Translate this page into:

Study of rheological behavior of a hybrid nano-lubricant (MWCNT-Al2O3 (20:80)/SAE40) using two-way laboratory method and response surface methodology

⁎Corresponding authors. Toghraee@iaukhsh.ac.ir (Davood Toghraie)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Peer review under responsibility of King Saud University.

Abstract

Rheological behavior of MWCNT/Al2O3 (20:80)-SAE40 hybrid nano-lubricant was investigated. This study aimed to identify the most optimal laboratory conditions in lubrication. We presented the correlation in predicting experimental data. A quadratic-three-variable model was used in the response level methodology (RSM). Margin of Deviation (MOD) was within the allowable range − 3.51 % <MOD < 3.15 %.

Abstract

In this paper, the rheological performance of MWCNT-Al2O3 (20:80)/SAE40 hybrid nano-lubricant (HNL) investigated and analyzed with different methods. The ranges of temperature, shear rate and volume fraction of nanoparticles (NP) are T = 25–50 °C, =666.5 s−1 to 13330 s−1 and = 0.0625–1 %. This study was conducted to investigate and determine the most optimal laboratory conditions in lubrication and provide a relationship to predict experimental data and investigate the effect of dispersion of NP on the base fluid (BF) and the average wall shear stress. The results show that in different laboratory conditions, the desired HNL flow behavior is pseudo-plastic, non-Newtonian. It is found that viscosity ( ) decreases, increases and decreases with increasing temperature (T), and , respectively. The highest increase 35.69 % in is recorded in the studied conditions. A quadratic-three-variable model with a coefficient of determination R-Squared = 0.9993 is used in the response surface methodology (RSM) to predict the experimental data. . The diagram of dynamic viscosity changes for this model under the influence of temperature, shear rate and volume fraction parameters was presented. Temperature parameter has the most effect on viscosity. The theoretical method in this study reduces many laboratory costs and increases the speed of obtaining results.

Keywords

Hybrid NLs

Rheological conduct

Viscosity

SAE40 oil

RSM

experimental data

1 Introduction

From the point of view of most researchers in the world, nanotechnology has been able to create many developments in the engineering sciences and various other branches in the last two decades, and for this reason, it is one of the interesting topics for researchers' research (Sun et al., 2021; Du et al., 2022; Wang et al., 2019; Cui et al., 2022; Tassew et al., 2022; Dwijendra et al., 2022; Mansouri et al., 2017; Suhad et al., 2021; Azin and Pourghobadi, 2021). Perhaps one of the most important applications of nanotechnology is in the field of fluid mechanics and heat transfer, which causes these two fields to have significant changes in indicators such as efficiency. Since ancient times, fluids were widely used in various fields such as heat transfer, lubrication, etc. (Putra, 2020; Wenhao et al., 2022; Yang et al., 2017; Li et al., 2022; Jia et al., 2022; Wang et al., 2022). Choi made the initial discovery of nanofluids (NFs) in 1995 at the National Argon Laboratory (ANL) (Choi and Eastman, 1995). Several investigators as innovators in this subject have worked on the thermal properties of NFs as a new fluid by advanced attributes (Jafarimoghaddam and Aberoumand, 2016; Aberoumand et al., 2015; Aberoumand et al., 2016). The thermal conduct of NFs belongs to some main parameters like thermal conductivity (

), viscosity (

), and heat capacity (Kole and Dey, 2010). Among the properties, the two properties of

and

have attracted the most attention (Afrand et al., 2016; Akbari et al., 2017; Mahyari et al., 2019; Ruhani et al., 2019a,b, 2022). Most investigators have presented that the

and

of NFs are higher than the BFs, because the addition of NPs increases the

and knf (Shahsavani et al., 2018; Yang et al., 2020; Nafchi et al., 2019) (See Fig. 1). By examining the rheological behavior of NFs, it is concluded that NPs not only increase the

but also alter the NFs from Newtonian to non-Newtonian (Dalkilic et al., 2016). Heat capacity plays a vital role in determining the capacity and performance of a fluid. The max the

, the more heat can be transferred by liquids from systems. On the other hand, increasing the

in systems is important because the flow characteristics like Reynolds number, heat transfer cofficient (HT), and pressure drop depend on the

(Siddiqui et al., 2019; Sidik et al., 2014). Also, the pipe geometry the through which the liquid flows is one of the significant parameters that can modify the rate of HT. Various pipe shapes can also increase HT, including secondary flow due to curvature in curved pipes and centrifugal force increasing the HT coefficient in spiral pipes (Razi, n.d.; Arani et al., 2016; Goharkhah et al., 2016). The use of helical tubes is one of the most common procedures for improving the HT of heat exchangers in many industries and devices such as heating systems, automotive industries, and power plants (Rakhsha et al., 2015). In helical tubes, the radial velocity is created by centrifugal force, and the flow of fluid outside the pipe is faster. This difference in velocity creates a secondary flow. Using spiral pipes instead of straight pipes, curved streamlines replace direct streamlines and increase HT, and as a result, the size of fluid flow pipes becomes smaller and the HT coefficient also increases (Mirgolbabaei et al., 2011; Jayakumar et al., 2010; Aly, 2014).

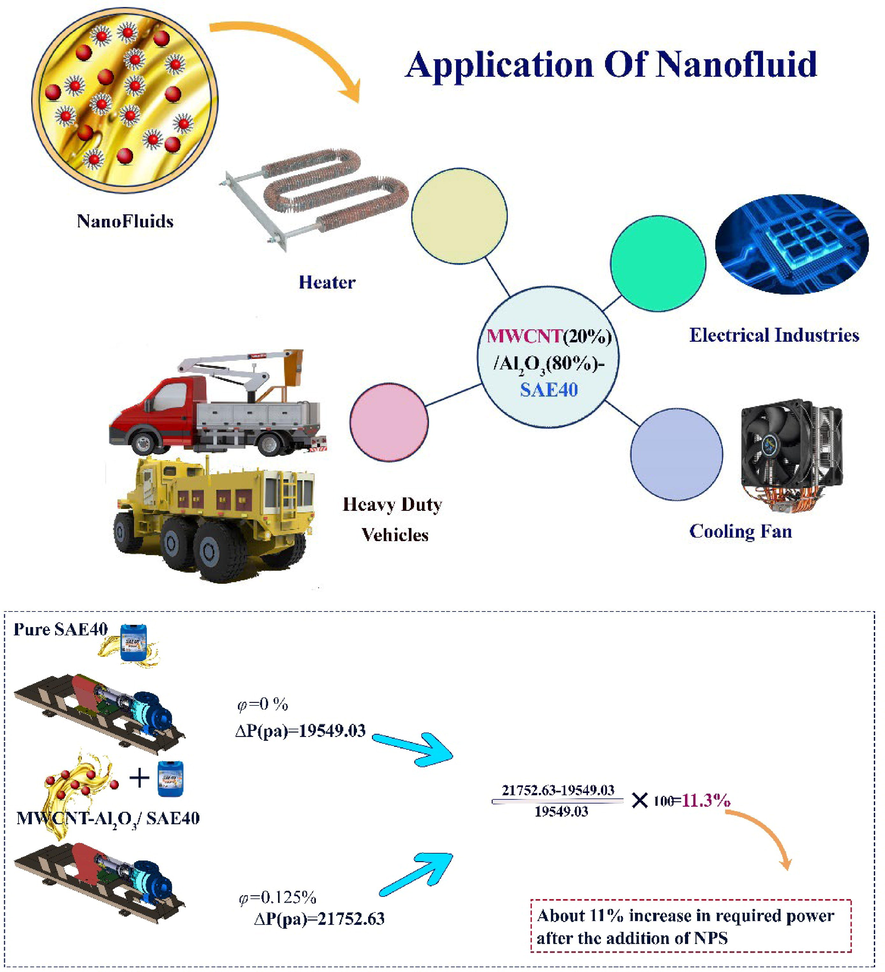

Applications of NFs.

In addition to assessing the type and classification of fluids, researchers are interested in studying the trend of

changes and its response to independent variables such as T,

and

. Table 1 reports the percentage increase in the

s with the addition of NPs in some studies.

Ref.

NPs

BFs

The highest percentage change in

lowest percentage change in

(Moghaddam and Motahari, 2017)

MWCNT-CuO

SAE40

Maximum percentage change in μnf (at T = 50 °C and φ = 1 %) = + 75 %

Minimum percentage change in μnf (at T = 25 °C and φ = 0.0625 %) = + 0.19 %

(Esfe and Alidoust, 2020)

MWCNT-Al2O3

5 W50

Maximum percentage change in μnf (at T = 55 °C, φ = 1 %) + 6 %

Minimum percentage change in μnf (at T = 15 °C, φ = 0.05 %) = -11 %

(Dardan et al., 2016)

MWCNT- Al2O3

SAE40

Maximum percentage change in μnf (at T = 35 °C, φ = 1 %)= +1.45 %

Minimum percentage change in μnf (at T = 50 °C, φ = 0.0625 %)= +1.12 %

(Tian et al., 2020)

MWCNT- Al2O3

10 W40

Maximum percentage change in μnf (at T = 65 °C, φ = 1 %) = 30.53 %

Minimum percentage change in μnf (at T = 25 °C, φ = 0.05 %) = 13.87 %

(Asadi et al., 2016)

MWCNT- MgO

SAE50

Maximum percentage change in μnf (at T = 40 °C, φ = 2 %)= +65 %

Minimum percentage change in μnf (at T = 25 °C, φ = 25 %)= +1404 %

(Liu et al., 2021)

MWCNT-TiO2

SAE20W40

Maximum percentage change in μnf (at T = 70 °C, φ = 0.8 %)= +24.42 %

Minimum percentage change in μnf (at T = 20 °C, φ = 0.1 %)= +5.75 %

(Chu et al., 2021)

MWCNT-TiO2

5 W40

Maximum percentage change in μnf (at T = 60 °C, φ = 1 %)= +25 %

Minimum percentage change in μnf (at T = 20 °C, φ = 0.05 %) = -1%

(Afrand et al., 2016)

MWCNT-SiO2

SAE40

Maximum percentage change in μnf (at T = 50 °C, φ = 1 %)= +25.8 %

Minimum percentage change in μnf (at T = 30 °C, φ = 0.0625 %)= +9.92 %

(Binu et al., 2014)

MWCNT- TiO2

SAE40

Maximum percentage change in μnf (at T = 50 °C, φ = 1 %)= +40 %

Minimum percentage change in μnf (at T = 25 °C, φ = 0.05 %) = 0 %

Sujith et al. (Sujith et al., 2021; Sujith et al., 2019) investigated the rheological behavior of NLs in their recent studies. For example, they investigated the rheological behavior and density of MoS2/sesame oil NLs. The results show that at different temperatures from 313 to 393 K, between 10 and 70 s−1 and from 0.2 % to 1.2 %, the and density of NLs increases with increasing and decreases with increasing temperature. In another study, investigating the viscosity of pure coconut oil/Al2O3 NLs with different of 0.2 % to 1.2 % was desired. By measuring the , the effect of and temperature on the thermophysical properties of coconut oil/Al2O3 NLs was determined. Based on the results, the of NLs decreases with increasing temperature, while it increases with increasing the number of NPs in the BF. Also, NLs show a relative viscosity > 1, which indicates the decisive effect of NPs desired NF. Hemmat's research group (HRG) has specialized in many of its studies (Esfe and Arani, 2018; Esfe and Sarlak, 2017; Esfe et al., 2022; Esfe et al., 2022) by using the RSM to forecast the thermophysical and rheological properties of different NFs. These studies forecast the or of NFs, a new relationship was presented that helps researchers to achieve results with high speed and accuracy without the need to spend exorbitant laboratory costs. In this examination, the changes in the conduct of rheological and comparison of of MWCNT -Al2O3 (20:80)/ SAE40 HNL at various T, and were studied. HNLs will be contrasted in distinct parts by various targets in this investigation. In the initial section of the article, the kind of HNLs (Newtonian and non-Newtonian) is investigated with the offered procedures. In the next part, the role of the HNL state in the enhancement of the life of components and promotion is considered. Finally, to avoid reducing laboratory costs and time, as well as verifying the accuracy of modeling predictive data relative to experimental data by the RSM, a three-variable mathematical relationship (T, and ) was selected to forecast the of the selected HNL. Eventually, the computation of the thermal performance for various conditions displays that the utilization of HNLs and coils of helical instead of the BF and straight pipes progresses the efficiency of HT.

2 Experimental process

2.1 Samples provision

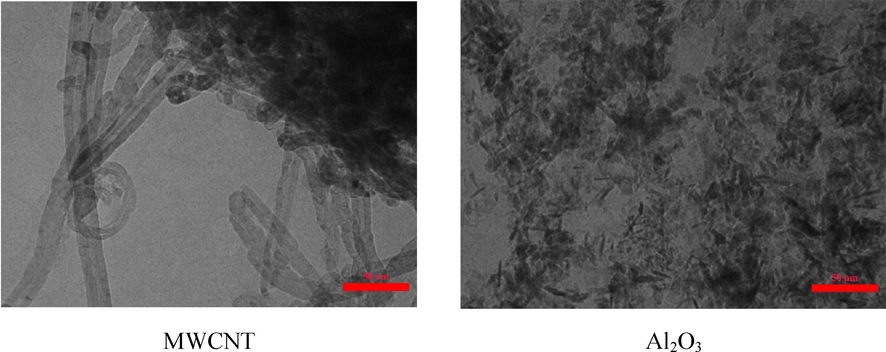

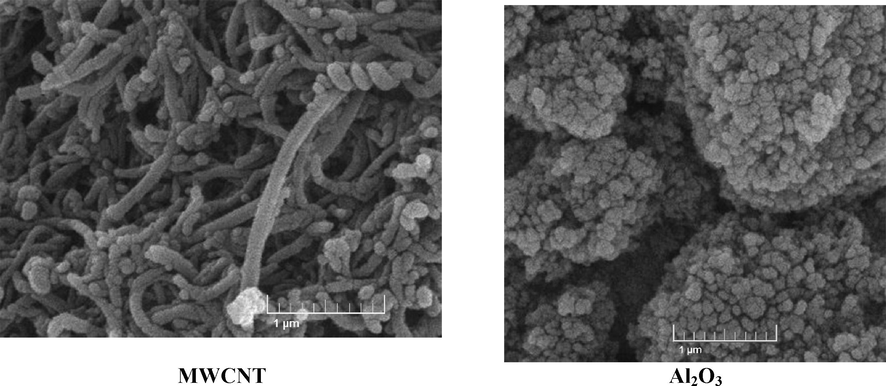

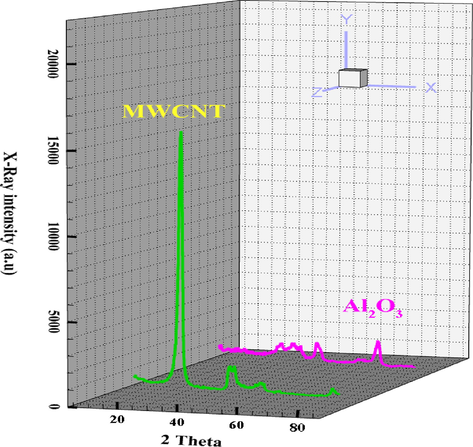

For the purpose of experimental tests, first, using the desired NPs (purchased from Sigma Aldrich), HNLs with different

are prepared. Fig. 2 shows the NPs. Eq. (1) was used to calculate the amount of NP samples at

= 0.0625 %, 0.125 %, 0.25 %, 0.5 %, 0.75 % and 1 %.

The used NPs.

Table 2 lists some specifications of NPs.

NPs

Purity

Color

True density

APS

SSA

Morphology

MWCNTs

> 95 wt%

Black

∼ 2.1 g/cm3

ID: 3–5 nmOD: 5–15 nm ∼ 50 um (Length)

> 233 m2/g

Cylindrical

Al2O3

≥ 99 %

White

3.97 g/cm3

20 nm

138 m2/g

nearly spherical

To recognize the attributes of the morphology of NPs and SEM images and XRD were utilized to confirm the nanoscale. MWCNT and Al2O3 NPs of specified sizes were used in a specified combination ratio. Pictures of 2D and 3D XRD, and SEM of NPs are shown in Fig. 3.

Images of 2D and 3D XRD, and SEM of NPs.

Images of 2D and 3D XRD, and SEM of NPs.

Images of 2D and 3D XRD, and SEM of NPs.

After weighing the NPs, to disperse the NPs to create the stable HNLs according to the two-stage technique, the magnetic stirrer was utilized for stability, prevent agglomeration, and sedimentation. Ultrasonic vibration was utilized to achieve excellent dispersion and stop the creation of NP clusters for 3 h. To stabilize the homogenized suspensions, they were located in an ultrasonic machine for 6 h. After around 3 weeks, solutions had no sedimentation, and HNLs were without sedimentation.

2.2 Measurement of

After making the HNL, the viscometer CAP2000+ was utilized to gage the

. The operating conditions of the viscometer are given in Table 3. The

was gaged in various

and at T = 25 °C to 50 °C in addition to

666.5 s−1 and 13330 s−1. Before measuring the

, to confide the efficiency of the viscometer and adjustment of the machine, the glycerin μ has experimented with at T = 85.26 °C, and it was seen that the acquired mistake was 93.2 %.

3 Outcomes and conversation

3.1 Conduct of rheological behavior

3.1.1 Influence of

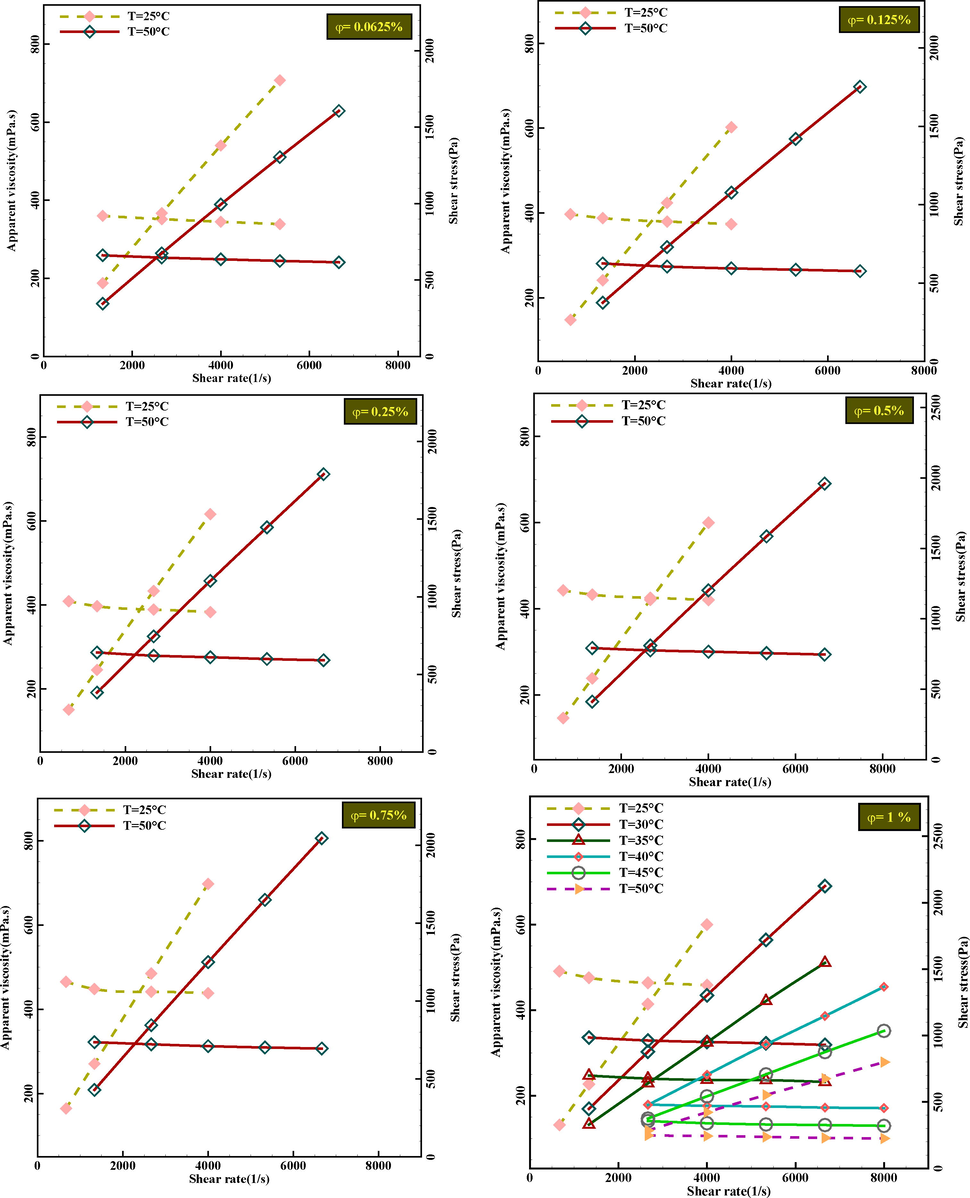

Fig. 4 shows the conduct of the rheological of NLs using the fitting of

-

-shear stress curves. This curve simultaneously examines the effect of critical factors such as rate of shear and stress of shear on the

. In all

, the

can be considered dependent on the two mentioned parameters. It seems that with increasing

, the

reduces slightly because of considerations of shear heating. With injecting

, the

was enhanced, which shows the effect of

. In this case, the dependence of the

on the

is slightly higher. Also, in the conduct of these diagrams, it can be observed that there is pseudo-plastic non-Newtonian conduct (He, 2020). Also, Hemmat Esfe research group in the past years (Esfe et al. 2018, Esfe et al. 2018) specifically and comprehensively investigated the rheological behavior of different nanofluids.This phenomenon can be assigned to the mechanisms of the BF with the hybrid NPs and the creation of particular and intricate interactions among them. As φ increases, the influence of the variations is improved. Thus, non-Newtonian behavior emerges.

The

and stress stress versus..

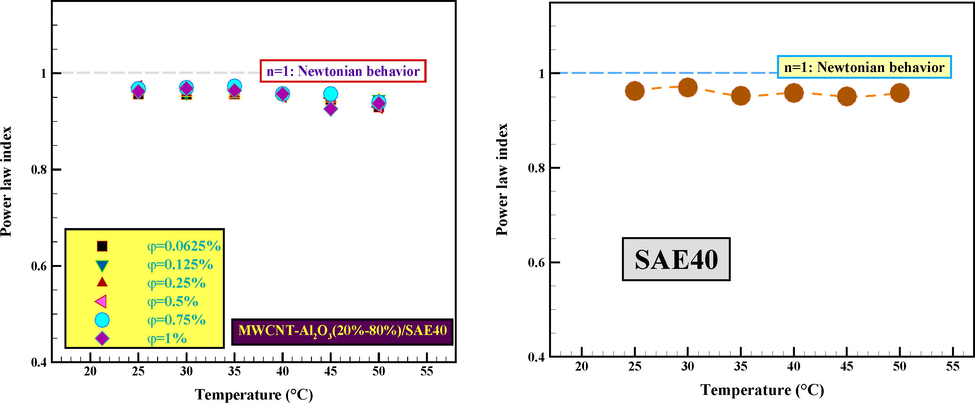

3.1.2 Index of power-law

If the conduct of rheological of NLs using the power-law model was considered, Eq. (2) (Esfe et al., 2022) could be used,

The power-law model using n values determines the fluid behavior. In Fig. 5, the rheological behavior of the BF was compared with that of HNLs. Most of the change in HNL behavior occurs at T = 45 °C and 50 °C. At these T, the prepared HNL is more prone to strong non-Newtonian conduct. According to Fig. 5 and Table 4, the most non-Newtonian tendency of HNL behavior occurs under certain conditions (

1 % and T = 45 °C) with an index of power-law of 0.9259.

Influence of T and

on an index of power-law.

HNL T (°C)

(%)

25

30

35

40

45

50

MWCNT-Al2O3 (20:80)/SAE40

0.0625

0.9573

0.9562

0.9569

0.9554

0.9455

0.93

0.125

0.9667

0.9594

0.9642

0.9556

0.9568

0.9463

0.25

0.9643

0.9591

0.9565

0.9527

0.9481

0.9443

0.5

0.9715

0.970

0.967

0.9528

0.9486

0.9301

0.75

0.9676

0.9699

0.9729

0.9573

0.9571

0.9396

1

0.962

0.9686

0.9641

0.9571

0.9259

0.9374

SAE40

0

0.9626

0.9701

0.9524

0.9585

0.9511

0.9584

3.2 μ analogy

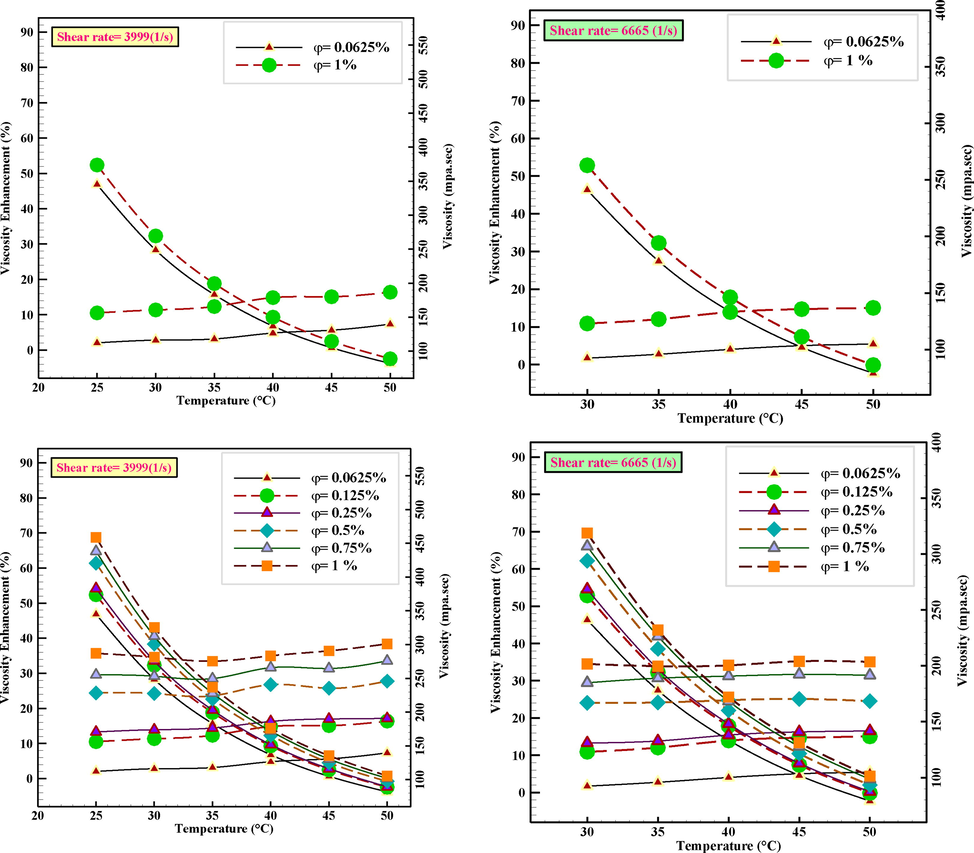

3.2.1 μ increasing

In Fig. 6, the μ-increasing and μ curves were merged based on the T variable and all

. According to Table 5, which reports the statistical results of μ enhancement percentage, from

= 0.0625 % to

= 1 %, approximately 33 % increase in

is observed. The lowest μ enhancement was 1.72 % at 500 RPM and φ = 0.0625 % based on the outcomes.

μ enhancement applying

at various T and

= 3999 and 6665 s−1.

HNL

(s−1)

T(°C)

(%)

(%)

MWCNT-Al2O3 (20:80)/SAE40

3999 (300 rpm)

T = 25

2.04

10.52

29.57

35.69

T = 30

2.81

11.36

29.18

34.60

T = 35

3.15

12.33

28.50

33.46

T = 40

4.82

14.85

31.62

34.99

6665 (500 rpm)

T = 30

1.72

10.92

29.45

34.51

T = 35

2.76

12.06

30.69

33.92

T = 40

4.05

13.95

31.25

34.13

T = 45

5.04

14.72

31.71

35.22

T = 40

4.05

13.95

31.25

34.13

T = 50

5.46

15.06

31.46

35.06

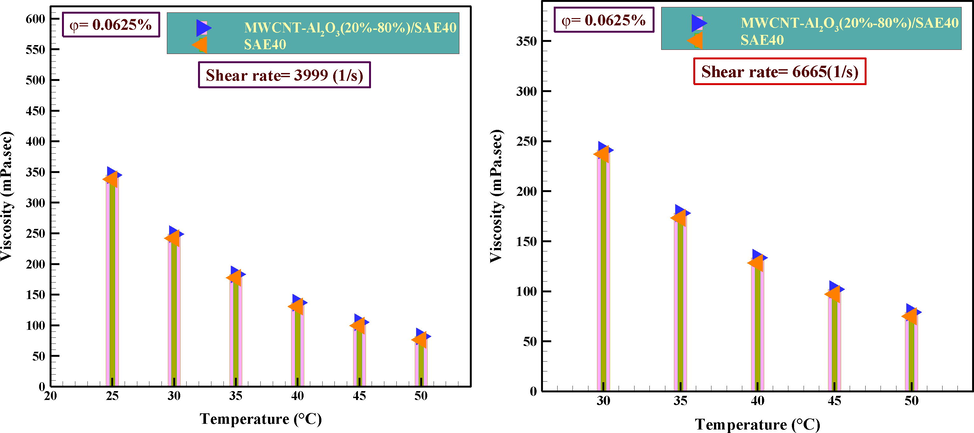

3.2.2 The influence of T on

Based on the curves in Fig. 7, which show the

at the lowest

and the engine speeds of 300 and 500 RPM, it is possible to compare the NL conditions to the base oil to justify the using or not using nanomaterials. The curves in Fig. 7 show that the dispersion of MWCNT-Al2O3 (20:80) NPs increases the viscosity of BF. As a result, this HNL cannot be used to lubricate car engines at conditions similar to this study.

The analogy of the influence of T on the

at

= 0.0625 %.

The effects of T on

are reported numerically in Table 6. This can be assigned to different issues. One of them is the morphology of Al2O3 NPs and the use of a high percentage (80 %) of these NPs to prepare this HNL. Or the occurrence of a μ phenomenon in all test conditions may be due to factors such as how the preparation is performed, stabilization of the HNL, or error of the tester. Because, in previous studies similar to this study, the opposite results were obtained (Esfe and Alidoust, 2020).

T (°C)

(s−1)

HNL

6.90

25

6.80

30

5.60

35

3999

6.30

40

4.80

35

5.20

40

4.90

45

6665

4.10

50

4 Impractical outcomes

4.1 RSM method

RSM is one of the important procedures in examining the target response to achieve the relationship between the independent variable and the dependent variable. Using Design of Experiment 11 software, T, , input data and output data were determined, and then, by processing the data, the desired model for predicting experimental data was extracted. A group of Chinese researchers investigated the properties of nanofluids theoretically and experimentally in their recent studies (Tu et al., 2022; Wang et al., 2022; Tu et al., 2022; Tang et al., 2022; Tu et al., 2022). They obtained good results using other new theoretical methods.

4.1.1 New correlation

In Eq. (4), the nonlinear predictive model based on three independent variables reports the output function. According to Eq. (4), the non-Newtonian conduct of the NL is quite obvious due to the dependence of the objective function on

. Also, the permissible range of use of Eq. (4) is Quartic model approved in the test conditions.

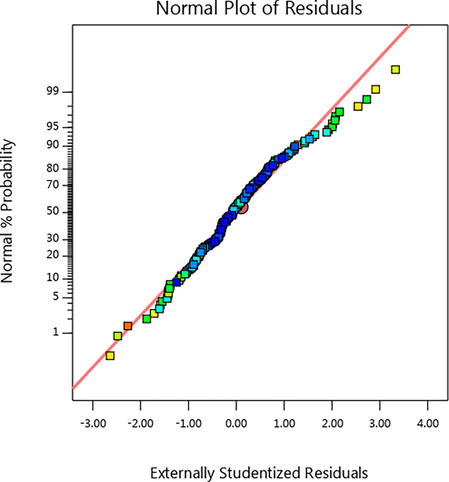

The normal probability diagram for the Quartic model is drawn in Fig. 8. Fig. 8 shows that the residuals follow the normal distribution of the data and the deviation between the data is very small and does not require an activation function.

Normal distribution curve in terms of residual values.

Tables 7 and 8 show detailed statistical information on important parameters based on p-value and R-Squared values related to the selected model.

Std. Dev.

3.21

R2

0.9993

Mean

207.16

Adjusted R2

0.9991

C.V. %

1.55

Predicted R2

0.9989

Adeq Precision

282.8758

Source

Sum of Squares

df

Mean Square

F-value

p-value

Model

2.013E + 06

34

59193.69

5728.71

< 0.0001

significant

A-T

23.37

1

23.37

2.26

0.1349

B-phi

22.70

1

22.70

2.20

0.1405

C-SR

8.46

1

8.46

0.8190

0.3670

AB

33.79

1

33.79

3.27

0.0727

AC

9.13

1

9.13

0.8831

0.3490

BC

1.17

1

1.17

0.1132

0.7371

A2

25.63

1

25.63

2.48

0.1175

B2

2.63

1

2.63

0.2542

0.6149

C2

0.1042

1

0.1042

0.0101

0.9201

ABC

0.0127

1

0.0127

0.0012

0.9721

A2B

39.97

1

39.97

3.87

0.0512

A2C

9.72

1

9.72

0.9410

0.3337

AB2

2.14

1

2.14

0.2070

0.6498

AC2

0.3739

1

0.3739

0.0362

0.8494

B2C

12.63

1

12.63

1.22

0.2707

BC2

0.0162

1

0.0162

0.0016

0.9684

A3

28.32

1

28.32

2.74

0.1001

B3

40.66

1

40.66

3.93

0.0493

C3

3.76

1

3.76

0.3635

0.5475

A2B2

12.85

1

12.85

1.24

0.2668

A2BC

0.3421

1

0.3421

0.0331

0.8559

A2C2

0.6492

1

0.6492

0.0628

0.8024

AB2C

5.43

1

5.43

0.5255

0.4697

ABC2

0.0026

1

0.0026

0.0002

0.9875

B2C2

0.1940

1

0.1940

0.0188

0.8912

A3B

66.62

1

66.62

6.45

0.0122

A3C

10.57

1

10.57

1.02

0.3136

AB3

66.39

1

66.39

6.43

0.0124

AC3

1.06

1

1.06

0.1028

0.7489

B3C

6.70

1

6.70

0.6487

0.4219

BC3

0.5782

1

0.5782

0.0560

0.8134

A4

35.60

1

35.60

3.44

0.0656

B4

153.75

1

153.75

14.88

0.0002

C4

3.66

1

3.66

0.3541

0.5528

Residual

1436.26

139

10.33

Cor Total

2.014E+06

173

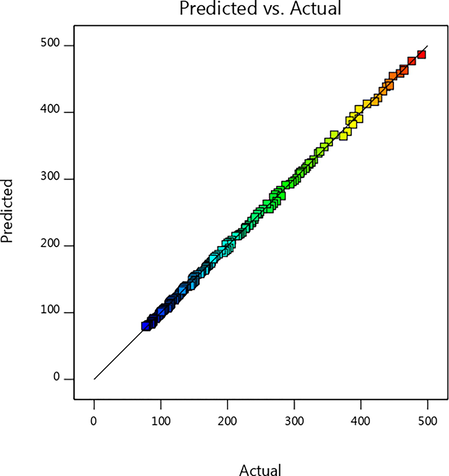

Fig. 9 shows the evaluation of the predicted response values against the actual values. As you can see in Fig. 9, there is a slight deviation between the predicted data and the real data, and this indicates the high accuracy of this model.

Comparison of predicted and actual values.

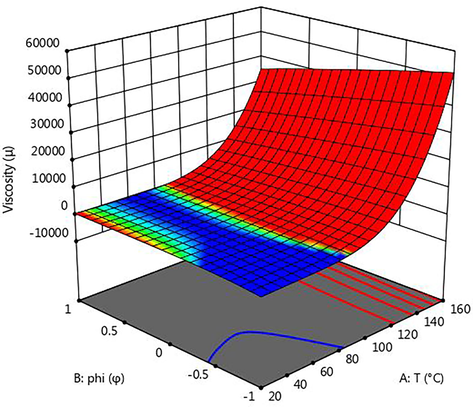

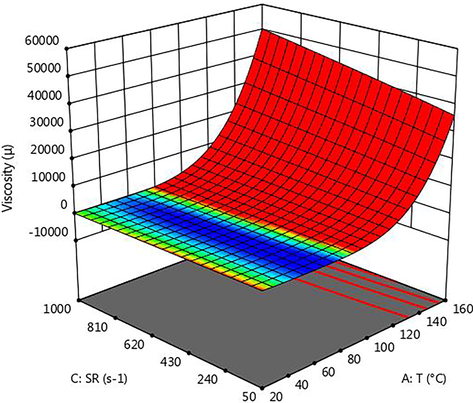

4.1.2 Viscosity changes in the selected model

The viscosity changes of MWCNT-Al2O3 (20:80)/SAE40 nanofluid for the Quartic model were presented using laboratory data. With the help of the designed model, we analyzed the viscosity for different parameters. The trend of viscosity changes is drawn in figures 10 and 11. Fig. 10 shows the trend of viscosity changes between temperature and volume fraction variables. As shown in the figure, viscosity increased with increasing temperature. But in Fig. 11, it shows the trend of changes in viscosity between temperature and cutting rate, and the viscosity has decreased slightly with increasing cutting rate.

Changes in nanofluid viscosity in terms of T and phi.

Variations of nanofluid viscosity in terms of T and SR.

5 Conclusion

In summary, the rheological behavior of HNL was investigated with various procedures. A summary of important results is stated in the following cases:

-

In different laboratory conditions, the HNL behavior is of the non-Newtonian type.

-

is inversely, directly, and inversely related to the independent variables of T, and , respectively.

-

With increasing NPs in the BF, the increases significantly (35.69 %), while at lower T, the decrease intensity increases.

-

The data were predicted with acceptable accuracy using the RSM and a four-point-three-variable model.

-

The graph of changes in viscosity for Quartic model under the influence of parameters of temperature, shear rate and volume fraction was investigated, which shows that temperature parameter has the most effect on viscosity.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- S. Aberoumand, K. Javaherdeh, A. Jafarimoghaddam, and H. Aberoumand, “Synthesis and rheological behavior of novel ecofriendly Ag–oil nanofluid and introduce general correlations for thermal conductivity and viscosity of any oil-based nanofluids,” Heat Trans Asian Res. https://doi. org/10.1002/htj, vol. 21193, 2015.

- Experimental study on the rheological behavior of silver-heat transfer oil nanofluid and suggesting two empirical based correlations for thermal conductivity and viscosity of oil based nanofluids. Appl. Therm. Eng.. 2016;101:362-372.

- [Google Scholar]

- Effects of temperature and solid volume fraction on viscosity of SiO2-MWCNTs/SAE40 hybrid nanofluid as a coolant and lubricant in heat engines. Appl. Therm. Eng.. 2016;102:45-54.

- [Google Scholar]

- Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: an experimental study. Exp. Therm. Fluid Sci.. 2016;77:38-44.

- [Google Scholar]

- An experimental study on rheological behavior of ethylene glycol based nanofluid: proposing a new correlation as a function of silica concentration and temperature. J. Mol. Liq.. 2017;233:352-357.

- [Google Scholar]

- Numerical study on turbulent heat transfer and pressure drop of nanofluid in coiled tube-in-tube heat exchangers. Energ. Conver. Manage.. 2014;79:304-316.

- [Google Scholar]

- An empirical investigation on thermal characteristics and pressure drop of Ag-oil nanofluid in concentric annular tube. Heat Mass Transf.. 2016;52(8):1693-1706.

- [Google Scholar]

- The effect of temperature and solid concentration on dynamic viscosity of MWCNT/MgO (20–80)–SAE50 hybrid nano-lubricant and proposing a new correlation: an experimental study. Int. Commun. Heat Mass Transf.. 2016;78:48-53.

- [Google Scholar]

- Electrochemical sensor based on nanocomposite of multi-walled carbon nano-tubes (MWCNTs)/TiO2/carbon ionic liquid electrode analysis of acetaminophen in pharmaceutical formulations. Iran. J. Chem. Chem. Eng. (IJCCE). 2021;40(4):1030-1041.

- [CrossRef] [Google Scholar]

- A variable viscosity approach for the evaluation of load carrying capacity of oil lubricated journal bearing with TiO2 nanoparticles as lubricant additives. Procedia Mater. Sci.. 2014;6:1051-1067.

- [Google Scholar]

- Enhancing thermal conductivity of fluids with nanoparticles. IL (United States): Argonne National Lab; 1995.

- Examining rheological behavior of MWCNT-TiO2/5W40 hybrid nanofluid based on experiments and RSM/ANN modeling. J. Mol. Liq.. 2021;333:115969

- [Google Scholar]

- Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J. Manuf. Process.. 2022;80:273-286.

- [CrossRef] [Google Scholar]

- Prediction of graphite nanofluids' dynamic viscosity by means of artificial neural networks. Int. Commun. Heat Mass Transf.. 2016;73:33-42.

- [Google Scholar]

- Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl. Therm. Eng.. 2016;109:524-534.

- [Google Scholar]

- Du, X., Tian, W., Pan, J., Hui, B., Sun, J., Zhang, K.,... Xia, Y. (2022). Piezo-phototronic effect promoted carrier separation in coaxial p-n junctions for self-powered photodetector. Nano energy, 92, 106694. doi: 10.1016/j.nanoen.2021.106694.

- Carbonyl sulfide gas detection by pure, Zn- and Cd-decorated AlP nano-sheet. Monatsh Chem. 2022

- [CrossRef] [Google Scholar]

- Esfe, M. H., Rostamian, H., & Sarlak, M. R. 2018. A novel study on rheological behavior of ZnO-MWCNT/10w40 nanofluid for automotive engines. Journal of Molecular Liquids, 254, 406-413.

- Esfe, M. H., Arani, A. A. A., Madadi, M. R., & Alirezaie, A. (2018). A study on rheological characteristics of hybrid nano-lubricants containing MWCNT-TiO2 nanoparticles. Journal of Molecular Liquids, 260, 229-236.

- Experimental evaluation of MWCNT–Al 2 O 3 (40–60%)/5W50 hybrid nanofluid and comparison with MWCNT–Al 2 O 3 (35–65%)/5W50 hybrid nanofluid with focus on thermophysical properties and cost performance index. Eur. Phys. J. Plus. 2020;135(10):1-17.

- [Google Scholar]

- An experimental determination and accurate prediction of dynamic viscosity of MWCNT (% 40)-SiO2 (% 60)/5W50 nano-lubricant. J. Mol. Liq.. 2018;259:227-237.

- [Google Scholar]

- Comparison of viscosity behavior of hybrid nano-lubricants containing Al2O3-MWCNT nanoparticles dispersed in SAE XWX engine oils to determine the optimal behavior of nano-lubricants based on experimental studies. Colloids Surf. A Physicochem. Eng. Asp.. 2022;641:128446

- [Google Scholar]

- Experimental investigation of switchable behavior of CuO-MWCNT (85%–15%)/10W-40 hybrid nano-lubricants for applications in internal combustion engines. J. Mol. Liq.. 2017;242:326-335.

- [Google Scholar]

- A comparative study of rheological behavior in hybrid nano-lubricants (HNLs) with the same composition/nanoparticle ratio characteristics and different base oils to select the most suitable lubricant in industrial applications. Colloids Surf. A Physicochem. Eng. Asp.. 2022;643:128658

- [Google Scholar]

- Experimental investigation on convective heat transfer and hydrodynamic characteristics of magnetite nanofluid under the influence of an alternating magnetic field. Int. J. Therm. Sci.. 2016;99:113-124.

- [Google Scholar]

- Using of artificial neural networks (ANNs) to predict the thermal conductivity of zinc oxide–silver (50%–50%)/water hybrid Newtonian nanofluid. Int. Commun. Heat Mass Transf.. 2020;116:104645.

- [Google Scholar]

- An empirical investigation on Cu/Ethylene Glycol nanofluid through a concentric annular tube and proposing a correlation for predicting Nusselt number. Alex. Eng. J.. 2016;55(2):1047-1052.

- [Google Scholar]

- CFD analysis of single-phase flows inside helically coiled tubes. Comput. Chem. Eng.. 2010;34(4):430-446.

- [Google Scholar]

- Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol. Int.. 2022;169:107461

- [CrossRef] [Google Scholar]

- Thermal conductivity and viscosity of Al2O3 nanofluid based on car engine coolant. J. Phys. D Appl. Phys.. 2010;43(31):315501

- [Google Scholar]

- Extreme pressure and antiwear additives for lubricant: academic insights and perspectives. Int. J. Adv. Manuf. Tech. 2022

- [CrossRef] [Google Scholar]

- Improved heat transfer of the engine oil by changing it to hybrid nanofluid: adding hybrid nano-powders. Powder Technol.. 2021;383:56-64.

- [Google Scholar]

- Effects of dispersed added graphene oxide-silicon carbide nanoparticles to present a statistical formulation for the mixture thermal properties. Physica A. 2019;521:98-112.

- [Google Scholar]

- Study of methyl tert-butyl ether (MTBE) photocatalytic degradation with UV/TiO2-ZnO-CuO nanoparticles. J. Chem. Health Risks. 2017;7(1):19-32.

- [CrossRef] [Google Scholar]

- Numerical estimation of mixed convection heat transfer in vertical helically coiled tube heat exchangers. Int. J. Numer. Meth. Fluids. 2011;66(7):805-819.

- [Google Scholar]

- Experimental investigation, sensitivity analysis and modeling of rheological behavior of MWCNT-CuO (30–70)/SAE40 hybrid nano-lubricant. Appl. Therm. Eng.. 2017;123:1419-1433.

- [Google Scholar]

- The evaluation on a new non-Newtonian hybrid mixture composed of TiO2/ZnO/EG to present a statistical approach of power law for its rheological and thermal properties. Physica A. 2019;516:1-18.

- [Google Scholar]

- PUTRA A.B.W (2020) Computer Technology Simulation towards Power Generation Potential from Coproduced Fluids in South Lokichar Oil Fields. International Journal of Communication and Computer Technologies, 8 (2), 9-12. doi:10.31838/ijccts/08.02.03.

- Experimental and numerical investigations of turbulent forced convection flow of nanofluid in helical coiled tubes at constant surface temperature. Powder Technol.. 2015;283:178-189.

- [Google Scholar]

- P. Razi, and M. Akhavan-Behabadi, “Heat Transfer Characteristics of CuO-Base Oil Nanofluid Laminar Flow Inside Flattened Tubes Under Constant Heat Flux.” pp. 591-597.

- Statistical investigation for developing a new model for rheological behavior of Silica–ethylene glycol/Water hybrid Newtonian nanofluid using experimental data. Physica A. 2019;525:616-627.

- [Google Scholar]

- Statistical investigation for developing a new model for rheological behavior of ZnO–Ag (50%–50%)/Water hybrid Newtonian nanofluid using experimental data. Physica A. 2019;525:741-751.

- [Google Scholar]

- Statistical modeling and investigation of thermal characteristics of a new nanofluid containing cerium oxide powder. Heliyon. 2022;8(11):11373.

- [Google Scholar]

- Using experimental data to estimate the heat transfer and pressure drop of non-Newtonian nanofluid flow through a circular tube: applicable for use in heat exchangers. Appl. Therm. Eng.. 2018;129:1573-1581.

- [Google Scholar]

- Dataset on critical parameters of dispersion stability of Cu/Al2O3 nanofluid and hybrid nanofluid for various ultra-sonication times. Data Brief. 2019;22:863-865.

- [Google Scholar]

- A review on preparation methods and challenges of nanofluids. Int. Commun. Heat Mass Transf.. 2014;54:115-125.

- [Google Scholar]

- Evaluating the biological activities of biosynthesized ZnO nanoparticles using Escherichia coli. Caspian J. Environ. Sci.. 2021;19(5):809-815.

- [CrossRef] [Google Scholar]

- Experimental evaluation on rheological behavior of Al2O3-pure coconut oil nanofluids. J. Mol. Liq.. 2019;286:110905

- [Google Scholar]

- Experimental investigations on viscosity and density of eco-friendly MoS2-sesame oil nano-lubricants and its influence on pumping power. Nanotechnology. 2021;32(36):365702

- [Google Scholar]

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid. Nanotechnol. Rev. (Berlin). 2021;10(1):1339-1348.

- [CrossRef] [Google Scholar]

- Thermal management of electronic components based on new wave bio-inspired structures and nanofluids. Int. Commun. Heat Mass Transf.. 2022;131:105840

- [Google Scholar]

- Green synthesized metallic nanoparticles as prospective therapeutics in fight against listeria monocytogenes. Eur. Chem. Bull.. 2022;11(3):14-33.

- [CrossRef] [Google Scholar]

- Efficacy of hybrid nano-powder presence on the thermal conductivity of the engine oil: an experimental study. Powder Technol.. 2020;369:261-269.

- [Google Scholar]

- Experimental study on the particle fouling properties of magnetic nanofluids in a corrugated tube with built-in twisted turbulator under variable magnetic field. Powder Technol.. 2022;400:117216

- [Google Scholar]

- Numerical analysis of flow and heat characteristic around micro-ribbed tube in heat exchanger system. Powder Technol.. 2022;395:562-583.

- [Google Scholar]

- Experimental study on the influence of bionic channel structure and nanofluids on power generation characteristics of waste heat utilisation equipment. Appl. Therm. Eng.. 2022;202:117893

- [Google Scholar]

- Wang, M., Deng, L., Liu, G., Wen, L., Wang, J., Huang, K.,... Pan, Y. (2019). Porous Organic Polymer-Derived Nanopalladium Catalysts for Chemoselective Synthesis of Antitumor Benzofuro[2,3‑b]pyrazine from 2‑Bromophenol and Isonitriles. Organic letters, 21(13), 4929-4932. doi: 10.1021/acs.orglett.9b01230.

- Tribology of enhanced turning using biolubricants: a comparative assessment. Tribol. Int. 2022107766

- [CrossRef] [Google Scholar]

- Study on the mechanism of modified surface and magnetic nanofluids on cooling performance of wireless charging equipment under magnetic field. Appl. Therm. Eng.. 2022;208:118258

- [Google Scholar]

- Wenhao Xu, Changhe Li, Yanbin Zhang, Hafiz Muhammad Ali, Shubham Sharma, Runze Li, Min Yang, Teng Gao, Mingzheng Liu, Xiaoming Wang, Zafar Said, Xin Liu, Zongming Zou. 2022. Electrostatic atomization minimum quantity lubrication machining: from mechanism to application. Int. J. Extrem. Manuf. https://doi.org/10.1088/2631-7990/ac9652.

- Numerical assessment of Ag-water nanofluid flow in two new microchannel heatsinks: thermal performance and thermodynamic considerations. Int. Commun. Heat Mass Transf.. 2020;110:104415

- [Google Scholar]

- Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions. Int. J. Mach. Tool Manu.. 2017;122:55-65.

- [CrossRef] [Google Scholar]