Translate this page into:

Volatilomics for halal and non-halal meatball authentication using solid-phase microextraction–gas chromatography–mass spectrometry

⁎Corresponding author at: Department of Food Science and Technology, IPB University, 16680 Bogor, Indonesia. nancy_dewi@apps.ipb.ac.id (Nancy Dewi Yuliana)

-

Received: ,

Accepted: ,

This article was originally published by Elsevier and was migrated to Scientific Scholar after the change of Publisher.

Abstract

The adulteration of beef meatballs with wild boar (Sus scrova) meat or chicken may be undertaken for economic reasons. This adulteration is a very sensitive issue, particularly for Muslim consumers, as the consumption of wild boar is strictly prohibited by Islamic law. This study aimed to discriminate volatile compounds in meatballs made from beef, chicken, and wild boar and mixtures thereof using solid-phase microextraction–gas chromatography–mass spectrometry (SPME/GC–MS) and multivariate data analysis. SPME is a non-destructive method for the extraction of volatile compounds and does not alter the original chemical composition of the volatiles. A validated partial least squares discriminant analysis (PLS-DA) model with three classes was used to uncover the discriminating volatiles of each type of meatball. The results indicated that β-cymene, 3-methyl-butanal, and 2-pentanol were among the positive discriminating volatiles with the highest variable importance in projection (VIP) values among the chicken meatballs. The highest VIP positive discriminating volatiles in the beef meatballs were 5-ethyl-m-xylene, benzaldehyde, and 3-ethyl-2-methyl-1,3-hexadiene. The mixed meatballs exhibited an interesting profile, with all appearing in the same group as the pure wild boar meatballs. However, the discriminating volatiles derived from a separate PLS-DA model indicated that they contained different compounds. In the pure wild boar meatballs, six compounds (pentanal, 2,6-dimethylcyclohexanone, 1-undecanol, cyclobutanol, 2,4,5-trimethyl-thiazole, and 5-ethyl-3-(3-methyl-5-phenyl pyrazol-1-yl)-1,2,4-triazol-4-amine) were identified as discriminating volatile compounds with the highest VIP values. These compounds were consistently found as significant discriminating volatile compounds in mixture meatballs group although with different VIP value. This research demonstrated that SPME-GC/MS combined with multivariate data analysis was a fast and reliable method for differentiating meatballs made from beef, chicken, and wild boar meat based on their volatile compound contents.

Keywords

Volatiles

Metabolomics

Halal

Meat

Adulteration

PLS-DA

1 Introduction

Beef meatballs are one of the most popular processed meat products in Indonesia. Since beef prices are rather high, meatballs are often adulterated by mixing beef with cheaper meats, such as wild boar (Sus scrova) or chicken, to illegally obtain economic benefits (Guntarti et al., 2017). This adulteration is a disadvantage for consumers, particularly Muslim ones, who are strictly prohibited from consuming wild boar meat. Wild boars are frequently obtained from recreational animal hunting since they are considered pests of plantation crops. They have larger carcass fatness and loin areas, darker meat color, and leaner and less tender meat compared with those of domestic pigs (Sales and Kotrba, 2013). This makes their meat visually more similar to beef.

Fast, sensitive, and affordable analytical methods are necessary to monitor the enforcement of regulations related to meatball consumer protection and support efforts to control the circulation of processed meat products with inappropriate labels. The two most commonly used methods to detect the contamination or adulteration of meat products are polymerase chain reaction (PCR) and enzyme-linked immunosorbent assay (ELISA). PCR is a DNA-based method and has high sensitivity, being able to detect 0.001–0.1 ng DNA from adulterant species (Sultana et al., 2018). Unlike PCR, ELISA uses a specific protein or peptide from each species as a test target. Several other instruments and methods aimed at detecting meat adulterant have also been developed, especially for halal-testing, including liquid chromatography–mass spectrometry (LC-MS) and Fourier transform infrared spectroscopy (FTIR; Kurniawati et al., 2014; Masiri et al., 2016; Rohman et al., 2020; Xu et al., 2012). However, these techniques are not without limitations. In particular, they require rigorous sample preparation and high technical skills, making them less than ideal for routine analysis.

Several previous studies have focused on the profile discrimination of volatiles to assess meat quality. Extracting volatiles from meat can be achieved using several techniques. In one study, 33 volatiles from chicken breast were successfully identified using distillation in dichloromethane (Ayseli et al., 2014). This method has limitations, as it can potentially lead to the loss of thermally unstable compounds. In addition, FTIR coupled with multivariate data analysis has been reported as a rapid and non-destructive yet powerful technique for determining meat types in meatballs (Rahmania et al., 2015). However, the information that can be obtained from FTIR is limited, as the spectra show only absorption bands attributable to the characteristic frequencies of different functional groups. Gas chromatography–mass spectrometry (GC–MS) provides more detailed information, as the spectra exhibit the specific mass spectrum of the compounds present in the samples, which are eluted at different retention times (Sim et al., 2014).

Solid-phase microextraction–GC–MS (SPME/GC–MS) is a rapid and straightforward technique integrating volatile compound extraction and analysis (Wang et al., 2018). Recently, SPME/GC–MS combined with principal component analysis (PCA) and orthogonal partial least squares discriminant analysis (OPLS-DA) was used to assess compounds related to pork volatiles during storage. This method revealed that ethanol, 2,3-butanediol, and 2-ethyl-1-hexanol can potentially serve as indicators of pork quality during storage (Song et al., 2021). A similar technique was used to study discriminating volatiles of minced beef and pork (Pavlidis et al., 2019) and raw and cooked beef (Wang et al., 2018).

The objective of the present work was to determine discriminating volatiles of beef, chicken, wild boar meat, and meatballs made from mixtures thereof. In Indonesia, consumers commonly buy ready-to-cook meatballs rather than raw ones. These meatballs have to be re-boiled for few minutes before they are consumed. Cases of adulteration occur often with these ready-to-cook meatballs and are difficult to trace because the modified meatballs have similar physical appearances to the unmodified ones. SPME/GC–MS combined with PCA and PLS-DA was here used to analyze discriminating volatiles in different types of meatball samples. We used PCA as a first-pass unsupervised tool in our volatilomics data, whereas sample classification patterns in score-space are the sole basis for further analysis using supervised methods, such as PLS-DA (Worley and Powers, 2016). PCA is commonly used to assess classification patterns within data sets containing unlabeled data. In addition to PCA and PLS-DA, soft independent modeling of class analogy (SIMCA) may also be used. SIMCA is a supervised method used to extract features and obtain classification tasks, according to which the training data are labeled, and the method is then separately applied to each data class. SIMCA has been demonstrated to be a superior method when working with larger data sets, whereas PCA and PLS-DA are more suitable for classification tasks when one has limited access to data (Nejadgholi and Bolic, 2015). PLS-DA is often used in metabolomics research to build predictive classification models and/or discover biomarkers. In PLS-DA, the ideal number of the modeled class is between two and four. When PLS-DA is used to model more than four classes, the classification results may be difficult to interpret (Eriksson et al., 2006)

In this study, PCA was initially used to observe the classification pattern of the meat samples. Once the PCA model had demonstrated satisfactory performance based on cross-validation parameters, a supervised PLS-DA model was developed. Discriminating volatile selection from the validated PLS-DA was performed based on the variable importance in projection (VIP) value and correlation coefficients.

2 Materials and methods

2.1 Meat sample collection

All samples were collected in December 2019. The wild boar meat samples used in this experiment were obtained from three male wild boars (40–50 kg) originating from Jambi Forest in Sumatera, Indonesia. The meat samples were chopped from the flanks, ribs, and shanks in equal amounts, tightly packed, and then sealed in plastic bags, put in an icebox, and transported to Bogor. The beef samples were obtained from three cattle (Brahman crossbred cattle, 400–550 kg) and taken from the flank only since this is most commonly used by meatball sellers in Indonesia. Three fresh broiler chicken meat samples were obtained from the local slaughterhouse in Bogor. All meat samples were immediately transported to the laboratory and kept in a freezer (−33 °C) prior to analysis.

2.2 Preparation of meatball samples

The meatballs were prepared according to the cooking method commonly used by meatball sellers in Indonesia, though we did not use any spices or taste enhancers, to avoid masking effects. The meat samples were homogenized using a Phillips ProMix hand blender (HR2533), and the meatballs were made by mixing 200 g of minced meat with 20 g of tapioca flour (Cap Pak Tani, Bogor, Indonesia) and 50 g of ice cubes. The dough was then formed by hand into balls with 3–4 cm diameters, put in water at a temperature of 80 °C–100 °C and boiled for 15 mins. The beef, chicken, and wild boar meatballs were each made in triplicate. Similar steps were conducted to prepare the mixed meatballs. The mixed meatballs also contained 200 g of chicken along with wild boar and with beef in the following ratios: 20:80, 40:60, 60:40, and 80:20. In addition, meatballs made of a combination of beef, chicken, and wild boar with a ratio of 40:40:20 were also prepared. Each mixed meatball was made in duplicate. A total of 31 meatball samples were used in this study (Table 1). For SPME analysis, the meatballs were crushed with a porcelain mortar and pestle. The crushed meatball samples (8 g) were put in a closed headspace vial with 5 mL of distilled water for exposure to SPME fiber.

No.

Chicken (g)

Beef (g)

Wild boar (g)

Tapioca (g)

Ice cube (g)

Code

Replication

1

100

0

0

10

25

C

3

2

0

100

0

10

25

B

3

3

0

0

100

10

25

W

3

4

80

0

20

10

25

CW82

2

5

60

0

40

10

25

CW64

2

6

40

0

60

10

25

CW46

2

7

20

0

80

10

25

CW28

2

8

0

80

20

10

25

WB82

2

9

0

60

40

10

25

WB64

2

10

0

40

60

10

25

WB46

2

11

0

20

80

10

25

WB28

2

12

20

40

40

10

25

WBC244

2

13

40

20

40

10

25

WBC424

2

14

40

40

20

10

25

WBC442

2

2.3 Analysis of volatile compounds

2.3.1 Headspace solid-phase microextraction procedure

The SPME fiber (DVB/CAR/PDMS, Supelco, Bellefonte, PA, USA) was cleaned before use by heating in a GC–MS injector at 250 °C for 5 mins. The pre-extraction process was carried out by placing the clean SPME fibers into the sample headspace in the vial for 10 mins. The vial was put on a heating plate at a constant temperature of 40 °C. The extraction continued for another 30 mins at the same temperature and with the same vial sample and fiber sphere positions as in the pre-extraction process. This procedure was previously described by Pavlidis et al. (2019). The samples were not stirred, and no NaCl was added.

2.3.2 Gas chromatography–mass spectrometry analysis

GC–MS analysis was carried out by inserting the fiber that had been exposed to the samples (as described in Section 2.3.1) into the GC–MS injection port. Sample injection was carried out in the split mode (split ratio: 1:2) at 250 °C. The separation of the compounds was carried out in a capillary DB-WAX column with 30 × 0.25 mm dimensions and a film thickness of 0.25 μm, (Agilent Technologies, Santa Clara, USA). The oven temperature was maintained at 40 °C for 5 mins and then increased at 4 °C/min until it reached 150 °C. Next, the temperature was further raised to 250 °C (30 °C/min) and held for 5 mins. The interface temperature was set at 280 °C. The mass spectrometer was operated in the electron ionization mode with the electron energy set at 70 eV and a scanning range of 29–350 m/z (speed: 4.37 scans/s; gain factor: 1). The ion source and quadrupole analyzer temperatures were set at 230 °C and 150 °C, respectively. This procedure was previously described (Pavlidis et al., 2019) with small differences, including a different column. Here the DB-WAX column was used instead of the HP-5MS column.

2.3.3 Identification of volatile compounds and data pretreatment

The identification of all volatile compound analytes was estimated using the mass spectra along with the built-in NIST MS 14.0 library as a reference. The compounds were then confirmed using the linear retention index (LRI) from the database and previous reports. To determine the LRI of each analyte, a homologous series of a n-alkane solution (C10-40, Polyscience, Niles, IL, USA; 5 mg/L) was used in dichloromethane under the same chromatographic conditions as those used for the samples. The LRI was calculated using the following equation, as described elsewhere (Dool and Kratz, 1962): Here, LRI (compound) is the LRI of the compound, tr is the retention time, and n and N are the numbers of carbon atoms in the eluting alkanes before and after the product is produced, respectively. Finally, z is the discrepancy in the number of carbon atoms in the smaller and larger alkanes.

Multivariate data analysis was performed using the SIMCA-P software (v. 16.0, Sartorius-Umetric, Umeå, Sweden). PCA was used to assess the classification patterns among the different types of meat and meatballs. The PCA performance was evaluated based on the value of the predictive coefficient Q2X. Next, PLS-DA was used to fine-tune the classification pattern obtained from the PCA. PCA and PLS-DA model validations were conducted by cross-validation, response permutation tests. Cross-validation assesses the reproducibility and the predictive power of PCA and PLS-DA models based on R2 and Q2 value, respectively. In PLS-DA, R2Y represents the goodness of fit, whereas Q2Y is the accuracy of the prediction parameters. In PCA, the same indicator is represented by the R2X and Q2 value. Generally, R2X, Q2, R2Y, and Q2Y values of at least 0.5 are considered acceptable (Eriksson et al., 2006). In some cases, 0.4 has been considered acceptable (Worley and Powers, 2016). Additionally, response permutation testing was also conducted since sometimes invalid model might have a high cross-validation Q2 value. In permutation testing, a reliable model should have a significantly larger Q2 value than Q2 values generated from random models using the same data set (Worley and Powers, 2012). All of the validation indicators were also calculated using the SIMCA-P software (v. 16.0, Sartorius-Umetric, Umeå, Sweden).

3 Results and discussion

3.1 Volatile profiling by gas chromatography–mass spectrometry

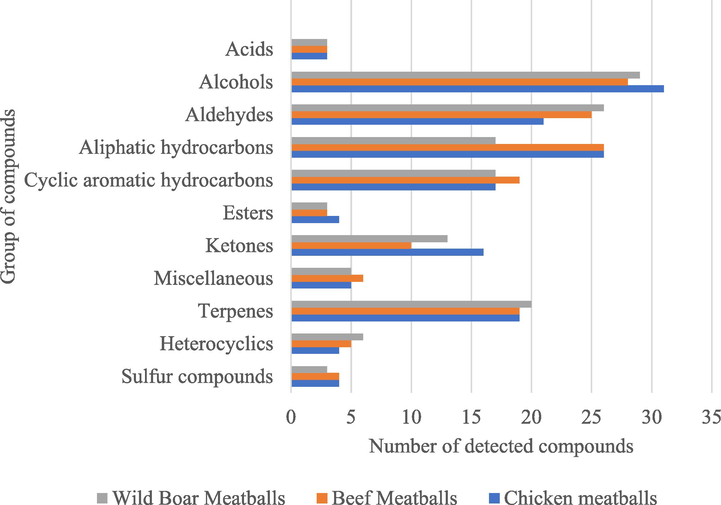

Table 2 presents the volatile compounds with known molecular formulas that were identified in the meatball samples. Only compounds detected in the control samples are listed, and data from the mixed meatballs are not presented. Overall, 150 volatile compounds were found in the chicken meatballs; 148, in the beef meatballs; and 141, in the wild boar meatballs. These volatiles consisted mainly of aldehydes, ketones, alcohols, acids, esters, aliphatic hydrocarbons, aromatic hydrocarbons, terpenes, and miscellaneous compounds (Table 2 and Fig. 1). They may have been formed as the result of lipid oxidation, the Maillard reaction, interactions between Maillard reaction products and lipid oxidation products, and/or the thermal degradation of thiamine that occurs during the cooking process (Kosowska et al., 2017). The oxidation of lipids produces a wide range of aliphatic compounds, including saturated and unsaturated hydrocarbons, alcohols, aldehydes, ketones, acids, and esters (Ayseli et al., 2014). At the same time, the Maillard reaction may include many heterocyclic compounds including sulfur and nitrogen compounds (Dashdorj et al., 2015). The data in Table 2 indicate that most of the volatiles detected in this study were the result of lipid oxidation (alcohols, hydrocarbons, aldehydes, and ketones), whereas a few were based on thiamin degradation (sulfur compounds) and the Maillard reaction (acetoin and aldehydes). Some compounds might also have resulted from an interaction of these three processes.

Volatilomes

LRI

Method Identificationa

Peak Area (×104)

Chicken Meatballs

Beef Meatballs

Wild Boar Meatballs

Acids

2-Amino-6-methylbenzoic acid

1813

M

10

9.69

1.84

2-Amino-5-methylbenzoic acid

1843

M

3.63

8.44

292

Caproic acid

1845

L

1.80

87

–

Lauric acid

2066

M

–

–

1.98

Alcohols

2-Ethylbutanol

1114

M

1.12

866

862

2-Butanol, 3-methyl-

1133

L

857

360

427

2-Pentanol

1146

L

1.16

380

137

2-Ethylcyclobutanol

1146

M

–

–

98

3-Methylbutanol

1215

M

–

34

–

2-Pentanol, 4-methyl-

1275

L

1.61

311

215

1-Pentanol

1289

L

3.07

76

1.48

3-Methyl-3-butenol

1265

L

539

–

649

6-Methyl-2-heptanol

1302

L

4.10

221

265

1-Undecanol

1328

M

1.01

74

1.50

1-Hexanol

1350

L

402

279

933

1-Octanol, 3,7-dimethyl-

1389

M

592

494

–

2-Butoxyethanol

1404

L

281

387

–

Ethanol, 2-(dodecyloxy)-

1440

M

93

93

171

1-Octanol, 2-butyl-

1447

M

67

1.99

–

1-Octen-3-ol

1451

L

2.35

–

2.09

1-Heptanol

1461

L

1.22

550

61

5-Hepten-2-ol, 6-methyl-

1476

L

87

762

194

7-Octen-2-ol, 2,6-dimethyl-

1471

L

129

30

54

2-Cyclohexen-1-ol

1511

L

98

–

–

2-Ethylhexanol

1523

L

–

39

–

Cyclobutanol

–

M

2.23

1.74

10

Cyclohexanol, 2-tert-butyl-

1529

M

127

–

–

1-Octanol

1558

M

1.28

1.03

368

1-Terpinenol

1576

L

44

–

24

Terpinen-4-ol

1602

L

213

54

135

Cyclooctanol

1610

L

128

85

52

2-Octen-1-ol, (E)-

1613

L

141

180

32

2-Nonen-1-ol, (E)-

1620

M

230

169

400

2-Methyl-1-indanol

1644

M

33

6

–

Phenol, 4-(2-propenyl)-

1694

M

176

–

–

5-Hexen-2-ol

1784

M

–

–

8

Phenol, 3,5-dimethoxy-

1936

M

189

273

25

1-Dodecanol

1982

L

211

369

117

m-Ethylphenol

1998

M

42

59

139

2,4-Di-tert-butylphenol

1994

M

601

729

494

Aldehydes

Glutaraldehyde

1073

M

3.30

2.07

259

Pentanal

–

M

2.48

2.22

2.98

Hexanal

1078

L

39.8

25.1

46.3

Heptanal

1170

L

6.78

5.21

1.02

5-Methylhexanal

1182

M

–

–

164

Octanal

1260

L

5.71

3.52

564

2-Heptenal, (Z)-

1313

L

1.06

272

2.83

Nonanal

1369

L

9.79

1.17

1.86

2-Dodecenal

1400

M

279

246

612

2-Undecenal

1412

M

927

149

62

2-Octenal, (E)-

1432

L

157

100

201

Undecanal

1429

M

–

20

408

2,4-Heptadien-1-al

1480

L

466

98

18

Decanal

1492

L

376

492

688

Benzaldehyde

1501

L

1.8

3.1

237

2-Nonenal, (E)-

1511

M

–

250

–

2-Tridecenal, (E)-

1523

M

–

–

335

2-Decenal, (E)-

1633

L

79

88

96

2-Octenal, 2-butyl-

1669

L

–

507

267

Benzaldehyde, 3-ethyl-

1688

M

1.1

1.05

425

2-Dodecenal, (E)-

1738

M

169

35

50

2-Undecenal, (E)-

1746

L

27

54

8

2,4-Decadienal

1760

L

14

8

18

2,4-Decadienal, (E,E)-

1803

L

–

–

27

Butanal, 3-methyl-

–

M

1.67

800

–

Tetradecanal

1927

L

57

498

–

Benzaldehyde, 4-pentyl-

1998

L

146

158

107

Heptadecanal

2000

M

302

266

47

17-Octadecenal

2025

M

24

124

19

Octadecanal

2015

M

–

138

253

Aliphatic hydrocarbons

5-Ethyl-2-methyloctane

1053

L

2.3

1.34

613

Undecane, 3-methyl-

1101

M

1.11

840

2.59

2,4-Dimethylhexane

1105

M

1.05

537

406

Undecane, 5-methyl-

1129

M

2.02

1.04

176

Undecane, 3,4-dimethyl-

1135

M

1.41

549

133

Dodecane

1177

L

1

–

403

3,5-Dimethylheptane

1193

M

738

56

–

4-Ethylcyclohexene

1211

M

–

–

70

2,4,6-Trimethyloctane

1196

M

697

189

265

Tridecane

1206

M

–

58

–

2-Methyltridecane

1210

L

611

141

–

3,8-Dimethyldecane

1216

M

1.31

114

–

3-Methyldodecane

1221

M

679

292

–

3,6-Dimethylundecane

1234

M

461

327

–

3,7-Dimethylnonane

1252

M

971

52

–

Undecane, 4,7-dimethyl-

1273

M

1.34

280

49

3,6-Dimethyldecane

1278

M

736

538

–

Hexane, 2,3,4-trimethyl-

1286

M

1.01

–

–

Hexane, 3-ethyl-4-methyl-

1284

M

886

194

–

Undecane, 3,7-dimethyl-

1348

M

168

–

–

3-Ethyl-2-methyl-1,3-hexadiene

1387

M

532

369

83

1-Octene, 3,7-dimethyl-

1393

M

–

–

38

Tetradecane

1396

L

487

256

53

1,3-Hexadiene, 3-ethyl

1396

M

–

190

–

1-Tetradecene

1425

L

150

77

21

2-Methyldecane

1456

M

87

156

1.18

1-Hexene, 3,5,5-trimethyl-

1485

M

170

113

–

2-Decanone

1489

L

165

206

64

Pentadecane

1603

M

–

25

–

2-Undecene, 8-methyl-, (Z)-

1540

M

824

1.08

–

3,5-Dimethyl-1-hexene

1564

M

–

–

–

Hexadecane

1596

L

88

192

96

1-Decene, 3,4-dimethyl-

1775

L

–

–

16

Cyclic aromatic hydrocarbons

Ethylbenzene

1111

L

4.13

2.75

1.1

o-Xylene

1117

L

1.95

1.02

–

m-Xylene

1123

L

1.76

344

314

p-Xylene

1152

L

534

118

80

Furan, 2-pentyl-

1201

L

2.06

1.21

966

Mesitylene

1247

M

1.26

34

137

Benzene, 1,2,3-trimethyl-

1256

L

959

208

588

Cyclooctane, methyl-

1295

M

301

–

–

cis-2-Methylcyclopentanol

1285

M

–

126

–

m-Xylene, 5-ethyl

1298

L

1.44

3.12

127

Benzene, 2-propenyl-

1349

M

277

289

83

2,6-Dimethylcyclohexanone

1359

L

536

–

127

Cyclopentane, nonyl-

1448

M

–

–

172

Acridine, 9-methyl-

1515

M

1.30

1.05

348

Isopropylcyclohexane

1550

M

–

22

301

4-Ethylbenzaldehyde

1652

L

40

20

12

Cyclopropane, nonyl

1658

M

61

84

4

Naphthalene

1703

L

939

155

550

Azulene

1731

M

–

22

–

Methyl ethyl cyclopentene

1754

M

–

6

–

Butylated Hydroxytoluene

1910

L

57

142

–

Cyclodecasiloxane, eicosamethyl-

2005

M

–

–

26

Indole

2048

M

2.79

1.74

1.18

Esters

Methyl caprylate

1354

L

416

106

50

Methyl caprate

1571

L

61

90

–

Methyl salicylate

1749

L

29

–

6

Methyl palmitate

1995

M

86

13

303

Heterocyclics

Thiophene, 2-pentyl-

1494

L

248

223

51

1,2,4-Triazol-4-amine phenylpyrazol-1-yl)-

1546

M

380

243

584

3-Methyl-2-thiophenecarboxaldehyde

1765

L

–

4

61

Thiazole, 2,4,5-trimethyl-

1867

L

–

32

698

Tetrahydrothiopyran-4-one

2006

M

–

–

2

Thiophene, 2-butyl-5-ethyl-

1999

M

22

–

14

Thiophene, 2-ethyl-5-isopentyl-

1996

M

41

11

–

Ketones

Nonane, 3-methyl-

1095

M

4.17

886

–

6-Dodecanone

1213

M

945

–

424

2-Heptanone, 6-methyl-

1224

L

175

168

120

2,3-Octanedione

1318

L

537

211

747

2-Methyl-3-octanone

1323

L

202

–

240

2,5-Octanedione

1330

L

1.49

138

98

5-Hepten-2-one, 6-methyl-

1334

L

474

–

129

2-Nonanone

1385

L

285

–

257

6,7-Dodecanedione

1527

M

11

137

195

4-Nonanone

1526

M

18

–

–

2-Undecanone

1576

L

11

–

11

11-Dodecen-2-one

1596

M

7

27

65

Acetophenone

1630

L

313

85

43

3-Tridecanone

1771

L

74

12

19

Nona-3,5-dien-2-one

1885

M

240

44

–

γ-Nonalactone

1999

L

85

50

44

Sulfuric Compounds

Disulfide, dimethyl

1068

L

1.99

1.06

439

Disulfide, di-tert-dodecyl

1316

M

729

182

–

Dimethyl trisulfide

1353

L

1.85

1.79

144

Benzothiazole

1952

L

331

623

70

Terpenes

o-Cresol

1142

M

1.10

604

195

1,4-Cineol

1159

L

1.41

570

259

D-Limonene

1165

L

1.01

744

250

γ-Terpinen

1226

M

948

123

–

β-Cymene

1230

L

1.95

432

117

Styrene

1237

L

897

67

210

o-Cymene

1240

L

1.16

228

246

2-Carene

1251

M

683

303

–

α-Terpinolene

1265

L

1.08

125

84

Copaene

1421

L

200

111

107

p-Cymenene

1492

M

–

–

199

1,3,8-p-Menthatriene

1466

M

321

119

–

(+)-2-Bornanone

1485

L

58

120

62

L-Camphor

1688

M

–

–

46

Fenchol

1580

L

35

154

21

β-Terpineol

1626

L

–

–

49

3-p-Menthol

1637

L

67

104

46

dl-Menthol

1641

L

–

–

49

Isoborneol

1653

L

10

9

15

o-Xylenol

1998

M

56

68

6

p-Cresol

2070

M

53

33

114

m-Cresol

1997

M

158

71

88

cis-Isoeugenol

1997

M

92

17

202

Miscellaneous

Acetoin

1294

L

1.21

129

321

2-Ethoxyethyl ether

1418

M

136

70

–

Benzyl nitrile

1920

L

239

127

–

5-Methyl-2-phenylindole

2068

M

–

28

45

3-Methyl-2-formyl

2051

M

46

88

–

p-Vinylguaiacol

2021

M

209

203

454

Diethyltoluamide

2090

M

–

–

475

Composition of the volatile compounds detected in each type of control meatball.

The volatile compounds found in each type of meatball were grouped based on their functional groups (Fig. 1). It can be seen that all the meatballs had a similar composition of volatile components. However, compounds from the ketone group were more common in the chicken meatballs, whereas aldehyde compounds were least present in the chicken. In fact, ketones and aldehydes are major contributors to the “chicken-like” scent (Kerler and Grosch, 1997). A number of compounds, including nonane; 3-methyl-, 2,3-octanedione, 4-nonanone, acetophenone, 6-dodecanone, 2-heptanone, 6-methyl-,2-methyl-3-octanone, 2,5-octanedione 5-hepten-2-one, 6-methyl-,2-nonanone, 6,7-dodecanedione, 2-undecanone, 11-dodecen-2-one, 3-tridecanone, and nona-3,5-dien-2-one, were detected in the chicken meatballs. A few of the aforementioned compounds, such as 4-nonanone and acetophenone, have previously been identified in boiled chicken (Kerler and Grosch, 1997), and 2,3-octanedione has been found in raw chicken breast (Ayseli et al., 2014).

Only a few previous reports on the composition of the volatile compounds in fresh or boiled wild boar meat were found. Sales and Kotrba (2013) reported that fried wild boar meat contained 48 volatile compounds, including 16 aldehydes, 5 ketones, 6 alcohols, 8 acids, 4 sulfur compounds, 8 pyrazines, 2 furanones, 1 pyrrole, and 3 aromatic compounds. In the present study, 141 volatile compounds were found in the wild boar meatballs, including 2 sulfur compounds, 6 heterocyclics, 20 terpenes, 13 ketones, 3 esters, 3 acids, 29 alcohols, 26 aldehydes, 17 aliphatic hydrocarbons, 17 cyclic aromatic hydrocarbons, and 5 miscellaneous compounds. Alcohol was the most abundant chemical family in the wild boar meatballs. One of the compounds, 1-octen-3-ol, is an important volatile compound and product related to meat fatty acid autoxidation (Mottram, 1998), leading to a mushroom-like scent (Lammers et al., 2009). Other alcohol compounds found in samples of fresh wild boar meat (Sales and Kotrba, 2013) and fried wild boar meat (Lammers et al., 2009) include 1-pentanol, 1-hexanol, 1-heptanol, and 1-octanol.

The volatile compounds detected in the raw and cooked beef were categorized into eight groups: hydrocarbons, alcohols, aldehydes, acids, esters, ketones, furans, and sulfur compounds. The alcohols, acids, and esters were less diverse in the cooked beef as compared with those in the raw beef. By contrast, the aldehydes and ketones were more diverse in the beef after cooking. In particular, the aldehyde diversity increased from four compounds before cooking to 20 compounds after cooking, with hexanal being one of the most abundant (Wang et al., 2018). Overall, 30 aldehydes were detected in the beef meatballs, with butanal being the most abundant (Table 2).

3.2 Volatilomics

Volatilomics is a term for volatilome analysis aimed at the detection, characterization, and quantification of volatile metabolites from organics (Lytou et al., 2019). The volatilome is defined as the group of all volatile organic compounds produced by a living organism (plants, animals, etc.), an ecosystem, or a substrate (such as food), and it includes exogenously derived compounds (organic and inorganic; Lytou et al., 2019). The volatilomic approach has recently been applied in various research fields, for applications such as plant analysis (Lytou et al., 2019) and the discrimination of beef and pork (Pavlidis et al., 2019). Most volatilomics studies have employed GC–MS and electronic nose methods. Multivariate data analysis has also been used to analyze the resulting high-dimensional data. Various multivariate methods can be used to extract information from large amounts of volatilomics data, with PCA, PLS-DA, and OPLS-DA being the most common (Worley and Powers, 2016).

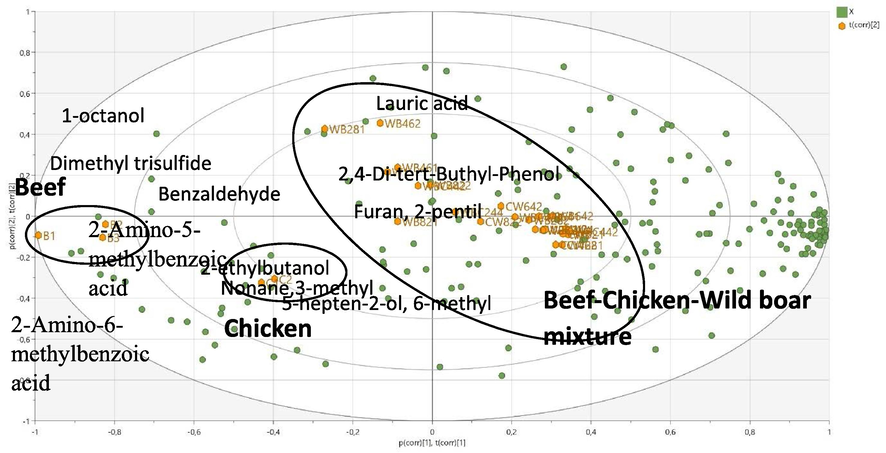

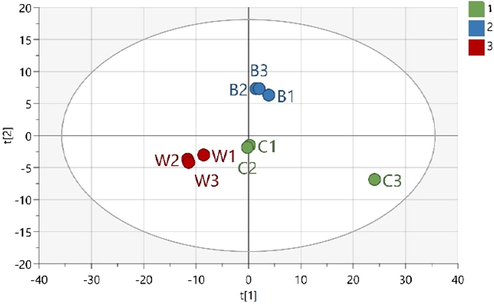

To evaluate the meatball classification pattern based on the volatile compound composition, unsupervised PCA was performed on the GC–MS data (chromatographic relative peak area) using unit-variance (UV) scaling. In UV scaling, the scaling weight is 1/sk, where sk is the standard deviation of parameter k. Thus, in UV scaling, all variables have an equal opportunity to influence the data, making it more objective than other scaling methods (Eriksson et al., 2006). Multiplicative signal correction (MSC) filtering was applied to remove the signal noise. The main objective of using MSC filtering is to remove artifacts and interference that are not correlated to the presence of the target analytes (Eriksson et al., 2006). After excluding three sample outliers (one 100%-chicken meatball sample, one mixed chicken–wild boar meatball sample with a 4:6 ratio, and one mixed chicken–wild boar meatball sample with a 6:4 ratio), a PCA model with three principal components explaining 59.8% of the variation was obtained using Hotelling’s T2 analysis with a 95% confidence interval. PC1, PC2, and PC3 of the PCA explained 43.8%, 9.14%, and 6.81% of the variation, respectively. Only the first two components are presented (Fig. 2). The aforementioned results are consistent with the minimum requirements for the model mentioned by Worley and Powers (2016), which includes Q2 = 0.41. The score plot revealed three distinct groups: beef meatballs (B1–B3), chicken meatballs (C1–C2; C3 was excluded because it was located outside the 95% confidence interval), and meatballs made from 100% wild boar meat or a mixture of wild boar with beef and/or chicken (Fig. 2). Notably, all meatballs made from a mixture of wild boar with beef and/or chicken at different ratios were clustered together with the 100%-wild boar meatballs. This may have occurred because of the strong influence of the volatile components present in wild boar meat. The loading plot revealed several volatiles responsible for the three groupings (Fig. 2). For the beef meatball group, the discriminating compounds were 2-amino-5-methylbenzoic acid, 2-amino-6-methylbenzoic acid, benzaldehyde, dimethyl trisulfide, and 1-octanol. For the chicken meatball group, 5-hepten-2-ol, 6-methylnonane, 3-methyl, and 2-ethylbutanol were among those predominant discriminating compounds. Lauric acid, 2,4-di-tert-buthyl-phenol, and furan 2-pentyl were the discriminating compounds for the wild boar meatballs and wild boar-containing meatballs.

PCA loading biplot of meatballs made from 100% beef (B1–B3), 100% chicken (C1–C3), 100% wild boar (W1–W3), and mixtures thereof (WB: wild boar–beef, WC: wild boar–chicken, and WBC: wild boar–beef–chicken). The loading biplot illustrates several markers of the beef, chicken, and mixed meatballs. The numbers after the letters represent the percentages of the respective meats. The last number represents the number of replications.

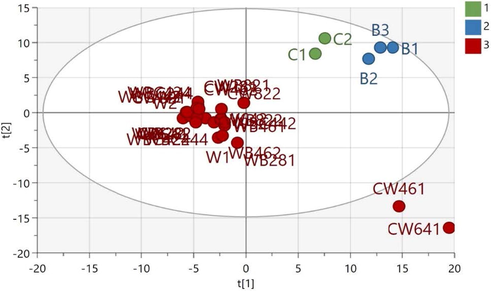

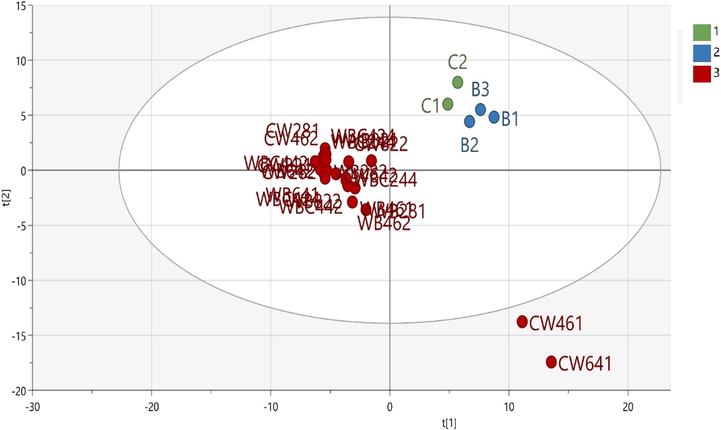

To obtain a clearer classification pattern, a supervised multivariate data analysis method (PLS-DA) was employed. Further analysis using a supervised method is only recommended when the PCA model for the same set of data has an acceptable predictive coefficient (Q2 of at least 0.4; Worley and Powers, 2016), which was fulfilled by the aforementioned PCA model. The PLS-DA score plot exhibited better performance than the PCA. The PLS-DA model with three classes (class 1: chicken meatballs, class 2: beef meatballs, and class 3: wild boar and wild boar–beef–chicken meatballs) had good performance, with a cumulative explained variance of R2X = 0.69, R2Y = 0.99, and Q2 = 0.84 (Zhang et al., 2020). Here, the beef and chicken samples were clustered separately from each other. Again, the wild boar meatballs and meatballs made from mixtures of wild boar with chicken and/or beef at different ratios were grouped separately from the beef and chicken samples (Fig. 3).

PLS-DA plot score of meatball samples (C: chicken, B: beef, W: wild boar, WB: wild boar–beef, CW: chicken–wild boar, and WBC: wild boar–beef–chicken). The number represents the ratio of each meat and replication number.

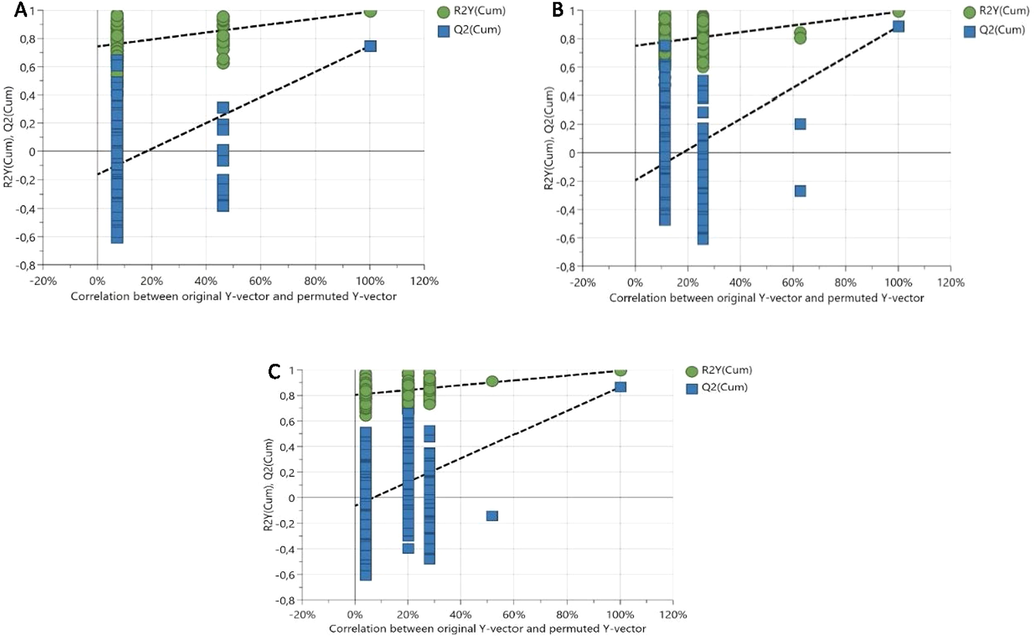

Further validation with 100 random permutations was performed. As illustrated in Fig. 4, the values of R2Y (green circles) and Q2Y (blue squares) from the permuted analysis (bottom-left corner) were lower than the associated initial values (top-right corner), indicating the stability of the model and the absence of overfitting (Song et al., 2021). The p-value for the cross-validated analysis of variance (CV-ANOVA) was less than 0.005 (2.6 × 10−4), demonstrating the model validity (Eriksson et al., 2008).

Permutation test for the PLS-DA model for (A) chicken meatballs, (B) beef meatballs, and (C) wild boar and beef–wild boar–chicken meatballs.

3.3 Potential volatile marker of wild boar meatballs

To elucidate the volatile compounds that serve as markers for each PLS-DA class, a correlation coefficient and the VIP values were used. The compounds that were positively or negatively correlated with the groupings could be determined using the coefficient, whereas the VIP value has only a positive value. Fifteen compounds with both positive and negative correlation values and the largest VIP values were selected from each PLS-DA class (Table 3).

PLS-DA Class 1 (Chicken Meatballs)

No.

Positive compound

VIP

Chemical group

No.

Negative compound

VIP

Chemical group

1

β-Cymene

2.08

terpenes

1

Benzaldehyde

1.95

aldehydes

2

Butanal, 3-methyl-

2.04

aldehydes

2

3-Ethyl-2-methyl-1,3-hexadiene

1.74

aliphatic hydrocarbons

3

1-Pentanol

1.98

alcohols

3

Benzaldehyde, 4-pentyl-

1.55

cyclic aromatic hydrocarbons

4

2-Pentanol

1.84

alcohols

4

Undecane, 5,7-dimethyl-

1.34

aliphatic hydrocarbons

5

3,8-Dimethyldecane

1.76

aliphatic hydrocarbon

5

Pentanal

1.27

aldehydes

6

Mesitylene

1.75

cyclic aromatic hydrocarbons

6

2-Amino-5-methylbenzoic acid

1.21

acids

7

3-Methyl-3-butenol

1.74

alcohols

7

2-Octenal, 2-butyl-

1.14

aldehydes

8

1,4-Cineol

1.7

terpenes

8

5-Hepten-2-ol, 6-methyl-

1.12

alcohols

9

Undecane, 3,4-dimethyl-

1.69

aliphatic hydrocarbons

9

1-Dodecanol

1.08

alcohols

10

Tridecane

1.56

aliphatic hydrocarbons

10

Decanal

1.04

aldehydes

11

2-Methyltridecane

1.47

aliphatic hydrocarbons

11

Butylated hydroxytoluene

0.99

cyclic aromatic hydrocarbons

12

3,5-Dimethylheptane

1.47

aliphatic hydrocarbons

12

2-Undecenal

0.86

aldehydes

13

Disulfide, dimethyl

1.36

sulfur compounds

13

Azulene

0.85

cyclic aromatic hydrocarbons

14

Undecane, 3,4-dimethyl-

1.3

aliphatic hydrocarbons

14

2-Decanone

0.8

ketones

15

Styrene

1.2

terpenes

15

Phenol, 3,5-dimethoxy-

0.70

alcohols

Class 2 (Beef meatballs)

No.

Positive compound

VIP

Chemical group

No.

Negative compound

VIP

Chemical group

1

m-Xylene, 5-ethyl

1.98

cyclic aromatic compounds

1

1-Pentanol

1.99

alcohols

2

Benzaldehyde

1.94

aldehydes

2

Mesitylene

1.75

cyclic aromatic hydrocarbons

3

3-Ethyl-2-methyl-1,3-hexadiene

1.74

aliphatic hydrocarbons

3

3-Methyl-3-butenol

1.74

alcohols

4

1-Octanol, 3,7-dimethyl-

1.63

alcohols

4

m-Xylene

1.70

cyclic aromatic hydrocarbons

5

Benzaldehyde, 4-pentyl-

1.54

aldehydes

5

2-Methyltridecane

1.47

aliphatic hydrocarbons

6

1-Octanol

1.42

alcohols

6

p-Xylene

1.45

cyclic aromatic hydrocarbons

7

1-Octanol, 2-butyl-

1.40

alcohols

7

Thiazole, 2,4,5-trimethyl-

1.43

heterocyclics

8

2-Nonenal, (E)-

1.36

aldehydes

8

Naphthalene

1.26

cyclic aromatic hydrocarbons

9

Dimethyl trisulfide

1.35

sulfur compounds

9

5-Hepten-2-one, 6-methyl-

1.21

ketones

10

Undecane, 5,7-dimethyl-

1.33

aliphatic hydrocarbons

10

Styrene

1.21

terpenes

11

2-Butoxyethanol

1.30

alcohols

11

Lauric acid

1.17

acids

12

5-Hepten-2-ol, 6-methyl-

1.21

alcohols

12

Terpinen-4-ol

1.11

alcohols

13

2-Amino-5-methylbenzoic acid

1.20

acids

13

Methyl palmitate

1.09

esters

14

Heptanal

1.16

aldehydes

14

4-Ethyl-o-xylene

1.03

cyclic aromatic hydrocarbons

15

Heptadecanal

1.16

aldehydes

15

Phenol, 4-(2-propenyl)-

0.94

alcohols

Class 3 (Wild boar and mixtures)

No.

Positive compound

VIP

Chemical group

No.

Negative compound

VIP

Chemical group

1

p-Xylene

1.40

cyclic aromatic compounds

1

β-Cymene

2.08

terpenes

2

Thiazole, 2,4,5-trimethyl-

1.40

heterocyclics

2

Butanal, 3-methyl-

2.05

aldehydes

3

6-Methyl-2-heptanol

1.31

alcohols

3

m-Xylene, 5-ethyl

1.93

cyclic aromatic hydrocarbons

4

Pentanal

1.27

aldehydes

4

2-Pentanol

1.85

alcohols

5

2-Octenal, 2-butyl-

1.14

aldehydes

5

3,8-Dimethyldecane

1.76

alyphatic hydrocarbons

6

Terpinen-4-ol

1.11

alcohols

6

3-Methyl-3-butenol

1.74

alcohols

7

4-Ethyl-o-xylene

1.03

cyclic aromatic compounds

7

o-Xylene

1.71

cyclic aromatic hydrocarbons

8

Indole

0.95

cyclic aromatic compounds

8

1,4-Cineol

1.7

terpenes

9

Phenol, 4-(2-propenyl)-

0.93

alcohols

9

Undecane, 3,4-dimethyl-

1.69

alyphatic hydrocarbons

10

2-Undecenal

0.86

aldehydes

10

Undecane, 5-methyl-

1.63

alyphatic hydrocarbons

11

Azulene

0.80

cyclic aromatic compounds

11

1-Octanol, 3,7-dimethyl-

1.63

alcohols

12

1,2,4-Triazol-4-amine, 5-ethyl-3-(3-methyl-5-phenylpyrazol-1-yl)-

0.80

heterocyclic compounds

12

Tridecane

1.56

alyphatic hydrocarbons

13

Copaene

0.80

terpenes

13

Disulfide, dimethyl

1.36

sulfur compounds

14

2-Decanone

0.79

ketones

14

Dimethyl trisulfide

1.20

sulfur compounds

15

1-Octen-3-ol

0.70

alcohols

15

Heptanal

1.16

aldehydes

The volatile with the highest VIP value in the chicken meatball class of the PLS-DA was β-cymene (Table 2). We could find no previous report on the occurrence of this compound in fresh or cooked chicken meat. However, a recent review indicated that cymene was found in essential oils, which are often added to poultry feed as natural antibiotics and immune-stimulants (Brenes and Roura, 2010). A previous study also reported that the second-strongest positive compound, 3-methylbutanal (an aldehyde), was detected in thermally processed chicken as a result of the Maillard reaction (Tian et al., 2007). This was also recently reported as one of the volatiles detected in Dezhou braised chicken (Duan et al., 2015) and grilled chicken (Ngamchuachit et al., 2015).

In the beef class, the most robust discriminator was 5-ethyl-m-xylene. Other discriminating volatiles, including benzaldehyde, octanol, 2-nonenal, and heptanal, have been found among the volatiles isolated from heat-treated beef, and 2-nonenal was also found in processed pork (Dwivedi and Brockmann, 1975). In this study, heptadecanal exhibited a significant contribution as a discriminating volatile in the beef, though it has been previously found in processed pork and ham (Dwivedi and Brockmann, 1975). Dimethyl trisulfide was also one of the potent odorants identified in stewed beef juice (Guth and Grosch, 1994).

In the wild boar and mixture meatballs group, xylene was identified as the strongest discriminator. This compound has previously been detected as a volatile in processed pork and ham (Dwivedi and Brockmann, 1975). The positive volatile with the second-highest VIP value in the wild boar and mixture meatball class was 2,4,5-trimethyl-thiazoles. Thiazoles have been reported as volatiles directly leading to a complex, meaty aroma (Piao et al., 2019). Pentanal has also been identified in cooked Iberian pigs (Estévez et al., 2003) and had a strong positive effect on the discrimination of minced pork from minced beef (Pavlidis et al., 2019).

As previously described, a strong discriminating volatile was assumed to be present in the 100% wild boar meatballs, which was responsible for clustering all the wild boar-containing meatballs in the same group. To address this, a PLS-DA model with three classes was created, including the meatballs made from 100% chicken, 100% beef, and 100% wild boar (Fig. 5). Although a CV-ANOVA indicated that the model was slightly overfitting, the R2Y and Q2Y values were 0.99 and 0.88, respectively. A further test with 200 random permutations also indicated an acceptable model (figure not shown). In this PLS-DA, 2-nonanone and pentanal were the two strongest positive discriminating volatiles from the wild boar group. Other discriminating compounds for 100% wild boar meatballs were summarized in Table 4. The compounds were compared with the 15 strongest positive discriminating volatiles when the wild boar meatballs were put in the same group with the meatballs made from a mixture of wild boar with beef and/or chicken at different ratios (Table 3; derived from the first PLS-DA model). As a result, six compounds (pentanal, 2,6-dimethylcyclohexanone, 1-undecanol, cyclobutanol, 2,4,5-trimethyl-thiazole, and 5-ethyl-3-(3-methyl-5-phenyl pyrazol-1-yl)-1,2,4-triazol-4-amine), were found as discriminating volatiles in mixture meatballs but with different VIP value (Table 3). However, the strongest pure wild boar meatballs discriminating volatiles (2-nonanone) was not found among volatiles that positively correlate with mixture meatballs grouping. This compound was reported as one of major ketones found in raw pork (Soncin et al., 2007), but there is no reports on its availability in wild boar.

PLS-DA score plot of meatball volatiles' data. Only samples of 100% chicken (class 1; C1, C2, and C3), 100% beef (class 2; B1, B2, and B3), and 100% wild boar (class 3; W1, W2, and W3) are included.

No.

Positive Compound

VIP

Chemical Group

1

2-Nonanone

1.6

ketones

2

Pentanal

1.47

aldehydes

3

2,6-Dimethylcyclohexanone

1.34

cyclic aromatic hydrocarbons

4

1-Undecanol

1.29

alcohols

5

Cyclobutanol

1.28

alcohols

6

1-Hexanol

1.27

alcohols

7

3-Ethyl-2-methyl-1,3-hexadiene

1.21

aliphatic hydrocarbons

8

Decanal

1.19

aldehydes

9

Thiophene, 2-pentyl-

1.16

heterocylics

10

2-Dodecenal

1.14

aldehydes

11

1,2,4-Triazol-4-amine, 5-ethyl-3-(3-methyl-5-phenyl pyrazol-1-yl)-

1.00

heterocyclic compounds

12

Lauric acid

0.98

acids

13

2-Methyldecane

0.97

aliphatic hydrocarbons

14

Thiazole, 2,4,5-trimethyl-

0.93

heterocyclics

15

Copaene

0.89

terpenes

In the further analysis, we excluded 100% wild boar meatballs data to obtain another PLS-DA with 3 classes (100% chicken, 100% beef, and mixture meatballs) Fig. 6. Fifteen compounds with both positive and negative correlation values and the largest VIP values were selected from each PLS-DA class and summarized in Table 5. Six discriminating volatiles found in pure wild boar meatballs (pentanal, 2,6-dimethylcyclohexanone, 1-undecanol, cyclobutanol, 2,4,5-trimethyl-thiazole, and 5-ethyl-3-(3-methyl-5-phenyl pyrazol-1-yl)-1,2,4-triazol-4-amine) were consistently found as discriminating volatiles of mixture meatballs class in this new PLS-DA model, although with different VIP value. Similarly, the strongest discriminating compound, 2-nonanone, was not found. These data may partially support the hypothesis that several strong wild boar-discriminating volatiles heavily influenced the clustering of all wild boar-containing meatballs in the same group.

PLS-DA score plot of meatball volatile compounds data. Only samples of 100% chicken (class 1; C1, C2, and C3), 100% beef (class 2; B1, B2, and B3), and mixture meatballs (class 3; WB with different compositions) are included. Pure wild boar meatballs are excluded. Only the first two PC is presented (PC1 = 46.4%, PC2 16.4%, R2Y = 0.984, Q2Y = 0835).

PLS-DA Class 1 (Chicken meatballs)

No.

Positive Compound

VIP

Chemical Group

No.

Negative Compound

VIP

Chemical Group

1

Butanal, 3-methyl-

2.00

aldehydes

1

Benzaldehyde

1.92

aldehydes

2

1-Pentanol

1.77

alcohols

2

3-Ethyl-2-methyl-1,3-hexadiene

1.49

aliphatic hydrocarbons

3

1,4-Cineol

1.63

terpenes

3

2-Undecenal

1.38

aldehydes

4

o-Xylene

1.60

cyclic aromatic compounds

4

5-Hepten-2-ol, 6-methyl-

1.3

alcohols

5

2-Pentanol

1.54

alcohols

5

Pentanal

1.2

aldehydes

6

Mesitylene

1.53

cyclic aromatic hydrocarbons

6

2-Octenal, 2-butyl-

1.16

aldehydes

7

2-Methyltridecane

1.52

aliphatic hydrocarbons

7

Undecane, 5,7-dimethyl-

1.15

aliphatic hydrocarbons

8

3,8-Dimethyldecane

1.50

aliphatic hydrocarbon

8

Cyclobutanol

1.12

alcohols

9

m-Xylene

1.49

cyclic aromatic compounds

9

Thiophene, 2-pentyl-

1.02

heterocylics

10

3,5-Dimethylheptane

1.45

aliphatic hydrocarbons

10

1-Undecanol

0.89

alcohols

11

3-Methyl-3-butenol

1.45

alcohols

11

1,2,4-Triazol-4-amine, 5-ethyl-3-(3-methyl-5-phenylpyrazol-1-yl)-

0.88

heterocyclic compounds

12

Tridecane

1.42

aliphatic hydrocarbons

12

Decanal

0.87

aldehydes

13

Undecane, 3,4-dimethyl-

1.40

aliphatic hydrocarbons

13

Butylated Hydroxytoluene

0.85

cyclic aromatic hydrocarbons

14

Styrene

1.36

terpenes

14

2-Decanone

0.83

ketones

15

Disulfide, dimethyl

1.36

sulfuric compounds

15

1-Hexanol

0.79

alcohols

PLS-DA Class 2 (Beef meatballs)

No.

Positive Compound

VIP

Chemical Group

No.

Negative Compound

VIP

Chemical Group

1

m-Xylene, 5-ethyl

2.11

cyclic aromatic compounds

1

1-Pentanol

1.77

alcohols

2

Benzaldehyde

1.92

aldehydes

2

Mesitylene

1.53

cyclic aromatic hydrocarbns

3

Tetradecanal

1.84

aldehydes

3

2-Methyltridecane

1.52

aliphatic hydrocarbon

4

3-Ethyl-2-methyl-1,3-hexadiene

1.50

aliphatic hydrocarbons

4

m-Xylene

1.49

cyclic aromatic compounds

5

1-Octanol, 3,7-dimethyl-

1.49

alcohols

5

3,5-Dimethylheptane

1.49

aliphatic hydrocarbons

6

1-Octanol, 2-butyl-

1.48

alcohols

6

3-Methyl-3-butenol

1.45

alcohols

7

2-Amino-5-methylbenzoic acid

1.42

acids

7

Styrene

1.36

terpenes

8

2-Ethylbutanol

1.35

alcohols

8

p-Xylene

1.35

cyclic aromatic

9

5-Hepten-2-ol, 6-methyl-

1.3

alcohols

9

Nonanal

1.29

aldehydes

10

1-Octanol

1.24

alcohols

10

Thiazole, 2,4,5-trimethyl-

1.28

heterocyclics

11

Heptanal

1.19

aldehydes

11

6-Dodecanone

1.27

ketones

12

Benzaldehyde, 4-pentyl-

1.17

aldehydes

12

5-Hepten-2-one, 6-methyl-

1.19

ketones

13

Undecane, 5,7-dimethyl-

1.15

aliphatic hydrocarbons

13

Lauric acid

1.08

acids

14

Dimethyl trisulfide

1.09

sulfuric compounds

14

Terpinen-4-ol

1.02

alcohols

15

2-Nonenal, (E)-

1.08

aldehydes

15

Methyl palmitate

1.01

esters

PLS-DA Class 3 (Mixtures)

No.

Positive Compound

VIP

Chemical Group

No.

Negative Compound

VIP

Chemical Group

1

2-Undecenal

1.38

aldehydes

1

m-Xylene, 5-ethyl

2.11

cyclic aromatic compounds

2

p-Xylene

1.35

cyclic aromatic compounds

2

Butanal, 3-methyl-

1.99

aldehydes

3

Thiazole, 2,4,5-trimethyl-

1.26

heterocyclics

3

Benzaldehyde

1.92

aldehydes

4

Pentanal

1.2

aldehydes

4

1,4-Cineol

1.63

terpenes

5

2-Octenal, 2-butyl-

1.16

aldehydes

5

o-Xylene

1.6

cyclic aromatic compounds

6

Cyclobutanol

1.12

alcohols

6

2-Pentanol

1.54

alcohols

7

2,6-Dimethylcyclohexanone

1.05

cyclic aromatic hydrocarbons

7

1-Octanol, 3,7-dimethyl-

1.49

alcohols

8

2,4-Heptadien-1-al

1.04

aldehydes

8

5-Ethyl-2-methyloctane

1.48

aliphatic hydrocarbons

9

Cyclohexanol, 2-tert-butyl-

1.03

alcohols

9

3-Methyl-3-butenol

1.46

alcohols

10

1-Octen-3-ol

0.97

alcohols

10

Undecane, 5-methyl-

1.45

aliphatic hydrocarbons

11

Phenol, 4-(2-propenyl)-

0.96

alcohols

11

Undecane, 3,4-dimethyl-

1.40

aliphatic hydrocarbons

12

1-Undecanol

0.88

alcohols

12

Ethylbenzene

1.40

cyclic aromatic hydrocarbons

13

1,2,4-Triazol-4-amine, 5-ethyl-3-(3-methyl-5-phenylpyrazol-1-yl)-

0.88

heterocyclics

13

Disulfide, dimethyl

1.36

sulfuric compounds

14

Caproic acid

0.86

acids

14

2-Ethylbutanol

1.35

alcohols

15

Indole

0.86

cyclic aromatic hydrocarbons

15

2-Butoxyethanol

1.20

alcohols

Meat flavor formation during heating, especially when involving volatiles, is a complex process involving various reactions, including the Maillard and unsaturated lipid reactions. Compounds resulting from the Maillard reaction may also react with those from the unsaturated lipid degradation. The exact volatile composition of the meat flavor formed by these reactions depends on not only the types of precursors present in the meat but also the temperature and reaction time (Aaslyng and Meinert, 2017). Meatballs made from a mixture of different types of meat (chicken, beef, and wild boar) at different ratios may develop different volatiles, as concentrations of the precursors vary. This assumption might explain why the discriminatory volatiles of wild boar meatballs were not exactly the same with when clustered together with mixed meatballs as when separated from them.

This study did not include commercial meatballs in its analysis. Instead, the present work is a preliminary study with a very simple meatball formulation. Commercial meatballs typically have a much more complex formulation. Besides meat, flour, salt, and pepper, commercial meatballs may also contain garlic, beef flavor, or a taste enhancer, which could affect the selection of volatile markers. Further research using more complex meatball formulations resembling those of commercial meatballs and including samples of commercial meatballs themselves is required.

In addition, this study did not consider the effect of the animal feed, which can significantly contribute to meat's volatile composition. The volatile compounds in cooked meat can be directly diverted from animal feed into the tissue by the transformation of feed molecules through the action of ruminal microorganisms or by both the Maillard reaction and the oxidation of lipids during the heating process (Vasta and Priolo, 2006). An example of such a case is in a study by (Resconi et al., 2010), in which male Corriedale lambs that were only fed by pasture were found to have significantly lower levels of alkanals, alkadienals, and ketones compared with those of lambs fed by pasture and concentrate and concentrate-plus-lucerne hay.

4 Conclusion

This study revealed that it is possible to classify meatball products according to the different types of meat they contain based on volatile profiles, including halal (beef and chicken) and non-halal species (wild boar). The PLS-DA model with three classes indicated that β-cymene, 3-methyl-butanal, and 2-pentanol were among the positive discriminating volatiles with the highest VIP in the chicken meatball group, whereas benzaldehyde, 3-ethyl-2-methyl-1,3-hexadiene, and 4-pentyl-benzaldehyde were the three strongest negative discriminating volatiles in this group. In the beef meatball class, the highest VIP positive discriminating volatiles were 5-ethyl-m-xylene, benzaldehyde, and 3-ethyl-2-methyl-1,3-hexadiene, whereas the three highest VIP negative ones were 1-pentanol, mesitylene, and 3-methyl-3-butenol. The mixed meatballs exhibited an interesting profile, with all being clustered with the 100%-wild boar meatballs. Discriminating volatiles derived from a separate PLS-DA model pointed to a consistent 6 compounds, those are pentanal, 2,6-dimethylcyclohexanone, 1-undecanol, cyclobutanol, 2,4,5-trimethyl-thiazole, and 5-ethyl-3-(3-methyl-5-phenyl pyrazol-1-yl)-1,2,4-triazol-4-amine. These compounds were identified as significant discriminating compounds in pure wild boar meatballs and mixture meatballs, but with different VIP value in each PLS-DA models. Further study to link the volatile characteristics of each class with the respective aroma perceptions using gas chromatography–olfactometry (GC-O) is recommended.

Funding

This study was supported by the Ministry of Research and Technology/National Agency for Research and Innovation, Republic of Indonesia, through the Penelitian Dasar Unggulan Perguruan Tinggi 2020 scheme under contract number 1/AMD/E1/KP.PTNBH/2020.

CRediT authorship contribution statement

Agy Wirabumi Pranata: Investigation, Formal analysis, Writing - original draft. Nancy Dewi Yuliana: Conceptualization, Methodology, Funding acquisition, Writing - review & editing, Supervision. Lia Amalia: Formal analysis, Project administration. Noviyan Darmawan: Validation, Visualization, Writing - review & editing, Supervision.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Meat flavour in pork and beef – from animal to meal. Meat Sci.. 2017;132:112-117.

- [CrossRef] [Google Scholar]

- Evaluation of volatile compounds in chicken breast meat using simultaneous distillation and extraction with odour activity value. J. Food Nutr. Res.. 2014;53:137-142.

- [Google Scholar]

- Essential oils in poultry nutrition: main effects and modes of action. Anim. Feed Sci. Technol.. 2010;158(1-2):1-14.

- [CrossRef] [Google Scholar]

- Influence of specific taste-active components on meat flavor as affected by intrinsic and extrinsic factors: an overview. Eur. Food Res. Technol.. 2015;241(2):157-171.

- [CrossRef] [Google Scholar]

- A generalization of the retention index system including linear temperature programmes gas–liquid partition chromatography. J. Chromatogr.. 1962;11:461-471.

- [CrossRef] [Google Scholar]

- Analysis of volatiles in Dezhou Braised Chicken by comprehensive two-dimensional gas chromatography/high resolution-time of flight mass spectrometry. LWT – Food Sci. Technol.. 2015;60(2):1235-1242.

- [CrossRef] [Google Scholar]

- Eriksson, L., Johansson, E., Kettenah-Wold, N., Trygg, J., Wikström, C., Wold, S., 2006. Multi- and Megavariate Data Analysis. Umetrics AB, Umeå.

- CV-ANOVA for significance testing of PLS and OPLS models. J. Chemom.. 2008;22:594-600.

- [CrossRef] [Google Scholar]

- Analysis of volatiles in meat from Iberian pigs and lean pigs after refrigeration and cooking by using SPME-GC-MS. J. Agric. Food Chem.. 2003;51(11):3429-3435.

- [CrossRef] [Google Scholar]

- Analysis of beef meatball adulteration with wild boar meat using real-time polymerase chain reaction. Int. Food Res. J.. 2017;24:2451-2455.

- [Google Scholar]

- Identification of the character impact odorants of stewed beef juice by instrumental analyses and sensory studies. J. Agric. Food Chem.. 1994;42(12):2862-2866.

- [CrossRef] [Google Scholar]

- Character impact odorants of boiled chicken: changes during refrigerated storage and reheating. Eur. Food Res. Technol.. 1997;205(3):232-238.

- [CrossRef] [Google Scholar]

- Volatile compounds in meat and meat products. Food Sci. Technol.. 2017;37:1-7.

- [CrossRef] [Google Scholar]

- Analysis of lard in meatball broth using Fourier transform infrared spectroscopy and chemometrics. Meat Sci.. 2014;96(1):94-98.

- [CrossRef] [Google Scholar]

- A comparison of the volatile profiles of frying european and australian wild boar meat with industrial genotype pork by dynamic headspace-GC/MS analysis. J. Muscle Foods. 2009;20:255-274.

- [CrossRef] [Google Scholar]

- Volatilomics for food quality and authentication. Curr. Opin. Food Sci.. 2019;28:88-95.

- [CrossRef] [Google Scholar]

- Development and validation of a rapid test system for detection of pork meat and collagen residues. Meat Sci.. 2016;121:397-402.

- [CrossRef] [Google Scholar]

- Flavour formation in meat and meat products: a review. Food Chem.. 1998;62(4):415-424.

- [CrossRef] [Google Scholar]

- A comparative study of PCA, SIMCA and Cole model for classification of bioimpedance spectroscopy measurements. Comput. Biol. Med.. 2015;63:42-51.

- [CrossRef] [Google Scholar]

- View of comparison of dynamic headspace trapping on Tenax TA and eadspace stir bar sorptive extraction for analysis of vrilled Chicken (Yakitori) Volatiles. LWT – Food Sci. Technol.. 2015;60:1235-1242.

- [Google Scholar]

- A volatilomics approach for off-line discrimination of minced beef and pork meat and their admixture using HS-SPME GC/MS in tandem with multivariate data analysis. Meat Sci.. 2019;151:43-53.

- [CrossRef] [Google Scholar]

- M.Y. Piao H.J. Lee H.I. Yong S.-H. Beak H.J. Kim C. Jo K.G. Wiryawan M. Baik Comparison of reducing sugar content, sensory traits, and fatty acids and volatile compound profiles of the longissimus thoracis among Korean cattle, Holsteins, and Angus steers Asian-Australasian J. Anim. Sci. 32 1 2019 126 136 10.5713/ajas.18.0065

- The employment of FTIR spectroscopy in combination with chemometrics for analysis of rat meat in meatball formulation. Meat Sci.. 2015;100:301-305.

- [CrossRef] [Google Scholar]

- Relationship between odour-active compounds and flavour perception in meat from lambs fed different diets. Meat Science. 2010;85:700-706.

- [CrossRef] [Google Scholar]

- Review on analytical methods for analysis of porcine gelatine in food and pharmaceutical products for halal authentication. Trends Food Sci. Technol.. 2020;101:122-132.

- [CrossRef] [Google Scholar]

- Meat from wild boar (Sus scrofa L.): a review. Meat Sci.. 2013;94(2):187-201.

- [CrossRef] [Google Scholar]

- Synchronized analysis of FTIR spectra and GCMS chromatograms for evaluation of the thermally degraded vegetable oils. J. Anal. Methods Chem.. 2014;2014:1-9.

- [CrossRef] [Google Scholar]

- Preliminary study of the volatile fraction in the raw meat of pork, duck and goose. J. Food Compos. Anal.. 2007;20(5):436-439.

- [CrossRef] [Google Scholar]

- Screening of volatile decay markers of minced pork by headspace-solid phase microextraction–gas chromatography–mass spectrometry and chemometrics. Food Chem.. 2021;342:128341.

- [CrossRef] [Google Scholar]

- Multiplex PCR to discriminate bovine, porcine, and fish DNA in gelatin and confectionery products. LWT.. 2018;92:169-176.

- [CrossRef] [Google Scholar]

- Preparation of natural isovaleraldehyde by the Maillard reaction. Chinese Chem. Lett.. 2007;18(9):1049-1052.

- [CrossRef] [Google Scholar]

- Ruminant fat volatiles as affected by diet. A review. Meat Sci.. 2006;73(2):218-228.

- [CrossRef] [Google Scholar]

- Analysis of volatile compounds between raw and cooked beef by HS-SPME–GC–MS. J. Food Process. Preserv.. 2018;42(2):e13503.

- [CrossRef] [Google Scholar]

- PCA as a practical indicator of OPLS-DA model reliability. Curr. Metabolomics. 2016;4(2):97-103.

- [Google Scholar]

- Multivariate analysis in metabolomics. Curr. Metabolomics. 2012;1:92-107.

- [CrossRef] [Google Scholar]

- Rapid discrimination of pork in Halal and non-Halal Chinese ham sausages by Fourier transform infrared (FTIR) spectroscopy and chemometrics. Meat Sci.. 2012;92(4):506-510.

- [CrossRef] [Google Scholar]

- Classification of the botanical and geographical origins of Chinese honey based on 1H NMR profile with chemometrics. Food Res. Int.. 2020;137:109714.

- [CrossRef] [Google Scholar]