Translate this page into:

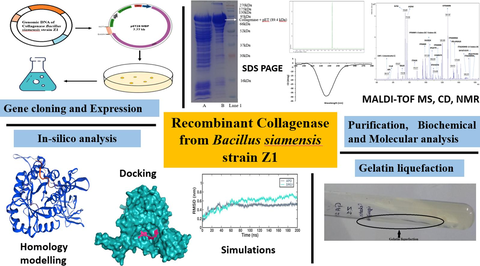

Molecular analysis of recombinant collagenase from Bacillus siamensis strain Z1: Gene Cloning, expression and in-silico characterization

⁎Corresponding author at: Dr.Zabin K. Bagewadi, Associate Professor, Department of Biotechnology, KLE Technological University, Vidyanagar, Hubballi 580031, India. zabin@kletech.ac.in (Zabin K. Bagewadi),

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

Abstract

Cloning and expression of collagenase gene from Bacillus siamensis strain Z1. Biochemical characterization for enzyme profiling. Analysis included MALDI-TOF-MS, N-terminal sequencing, CD, 1H NMR and TGA. In-silico studies included characterization, Molecular docking, simulations and MMPBSA.

Abstract

This study focuses on gene cloning, expression, biochemical and analytical characterization along with structural and functional characterization of collagenase followed with molecular docking, dynamics study and Molecular Mechanics Poisson-Boltzmann Surface Area (MMPBSA). The collagenase gene identified from the genome of the novel collagenase Bacillus siamensis strain Z1 is introduced into E.coli DH5α, subsequently expressed in E.coli BL21 (DE3) withisopropyl β −d – 1 − thiogalactopyranoside(IPTG) induction and further affinity purified yielding in ∼ 89.4 kDa recombinant collagenase which demonstrated alkali characteristics and thermostability determined by thermodynamic parameters. Recombinant collagenase revealed good stability when exposed to diverse biochemical components. The recombinant collagenase identity was confirmed through matrix assisted laser desorption ionization-time of flight mass spectrometry (MALDI-TOF MS) showing specific mass peaks and via N-terminal sequence analysis as MTAVNQTISK. Moreover, the concluded N-terminal amino acid sequence from Edman degradation displayed significant resemblance. The structural and functional analysisof recombinant collagenase was analysed by Circular dichroism (CD), Proton nuclear magnetic resonance (1H NMR) spectrometry and Thermogravimetric analysis (TGA). The recombinant collagenase also showed gelatin liquefaction ability. The collagenase gene sequence is also assessed for structural and functional characterizations by using various computational tools and revealed its classification in U32 family peptidase. A Grand average of hydropathicity index (GRAVY) score of −0.295 and instability index of 37.22 was obtained. Homology model of collagenase gene was generated by employing SWISS-MODEL and structure analysis by Ramachandran plot. Molecular docking of modelled collagenase with four different substrates was carried out by PyRx and Autodocking. Highest docking score of −12.7 kcal/mol was obtained for Alaska pollock hydroxyproline containing marine collagen peptide (APHCP). Subsequently, Molecular dynamics and simulations for highest score docked complex was assessed using GROningenMAchine for Chemical Simulations (GROMACS).

Keywords

U32 peptidase

Molecular cloning

Purification

Biochemical and structural evaluation

Computational analysis

1 Introduction

The expanding fishery industry generates substantial collagen-rich waste yet inefficient management leads to underutilization (Bhagwat and Dandge, 2018). Collagen fibrous structure resists degradation. The trimeric helix of collagen consists of similar or different polypeptide chains supercoiled counterclockwise around an axis, forming a single triple helix with glycine atoms. Collagenases are a class of hydrolytic proteases that can break down different kinds of collagen. The primary sources of collagenases include microorganisms, plants and animals with varying substrate specificities. Microbial collagenases (EC 3.4.24.3) possess extensive substrate specificity that aids in breaking down both water-insoluble and water-soluble forms of collagens within the triple helical regions at X-Gly bonds (Pal and Pv, S, 2016). Marine collagenases excel in catalyzing marine collagen, especially from fish, attracting interest due to their exceptional qualities (Yang et al., 2017). Microbial collagenases consist of matrix metalloproteases (MMP)that comprise of collagenases (MMP-1, MMP-8, MMP-13 and MMP-18) that can break down four types of collagens (I, II, III, IV) (Alipour et al., 2016). Serine proteases from families S8, S1, and S53 might also fall into collagenases. Keratinases, a new class of proteases, hydrolyze tough keratins and are classified within the serine and metalloprotease families, as documented in the MEROPS database (Rawlings et al., 2018). They primarily fall under family S8 of clan SB, which encompasses enzymes like trypsin and subtilisin. Furthermore, certain U32 family members are also recognized as collagenases (Bhagwat and Dandge, 2018). Not many reports of collagenase mechanism of Bacillus sp. are reported, Vibrio collagenase hydrolyzes collagen using peptidase M9N and pre-peptidase C-terminal domains, breaking down the C – telopeptide region and fragmenting tropocollagen fragments into peptides and amino acids, primarily at Y-Gly bonds(Wang et al., 2022).

Microbial collagenases have numerous industrial applications, including wound healing, placenta treatment, and therapeutic applications like Dupuytren’s disease, Peyronie’s disease and Glaucoma(Alipour et al., 2019). They also produce bioactive collagen peptides with antioxidant, antimicrobial, anticancer, antidiabetic, and anti-inflammatory properties(OLIVEIRA et al., 2017; Yang et al., 2017;Nurilmala et al., 2020; Lima et al., 2015; Kumar et al., 2019). They are crucial in scientific research and food industry(Bhagwat and Dandge, 2018).

Researchers have modified collagenase through genetic engineering to improve its expression, purifying microbial collagenases from selected bacterial species and sequencing associated genes. (Pal and Pv, S, 2016). Molecular cloning with suitable vectors is a suitable method for obtaining collagenase, as native collagenases can negatively impact biosynthesis due to lack of firmness and different iso-enzymatic configurations. (Song et al., 2021). Recombinant collagenase is constructed using tags like, His tag and MBP tag. MBP tag improves the solubility of the target protein by aiding in correct folding and leads to subsequent increase in yield (Dutta and Bose, 2022). Expression systems like E.coli and Brevibacillus are used for successful collagenase gene expression(Zhu et al., 2022; Teramura et al., 2011). Using amylose affinity chromatography recombinant proteins have been purified. Through biochemical characterization of recombinant collagenase it is important in evaluating their suitability across various fields where they are intended for practical utilization(Bhagwat and Dandge, 2018).

In today’s scientific research, various in-silico tools are utilized to analyze protein structures, exploration of folding patterns, identify structural elements and family domains. 3D structures are predicted and elucidate functional features (Rani and Pooja, 2018). In-silico studies enable protein engineering for various biotechnological applications. Molecular docking predicts interactions between proteins and ligands, aiding in drug development and enzyme substrate binding. Advancements in in-silico techniques involve molecular dynamics and simulations, providing insights into dynamic behavior, interactions, and structural changes. This computational approach helps to understand biological processes and explore molecular mechanisms(Revankar et al., 2023; Mechri et al., 2022; Bhatt et al., 2021).

The cloning and expression of the collagenase gene from Bacillus siamensis strain have not been previously reported, and there is limited analytical characterizations available and very rare reports on structural, functional characterization of collagenases from Bacillus sps., and their molecular docking and dynamics studies with substrates indicates limited prior research and novelty in this area. The current research identified collagenase gene, cloned it using a pET28 vector, and expressed it in E. coli. subsequently, purification and biochemical characterization of recombinant collagenase gene yielded a molecular weight of ∼ 89.4 kDa. Various analytical methods were used, including matrix assisted laser desorption ionization-time of flight mass spectrometry(MALDI-TOF-MS), Circular Dichroism (CD),Nuclear Magnetic Resonance spectroscopy (NMR), and Thermogravimetric Analysis(TGA), while computational tools were employed to study its structural and functional characteristics, molecular docking and stability with Alaska pollock hydroxyproline containing marine collagen peptide(APHCP) substrate.

2 Materials and methods

2.1 Chemicals and vectors

The chemicals and resins utilized in the current study was sourced through reputable suppliers, including Sigma-Aldrich Co. and Merck and Co., Inc. (USA). The collagenase gene was identified from Bacillussp. strain Z1 and cloning, expression and sequencing method was conducted. Molecular cloning and expression procedures involved the utilization of E. coli strains DH5α and E. coli BL21 (DE3), along with the pET28b (His Tagged) vector and pET28(Maltose Binding Protein (MBP) Tagged) vector. All reagents employed in this research were of research grade and readily accessible from marketable sources.

2.2 Identification of gene of interest

The quest to identify the gene of interest initiated with a nucleotide Basic Local Alignment Search Tool (BLAST) analysis of the 16S rRNA sequence, in tandem with the submission of the bacterial strain’s nomenclature. This analysis was conducted to uncover closely related sequences within BLAST search results. Subsequently, the BLAST outcomes were reviewed and selecting the accession number displaying the highest degree of sequence identity (Clough and Barrett, 2016). Sourced with this information, it was further accessed the respective National Center for Biotechnology Information (NCBI) whole genome sequences, which are customized to display all genetic features. Within this customized genomic context, the option to explore the entire genome sequence was selected that enabled to find and locate collagenase gene. This intricate process was iterated across multiple bacterial strains within the same species, ensuring a comprehensive survey. Furthermore, CLUSTAL Omega Multiple Sequence Alignment (MSA) Tool was employed to elucidate the degree of genetic correspondence between the collagenase gene sequences and that of strain Z1. This tool facilitated a systematic MSA of the collagenase gene sequences, thereby spotlighting collagenase genes that exhibited remarkable similarity to the one in strain Z1.

2.3 Primer designing, isolation of genomic DNA, amplification and cloning

Gene sequence primers are carefully designed with Snapgene Tool, optimizing the guanine-cytosine (GC) content and length. To ensure precise restriction digestion, BamHΙ and NotΙ restriction enzymes were utilized. The primers were strategically designed to include the respective restriction sites (BamHΙ – GGATCC; NotΙ – GCGGCCGC), positioned ahead of the primer sequences (Forward primer – 5′- AAAGGATCCATGACAGCCGTAAATCAAAC; Reverse Primer – 5′- AAAGCGGCCGCTTACTTCCCCTTTCTCATC). The genomic DNA (gDNA) was isolated from strain Z1 using Phenol Chloroform Extraction method. The collagenase gene was been amplified from genomic DNA utilizing specific designed primers mentioned above through Polymerase Chain Reaction (PCR). Subsequently, standard protocols were employed for conducting restriction digestion. The PCR procedure was performed utilizing a thermocycler and a Q5 High Fidelity DNA Polymerase with a reaction mixture volume of 50 µl. The protocol commenced with an initial denaturation step, which lasted for 2 min 30 sec at 98 °C. This was followed by denaturation at 98 °C for 20 sec by 35 cycles. Subsequently, primer annealing was subjected at hybridization temperature for a duration of 30 sec. the extension step followed, lasting 1 min 50 sec at 72 °C. The reaction was completed with a final extension step of 3 min at 72 °C. The resultant PCR products were then subjected to purification using purification kit(Bagewadi et al., 2016; Alei et al., 2023). The plasmid pET28 (MBP Tagged) was digested using restriction enzyme and then the plasmid and digested target gene were ligated and transformed into host E. coli DH5α competent cells by Heat shock method and further screened on Luria-Bertani (LB) agar plates supplemented with antibiotic Kanamycin. PCR analysis was performed on the recombinant plasmid employing primers specific to the plasmid in order to confirm the insertion and accurate alignment of target gene inside the vector and is confirmed by Gel Electrophoresis (Alei et al., 2023). To validate the accuracy of cloning, the isolated recombinant plasmid DNA obtained from the identified positive colonies was subjected to DNA sequencing. Further the plasmid was introduced into E. coli BL21 (DE3) cells using heat shock method, thereby facilitating the integration of plasmids within the cells. Colonies that showed successful transformation were then cultivated in LB media and collagenase protein expression was evaluated.

2.4 Collagenase expression by isopropyl β-D-1-thiogalactopyranoside (IPTG) induction

New colony of the transformed pET28 (MBP Tagged) vector was selected and cultivated on LB agar plate with E. coli BL21 competent cells. Initial culture was formed by introducing the culture into sterile LB medium (120 ml) supplemented with Kanamycin (50 µg/ml). The inoculated media was kept for overnight incubation at 37 °C under constant agitation at 180×g. The 120 ml starter culture was mixed with flask consisting 5 L of sterile LB medium contained Kanamycin and incubated at 37 °C under constant agitation (200 × g) for 4 h. Biomass concentration was checked to reach an optical density (OD) (600 nm) value of 0.55 – 0.7. Further 1 mM of IPTGwas been added to 4 h culture for inducing the protein expression and then the broth was incubated at 16 °C for 16 h under agitation condition (180 × g). Induced cell culture broth was centrifuged at 4500 × g, 4 °C for 45 min and the obtained cell pellets were preserved at −80 °C. Cell pellet was suspended again in chilled lysis buffer (0.5 mM NaCl, 10 mM Tris, 2.5 % v/v glycerol, and 0.2 % v/v Triton) and further to this 20 µL of benzamidine, 80 mg of lysozyme and 20 µL of phenylmethylsulfonyl fluoride (PMSF) is added and sonicated for 1 min at 60 amplitude for 6 cycles. The sonicated cells were centrifuged at 6000 × g at 4 °C for 45 min. Supernatant obtained was been recentrifuged at 13000 × g for 30 min at 4 °C to separate any debris and obtain a clean supernatant possessing genetically altered collagenase protein and is further assayed for collagenase activity as mentioned below. Purification by affinity chromatography was been carried using clear supernatant(Bagewadi et al., 2016; Alei et al., 2023).

2.5 Affinity purification, determination of molecular weight and enzymatic assay of genetically modified collagenase

Affinity chromatography was employed to purify recombinant collagenase using Amylose resin as solid matrix. The column loaded with resin was first washed with distilled water, then the column with amylose resin was pretreated with lysis buffer composing 0.5 mM NaCl, 10 mM Tris, 2.5 % v/v glycerol, and 0.2 % v/v Triton. Centrifugation was employed to obtain clear supernatant and it was mixed amylose resin in buffer followed by loading into column. Subsequently, the column underwent rinsing with wash buffer (50 mM Tris, 0.5 mM NaCl and 2.5 % Glycerol) to remove unbound proteins and contaminants effectively. The elution of the MBP-tagged protein was achieved by applying an elution buffer (50 mM Tris, 0.15 mM NaCl, 10 mM Maltose and 2.5 % Glycerol). Protein concentration at 280 nm was measured in order to record protein elution profile. After affinity chromatography, 12.5 % sodium dodecyl sulphate polyacrylamide gel electrophoresis was used to assess the purity of recombinant collagenase. Bradford assay with Bovine serum albumin (BSA) as standard was carried out to determine the recombinant collagenase concentration by measuring absorbance at 595 nm (Yaraguppi et al., 2022b). Collagenase activity was carried out according to Tran and Nagano (2002), with slight modifications. The reaction mixture was prepared by adding 1 ml of recombinant collagenase to 1 ml of collagen (marine fish collagen) (10 mg/ml) prepared in 50 mM Tris HCl buffer, supplemented with 4 mM CaCl2, pH 7.5. The reaction was performed for 30 min at 30 °C with agitation to suspend insoluble collagen and halted by adding 1 ml of 0.1 M acetic acid. Followed by centrifugation at 10,000 × gfor 15 min the quantity of liberated amino groups from the collagen was determined using Ninhydrin method. The absorbance was recorded at optical density 600 nm. The expression of collagenase activity is quantified as the µmol of leucine equivalent per min/ml of the culture (Tran and Nagano, 2002).

2.6 Biochemical characterization of purified recombinant collagenase

2.6.1 Determination of optimum pH and stability

The optimal pH of the recombinant collagenase has been ascertained by using different buffers at different pH levels previously outlined in the study conducted by Zhu et al. (2022), Alei et al., 2023. Using collagen as substrate, the effects of pH on collagenase activity was been examined in the pH range of 3––12 at 80 °C. The buffers included glycine – HCl (pH 3–4), sodium citrate buffer (pH 5–6), Tris – HCl (pH 7–9) and glycine NaOH (pH 9–12). To ascertain the pH stability, the enzyme was incubated for 20 h at 35 °C at pH 9 and pH 10. Samples were collected at fixed time intermittent and residual collagenase activity were measured, reported as relative collagenase activity.

2.6.1.1 Determination of optimal temperature and thermostability

The optimal temperature of recombinant collagenase was evaluated in selected temperature range from 35 °C to 80 °C at pH-9 (glycine – NaOH buffer) for 30 min using collagen as substrate. The control was collagenase activity without any additives. While for thermostability assessment of collagenase was done at regular intermittent of 2 h by incubating at temperature range of 50 – 60 °C for 20 h. Residual activity was measured at regular intervals and expressed as relative collagenase activity (Alei et al., 2023).

2.6.1.2 Effect of metal ions, chemicals, organic solvents and additives

The purified recombinant collagenase was used for its characterization. The study was assessed for effect of various metal ions (FeSO4, MgSO4, NaCl, KCl, CaCl2, ZnSO4, CuSO4 and MnSO4 at 0.5 M) and some additives (Urea, β- mercaptoethanol, dithiothreitol (LD-DTT) and ethylenediaminetetraacetic acid (EDTA) at 1 M). The evaluation involved the incubation of 100 µL collagenase with 200 µL of respective metal ion or additive for 4 h at 37 °C(Joshi and Satyanarayana, 2013). The surfactants effects were assessed by incubation of collagenase (100 µL) with 1 % of sodium dodecyl sulfate (SDS), Tween 80 and Triton X-100 respectively for 4 h at 37 °C (Wanderley et al., 2020). Collagenase stability with organic solvents (methanol, ethyl acetate, benzene, chloroform at 10 %) was been examined by incubating collagenase (100 µL) for 4 h at 37 °C with respective solvent (200 µL) (Joshi and Satyanarayana, 2013).

2.6.1.3 Thermodynamic analysis of collagenase

Thermodynamic assessment of the recombinant collagenase was conducted in accordance with the methodologies and formulas described by Abdella et al., 2023 and Mechri et al., 2022. The assessment of collagenase thermal deactivation was based on the specific equation:

Ln (Kd) and Ed (deactivation energy) were derived from the Arrhenius plot. The half-life (t1/2) of collagenase represents the time needed for a 50 % reduction in activity. The reduction time (D) indicates the time required for a 90 % reduction in activity at a given temperature range (70–90 °C) and can be calculated using the following formula:

The parameters associated with the thermal denaturation of collagenase, including thermodynamic denaturation (Kd), alterations in denaturation enthalpy (ΔHd), denaturation gibbs free energy (ΔGd) and denaturation entropy (ΔSd) were determined using the equations outlined in prior descriptions(Mechri et al., 2022).

2.6.1.4 Substrate specificity

The assessment of the substrate specificity of the recombinant collagenase involved testing its activity with a range of substrates. These substrates included collagen, gelatin, BSA, casein, azo-casein and hemoglobin. The collagenase reactions with each of these substrates followed standard assay procedures previously outlined (Tran and Nagano, 2002). In case of collagen and gelatin as substrates, one unit of collagenase activity was defined as the µmol of leucine equivalent per min/ml of the culture. For casein as substrate, one unit of collagenase activity was defined as the amount of enzyme that liberates 1.0 nmol of tyrosine s−1 under assay conditions. For azo-casein as substrate, a single activity unit was defined as the quantity of µmol of L-leucine liberated when exposed to 1 ml culture filtrate consisting collagenase, following 18 h at 37 °C (Wanderley et al., 2020) and for Hemoglobin as substrate, one unit of collagenase (protease) activity was defined as the amount of enzyme required to hydrolyze hemoglobin and release equivalent to 1.0 µg of tyrosine within 1 min reaction at 37 °C (Yin et al., 2013).

2.6.1.5 Determination of kinetic parameters

The kinetic parameters, which include the Michaelis – Menten constant (Km), maximal velocity (Vmax), turnover number (kcat), and kcat/km,Vmax/Km were calculated using the Lineweaver- Burk plot and equation based on the methodology described by Kerouaz et al., 2021; Teramura et al., 2011. The kinetic constants were evaluated by using collagen and gelatin as substrates at concentration from 0.4 to 2.0 mg/ml conducted under standard assay conditions.

2.7 Analytical characterization of recombinant collagenase

2.7.1 Mass spectrometry analysis

Tryptic enzymatic digests of collagenase expressed with MBP tag were subjected to mass spectrometry (MS) analysis in order to verify the authenticity of the recombinant collagenase. The digestion of collagenase-MBP protein was carried out by utilizing Trypsin-ultraTMmassspectrometry grade from New England Biolabs (NEB, Hertfordshire, UK). Trypsin stock solution (1 µg/µL) was produced by adding 20 µL of pure sterilized water to 20 µg lyophilized Trypsin- ultraTMand stored at −20 °C until further use. Trypsin digestion reaction for the recombinant collagenase protein was initiated with substrate (protein): trypsin ratio of 25:1. This included the addition of 1 µL of trypsin stock solution, 25 µL of protein, 2.5 µL of 2 × trypsin reaction buffer and 2.5 µL of ultra-purified water. The reaction mixture was kept for incubation in shaking condition for 16 h at 37 ± 2 °C and preserved at −80 °C. Reaction samples forMALDI-TOF-MS analysis was formed by desalting the reaction mixtures with C-18 Zip-Tip (Millipore). MALDI-TOF MS analysis was carried out at Mass Spectrometer facility, Department of Biological Sciences at the Indian Institute of Science (IISc), Bangalore using Sinapic acid as the matrix for analysis(Yaraguppi et al., 2022b).

2.7.2 2.7.2. N-terminal sequence identification by MALDI-TOF-MS and Edman degradation

In order to gain additional insight into N-terminal sequence of the peptide, confirm its authenticity, the digestion of recombinant collagenase was conducted as detailed in section 2.7.1. Subsequently, peptide mapping was executed using MALDI-TOF-MS. For the execution of mass spectrometric peptide mapping, a 0.5 µL of sample solution was spotted onto a stainless-steel target plate and permitted to dry. Further, 1 µL matrix was added on top of sample. The matrix solution consisted of concentrated solution of α-cyano-4-hydroxycinnamic acid (CHCA) dissolved in acetonitrile (ACN) and 0.1 % trifluoroacetic acid (TFA) in water. The sample and matrix solution were directly blended on target. The MALDI-TOF measurements was carried out employing a RapiflexX mass spectrometer (Bruker Daltonik, Bremen, Germany). At an accelerating voltage of 20 kV, the device was run in positive ion reflector mode with delayed extraction. For MALDI, a smart 3D laser beam (UV solid-state laser) with pulse width of 3–5 ns at 337 nm was employed (Meier-Credo et al., 2022; Duncan et al., 2016; Chotichayapong et al., 2016). To analyse peptides in reflector mode, the parameter settings were optimized. Sum spectra spanning from m/z from 500 to 4000 were produced by taking 1000 laser shots at different positions, depending on the signal-to-noise (S/N) ratio reflected on the oscilloscope. An external peptide calibration standard (Bruker Daltonik, Bremen, Germany) was used to calibrate the obtained spectra that is available commercially. Bruker flex control software RP_600-3200_Da.par method was employed to obtain sample data and further Bruker flex analysis v 4.2 program for used for data processing. Later Bruker Biotools software v 3.2, was used to carry out Protein sequence confirmation and N-terminal peptide sequencing (MTAVNQTISK with methionine oxidation) (Duncan et al., 2016; Torres-Sangiao et al., 2021).

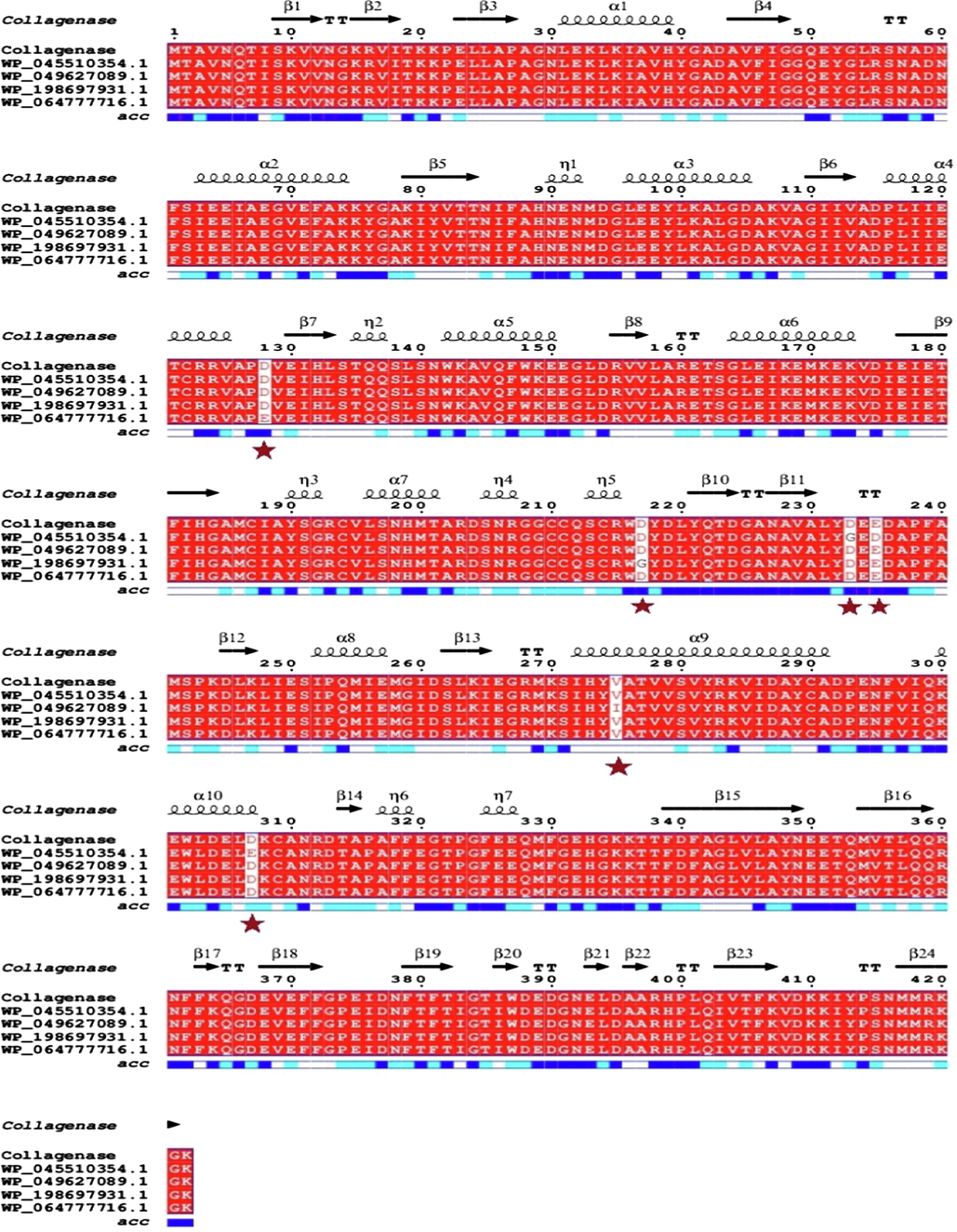

The recombinant collagenase was subjected to Sodium dodecyl-sulfate polyacrylamide gel electrophoresis (SDS-PAGE) gel transfer onto the ProBlott membrane for subsequent N-terminal sequence analysis using automated Edman degradation via a protein sequencer (Shimadzu PPSQ-31A/33A) (Das et al., 2018; Laribi-Habchi et al., 2020). Identification of amino acid residues was accomplished through individual signal analysis. To perform an analysis of amino acid sequence similarity and multiple sequence alignments, the Protein BLASTwith the Swiss-Prot/TrEMBL(Translation of European Molecular Biology Laboratory) database was employed. Additionally, the Clustal Omega program, accessible on the European Bioinformatics Institute server (https://www.ebi.ac.uk/Tools/msa/clustalo/) was also utilized for these analyses. Dissimilar amino acids were uncovered. A comparison was performed between the N-terminal sequence of the recombinant collagenase and related collagenase sequences from Bacillus species found in the Swiss-Prot/TrEMBL database. This analysis aimed to ascertain identities in terms of percentage similarity (Laribi-Habchi et al., 2020).

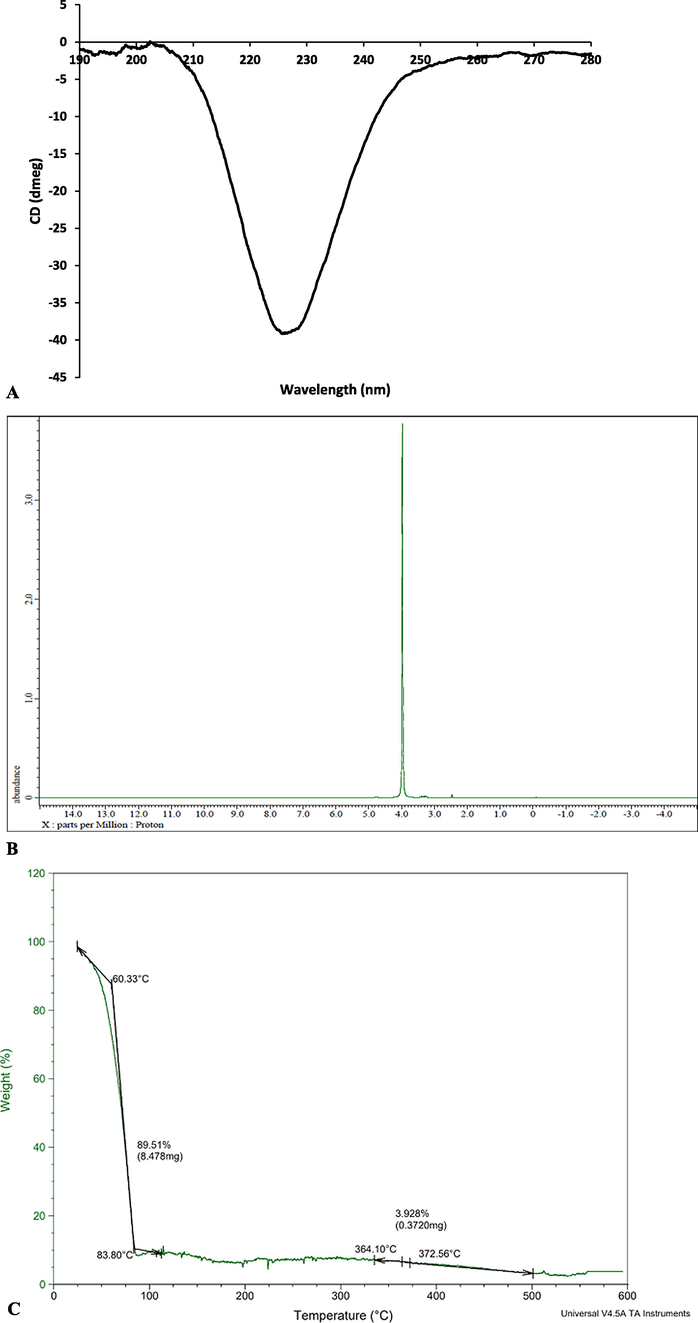

2.7.3 CD spectroscopy analysis

The secondary structure of purified recombinant collagenase was examined in a liquid environment at 25 °C using a Jasco J-1500 Circular Dichroism Spectrophotometer, which was purged with N2 gas. The purified recombinant collagenase was diluted in 50 mM Tris HCl buffer (pH 7.0) resulting in final concentration of 50 µg/mL. Subsequently, CD spectra was recorded from 190 to 280 nm using a quartz cuvette with scanning rate of 50 nm/min. The CD spectra were recorded (CD mdeg) and transformed into molar ellipticity. To ensure accuracy, any influence from the solvent was eliminated by subtracting the CD spectrum of the solvent from that of the protein spectra. K2D2 software was used to determine the secondary structure and helical content of the protein (Indra et al., 2005).

2.7.4 1H NMR spectroscopy analysis

NMR spectroscopy (Jeol Resonance) operating at 400 MHz, was utilized to perform 1H NMR analysis on the purified recombinant collagenase. This analysis was conducted under room temperature (37 °C) conditions, with tetramethylsilane (internal standard). The purified collagenase was dissolved in Dimethyl sulfoxide (DMSO)as the solvent. Signals in the 1H NMR spectra were recorded within the range of 0–14 ppm, and the assignment of peaks in spectra was based on reported literature (Bagewadi et al., 2019).

2.7.5 TGA analysis

Assessment of thermostability of recombinant collagenase was done by TGA (Perkin-Elmer, USA). The sample (3 ml) was examined by heating at 25–800 °C) under nitrogen – controlled conditions with heating rate of 10 °C/min (Bagewadi et al., 2019; Bagewadi et al., 2020).

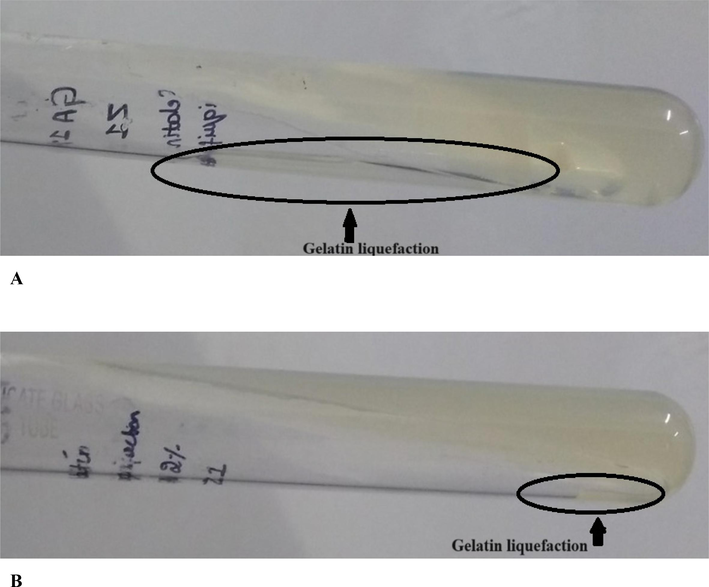

2.8 Application of recombinant collagenase in gelatin liquefaction

A gelatin liquefaction test was performed by inoculating purified recombinant collagenase into deep agar gelatin test tubes containing agar at concentrations of 1 % and 2 % and gelatin at 0.4 % and the test tubes were then incubated at 37 °C for 24 h. Isolates demonstrating the ability to induce liquefaction of the gelatin were considered as having potential applicability for the degradation of gelatin. This test serves as an indicator of the enzymatic activity of the recombinant collagenase and its capacity to hydrolyze gelatin substrates (Joseph et al., 2019).

2.9 In-silico studies

2.9.1 Structural and functional characterization of collagenase gene

The ExPASy(Expert Protein Analysis System)translate tool is employed for translating nucleic acid sequences (DNA/RNA) into corresponding protein sequences (amino acid sequences). The collagenase gene sequence of Bacillus sp.strain Z1 is submitted to ExPASy translate tool (https://web.expasy.org/translate/) online server to obtain translated protein sequence. The obtained amino acid composition of Bacillus sp.strain Z1 collagenase gene, was assessed for physical and chemical attributes utilizing the ExpasyProtParam online tool (https://web.expasy.org/protparam/). ProtParam is an in-silico tool utilized to compute diverse physiochemical parameters of proteins. The analysis involved evaluating amino acid composition, molecular weights, extinction co-efficient, theoretical isoelectric points (pI), aliphatic index, instability index, atomic compositions, estimated half-life, and the grand average of hydropathicity of selected protein(GRAVY) (Rani and Pooja, 2018). Collagenase protein sequence was submitted to EBI (European Bioinformatics Institute)- InterPro scan tool (https://www.ebi.ac.uk/interpro/search/sequence/) wherein the sequence is scanned to match related sequences and the tool offers a comprehensive categorization of protein sequences into groups, detecting important functional domains and key active sites. Phylogenetic trees were formulated by utilizing collagenase gene nucleotide sequence to explore the evolutionary connections among these genes. The gene sequences used in the study were from Bacillus siamensis, Bacillus velezensis and Bacillus amyloliquefaciensstrains. The full-length collagenase nucleotide sequences were retrieved from the NCBI database in FASTA format. The selected nucleotide sequences were aligned using multiple sequence alignment clustalW2 server. Phylogenetic tree of collagenase nucleotide sequence from different strains of Bacillussps. was analyzed using MEGA(Molecular Evolutionary Genetics Analysis) software. Similarly, phylogenetic tree of collagenase gene protein sequence was constructed with related collagenase gene protein sequences of Bacillus species. In this study collagenase gene protein sequences were retrieved from NCBI database in FASTA format. Total 5 protein sequences of collagenase gene from U32 family peptidase Bacillussps. with accession number namely Bacillus siamensis (WP_064777716.1), Bacillus siamensis (WP_19867931.1), Bacillus sp. JFL15 (WP_049627089.1), Bacillus amyloliquefaciens (WP_045510354.1) and Bacillus nakamurai (WP_061522884.1) were used in this study. Sequences of the selected protein was aligned using MSA clustalW2 server and using MEGA software phylogenetic tree was constructed. The evolutionary lineage of collagenase was done utilizing the neighbor-joining approach (Rani and Pooja, 2018).

Homology modelling is widely used technique to generate valid protein structure utilizing the amino acid sequence. To date, the crystal structure of collagenase gene from Bacillus siamensis is not established, so in the present study SWISS MODEL server (https://swissmodel.expasy.org/interactive) was employed for generating the homology model for collagenase gene from Bacillus siamensis. The protein sequence of collagenase gene was submitted to SWISS MODEL server, tRNA hydroxylation protein P1 (O32034.1. A) of Bacillus subtilis (strain 168) showed 93.13 % identity. After preparing the 3D structure of protein by SWISS MODEL server, the Protein Data Bank (PDB) file was downloaded and used for further analysis and molecular docking. The modeled structure stability and quality was checked by Ramachandran plot analysis by SWISS MODEL server, MOLPROBITY, ERRAT tools. The secondary structure of collagenase protein was included in MSA figure generation employing ESPript 3.0 (https://espript.ibcp.fr/ESPript/cgi-bin/ESPript.cgi). The highly flexible regions of collagenase gene were predicted by bio-informatic tool FoldUnfold (https://bio.tools/foldunfold) (Su et al., 2022).

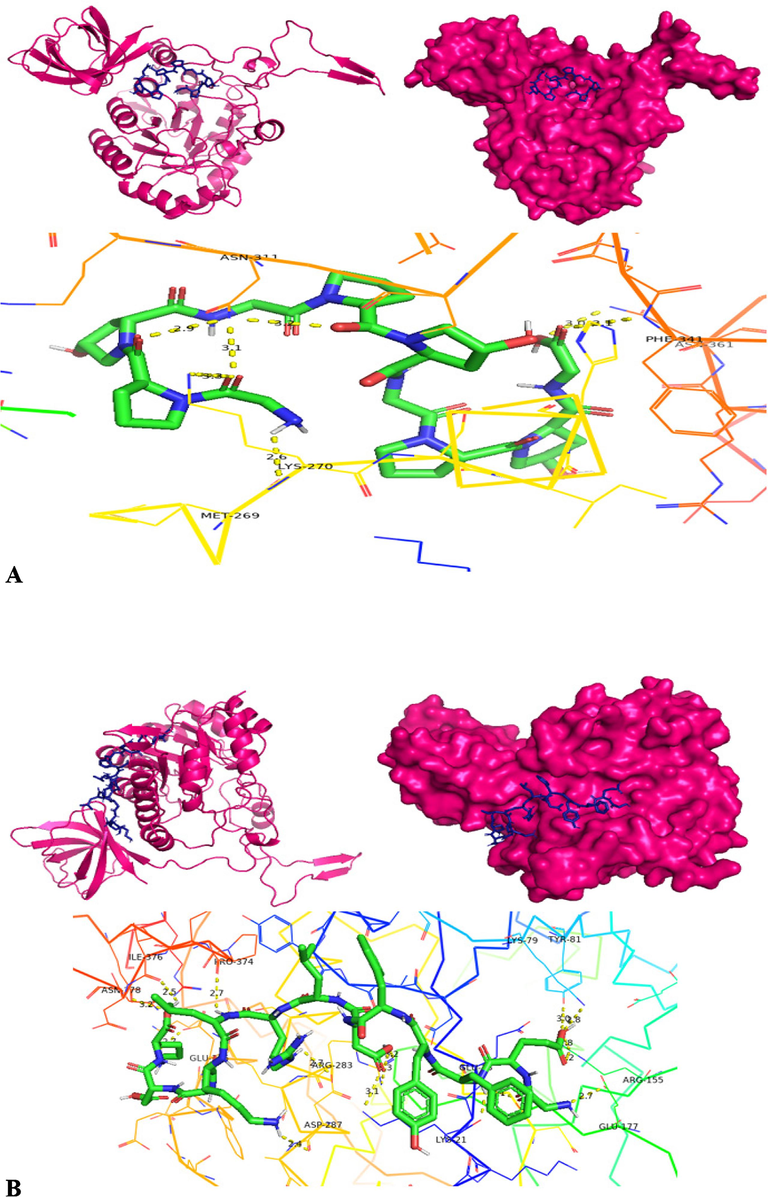

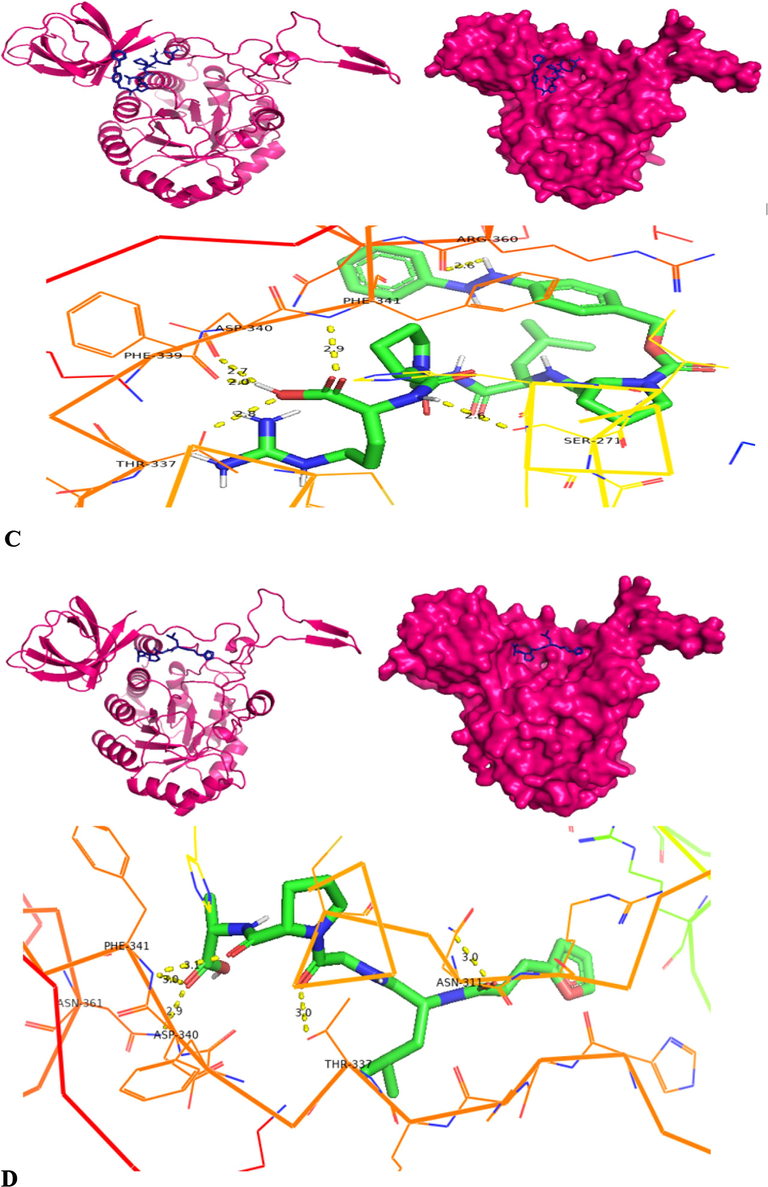

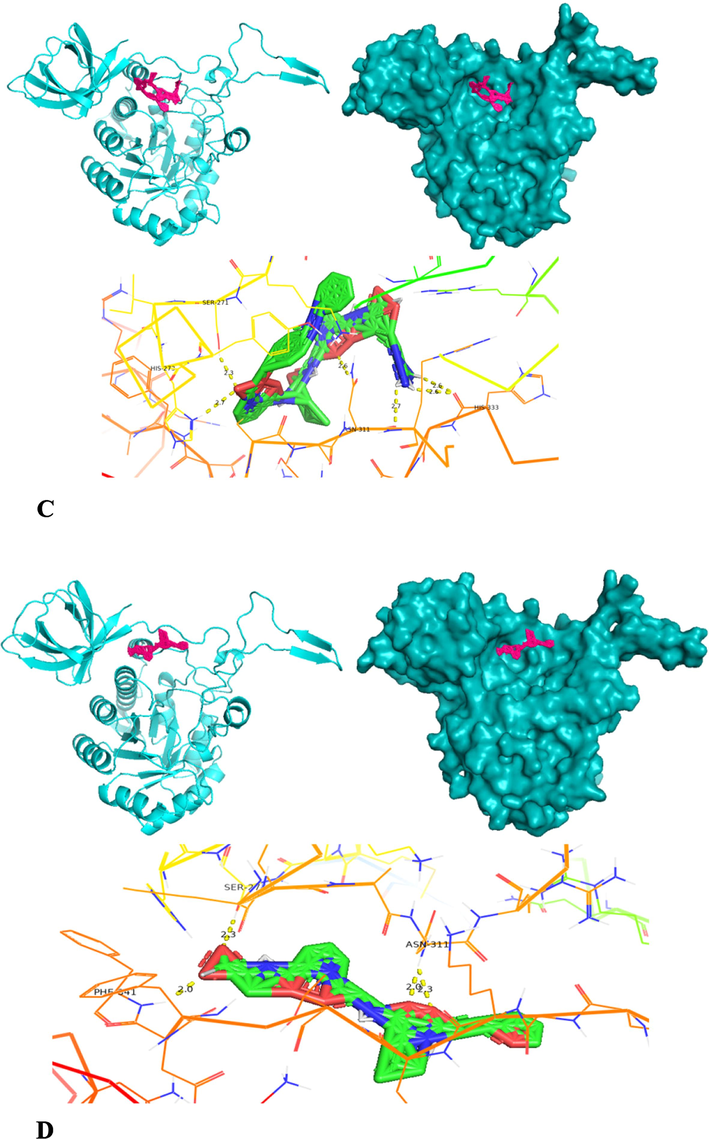

2.9.2 Molecular docking of collagenase with substrates

The molecular docking of homology modelled collagenase gene on four different substrates was carried out using PyRx software (version 0.8). The PyRx software is employed with Autodock Vina, Open Babel and Python Shell. The four substrates employed for molecular docking are APHCP (Alaska pollock hydroxyproline containing marine collagen peptide) (ID-129908191); Collagen type 4 alpha (531–543) (ID-16132108); PZ-peptide (ID-161208) and FALGPA (2-furanacryloyl-l-leucylglycyl-l-prolyl-l-alanine) (ID-6439513). SDF (Structured Data File) files of all substrates were downloaded from Pubchem server. Both the protein and substrates were loaded into PyRx software and collagenase protein was put as fixed. A grid box was designed to cover the whole protein, with an exhaustiveness parameter of 8 for all docking. The binding affinity of substrates was analyzed for inter-residue interaction. To validate the docking scores of complexes obtained from PyRx Autodocking Vina, the classic Autodocking was utilized. The protein and substrate interaction were generated using PyMOL (version 2.5.5) and Discovery studio visualizer (DSV) (version 21.1.0.0), from BIOVIA (Adeniji et al., 2020).

Molecular docking was also carried out using the Autodock software (autodock suite-4.2.6-×86_64 linux3.tar) as part of its execution process (Revankar et al., 2023). Autodock, an efficient web-based application, specializes in conducting computational screenings of ligands/substrates for specific target protein of interest. The modelled collagen protein is pre-processed by removing water molecules and added with hydrophilic hydrogens and Kollman charges and converted to pdbqt through the autodock software. The ligand is prepared by converting the.sdf files into.pdb by using pymol and converted to.pdbqt by employing autodock tools. Forming the grid box is a crucial step in the molecular docking process. A config file is prepared comprising x, y, z co-ordinates, energy range and exhaustiveness. Over here, the same x, y, z co-ordinates employed in PyRx software is used in autodock to known the binding stability of collagenase gene with 4 different substrates. Finally a command prompt is run to obtain output.pdbqt and log.pdbqt files. The outcomes from multiple docking are automatically assessed, resulting in the generation of a hierarchical list featuring the top 10 docked structures for Collagenase protein and from it the first docked structure with each substrate having highest docked score is considered for further hydrogen bond interaction analysis. The highest docking score pose achieved by the collagenase protein target with substrate is recognized as an optimal binding configuration and this outcome is selected for subsequent Molecular Dynamics and Simulations studies. Post-docking, the best scored docking pose of each substrate is visualized using Pymol tool to identify the interacting residues such as hydrogen bonds between the protein and substrates (Ligands).

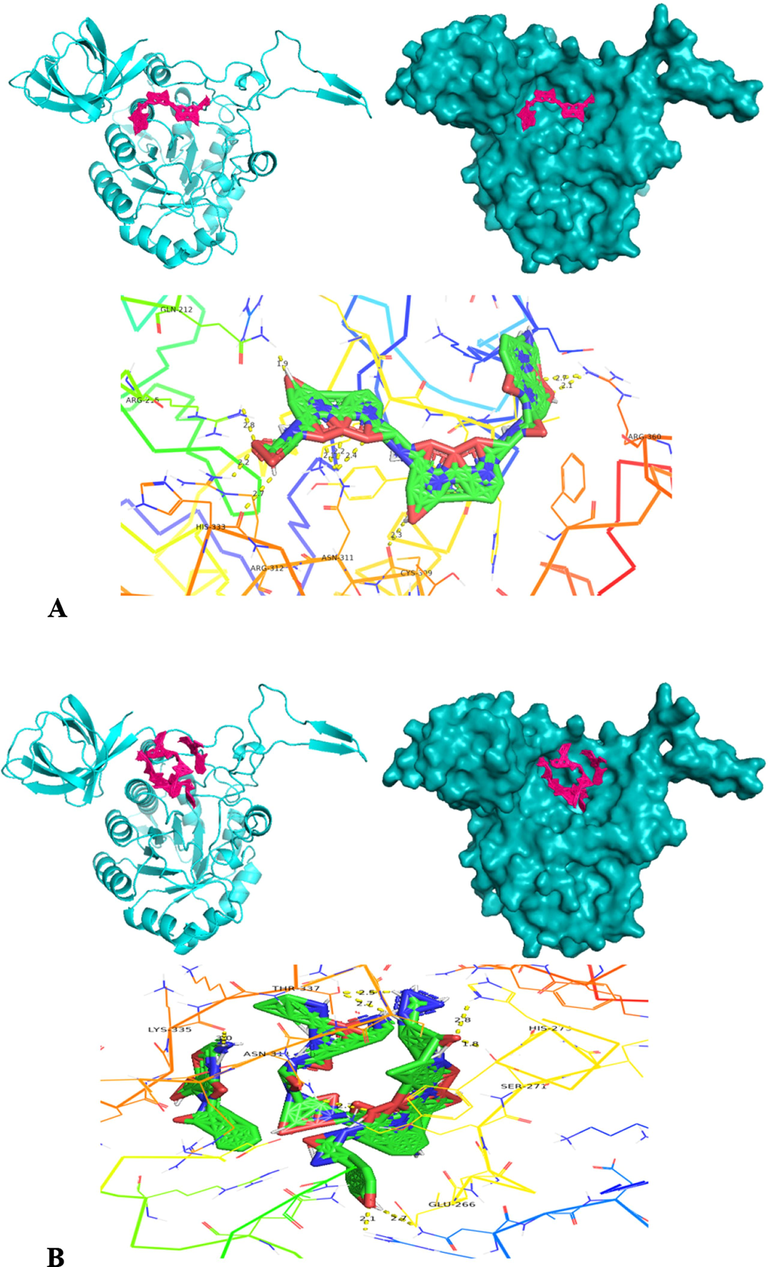

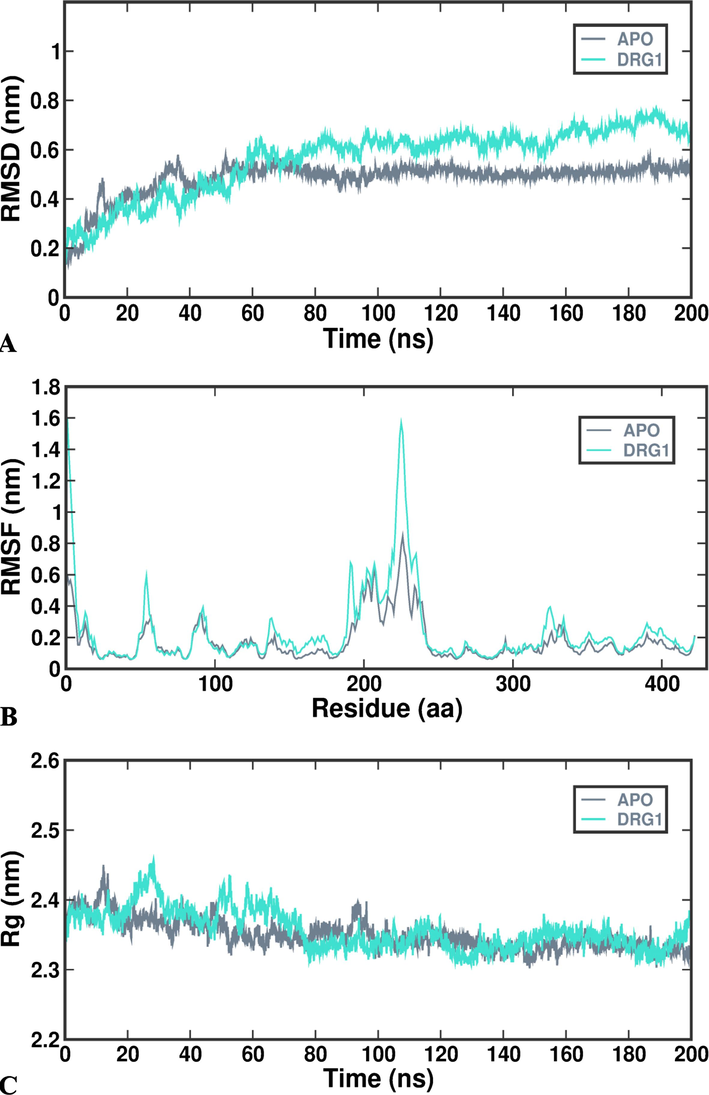

2.9.3 Molecular dynamics and simulations (MDS)

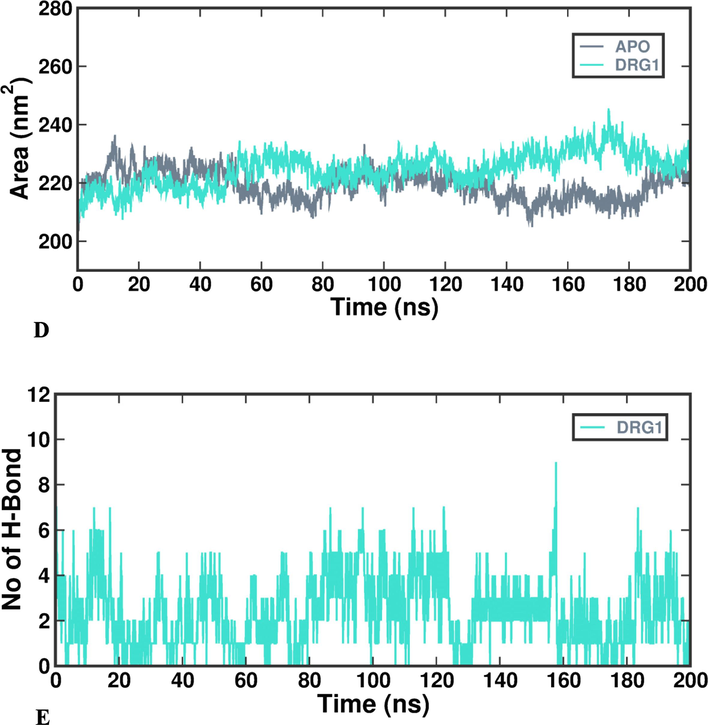

In the study, modelled collagenase gene docked with APHCP using Autodock software is chosen for further Molecular dynamics (MD). GROningenMAchine for Chemical Simulations (GROMACS) software (2019.4) is used for molecular dynamics to determine the stability of substrate specificity between collagenase gene and APHCP. The study employed the Gromos54a7 force field combined with the single point charge (SPC) water model. A prodrug server was utilized to acquire Ligand topology. MD simulations were set at 300 K using Berendsen thermostat for 200 ns, maintaining pressure at 1.01325 bars similar to physiological conditions. The tool imports the complex for protein preparation, addressing any errors. Explicit solvents, Na + and Cl-ions were used for solvation and system neutralization by the steepest decent method. The system underwent complete energy minimization for the entire 200 ns of MD simulations. Two steps were used to equilibrate the system. Two phases were involved in the equilibration process, which involved a few thousand molecules and the collagenase – substrate complex. Using an NVT ensemble, wherein the number of simulated particles (N), simulation cell volume (V) and temperature (T) are all kept fixed throughout the simulation, first phase equilibration was carried out for 30 ps at 300 K. This stabilized the temperature of the system. The NPT ensemble herein Number of moles (N), Pressure (P) and temperature (T) will be conserved was carried out in second phase equilibration up to 30 ps NPT simulation per atom. In addition, the system was simulated using Berendsen at a time step of 5 ps while maintaining a constant temperature of 300 K and pressure of 1 atm. The input file name. coherence of grid maps, and presence of non-standard atoms were assessed to verify the accuracy of the MD simulations (Tohar et al., 2021; Yaraguppi et al., 2021; Yaraguppi et al., 2022a).

The Gromacs Package is employed for analyzing the data derived from Protein – substrate complex molecular dynamics. It computes the RMSD (Root Mean Square Deviation) value by evaluating the atoms within the collagenase protein matrix and those bound to the protein in the ligand. Throughout the Molecular dynamics simulation, various supplementary factors such as Rg (Radius of Gyration), SASA (Solvent accessible Surface Area), and the analysis of hydrogen bonds are considered. The tools gmx-rms (RMSD), gmx-rmsf (RMSF), gmx-gyrate (Rg), gmxhbond (hydrogen bond) and gmx-sasa (SASA) were used to calculate and examine these factors using commands present in Gromacs (Revankar et al., 2023). For plotting of data, the 200 ns trajectory is divided into segments of 20 ns each to facilitate analysis of plots compared to visualizing a continuous 200 ns stretch. Tools like PyMol and Visual Molecular Dynamics (VMD) are utilized for the analysis and visualization of the simulation – derived data. Additionally, the xmgrace tool is employed for generating graphs and plots derived from simulation.

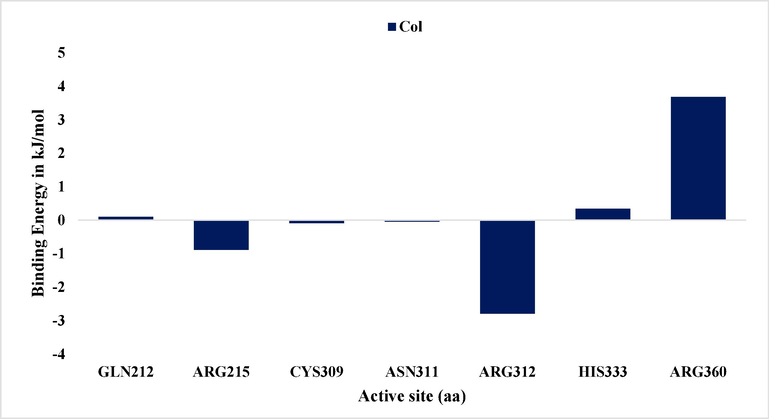

2.9.4 Molecular Mechanics poison surface Area analysis (MMPBSA)

The MM-PBSA method assesses protein’s binding free energy (DG binding), employing the open-source tool g_mmpbsa to evaluate the interaction potential of drug molecules within the stable simulation structure. Specifically, the GROMACS utility g_mmbpsa (https://rashmikumari.github.io/g_mmpbsa/) is employed to perform the needed calculations (Revankar et al., 2023). MM-PBSA process is used with g_mmbpsa tool to assess various binding energy components. This assessment encompasses an analysis of the entropy contribution and energy engagement of individual amino acids, employing an energy deposition strategy. The final 50 ns of simulations, being stable, are used for DG computation in MMPBSA. The interaction affinity of the inhibitor with the unbound protein is derived from the difference between ligand-bound and free protein conformations, calculated by a specific formula as follows:

ΔG binding = G-complex – (G-protein + G – ligand) (Yaraguppi et al., 2022a).

2.10 Statistical analysis

All experiments and reactions were conducted in triplicates for each data point. The data is presented as mean ± standard deviation (SD). In the figures, the error bars depict the standard deviation and were computed using Microsoft Excel.

3 Results and discussions

3.1 Identification of gene of interest

A pivotal and foundational step in any recombination study involves the precise identification of target gene. The gene of interest is collagenase gene, and to identify this gene comprehensive bioinformatic analysis was conducted. The alignment of genetic sequences, encompassing both the collagenase gene and the amino acid sequence derived from various bacterial variants in relation tostrain Z1, was undertaken through the utilization of the CLUSTAL Omega Multiple Sequence Alignment Tool (Sievers et al., 2011). This sequence alignment process was conducted utilizing genetic data sourced from the expansive NCBI repository. The choice of the 422 amino acid coding collagenase gene, which spans a genetic length of 1269 base pairs, was predicated with 99 % genetic similarity to the collagenase gene present in strain Z1. Teramura et al., 2011, isolated collagenase gene from Grimontia (Vibrio) hollisae by cloning and sequencing method. Collagenase gene consisted of 2,301 nucleotides and amino acid sequencing comparison of 767 amino acids revealed high homology to several collagenases by employing CLUSTAL W2 program.

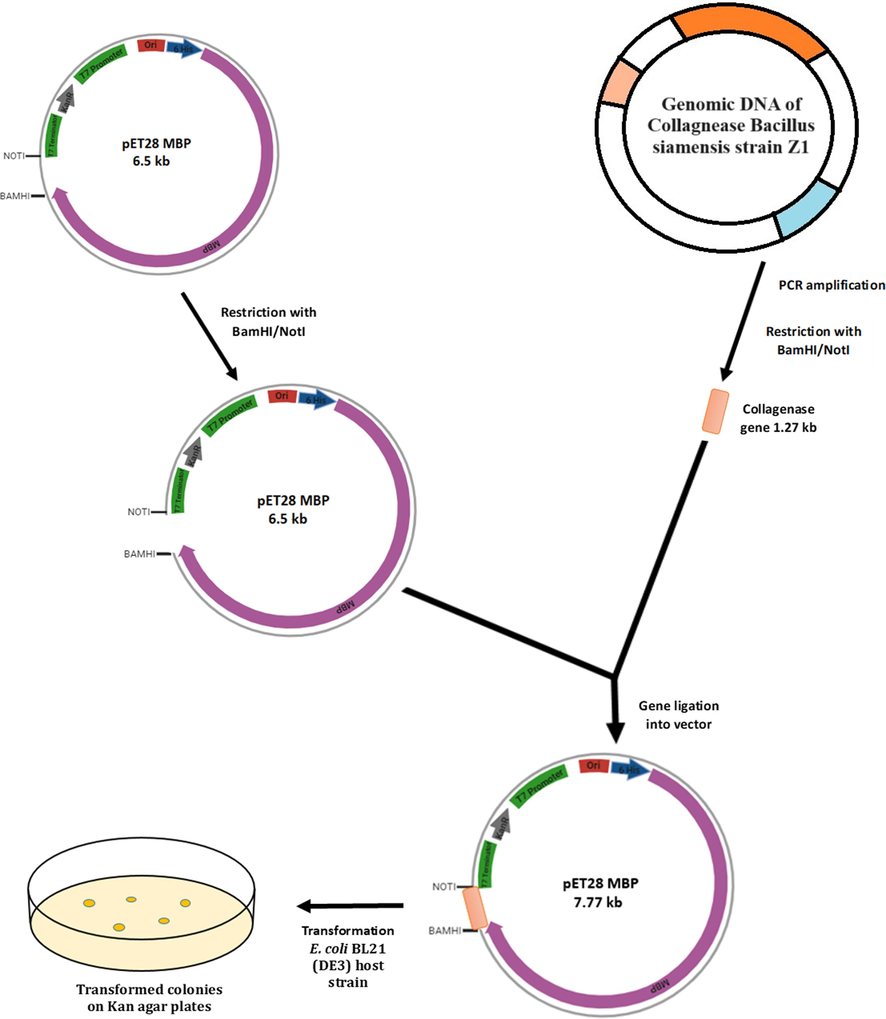

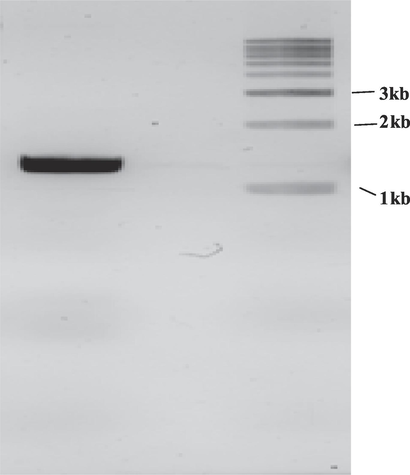

3.2 3.2. Cloning of collagenase gene into vector

Phenol chloroform extraction was employed to isolate genomic DNA that possessed a concentration of 1119 ng/µl. Custom primers were purposefully crafted utilizing the DNA sequence unique to the collagenase gene. These primers were instrumental in driving the amplification process of the collagenase gene through PCR. Amplification process plays a pivotal role in successful attainment of genetic recombination. In order to validate that the amplified product corresponded to target gene, electrophoresis was employed. The outcome of this electrophoretic analysis confirmed the presence of a solitary band, 1.27 kb and is depicted in Fig. 2. The amplified gene product from PCR was purified and inserted into pET28 (MBP Tagged) vector. This integration process was carefully facilitated through restriction digestion, employing the BamHΙ and NotΙrestriction enzymes. Subsequently, a ligation step was carried out, followed by the transformation of the construct into E. coli DH5α cells. Similarly to current research, ColA, the collagenase was obtained through the amplification process using genomic DNA extracted from B. cereus strain ATCC14579. Specifically, designed PCR primers was used to amplify ColA, lacking both the predicted signal peptide and propeptide regions. Subsequently, the PCR products flanked by BamHΙ and XhoΙ, was inserted into pGEX-6P-1 plasmid. This construct was then introduced into E. coli BL21, resulting in the creation of a fusion protein – GST-ColA as described by Abfalter et al., 2016.

The identification of positive transformed colonies was picked by antibiotic-based screening method. These selected colonies were cultured on agar plates infused with kanamycin. To validate the presence of collagenase target gene within these transformants, a series of screening steps was carried out. This included utilization of colony PCR amplification, and the outcomes were made visible through agarose gel electrophoresis. The colonies that exhibited positive transformation were isolated and their plasmids were extracted possessing a concentration of 365.9 ng/µL and were preserved for subsequent utilization. Similar to current approach, a recombinant serine alkaline protease from Bacillussp RAM53 was selected by antibiotic screening and grown in kanamycin plates and positive single colonies were examined by PCR colony test and transferred to E. coli BL21 expression host. Genetic engineering of these serine proteases makes them commercially industrially important organisms (Alei et al., 2023). A visual representation of the strategy employed for subcloning to construct the recombinant collagenase- pET plasmid can be found in the Fig. 1. In the present study, the collagenase gene was identified from Bacillus siamensis strain Z1 (accession number OR054215.1). The recombinant cloned sequence obtained from sequencing were subjected to alignment, and the alignment revealed a consistent correspondence with the reference sequences, thereby confirming the accuracy.

Illustrative representation of the subcloning process involved in constructing the recombinant collagenase.

Amplification of collagenase gene by PCR from Bacillus siamensis strain Z1.

3.3 Expression and purification of recombinant collagenase

The genetic sequence was subjected to optimization and synthesis to ensure its adaptability for expression within the E. coli and collagenase gene of 1.269 bp was been cloned into pET28 (MBP Tagged) vector. The recombinant plasmids were transformed into E. coli DH5α cells. The plasmids extracted from these cells were transformed in E. coli BL21 (DE3) cells to enable their over expression. This over expression was carried out in sterile LB media supplemented with kanamycin (50 µg/ml) creating an environment that was favorable for the thriving of intended genetic process. The same procedure of expression with IPTG was also followed by Hu et al. (Hu et al., 2019) for expressing recombinant Matrix metalloproteinases (MMP1) HcMMP1. It is widely accepted and demonstrated fact that E. coli is renowned as one of the predominant microorganisms employed in the synthesis of recombinant proteins. Its widespread use can be attributed to several factors. E. coli has consistently been recognized for its adaptability as an expression system, characterized by its rapid growth, suitability for cultivation in cost effective culture media, and its ability to generate substantial cellular biomass while maintaining a rapid protein production rate (Alei et al., 2023). In present study expression of recombinant collagenase was induced by 1 mM IPTG. A concentration of 1 mM IPTG has been sufficient for induction of clostridial collagenases too (Eckhard et al., 2014). Ducka et al., 2009, reported usage of two concentrations (0.1, 1 mM) of IPTG for induction and cells were mainly induced by 0.1 mM and it was noted that no difference in soluble expression yield could be observed upon increasing IPTG concentration. The harvested cells were lysed and purified through Amylose resin column. The concentrated purified protein increased by 48.11 folds through buffer exchange. After 24 h of incubation, the crude recombinant protein from fermentation broth exhibited a collagenase activity of 117 U/ml and a protein concentration of 0.41 g/L. The MBP tag aided in one- step purification by amylose resin affinity chromatography, as detailed in Table 1. In comparison to cell lysate, collagenase obtained 20.76 folds increase in purity. The specific activity achieved of the purified collagenase was 5926.3 U/mg, which was significantly greater than the cell lysate. The chromatographic process yielded a recovery rate of 48.11 %. The purification of MBP fusion protein exploits the natural affinity of MBP for recombinant collagenase. It is important to view the MBP fusion tag as a means to enhance protein solubility and as an affinity tag for ease of purification process using column. Many vectors are available to construct fusion proteins with MBP (Duong-Ly and Gabelli, 2015). Amylose resin contains covalently linked amylose. Proteins tagged with MBP have a natural affinity for amylose and their specific binding allows for the isolation of target protein, while non-specific proteins and complex mixtures pass through (Pattenden and Thomas, 2008; Rodriguez et al., 2020). In accordance with this present research, recombinant L. sericata collagenase (MMP-1) expressed in SF9 cells showed crude activity to be 3.7 U/ml with 68.5 µg/ml concentration (Alipour et al., 2019). Zhu et al., 2022, reported purification of recombinant collagenase from B. subtilis WB600/pP43NMK-col was assisted by His – Tagged Nickel column resin yielding 2.14 % with 4.71 folds. Purification of collagenase from Bacillus pumilus Col-J was done yielding 7.0 % (Wu et al., 2010). Zhang et al., 2015 reported 73.2 % of relative activity recovery of recombinant collagenase with Histidine tagged (His-cdMMP-13).

Purification step

Total activity (units)a,b × 103

Total protein (mg)a,c

Specific acivity (U/mg of protein)

Activity yield (%)

Purification fold

Cell lysate

Amylose affinity chromatography58.5 ± 9.3

28.15 ± 1.3205 ± 16

4.75 ± 4.1285.36

5926.3100

48.111

20.76

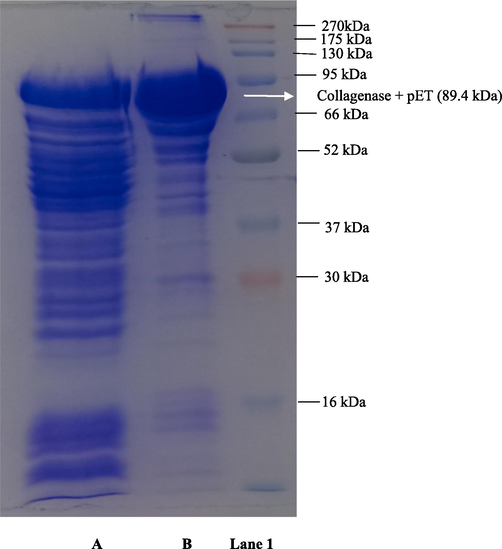

The SDS-PAGE analysis of recombinant collagenase confirmed the successful expression of the gene, resulting in fusion protein with molecular weight of ∼ 89.4 kDa. This fusion comprised collagenase mass of 47.4 kDa and 42 kDa of MBP tag as observed in gel in Fig. 3. with protein molecular marker. It was found that the recombinant collagenase concentration was 203.356 µM. Fusion proteins have gathered interest owing to many advantages, including providing stability to the protein, augmenting protein solubility, and boosting folding characteristics. The signaling peptide is of crucial importance in the expression of fusion proteins, as it serves as recognition point for the secretory system. A larger concentration of released proteins was found in the culture broth because of the periplasm’s higher membrane permeability and easier downstream. The periplasm aids in protein folding, and the signal peptide facilitates the movement of recombinant proteins through the inner periplasmic membrane, enabling secretion in E. coli BL21 (DE3). This enhances soluble protein production (Shettar et al., 2023). Suberu et al., 2019, reported cloning of serine alkaline protease gene (R5) from Bacillus subtilis strain RD7 in pET15b and transformed in E. coli DH5α competent cells which is in line with this study. They expressed the gene in BL21 host cells and the product had a molecular weight of 43 kDa. Recombinant collagenase protein reveled a band of 52 kDa expressed of collagenase (MMP-1) (Alipour et al., 2019). An alkaline protease gene from Bacillus lehensis jo-26 was introduced into pET28 + a expression vector and transferred to E. coli BL21 expression host, yielding an enzyme with molecular weight of 34.6 kDa(Bhatt and Singh, 2020). Similarly, the serine alkaline protease gene from Bacillus sp. RAM53 was cloned into pET28a + vector, transferred to E. coli BL21, resulting in a recombinant enzyme with a molecular weight of 40 kDa (Alei et al., 2023). A recombinant keratinase was constructed using keratinase gene from Meiothermustaiwanensis WR-220 and expressed in E. coli expression system, further purified by affinity chromatography yielded molecular weight of ∼ 28.5 kDa. It also retained broad proteolytic activity for different substrates like feathers and casein and also retained activities in varying pH range 3 to 10 (Ho et al., 2016). In current study, the development of a highly effective approach for expressing and secreting recombinant collagenase into culture medium has led to a significant improvement in the recovery of product.

SDS-PAGE analysis of recombinant collagenase. (A) Z1 pET crude collagenase (B) Z1 pET MBP tagged Affinity purified collagenase (Lane 1) protein molecular weight marker.

3.4 Biochemical properties of purified recombinant collagenase

3.4.1 Effect of pH and temperature on the activity and stability of recombinant collagenase

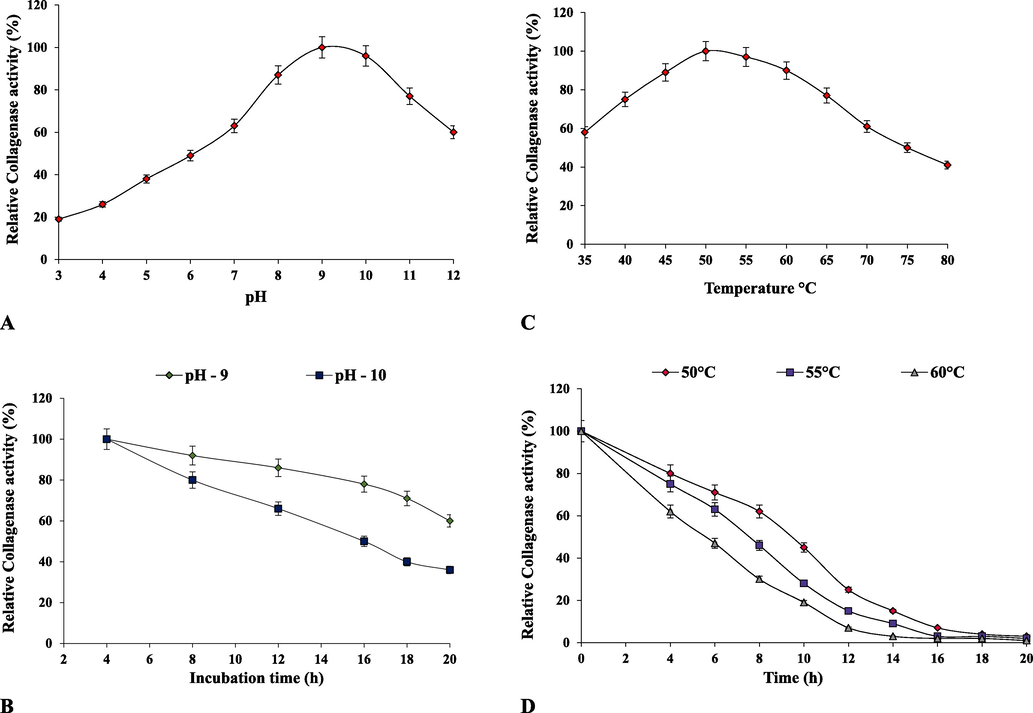

The recombinant collagenase was highly active in alkaline pH range of 8––10 retaining > 90 % of the relative activity and with optimum pH at 9 and 10 as shown in Fig. 4A. In acidic pH range of 3–5, < 50 % of relative activity was observed. The reduction in the activity at acidic pH may be contributed by the variations occurring in the ionic forms of active sites of the enzyme further influencing the structure and folding attributes of proteins. However, at higher alkaline pH range of 11–12 the relative activities are evidenced to be 60 – 77 %. The pH stability of recombinant collagenase was studied by pre-incubating it at pH 9 and 10 for a period of 20 h at 35 °C. Collagenase showed a notable stability at pH 9 up to 20 h with > 95 % of relative activity as depicted in Fig. 4B indicating its alkaline nature. Fig. 4C illustrate the temperature effect on the collagenase activity. The optimum activity of the enzyme was observed at 50 °C at pH 9, and about > 75 % of the activity was retained between 40 and 60 °C. The enzyme activity declined sharply when the temperature exceeded 60 °C with less than 40 % of its activity retained. The recombinant collagenase possesses thermostability up to 50 °C. The thermostability was studied in the temperature range of 50 – 60 °C for 20 h. The half-life times of collagenase at 50, 55 and 60 °C were found to be 9, 7.5 and 5 respectively as shown in Fig. 4D. In context with present study, Zhu et al. (2022), reported recombinant collagenase from Bacillus subtilis WB600 showing maximum collagenase activity at pH 9.0. and it was relatively stable in the pH range 8–10 for 90 min by retaining ∼ 60 % of relative activity and optimum temperature was observed at 50 °C with retaining 75 % of its activity between 30 and 50 °C. A thermophilic collagenase from NocardiopsisdassonvilleiNRC2aza showed optimum activity at pH 8.0 and temperature of 60 °C, and stability at various pH levels (7.0–8.5) and temperatures (40–60 °C) (Abood et al., 2018). A recombinant serine protease by Bacillus sp. RAM53 displayed optimum activity at pH 9.0 and 40 °C temperature (Alei et al., 2023). A maximum collagenase activity of B. cereus isolated from pollen of bee of Amazon region was noted to be at 45 °C and pH 7.2 and had wide working ranges of pH values (7.2–10.0) and temperatures (25––50 °C) (Pequeno et al., 2019). The enzyme’s capacity to withstand high alkalinity is a crucial attribute for its utilization across various industries. Notably, the recombinant collagenase displayed high alkalinity and slight thermostability, the inclusion of MBP tag might also play significant role in enhancing the enzyme’s stability.

Biochemical characterization of purified recombinant collagenase. (A) effect of pH on collagenase activity, (B) pH stability, (C) effect of temperature on collagenase activity and (D) temperature stability.

3.4.2 Effect of metal ions, chemicals, organic solvents and additives

The effect of some metal ions such as FeSO4, MgSO4, NaCl, KCl, CaCl2, ZnSO4, CuSO4 and MnSO4 on the enzyme activity was evaluated (Table 2). The catalytic efficiency of the recombinant collagenase was stimulated by CaCl2, MgSO4 and FeSO4and MnSO4 with > 85 % activity retained. The biggest stimulation was observed in the presence of CaCl2with 110 % relative activity, while the notable inhibition was observed in presence of KCl with relative activity of 41 %. A similar collagenase relative activity enhancement was observed with metal ion Ca2+ on rBLAP recombinant collagenase (Joshi and Satyanarayana, 2013). Li et al., 2022, reported novel marine gelatinase Flocculibactercollagenilyticus also possessing collagenase activity. Metal ions like Ca2+, Ba2+, Mg2+ significantly increased activity towards bovine bone collagen, but inhibited by Zn2+. Metal ions such as Zn2+, Co2+, Mg2+ and Ca2+ stimulated the recombinant collagenase activity, but was inhibited by Fe3+ and Cu2+(Zhu et al., 2022), and in another study collagenase activity was inhibited by Na+ and K+, while stimulated by Ca2+, Mg2+ and Fe2+(Al-Bedak et al., 2022). The relative collagenase activity in absence of any surfactants, organic solvents, metal ions and additives was considered as control.

Factors

Relative Collagenase activity (%) a

Control

Metal Ions

Surfactants

Organic Solvents

AdditivesWithout treatment

FeSO4

MgSO4

NaCl

KCl

CaCl2

ZnSO4

CuSO4

MnSO4

SDS

Triton X-100

Tween 80

Methanol

Ethyl acetate

Benzene

Chloroform

Urea

LD-DTT

β – mercaptoethanol

EDTA100

88

102

50

41

110

78

80

85

94

96

92

60

55

52

43

88

93

96

72

The influence of surfactants such as SDS, Tween 80 and Triton X-100 on the collagenase relative activity is illustrated in Table 2. All the surfactants have shown > 90 % of relative activity. Corresponding to present study, an ionic detergent SDS has shown stimulatory activity on recombinant rBLAP collagenase assuming the SDS must have assisted in attaining favorable conformation of protein rather than the amphiphilic nature of SDS, that allows interactions with amino acids leading to unfolding of protein and loss of enzyme activity (Joshi and Satyanarayana, 2013). Wanderley et al. (2020), reported collagenase activity from Chlorella vulgaris for surfactants such as Triton X, Tween 80 and SDS to be 40 %, 74 % and 62 % respectively. Free collagenase and collagenase nanoparticles of Bacillussp when treated with same surfactants exhibited stability (Badoei-dalfard et al., 2022). Recombinant serine protease displayed increase in enzyme activities in presence of surfactants, SDS is a serine protease activator and indicates the suitability of SDS as detergent and is suggested that positive charges of calcium and magnesium found in hard water combine with negative charges of SDS to deactivate them (da Silva et al., 2018).

It can be seen that organic solvents like Methanol and ethyl acetate have retained > 50 % relative activity as there is a high demand for alkaline proteases that maintain stability in organic solvents because they can efficiently catalyze product synthesis in organic environments, while aromatic solvents such as benzene and chloroform have displayed slight inhibitory activity (Table 2). Inhibitory activity of recombinant collagenase was observed by aromatic solvents such as benzene and toluene and this enzymatic catalysis changes might be due to factors such as the disruption of hydrogen bonds, alterations in hydrophobic interactions, enzyme compaction and modifications in protein conformation (enzyme unfolding) and inactivation. A study exhibited that aromatic solvent benzene adversely affected collagenase activity, whereas methanol enhanced the activity (Joshi and Satyanarayana, 2013). Similar result of inhibition was displayed by free collagenase (Badoei-dalfard et al., 2022) and activity enhancement by methanol (Taghizadeh Andevari et al., 2019).

The stability of collagenase was assessed by treatment with inhibitors. Among the inhibitors tested, EDTA, a well-known metalloprotease inhibitor inhibited the collagenase thus indicating recombinant collagenase gene is a metalloprotease. LD-DTT and β – mercaptoethanol had a slight enhancing activity on collagenase, indicating the involvement of thiol groups in proteolysis (Table. 2). In accordance with current results EDTA had shown inhibitory activity, whereas β – mercaptoethanol and LD-DTT showed slight stimulatory activity on recombinant collagenase rBLAP (Joshi and Satyanarayana, 2013). Similar activity reducing profile was displayed by EDTA on collagenolytic metalloprotease isolated from banana peel and stated higher concentration inhibition by metalloprotease inhibitor classifies enzyme as metalloprotease (Gurumallesh et al., 2019). EDTA acts as chelating agent that binds and removes metal ions from active metalloproteases. Consequently, this action results in inactivation of metalloprotease (Ghauri et al., 2022; Laustsen et al., 2016).

3.4.3 Thermodynamic analysis of collagenase

The thermodynamics analysis of recombinant collagenase is essential for understanding stability and behavior under varying temperature conditions. Table 3. presents thermodynamic attributes of recombinant collagenase. Rise in temperature from 50 to 60 °C showed decrease in t1/2 and D values. A notable rise in thermal stability was observed at 70 °C. An apparent correlation was seen between the increase in temperature and increase of deactivation rate constant (Kd). The enthalpy of denaturation (ΔHd) quantifies the amount of heat absorbed during the denaturation of protein. A greater ΔHd signifies increased enzyme thermostability. The ΔHd values appeared to decrease as temperature rised, suggesting minimal energy needed for enzyme denaturation. This might relate to structural alterations in proteins at elevated temperatures. Gibbs free energy (ΔGd) combines enthalpy and entropy, and a robust tool for precise enzyme stability assessment. Higher temperatures leading to increased ΔGd values suggest a direct correlation between protein stability and elevated ΔGdvalues, indicating a non-spontaneous thermal inactivation mechanism. The entropy ΔSd is enzyme thermal denaturation, representing the energy/degree in the shift from the native to denatured state. Increased ΔSd signifies increased disorderness linked to enzyme structure, observed with elevated temperatures. Negative ΔSd valued denote non-spontaneous reactions and also highlight enzyme is stable during thermal denaturation process. The thermodynamic factors notably indicate the thermostability of recombinant collagenase. The thermodynamic characteristics of the enzymes associated with thermal deactivation are also been addressed by other researchers as well. Costa et al. (2023), have showed thermodynamic properties with ΔGdand ΔSd value of 62.16 kJ/mol and 1.96 J/mol respectively of collagenase from Streptomyces antibioticus. A lower t1/2 and Kd values in range of 0.1 – 2.0 h and 0.0035–––0.057 m-1 were observed for purified alkaline protease from N. dassonvillei OK-18 at varying conditions (Sharma et al., 2020). Thermal inactivation of free and immobilized alkaline serine protease showed extended half-life and greater thermal stability in bead form. Higher values of kinetic parameters like enthalpy denaturation, ΔGd, entropy was observed in immobilized enzyme (Mechri et al., 2022). A serine protease thermodynamic attributes such as Kd and t1/2 ranged from 2.50 × 103to 5.50 × 103and 277.25––111.25 min respectively within temperature range of 50 – 80 °C(Chauhan et al., 2021).

Temperature (°C)

Half-life t1/2 (h)

Kd (h−1)

D (h)

ΔHd (kJ.mol−1)

ΔGd (kJ.mol−1)

ΔSd (kJ.mol−1)

50

55

609

7.5

50.11

0.13

0.220.93

17.71

11.5116.74

16.63

16.5185.12

85.26

85.79−0.211

−0.209

−0.207

3.4.4 Evaluation of substrate specificity

To assess the substrate specificity of recombinant collagenase, the relative activities (%) were examined using various types of substrates as detailed in Table 4. Recombinant collagenase showed the hydrolysis of natural substrates such as collagen, gelatin, BSA, casein and hemoglobin and azo-casein (modified). Collagenase demonstrated outstanding catalytic performance when acted on collagen and gelatin with > 100 % relative activity. The collagenase also acted on other natural and modified substrates with retaining > 90 % relative activity and 40 % of activity was observed with hemoglobin. Badoei-dalfard et al., 2022, showed higher affinity of free and immobilized collagenase nanoparticles towards collagen about 2.44, 4.05 folds time compared to casein. It also showed activity towards fibrin acting as fibrinolytic protease in hydrolysis of blood clots. The present study finding aligned with prior research demonstrating significant substrate specificity towards bovine bone collagen and gelatin, as illustrated involving recombinant gelatinase Aa2_1884 (Li et al., 2022). In accordance to present results, Higher affinity of gelatin and collagen towards ATPS purified collagenase produced by microalgae C. vulgaris was reported by Wanderley et al. (2020). Proteolytic activity towards other substrates such as casein, azocasein, BSA. and hemoglobin were reported by other researchers (Suberu et al., 2019; Yin et al., 2013; Sriket et al., 2011).

Substrate

Concentration

Relative Collagenase activity (%) a

Collagen

Gelatin

BSA

Casein

Azo-casein

Haemoglobin10 g/L

2 g/L

10 g/L

20 g/L

30 g/L

20 g/L100 ± 2.3

115 ± 1.4

98 ± 0.8

92 ± 1.5

90 ± 2.2

43 ± 1.9

3.4.5 Determination of kinetic parameters

The Table 5 showcases the analyzed kinetic parameters of purified recombinant collagenase, illustrating its adherence to the classical Michaelis-Menten kinetics, as revealed through the Lineweaver-Burk plot analysis. The activity of Collagenase progressively elevated up with increased substrate concentration and reached saturation point, signifying the complete occupancy of active sites. The Km values for collagen and gelatin was found to be 0.33 mg/ml and 0.43 mg/ml respectively. Vmax values were found to be 5.926 × 103 and 6.432 × 103 U/mg respectively. Lower Km value indicates increased substrate specificity and strong substrate binding. The observed Km values signify the increased affinity of the gelatin substrate for collagenase. A lower Km and Vmax of 1.09 × 10-3 and 4.06 × 10-4 was observed for recombinant collagenase showing good affinity and catalytic efficiency for collagen (Tanaka et al., 2020). Vmax refers to the maximum rate achieved when the enzyme is fully saturated with substrate. The calculated Kcat and deduced catalytic efficiency Kcat/Km for collagen was 11.852 × 103 min−1 and 35.915 × 103 min−1 mM−1 respectively and for gelatin was 12.864 × 103 min−1 and 29.916 × 103 min−1 mM−1 respectively. Specific constant (Vmax/Km) for collagen and gelatin were found to be 17. 95 × 103 and 14.95 × 103respectively. A Km value of 3.03 µg/ml and Vmax of 0.15 µg/ml min−1 was observed for EDTA inhibited gelatinase towards gelatin (Silvestre and Ramos, 2015). Kinetic parameters were studied for collagenase produced with Kcat/Km value of 2.95 mL/mg/s (Costa et al., 2023). A mutant keratinases derived from Brevibacillusparabrevis hadKcat/Km varying in range 11 to 20 s−1 mM−1, while the wild exhibited 12.5 s−1 mM−1(Shi et al., 2021). Abdella et al., (2023), demonstrated enhanced Km and Vmax in the immobilized enzyme, suggesting improved enzyme activity post-immobilization, due to enhanced substrate conversion rates. The elevated Vmax might be from enzyme-carrier binding, enhancing active site affinity for substrate interaction.

Substrate

Km (mg/ml)a

Vmax (×103 U/mg) a

kcat (×103 min−1)

Kcat/Km (×103 min−1 mg−1)

Vmax/Km (×103 min−1/mg−1)

Collagen

Gelatin0.33

0.435.926

6.43211.852

12.86435.915

29.91617.95

14.95

3.5 Analytical characterization of collagenase

3.5.1 Mass spectrometry analysis

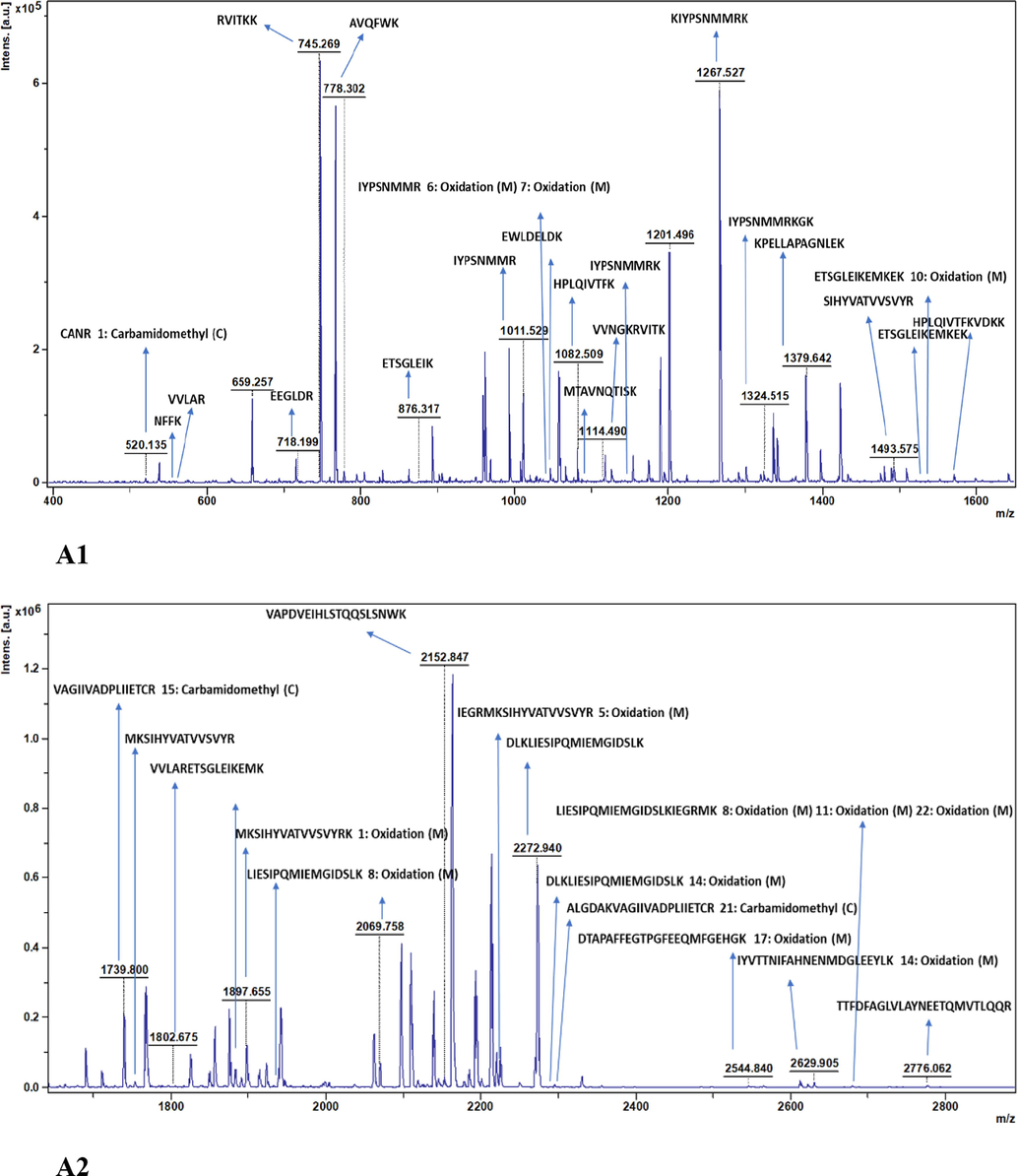

The collagenase protein with MBP tag was subjected to enzymatic digestion using trypsin, an enzyme known for cleaving at the C-terminal of arginine (R) and lysine (K). The digestion was carried out with collagenase protein to trypsin ratio 25:1 and the resulting fragments were subsequently analysed using MALDI-TOF-MS. Table 6. displays the mass profiles of predicted and observed fragments resulting from the trypsin digestion of collagenase protein. The predicted mass fragments were calculated based on the primary protein sequence of collagenase by employing the EXPASY: PeptideMass tool (https://web.expasy.org/peptide_mass/). The mass spectra unveiled a total of 21 [M+H]+ fragments for collagenase – MBP with 68.7 % sequence coverage. Therefore, the data obtained from MALDI-TOF-MS analysis for the digestion of recombinant collagenase validates authenticity of the collagenase protein. Analogous analyses are reported in diverse literatures. Using MALDI-TOF-MS/MS analysis, the functional collagenase of Pseudoalteromonasagarivorans NW4237 was recognised as a member of U32 family peptidases, exhibiting a molecular mass of 52,509 Da (Bhattacharya et al., 2019). In a study molecular weight of collagen hydrolysates (peptides) produced from digestion by Penicillium aurantiogriseum URM 4622 were analysed by MALDI-TOF-MS ranging between 11 – 2 kDa (Lima et al., 2015). Saxena and Singh, 2015, analysed the masses of peptide fragments obtained by MALDI-TOF MS were in range 600 – 3000 Da produced by fibrinolytic collagenase. Thakrar et al., 2023, proposed recombinant alkaline serine protease gene from haloalkaliphilic actinobacteria, Nocardiopsis sp. had a molecular weight of 34 kDa determined using Mass spectrometer (MALDI-TOF). Liu et al., 2011, reported a molecular mass of 5200 and 5206 Da for two bacteriocins, enterocin 7A and 7B respectively, produced by Enterococcus faecalis 710C.

Predicted masses of collagenase,

[M+H]+

Observed masses of collagenase-MBP,

[M+H]+

2614.2493

2282.0943

2225.0729

2152.1033

2136.0872

2069.9661

1917.0071

1914.9252

1824.8836

1881.9509

1682.9509

1379.7892

1188.5612

1082.6357

1047.4993

1011.4750

984.3444

778.4246

718.3366

520.2296

175.11892614.917

2282.929

2225.930

2152.851

2136.825

2069.761

1917.732

1914.671

1824.733

1882.697

1682.779

1379.803

1189.617

1082.513

1047.369

1011.531

983.437

778.303

718.186

520.136

175.754

3.5.2 N − terminal sequence analysis by MALDI – TOF – MS and Edman degradation

In order to understand the functional characteristics of peptides and proteins, it is vital to determine their structure and identity. Edman sequencing, a conventional approach, offers high sensitivity in identifying the structural details of bioactive peptides. However, with the advancements in analytical methods, advanced mass spectrometry emerges as an alternate technique for the identification and mapping of peptides. Amino acid sequencing analysis can be performed utilizing MALDI-TOF-MS, liquid chromatography – tandem mass spectrometry (LC-MS) or quadrupole time-of-flight mass spectrometry (Q-TOF-MS). MALDI-TOF-MS was utilized for conducting the N-terminal sequence analysis of the recombinant collagenase. The resulting spectra was used to identify matching proteins in the NCBI database (https://www.ncbi.nlm.nih.gov/) using the Mascot search program (https://www.matrixscience.com, Matrix Science, London, England) or using online tools to confirm sequence coverage of known sequences. There was a mass range of 500–––4500 m/z. The mass spectra showed 21 fragments of [M+H]+ collagenase – MBP (Table 6). Additional analysis of tryptic peptides from 47.4 kDa protein was conducted to obtain sequence information from peptide ions, to confirm the identity of collagenase. Using parameters like fragment peak width of 0.2 m/z and signal-to-noise threshold of 2, the peaks were labelled using flex analysis software. Techniques including de-isotoping and centroiding of the spectrum were utilized. These techniques were employed to encompass the monoisotopic masses in peptide mass fingerprinting (PMF). This highlights the importance of identifying the monoisotopic masses in MALDI-TOF-MS for the structural analysis of the collagenase protein. Biotools software version 3.2 was used to analyze and validate the N-terminal sequence of the collagenase protein by applying it to the MALDI-TOF spectra. Parameters for sequence confirmation was set, including enzyme: trypsin, ion mode: positive, optimal modifications of methionine oxidation, and subsequent adjustments specifying methionine at position 1 and oxidation modification. The trypsin digestion uncovered a sequence starting with 10 amino acid residues at the N-terminus, identified as MTAVNQTISK, presenting a mass of 1092.57 m/z (calculated) and 1092.381 m/z (measured) via Biotools software v 3.2, as indicated in Table 7. Fig. 5 A1, A2 illustrates collagenase peptide fragmentation. Here, 35 peaks including the confirmation of the N-terminal peptide sequence are labelled according to their individual masses in m/z. The complete protein sequence is been provided in Supplementary Information (SI-S1) with matching sequences having an MS coverage of 63.8 %. Since trypsin cleaves specifically at R (arginine) and K (lysine) amino acids, it specifically cleaved at the K amino acid at position 10, confirming the peptide’s amino-terminal nature. Similar methodologies have been adopted by other researchers in their respective studies. The Edman degradation process unveiled 27 aa residues at the N-terminal sequence of the serine alkaline protease SAPGB from Gracilibacillusboraciitolerans LO15, showing the closest identity to the S8 protease family (Ouelhadj et al., 2020). A protein of bovine neutrophil gelatinase associated lipocalin (bNGAL) with relative molecular mass of ∼ 25,000 Da showed N-terminal homolog with hNGAL, 24p3 and A2UMRP having 68, 54 and 49 % of identity and 7 significant peaks were observed by MALDI-TOF Analysis (van Veen et al., 2006). The identity of a recombinant collagenase that is highly expressed is clearly shown by the current analysis.

Meas. m/z

Calc. MH+

Range

Sequence

1092.381

1114.49

745.269

1379.642

2069.758

2629.905

2294.904

1739.8

2152.847

778.302

718.199

557.238

1802.675

876.317

1522.548

1537.568

2272.94

2288.88

1932.718

2678.941

2224.925

1897.655

1753.799

1493.575

1882.702

1047.36

520.135

2544.84

2776.062

555.166

1082.509

1552.592

1267.527

1011.529

1043.359

1139.428

1324.5151092.57

1113.71

744.509

1379.789

2069.966

2630.244

2295.274

1739.972

2152.103

778.425

718.337

557.377

1803.004

876.467

1521.78

1537.778

2273.213

2289.208

1933.002

2679.377

2224.191

1897.04

1752.95

1493.81

1881.91

1047.5

520.23

2545.1

2775.37

555.293

1082.636

1552.921

1267.665

1011.475

1043.465

1139.57

1324.69

1–10

11–20

16–21

21–33

56–74

80–101

102–123

108 – 123

125––143

144 – 149

150 – 155

156 – 160

156 – 171

161 – 168

161 – 173

161 – 173

245 – 264

245 – 264

248 – 264

248 – 270

265 – 283

269 – 284

269 – 283

271 – 283

285 – 300

301 – 308

309 – 312

313 – 335

337 – 360

361 – 364

399 – 407

399 – 411

411 – 420

412 – 419

412 – 419

412 – 420

412 – 422MTAVNQTISK

VVNGKRVITK

RVITKK

KPELLAPAGNLEK

SNADNFSIEEIAEGVEFAK

IYVTTNIFAHNENMDGLEEYLK 14: Oxidation (M)

ALGDAKVAGIIVADPLIIETCR 21: Carbamidomethyl (C)

VAGIIVADPLIIETCR 15: Carbamidomethyl (C)

VAPDVEIHLSTQQSLSNWK

AVQFWK

EEGLDR

VVLAR

VVLARETSGLEIKEMK

ETSGLEIK

ETSGLEIKEMKEK

ETSGLEIKEMKEK 10: Oxidation (M)

DLKLIESIPQMIEMGIDSLK

DLKLIESIPQMIEMGIDSLK 14: Oxidation (M)

LIESIPQMIEMGIDSLK 8: Oxidation (M)

LIESIPQMIEMGIDSLKIEGRMK 8: Oxidation (M) 11: Oxidation (M) 22: Oxidation (M)

IEGRMKSIHYVATVVSVYR 5: Oxidation (M)

MKSIHYVATVVSVYRK 1: Oxidation (M)

MKSIHYVATVVSVYR

SIHYVATVVSVYR

VIDAYCADPENFVIQK 6: Carbamidomethyl (C)

EWLDELDK

CANR 1: Carbamidomethyl (C)

DTAPAFFEGTPGFEEQMFGEHGK 17: Oxidation (M)

TTFDFAGLVLAYNEETQMVTLQQR

NFFK

HPLQIVTFK

HPLQIVTFKVDKK

KIYPSNMMRK

IYPSNMMR

IYPSNMMR 6: Oxidation (M) 7: Oxidation (M)

IYPSNMMRK

IYPSNMMRKGK

The Edman degradation method used for N-terminal sequencing of the blotted recombinant collagenase (30 aa) revealed the sequence as, affirming the consistency and purity of the purified enzyme. Using the GenBank non-reductant protein database, the amino acid sequence was compared to the available protein sequences using the BLASTP search program. The sequence displayed slight varying degrees of similarity, showing the highest homology within the Bacillus species family.

Table 8 revealed the sequence similarity to U32 family peptidase (WP_064777716.1) from Bacillus siamensiswith 99.76 % similarity, U32 family peptidase (WP_198697931.1) from Bacillus siamensiswith 99.76 % identity, U32 family peptidase (WP_049627089.1) from Bacillus sp. JFL15 with 99.76 % identity, U32 family peptidase (WP_045510354.1) from Bacillus amyloliquefacienswith 99.29 % identity, U32 family peptidase (WP_061522884.1) from Bacillus nakamuraiwith 98.10 %, U32 family peptidase (WP_059335499.1) from Bacillus halotoleranswith 93.13 % and U32 family peptidase (MCY7851673.1) from Bacillus spizizeniiwith92.89 % identity. The high similarity of the amino acid sequences with related collagenases shows that recombinant collagenase is a distinct addition to the U32 family peptidase that falls within the classification microbial collagenases.

Enzyme

Origin

N – terminal amino acida,b

Identity (%)

Recombinant Collagenase (Current study)

U32 family peptidase (WP_064777716.1)

U32 family peptidase (WP_198697931.1)

U32 family peptidase (WP_049627089.1)

U32 family peptidase (WP_045510354.1)

U32 family peptidase (WP_061522884.1)

U32 family peptidase (WP_059335499.1)

U32 family peptidase (MCY7851673.1)

Bacillus siamensis

Bacillus siamensis

Bacillus siamensis

Bacillus sp. JFL15

Bacillus amyloliquefaciens

Bacillus nakamurai

Bacillus halotolerans

Bacillus spizizenii

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNQTISKVVNGKRVITKKPELLAPAGN

MTAVNDKISKIVDGKRVITKKPELLAPAGN

MTAVNDKISTIVNGKRVITKKPELLAPAGN−

99.76 %

99.76 %

99.76 %

99.29 %

98.10 %

93.13 %

92.89 %