Translate this page into:

The multi-dimensional approach to synergistically improve the performance of inorganic thermoelectric materials: A critical review

⁎Corresponding author at: Laser Research Group, Physics Department, King Fahd University of Petroleum & Minerals (KFUPM), Mailbox 5047, Dhahran 31261, Saudi Arabia. magondal@kfupm.edu.sa (M.A. Gondal)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

This review discusses the recent progress and persistent challenges toward achieving high thermoelectric (TE) figure of merit with inorganic TE materials. For decades, the interdependence between the relevant thermoelectric parameters has been the main impediment halting the large-scale usage of these materials for clean energy production. The thermoelectric performance can be improved by reducing the thermal conductivity or maximizing the power factor. We summarized the state-of-the-art methodologies adopted to reduce the lattice thermal conductivity to its amorphous limit, thus enhancing the figure of merit. The synergistic approach of utilizing valence band convergence, carrier filtering together with resonant levels formation has also been found to improve the power factor and the figure of merit of some TE materials. The work gives particular emphasis to systems in which spectacular advances have been demonstrated, such as chalcogenides, Heusler compounds, clathrates, and skutterudites. We further summarized different materials fabrication techniques with their success in tuning the TE performance. A discussion on future perspective where both the power factor and the thermal conductivity can be significantly tuned via a multi-scale approach to yield high-performance TE materials for industrial applications has been presented.

Keywords

Thermoelectric

Thermal conductivity

Power factor

Power generation

Seebeck coefficient

Renewable energy

1 Introduction

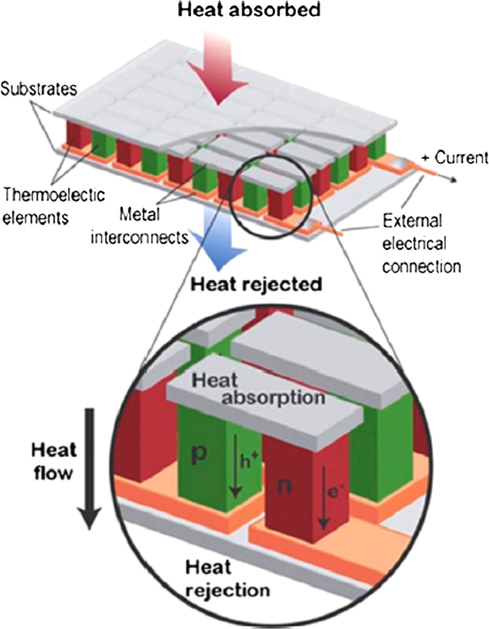

Energy generation for domestic and industrial applications through the conversion of waste-heat heat via thermoelectric effect has consistently received attention and aroused widespread interest globally due to the ever-growing environmental crisis such as global warming resulting from burning fossil fuels and a decline in energy resources (Wu et al., 2020). Thermoelectric materials can convert the thermal energy to electricity via the Seebeck effect, and they can be utilized for refrigeration and heating applications via the Peltier effect (Heo et al., 2019; Pavan Kumar et al., 2019; Hsieh et al., 2019; Ahmad et al., 2019). The performance of TE materials can be assessed by the dimensionless figure of merit ZT, given as where S is the Seebeck-coefficient, ρ is the electrical resistivity, T is the absolute temperature, are electronic and lattice thermal conductivities respectively (Mao et al., 2019). Thus, TE material is expected to demonstrate high electrical conductivity and Seebeck coefficient while maintaining low thermal conductivity (Kleinke, 2010). The interdependence of the physical parameters makes it challenging to develop efficient TE systems.

For the past few decades, researchers have worked assiduously to improve the figure of merit using various techniques leading to decreased thermal conductivity or enhanced power factor (Qian et al., 2019; Xi et al., 2018). However, the major challenge is the coupling between the relevant parameters, an impediment halting the large-scale applications of TE materials (Liu and Rajagopal, 2019; Salhi et al., 2018). For instance, high carrier concentration provides excellent electrical conductivity with reduced Seebeck coefficient and higher thermal conductivity. Therefore, although metals have high electrical conductivity due to large charge carriers, they exhibit small ZT value resulting from low Seebeck coefficient and increased thermal conductivity. On the contrary, insulators cannot be utilized for TE energy generation since they have zero electrical conductivity, which implies almost zero TE figure of merit. Typically, TE materials are neither insulators nor metals, but small bandgap semiconducting compounds with optimum carrier density between 1019 – 1021 cm−3 (Nolas, 2019).

Recently, a remarkable increase in ZT has been accomplished through lattice thermal conductivity minimization resulting from all length-scale phonon scattering by hierarchical architecture via mesoscale grain boundaries, second phase nanoscale endotaxial precipitates, intrinsic bond anharmonicity, and solid solution point defects. Increased Seebeck coefficient has also been achieved due to the convergence of degenerate electronic band valleys, band energy offset minimization, and resonance state formation in the electronic bands caused by alloying and carrier engineering. Another essential feature determining the quality of TE materials is the complexity of the crystal structure, as it promotes the thermopower due to the presence of spikes in the density of state (DOS), which gives rise to large first-derivative of the DOS, thus improving the thermopower as depicted by Mott Jone’s equation (1) (E represents energy and EF is the Fermi energy) (Wudil et al., 2020). The reduction in the value of к in complex materials is a consequence of phonons scattering assisted by the plenty of grain boundaries, thus, decreasing the phonons’ mean free path length (Mott and Jones, 1958; Rao et al., 2006).

Furthermore, the nanoinclusion of domains has been employed to reduce the intrinsic lattice thermal conductivity as well. In such a case, the structure impedes the phonons' motion only but transparent to electron flow. The concept is termed phonon-glass-electron-crystal (PGEC), a typical behavior whereby materials act like crystal with respect to electron scattering (high electrical conductivity) and behave like glass with respect to phonon scattering (low thermal conduction) (Slack, 1997). Furthermore, compounds made of heavy elements are principally known to possess low intrinsic lattice thermal conductivity resulting from the constituent atoms' minimized vibrational frequencies. Such elements generally form contemporary thermoelectrics (Wei et al., 2019).

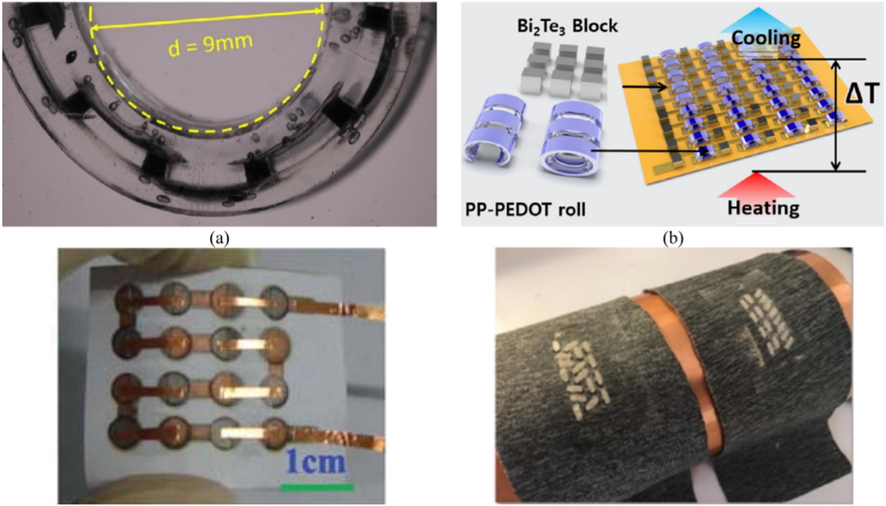

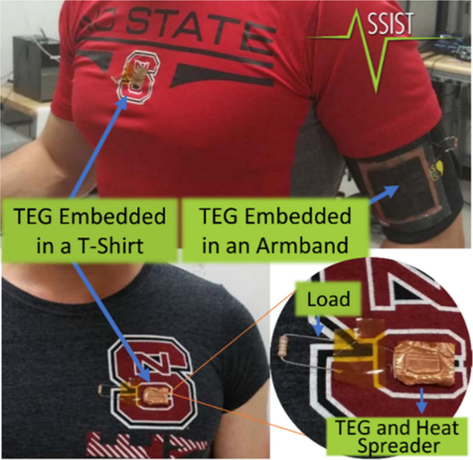

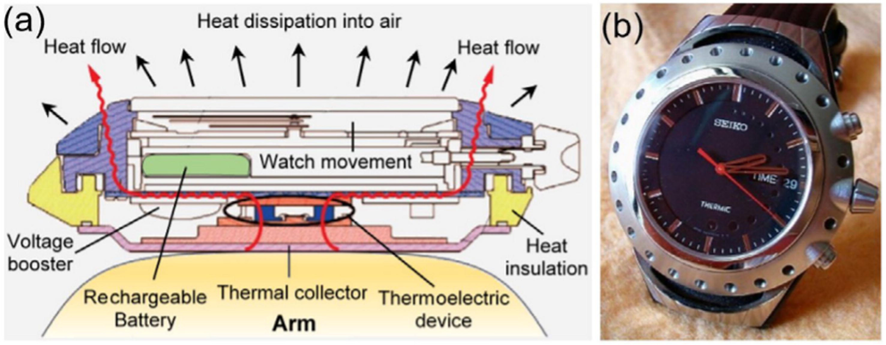

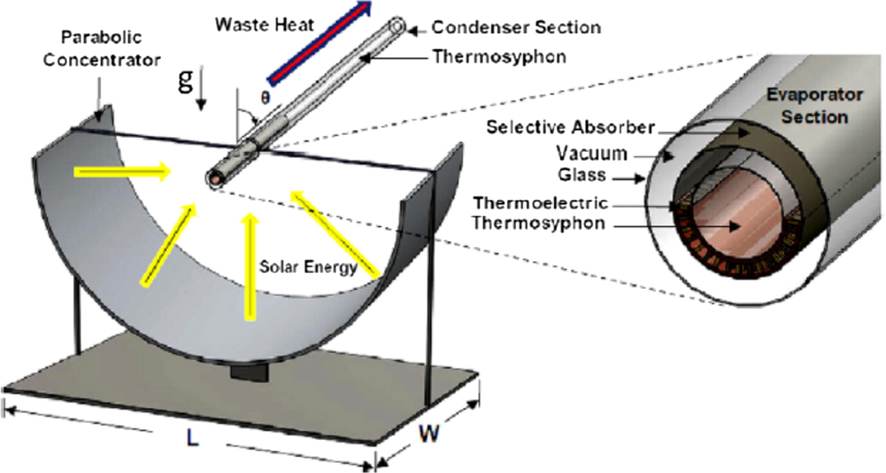

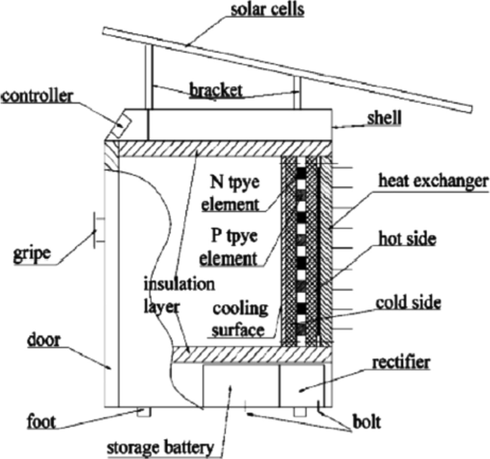

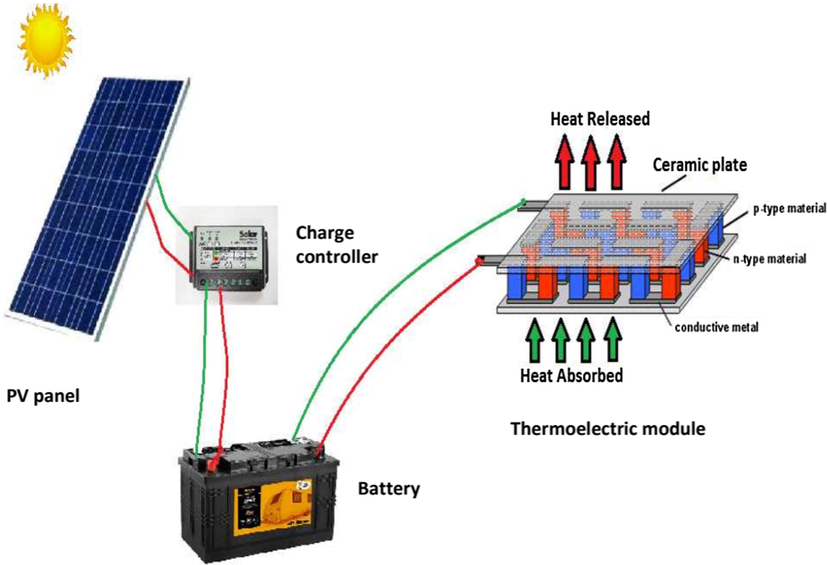

In the near future, it is expected that advanced thermoelectric devices could produce sufficient energy from the waste-heat lost in industries, automobiles, and domestic appliances, thereby replacing the currently operational alternators (Wudil et al., 2019; Mahmoudinezhad et al., 2020; Angeline et al., 2019; Elmoughni et al., 2019; Karthick et al., 2019; Pourkiaei et al., 2019; Zhou et al., 2020; Kong et al., 2019; Yang et al., 2019; Rodrigo et al., 2019; Choi et al., 2019; Kanimba and Tian, 2019; Mohammadnia et al., 2020; Houshfar, 2020; Cui et al., 2019; Allison and Andrew, 2019; Zhao et al., 2019; Karthick et al., 2019; Yuan et al., 2019; Marefati and Mehrpooya, 2019). Thermoelectric materials find applications in almost all sectors of human endeavor. They can be used for power generation, refrigeration, or thermal energy sensors. They are used continuously in fields where efficiency is uniquely essential, like medicine, aerospace, biology, military, and industries.

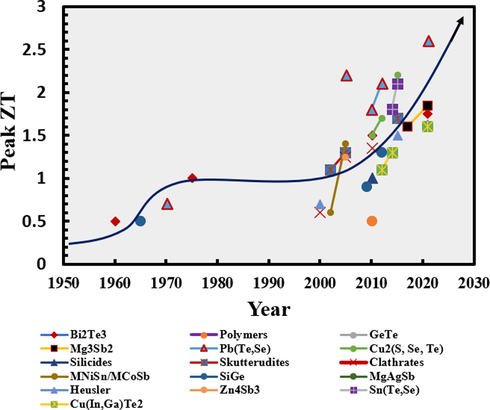

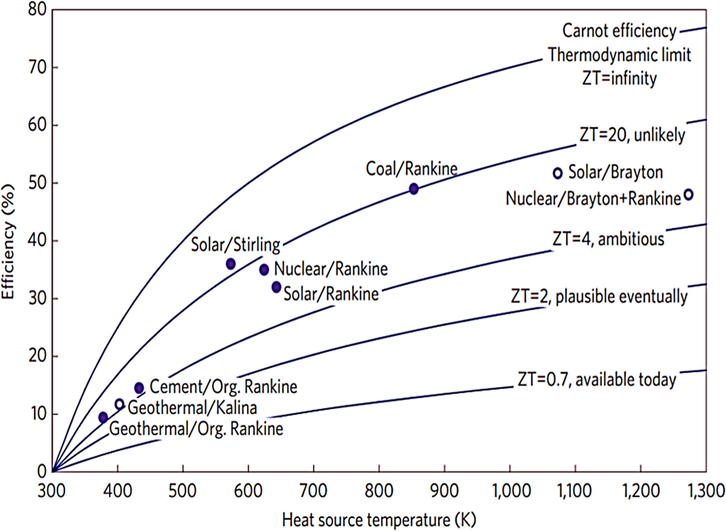

Even the heat generated from human body can be used to energize low-power electronics such as wrist-watch on a smaller scale. In addition to photovoltaics, thermoelectric generators can generate electricity from solar thermal energy at long wavelengths (Toberer, 2016). The projected current thermoelectric efficiency of different p-types and n-types compounds is presented in Fig. 1a and 1b, respectively, according to their operation temperatures (Beretta et al., 2019). The compounds are grouped as low, medium, and high-temperature materials using blue, brown, and red colors respectively. For the thermoelectric devices to completely replace the existing freon compressors and other environmentally degrading energy sources in the global market, a ZT value above unity is required to ensure maximum energy extraction from waste-heat (He et al., 2019). Fig. 2 summarizes TE generators' relative performance compared with other conventional solar, nuclear, and coal engines.

Evolution of thermoelectric figure of merit for different high-performance TE materials within their optimal operation temperatures. Generated from refs (Beretta et al., 2019; Zhao et al., 2013; Biswas et al., 2012; Ma et al., 2021; Bos, 2021; Tsai et al., 2021; Yang et al., 2016; Song et al., 2019; Wu et al., 2019)

Comparison of the conventional engines with optimistic TE efficiencies.

Adapted from Vining, 2009

Owing to the diversity in thermoelectric research, which covers materials investigation, processing and design, theoretical research and device assembly, we report in this review only recent advances and existing challenges hitherto in the development of inorganic thermoelectric materials (chalcogenides, complex materials, and Heusler compounds) using cutting-edge approaches. These approaches include nanostructuring, intra-matrix band engineering, and all-scale hierarchical architecture. We have demonstrated the mechanisms to simultaneously apply these techniques additively and synergistically to improve the figure of merit. Different materials fabrication techniques have also been highlighted as they relate to ZT enhancement. A discussion of the challenges to further advance these new insights to achieve optimum ZT has also been presented.

2 Challenges in improving the TE figure of merit

The ideal thermoelectric materials are expected to the electrically short-circuited and thermally open-circuited due to their PGEC properties, i.e., thermoelectric materials are expected to acquire crystal behavior with respect to electrical conduction and glass behavior with regards to thermal conduction. The coupling existing between the transport parameters makes ZT enhancement somewhat tedious since any effort to improve one term could negatively affect the other (Wudil et al., 2020). The conventional approach to improving the figure of merit is either to enhance the power factor or to reduce the lattice thermal conductivity (Bell, 2008). While the former is achieved by optimizing charge carrier concentration, the latter is usually accomplished by creating scattering centers. TE parameters are generally defined by the carrier mobility (µ), the effective mass of the charge-carriers (m*), and the scattering factor (r). The interdependence of these parameters has marked an upper bound to ZT to around unity for bulk materials.

The kinetic definition of the Seebeck coefficient describes it as the difference between the average energy of the charge-carriers and the Fermi energy (Pichanusakorn and Bandaru, 2010). Nevertheless, both the Fermi energy and the energy of the mobile charge carriers increase with carrier concentration (n). However, the rise in the latter is less significant compared to the Fermi energy. Thus, an attempt to improve ZT by increasing the concentration of n could drag S down, reducing the overall power factor except for optimum concentration of n, where both the electrical conductivity and the thermopower are improved. Hence, for most of the homogeneous materials, increased carrier concentration improves the electrical conductivity (

) and drags down the Seebeck coefficient. Consequently, the energy-independent scattering approximation requires that for most of degenerate semiconductors and metals, S can be defined as (Alam and Ramakrishna, 2013).

The high charge-carrier effective mass m* improves the thermopower which consequently enhances the power factor, as depicted in equation (2). Generally, materials with high effective mass possess low charge carrier mobility, limiting the value of the power factor, which can equally be expressed as ( ). Noteworthy, there is nothing like an optimal effective mass. However, there exist low effective mass high mobility semiconductors (GaAs, SiGe) and high effective mass low mobility polaron semiconductors (chalcogenides, oxides) as well (Snyder and Toberer, 2010).

To lower the lattice thermal conductivity, defects are usually introduced to the material's matrix to scatter-off phonons, which are responsible for the lattice contribution to heat transport. Nevertheless, electrons too can get scattered in the process, causing reduced carrier mobility. Thus, the ratio can be used to ascertain how efficiently ZT is enhanced (D.R.-Crcp.B. Raton, undefined, 2005). Experimentally, the ratio is usually improved through reduced kth instead of enhanced µ, which requires deeper exploitation of the fundamental mechanisms governing the process.

According to the Wiedemann-Franz law, the electronic contribution to the thermal conduction is proportional to the electrical conductivity of the material as (Snyder and Toberer, 2010)

Where L represents the Lorenz number. The electrical conductivity can also be expressed in terms of the chemical potential, electronic charge, and carrier concentration as:

Thus, the electronic contribution to the thermal conduction becomes

It can, therefore, be deduced that although the low concentration of the charge carriers results in low thermal conductivity, typical of what is needed for better ZT, it also amounts to low electrical conductivity, which in turn lower the figure of merit. Similarly, equation (5) reveals that for enhanced electrical conduction, high mobility carriers are required. It is pertinent to note that equation (2) signifies that increased charge carrier effective mass improves the value of S. However, it has a negative consequence on the mobility of the charge carriers, which ultimately decreases the electrical conductivity and the figure of merit. For narrow bandgap semiconductors, carriers' thermal excitation from the valence to conduction bands generates electrons and holes, but the majority carrier's concentration does not change significantly. When two different charge carriers are present, the bipolar effect exists, which is critical for thermoelectrics (Goldsmid, 2009).

In summary, the electronic contribution to the thermal conductivity is always enhanced while improving electrical conductivity. To minimize this impact, kth needs to be significantly reduced using various means. However, the most widely employed method, i.e. through defect incorporation, lowers the carrier mobility and . These are the most significant challenges for TE materials being addressed for decades. Until recently, the emphasis was mainly given to the nanostructuring approach by producing low dimensional TE materials and phonon engineering in bulk TE compounds.

3 Current strategies employed to improve the thermoelectric figure of merit

3.1 Nanostructuring

There exist two main classes of nanostructured TE materials. The first consists of a large assembly of nanoparticles as a single-phase material while the second constitutes a dominant bulk materials alloyed with a minor nanostructured second phase, generally introduced through precipitation or solid solutions (Dylla et al., 2019; Ge et al., 2019; Alagar Nedunchezhian et al., 2019; Wang et al., 2019; Wu et al., 2019). The bulk material may not necessarily be at the nanoscale. Nucleation and growth of a second phase is the primary method of introducing such nanostructures to the parent. The secondary phase nanostructures are expected to be completely soluble in the liquid state but insoluble in the solid-state. Rapid cooling of the melt by quenching causes the second phase to precipitate since it exceeds the solid-solution limit. For large-scale thermoelectric applications, either nanostructured bulk-materials or thin-films are employed depending on the current need. For example, thin-films show more promise in Peltier micro-chips applications, while nanostructured bulk materials are considered more appropriate for stand-alone materials.

Multiple reports have indicated that a reduction in klatt is the main reason for enhancing thermoelectric performance in nanostructured bulk materials. The phonons with a varying wavelength in solid crystalline materials contribute to the heat transport at different scales. The lattice thermal conductivity is minimized due to the increased scattering of the heat-carrying phonons by the interfacial boundaries.

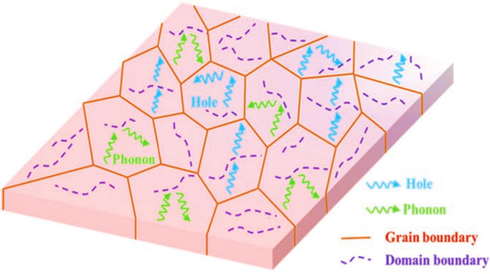

Thermal conductivity minimization through nanostructuring was observed in the bulk thermoelectric systems by Kanatzidis et al. (Hsu et al., 2004). They studied AgPbmSbTe2+m systems and found the nanostructures embedded in the matrix of the parent compound. They attributed the decrease in the thermal conductivity to the ubiquitous and spontaneous nanoscale precipitation of the secondary phase in the host material. Generally, the nano-crystals are embedded in the matrix endotaxially with a low lattice mismatch (Kang et al., 2020). A schematic of the typical interface boundaries depicting carriers’ motion is presented in Fig. 3.

A schematic of the material’s grain boundaries illustrating the motions of holes and phonons. Adapted from ref (Zhang et al., 2019).

Low-dimensional materials possess an excellent potential for improving the power factor or lowering the thermal conductivity. While the former is usually achieved through quantum confinement formation by the nanostructures, the latter could be accomplished by introducing intrinsic interfaces to impede phonon transport. Higher thermopower could be realized in nanomaterials due to the increased density of states around the Fermi level. Anisotropic Fermi surfaces in nanomaterials of multi-valley cubic-semiconductors are critical to achieving delta doping and modulation doping. Nanomaterials with a delta-like density of states do not obey the Wiedemann-Franz law, thus, making them promising candidates for improved thermoelectric performance (Venkatasubramanian et al., 2001).

Due to the change in the density of states with spatial confinement of charge-carriers, theoretical predictions on ZT enhancement via nanostructuring were based on the power factor modification and the electronic contribution to the thermal conductivity. These studies mainly used the bulk values for kph by ignoring the phonon spatial confinement. However, it is essential to mention that due to mini-Umklapp mechanisms and mini-band formation, the phonon transport can be modified even for superlattice of similar compounds. The relaxation rate of the phonons is affected mainly by the phonon confinement effect, which caused the significant difference between the thermal properties of bulk materials and nanostructured materials (Balandin and Wang, 1998).

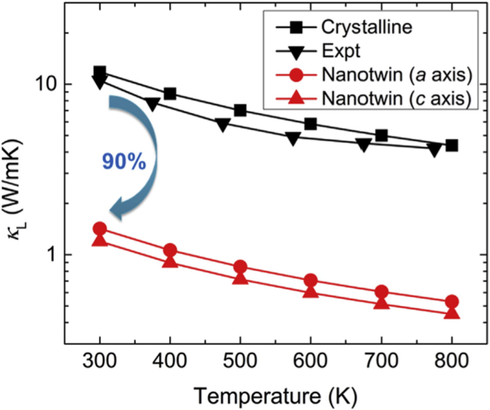

There exist multiple attempts to improve the efficiency of TE materials using low-dimensional structures. Recently, Guodong et al. (Li et al., 2019) reported an exciting twin boundary mechanism to reduce the lattice thermal conductivity of Mg2Si without adversely affecting the electrical transport properties such as the Seebeck coefficient and electrical conductivity. They introduced the concept of nano-twinning and validated it through the density functional theory approach. A significant reduction of thermal conductivity ∼ 90% was recorded (Fig. 4), which they attributed to higher phonon scattering rate, short phonon lifetime, Mg-Mg pair rattling, and lower phonon velocities. The authors suggested the possible extension of this technique to other low-thermal conductivity desired materials.

Comparison of the nano-twinned Mg2Si lattice thermal conductivity with crystalline Mg2Si and experimental result for bulk Mg2Si.

Adapted from Li et al., 2019

Yuan et al. (Wang et al., 2019) realized a significant improvement in the peak ZT value from 0.7 at 470 K to 1.1 for nanostructured Bi2Te3. They employed a non-equilibrium reaction triggered by spark plasma sintering to suppress the Te-vacancies in order to lower the carrier concentration, which eventually led to low electronic thermal conductivity. The authors suggested that the method could be utilized to control point defects in TE materials.

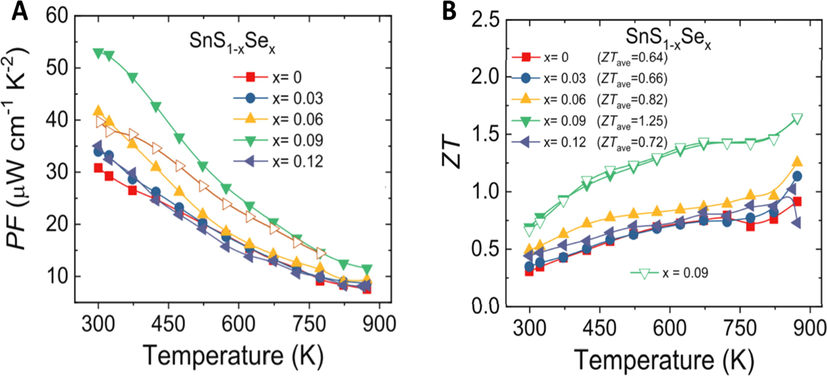

Recently, Wenke et al. (He et al., 2019) reported a significant improvement in the value of ZT through selenium inclusion in tin sulfide (SnS) material to form environmentally-friendly and low-cost SnS0.91Se0.09. They observed an appreciable decrease in the lattice thermal conductivity with an enhanced thermoelectric power factor leading to a ZT of ∼ 1.6 at 873 K (Fig. 5). Such remarkable performance was accomplished through electronics band manipulation, which allows synergistic optimization of charge-carrier mobility and effective-mass.

(a) The thermoelectric power factor for Se-doped SnS (b) Temperature-dependent ZT of Se-doped SnS. Adapted from ref (He et al., 2019).

Xiaoming et al. (Hu and Hu, 2019) developed highly uniform and porous p-type Bi0.4Sb1.6Te3 bulk material using resistance pressing sintering. A significant decrease in thermal and electrical conductivities was observed with increasing porosity. However, the reduced electrical conductivity was compensated by the decreased thermal conductivity, thereby attaining a high ZT of ∼ 1.1 at 343 K, about 20% enhancement compared to the pure dense sample. The authors proposed that the porous structures' uniformity is critical for enhanced thermoelectric performance and mechanical properties.

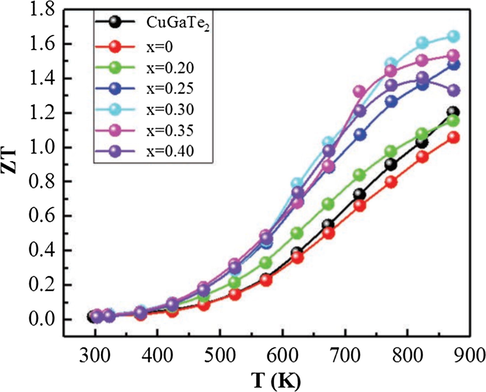

Jian et al. (Zhang et al., 2019) investigated chalcopyrite CuGaTe2 due to its remarkable power factor. They prepared a complex nano-scaled quinary system of Cu1−xAgxGa0.4In0.6Te2 (0 ≤ x ≤ 0.4). They achieved an impressive reduction in thermal conductivity from 6 W m−1 K−1 to 1.5 W m−1 K−1 (for × = 0.4) via alloying of Ag and In isoelectronic elements to provide scattering sites. Consequently, an outstanding ZT of 1.6 was realized for the chalcopyrite Cu0.7Ag0.3Ga0.4In0.6Te2 at 873 K, about 37% enhancement compared with the pristine CuGaTe2 (Fig. 6). The authors propose that such isoelectronic multi-element alloying can significantly reduce chalcopyrite compounds' thermal conductivity and improve its overall thermoelectric performance.

Temperature dependence of ZT values for pure CuGaTe2 and samples of Cu1−xAgxGa0.4In0.6Te2 (x = 0, 0.20, 0.25, 0.30, 0.35, 0.40). Adapted from ref (Zhang et al., 2019).

Elsewhere, Zhou et al. (Zhou et al., 2005) fabricated BiyTe1-y nanowires on Al2O3 membrane at different ratios. Compared to the bulk phase, improved thermopower was observed at 300 K when y = 0.46. However, a higher value of y showed decreased thermopower. The average surface-roughness of the nanowires (∼1nm) was believed to contribute to the reduction of the intrinsic lattice thermal conductivity without deteriorating the electronic conductivity despite the wavelength of electrons is of the order of 10 nm while for the phonons is of the order of 1 nm. Similarly, the thermal conductivity of Si0.8Ge0.2 prepared by pressure sintering was found to be below that of its bulk crystalline powder due to the presence of defects. However, a simultaneous decrease in ZT was observed, which was harmful to ZT enhancement. Several of these cases have been reported where a decrease in k could not improve the value of ZT for one reason or the other (Lee et al., 1997). Kim et al. (Kim et al., 2006) reported the epitaxial embedding of ErAs into In0.53Ga0.47As where they observed a decrease in the lattice thermal conductivity with an increased electronic contribution to the thermal conductivity due to phonon scattering and electron–phonon scattering, respectively. ErAs was assumed to provide more scattering-mechanism for low to high wavelength phonons. Hitherto, the fundamental explanation of how and why thermal conduction of crystalline materials is reduced through nanostructuring is still not sufficient. . Nano-structuring has opened a new window for thermal conductivity suppression apart from using the complex structures as the interdependence of the transport properties which are difficult to control in bulk materials becomes relatively more comfortable to deal with (Wang et al., 2020; Marinho et al., 2019; Sivaprahasam et al., 2019; Dylla et al., 2019; Gainza et al., 2019; Fitriani et al., 2016; Yin et al., 2019).

3.2 Mass fluctuations

The concept of mass fluctuations is yet another promising technique employed to reduce the lattice thermal conductivity. Once the difference between the masses of the dopant atom and the host element is large, the lattice periodicity is disturbed and consequently increases phonon scattering, thereby minimizing the lattice thermal conductivity (Lu et al., 2019).

Elsewhere (Hooshmand Zaferani et al., 2019), reduced lattice thermal conductivity was observed while using heavy masses with large unit cells and low spring constants. Similarly, solid-solution alloying has been reported to lower the lattice thermal conductivity due to mass fluctuations (Biswas et al., 2019). For the alloying approach, the constituent alloys' mass ratio significantly determines the scattering rate, and the random vacancies produced serves as the typical scattering regions.

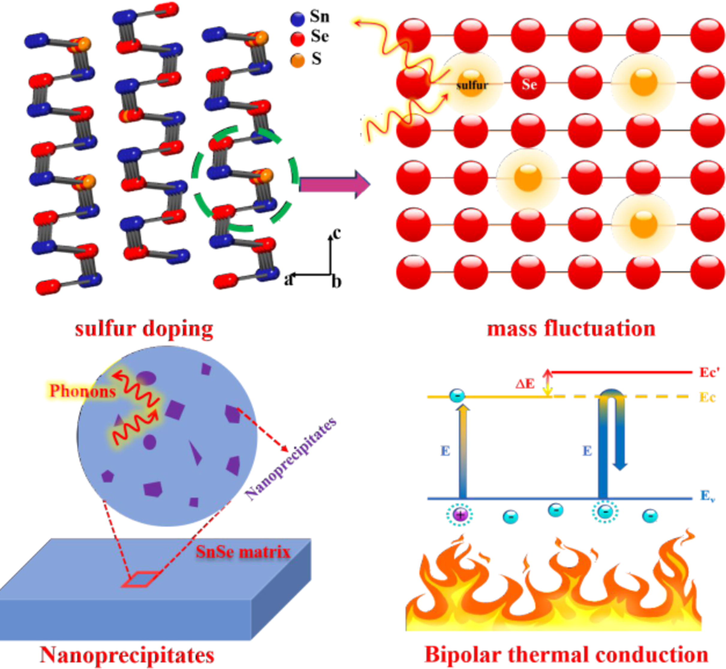

Wenqi et al. (Lu et al., 2019) reported a remarkable ZT of 1.85 for lead and sulfur co-doped tin selenide at 873 K. They claimed that co-doping has widened the bandgap and consequently reduced the bipolar thermal conductivity. They observed a record low thermal conductivity of 0.13 W m−1 K−1, resulting from the synergistic approach of thermal conductivity minimization and mass fluctuations triggered by nanoprecipitates and sulfur incorporation, as depicted in Fig. 7. The authors proposed that high thermoelectric performance could be accomplished by introducing large mass fluctuations, suppressing bipolar thermal conductivity, and tailoring the band structure.

Schematic description of thermal conductivity suppression due to Pb and Se co-doping. Adapted from ref (Lu et al., 2019).

The introduction of mass fluctuations to half Heusler materials is yet another critical mechanism to reduce kth (Kang et al., 2020). For example, ZrNiSn having a crystal structure of MgAgAs family possesses bandgaps of about 0.20 – 0.25 eV. Their crystal structure consists of three interpenetrating face-centered cubic sublattices and a nickel sub-lattice vacancy. Shen et al. (Shen et al., 2001) introduced Hf on Zr site, causing phonon mass-fluctuations scattering, which led to the decrease in the value of k. They also studied the effects of introducing Sb on the Sn sites where they observed a significant increase in the thermopower due to the reduction of electrical resistivity without deteriorating the Seebeck coefficient. Also, they investigated the effect of isoelectronic incorporation of palladium in nickel sites on the overall thermal conductivity. Finally, a thermal conductivity value of 4.5 W/mK and a power factor of 22.1 µW/K2cm were obtained at room temperature for the composite Hf0.5Zr0.5Ni0.8Pd0.2Sn0.99Sb0.01. On the other hand, Browning et al. (Browning et al., 1999) suggested that although chemical substitutions immensely alter the chemical properties of ZrNiSn, the effect on the enhancement of the figure of merit is insignificant.

3.3 All-scale hierarchical architecture

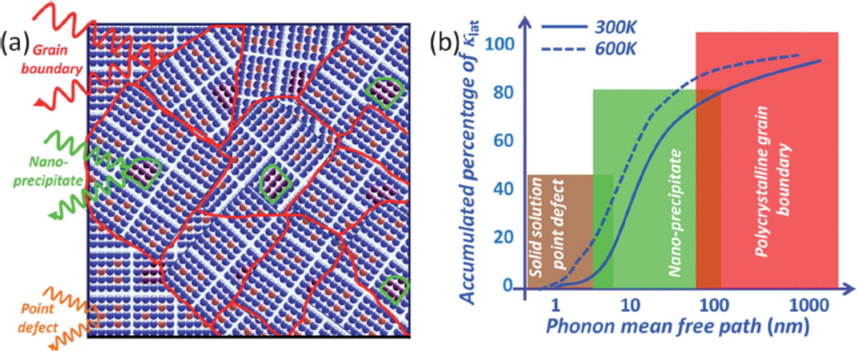

The all-scale hierarchical approach involves the simultaneous scattering of heat-carrying phonons through the full-spectrum range of their mean free path, via defect incorporation, nanoscale precipitation, and mesoscale grain boundary creation integrated to reduce the lattice thermal conductivity synergistically (Zhao et al., 2013). The strategy is robust enough to bring the thermal conductivity to its amorphous limit. Generally, nanostructured bulk thermoelectric materials contain some atomic defects either due to the dissolution of the dopants or partial dissolution of the second phase. Acoustic phonons are majorly responsible for the thermal transport in crystalline materials, and the phonons can be defined in terms of their mean free path and wavelength, each of which contributes to the heat transport (Biswas et al., 2012).

Atomic defects can quickly scatter the phonons with a mean free path between 0.1 and 1 nm due to defect-induced local bond-strain or mass contrast. Meanwhile, the phonons with a mean free path in the range 1–100 nm can be scattered by the nanoprecipitates. Such scattering predominantly occurs at the interface between the matrix and the precipitates or due to mass contrast. However, the phonons with a mean free path in the range 0.1–1 µm are mostly unaffected. Thus, the need to devise a means to suppress the long-wavelength phonons becomes necessary (Kang et al., 2020). To scatter the long mean free path phonons, there is a need to break the crystal to a mesoscopic scale (0.1 – 5 µm) followed by sintering of the fine powders to facilitate scattering at the interfacial regions. Elsewhere, it is reported that Si/Ge alloys grain sizes of 4 µm facilitated thermal resistance up to 26% due to grain boundary scattering (Zhao et al., 2014).

Therefore, to scatter the phonons through all mean free path ranges, from the nanoscale to microscale, the solid solution atomic defects, nanostructuring, and mesoscale approach must be integrated into a single sample as presented in Fig. 8. Fig. 8b shows the phonons distribution according to their mean free path and consequently assigned to their preferred mode of scattering. Biswas et al. (Biswas et al., 2012) applied the all-scale architectural approach to study the thermoelectric properties of PbTe-SrTe (4 mol%) composite doped with 2 mol% Na prepared by melting reactions of the solid precursors, followed by spark plasma sintering of the crushed ingots. They recorded a 30 – 50% enhancement in ZT compared to the melt-processed samples. They achieved a record high ZT of 2.2 at 915 K, underscoring the significance of the multi-scale approach to effectively reduce the lattice thermal conductivity, thus remedying the challenge of improving ZT.

The all-scale hierarchical approach to minimize the lattice thermal conductivity showing (a) atomic defects, nano-precipitate, and mesoscale grain boundary (b) Phonons distribution according to their mean free path. ()

Adapted from Zhao et al., 2014

Recently, Priya et al. (Kang et al., 2020) reported the successful implementation of the all-length-scale hierarchical approach on (Hf0.6Zr0.4)NiSn0.99Sb0.01 half-Heusler material doped with tungsten nanoprecipitates prepared using RF induction melting and spark plasma sintering to produce the required pellets. At the atomic scale, the multi-element alloying at M site facilitated reduced thermal conduction due to scattering at point defects within the lattice. At the nanoscale, hafnium nano precipitates were generated at the half-Heusler matrix due to the rapid fabrication process involved, contributing to the scattering of the medium range (1–100 nm) mean free path phonons. Finally, the long-scale mean free path phonons were scattered by the mesoscale grain boundaries resulting from sintering the sample. The integrated approach triggered an ultra-low thermal conductivity for the half-Heusler material, which consequently yielded ZT of 1.4 at 773 K and a ZT average of 0.93 between 300 K and 973 K. The material also exhibited a power density of 13.9 W/cm When used as in thermoelectric generator.

Elsewhere (Zhao et al., 2013), a ZT of 2.0 at 823 K was achieved for PbTe-MgTe composites doped with 2% Na via the all-scale hierarchical architecture. The Mg endotaxial nanostructures, coupled with the mesoscale microstructure, facilitated the reduction in the lattice thermal conductivity. Further decrease in the thermal conductivity was enhanced by Mg alloying, which increases the energy gap of PbTe, thus lowering the effect of thermally excited minority carrier diffusion, which increases the bipolar thermal conductivity.

Tingle et al. (Li, n.d.) found out that the thermoelectric properties of Sn2Bi can be significantly enhanced through fluorination. They observed a record-low thermal conductivity of 0.19 W m−1 K−1 and ultra-high ZT of 1.70 and 2.45 at 300 K for p-doped and n-doped compounds, respectively higher than the reported ZT of Bi0.48Sb1.52Te3 (ZT ∼ 1.4 at 475 K) and Bi2Te2.79Se0.21 (ZT ∼ 1.2 at 357 K). They attributed such improvement to the enhanced anharmonicity, reduced group velocity, and increased three-phonon scattering phase space.

3.4 Electronic band engineering

The preceding sections have discussed various ZT enhancement mechanisms through lattice thermal conductivity minimization, including nanostructuring, mass fluctuations, and an all-scale hierarchical approach. Herein, we discuss the power factor enhancement strategies by mainly boosting the Seebeck coefficient through intra-matrix band engineering via band convergence, band alignment, or resonance level formation. We demonstrated that a simultaneous increase in the Seebeck coefficient and electrical conductivity could be achieved at optimum carrier concentration.

3.5 Band convergence

Lead and tin chalcogenides exhibit a fascinating valence band structure. Apart from the conventional light hole valence band existing at the high-symmetry L-point of the Brillion zone, they possess an additional valence sub-band at the point, known as the heavy valence-band, at a relatively lower energy level (Banik et al., 2015).

At high temperatures, the p-type charge carriers can be accommodated into the two valence sub-bands. Due to their cubic symmetry, the two bands exhibit high degeneracy, which ultimately improves the thermopower. Previously, the literature suggested that while the

-band remains roughly at a constant energy level with respect to the conduction band, the L-band moves down gradually as temperature increases, depending on the energy offset between the two valence sub-bands, and passes the

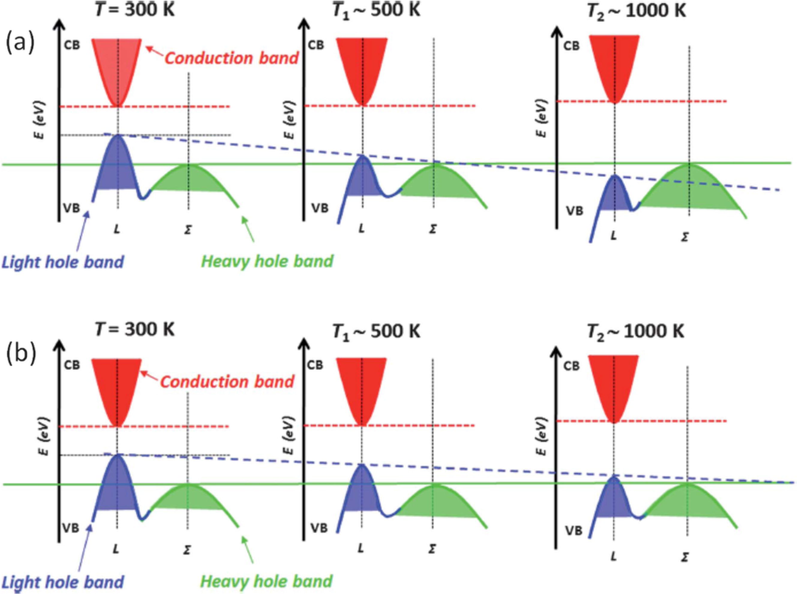

-band edge at a specific temperature (see Fig. 9) (Zhao et al., 2014). This model implies that the material rapidly changes from a direct gap to an indirect gap semiconductor with increasing temperature. However, recent studies have challenged this proposition. Hall-effect investigations revealed that the proposed convergence does not occur up to 1000 K temperature. Experimental results showed that PbTe maintained its direct gap behavior up to 800 K (Biswas et al., 2012), indicating the absence of valence band convergence with increasing temperature.

The two proposed models for the valence band convergence in the PbTe system as a function of temperature (a) The light hole band crosses below the heavy hole band (b) The second model showing the slow convergence with the L-band above the

-band. ()

Adapted from Zhao et al., 2014

This new perspective implies that as the temperature increases, the difference in energy between the two valence sub-bands may decrease. However, the L-band does not cross below the energy level of the -band. Thus, there exists a little controversy that needs to be rectified experimentally. In this notion, as the energy difference between the two valence sub-bands decreases, the heavy valence sub-band contribution to the transport increases due to the thermal excitation of the holes from the L to the band. Generally, heavy doping facilitates the heavy valence band's contribution to the Seebeck coefficient as it lowers the Fermi energy and minimizes the energy offset between the two valence sub-bands. Therefore, the contribution of the sub-band can be realized at low temperatures via heavy doping.

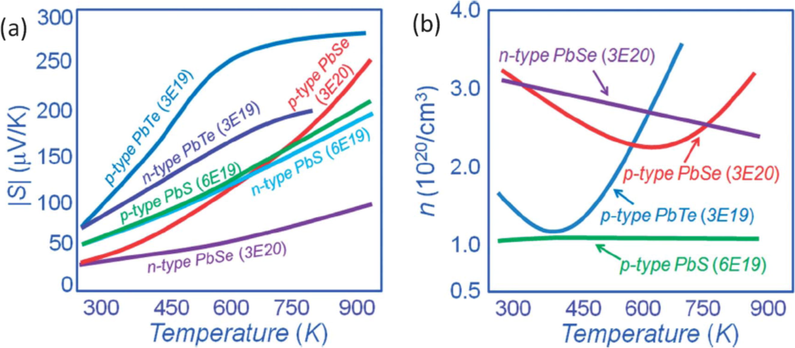

As depicted in Fig. 10, at a given carrier concentration, p-type PbTe exhibited a remarkably larger Seebeck coefficient than the n-type PbTe, especially at higher temperatures. Specifically, the Seebeck coefficient of the n-type PbTe is −180 µV/K, while that of the p-type PbTe with the same carrier concentration is + 270 µV/K (Pei et al., 2012; Lalonde et al., 2011). The excesses in the Seebeck coefficient can be attributed to the contributions from the heavy valence band. The n-type materials could not demonstrate such improvement due to the single-nature of the conduction band. The production of holes at the

band further enhances the Seebeck coefficient due to their large effective mass, as shown in equation (2). On the other hand, both p- and n-type PbSe exhibited nearly the same Seebeck coefficient at room temperature. However, the Seebeck coefficient of the p-type PbSe increased dramatically with rising temperatures. For instance, at 920 K, the value of the Seebeck coefficient for p-type PbSe is + 250 µV/K, while for n-type, it is −100 µV/K at the same carrier concentration (Zhao et al., 2013). The increase in the Seebeck coefficient for the p-type PbSe is attributed to the role played by the

band at higher temperatures. For the PBS system, both the n-type and the p-type samples exhibited a similar Seebeck coefficient up to 900 K temperature demonstrating the lesser impact of the heavy valence band (Zhao et al., 2011). This unique characteristic different from PbSe and PbTe may be attributed to the considerable energy offset between the light and heavy hole valence bands (about 0.4 eV).

(a) Seebeck coefficient as a function of temperature for lead chalcogenides showing the enhancement in p-type samples except for PbS which remains almost the same up to 900 K (b) Carrier concentration as a function temperature, the upturn shows the onset of

-band contribution.

Elsewhere, Shenoy et al. (Shenoy and Bhat, 2019) have demonstrated that Bi-doping in SnTe also facilitated valence band convergence. They reported an optimized ZT of 1.32 at 840 K due to the increase in the Seebeck coefficient. Similarly, Biswas et al. (Banik et al., 2015) have reported an increased Seebeck coefficient in SnTe resulting from Mg-alloying. They achieved a ZT of 1.2 at 860 K temperature. In summary, doping lead and tin chalcogenides with Hg, Mg, Cd, Ca, and Mn has resulted in valence band convergence (Banik et al., 2015).

DFT calculations demonstrate that the compositional alloying of these compounds Pb1-xAxQ (Q = Se and Te) with metals may trigger the convergence of the two valence sub-bands (D’Souza et al., 2020). As the solid solution fraction of A increases, both the L- and sub-bands lower their energies with the L-band moving faster than the sub-band, thus, narrowing their energy offset. Noteworthy, if the second phase has a larger bandgap, the principal bandgap (L- point to conduction band) will increase with the increase in the second phase. In general, such calculations suggest that the energy level of the sub-band does not change significantly. Hence, alloying via a solid solution is a practical approach to improve the Seebeck coefficient.

3.6 Resonance level formation

The distortion in the density of state can significantly enhance the Seebeck coefficient of thermoelectric semiconductors. Some group III impurities induce specific characteristics in IV-VI semiconducting materials related to the creation of deep and resonance energy levels. The discovery of this phenomenon has opened a new window for manipulating the thermoelectric properties of IV-VI compounds. The Fermi level is mainly pinned at the impurity states. The origin of the doping-induced virtual energy levels is still a subject of research. They are ascribed to either existence of an additional Fermi surface, or hybridization between neighboring Te-state (for Tellurides) and an excited resonant atom, or due to valence fluctuation (Heremans et al., 2008).

The electronic properties of different compounds doped with a particular group III elements turned out to be diverse. Meanwhile, doping the same compound with different group III elements also yielded different results. The critical factor here determining the expected outcome is the region in the electronic spectrum in which the impurity states exist. For instance, indium acts as a donor in PbTe, creating impurity levels near the conduction band, pinning the chemical potential in this part of the electronic spectrum. However, it forms a resonant state within the valence band of SnTe and therefore acts as an acceptor element (Heremans et al., 2012).

Generally, the formation of resonant states influences the thermoelectric transport properties due to two main reasons: (1) The distortion of the electronic density of states, which translates itself as increased DOS near a characteristic energy level, and (2) Enhanced scattering resulting from the resonance of carriers between the conduction band of the host matrix and the localized impurity states from the dopants. To achieve maximum performance, extrinsic doping is often necessary to optimize the figure of merit because usually, intrinsic defects do not provide the optimum carrier density. Another viable means of improving the performance of materials doped with resonant elements is to control the carrier concentration via the introduction of an extrinsic (non-resonant) element to independently tune the carrier density for optimum ZT (Zhou et al., 2016).

Several works have been conducted to improve the TE performance of IV-VI compounds by forming resonant energy levels (virtual states). For example, Zhang et al. (Zhang et al., 2013) reported a high ZT of 1.1 for resonant In-doped SnTe at 873 K. Similarly, Heremans et al. (Heremans et al., 2008) observed a high ZT of 1.5 at 773 K for resonant Tl-doping in PbTe for Tl0.02Pb0.98Te. Recently, Shenoy et al. co-doped SnTe with two resonant atoms (Bi and Zn). They observed remarkable improvement in the performance, with ZT reaching 1.6 at 840 K and a record high figure of merit of 0.86 between 300 K and 840 K. Thus, this unveils a novel strategy to improve the performance of the Pb-free compound further. Elsewhere, Zhang et al. (Ma et al., 2019) reported a dramatic increase in the figure of merit of SnTe resulting from Pd-In co-doping, where indium facilitated the formation of resonant levels while Pd stimulated valence band convergence.

3.7 Substructure approach

Another distinctive approach to mitigate the PGEC difficulty is via the substructure approach, where each region serves a different purpose (Zhu et al., 2019; Zhang et al., 2019). An insulating oxide layer could be used to separate free charge-carriers encapsulated to planar Cu-O sheet. The oxide layer accommodates the dopant-atoms that produce electrons to the planar Cu-O sheet. The isolation of the conducting region from the doping region ensures effective screening of the charge-carriers from the dopants, thus, avoiding a decrease in mobility due to carrier-trapping. In this proposed configuration, the phonon-glass region accommodates the dopant atoms and disordered-structures without deteriorating the electron-crystal region. The dimension of the electron-crystal regions is desired to be in the order of angstroms or nanoscale to facilitate electron filtering, thereby enhancing the Seebeck coefficient. Additionally, phonons with short mean free-path can be scattered within the phonon-glass region. CaxYb1-xZn2Sb2 is a promising thermoelectric material that uses the substructure approach. However, its thermal conductivity is relatively high (about 1.5 W/mK) compared with the state-of-the-art materials (Gascoin et al., 2005). For heat transport, a wide range of phonons are involved, and hence the need to introduce a large-scale disorder to scatter long-wavelength phonons. Combining the nanostructuring and substructure approach could be crucial in improving the thermoelectric performance.

We have summarized in table 2, those materials that have exhibited an excellent thermoelectric figure of merit together with some important remarks on the potential reasons behind their performance.

Fabrication Technique

Materials produced

Precursors used

Remarks

Refs.

Solvothermal processNanoflowers of Bi2Te3

Single crystals of Bi2Te3 nanostructuresNa2TeO3, Bi(NO3)3·5H2O, acetone, ethanol, PVP K30, and formic acid

Ethylene glycol, sodium dodecyl benzene sulfonates, EDTA, NaOH, Na2TeO3, and BiCl3

Low-cost. defective nanoflowers yielded medium performance (ZT = 0.68). The authors observed that the nucleation process of thermoelectric compounds is controlled by the type of solvent used.

Optimum TE power conversion was realized due to increased phonon scattering which lowers the thermal conductivity.(Guo et al., 2016); (Liang et al., 2011)

(Deng, 2002)

(Zhang et al., 2013)

Chemical method

(solution process)

single crystal of SnSe

Bi2Te3 nanoparticlesEthylenediamine, SnSe powder, and acetonitrile,

hydrazine hydrate, glycol, ethylene, BiCl3, and Te powderA remarkable power factor was obtained emanating from the synergistic effect of the textured-microstructure due to transitions from 2D SnSe2 to SnSe phases

The authors recorded high ZT as a consequence of reduced thermal conductivity.(Heo et al., 2019)

(Srivastava and Singh, 2012)

Facile solution

Nanocrystalline Bi2Se3 and Bi2Te3

[BiCl3], NaBH4, methanol, Se, powder, [Bi(NO3)3] and [Bi(CH3COO)3]

They carried out microstructural characterization and obtained spherically shaped Bi2Se3.

(Mntungwa et al., 2014)

Hydrothermal

method

Hydrothermal methodnanorods, nano-plates, and nanotubes of Bi2Te3

Bi2Te3-flakes

2D nanoplates of Ge-doped SnSe

Te powder, BiCl3, Na2-EDTA

BiCl3 and Te powder assisted by NaBH4 and NaOH

-

-

SEM revealed non-uniform structures, enhanced carrier mobility led to an increase in the overall TE performance

Incredible TE performance was achieved, ZT of ∼ 2.1 at 873 K, resulting from an increased flow of p-type carriers induced by Ge(Kim et al., 2012)

(Li et al., 2011)

(Chandra and Biswas, 2019)

Large-scale zone melting technique

Zn and Cu-doped Bi2(Te0.9Se0.1)3 ingots

–High ZT of 1.10 and 1.15 was recorded for the Zn and Cu loaded ingots, resulting from decreased thermal conductivity.

(Wang et al., 2013)

Molecular-Beam-Epitaxy

PbTe/Pb1-xEuxTe

–A Remarkable increase in ZT to 2.0 at 300 K temperature was observed

(Tan et al., 2016)

Bridgman technique

single-crystalline Bi2Te3

–Anisotropic transport properties induced by the growth mechanisms were observed.

(Nassary et al., 2009)

RC-sputtering

Fe2V1-xWxAl thin film samples

An incredible TE figure of merit above 5.0 was accomplished for the Heusler materials.

(Hinterleitner et al., 2019)

High-pressure torsion

NbFeSb and Ti0.5Zr0.5NiSn-based materials

–ultra-low к resulting from deformation-induced defects + lattice stiffening caused by the torsion method was realized.

(Rogl et al., 2020)

Arc-melting technique

(Ti, Hf, Zr)CoSb composites

–Fe-inclusion in the Co sites to make TiFexCo1-xSb (at × = 0.15) has improved the TE performance of such material

(Sekimoto et al., 2005)

Ball-milling followed by dc-current hot-pressing

Zr0.5Hf0.5CoSb0.8Sn0.2

–Increased phonon scattering reduces к, however, high agglomeration gives rise to larger grains scattering electrons at the detriment of the charge-carrier mobility.

(Yan et al., 2011)

Czochralski technique

Ba8Ga16Ge30

–They obtained homogeneous crystal with a larger Ga/Ge ratio due to higher pressure and larger pulling, plus low к.

(Hou et al., 2009)

Materials

Synthesis method

ZT

Temp.

Remark

Ref.

Fe2V0.8W0.2Al thin-films

Sputtering + DFT

6.0

393 K

The authors attributed the high ZT value to mass fluctuations, their DFT suggested the films to be at metastable states.

(Hinterleitner et al., 2019)

Bi2Te3/Sb2Te3 superlattice

–

2.4

300 K

The potential barrier served as phonon scattering centers to lower the value of lattice thermal conductivity

(Venkatasubramanian et al., 2001)

Bi2Te3 nanostructures

Hydrothermal technique

1.16

300 K

High thermopower was achieved leading to increased ZT

(Wu et al., 2013)

nanoplates of Ge-doped SnSe

Hydrothermal + spark plasma sintering

2.1

873 K

Ge-inclusion facilitated p-type carrier supply thereby boosting the TE power factor

(Chandra and Biswas, 2019)

Zn and Cu-doped Bi2(Te0.9Se0.1)3

Large-scale zone melting technique

1.15

300 K

Metal doping helps scatter phonons which are the major contributors to thermal conductivity

(Wang et al., 2013)

PbTe/Pb1-xEuxTe

Molecular-Beam-Epitaxy

2.0

300 K

Narrowed MQW creates a spike in the DOS near the Fermi level which improves the Seebeck coefficient

(Hicks and Harman, 1996)

hole-doped SrTe-alloyed PbTe

Chemical method

2.5

923 K

Enlargement of the bandgap due to the heavily Sr-doped into the matrix of PbTe enhances TE performance

(Tan et al., 2016)

CdSe-modified PbSe

–

1.4

870 K

High ZT achieved through synergistic optimization of thermal and electrical transport properties

(Qian et al., 2019)

Ba8Ga16Ge30

Czochralski technique (Hou et al., 2009)

1.3

1000 K

Reduced thermal conductivity with elevated electrical conductivity at a high Ga/Ge ratio was recorded

(Bentien et al., 2004)

Ba8CuxGa16-xSn30

Sn-flux method

1.35

540 K

Different Cu concentration at Ga sites yielded high ZT.

(Deng and Saiga, 2010)

Yb0.3Co4Sb12/0.05CoSi composite

In-situ precipitation

1.5

873 K

Enhanced low-energy carrier filtering at the potential barrier improved Seebeck coefficient

(Qin et al., 2019)

Ba0.08La0.05Yb0.04Co4Sb12

Induction melting

1.7

800 K

The introduction of ions to the structure facilitates electron transfer to the cations for charge-balancing

(Shi et al., 2011)

Se-doped Mg3.2Sb1.5Bi0.5

Ball milling and hot pressing

1.7

700 K

Mn, Co inclusion enhances charge carrier scattering mechanisms

(Zhang et al., 2019)

SnS0.91Se0.09

DFT

1.6

873 K

A remarkable increase in ZT achieved through the synergistic optimization of carrier mobility and effective mass

(He et al., 2019)

Bi0.4Sb1.6Te3

Resistance pressing sintering

1.1

343 K

The authors observed a decrease in both к and σ due to an increase in porosity.

(Hu and Hu, 2019)

chalcopyrite Cu0.7Ag0.3Ga0.4In0.6Te2

Ball-Milling and hot-pressing

1.6

873 K

The authors propose that isoelectronic multi-element alloying reduces the value of к for chalcopyrite compounds

(Zhang et al., 2019)

S,Pb-co-doped SnSe

Facile hydrothermal method

1.85

873 K

They claim that co-doping widens the bandgap and consequently reduced the bipolar thermal conductivity

(Lu et al., 2019)

F-doped Sn2Bi

DFT

2.45

300 K

High ZT achieved via enhanced anharmonicity, reduced group velocity and increased three-phonon scattering phase space

(Li, n.d.)

Bi2Te3

Non-equilibrium reaction triggered by spark plasma sintering

1.1

470 K

Appreciable ZT achieved by suppressing Te-vacancy to control point defect

(Wang et al., 2019)

3.8 Synergistic integration of multiple mechanisms

The most effective way to realize a cutting-edge figure of merit in thermoelectric materials is to devise a means of strategically integrating the multiple approaches in a single sample. The electronic structure engineering tactics can enhance the power factor while the thermal conductivity can be minimized by considering the all-length scale hierarchical techniques. However, such synergistic improvements are not easy to apply. For example, when extrinsic dopants are introduced to regulate the carrier density stimulate band convergence, they tend to increase the electronic thermal conductivity and reduce the figure of merit. Similarly, when nano precipitates are injected to scatter the medium wavelength phonons, the low energy charge carriers produced affect the Seebeck coefficient's value adversely. Therefore, the systematic improvement of one parameter without inducing a deleterious impact on the rest is the field's future research trend.

Recently, many groups have attempted to combine as many of the approaches as possible to achieve high ZT. Kanatzidis et al. (Zhao et al., 2016) reported a remarkable improvement in ZT for the SnTe system nanostructured with SrTe and doped with several elements (Ga, Bi, and In). They successfully lowered thermal conductivity and enhanced electrical transport properties. Similarly, Kang et al. (Kang et al., 2020) achieved a ZT of 1.4 at 773 K for half Heusler (Hf0.6Zr0.4)NiSn0.99Sb0.01 via a synergistic effect of carrier filtering integrated with all-scale hierarchical phonon scattering. Furthermore, Zhao and his team (Zhao et al., 2013) achieved a ZT of 2.0 for Na-doped PbTe in 6% MgTe. They ascribed the high performance to the simultaneous increase in the power factor through valence band convergence, a decrease in the lattice thermal conductivity via an all-scale hierarchical approach, and bipolar thermal conductivity suppression.

Some groups combined binary thermal conductivity minimization and enhancement of the carrier transport properties (Khitun et al., 2000; Balandin and Lazarenkova, 2003). They achieved such a milestone using Quantum-dot-superlattice (QDS) to improve the quantum confinement of carriers. For the QDS materials, the electronic conduction occurs due to the hopping between the dots, mainly characterized by low-mobility. Therefore, with QDS, the electrical transport properties should be equally a matter of concern as the thermal transport. The formation of 3D extended mini bands through regimentation and strong coupling was proposed instead of localizing the quantum-dot states. The fabrication of 3D regimented quantum dot superlattices of Ge grown on Si was suggested (Balandin and Lazarenkova, 2003). Typically, due to the spatial confinements, an improved phonon relaxation rate was observed, resulting from substantial modification in phonon group velocity. Multiple works indicated a considerable reduction in the lattice thermal conductivity of Ge/Si QDS than their bulk counterparts (Khitun et al., 2000).

The use of superlattices as promising thermoelectric materials also enables the application of multiple approaches to improve ZT. A superlattice system of Si/SiGe multiple-quantum-well (MQW) structured samples was studied by Dresselhaus et al. (Dresselhaus et al., 1999), where they recorded a dramatic increase in the power factor. Similarly, PbTe/Pb1-xEuxTe MQW was grown using the MBE technique at different quantum well’s width (Hicks and Harman, 1996). A remarkable increase in ZT to 2.0 at 300 K temperature was realized. Generally, compared with their bulk counterparts, the 2D MQW structures demonstrate an improved figure of merit with narrowed quantum well's width, which causes a hike in charge carriers' density per unit volume. In summary, the thermoelectric power factor can be enhanced by the carrier pocket engineering (CPE), and the Seebeck coefficient can be boosted through trapping of cold charge-carriers by the band discontinuities in the quantum wells (Dresselhaus et al., 2007). It was established that CPE could be employed to adjust the barrier thickness and the quantum well's width to set the energies of the L and X point sub-bands to below the lowest gamma point sub-band, thereby increasing the density of states of the L and X point sub-bands. This phenomenon was typical in the whole superlattice materials like GaAs/AlAs. A figure of merit of 0.41 was obtained for the whole superlattice GaAs/AlAs at room temperature, which is more than 40 times that of GaAs. Experimentally, the enhancement in Z3DT was observed for several superlattices such as Si/SiGe, PbTe/Pb1-xEuxTe, and Bi2Te3/Bi2Se3. However, their power factor did not reflect the quantum carrier-confinement enhancement effect (Dresselhaus et al., 1999).

4 Multiple techniques for thermoelectric materials fabrication

In this section, different sample fabrication techniques for various high-performance TE materials have been summarized together with their significant achievement to provide a clear insight into the choice of the synthesis process for efficient thermoelectric power conversion efficiency.

Several PGEC materials have been studied for improved TE figure of merit (Pavan Kumar et al., 2019; Hsieh et al., 2019; Parbatani et al., 2019; Li et al., 2019; Li et al., 2018; Vikram and Johnson, 2018; Chen et al., 2018; Ge et al., 2018). Researchers have also employed different synthesis methods to develop such materials to control the structures down to the nanoscale. Efficient thermoelectric compounds are often intensively researched, e.g., group IV-VI materials like SnTe, PbS, PbSe, SiGe, PbTe, BiTe, and GeTe. Pb's toxicity, coupled with the shortage of Ge, enables materials such as BiTe and SnSe (Jin et al., 2018) to dominate the thermoelectric field (He et al., 2019).

The two main approaches used to fabricate nanomaterials are the bottom-up and top-down mechanisms. In the former, nanostructures are grown by bringing pieces together (Ramirez et al., 2020). However, in the latter, bulk materials are broken down into nanostructure level (Mamur et al., 2018). For over a decade, the bottom-up approach has outshined the top-down approach and is becoming more promising for different nanoscale applications as it enhances nanostructured-materials development with highly stoichiometric compositions and fewer defect records. For the bottom-up approach, generally, the growth processes are categorized into chemical and physical methods. The former comprises solvothermal processes, electrolysis deposition, laser chemical vapor, electrochemical, wet chemical method, chemical oxidation, facile solution, and biomolecule-assisted hydrothermal. The physical growth methods include spray pyrolysis, pulsed laser deposition, sputtering, and thermal evaporation methods.

Bulk Bi2Te3-based compounds have exhibited promising thermoelectric performance compared with their counterparts. There have been several efforts to increase the TE efficiency of these materials via a nano-structuring approach where low-dimension nanocomposites such as nanoplates, nanorods, nanosheets, nanoflowers, nanotubes, and nanowires are developed using different fabrication techniques. For example, Rama et al. (Venkatasubramanian et al., 2001) obtained a remarkable ZT ∼ 2.4 in a thin film-based superlattice of p-type Bi2Te3/Sb2Te3, which is an incredible improvement compared to the state-of-the-art Bi2Te3 materials. They attributed the enhancement in the figure of merit to the relative advantage of thin-film materials over the bulk TE compounds since quantum confinement of charge carriers is feasible in the former.

Guo et al. (2016) used a solvothermal process to prepare hierarchical nanoflowers of Bi2Te3 with additive nanostructured defects. They used precursors such as Na2TeO3, Bi(NO3)3·5H2O, acetone, ethanol, PVP K30, hydrazine monohydrate, and formic acid. Highly stoichiometric Bi2Te3 was realized under energy dispersive spectroscopy (EDS). X-ray diffraction analysis of their sample matched well with the rhombohedral crystal structure of Bi2Te3, and the crystalline lattice fringe was obtained through a high-resolution transmission electron microscope (HRTEM) as 0.31 nm Field emission scanning electron microscopy revealed structures consisting of nanoflowers with an average diameter of about 550 nm. Their thermoelectric characterizations yielded a maximum ZT value of 0.68 at 475 K. Finally, the authors inferred that the optimum efficiency of the defective nanoflowers provides for a new dimension to utilizing nanomaterials as thermoelectric power generation and refrigeration applications.

Similarly, Zhang and his team (Zhang et al., 2013) used a low-temperature solvothermal synthesis method to fabricate single crystals of Bi2Te3 nanostructures. Morphological and structural characterizations of their samples showed a uniform surface having rhombohedral geometry and near stoichiometric compositions. They used starting materials such as ethylene glycol, sodium dodecyl benzene sulfonates, EDTA, NaOH, Na2TeO3, and BiCl3. The authors realized several hexagonal nanostructures and nanosheets for different experimental conditions. The nanostructures' sharp edges demonstrated the samples' high-crystallinity, while HRTEM images vividly depicted the structurally uniform lattice fringes having about 0.21 nm spacing. The authors suggested that the Bi2Te3 microstructure could be affected by many factors, including the type of surfactants, NaOH concentration, the reaction temperature, etc. Lastly, they studied the transport properties of hot-pressed bulk samples where they observed a significant reduction in the thermal conductivity resulting from increased phonon scattering at the interfaces.

Also, Liang et al. (Liang et al., 2011) fabricated Bi2Te3 from Bi2O3 and Te powder using a solvothermal approach. For the preparation method, the two starting materials were added to the solution of ethylene glycol and polyvinylpyrrolidone without NaOH. The authors obtained a hexagonal crystal structure with lattice parameters a = 0.4395 nm and c = 3.044 nm. Similarly, TEM images revealed the anticipated hexagonal lattice fringes with an average spacing of 0.22 nm, indicating the material's single crystalline phase. Besides, they obtained infrared-active mode with Raman spectroscopy indicating the presence of forbidden structure in the bulk crystal.

Furthermore, Deng and coworkers (Deng, 2002) employed a solvothermal reaction to fabricate nanostructured Bi2Te3. They carried out a reaction of hydrated bismuth (III) chloride (BiCl3·2H2O), KBH4, Te powder, and KOH with N,N-dimethyl formamide as solvent at temperatures between 100 and 180 °C. The authors suggested two mechanisms to obtain the material. First is the reduction of Te to Te2- followed by a reaction with Bi3+. The second approach is through the direct combination of the metals where Bi ions would be easily reduced to Bi metal by KBH4 to produce the nanocrystalline Bi2Te3. Consequently, they highlighted that the first mechanism would likely occur for low reaction temperatures or short reaction times while the second mechanism would likely dominate at higher temperatures or longer reaction times. They observed the dependence of the samples' morphology on the reaction and the growth temperature as well. Furthermore, structural characterization revealed rhombohedral geometry with lattice parameters a = 0.438 nm and c = 3.050 nm, and they achieved excellent stoichiometric compositions under energy dispersive spectroscopy. Finally, the authors observed a significant effect of the type of solvent used in the nucleation process of thermoelectric compounds.

Recently, Sueng et al. (Heo et al., 2019) prepared a highly-textured and hole-doped single crystal of SnSe thin-films using a scalable and low-cost solution process. They recorded a remarkable power factor of 4.2 µW/cm-1K−2 at 550 K more than the previously obtained value for single-crystal SnSe. They attributed such improvement in the thermoelectric performance to the uniformity of the film, high-stoichiometry, and synergistic effect of the textured-microstructure, which were achieved through the transitions of 2D SnSe2 to SnSe phases.

A facile solution technique was used by Mntungwa and his team (Mntungwa et al., 2014) to synthesize nanocrystalline Bi2Se3 and Bi2Te3. Their starting materials were bismuth carbonate salts [Bi2(CO3)O2], toluene, tri-n-octylphosphine (TOP), bismuth chloride [BiCl3], hexadecylamine (HDA), NaBH4, methanol, deionized water, bismuth nitrate [Bi(NO3)3], and bismuth acetate [Bi(CH3COO)3]. Their method involves Te-reduction by NaBH4 and high-temperature thermolysis in alkylamine. They realized spherically oriented crystals having an average diameter of about 25 nm with oleylamine and hexadecylamine as capping agents over the temperature ranges. They observed a microstructure having distinct lattice fringes with an average spacing of 0.34 nm under HRTEM, in tandem with the high-intensity planes of Bi2Te3 rhombohedral geometry.

Wu and his team (Wu et al., 2013) prepared the alloy nanostructures of Bi2Te3 using a hydrothermal technique. The precursors used were NaBH4, NaOH, EDTA, Te-powder/Na2TeO3, and BiCl3. The experiment was carried out in an open beaker, and a magnetic stirrer was employed for thorough mixing. The X-ray diffraction peak matched well with the rhombohedral crystal geometry of the Bi2Te3 without any observed impurity, although different Te sources were used during the synthesis. However, they observed a slight broadening in the diffraction peaks attributed to the small particles' sizes evident from the FESEM images. On the other hand, the SEM images exhibited varying morphological characteristics. Finally, the authors recorded a high ZT value of 1.16 resulting from high electrical conductivity and thermopower coupled with low thermal conductivity. These findings would be useful to produce cost-effective and large-scale thermoelectric materials with a high figure of merit.

On the other hand, nanostructured thermoelectric Bi2Te3 powders with varying morphological characteristics (nanorods, nanoplates, and nanotubes) were prepared using a hydrothermal approach by Kim et al. (Kim et al., 2012). During the preparation process, Te powder was mixed with BiCl3 and Na2-EDTA at different temperatures. According to the authors, the growth temperatures and the stabilizing agents influence the morphology greatly. Interestingly, X-ray diffraction confirms the rhombohedral geometry of Bi2Te3 with lattice parameters a = 0.4381 nm and c = 3.0460 nm for all the different morphologies. The authors proposed that the formation of Bi2Te3 could be explained as; The Bi3+ ions regulated by Na2-EDTA while the reduction of Te by NaBH4 produced Te2- and consequently, the target materials are constructed.

Li and coworkers (Li et al., 2011) used hydrothermal and chemical oxidation techniques to synthesize Bi2Te3-flakes. The authors fabricated the compound through the mechanical blending of BiCl3 and Te powder assisted by NaBH4 and NaOH to regulate the PH parameter. The structural study using XRD indicated the hexagonal phase of Bi2Te3 without any traceable impurity. However, the FESEM images revealed non-uniform structures with dimensions ranging from 20 to 500 nm. Finally, they observed the enhancement of the thermoelectric power factor at elevated temperatures, which could be attributed to improved carrier mobility.

Chandra and his team (Chandra and Biswas, 2019) synthesized 2D nanoplates of Ge-doped SnSe using a hydrothermal approach followed by spark plasma sintering and realized a peak ZT of ∼ 2.1 at 873 K. Also, a peak anisotropic ZT of 1.75 parallel to the pressing direction was obtained at the same temperature. They attributed such a figure of merit improvement to the supply of p-type charge-carriers induced by Ge inclusion, which ultimately increased the power factor. Ultra-low thermal conductivity was also observed due to the plenty of interfaces and high anharmonicity in the lattice.

A biomedical-assisted hydrothermal technique was utilized by Mi et al. (2010) to grow Bi2Te3-based nanostructures for enhanced thermoelectric performance. The chemicals used by the team include K2TeO3, NaOH, BiCl3, and alginic acid. The sample was grown at 220 °C temperature for 24 h. Their morphological studies showed a cluster of plate-like structures with average thickness and diameter of 10 and 100 nm respectively. The NaOH density was found to play a significant role in tuning the morphology of the material. Furthermore, their thermoelectric properties study revealed high room-temperature performance.

Additionally, Zhao et al. (Zhao and Wang, 2010) fabricated Bi2Te3 with different morphologies such as flakes, flower-like clusters, nanotubes, and nanowires using a hydrothermal approach. They used precursors such as Te powder and BiCl3, while NaBH4 was used as a reducing agent, and NaOH was used to control the PH level. The XRD peaks were all indexed to the hexagonal Bi2Te3 without any traceable phase. Their SEM images revealed irregular flakes with dimensions ranging between 60 and 400 nm. The authors have emphasized the importance of temperature and reaction time in their experiment to achieve the nano-structuring of these materials to improve their thermoelectric figure of merit.

Wang and his team (Wang et al., 2013) used a large-scale zone melting technique to prepare Zn and Cu-inclusions in Bi2(Te0.9Se0.1)3 ingots. Their surface and chemical characterizations revealed that the metal elements were embedded at the interfacial grain boundaries influencing the thermal transport. They reported appreciable enhancement in the ZT value resulting from the increased density of state effective mass even though Zn acted as a weak donor. The authors reported a significant increase in the power factor for Cu nanoinclusion coupled with a decrease in the lattice thermal conductivity resulting from increased phonon scattering. A ZT value of 1.10 and 1.15 was recorded for the Zn and Cu loaded ingots, respectively, indicating a 21% increase relative to the commercially doped ingots. Such an increase in the thermoelectric figure of merit makes the technique suitable for TE materials' commercial-scale production.

Chen and coworkers (Chen et al., 2012) utilized a cryogenic grinding technique to fabricate nanostructures of Bi2Te3 from its powdered coarse particles having an average size of 5 mm. Their XRD studies revealed more textured materials from the ingots compared to the grinded particles. They observed more defects along the basal plane during the manufacturing phase. Furthermore, they presented a comparative analysis between their work and others that utilized spark plasma sintering (SPS) and high energy ball milling (HEBM) techniques, results of which signals the high potential of their synthesis process to produce finer and high-quality nanostructures.

A refluxing method was used by Gupta et al. (2012) to grow nanostructured Bi2Te3. They used precursors such as KOH, EDTA, BiCl3, NaBH4, and Te powder. Morphological studies of their samples revealed a nanorod-like structure of 100 nm length and a 10 nm radius. They observed a reduction in the particles’ dimension with increased KOH concentration. The authors suggested that a substantial variation in the particle form and sizes could be realized by changing the reaction parameters.

A low-cost chemical method was employed by Srivastava et al. (Srivastava and Singh, 2012) to fabricate Bi2Te3 nanoparticles at 50 °C. They used starting materials; hydrazine hydrate, glycol, ethylene, BiCl3, and Te powder. X-ray diffraction analysis of the samples revealed the polycrystalline rhombohedral crystal geometry of Bi2Te3 nanostructures with an average crystallite size of 30 nm. The authors recorded a high thermoelectric figure of merit consequence of low thermal conductivity at room temperature. Similarly, Kim et al. (Kim et al., 2010) used a simple chemical method to fabricate Bi2Te3 nanostructures. The precursors used include TeCl4, BiCl3, and polyol solvent of ethylene–glycol. X-ray diffraction analysis revealed the rhombohedral geometry of Bi2Te3 with an average grain size of 300 nm. The authors observed significantly low thermal conductivity, which consequently improved the thermoelectric figure of merit for the Bi2Te3 nanomaterials.

Nanoparticles of Bi2Te3 were prepared by Kim and his colleagues (Kim et al., 2011) using a wet chemical reduction approach. They started with chemicals such as (Bi(NO3)3) and Te powder, while ascorbic acid and ethylene diamine tetraacetic acid were used to stabilize the precursors as reducing agents. They realized the rhombohedral geometry of the materials with uniform crystallite dimensions. Their thermoelectric transport properties yielded significantly low thermal conductivity, which eventually improved the compound's thermoelectric figure of merit.

Scheele et al. (Scheele et al., 2009) employed a Schlenck technique to synthesize Bi2Te3 nanostructures in the inert atmosphere. Single-crystalline bismuth telluride of 10 nm average crystallite sizes was realized. Their x-ray diffraction spectroscopy revealed the rhombohedral crystal geometry of the material with slight peak broadening indicating the particles' small size. The authors observed polycrystalline behavior from the selected area electron diffraction fringe patterns. Their thermoelectric transport properties measurements demonstrated a low concentration of charge carriers leading to small electrical and thermal conductivities.

The mechanical alloying technique was employed by Zakeri and coworkers (Zakeri et al., 2009) to fabricate Bi2Te3 nanocrystals by using Bi and Te as initial materials. They accomplished the nanocrystalline material only after 5 h of milling, although the complete process takes about 25 h. The hexagonal crystal structure of the material was realized and the Scherrer formula was used to estimate the average domain size (9 – 10 nm). Morphological studies revealed flakes-like structures scattered across the sample. The stability of the synthesis phase at high temperature (500 °C) was realized during the heating of the ball-milled particles with differential thermal analysis.

PbTe/Pb1-xEuxTe multiple-quantum-well-structured samples were prepared using the Molecular-Beam-Epitaxy technique with varying quantum well’s width at × = 0.07 (Hicks and Harman, 1996). A remarkable increase in ZT to 2.0 at 300 K temperature was observed, which they attributed to enhanced power factor. Similarly, Tan et al. observed a record ZT of ∼ 2.5 at 923 K in a heavily hole-doped SrTe-alloyed PbTe beyond its solubility limits (less than 1 mol%). They attributed the enhancement of the TE performance to the bandgap's enlargement due to the high Sr doped into the matrix of PbTe, which significantly intensified the power factors (Tan et al., 2016).

Qian et al. (Qian et al., 2019) reported an exciting work on the modification of PbSe to replace the costly and less abundant moderate-temperate thermoelectric PbTe. They introduced CdSe, which possesses a larger bandgap and similar crystal structure compared with PbSe leading to improved effective-mass through conduction band flattening, and suppression of both the bipolar and lattice thermal conductivities due to bandgap enlargement and the presence of nano-defects respectively. They achieved a high ZT of ∼ 1.4 at 870 K resulting from synergistic optimization of thermal and electrical transport properties, making the material a promising candidate for moderate-temperature TE applications.

Nassary and his team (Nassary et al., 2009) used the Bridgman technique to grow single crystalline Bi2Te3. The authors studied the dependence of electrical conductivity on temperature, Hall coefficient, and other thermoelectric properties for two crystallographic directions. Their investigations revealed a positive sign of the Hall coefficients and Seebeck parameters, implying that holes are the dominant charge carriers, and hence the material is a p-type. On the other hand, they observed the transport properties to be completely anisotropic. They reported three distinct regions in their Hall effect measurement curve; extrinsic, transition, and intrinsic regions between 163 and 293 K, 293 – 388 K, and 388 – 528 K respectively. They attributed the scattering process in the material to some faults and stoichiometric vacancies. Finally, they suggested that increased defects existed at higher temperatures.

The effects of 0-D defects such as antisites, dopants, interstitials and vacancies, 1-D defects like a screw and edge dislocations, 2-D defects e.g. grain boundaries, and 3-D defects like nanoinclusion of structures on the performance of TE materials was investigated by Liu and his colleagues (Liu et al., 2016). They suggested that the defects should be drastically minimized for better TE efficiency since the Seebeck coefficients, electrical and thermal conductivities are reflections of phonon and charge transports. An alternative approach to enhance the thermoelectric efficiency of these materials was developed in their experiments.

Elsewhere (Ashalley et al., 2015), a detailed review of the fabrication and characterization of Bi2Te3 compounds of 0D, 1D, and 2D was presented. Their work encompasses the synthesis method, nanostructure control, and thermoelectric properties studies. Furthermore, the interconnection between the topological insulating characteristics of the Bi2Te3-based materials and the enhancement of their thermoelectric figure of merit was highlighted. The authors suggested that Bi2Te3-based nanomaterials would continue to be the leading next-generation thermoelectric energy harvesters.

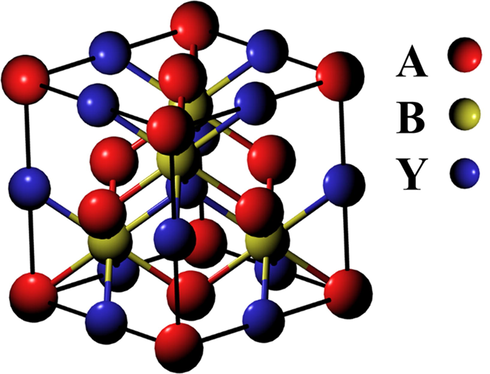

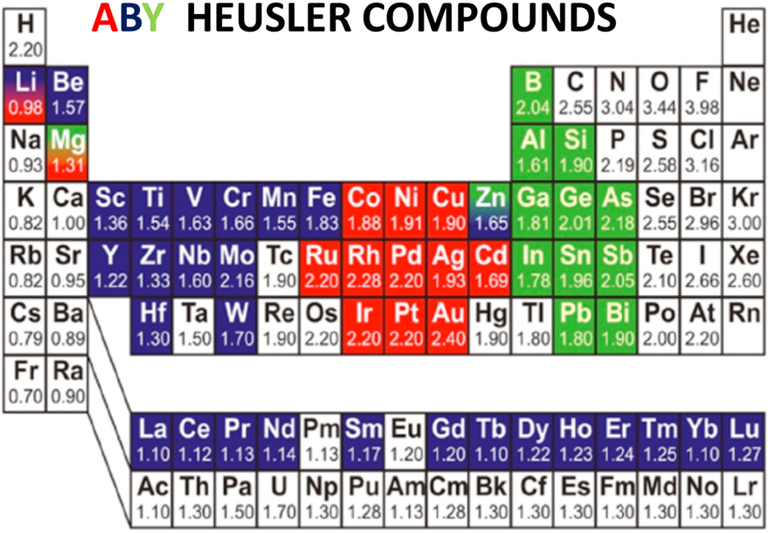

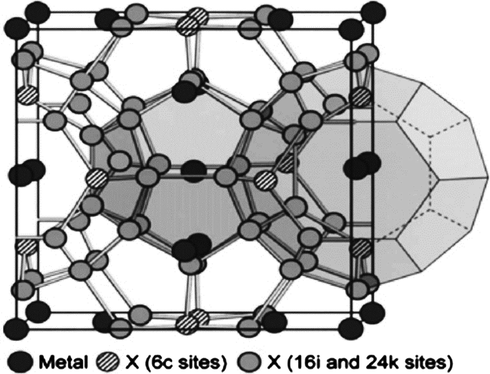

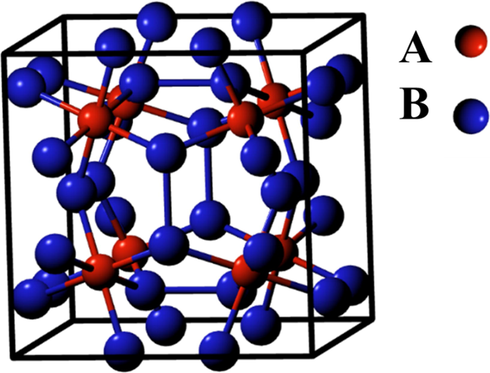

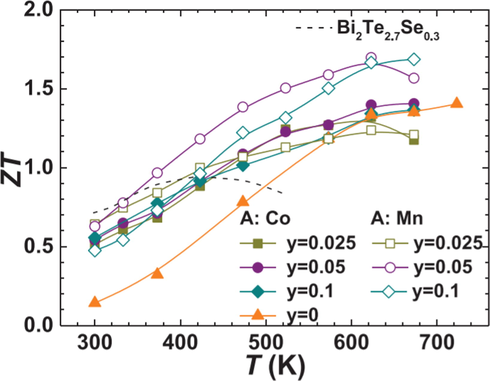

Another important class of high-temperature thermoelectric materials is the half Heusler compounds (HHM). They possess a simple rock salt structure generally represented by ABY, as depicted in Fig. 11. Where A and Y form the material structure and element B occupies a position (1/4, 1/4, 1/4) along the body diagonal (Liu et al., 2012). On the other hand, the full Heusler compounds can be denoted by A2BY structure. A and B are generally transition metals, while Y is the main group element, as represented in Fig. 12. The HHM exhibit excellent chemical and mechanical stability and a high thermoelectric power factor resulting from their high electrical conductivity and thermopower. However, the relatively large thermal conductivity (∼10 W/mK) impedes the improvement of the figure of merit (Bhattacharya et al., 2000). These challenges were tackled via increased phonon scattering through nanograins inclusion and chemical substitutions.

Schematic representation of the unit cell of the half-Heusler crystal structure.

Periodic table of elements showing different possible Heusler compounds configuration according to the assigned colors. Adapted from ref (Beretta et al., 2019).

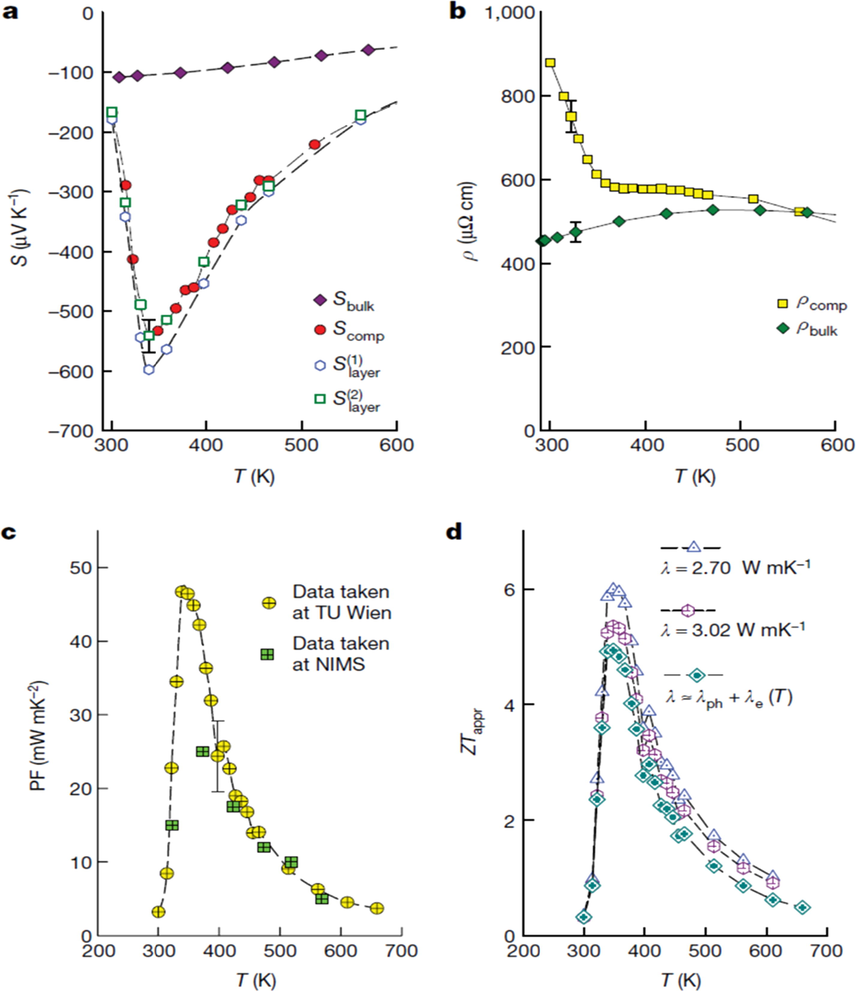

The latest report in the development of Heusler compounds with a record maximum thermoelectric figure of merit reaching above 5.0 was carried out by Hinterleitner et al. (2019). They fabricated a series of Fe2V1-xWxAl thin film samples using RC-sputtering and investigated the thermoelectric properties with Fe2V0.8W0.2Al demonstrating the best thermoelectric performance. They also studied the electronic structure using the density functional theory as implemented in the VASP package. Their incredible thermoelectric measurements are presented in Fig. 13.

Temperature-dependent transport measurements of Heusler thin-film Fe2V0.8W0.2Al with (a) Seebeck coefficient (b) electrical resistivity (c) power factor (d) figure of merit.

Adapted from Hinterleitner et al., 2019