Translate this page into:

Preparation of γ-polyglutamic acid from enzymatic hydrolysate of poplar sawdust

⁎Corresponding author at: School of Municipal and Environmental Engineering, Shandong Jianzhu University, JiNan 250101, China. zhangmeili8292@sina.com (Chao Zhang)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The use of poplar sawdust as carbon source for γ-PGA production was feasible. The γ-PGA yield in enzymatic hydrolysate medium was 5.11% higher than that in glucose medium. The process could offset the disposal cost of forestry waste.

Abstract

The treatment of forestry waste has always been an environmental problem. In this study, poplar sawdust was used to produce γ-polyglutamic acid (γ-PGA). Poplar sawdust was treated with acid and then hydrolyzed with cellulose. The enzymatic hydrolysate was used to produce γ-PGA. Through single factor and orthogonal experiments, the optimum enzymatic conditions were determined as follows: solid-liquid ratio 1:5, enzyme amount 22 FPU/g, pH 5.0 and 53 min. Under the enzymatic hydrolysate medium, the γ-PGA yield reached 30.87 ± 0.44 g/L, which was 5.11% higher than that in glucose medium (29.37 ± 0.43 g/L). In addition, the amount of glucose added to the medium was reduced, which realized the comprehensive utilization of various sugars in sawdust enzymatic hydrolysate. Although the fermentation time was prolonged by 4 h, this study provided a new and feasible method for the industrial utilization of forestry waste and the clean production of γ-PGA.

Keywords

Poplar sawdust

Bacillus subtilis

γ-polyglutamic acid

1 Introduction

γ-polyglutamic acid (γ-PGA) is a kind of water-soluble, biodegradable and multifunctional biopolymer synthesized by microorganisms. It is a water-soluble amide compound, which can be produced by Bacillus (Zhang et al., 2018). It is composed of D-glutamic acid and L-glutamic acid monomers in the form of γ-carboxyl group and α-amino group, and its molecular weight is generally 105-106 U (U is one twelfth of the mass of C12). γ-PGA has unique physicochemical and biological properties such as excellent film-forming, fiber-forming, oxygen resistance, plasticity, adhesion, moisture retention and biodegradability (Zhang et al., 2019a). In the field of food, it can be used as thickener of food and beverage. As an additive used in starch food (bread or noodles), it can avoid aging and improve food texture. In the aspect of health care, it is beneficial to the absorption of calcium in patients with osteoporosis (Luo et al., 2016). As an eco-friendly biological product, γ -PGA has more and more broad research value and application prospect.

With the increasing demand of the market, the high production cost of γ-PGA limits its application. Bacillus subtilis has a great demand for carbon source in the growth process. If the carbon source cost can be reduced, the production cost of γ-PGA will be greatly reduced. The traditional fermentation of γ-PGA by B. subtilis mainly uses sucrose, glucose and corn saccharified liquid as carbon sources. Yao et al. using glucose as carbon source, the γ-PGA yield in fermentation broth was reached 42 g/L (Yao et al., 2010). It was reported that the γ-PGA yield reached 42.55 g/L with sodium citrate and soybean meal extract as carbon source (Li et al., 2020). From the perspective of resource recycling and waste reuse, it was of practical significance to use forestry waste as carbon source instead of traditional glucose fermentation to prepare γ-PGA.

With the rapid expansion of plantation scale, China has become the country with the largest preserved area of plantation in the world (Carle et al., 2002). Poplar is one of the main afforestation tree species in the artificial fast-growing and high-yield forest project. The rapid development of fast-growing poplar has not only met people's demand for wood, but also produced a large number of cutting residues and processing residues, which are rich in bioactive substances, cellulose and hemicellulose (Xue et al., 2016; Devappa et al., 2015). Zheng Guangyao et al. cultivated Agaricus blazei and Flammulina velutipes with poplar sawdust and bark instead of cottonseed hull (Guang-yao et al., 2013). Wu et al. used sawdust to make feed, and the effect of poplar sawdust was the best (Wu, 1993). Li Xiaoming et al. cultivated Auricularia auricula with poplar sawdust, the yield of Auricularia auricula increased by 7.7% compared with the conventional tilia sawdust (Chin, 1998). Lignocellulose has the potential to replace starch biomass to hydrolyze into monosaccharide and then ferment to produce fuel ethanol and probiotics (Carvalho et al., 2013). In addition, forestry wastes could also be used as adsorbents to adsorb toxic dyes in water (Banerjee and Chattopadhyaya, 2017;Sartape et al., 2017;Omri et al., 2016). The research on the hydrolysis of lignocellulose to monosaccharide is mainly concentrated on crop straw, and the research on forestry residues is less (Jiang et al., 2015; Kim et al., 2017). Moreover, the production of γ-PGA by microbial fermentation using poplar sawdust hydrolysate as carbon source had not been reported.

In this paper, poplar sawdust was used as raw material to study the hydrolysis conditions of cellulose complex enzyme. In order to provide theoretical and technical reference for industrial utilization of forestry waste, the feasibility of using enzymatic hydrolysate as carbon source to ferment γ-PGA was discussed.

2 Experimental

2.1 Strain

Bacillus subtilis A34, purchased from China Center of Industrial Culture Collection (CICC) as CICC 20646, was used as the working strain.

2.2 Sawdust

The raw material of poplar sawdust was provided by Shandong Jianzhu University. The particle size was 100 mesh and dried in 105 °C oven. The main components of sawdust were 35.03 ± 0.68% cellulose, 17.90 ± 0.58% hemicellulose, and 22.35 ± 0.54% lignin and ash (Table 1).

Material

Component content/%

Cellulose

Hemicellulose

Lignin and ash

Raw material

35.03 ± 0.68

17.90 ± 0.58

22.35 ± 0.54

Solid residue

52.82 ± 0.43

2.61 ± 0.75

36.35 ± 0.71

Cellulose complex enzyme was provided by Contien biotechnology company with enzyme activity of 70 FPU/mL. Filter paper unit (FPU) was the enzyme activity of filter paper. One FPU was the amount of enzyme used to produce 1 μ mol glucose in 1 min.

2.3 Media

Slant medium (SM), in g/L: glucose, 20; yeast extract, 10; L-glutamate, 20; NaCl, 5; agar 18. The pH was adjusted to 7.0 by HCl or NaOH.

Seed medium (SM), in g/L: glucose, 20; yeast extract, 10; L-glutamate, 20; K2HPO4·3H2O, 2; MgSO4, 0.1; MnSO4, 0.03.

The optimal fermentation medium without waste for B. subtilis A34, in g/L: glucose, 36; tryptone, 9; L-glutamate, 28; K2HPO4·3H2O, 2; MgSO4, 0.25 (Zhang et al., 2019b).

Enzymatic hydrolysate medium (EM): enzymatic hydrolysate, 550 mL; tryptone, 9 g/L; L-glutamate, 28 g/L; K2HPO4·3H2O, 2 g/L; MgSO4, 0.25 g/L. The pH was adjusted to 7.0 by HCl or NaOH.

All media were autoclaved for 20 min at 121 °C.

2.4 Pretreatment of poplar sawdust

Poplar sawdust was pretreated with solid-liquid ratio of 1:10. The solution was 5% acetic acid, 10% NH3OH and water respectively. They were put it in the sterilizer at 121 °C for 2 h. After the heat preservation, the sterilizer was cooled down to 80 °C. The sawdust was removed from the sterilizer and cooled it in cold water to room temperature. The washing volume multiple was defined as the ratio of the washing volume used to detoxify the pretreatment solution to the volume of the pretreatment solution. Wash thoroughly meant that the pH of washing solution was neutral and colorless. The purpose of water washing was to remove furfural, acetic acid and other harmful substances adsorbed on solid residues. The washed solid was dried in an oven at 105 °C to constant weight.

2.5 Preparation of enzymatic hydrolysate

The pretreated poplar sawdust was placed in a 500 mL triangular flask, added with cellulase, and placed in a constant temperature incubator for enzymolysis. After enzymolysis, the enzyme was quickly killed (boiling water bath for 10 min). After centrifugation at 4 000 r/min for 10 min, the supernatant was cellulase hydrolysate.

2.6 Culture method

The γ-PGA production by B. subtilis A34 was conducted in 5-L bioreactor (Baoxing Corp., Shanghai, China) containing 3-L fermentation medium inoculated with 10% seed culture. The temperature and pH of the fermentative broth were maintained at 37 °C and 7.0.The broth was cultured at 200 rpm for 60 h. Three replicates were carried out for each experiment.

2.7 Analysis method

According to the method in the literature, the content of poplar sawdust components were determined (Bule et al., 2013). The content of cellulose was expressed as the ratio of the mass of glucose to the mass of raw material. The content of hemicellulose was expressed by the mass of xylose and arabinose and the ratio of xylose to raw material. The calculation formula were shown in equations (1) and (2).

Wh was hemicellulose content (mass fraction, %), M2 was the mass of xylose in hydrolysate (g), M3 was the mass of arabinose in hydrolysate (g).

The glucose content was determined by SBA-40D biosensor. Cellulose conversion rate was calculated according to equation (3).

The γ-PGA yield was measured by gel permeation chromatography (GPC) system following the method reported previously (Wu et al., 2006). Dry cell weight was determined after the cells were precipitated from 30 mL fermentation broth, washed once with distilled water, and dried at 105 °C overnight.

3 Results and discussion

3.1 Determination of pretreatment method

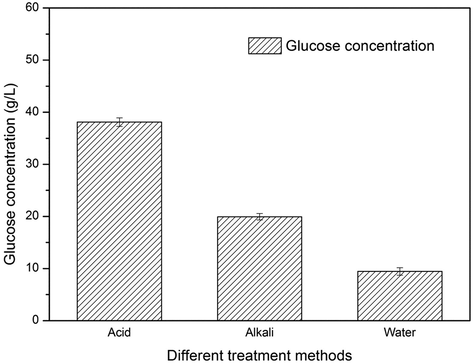

Fig. 1 shows the comparison of water, acid and alkali pretreatment. Acid pretreatment significantly increased the concentration of glucose in the hydrolysate. The principle might be that the acid treatment increased the contact area of sawdust and made the enzymolysis reaction fully carried out (Carvalho et al., 2013). The results showed that the sawdust treated by acid was more suitable for the biotransformation of energy.

Effect of pretreatment methods on glucose concentration.

As shown in Table 1, compared with the raw material, the content of cellulose in the solid residue by washing thoroughly after pretreatment was increased by 50.8%, and the content of hemicellulose was decreased by 85.4%. It showed that the effect of pretreatment was very obvious, and most of hemicellulose could be dissolved. Due to the limited degradation of lignin by dilute acid, most of the lignin was retained.

3.2 Effect of washing volume on enzymatic hydrolysis

Dilute acid pretreatment can effectively improve the enzymatic hydrolysis effect of cellulose. The principle is that hemicellulose is degraded into monosaccharide or oligosaccharide in dilute acid solution, resulting in cellulose expansion and increase of specific surface area, which is conducive to the decomposition of cellulose by cellulase, thus improving the conversion rate of cellulose. In the pretreatment process, the degradation products of sugars such as furfural, hydroxymethyl furfural, formic acid and acetic acid can significantly inhibit the activity of cellulose (Szengyel and Zacchi, 2000). Therefore, it is necessary to detoxify the pretreated lignocellulosic materials. The simplest and most effective method for detoxification is washing. That is to say, a large amount of water is used to remove furfural, acetic acid and other harmful substances in the sawdust residue, and then cellulase is added for enzymatic hydrolysis. Table 2 showed the enzymatic hydrolysis of solid residues under different washing volumes. Ten g of 0, 5, 10 times volume of water washed solid sawdust residue were taken respectively, added 60 mL water, and shook well. The cellulose conversion of sawdust residue in different washing volumes was 25.73%, 40.52%, 46.94% and 53.93%, respectively. The conversion rate of cellulose of sawdust residue washed with water was 2.1 times of that without detoxification. From the economic point of view, although the full water washing method could improve the cellulose conversion rate, it needed to consume a lot of water resources. Therefore, considering the conversion rate of cellulose and economy, 10 times of washing volume of solid residue was selected to explore the optimal conditions of enzymatic hydrolysis.

Washing volume multiple

Glucose concentration (g/L)

Cellulose conversion (%)

0

24.12 ± 0.46

25.73 ± 0.43

5

38.11 ± 0.32

40.52 ± 0.43

10

41.53 ± 0.54

46.94 ± 0.51

Wash thoroughly

52.57 ± 0.42

53.93 ± 0.55

3.3 Effect of solid-liquid ratio on enzymatic hydrolysis

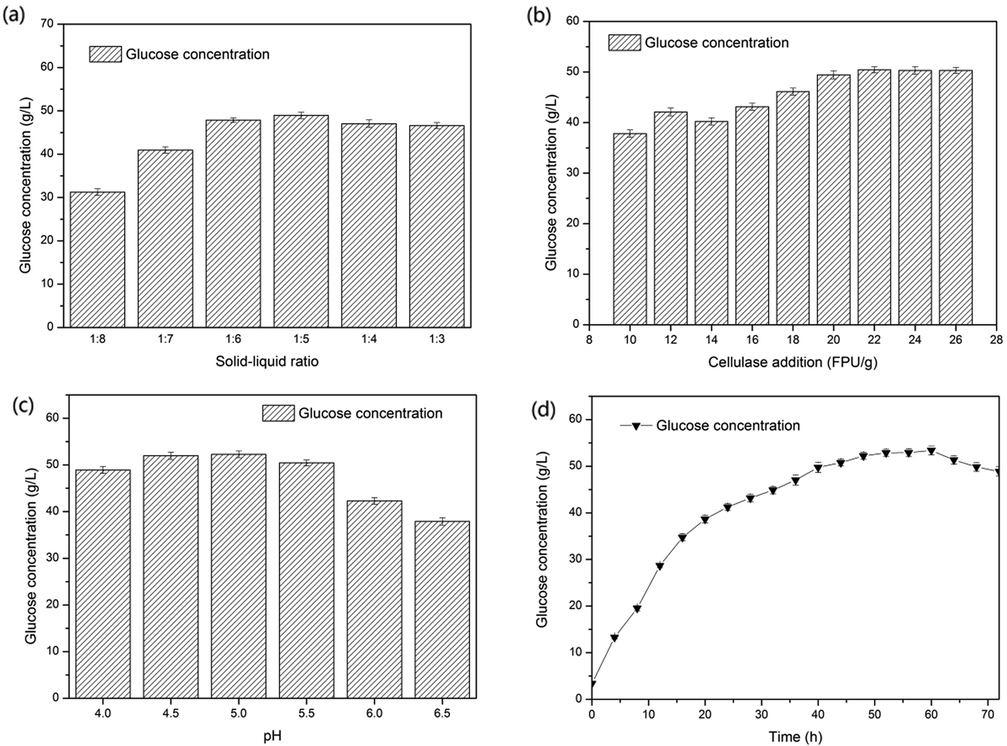

The solid-liquid ratio is expressed as the ratio of dried sawdust mass to buffer volume (g/mL). The solid-liquid ratio determines the upper limit of reducing sugar concentration in the hydrolysate. When the substrate is sufficient and the heat and mass transfer is good, the enzymatic hydrolysis effect is good. Under the conditions of cellulase dosage 20 FPU/g, pH 5.5, 50 °C, hydrolysis for 48 h, the conversion of cellulose under different solid-liquid ratio was investigated, and the results were shown in Fig. 2(a). In the range of the solid-liquid ratio, the glucose concentration increased with the increase of the solid-liquid ratio, while the cellulose conversion first increased and then decreases. When the solid-liquid ratio was 1:5, the glucose concentration reached the maximum. Therefore, the solid-liquid ratio of 1:5 was determined as the amount of substrate.

Effect of enzymatic hydrolysis conditions on glucose concentration. (a) solid-liquid ratio; (b) enzyme dosage; (c) pH; (d) hydrolysis time.

3.4 Effect of cellulase addition on enzymatic hydrolysis

The high price of cellulase required a balance between the amount of cellulase added and the rate of enzymatic hydrolysis. Under the conditions of solid-liquid ratio of 1:5, pH 5.5, 50 °C for 48 h, the effect of cellulase addition on enzymatic hydrolysis was investigated. It can be seen from Fig. 2(b) that when the cellulase amount increases from 10 FPU/g to 22 FPU/g, the glucose concentration in the hydrolysate increases from 37.82 ± 0.75 g/L to 50.45 ± 0.61 g/L. On this basis, the glucose concentration remained unchanged with the increase of enzyme amount. This was because the binding sites of cellulose were limited, and the excess enzyme could not effectively attack these sites, so the optimal enzyme dosage was 22 FPU/g.

3.5 Effect of pH on enzymatic hydrolysis

Cellulase is a complex protein enzyme system composed of a variety of hydrolases, and its activity is closely related to pH. Under the conditions of solid-liquid ratio of 1:5, enzyme dosage of 22 FPU/g, 50 °C for 48 h, the enzymatic hydrolysis of poplar sawdust in different pH systems was investigated. It can be seen from Fig. 2(c) that with the increase of pH, glucose concentration increases first and then decrease synchronously. When the pH was 5, the glucose concentration was the highest and the enzymolysis effect was the best. Therefore, the optimum pH of enzymolysis was 5.

3.6 Effect of time on enzymatic hydrolysis

The cellulase hydrolysis of poplar sawdust in 0–72 h was investigated, as shown in Fig. 2(d). The glucose concentration was analyzed. When the enzymolysis time was more than 52 h, the glucose concentration did not increase. So the optimal enzymolysis time was 52 h.

3.7 Optimization of enzymatic hydrolysis conditions

The single factor experiment only considers the influence of a single variable on the results. Because these single factors influence each other, the best result is not necessarily a combination of single factor results. The orthogonal experiment generally considers the combination effect of multiple factors, so it is necessary to do the orthogonal experiment after the single factor experiment. The enzymatic hydrolysis conditions of sawdust were optimized. Solid-liquid ratio (A), enzyme dosage (B), pH (C) and hydrolysis time (D) were selected. Each factor had four levels. L16 (44) was used to optimize the enzymatic hydrolysis conditions of sawdust with glucose concentration as the evaluation index. The results were shown in Table 3 and Table 4. * RATIO: solid-liquid ratio (mL/g).

Trial no.

A RATIO (g/ mL)

B Dosage (FPU/g)

D pH

E Time(min)

Glucose concentration (g/L)

1

1:7

20

4.0

51

35.44 ± 0.44

2

1:7

21

4.5

52

38.82 ± 0.65

3

1:7

22

5.0

53

46.92 ± 0.31

4

1:7

23

5.5

54

32.11 ± 0.34

5

1:6

20

4.5

53

47.98 ± 0.36

6

1:6

21

4.0

54

48.05 ± 0.38

7

1:6

22

5.5

51

45.76 ± 0.62

8

1:6

23

5.0

52

43.54 ± 0.52

9

1:5

20

5.0

54

52.26 ± 0.39

10

1:5

21

5.5

53

50.82 ± 0.33

11

1:5

22

4.0

52

48.16 ± 0.39

12

1:5

23

4.5

51

46.22 ± 0.33

13

1:4

20

5.5

52

48.88 ± 0.47

14

1:4

21

5.0

51

48.66 ± 0.66

15

1:4

22

4.5

54

48.99 ± 0.42

16

1:4

23

4.0

53

48.60 ± 0.64

k1

38.322

46.140

45.062

44.020

k2

46.322

46.587

45.502

44.850

k3

49.365

47.458

47.845

48.580

k4

48.782

44.392

44.392

45.352

R

11.043

4.841

3.453

4.560

Factors

SS

df

F

F0.05

Significant

A

311.046

3

11.250

9.280

*

B

54.287

3

1.963

9.280

C

27.024

3

0.977

9.280

D

47.840

3

1.730

9.280

Error

27.65

3

Table 3 showed that the order of influencing factors was A > B > D > C. Table 4 showed that factor A (i.e. the solid-liquid ratio) had a significant effect on the enzymatic hydrolysis of sawdust (P < 0.05), while factor B, C and D had little effect (P > 0.05). Therefore, the optimal conditions were as follows: A3B3C3D3, that was, solid-liquid ratio 1:5, enzyme amount 22 FPU/g, pH 5.0 and 53 min. Under the optimal conditions, the concentration of glucose was 53.17 ± 0.48 g/L.

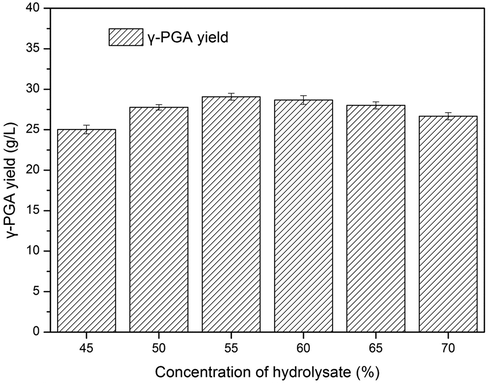

3.8 Effect of hydrolysate concentration on γ-PGA yield

Because of using sawdust hydrolysate instead of glucose to produce γ-PGA, it was necessary to investigate the optimal concentration of the hydrolysate. The results are shown in Fig. 3. The optimal concentration of the hydrolysate was 55%. The optimal medium for γ-PGA production was 36 g/L glucose (Zhang et al., 2019b). According to the previous experimental results, the concentration of glucose in the hydrolysate was 53.17 ± 0.48 g/L. It should be 67.92% of the hydrolysate concentration to reach 36 g/L glucose concentration. However, Fig. 3 showed that the optimal concentration of the hydrolysate was 55%. This indicated that B. subtilis could use not only glucose in the hydrolysate as carbon source, but also other carbon sources in the hydrolysate, such as xylose.

Effect of hydrolysate concentration on γ-PGA production.

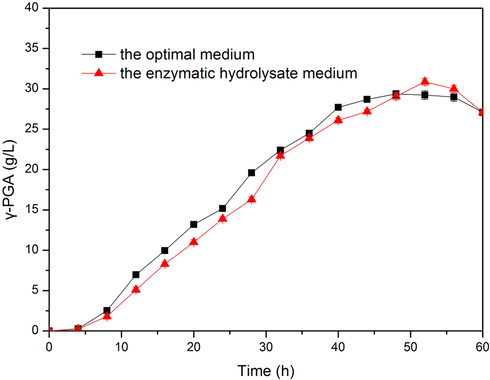

3.9 Comparison of different media on γ-PGA production

In order to further illustrate the feasibility of sawdust enzymatic hydrolysate as carbon source, the enzymatic hydrolysate medium and the optimal medium were put together for comparison. The results are shown in Fig. 4. At 0–36 h, the γ-PGA yield in enzymatic hydrolysate medium was always lower than that in the optimal medium. At 36–48 h, the γ-PGA yield in the enzymatic hydrolysate medium gradually approached the optimal medium. At 48 h, the γ-PGA yield in the enzymatic hydrolysate medium was higher than that in the optimal medium. At 52 h, the γ-PGA yield in the enzymatic hydrolysate medium reached the maximum. The results showed that the enzyme hydrolysate medium could completely replace the optimal medium for B. subtilis, and the γ-PGA yield was 5.11% higher than the optimal medium (30.87 ± 0.44 g/L VS 29.37 ± 0.43 g/L). However, the disadvantage of enzymatic hydrolysate medium was that the fermentation time of γ-PGA maximum yield was delayed by 4 h. Although there was a gap between the γ-PGA production in this study and that reported in the literature, it was mainly due to different strains (Yao et al., 2010; Li et al., 2020). Comparisons of various technologies for γ-PGA production using different carbon sources were summarized in Table 5. The above results showed that it was feasible to produce γ-PGA from sawdust hydrolysate. Although the fermentation time was extended by 4 h, the technology still had great development potential from the perspective of utilization of poplar sawdust waste and saving glucose consumption.

Fermentation curve in different media.

Forms

Carbon source

γ-PGA (g/L)

Carbon source price (dollar/kg)

Is waste used?

Remarks

Reference

Traditional technologies 1

Glucose

42

0.5–0.6

No

γ-PGA yield was higher than that in this study, mainly due to different strains.

Yao et al., 2010

Traditional technology 2

sodium citrate and soybean meal extract

42.55

0.7–0.8

No

γ-PGA yield was higher than that in this study, mainly due to different strains.

Li et al., 2020

This study

Poplar sawdust

30.87 ± 0.44

0

Yes

In summary, this technology had the following advantages: (1) the recycling of poplar sawdust was realized; (2) the amount of glucose added to the medium was saved, and the comprehensive utilization of various sugars in sawdust enzymatic hydrolysate was realized; (3) γ-PGA yield in the enzymatic hydrolysate medium was even 5.11% higher than that in glucose medium. Although the fermentation time was extended by 4 h, the difference of fermentation time could be gradually narrowed by improving the strain and further optimizing the medium.

4 Conclusion

The reuse of forestry waste has always been a difficult problem, and the high production cost of γ-PGA has always limited its application. In this study, the enzymatic hydrolysate of poplar sawdust was used to produce γ-PGA. The pretreatment methods of acid, alkali and water were studied. The results showed that acid treatment had the best effect. Then the enzymatic hydrolysis conditions of sawdust were studied. Through single factor and orthogonal experiments, the optimum enzymatic conditions were determined as follows: solid-liquid ratio 1:5, enzyme amount 22 FPU/g, pH 5.0 and 53 min. Under the enzymatic hydrolysate medium, the yield of γ-PGA reached 30.87 ± 0.44 g/L, which was 5.11% higher than that in glucose medium(29.37 ± 0.43 g/L). In addition, the amount of glucose added to the medium was reduced, which realized the comprehensive utilization of various sugars in sawdust enzymatic hydrolysate. Although the fermentation time was prolonged by 4 h, this study provided a new and feasible method for the industrial utilization of forestry waste and the clean production of γ-PGA.

CRediT authorship contribution statement

Chao Zhang and Huixue Ren conceived of the study. Chao Zhang designed experiments, analyzed data, and performed experiments with assistance from Chuanqing Zhong. Chao Zhang drafted the manuscript. All authors read and approved the final manuscript.

Acknowledgments

This research was financially supported by State Key Laboratory of Microbial Technology (M2012-14), Shandong University.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Adsorption characteristics for the removal of a toxic dye, tartrazine from aqueous solutions by a low cost agricultural by-product. Arab. J. Chem. 2017

- [CrossRef] [Google Scholar]

- Structural modification of lignin and characterization of pretreated wheat straw by ozonation. J. Agric. Food Chem. 2013

- [CrossRef] [Google Scholar]

- Xylo-oligosaccharides from lignocellulosic materials: Chemical structure, health benefits and production by chemical and enzymatic hydrolysis. Food Res. Int. 2013

- [CrossRef] [Google Scholar]

- Chin, O.F., 1998. Study on High - yield Cultivated Techniques of Using Scraps of Willow to Grow Auricularia auricula.

- Potential of Poplar Bark Phytochemicals as Value-Added Co-products from the Wood and Cellulosic Bioethanol Industry. Bioenergy Res. 2015

- [CrossRef] [Google Scholar]

- Guang-yao, Z., Chun-qin, X.I.E., Cai-ying, B.O., Gui-hua, Z., Zhen-lin, X.I.E., 2013. Experimental cultivation of Pleurotus cortmcopiae and Flammulina velutipes by partially.pdfusing poplar sawdust or poplar bark as a substitute for cottonseed hull 40, 47–50. https://doi.org/10.13610/j.cnki.1672-352x.2013.01.020.

- Enhancement in the enzymatic digestibility of hybrid poplar with poor residual hemicelluloses after Na2SO3 pretreatment. Bioresour. Technol. 2015

- [CrossRef] [Google Scholar]

- Impact of lignin polymer backbone esters on ionic liquid pretreatment of poplar. Biotechnol. Biofuels. 2017

- [CrossRef] [Google Scholar]

- Microbial synthesis of poly-γ-glutamic acid (γ-PGA) with fulvic acid powder, the waste from yeast molasses fermentation. Biotechnol. Biofuels. 2020

- [CrossRef] [Google Scholar]

- Microbial synthesis of poly-γ-glutamic acid: Current progress, challenges, and future perspectives. Biotechnol. Biofuels. 2016

- [CrossRef] [Google Scholar]

- Adsorption of bentazon on activated carbon prepared from Lawsonia inermis wood: Equilibrium, kinetic and thermodynamic studies. Arab. J. Chem. 2016

- [CrossRef] [Google Scholar]

- Removal of malachite green dye from aqueous solution with adsorption technique using Limonia acidissima (wood apple) shell as low cost adsorbent. Arab. J. Chem. 2017

- [CrossRef] [Google Scholar]

- Effect of acetic acid and furfural on cellulase production of Trichoderma reesei RUT C30. Appl. Biochem. Biotechnol. - Part A Enzym. Eng. Biotechnol. 2000

- [CrossRef] [Google Scholar]

- Biosynthesis of poly(γ-glutamic acid) in Bacillus subtilis NX-2: Regulation of stereochemical composition of poly(γ-glutamic acid) Process Biochem. 2006

- [CrossRef] [Google Scholar]

- A review on the operating conditions of producing bio-oil from hydrothermal liquefaction of biomass. Int. J. Energy Res. 2016

- [CrossRef] [Google Scholar]

- Analysis of carbon metabolism and improvement of γ-polyglutamic acid production from bacillus subtilis NX-2. Appl. Biochem. Biotechnol. 2010

- [CrossRef] [Google Scholar]

- Stimulatory effects of amino acids on γ-polyglutamic acid production by Bacillus subtilis. Sci. Rep. 2018

- [CrossRef] [Google Scholar]

- Economical production of agricultural Γ-polyglutamic acid using industrial wastes by Bacillus subtilis. Biochem. Eng. J. 2019

- [CrossRef] [Google Scholar]

- Fishmeal Wastewater as A Low-Cost Nitrogen Source for γ-Polyglutamic Acid Production Using Bacillus subtilis. Waste Biomass Valorizat. 2019

- [CrossRef] [Google Scholar]