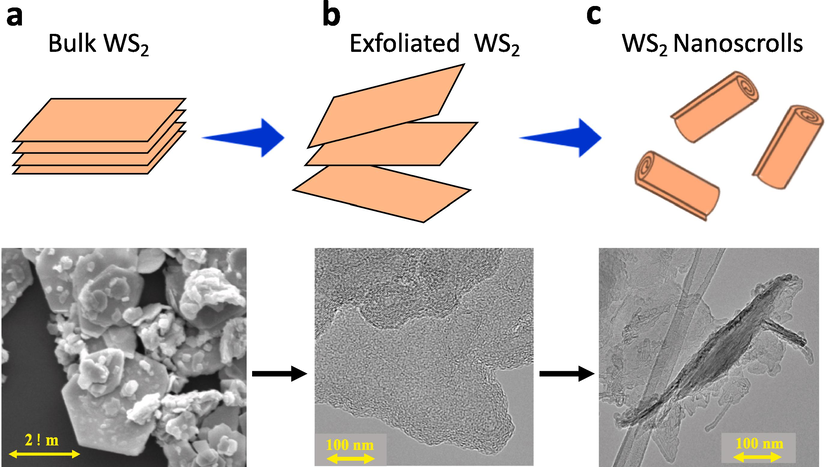

In this contribution, we have reported a simple, straightforward, and scalable method for directly scrolling WS2 from their bulk in DMF, which is cost-effective and can be achievable in most laboratories. The procedure for fabricating WS2 nanoscrolls from their bulk material via ultrasonication is illustrated schematically in Fig. 1a. The scanning electron microscopy (SEM) image of bulk WS2 powder revealed the typical multilayered structure with a lateral size ranging from sub micrometer to a few micrometers (Fig. 1b). A dramatic change can be seen in the morphology of the bulk WS2 after ultrasonication processing with the nanoscroll formation (Fig. 1c), depending on the time processing, solvent choice, and concentration of the bulk WS2.

(a) Schematic of the experimental procedure for fabricating WS2 nanoscrolls via probe ultrasonication in DMF with a concentration of 5 mg/mL. SEM image of (b) bulk WS2 and (c)WS2 nanoscrolls.

Initially, we dispersed the bulk WS2 powder in various solvents, such as N-methyl-2-pyrrolidone (NMP), water, and ethanol. Despite these solvent systems being reported in the literature for exfoliating TMD, some of them were forming scroll structures either in a low yield or requiring complex steps to fabricate such structures.(Cui et al., 2018; Thangasamy and Sathish, 2016; Suh, 2016) They were ineffective in the probe ultrasonication processing with a concentration of 5 mg/mL for two hours and at a 20 KHz frequency (Figs. S1–S3).

Next, we chose DMF as the solvent, which led to the formation of WS2 nanoscrolls in a high yield of approximately 90 %, as we will discuss below. The effects of other parameters, including the concentration of WS2 (i.e., 3, 5 and 10 mg/mL; Fig. S4 and S5c) and sonication time (i.e., 30 mins, 1 h, and 2 h) on WS2 nanoscroll formation were studied (Fig. S5).

Establishing the optimal conditions for fabricating WS2 nanoscrolls using DMF as a solvent at a concentration of 5 mg/mL, the black suspension of the bulk WS2 powder was sonicated in a bath sonicator for 15 min and then placed in a 100-mL glass beaker. The probe ultrasonicator was placed in the middle of the solution from the top and set on a low frequency of 20 KHz from 2 h (Fig. 1b). The morphology of WS2 changes dramatically from flat flakes to WS2 nanoscrolls after the probe ultrasonication (20 KHz) (Fig. 1c).

3.2 Characterization of WS2 nanoscrolls

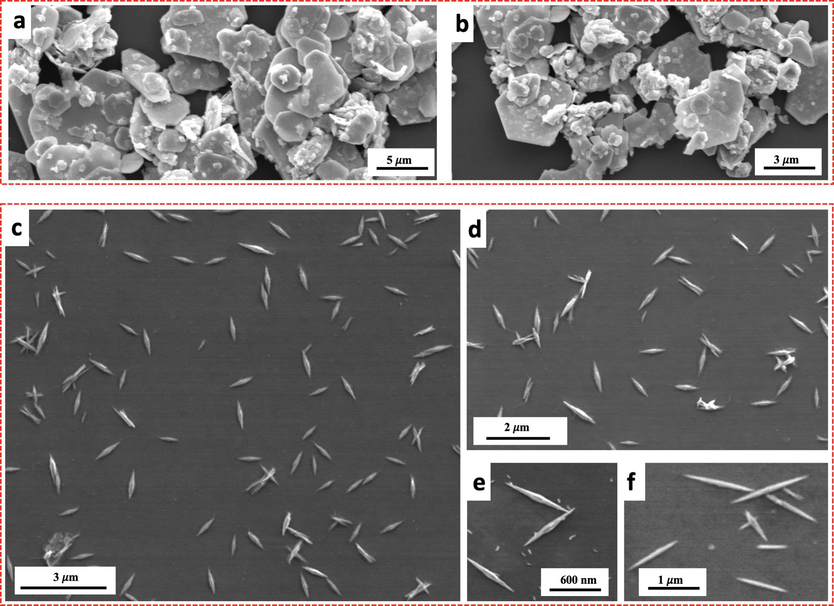

The structure and morphology of the fabricated WS2 nanoscrolls were systematically investigated by SEM, AFM, TEM, HRTEM, STEM, XRD, Raman, and XPS. Fig. 2a, b shows low-magnification SEM images of the bulk WS2 before processing; they exhibit an irregular structure and sizes ranging from a few micrometers to tens of micrometers. After processing the bulk power of WS2 using the probe ultrasonication under the optimized conditions; including “concentration, low frequency, solvent and reaction time”. They have dramatically changed from the 2D bulk WS2 structure and completely converted to 1D nanoscrolls of WS2, as it can be clearly observed from SEM images in Fig. 2c–f. In addition, no bulk structure from WS2 flakes is seen in the solution after processing (Fig. 2c–f).

SEM images of (a-b) bulk WS2 (before processing) and (c-f) WS2 nanoscrolls (after processing using the probe ultrasonication under the optimized conditions).

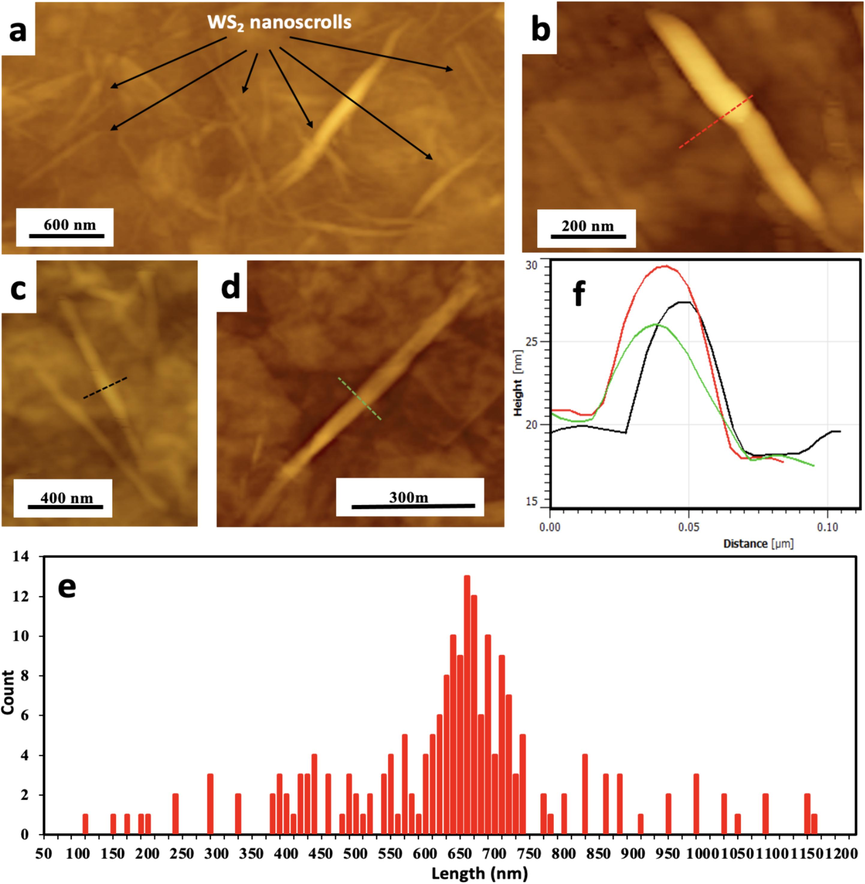

AFM measurements were performed to characterize the structure of WS2 nanoscrolls and investigate their size and shape (Fig. 3), AFM images further confirm that the fabricated WS2 nanoscrolls exhibit a nanoscroll structure with a closely uniform shape (Fig. 3a–d). They have a length distribution of 650 nm (Fig. 3e), which is consistent with what is observed by SEM. The height profile of the selected WS2 nanoscrolls revealed a height ranging between 5 and 10 nm, (Fig. 3f), indicating that more than one layer of WS2 was rolled up during the processing, which is in good agreement with the literature (Thangasamy,Raj,and Sathish, 2020).

(a-d) AFM images, (e) The length distribution and (f) The height profiles of WS2 nanoscrolls.

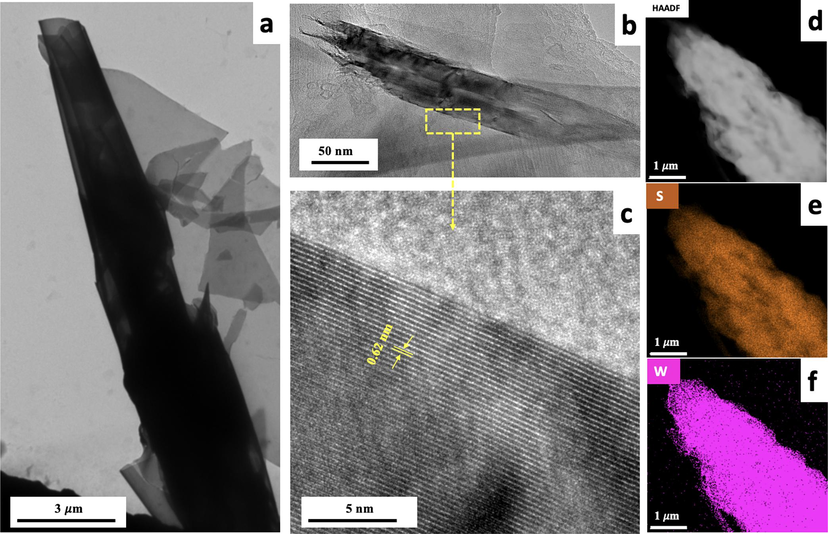

The nanoscrolls of WS2 were further investigated using TEM and HRTEM. Fig. 4a, b shows a low and high magnification TEM image of the WS2 nanoscrolls, which unambiguously confirms the formation of WS2 nanoscrolls. The HRTEM image, Fig. 4c, shows that in the nanoscrolls formed using multiple layers of WS2, the interlayer spacing between adjacent layers of WS2 nanoscrolls is ∼ 0.62 nm (Fang et al., 2018; Cui et al., 2018). Additionally, we performed the elemental mapping of WS2 nanoscrolls using high-resolution STEM. The high-angle annular dark-field (HAADF) STEM image shows that the WS2 nanoscrolls have a tubular structure. The elemental mapping shows the presence of W and S throughout the WS2 nanoscrolls (Fig. 4d–f). These findings are in line with the above SEM and AFM results.

(a-b) TEM images, (c) HRTEM image, (d) STEM image, and (e-f) elemental mappings of WS2 nanoscrolls.

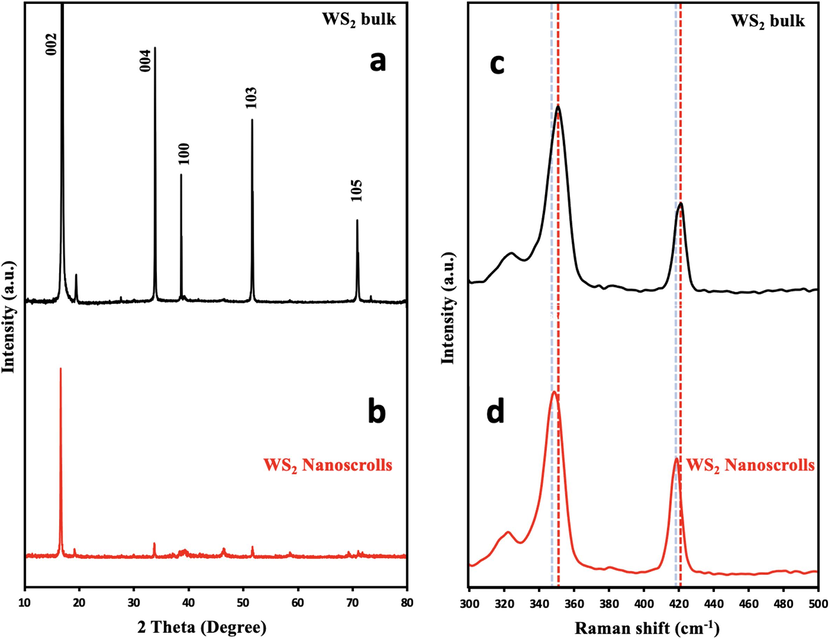

To further investigate the structure of WS2 nanoscrolls, X-ray diffraction (XRD) was conducted for both the bulk and nanoscrolls of WS2. For the bulk WS2, (Fig. 5a), there are five obvious and sharp diffraction peaks at 17°, 35°, 40°, 53° and 72°, which can be assigned to the (0 0 2), (0 0 4), (1 0 0), (1 0 3) and (1 0 5) planes, which reflects of the hexagonal crystal structure of 2H-WS2.(Štengl and Henych, 2013) After fabricating of WS2 nanoscrolls, (Fig. 5b) only one main diffraction peak at 2θ of 14.97° corresponding to the crystal plane of (0 0 2). The two weak peaks at 2θ = 35° and 53° in the XRD pattern of the WS2 nanoscrolls are attributed to the (0 0 4) and (1 0 3) diffractions, respectively (Thangasamy,Raj,and Sathish, 2020; Thangasamy and Sathish, 2016). Sathish et al. also reported the appearance of similar diffraction peaks after forming WS2 nanoscrolls using energy efficient supercritical fluid processing at 400C° (Thangasamy,Raj,and Sathish, 2020).

XRD patterns of (a) bulk WS2 and (b) WS2 nanoscrolls and Raman spectra of (c) bulk WS2 and (d) WS2 nanoscrolls.

Raman spectroscopy is employed to characterize the crystal structure of the bulk WS2 and nanoscrolls, using 532 nm excitation as shown in Fig. 5c, d. There are two characteristic peaks can be observed for both materials, assignable to the (E2g) mode at 350 cm−1 and the (A1g) mode at 420 cm−1,(Fig. 5c), corresponding to the in-plane W − S vibrations and sulfur out-of-plane vibrations (Adilbekova et al., 2020; Liu and Komatsu, 2016), respectively, which indicates the fabricated WS2 nanoscrolls show a good crystallinity.(Adilbekova et al., 2020; Liu and Komatsu, 2016) After fabricating nanoscroll structure from the bulk WS2,(Fig. 5d), the (E2g) mode peak has a red shift, from 350 to 348 cm−1 compared with those of the starting WS2, which can be attributed to the bond strain present in the WS2 nanoscrolls after processing (Yue et al., 2020; Wang et al., 2020). Whereas there is a blue-shifted for (A1g) mode of the WS2 nanoscrolls from 420 to 418.3 cm−1, which can be attributed to the van der Waals interactions between neighboring layers in the nanoscrolls structure (Aftab,Iqbal,and Rim, 2023; Wang et al., 2016).

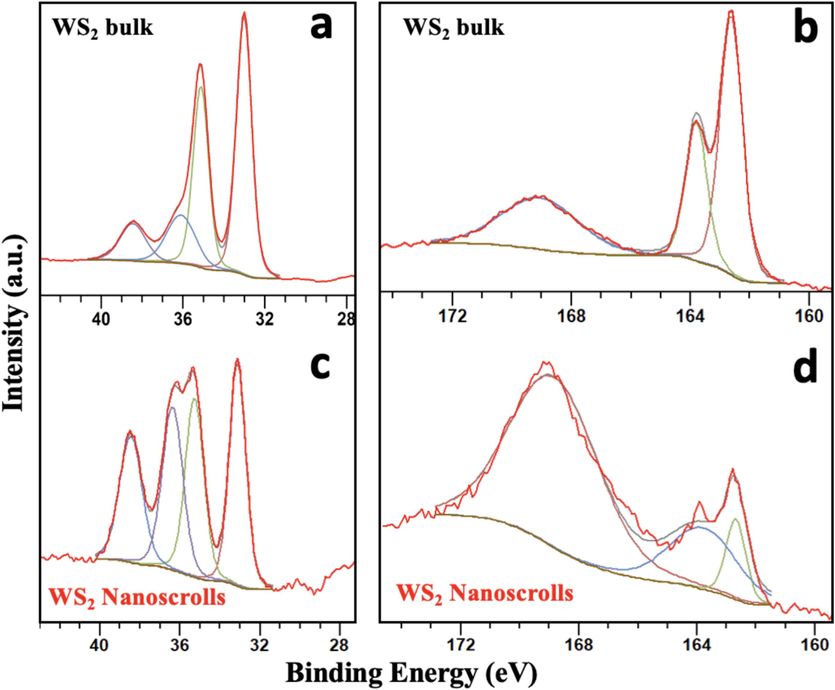

XPS was used to study the elemental composition of bulk WS2 and WS2 nanoscrolls. Herein, the expected elements in the XPS spectra are W and S. Fig. 6 shows the high-resolution XPS spectra of bulk and nanoscrolls of WS2. In the XPS spectrum of bulk WS2, two strong peaks are observed at 33.14 and 35.45 eV, which correspond to W 4f7/2 and W 4f5/2, respectively (Fig. 6a) (Ghosh et al., 2022; Nethravathi et al., 2013). Similarly, the S 2p XPS spectra of bulk WS2 show two peaks at 162.75 and 163.93 eV, corresponding to S 2p3/2 and S 2p1/2, respectively (Mao et al., 2013; Nethravathi et al., 2013) (Fig. 6b). After the formation of WS2 nanoscrolls, two additional main peaks can be observed at 37.10 and 39.25 eV in the W 4f XPS spectrum of WS2 nanoscrolls, which are assigned to W–O. These peaks may appear in the XPS spectra because after processing, the fabricated nanoscrolls are oxidized (Fig. 6c) (Huang et al., 2018; Zhou et al., 2014; Cohen et al., 2023). Similarly, the S 2p XPS spectra of the WS2 nanoscrolls show another main peak at 169.7 eV, which is attributed to S6+ from oxidized S (Fig. 6d) (Miao et al., 2022).

High-resolution W 4f and S 2p XPS spectra of bulk WS2 (a-b) and WS2 nanoscrolls (c-d).

3.3 Mechanism of WS2 nanoscroll formation

The schematic of the mechanism for the formation of WS2 nanoscrolls is shown in Fig. 7. The experiment was performed using the probe ultrasonication at a low frequency (20 KHz) because high-frequency ultrasonic waves can change and may damage the crystal structure of the WS2 materials and destroy their properties (Fig. S6).(Gopalakrishnan,Damien,and Shaijumon, 2014) The mechanism of WS2 nanoscroll formation from bulk WS2 is as follows: First, the bulk WS2 is exfoliated by the force induced by cavitation bubble collapse. (Telkhozhayeva et al., 2021; Deshmukh et al., 2019) When the cavitation-induced bubbles collapse with massive energy, and shock stress waves will act on the bulk WS2 crystal rapidly (Fig. 7a), resulting in breaking down bulk WS2 into smaller flakes in the solution as well as exfoliating WS2 into nanosheets of WS2 and that occurred after 1 h of sonication, as shown in Fig. 7b, the formation of nanosheets is well understood, as reported by several researchers. (Telkhozhayeva et al., 2021; Deshmukh et al., 2019) Increasing the probe ultrasonication time to 2 h resulted in the scrolling of these exfoliated WS2 nanosheets and the formation of the 1D structure of WS2 nanoscrolls (Fig. 7c).

Schematic showing the mechanism for the formation of WS2 nanoscrolls.

4 Conclusion

In summary, we have successfully fabricated WS2 nanoscrolls in high yield (90 %) directly from their bulk WS2 in DMF using ultrasonication (20 KHz) for two hours. This simple, low-cost, and scalable method eliminates the need for surfactant or other harsh chemicals and can be achieved in any laboratory. Crucial parameters such as choice of solvent, WS2 concentration, and sonication time are systematically explored to establish the optimal conditions for fabricating WS2 nanoscrolls in high yields. SEM and TEM characterizations confirmed the successful fabrication of WS2 nanoscrolls with a closely uniform shape. AFM measurements showed that the 1D WS2 nanoscrolls have a height of 5–10 nm with a length distribution centered at 650 nm. This developed strategy for fabricating WS2 nanoscrolls on demand, with the ability to prepare them in high yield, paves the way for developing WS2 nanoscroll applications.

Disclosure statement

The author has no conflict of interest to declare.

CRediT authorship contribution statement

Thaar M.D. Alharbi: Formal analysis, Investigation, Methodology, Supervision, Visualization, Writing – original draft, Writing – review & editing.

Acknowledgement

Thaar Alharbi thanks Prof. Colin L. Raston from Flinders University, Adelaide, Australia for his help and support. The authors extend their appreciation to the Deputyship for Research & Innovation, Minsitry of Education in Saudi Arabia for funding this work through Researchs Supporting Project number (445-9-766).

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liquid phase exfoliation of MoS 2 and WS 2 in aqueous ammonia and their application in highly efficient organic solar cells. J. Mater. Chem. C. 2020;8:5259-5264.

- [Google Scholar]

- Recent Advances in Rolling 2D TMDs Nanosheets into 1D TMDs Nanotubes/Nanoscrolls. Small. 2023;19:2205418.

- [Google Scholar]

- Continuous Flow Fabrication of MoS2 Scrolls for Electrocatalytic Hydrogen Evolution. ACS Sustain. Chem. Eng. 2022

- [Google Scholar]

- Alharbi, Thaar MD, David Harvey, Ibrahim K Alsulami, Nazila Dehbari, Xiaofei Duan, Robert N Lamb, Warren D Lawrance, and Colin L Raston. 2018. 'Shear stress mediated scrolling of graphene oxide', Carbon.

- A vacancy-driven phase transition in MoX 2 (X: S, Se and Te) nanoscrolls. Nanoscale. 2018;10:7918-7926.

- [Google Scholar]

- Tungsten Oxide Mediated Quasi-van der Waals Epitaxy of WS2 on Sapphire. ACS Nano. 2023;17:5399-5411.

- [Google Scholar]

- Rolling up transition metal dichalcogenide nanoscrolls via one drop of ethanol. Nat. Commun.. 2018;9:1-7.

- [Google Scholar]

- High-Performance Photodiode Based on Atomically Thin WSe2/MoS2 Nanoscroll Integration. Small. 2019;15:1901544.

- [Google Scholar]

- Ultrasound-assisted facile green synthesis of hexagonal boron nitride nanosheets and their applications. ACS Sustain. Chem. Eng.. 2019;7:17114-17125.

- [Google Scholar]

- Theoretical Study of Chemical Vapor Deposition Synthesis of Graphene and Beyond: Challenges and Perspectives. The Journal of Physical Chemistry Letters. 2021;12:7942-7963.

- [Google Scholar]

- Fang, Xiangru, Pei Wei, Lin Wang, Xiaoshan Wang, Bo Chen, Qiyuan He, Qiuyan Yue, Jindong Zhang, Weihao Zhao, Jialiang %J ACS applied materials Wang, and interfaces. 2018. 'Transforming Monolayer Transition-Metal Dichalcogenide Nanosheets into One-Dimensional Nanoscrolls with High Photosensitivity', 10: 13011-18.

- Enhancing the Photoelectrochemical Hydrogen Evolution Reaction through Nanoscrolling of Two-Dimensional Material Heterojunctions. ACS Nano. 2022;16:5743-5751.

- [Google Scholar]

- MoS2 quantum dot-interspersed exfoliated MoS2 nanosheets. ACS Nano. 2014;8:5297-5303.

- [Google Scholar]

- van der Waals metallic transition metal dichalcogenides. Chem. Rev.. 2018;118:6297-6336.

- [Google Scholar]

- 'fracture-Induced Nanoscrolls from CVD-Grown Monolayer Molybdenum Disulfide', Physica Status Solidi (RRL)–Rapid Research Letters. 2016;10:549-553.

- Nanoscale tungsten nitride/nitrogen-doped carbon as an efficient non-noble metal catalyst for hydrogen and oxygen recombination at room temperature in nickel–iron batteries. RSC Adv.. 2018;8:35343-133537.

- [Google Scholar]

- Self-assembly of two-dimensional nanosheets into one-dimensional nanostructures. Chem. 2016;1:59-77.

- [Google Scholar]

- Epitaxial growth of two-dimensional layered transition-metal dichalcogenides: growth mechanism, controllability, and scalability. Chem. Rev.. 2017;118:6134-6150.

- [Google Scholar]

- Readily available “stock solid” of MoS2 and WS2 nanosheets through solid-phase exfoliation for highly concentrated dispersions in water. ChemNanoMat. 2016;2:500-553.

- [Google Scholar]

- Transition metal dichalcogenides and beyond: synthesis, properties, and applications of single-and few-layer nanosheets. Acc. Chem. Res.. 2015;48:56-64.

- [Google Scholar]

- Ferromagnetism in exfoliated tungsten disulfide nanosheets. Nanoscale Res. Lett.. 2013;8:1-6.

- [Google Scholar]

- Excitation induced asymmetric fluorescence emission in 2D-WS 2 quantum dots. Materials Advances. 2022;3:1772-11179.

- [Google Scholar]

- Influence of probe amplitude on the preparation of graphene scroll by probe ultrasonicator technique. Mater. Today:. Proc.. 2021;45:4012-4409.

- [Google Scholar]

- Sharifi, Tiva, Eduardo Gracia-Espino, Hamid Reza Barzegar, Xueen Jia, Florian Nitze, Guangzhi Hu, Per Nordblad, Cheuk-Wai Tai, and Thomas Wågberg. 2013. 'Formation of nitrogen-doped graphene nanoscrolls by adsorption of magnetic γ-Fe 2 O 3 nanoparticles', Nature communications, 4: ncomms3319.

- Fabrication of ultrasound-mediated tunable graphene oxide nanoscrolls. Ultrason. Sonochem.. 2020;63:104976

- [Google Scholar]

- Strongly luminescent monolayered MoS 2 prepared by effective ultrasound exfoliation. Nanoscale. 2013;5:3387-3394.

- [Google Scholar]

- Evolution of a high local strain in rolling up MoS2 sheets decorated with Ag and Au nanoparticles for surface-enhanced Raman scattering. Nanotechnology. 2016;28:025603

- [Google Scholar]

- Higher ultrasonic frequency liquid phase exfoliation leads to larger and monolayer to few-layer flakes of 2D layered materials. Langmuir. 2021;37:4504-4514.

- [Google Scholar]

- Transformation of multilayer WS2 nanosheets to 1D luminescent WS2 nanostructures by one-pot supercritical fluid processing for hydrogen evolution reaction. Mater. Sci. Semicond. Process.. 2020;119:105167

- [Google Scholar]

- Rapid, one-pot synthesis of luminescent MoS 2 nanoscrolls using supercritical fluid processing. J. Mater. Chem. C. 2016;4:1165-2119.

- [Google Scholar]

- Strain-induced phonon shifts in tungsten disulfide nanoplatelets and nanotubes. 2D Materials. 2016;4:015007

- [Google Scholar]

- Scrolling bilayer WS 2/MoS 2 heterostructures for high-performance photo-detection. Nano Res.. 2020;13:959-966.

- [Google Scholar]

- Wrapping plasmonic silver nanoparticles inside one-dimensional nanoscrolls of transition-metal dichalcogenides for enhanced photoresponse. Inorg. Chem.. 2020;60:4226-4235.

- [Google Scholar]

- Solvent-Free Preparation of Closely Packed MoS2 Nanoscrolls for Improved Photosensitivity. ACS Appl. Mater. Interfaces. 2022;14:9515-9524.

- [Google Scholar]

- Tungsten oxide nanorods: an efficient nanoplatform for tumor CT imaging and photothermal therapy. Sci. Rep.. 2014;4:3653.

- [Google Scholar]

- Rolling up MoSe2 nanomembranes as a sensitive tubular photodetector. Small. 2019;15:1902528.

- [Google Scholar]

Appendix A

Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.arabjc.2024.105819.

Appendix A

Supplementary data

The following are the Supplementary data to this article:Supplementary Data 1

Supplementary Data 1